Pneumatic feeding mechanism

A technology of discharging mechanism and feeding mechanism, applied in metal processing equipment, feeding device, manufacturing tools, etc., can solve the problems of wasting manpower, easy to cause industrial accidents, etc., and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

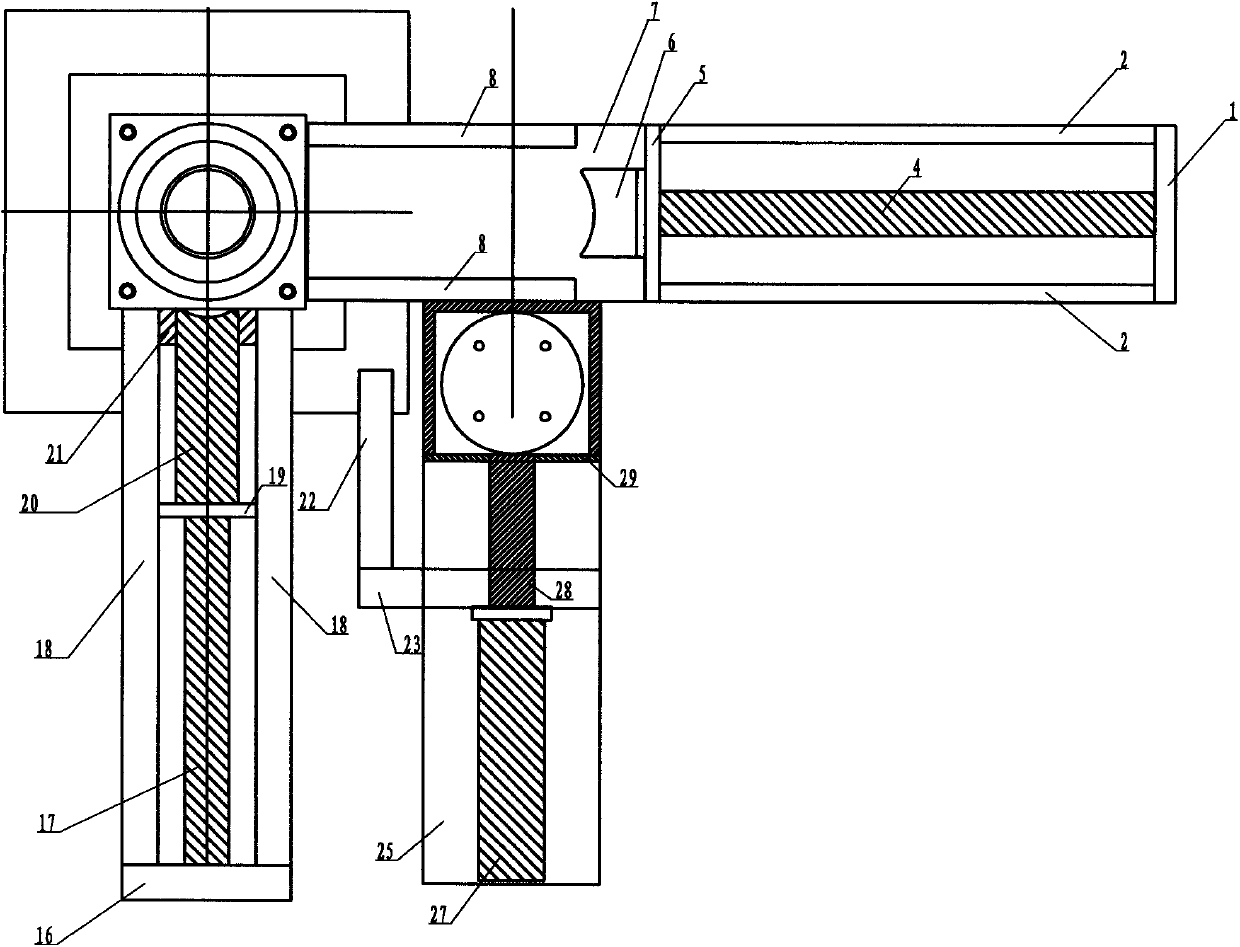

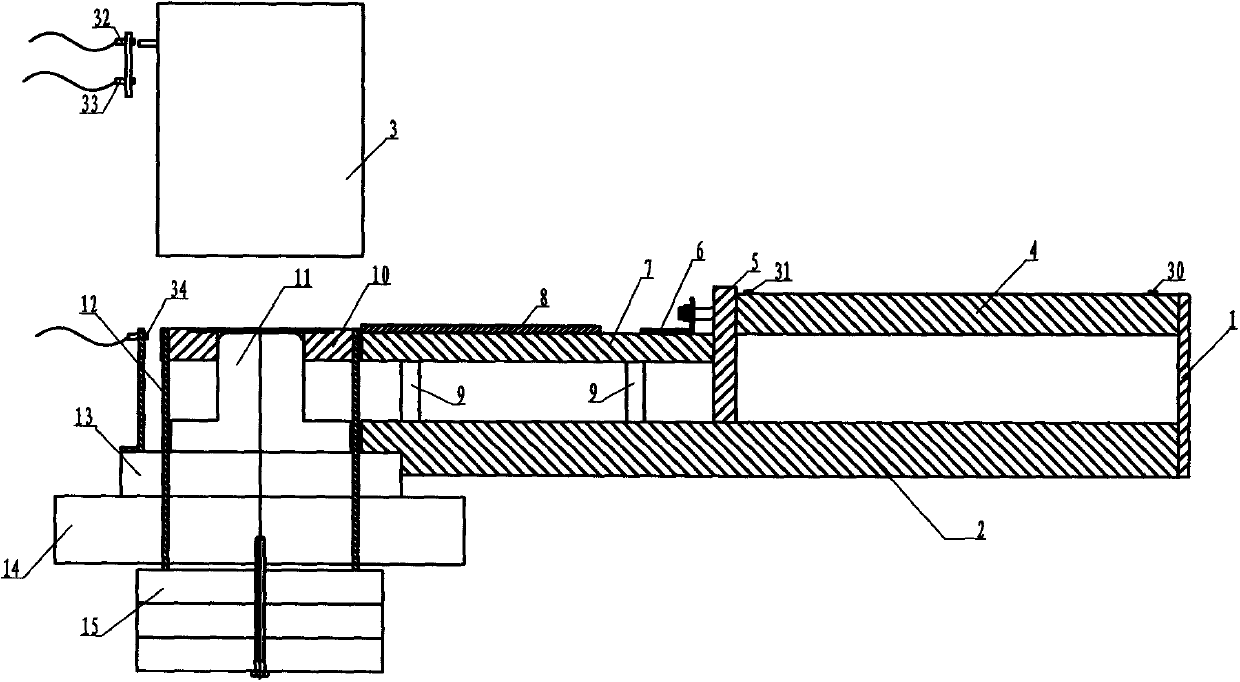

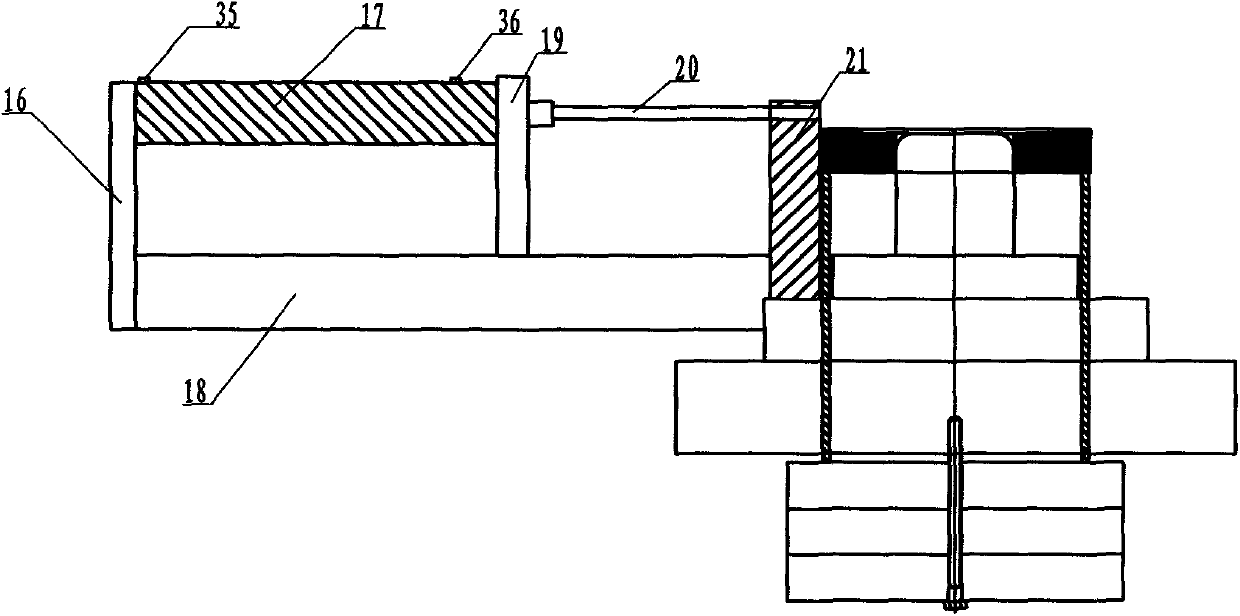

[0011] Please refer to the attached Figure 1 to Figure 4 As shown, a pneumatic feeding mechanism of the present invention, the pneumatic feeding mechanism includes a feeding mechanism, a stretching mold, and a mold ejection mechanism; the stretching mold is installed on the working plane of the punch press; the feeding module and the mold ejection mechanism are installed through support bars on the drawing die.

[0012] The drawing die includes a die 3 on the punching machine, a discharge plate 10, a lower convex head 11, a push rod 12, a convex head seat 13, a base 14, a rubber pad 15, an induction switch three 32, an induction switch four 33, an induction switch Switch five 34 . Described base 14 is installed on the machine tool platform; Protruding seat is fixed on the base; Protruding head 11 and induction switch 5 34 are installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com