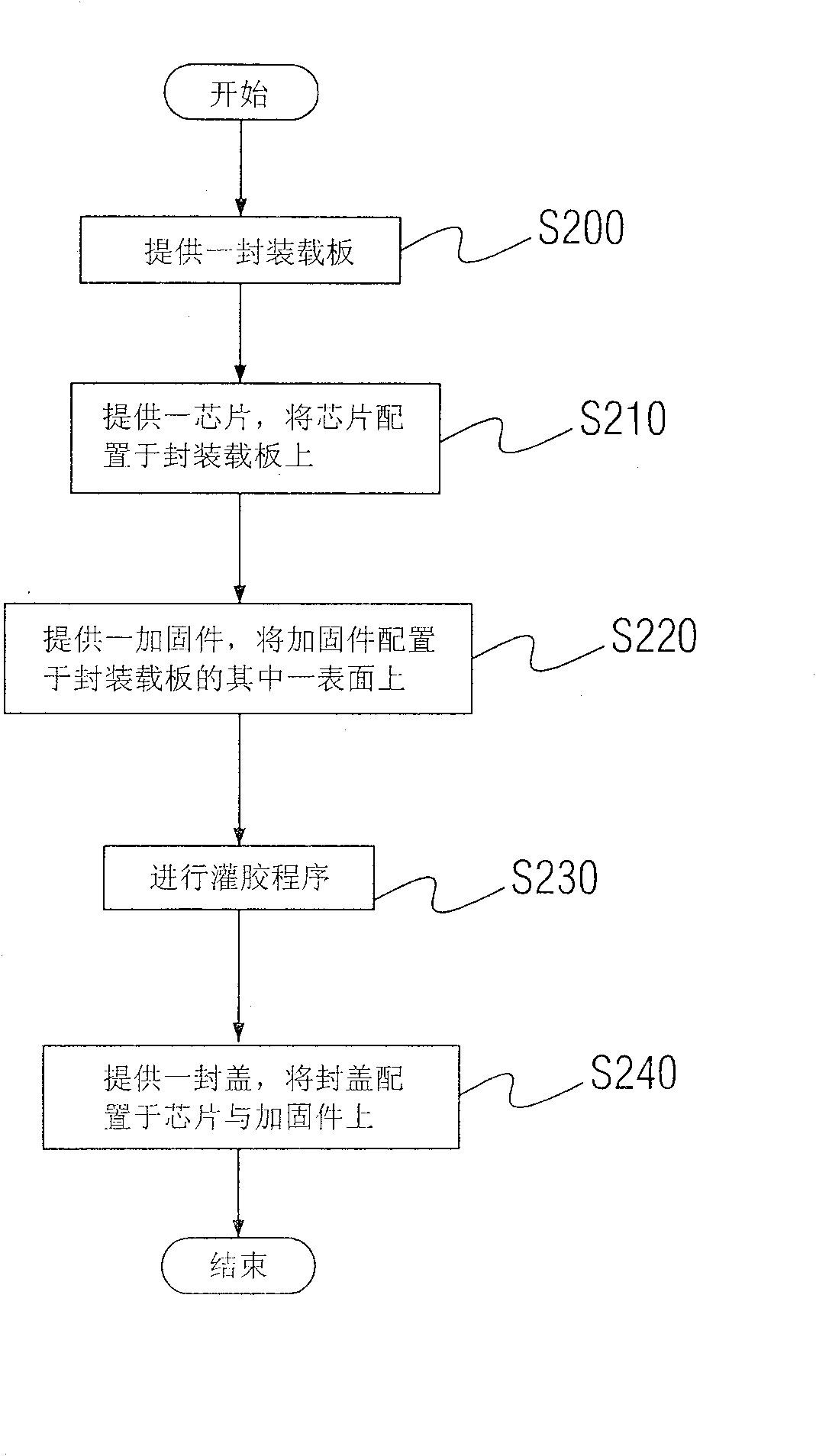

Patents

Literature

34results about How to "To achieve the purpose of packaging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

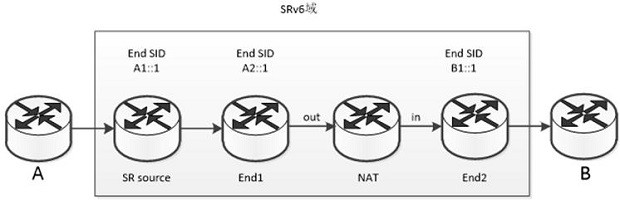

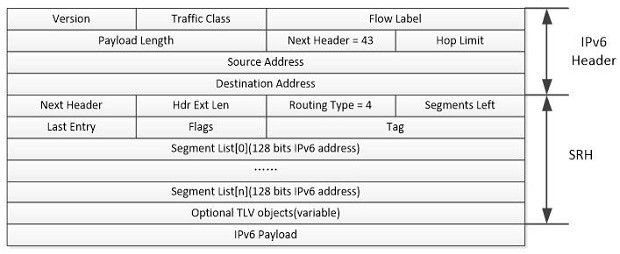

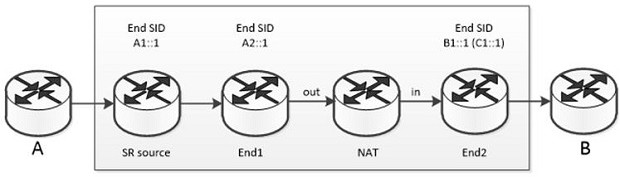

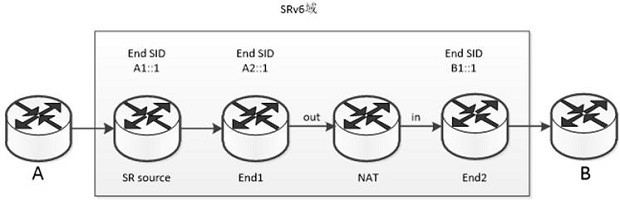

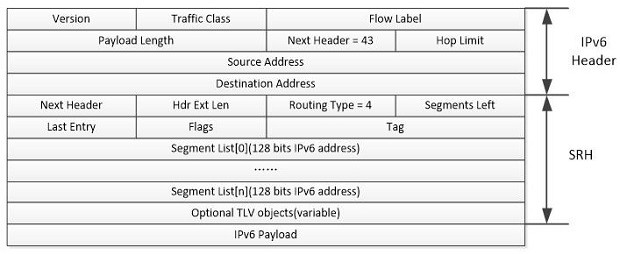

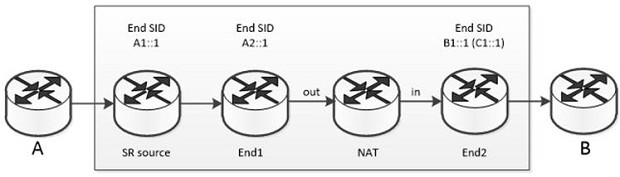

Message forwarding method and device based on SRv6 network, storage medium and electronic device

ActiveCN111935014ATo achieve the purpose of packagingIncrease detection functionNetworks interconnectionCommunications systemPrivate network

The invention discloses a message forwarding method and device based on an SRv6 network, a storage medium and an electronic device, an original message is sent by a device A to reach a device B through a plurality of End nodes and at least one NAT device, and the NAT device is located between the two End nodes. The SRH structure is different from a traditional SRH structure, the NAT detection message based on the SR strategy is sent through the End node and is used for public network address learning, meanwhile, an NAT-det type is added into a Next Header of an SRH message extension header, sothat an End operation type End.N of an SRv6 is newly added in an End node; and NAT public network address learning and message packaging during forwarding can be carried out according to different Next Header types, and the problem that in an existing SRv6 communication system, a message cannot be forwarded due to existence of equipment of a private network IP is solved.

Owner:PURPLE MOUNTAIN LAB

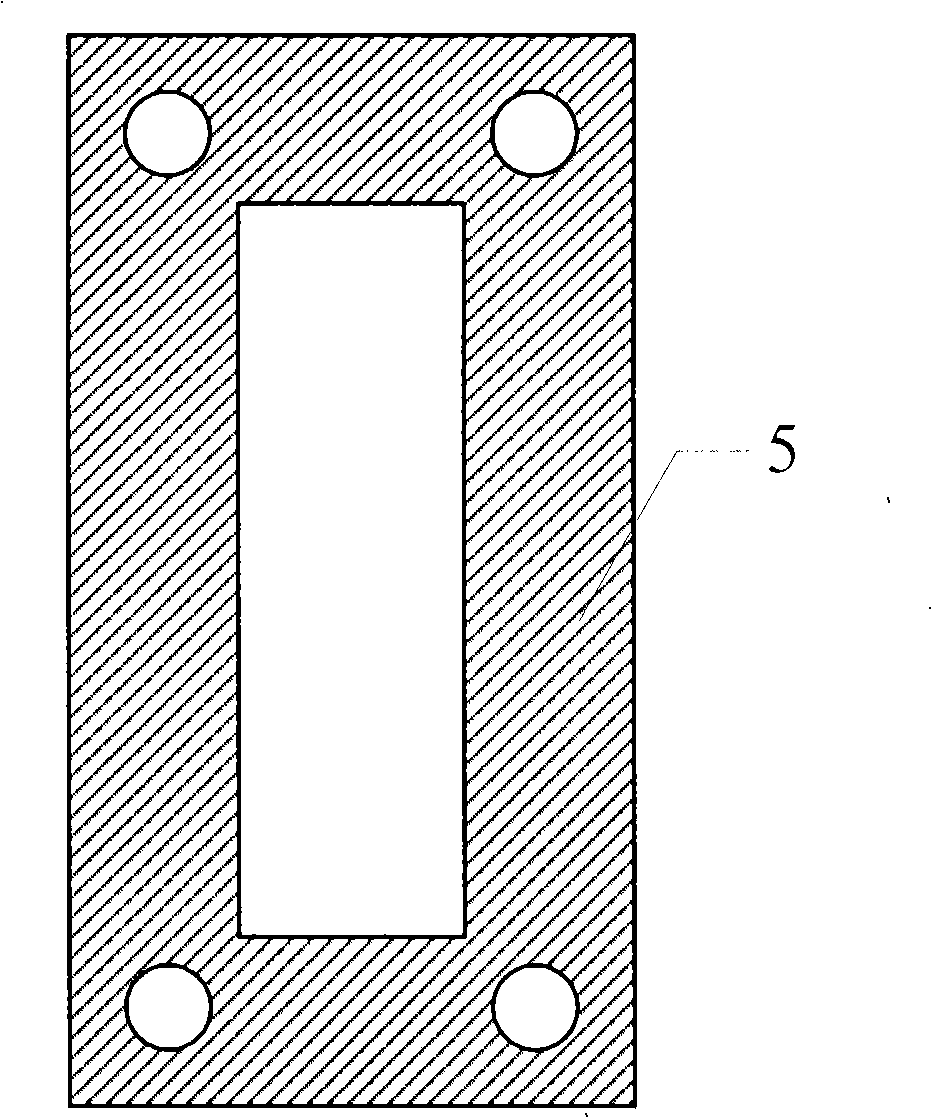

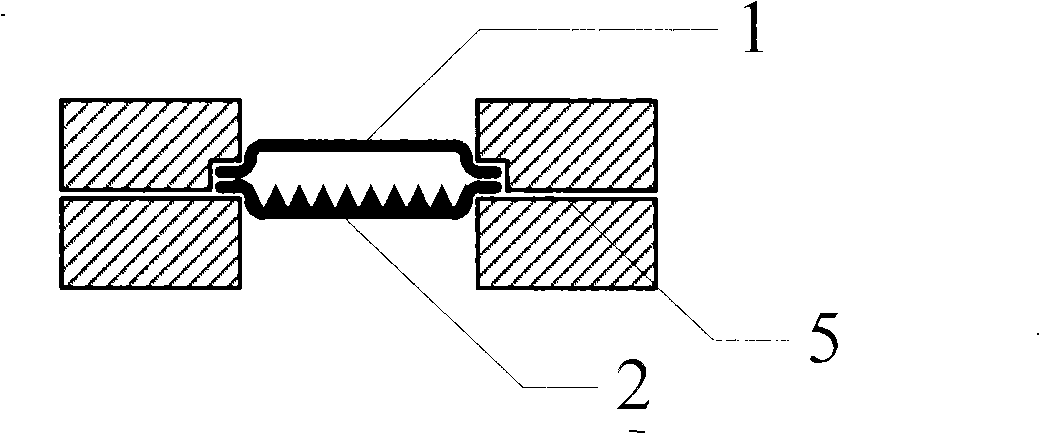

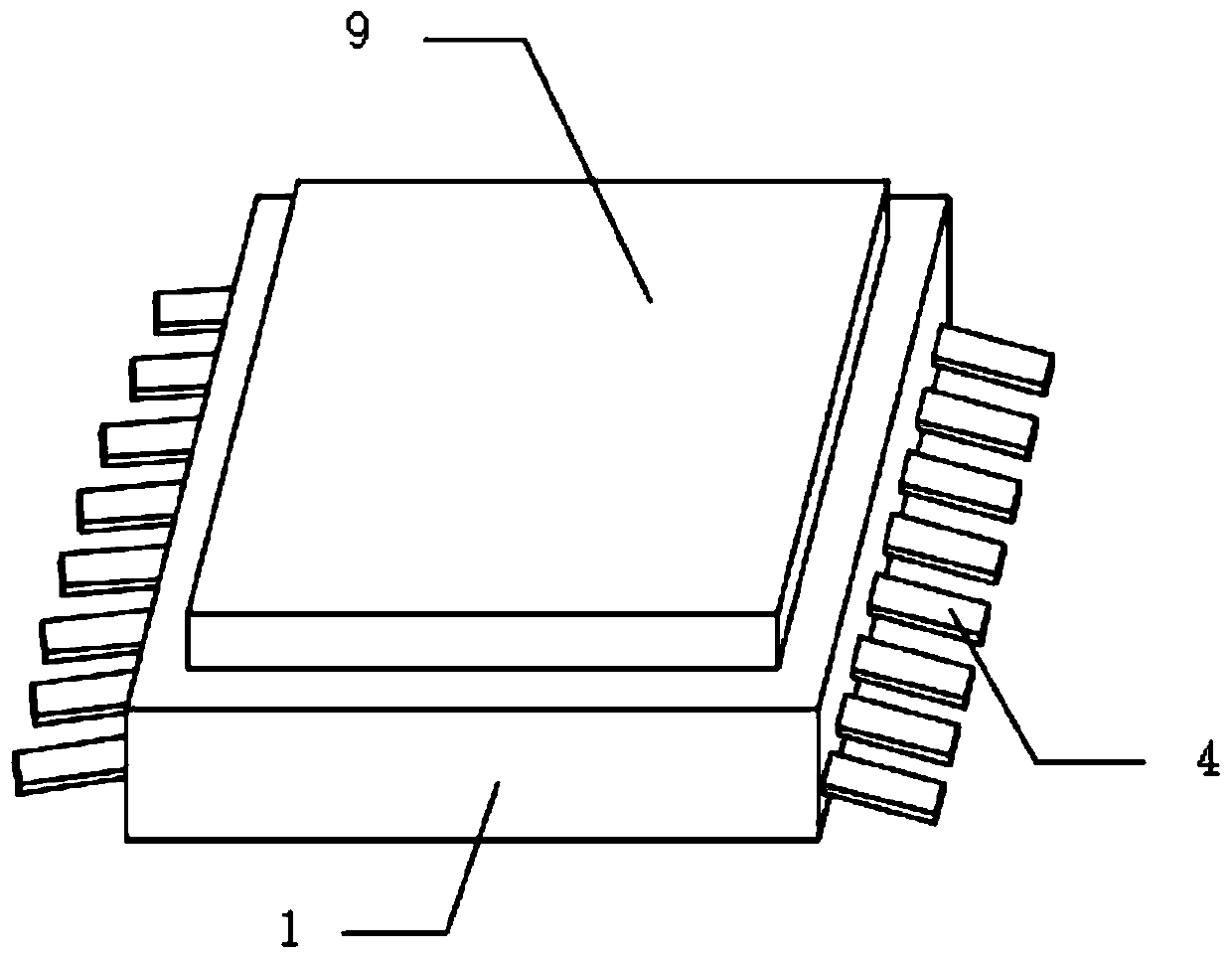

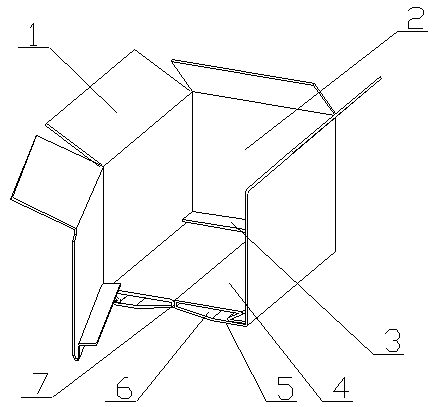

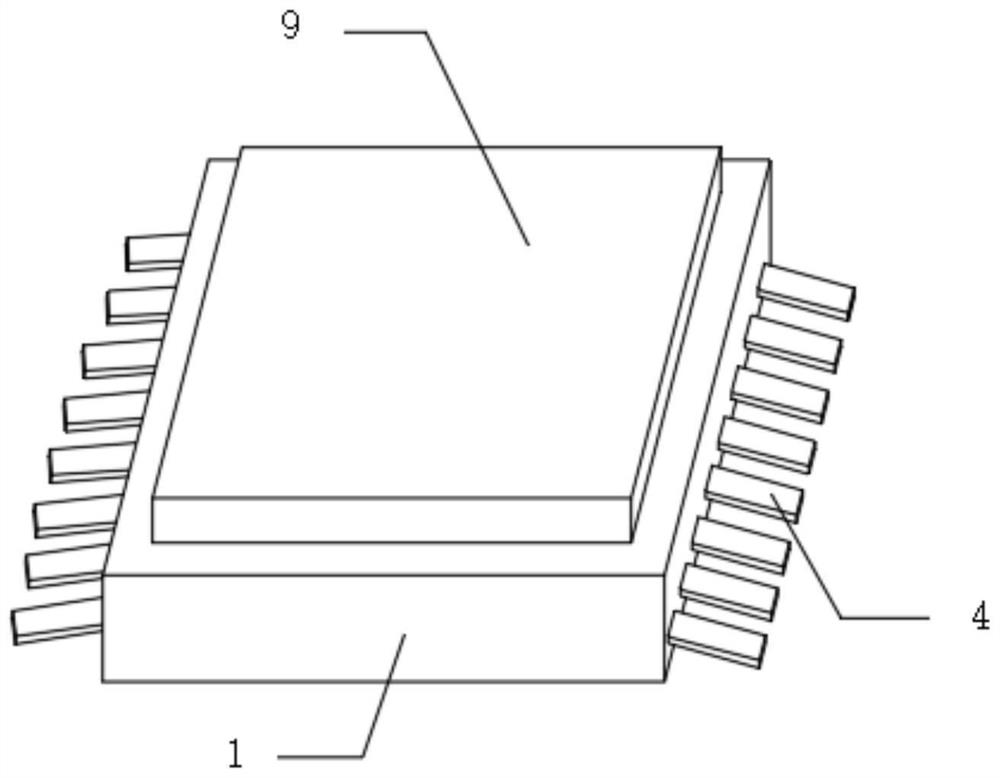

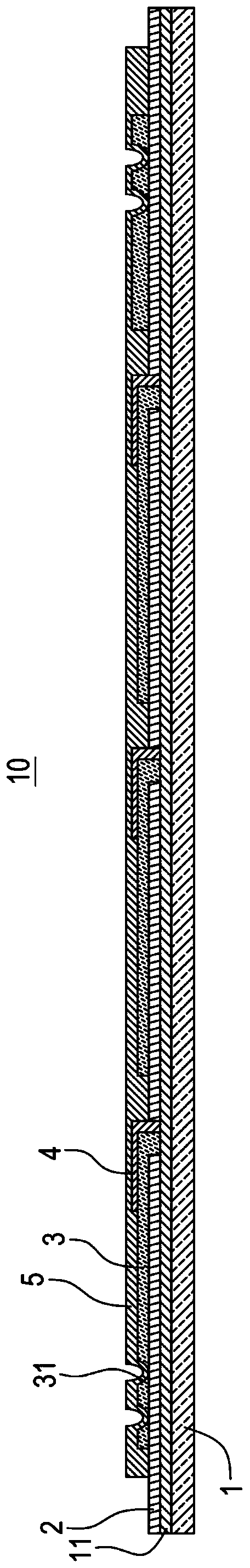

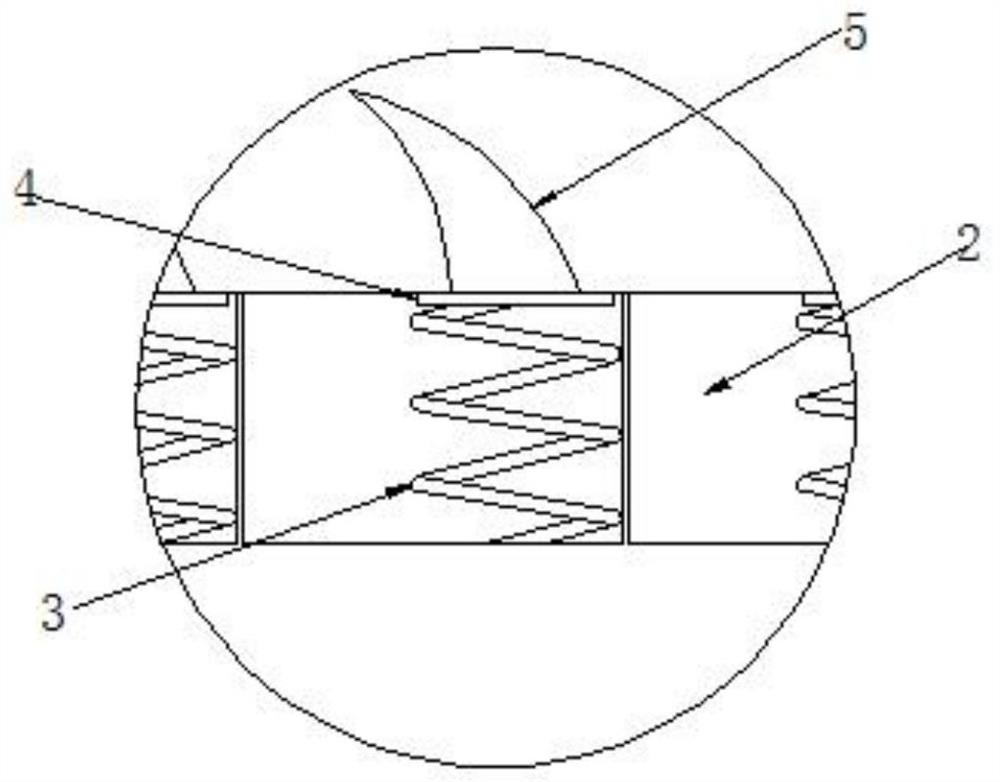

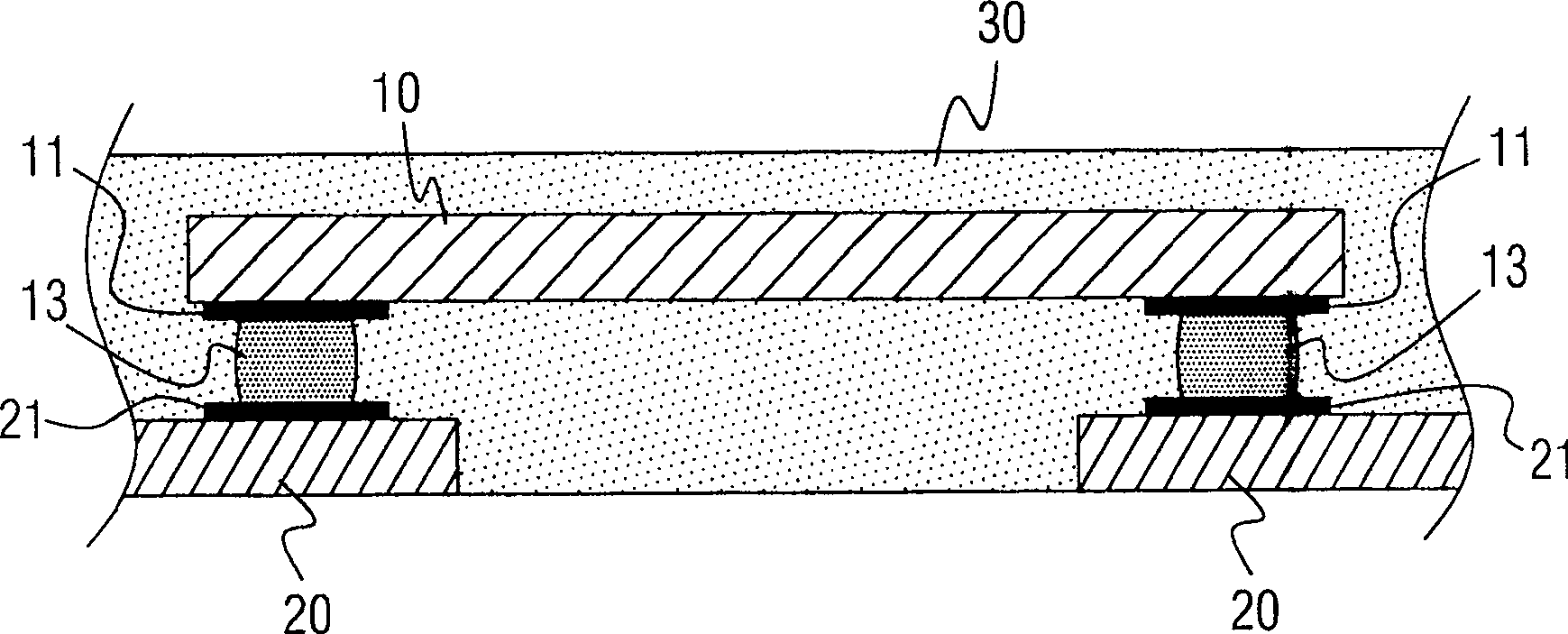

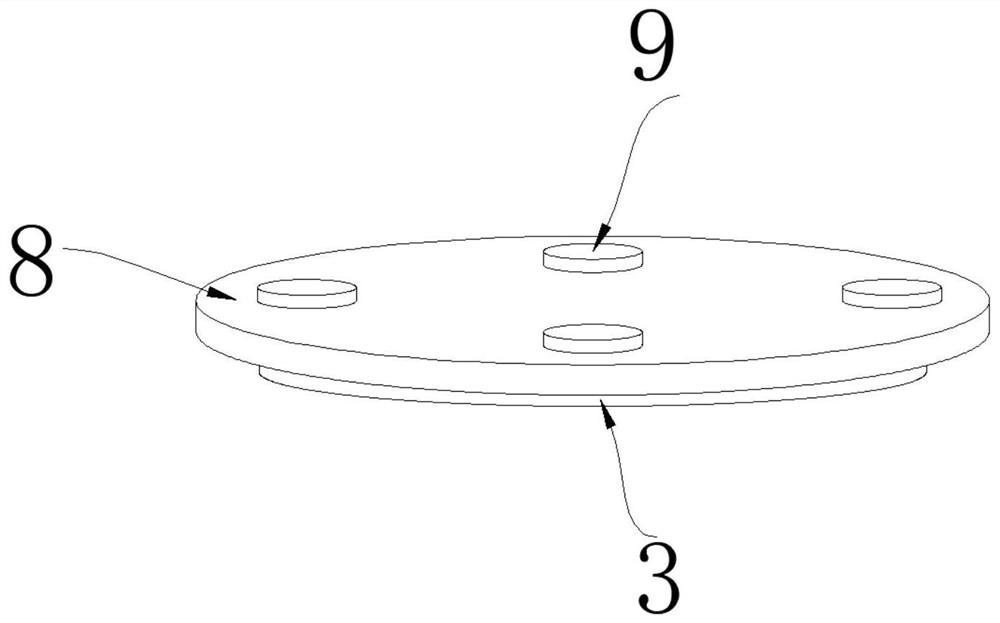

Encapsulation method of minitype flat plate hot pipe

InactiveCN101349517ATo achieve the purpose of packagingEasy to operateSoldering apparatusIndirect heat exchangersShielding gasEngineering

The invention provides a packaging process for a mini-size flat heat pipe, wherein the upper basal plate and the lower basal plate of the mini-size heat pipe are made of metal, a ring welding belt is respectively produced on the peripheries of the upper basal plate and the lower basal plate, solder is plated on the welding belt, and the upper basal plate and the lower basal plate are calibrated to tighten by holding fixtures, and are heated up to smelt down solder, and are tightly connected through the solder after the solder is cooled, thereby forming the packaging of a flat micro-thermal pipe. The invention utilizes metal with low melting point as solder, and forces a certain pressure for the shell of the micro-thermal pipe through a special die, heats and smelts solder metal under the condition of vacuum or protective gas, and facilitates the upper basal plate and the lower basal plate of the mini-size flat heat pipe to adhere after the solder is cooled down, thereby realizing the packaging purpose of the micro-thermal tube. The invention has the advantages of convenient and reliable operation, simplification and flexibility, low cost and wide application.

Owner:HARBIN INST OF TECH

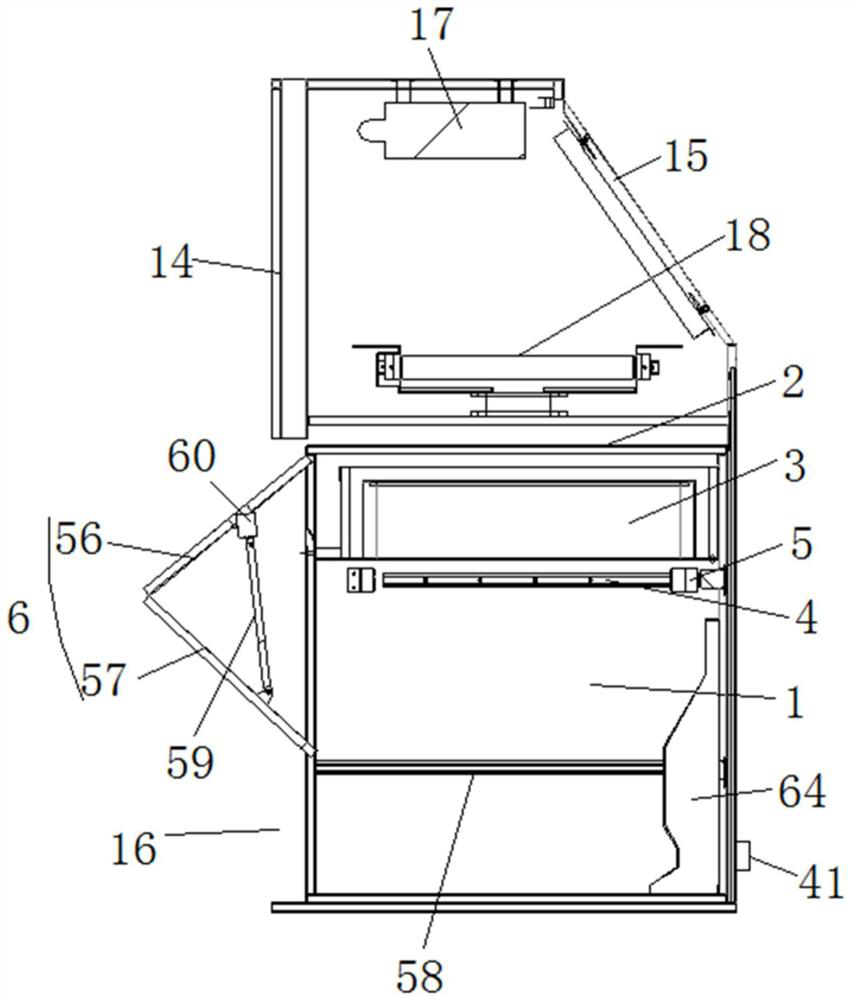

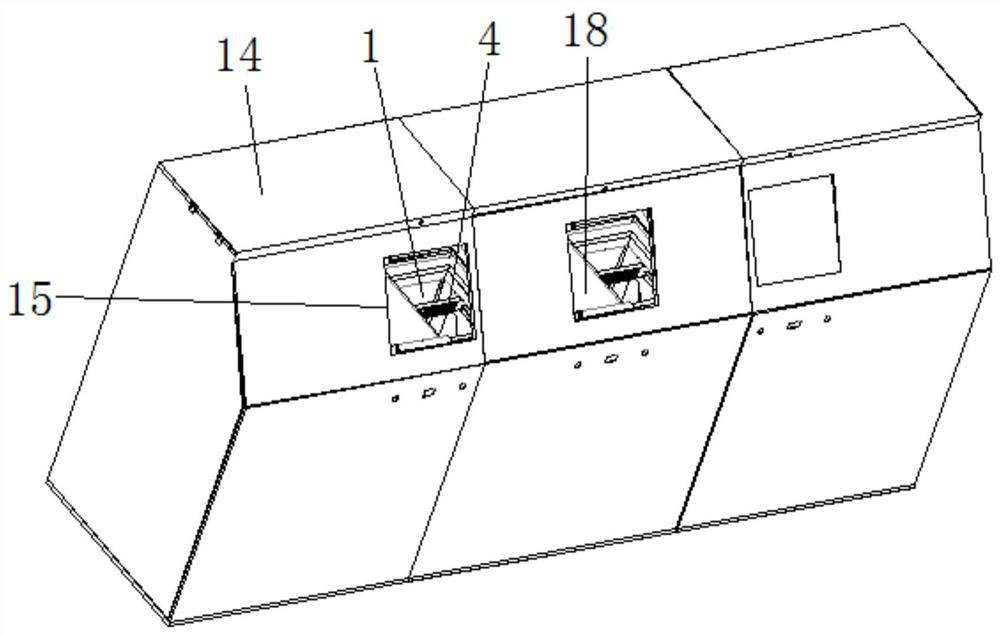

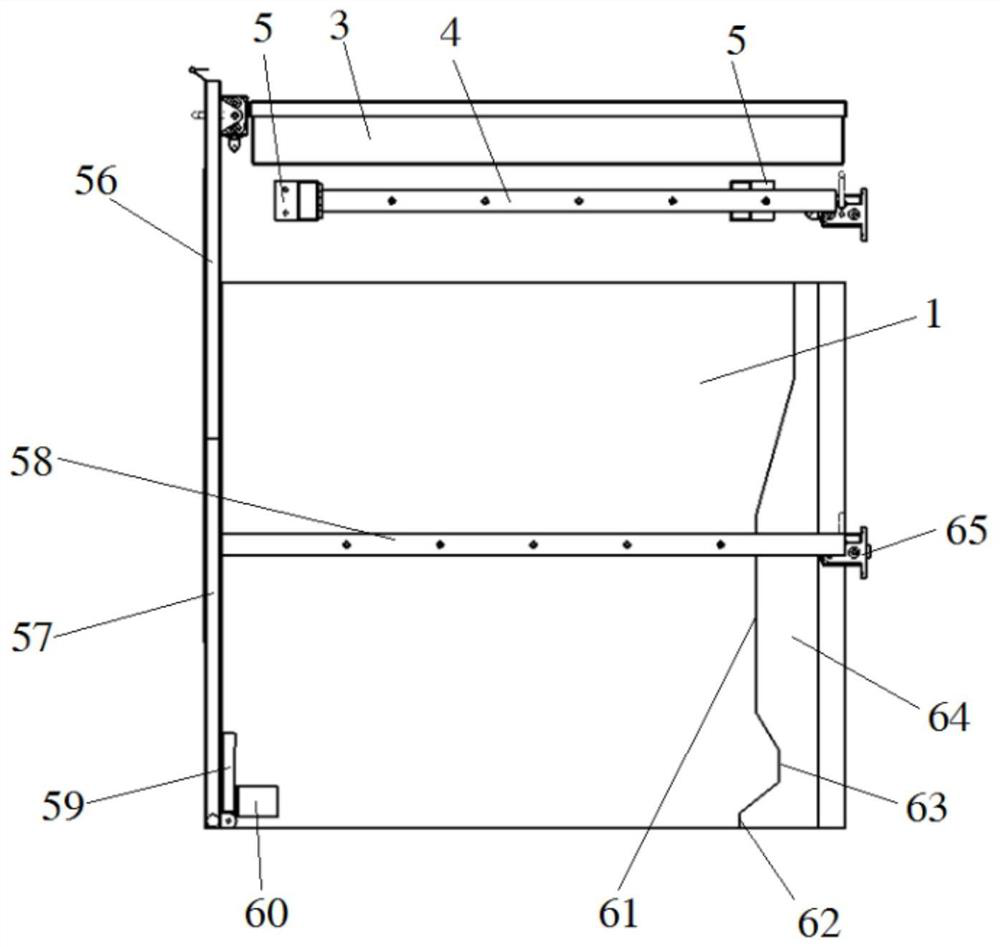

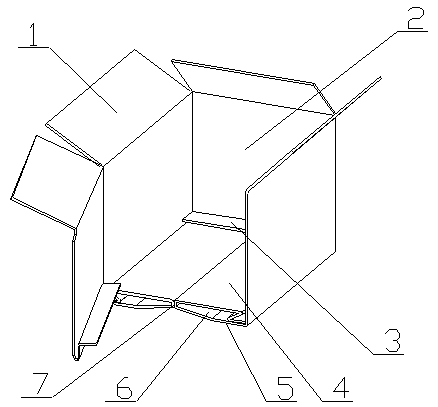

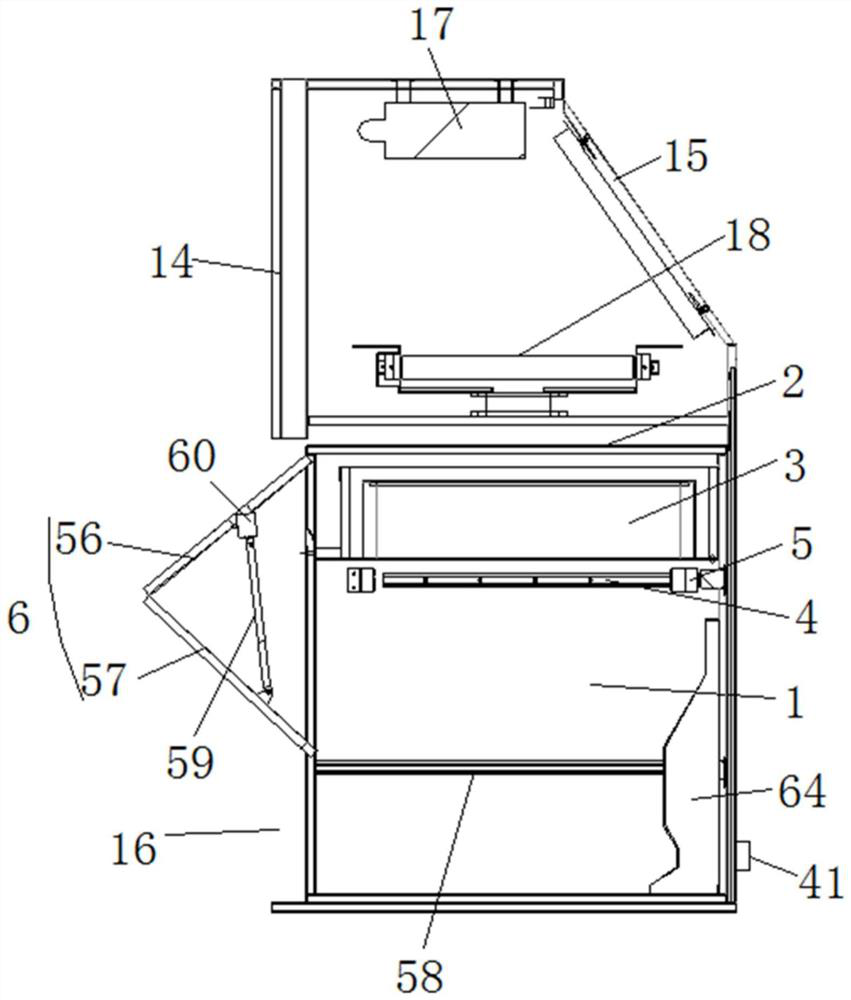

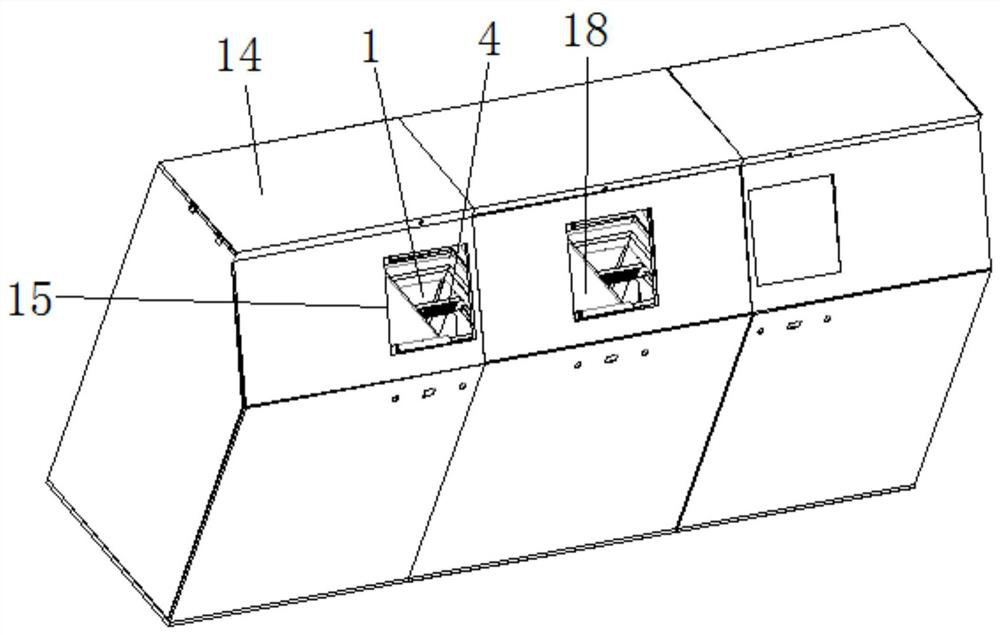

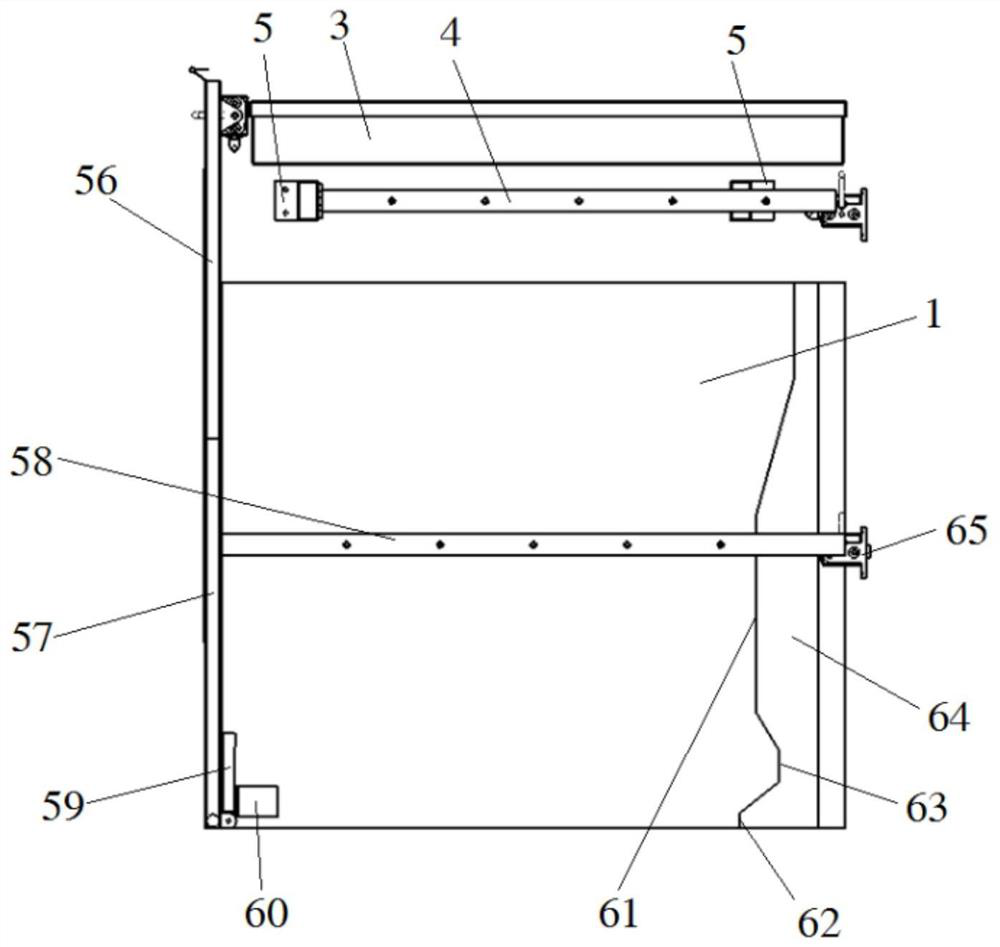

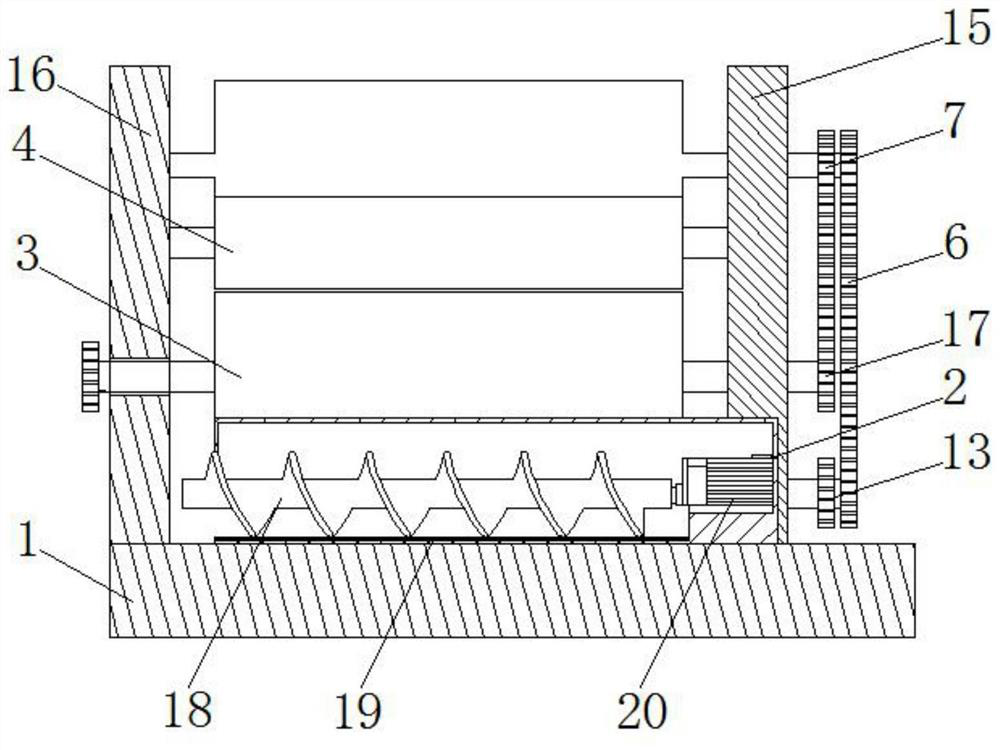

Automatic sealing and bag pushing garbage can

ActiveCN112573044AReduce configurationLow costRefuse receptaclesWrapper twisting/gatheringRefuse collectionSoftware engineering

The invention relates to an automatic sealing and bag pushing garbage can. The garbage can comprises a shell, and the shell corresponds to a set of independent garbage bins. The garbage capacity in the shell is detected through a garbage capacity detection system, the purposes of automatically packaging full-load garbage bags and automatically pushing the packaged garbage out of the shell are achieved through a sealing mechanism and a pushing mechanism, and the situations that in the traditional garbage collection work process, the full-load garbage bags are manually sealed and taken out of the garbage can are completely replaced; according to the intelligent classification garbage can, the purposes of automatically sealing the bags, packaging the garbage and pushing the bags out of the garbage can are further achieved while the garbage is intelligently thrown and intelligently recognized, and configuration of garbage collection workers in a community is further reduced; the purpose ofreducing the personnel allocation cost is achieved, the situation that personnel make contact with the garbage in the packaging process is avoided, and the body health of garbage transportation workers is effectively guaranteed.

Owner:广州东软科技有限公司

Compounded phase change heat storage material and preparation method thereof

InactiveCN107338026AImprove thermal conductivityTo achieve the purpose of packagingHeat-exchange elementsHigh absorptionHeat resistance

The invention relates to a compounded phase change heat storage material and a preparation method thereof and belongs to the technical field of compounded materials. According to the preparation method, expansible graphite is processed, so that the interlayer spacing and specific surface area of the expansible graphite are enlarged, and expanded graphite is obtained, wherein the expanded graphite is of a porous reticulate space structure and has high thermal conductive performance of natural graphite and higher absorption performance; multi-wall carbon nanotubes diffuse into thermal conductive nets formed in spaces of the expanded graphite, accordingly thermal conductive performance is further improved, and heat resistance is reduced; under a high temperature condition, an organic phase change material is absorbed to the inner portion of the graphite through a microporous adsorption method, and the aim of phase change heat storage material packaging is achieved. The prepared compounded phase change heat storage material has large specific heat and is low in thermal resistance change during phase change, thermal storage performance is improved, and the material has broad application prospects.

Owner:常州苏达欧包装材料有限公司

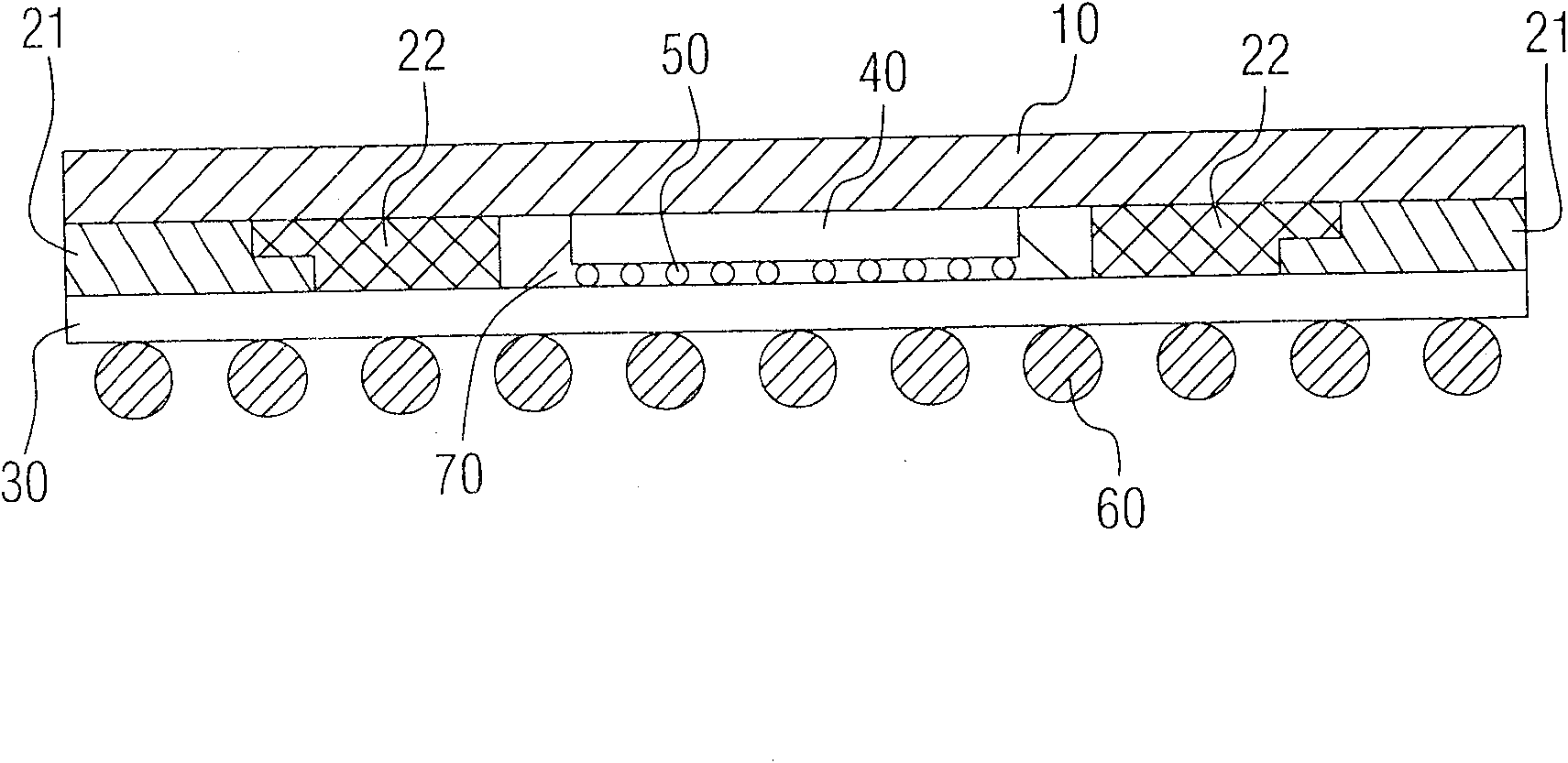

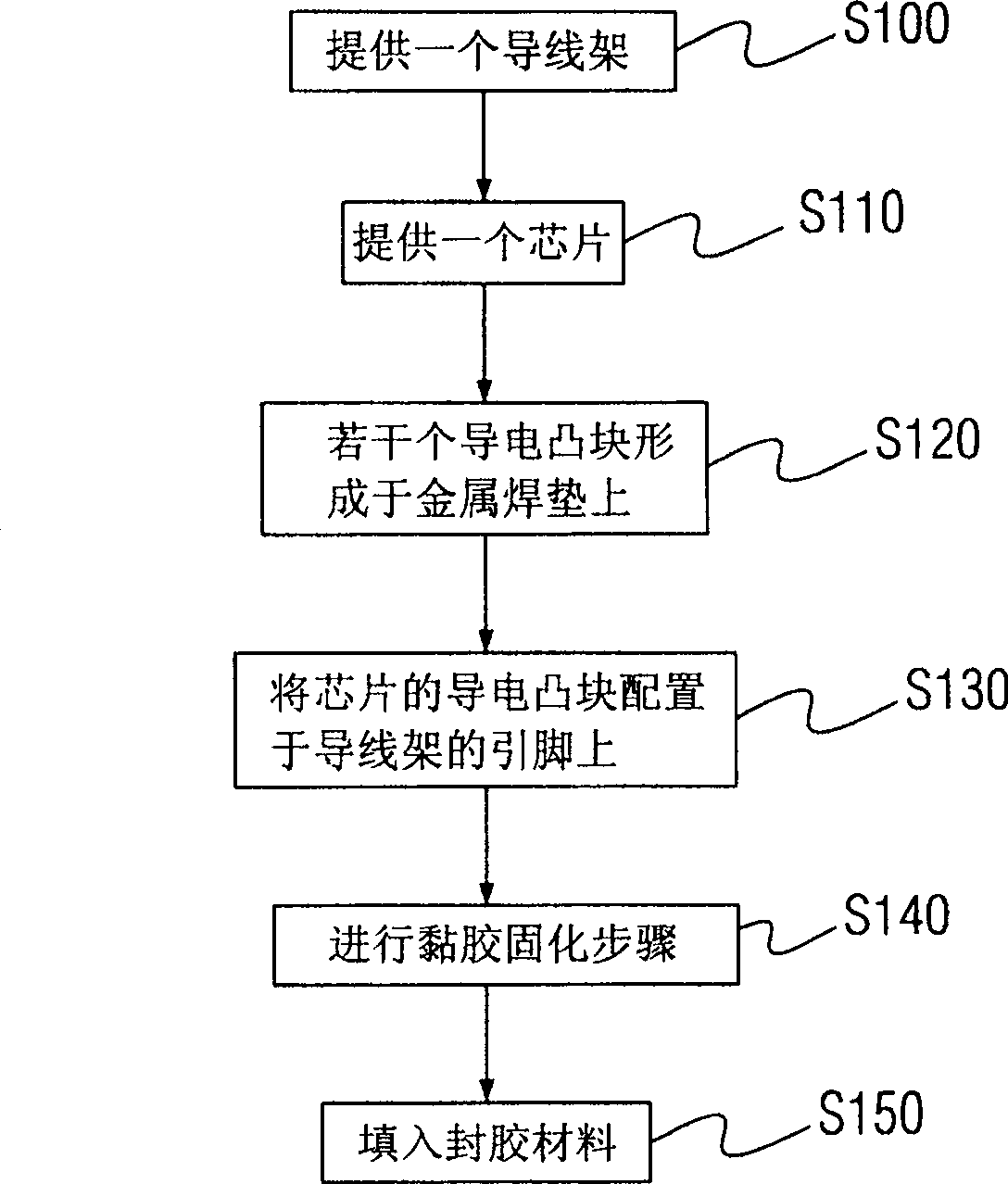

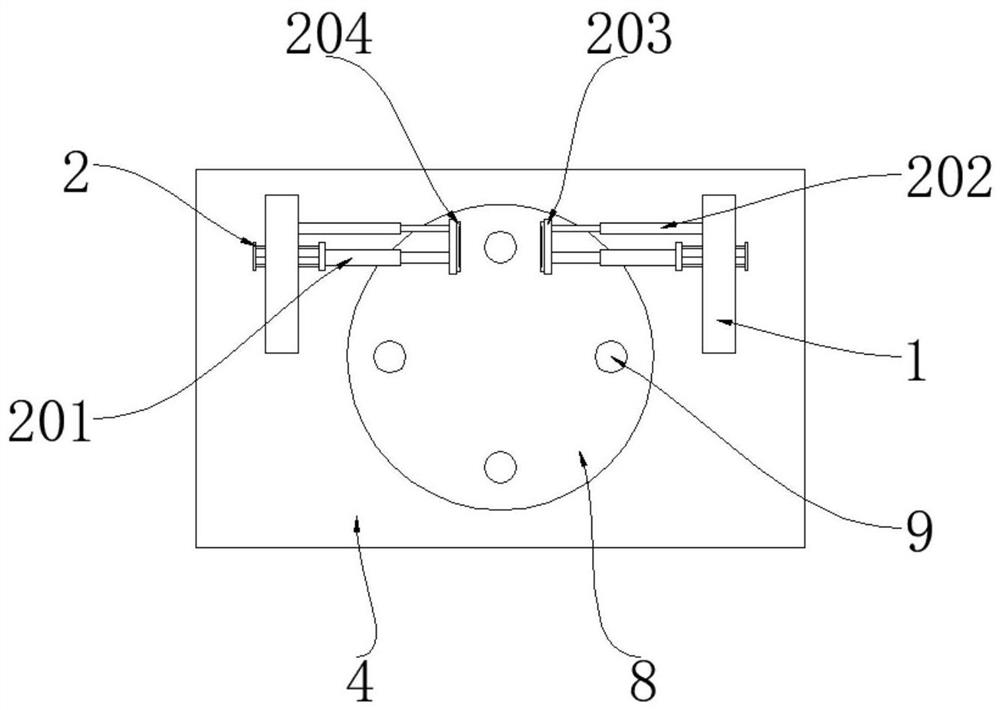

Method for packaging densely-arranged semiconductor chips for Internet of Things terminal

ActiveCN111092057APlay the role of fixing the chipSo as not to damageSemiconductor/solid-state device detailsSolid-state devicesPlastic packagingSemiconductor chip

The invention discloses a method for packaging densely-arranged semiconductor chips for an Internet of Things terminal and belongs to the semiconductor packaging field. The method for packaging densely-arranged semiconductor chips for the Internet of Things terminal is characterized in that a placement groove is formed in an upper surface of a lower shell, the upper surface of the lower shell is fixedly connected with two groups of conductive columns, the two groups of conductive columns are respectively positioned on two sides of the placement groove, a through hole is formed in the lower shell, the through hole is formed below the conductive columns, a pin is placed in the through hole, an upper end of the pin is fixedly connected with the conductive columns, adhesive is adhered to the bottom of the placement groove, a chip is placed in the placement groove, a lower end of the chip is bonded with the adhesive, and an upper surface of the chip is connected with the conductive columnsthrough a plurality of wires. The method is advantaged in that indirect connection between the chip and the pins can be realized, shaking or damage of the chip due to the fact that the pin drags the chip can be avoided, an elastic packaging mode is adopted during plastic packaging, so the fixing effect can be achieved, and the chip cannot be damaged.

Owner:袁晓华

Packaging carton

ActiveCN109264206AGuaranteed overlapping areaGood lap stabilityContainers preventing decayRigid containersCardboardCarton

The invention provides a packaging carton and discloses a packaging carton which uses a bottom inverted trapezoid hollow area for buffering and ventilation. The packaging carton is characterized in that an inner bottom plate is arranged on an outer bottom plate, the outer bottom plate is bent from the middle, and one side of the outer bottom plate is higher than the other side; two side edges of the inner bottom plate are bent downwards to be connected with two side edges of the outer bottom plate, the hollow area is arranged between the inner bottom plate and the outer bottom plate, the innerbottom plate and the outer bottom plate are combined to form a bottom plate, one side of the bottom plate is bent inwards, the hollow area is of an inverted trapezoid structure, an adhesive layer isarranged on the other side of the bottom plate, and the two bottom plates are horizontally placed; the two bottom plates adhere to each other through the adhesive layer, side face paper boards are distributed around the peripheries of the two bottom plates, and the side face paper boards are bent three times to form four parts; the included angle between every two adjacent parts is 90 degrees, andthe side panel paper boards are of a closed structure.

Owner:烟台欧亚塑料包装有限公司

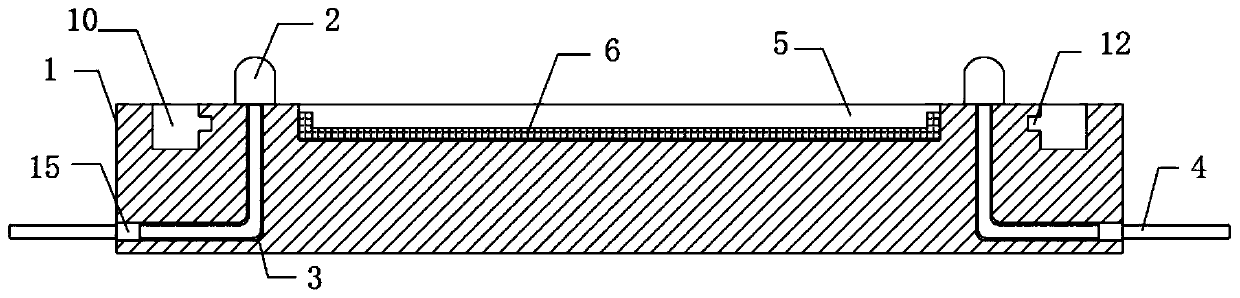

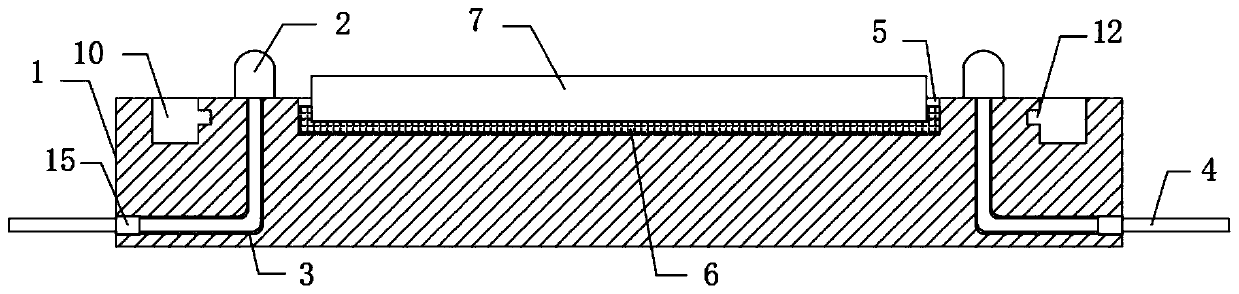

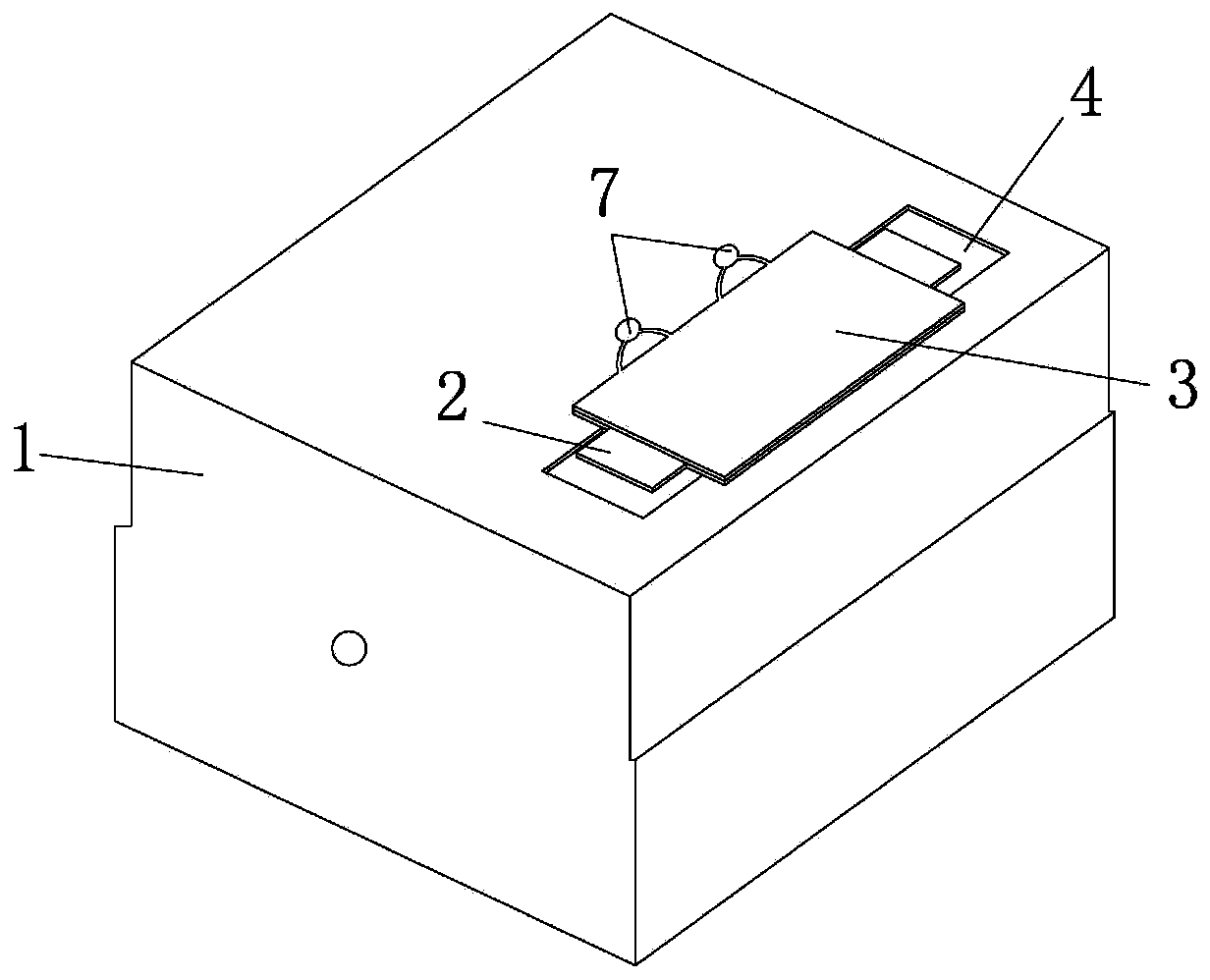

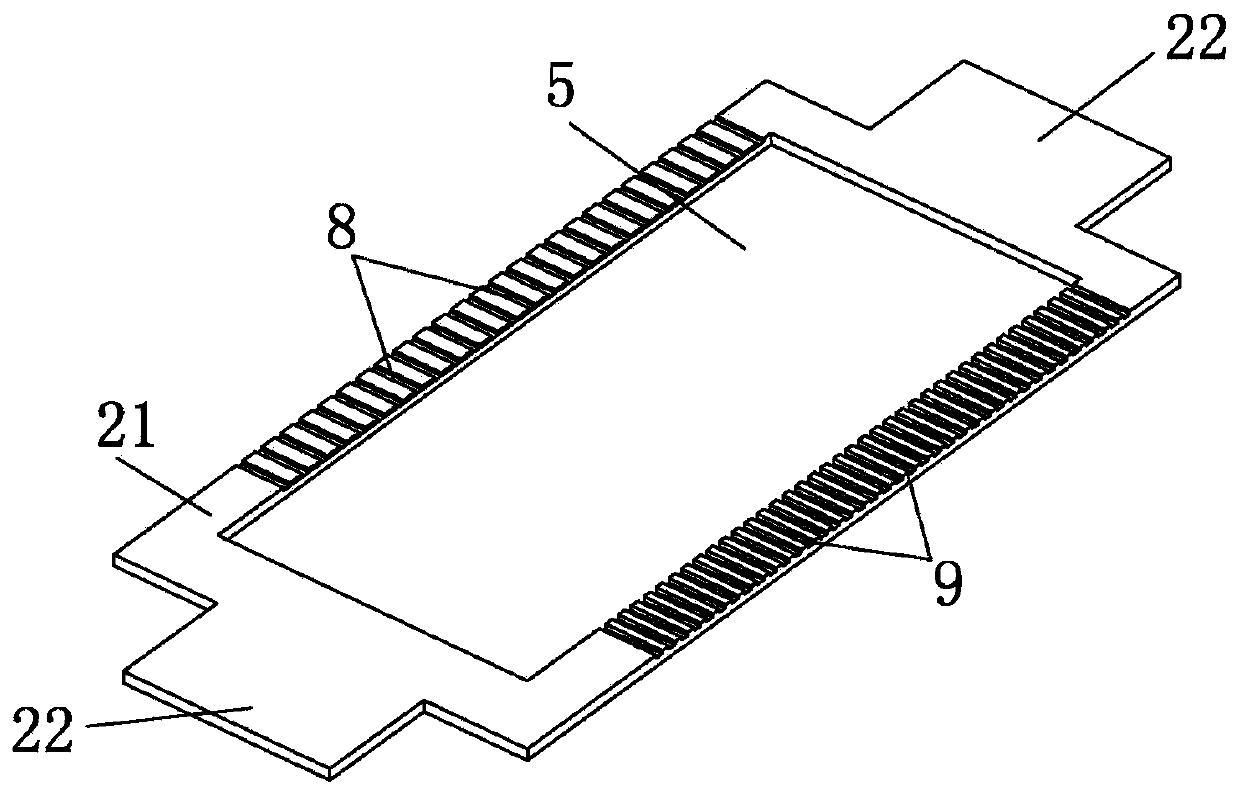

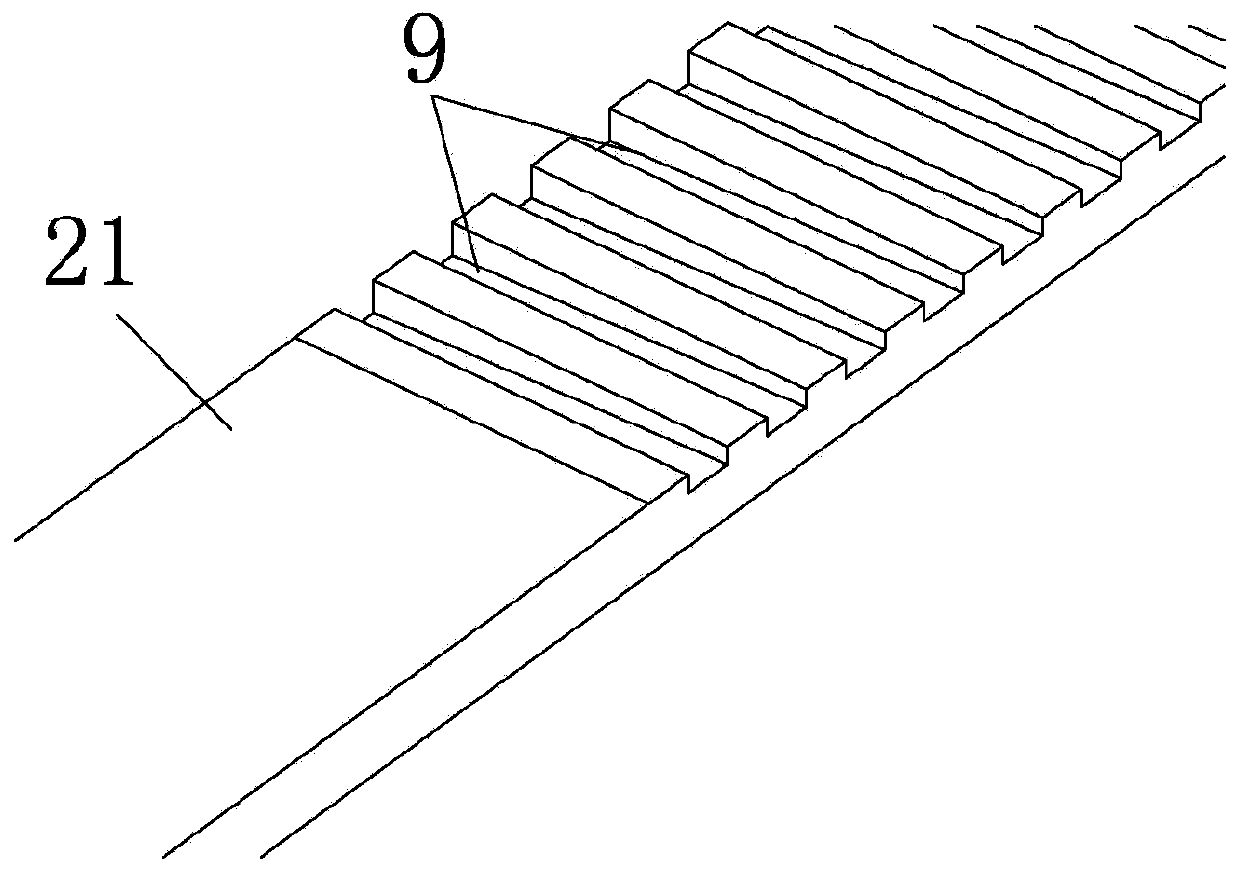

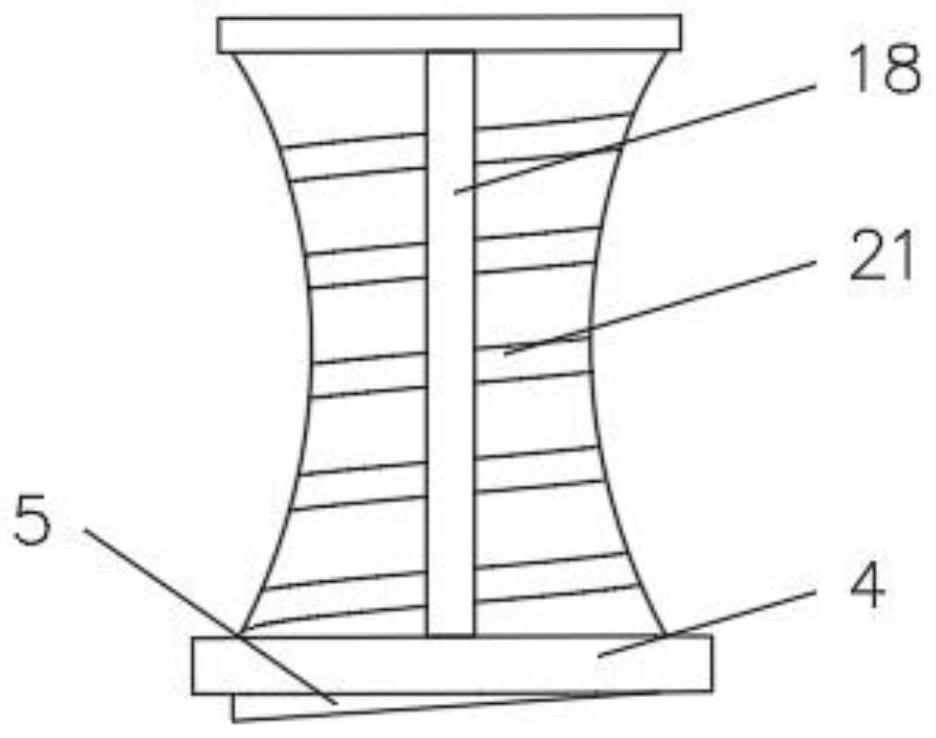

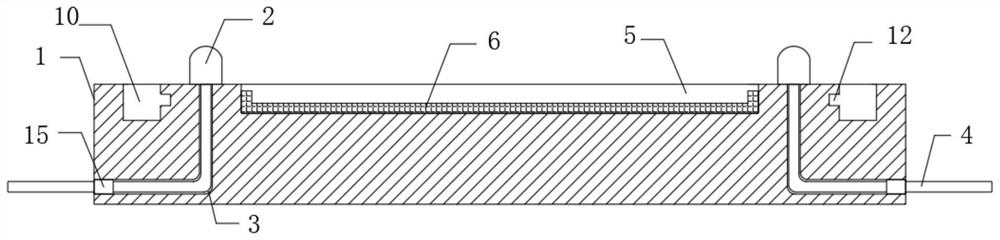

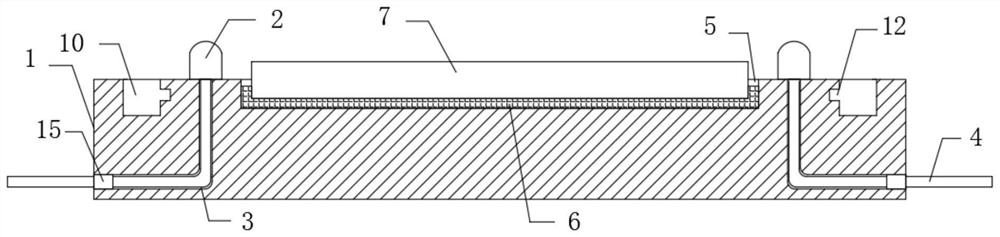

Whole-board packaging mold of flexible board and packaging method of whole-board packaging mold

PendingCN110444481ASolve technical problemsTo achieve the purpose of the whole board packageSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLed packaging

The invention discloses a whole-board packaging mold for a flexible board. The mold comprises a packaging lower mold and a packaging upper mold, and a material sheet groove for placing the flexible board is formed in the central position of the packaging lower mold; a polishing boss is arranged on the side face, facing the packaging lower mold, of the packaging upper mold in a protruding mode. Thepackaging upper mold covers the packaging lower mold, and the polishing boss is embedded into the material sheet groove. The polishing boss and the material sheet groove are combined to form a wholeplate packaging chamber; an exhaust component and a glue inlet component are arranged on the two sides, located in the material piece groove, of the lower packaging mold respectively, and the exhaustcomponent and the glue inlet component are arranged on the different sides. A glue injection sleeve used for injecting glue into the whole plate packaging cavity is arranged on the side, correspondingto the glue inlet component arranged on the lower packaging mold, of the upper packaging mold. The technical problem of flexible board LED packaging in the industry can be effectively solved, the purpose of whole board packaging is achieved, the technological process is effectively simplified, the manufacturing period is shortened, and the effects of reducing cost and reducing supply chains are achieved.

Owner:YANCHENG DONGSHAN PRECISION MANUFACTURING CO LTD

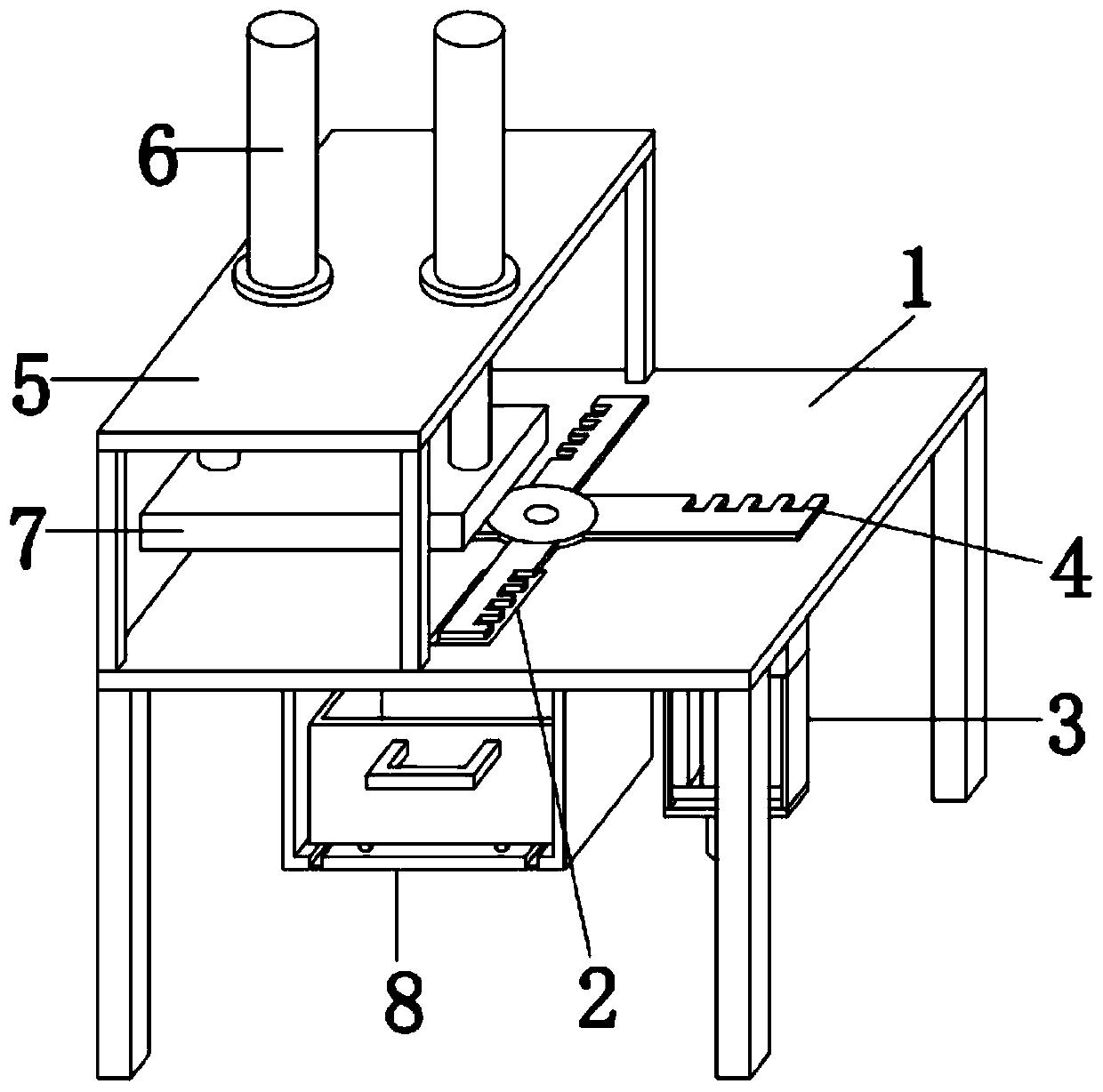

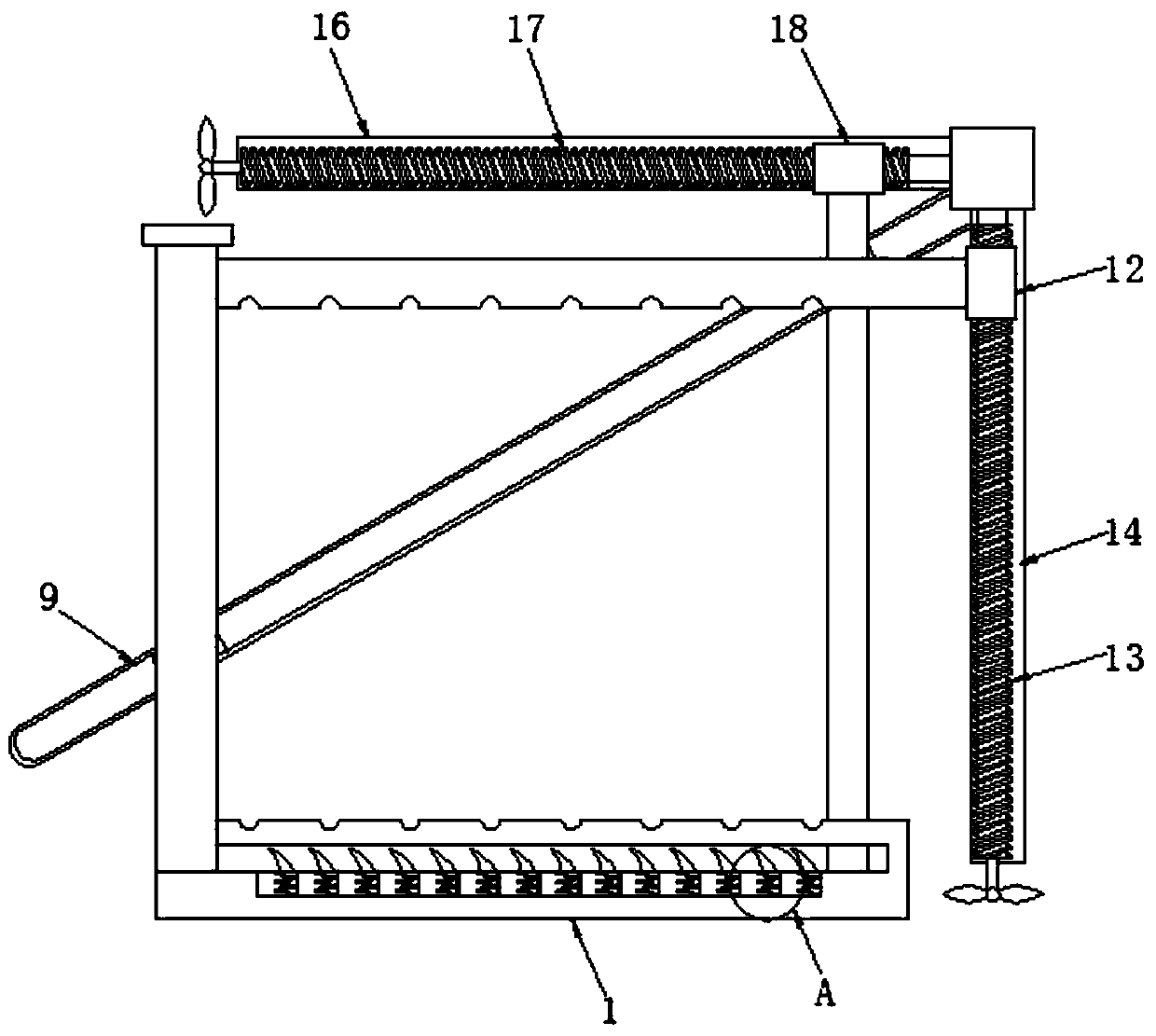

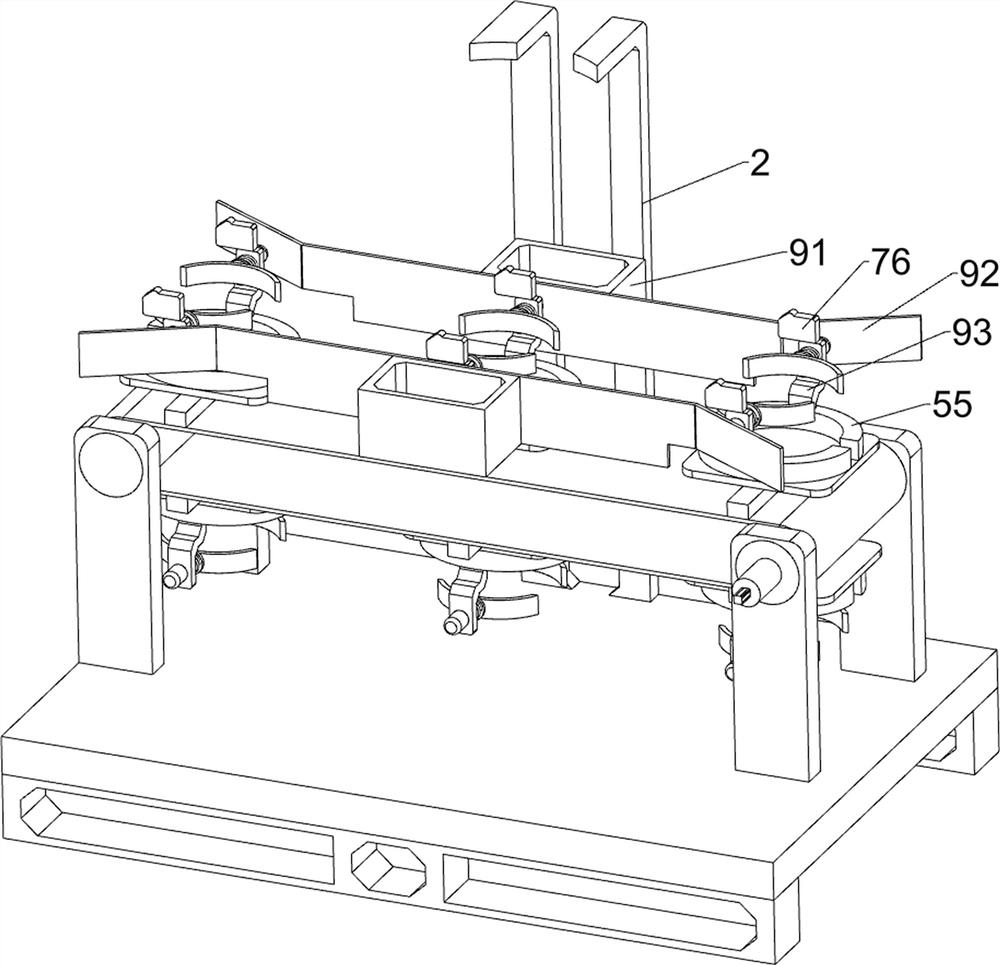

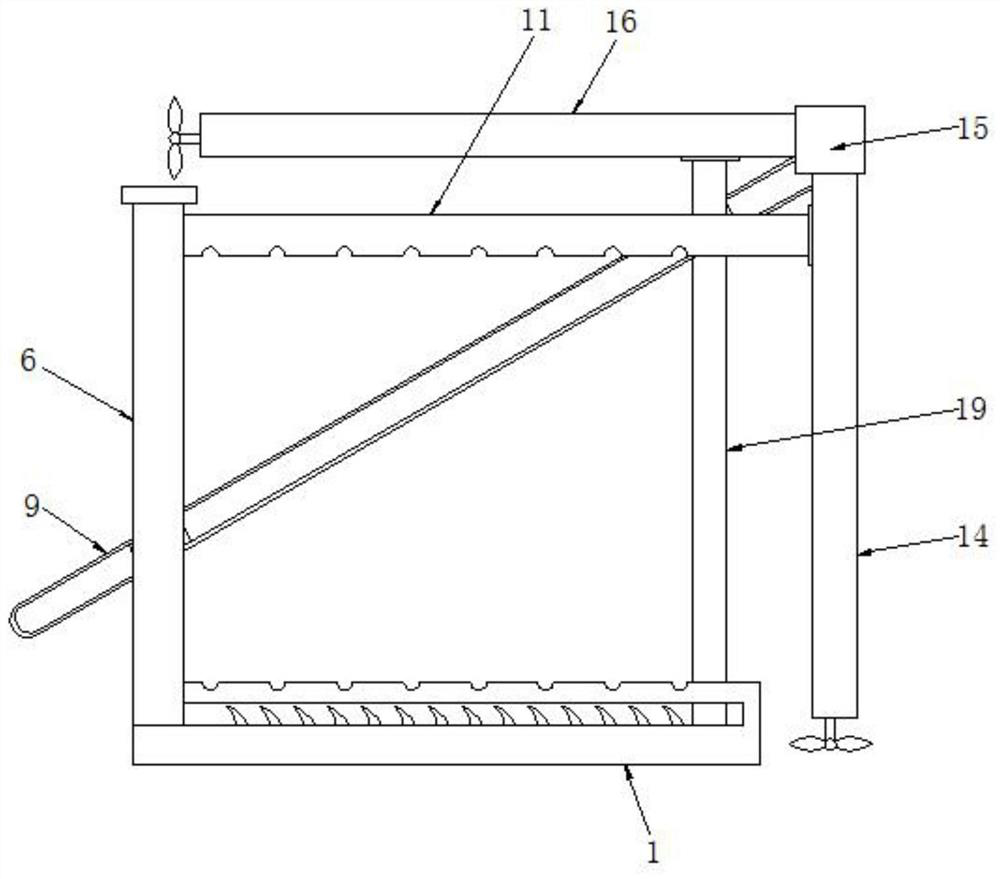

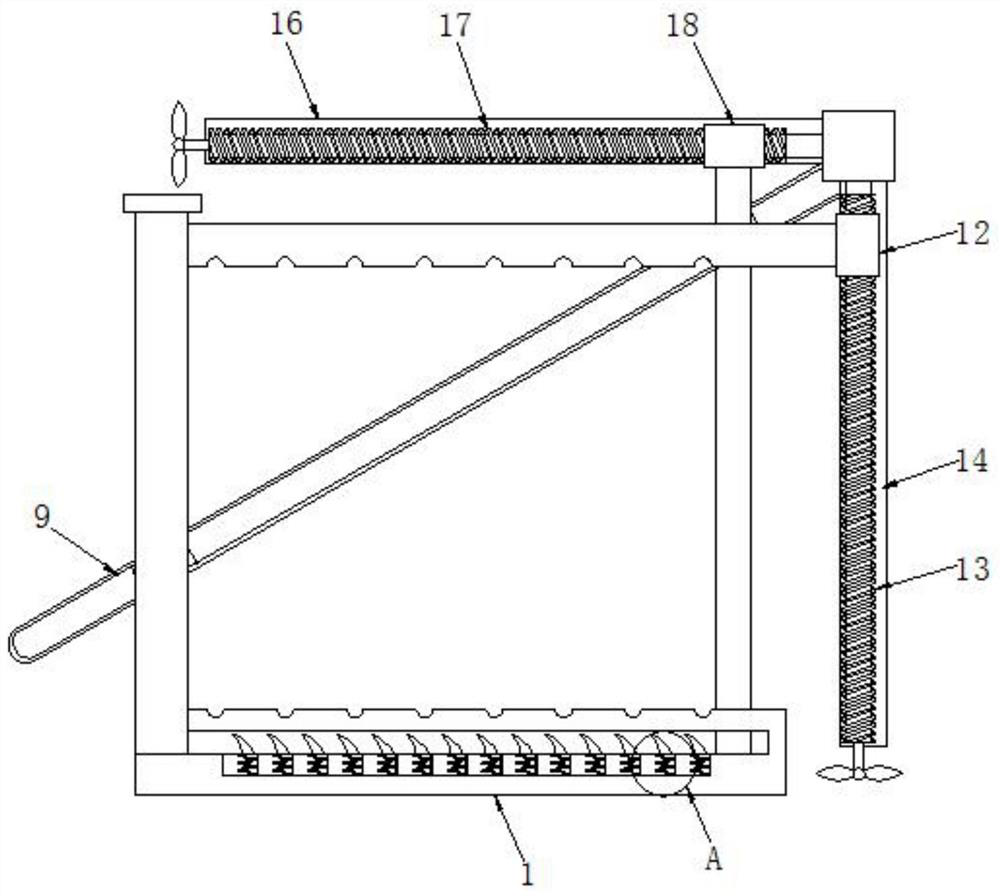

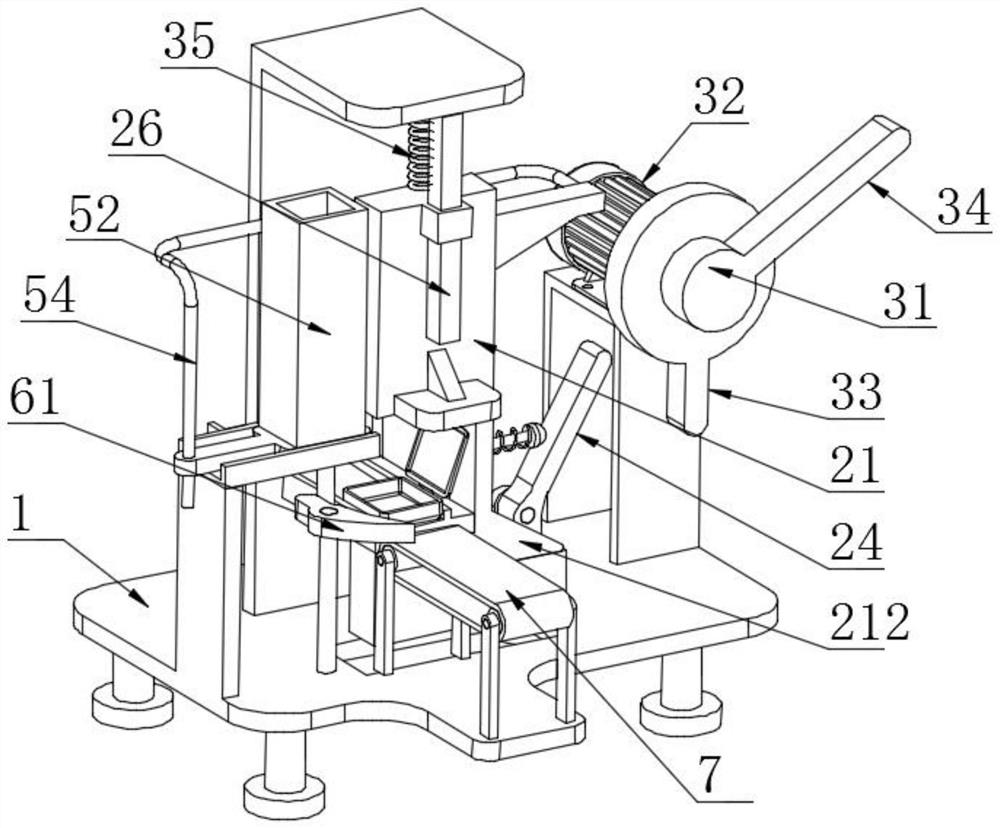

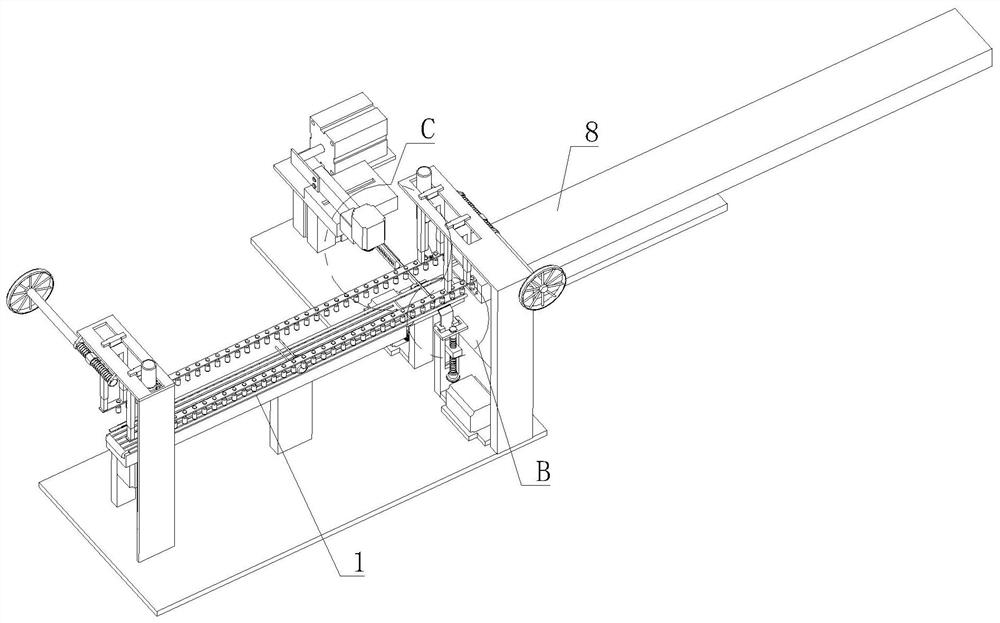

Special packaging device for electrocardiograph paper

The invention discloses a special packaging device for electrocardiograph paper, which comprises a packaging table. Two placing slots are formed in the upper surface of the packaging table; the approaching side walls of two placing slots are both fixedly connected with a first fixed block; a circular through hole is formed on one side of each of the two placing slots far away from the first fixedblock; the hole wall of the circular through hole is fixedly connected with a rolling bearing; a threaded cylinder is fixedly connected to the inner wall of each of the rolling bearings; the inner wall of the threaded cylinder is in screw-thread fitting connection with a threaded rod; one opposite end of each of the two threaded rods is fixedly connected with a second fixed block; the outer wall of each of the two threaded cylinders is fixedly sleeved with a first gear; and the lower surface of the packaging table is in fixed connection with a double-shaft motor. The special packaging device for electrocardiograph paper in the invention does not need to manually fix rolls of electrocardiograph paper, thereby saving time and labor and reducing the labor intensity of a worker; and two rollsof electrocardiograph paper can be once packaged as well, thereby improving the speed of packaging the rolls of electrocardiograph paper and the packaging efficiency.

Owner:TIANJIN GRAND PAPER IND

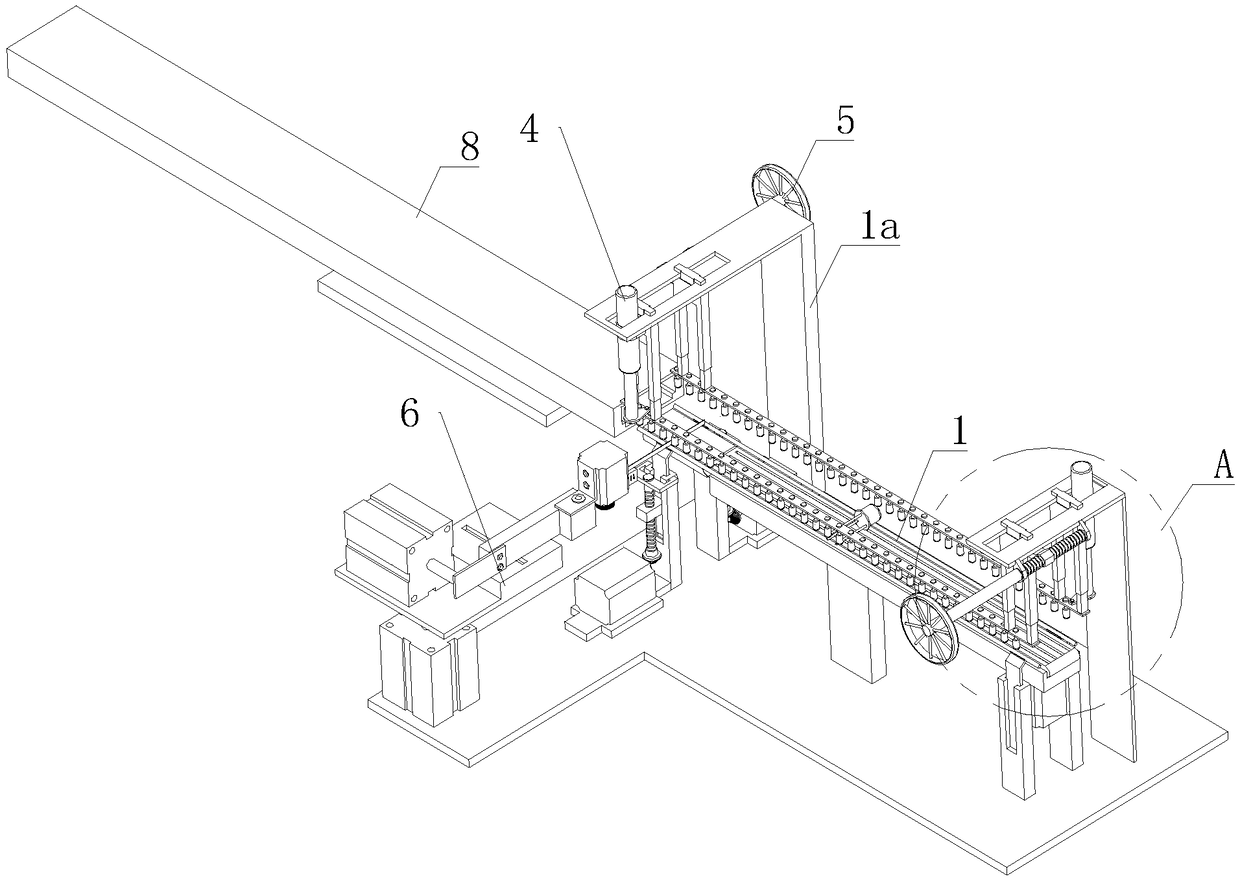

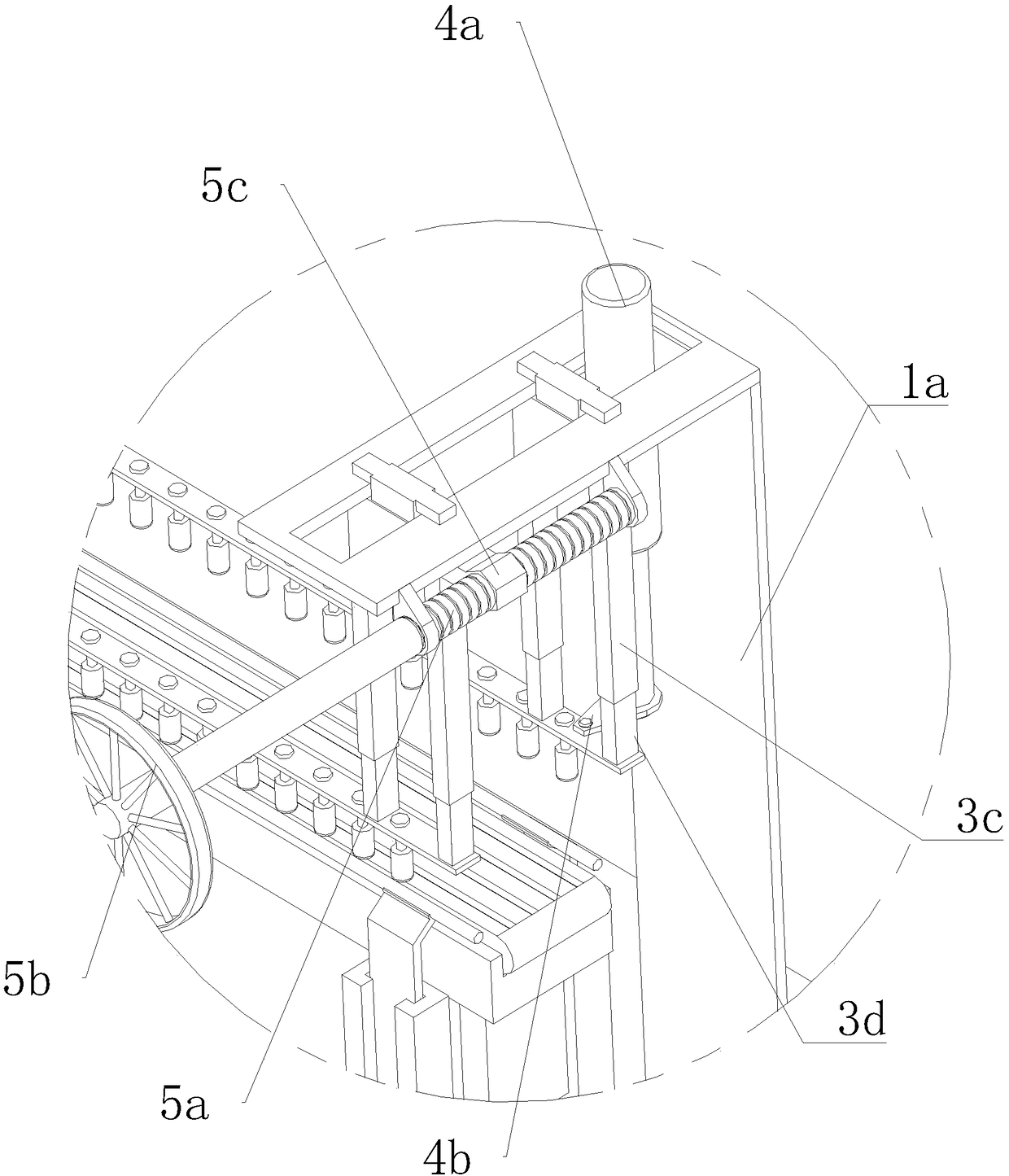

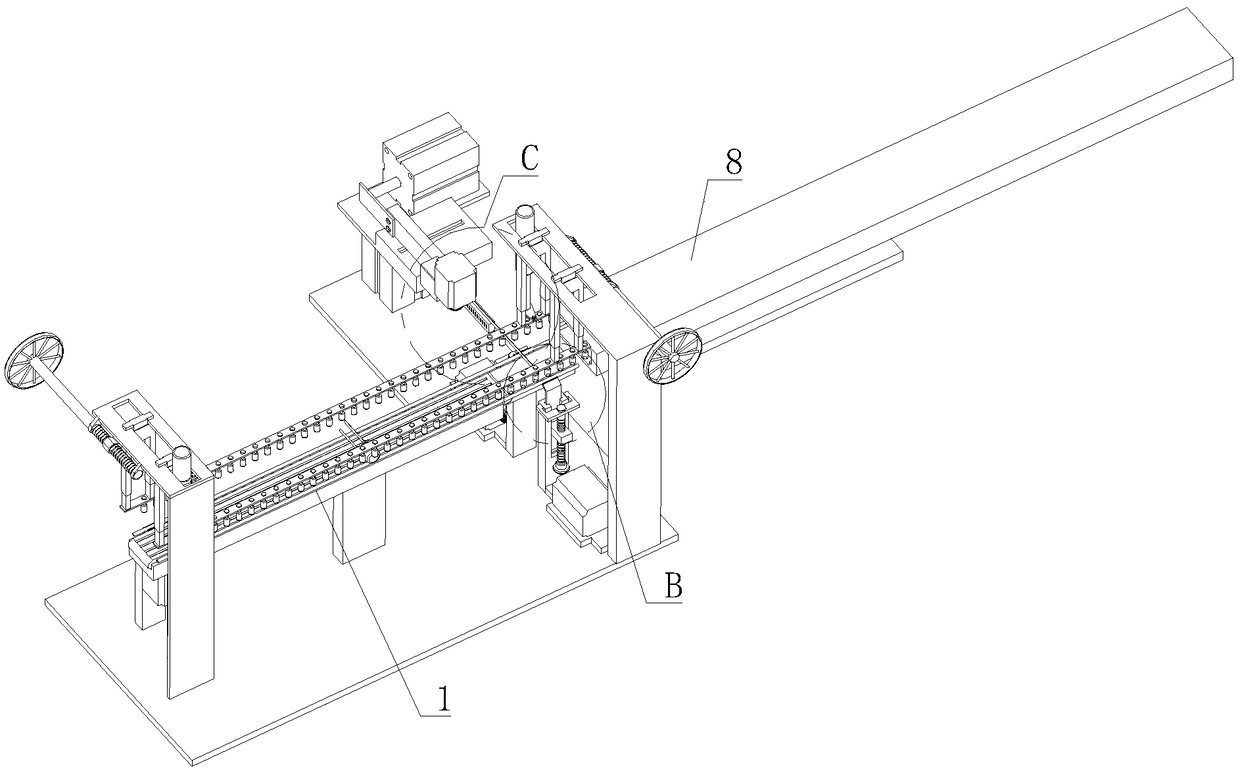

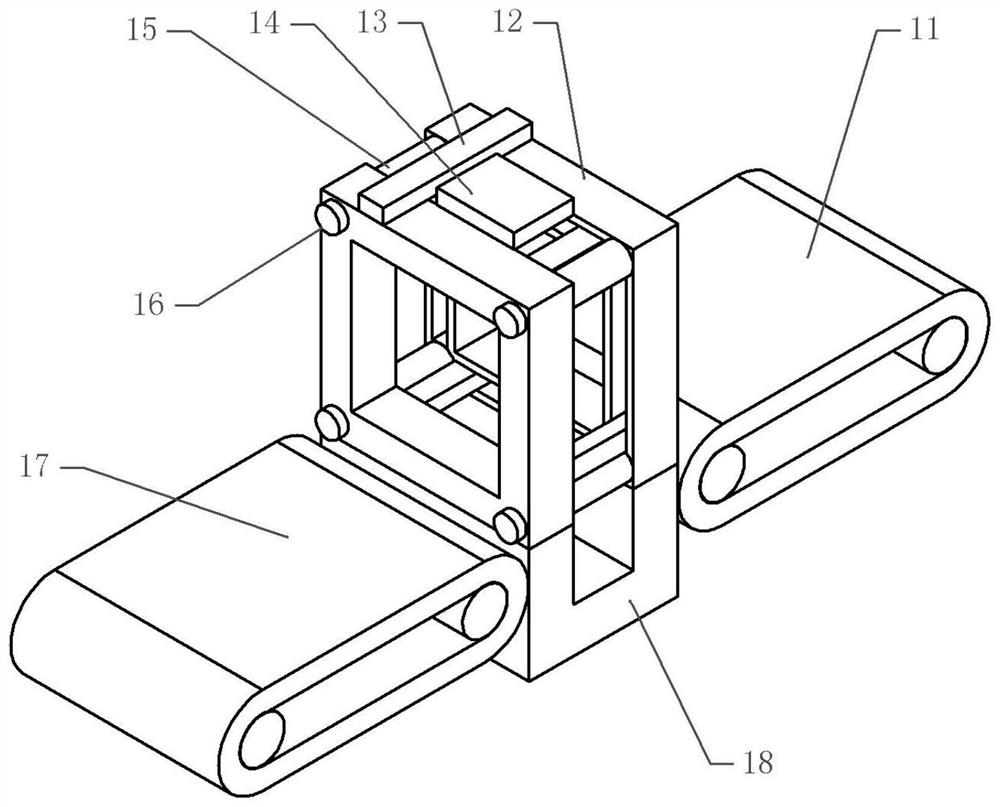

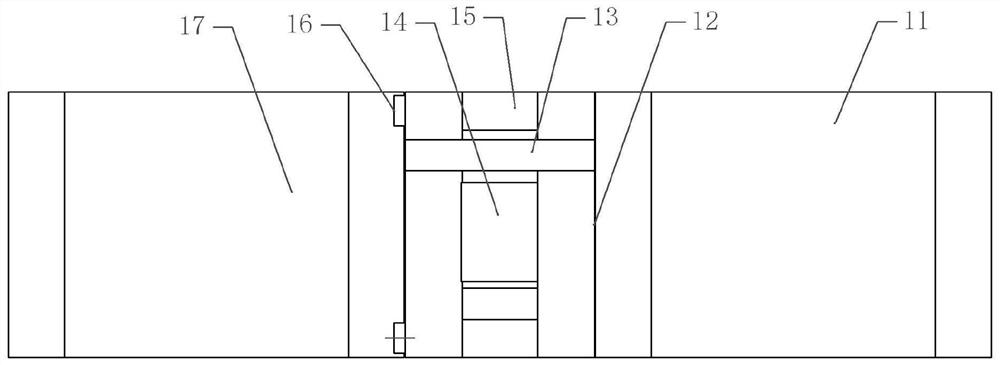

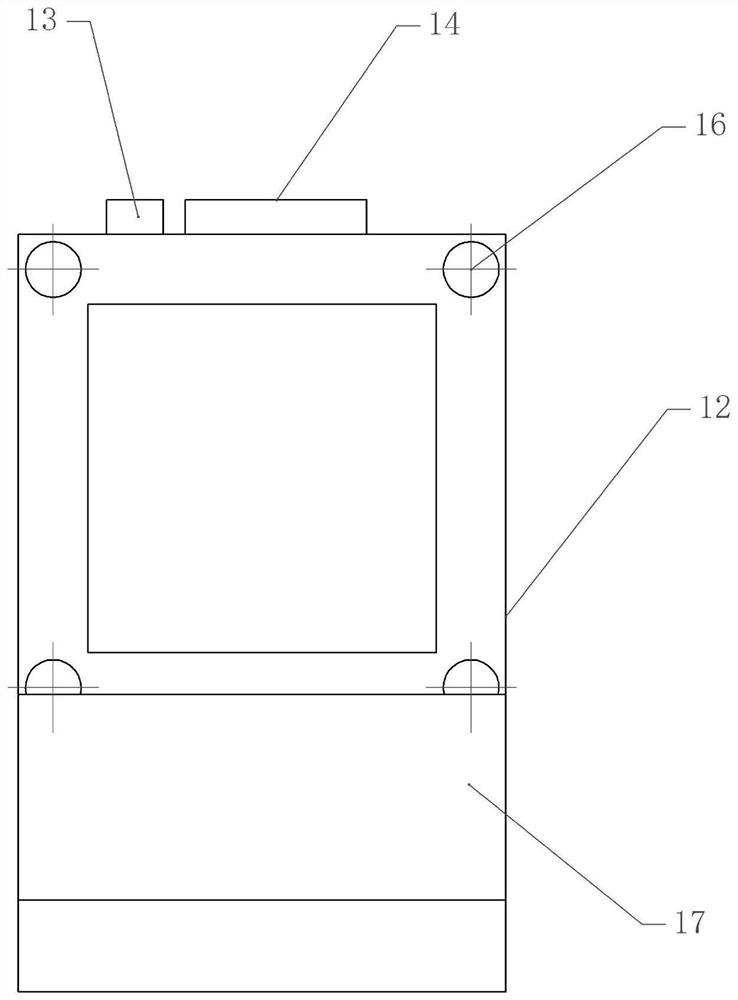

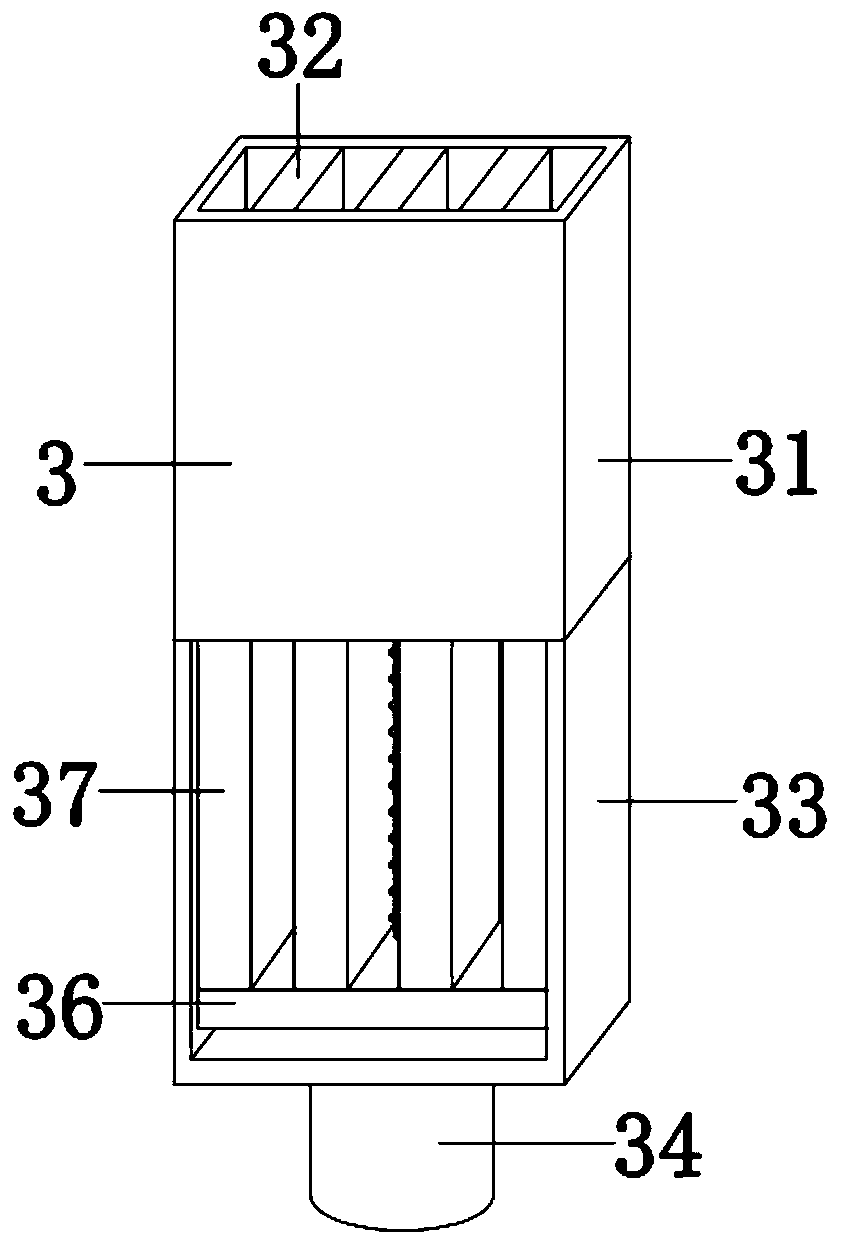

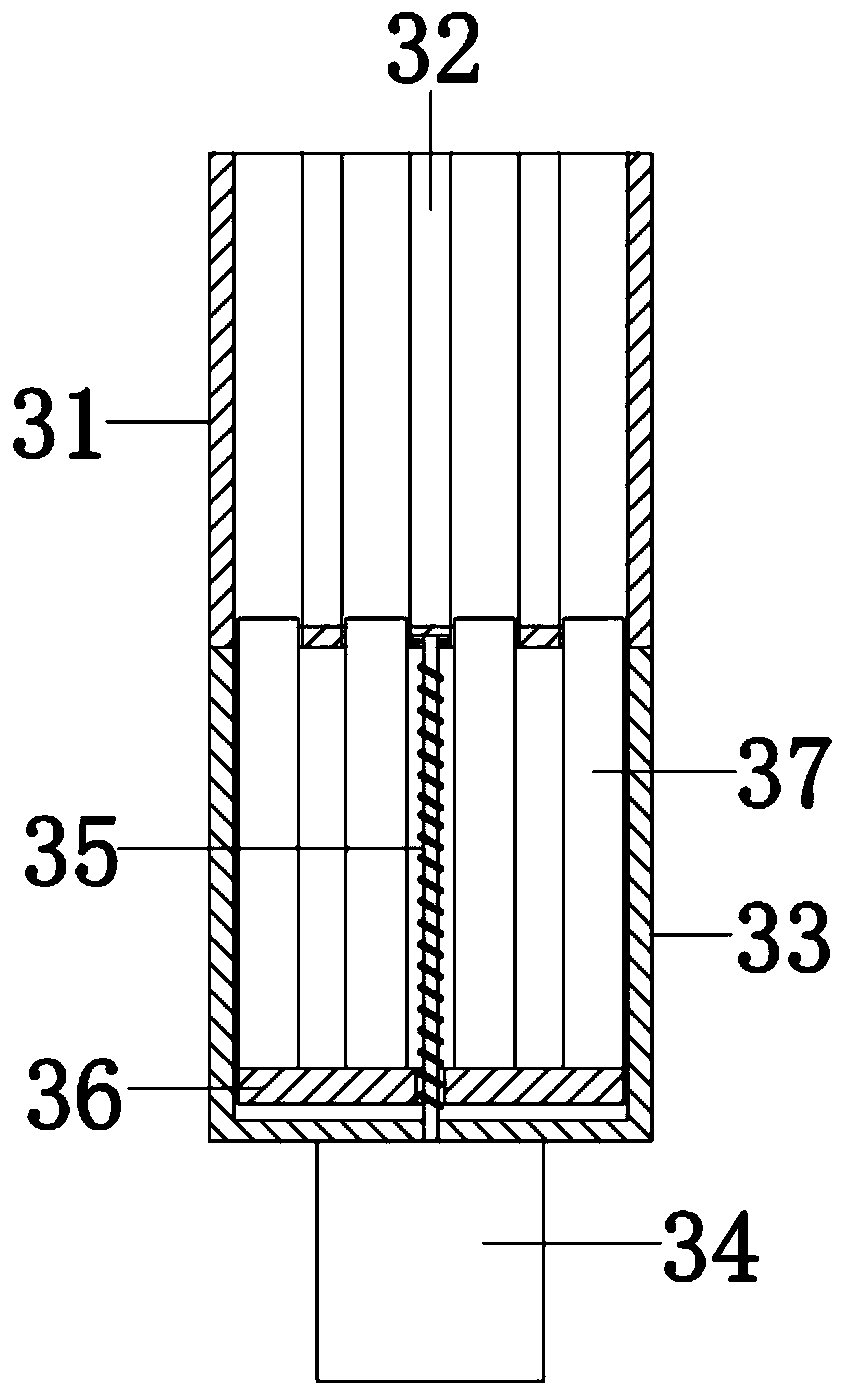

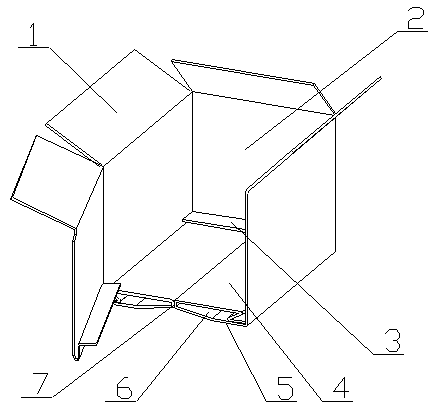

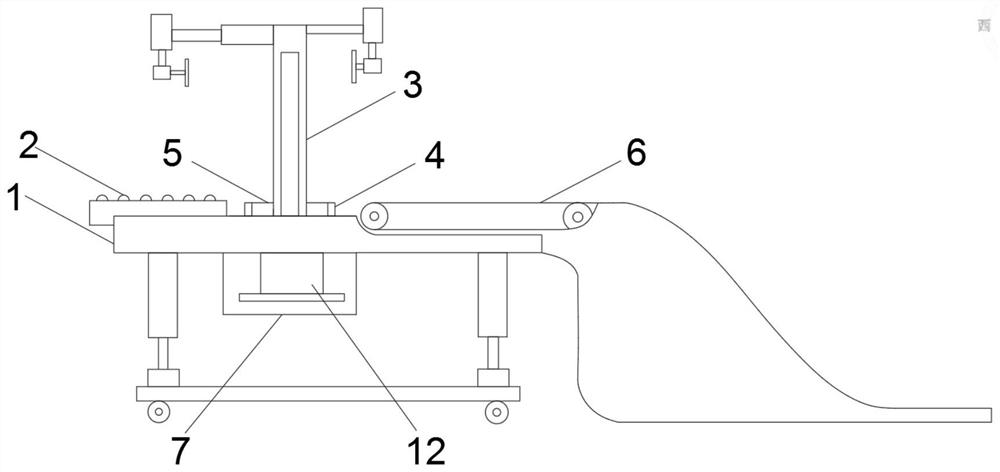

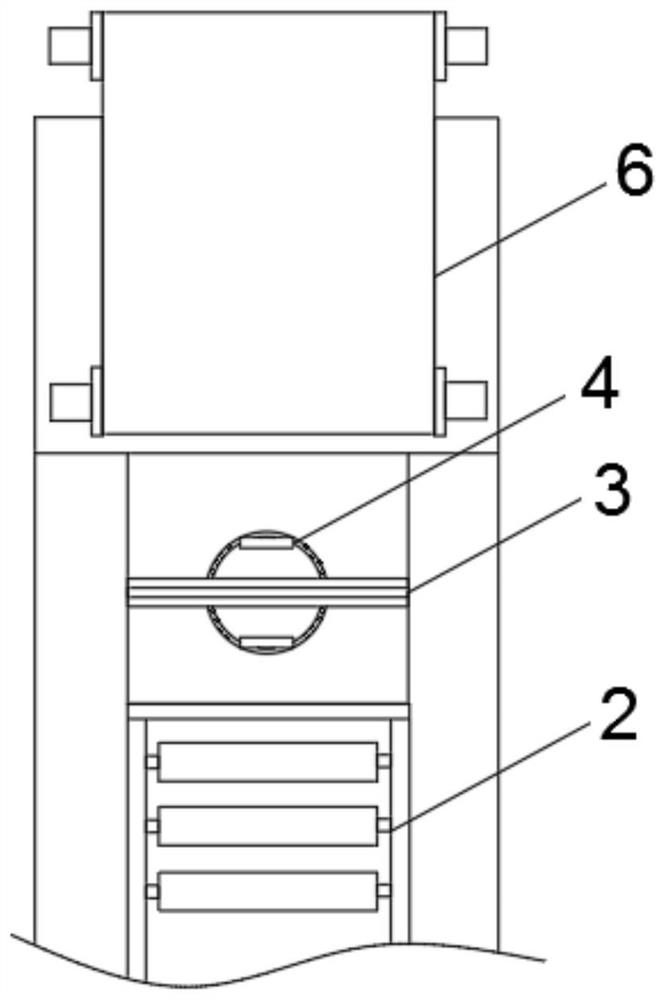

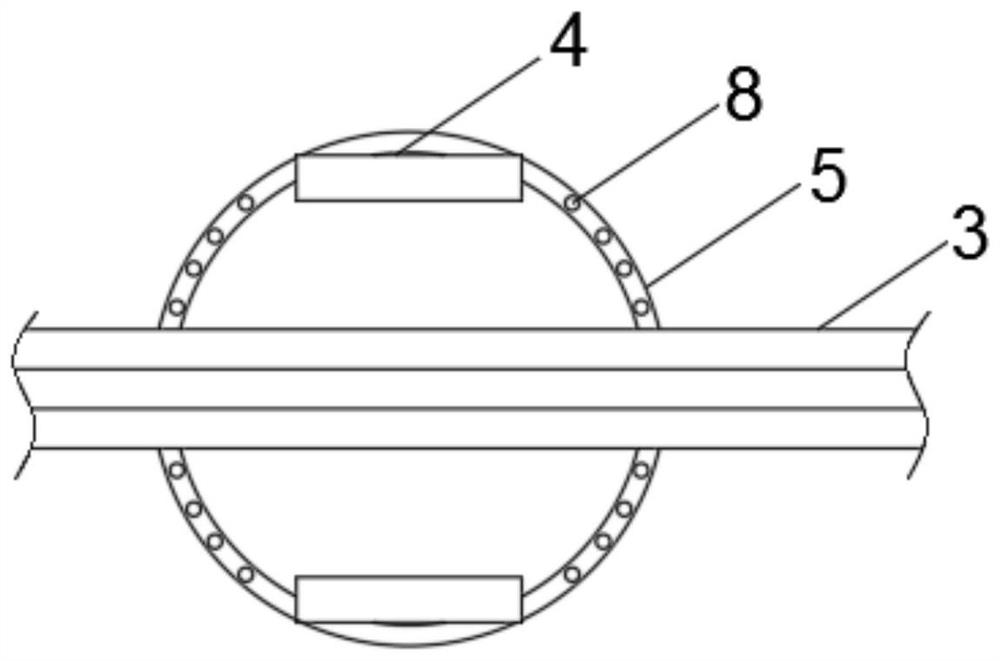

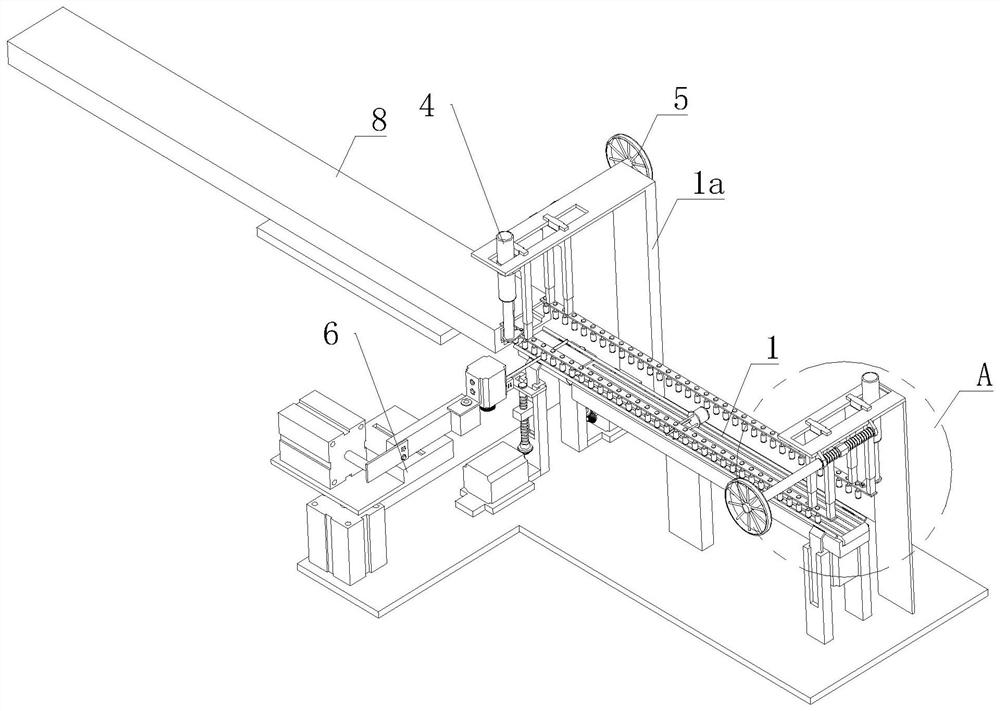

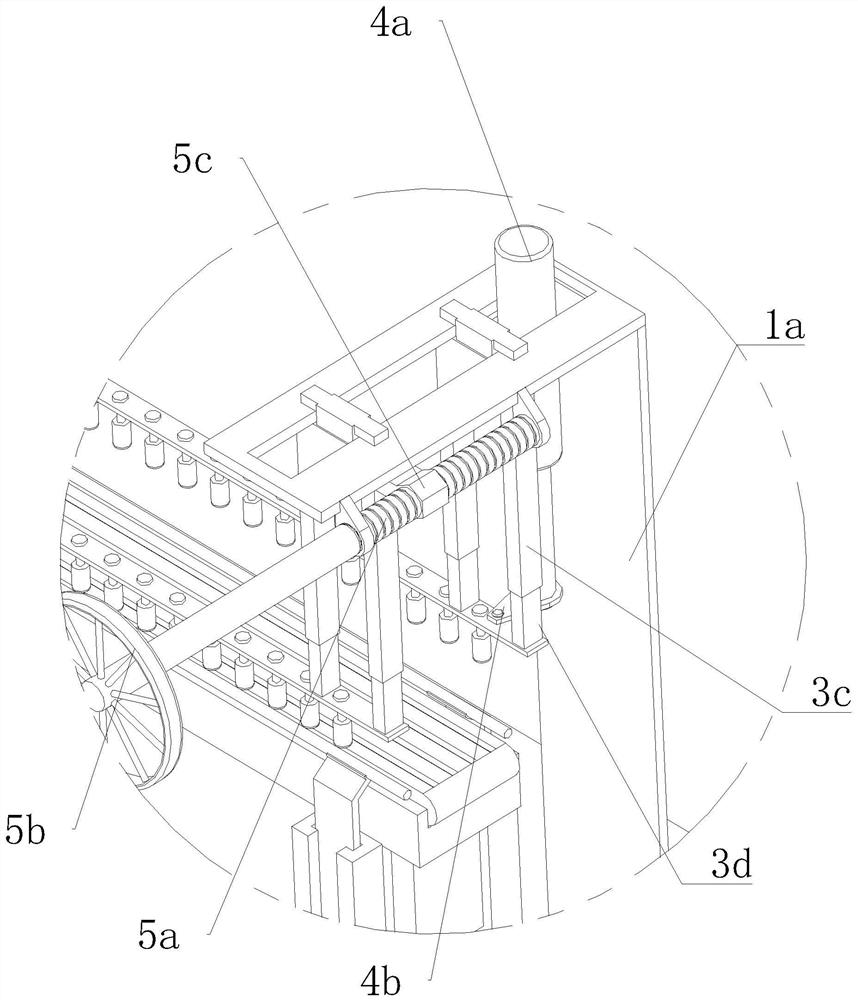

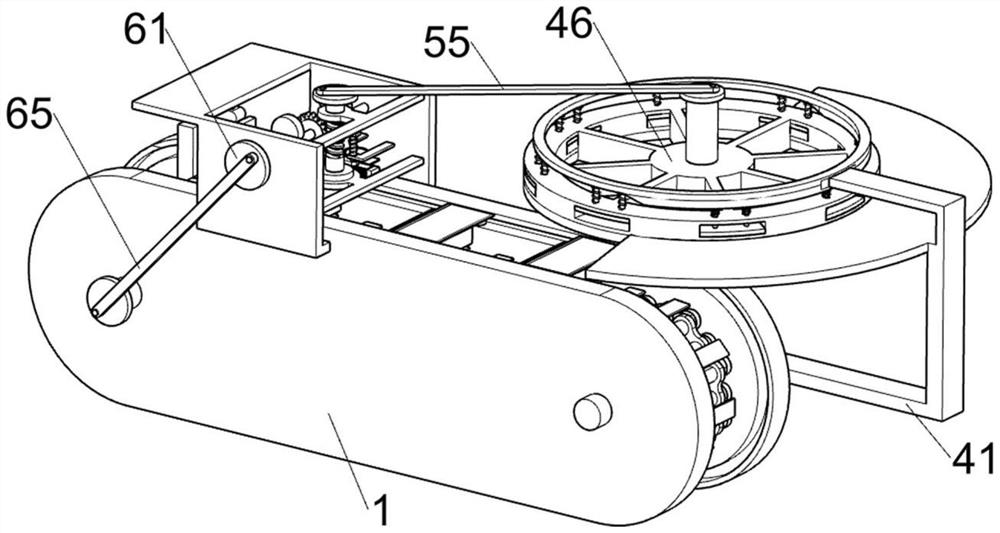

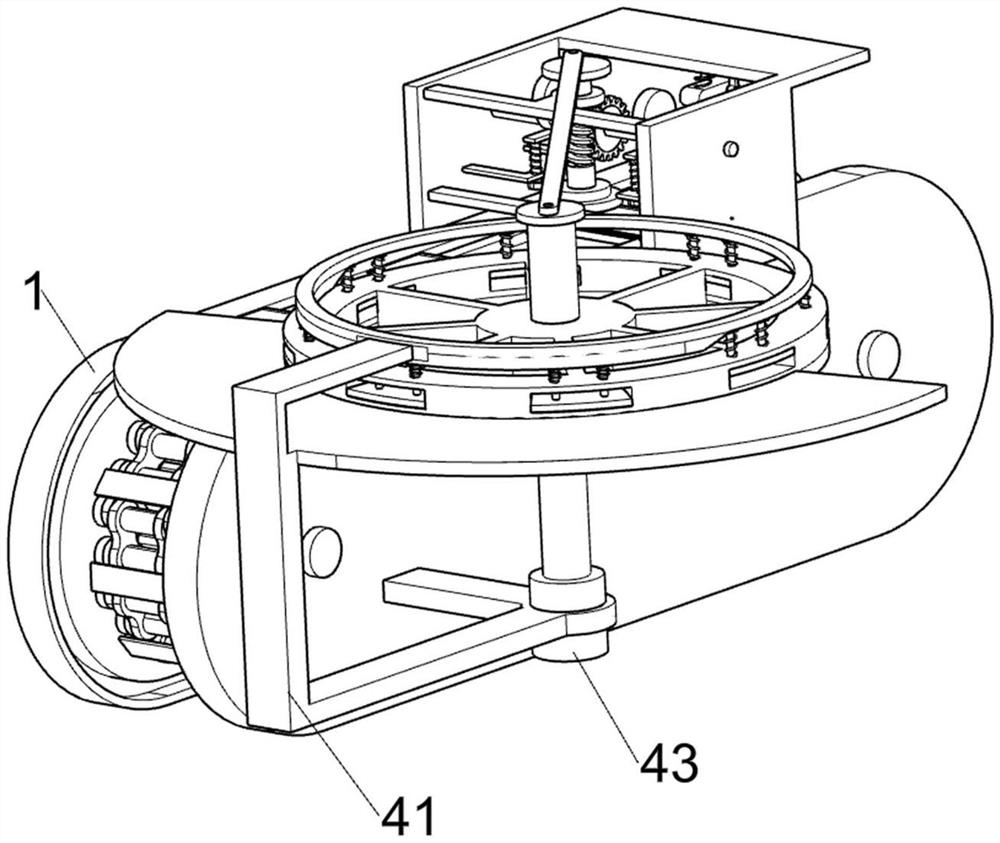

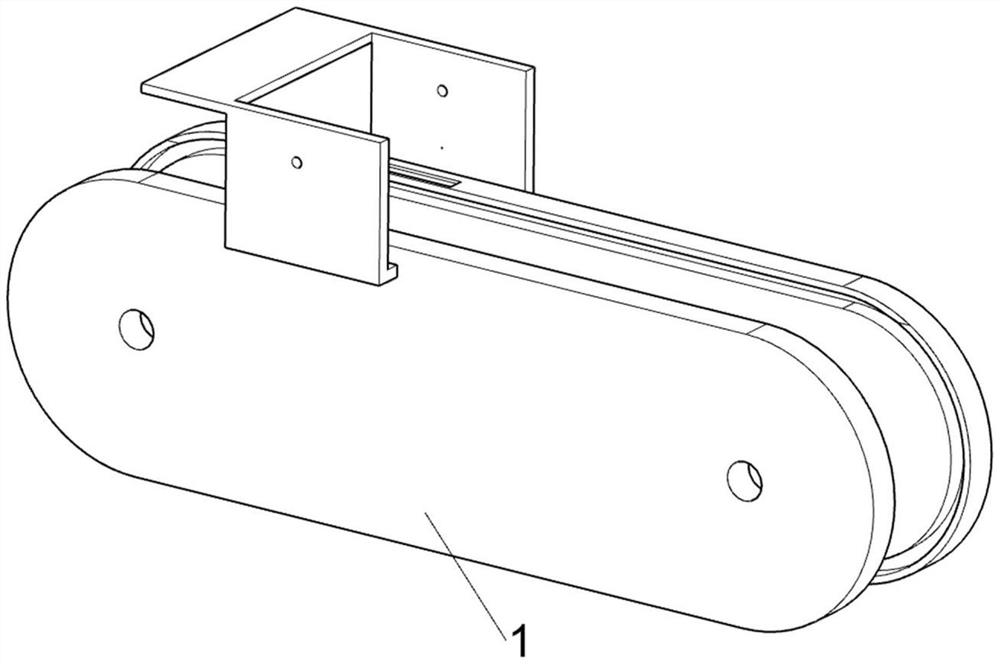

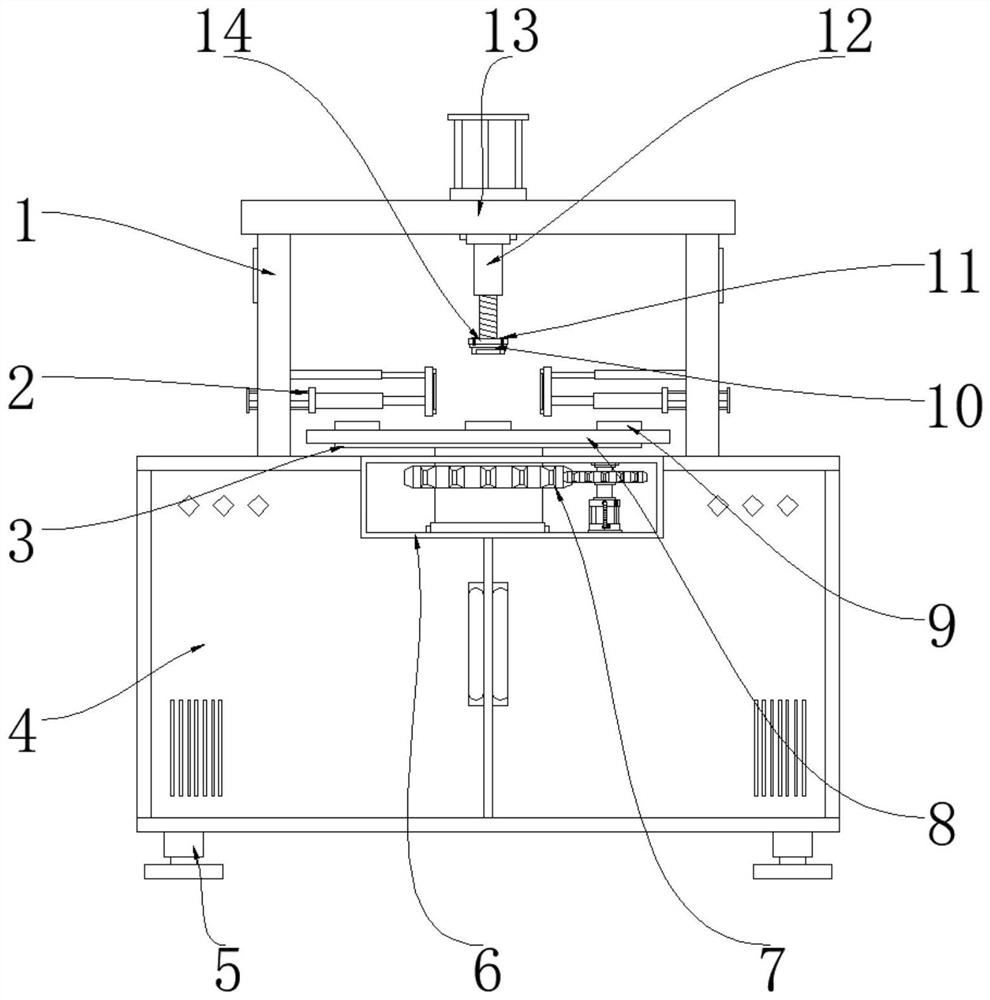

Packaging equipment applicable to semiconductor elements of different types and specifications

The invention relates to the field of packaging of semiconductor elements, in particular to packaging equipment applicable to semiconductor elements of different types and specifications. The equipment comprises a stepping conveying belt, a guiding device, a limiting device and a feeding device; the guiding device comprises two guiding polish rods which are arranged at one sides of the stepping conveying belt respectively, each guiding polish rod can move vertically through one lifting device, and the limiting device comprises two guide assemblies which are arranged at one sides of the stepping conveying belt respectively; each guide assembly is always located above the stepping conveying belt and can vertically move through a height fine-adjustment device, the two guide assemblies can bemovably arranged face to face or back to back through spacing fine-adjustment devices, and the feeding device is arranged outside one side of the downstream end of the stepping conveying belt. The equipment can be applicable to automatically packaging the semiconductor elements of different types and specifications, and the product output efficiency of manufacturers is greatly improved.

Owner:江苏尖端半导体有限公司

Carton packing device

PendingCN114212324AReduce work intensityReduced packaging efficiencyWrapper twisting/gatheringAdhesive beltCarton

The invention belongs to the technical field of carton packaging equipment, and provides a carton packaging device which comprises a rack, a conveying mechanism is mounted on one side of the rack, a conveying mechanism is mounted on the other side of the rack, and a packaging support is arranged between the conveying mechanism and the conveying mechanism; adhesive tape output modules, cutting modules used for cutting off adhesive tapes and pressing modules used for pressing the adhesive tapes are arranged on the upper portion and the lower portion of the packaging support, each adhesive tape output module comprises an adhesive tape roller rotationally connected with the packaging support, a clamping part is arranged on one side of each adhesive tape roller, and a driving part used for driving the clamping parts is installed on the support; the cutting module comprises a power piece, and a cutting knife is fixed to an output shaft of the power piece. The pressing module comprises a pressing piece, and a pressing plate is fixed to the output end of the pressing piece. The carton packaging device is simple in structure, cartons are mechanically packaged, the packaging efficiency of the cartons is improved, and labor consumption is reduced.

Owner:重庆联大包装制品有限公司

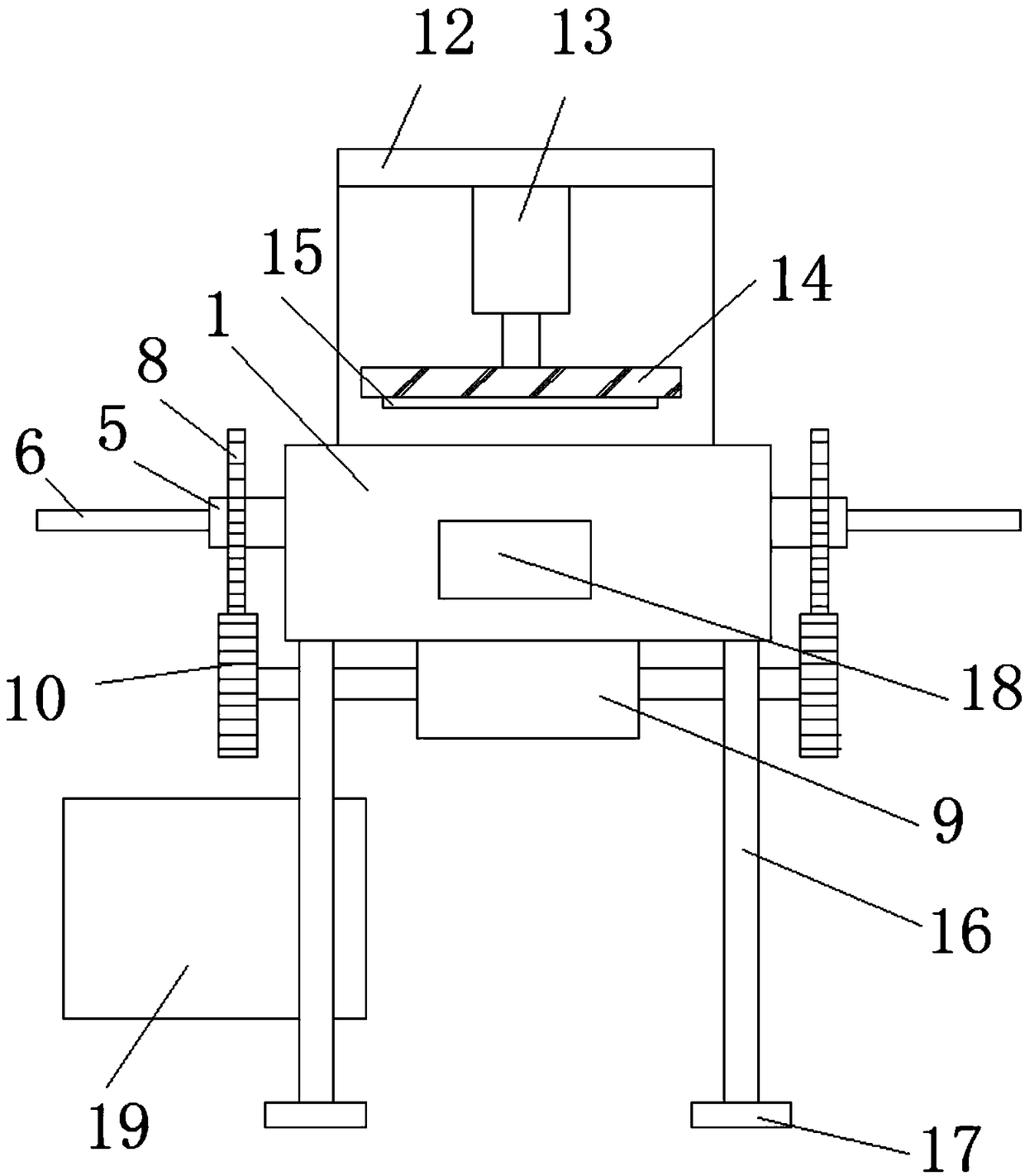

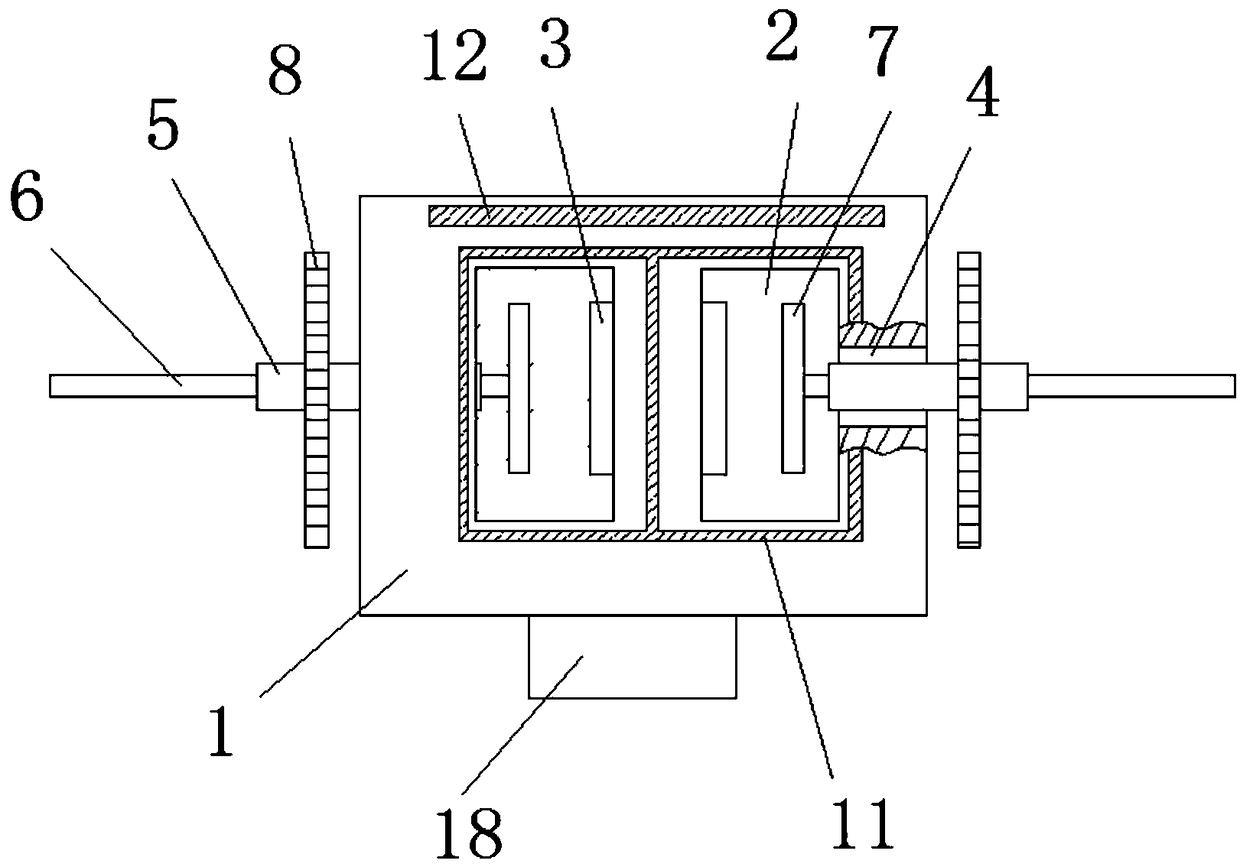

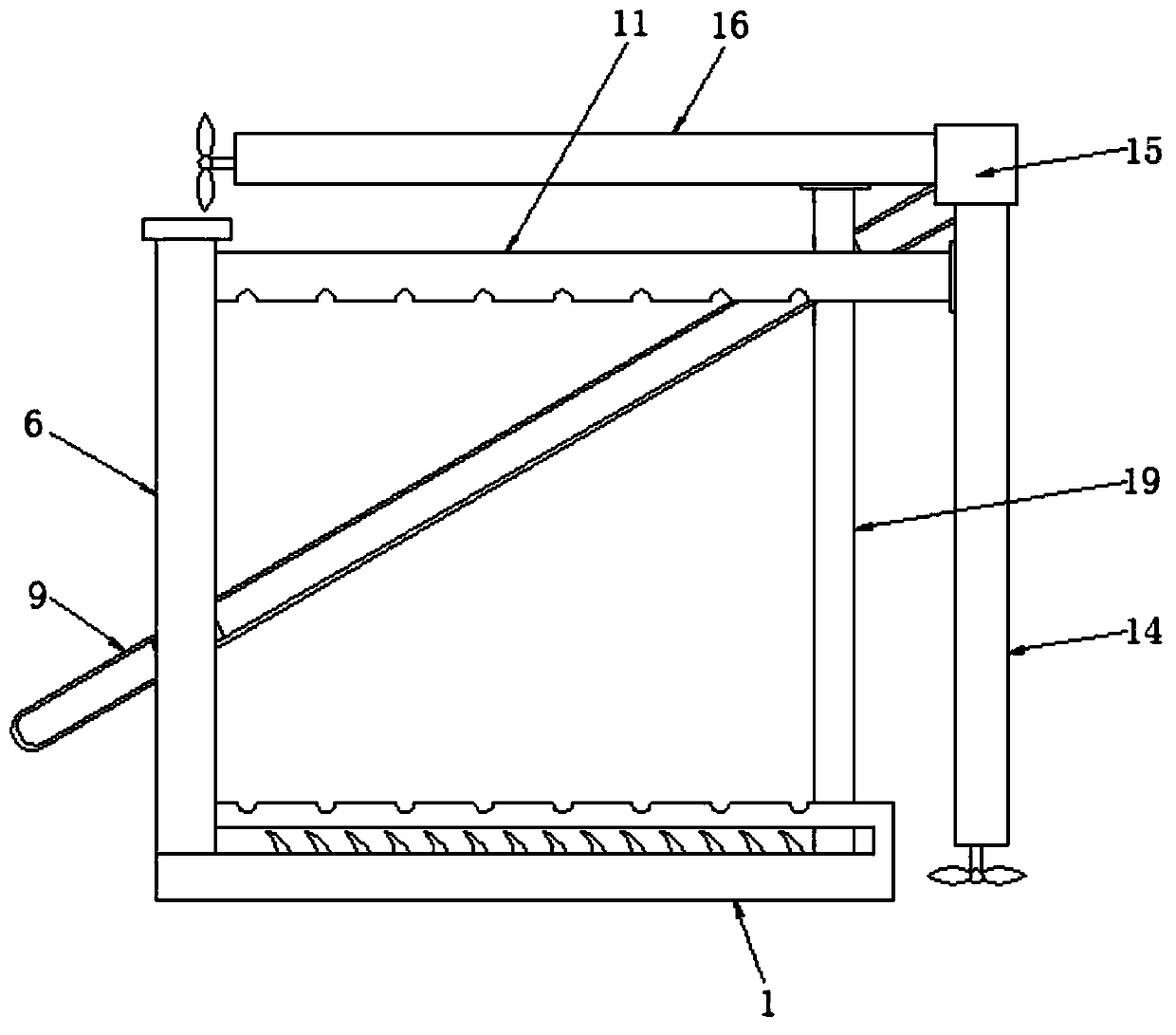

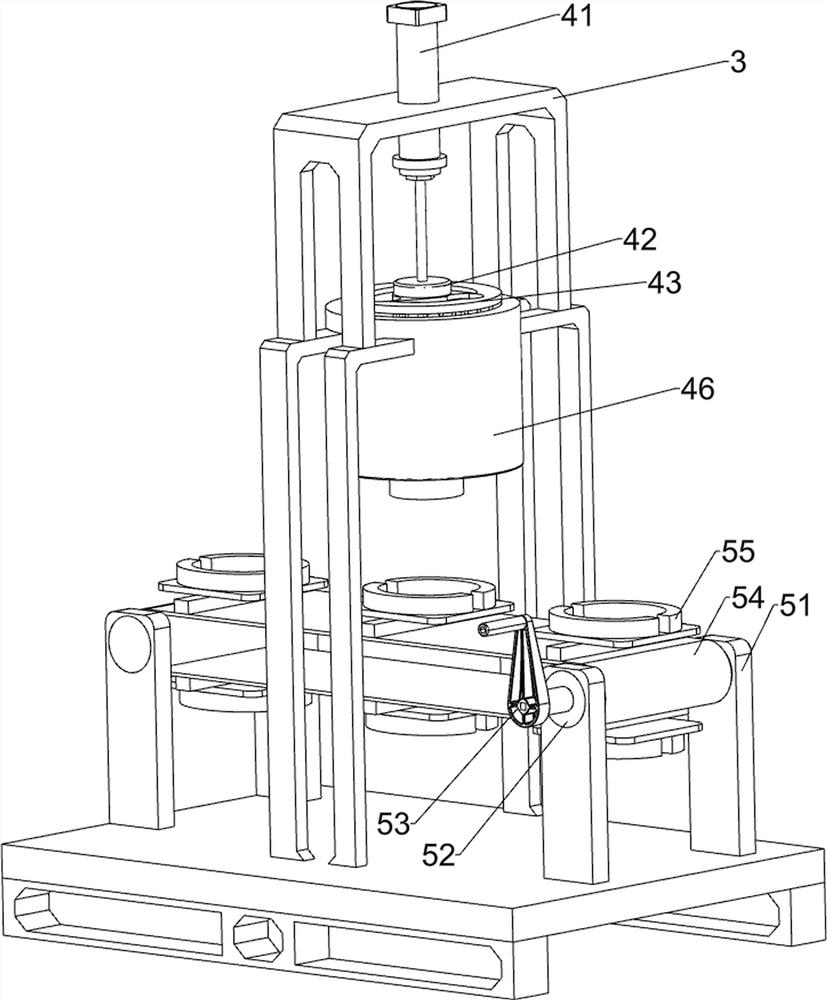

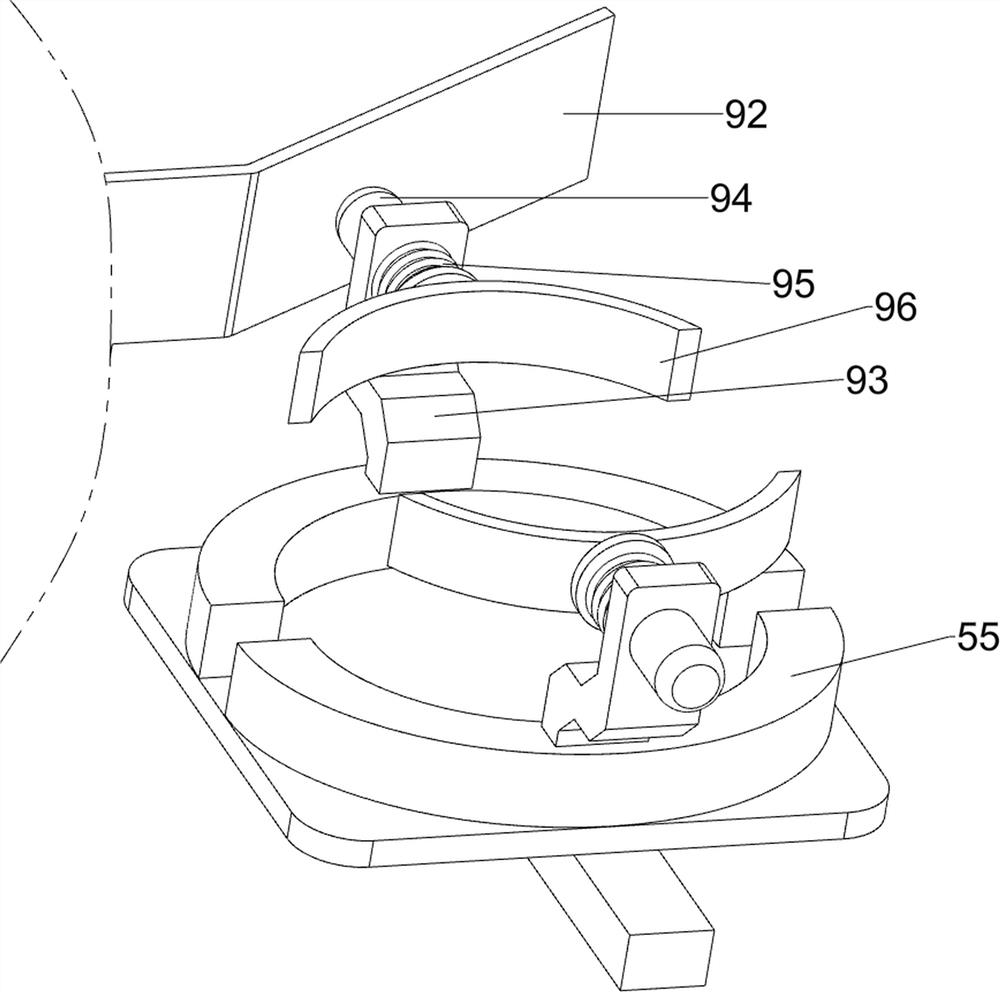

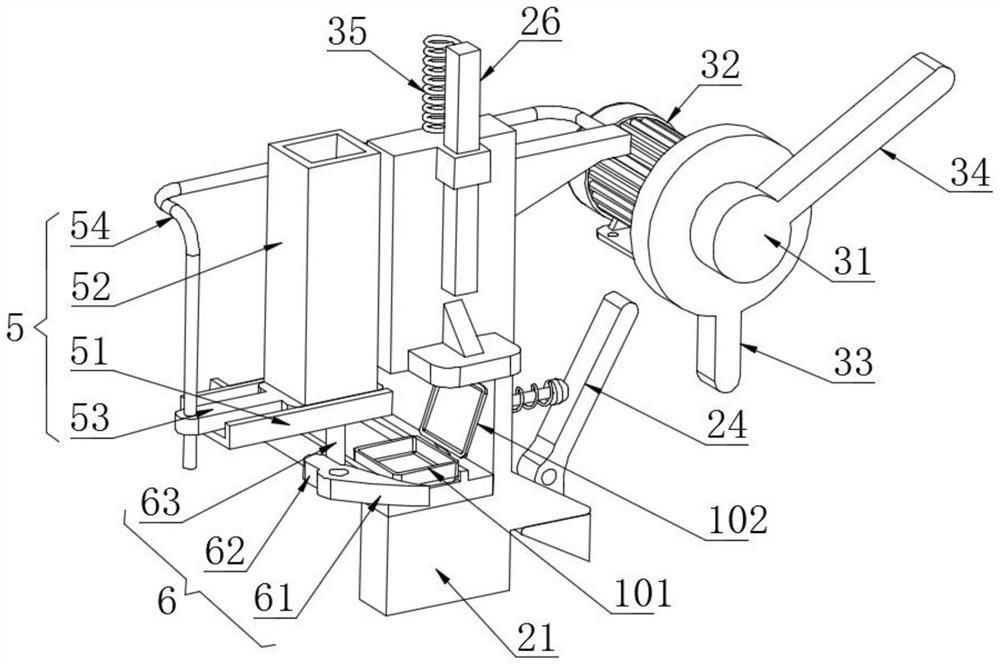

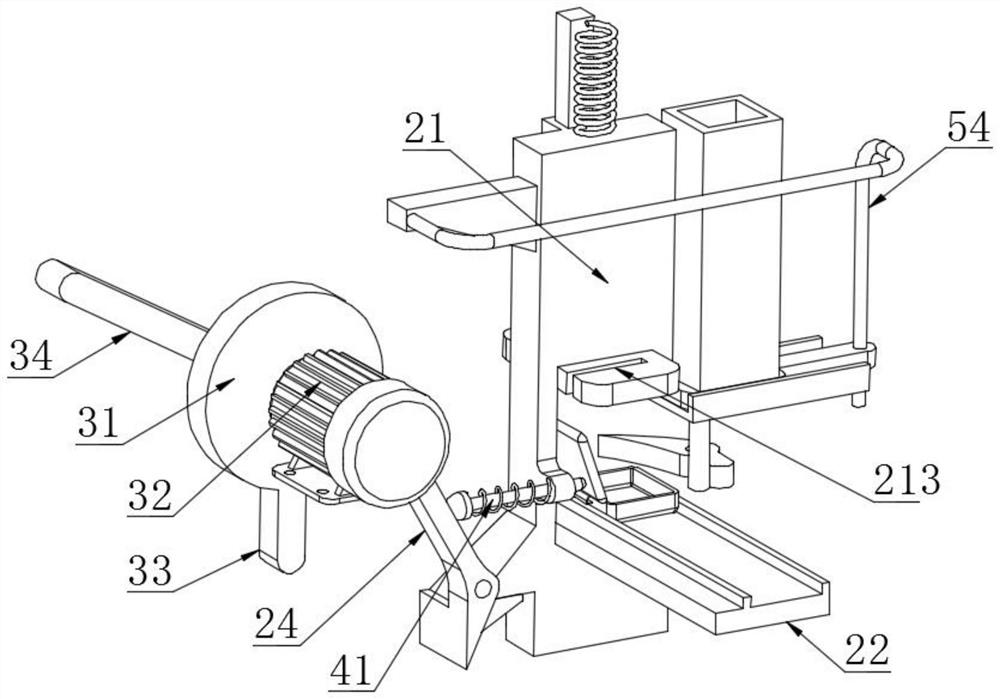

Leading device for press-seal and discharge of quartz crystal shell

ActiveCN111573238AReduce riskTo achieve the purpose of feedingPiezoelectric/electrostrictive device manufacture/assemblyConveyor partsHydraulic cylinderWorkbench

The invention discloses a leading device for press-seal and discharge of a quartz crystal shell. The leading device comprises a working table, a feeding mechanism, a conveying and locating mechanism,a rack, hydraulic cylinders and pressure plates; a discharging hole is formed in the center position of the front end of the top of the working table; the feeding mechanism is detachably arranged at the center position of the right end of the bottom of the working table; the conveying and locating mechanism is detachably arranged at the center position of the bottom of the working table; the rackis fixedly connected with the left end of the top of the working table; the two hydraulic cylinders are detachably arranged on the right and left sides of the top of the rack respectively; and the pressure plates are detachably arranged at the bottom ends of the hydraulic cylinders. According to the leading device, mechanical automatic press-seal can be achieved; the leading device saves time andlabors; the risk of staff is reduced, and press-seal of a plurality of components can be performed in one time; the press-seal efficiency is improved; and in addition, the leading device facilitates finishing of the components after press-seal, and the production requirements of a resonator, an oscillator and the like are met fully.

Owner:泰兴市和宸晶体科技有限公司

Packing machine for printing processing and capable of bundling publications of different specifications

ActiveCN110844152AEasy to tieTo achieve the effect of packagingBinding material applicationBundling machine detailsStructural engineeringMechanical engineering

The invention relates to the technical field of printing processing, and discloses a packing machine for printing processing and capable of bundling publications of different specifications. The packing machine comprises a stand, and first empty slots are formed in the stand. The publications are placed on the stand, a rocking bar at the bottom of a first threaded bar is rocked to rotate, an uppersliding rod moves to the position of the publication accumulation height, a side sliding rod synchronously moves leftwards, the side sliding rod moves from the upper portions of stop dogs and extrudes the stop dogs to be concaved, and when the side sliding rod is separated from the stop dogs, the stop dogs return to the original positions; the function of limiting the position is achieved on theside sliding rod, and therefore the upper sliding rod moves downwards, the side sliding rod moves leftwards, the publications are located and extruded, ropes can conveniently penetrate through groovesof the stand and grooves of the upper sliding rod to bundle the publications, and therefore the packing effect is achieved; and a first sliding block moves up and down, the movement height of the upper sliding rod and the left-and-right movement range of the side sliding rod are increased, and therefore the aim of packing publications of different sizes and different accumulation heights is achieved.

Owner:SHAANXI JINYE SCREEN PRINTING +2

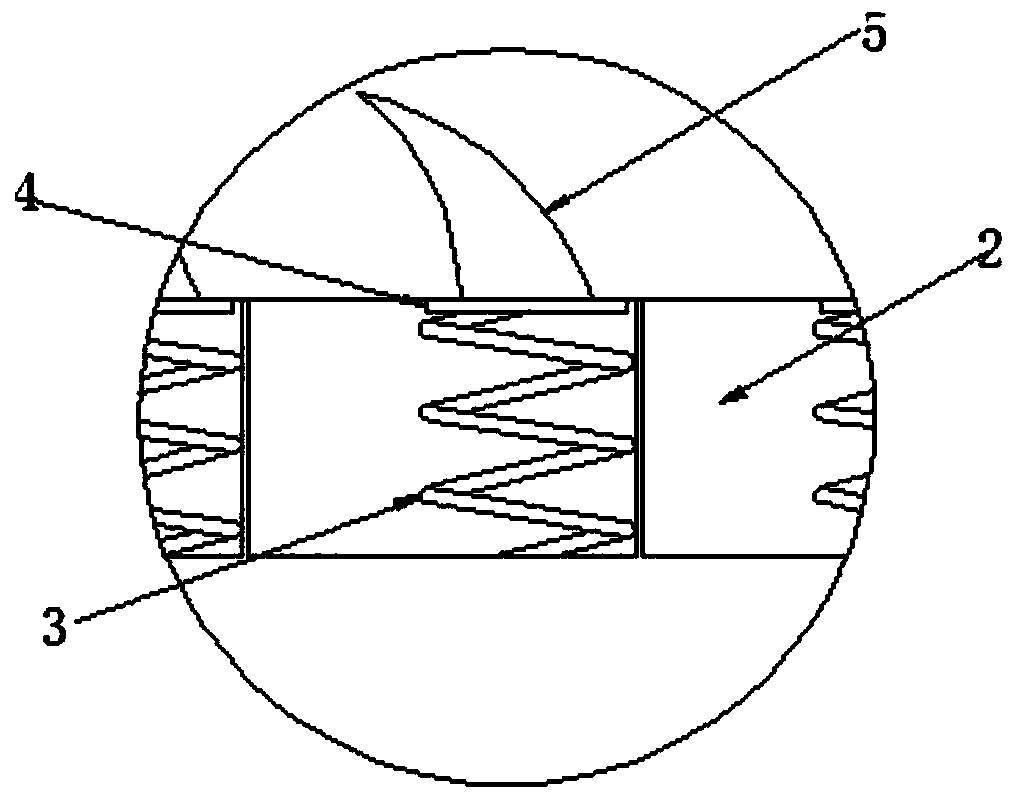

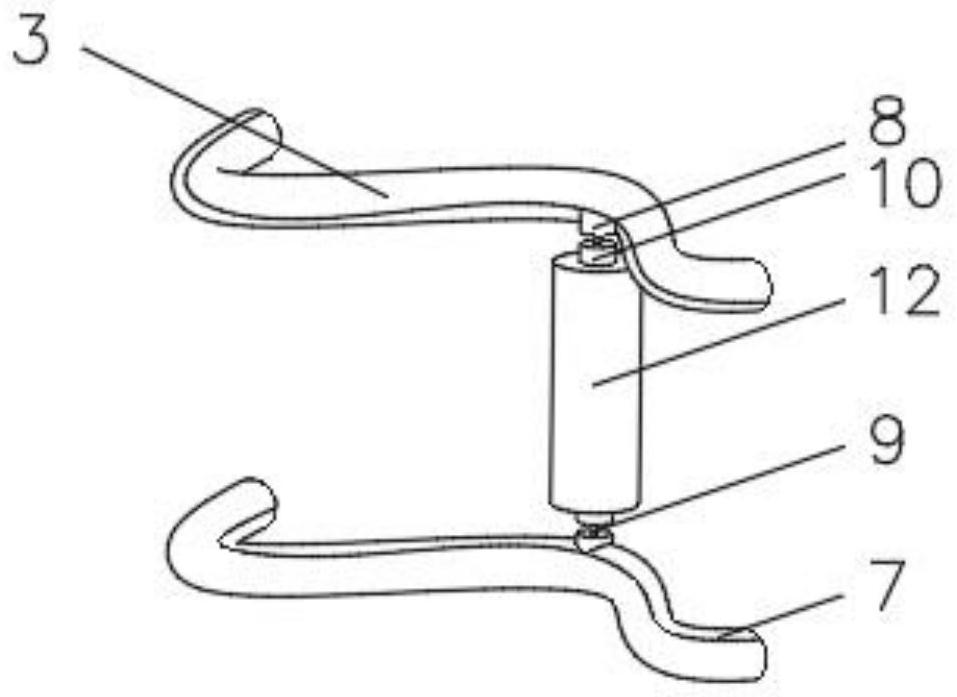

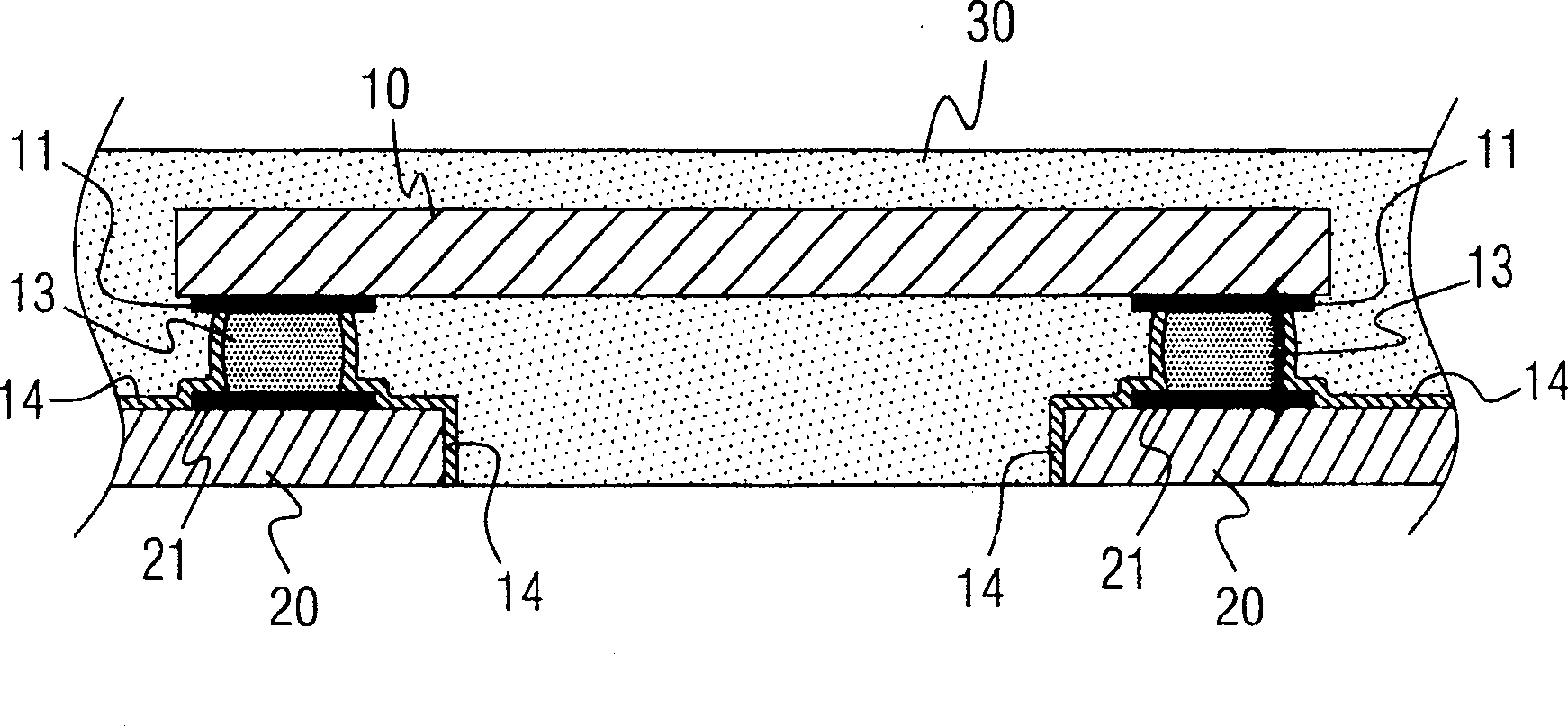

Flip chip packaging structure with girth member and packaging method thereof

ActiveCN100552927CReduce packaging purposeTo achieve the purpose of packagingSemiconductor/solid-state device detailsSolid-state devicesElectrical connectionEngineering

The invention discloses a flip chip package structure with a strengthening part and a method for packing the same, wherein the flip chip package structure comprises a package carrier plate, a first strengthening part, a chip and a second strengthening part; the first strengthening part is arranged on the surface of the package carrier plate; the chip has a plurality of welding convex blocks to realize electrical connection between the chip and the package carrier plate; the second strengthening part which is also arranged on the surface of the package carrier plate is connected with the first strengthening part; moreover, the first strengthening part is arranged outside the second strengthening part.

Owner:ADVANCED SEMICON ENG INC

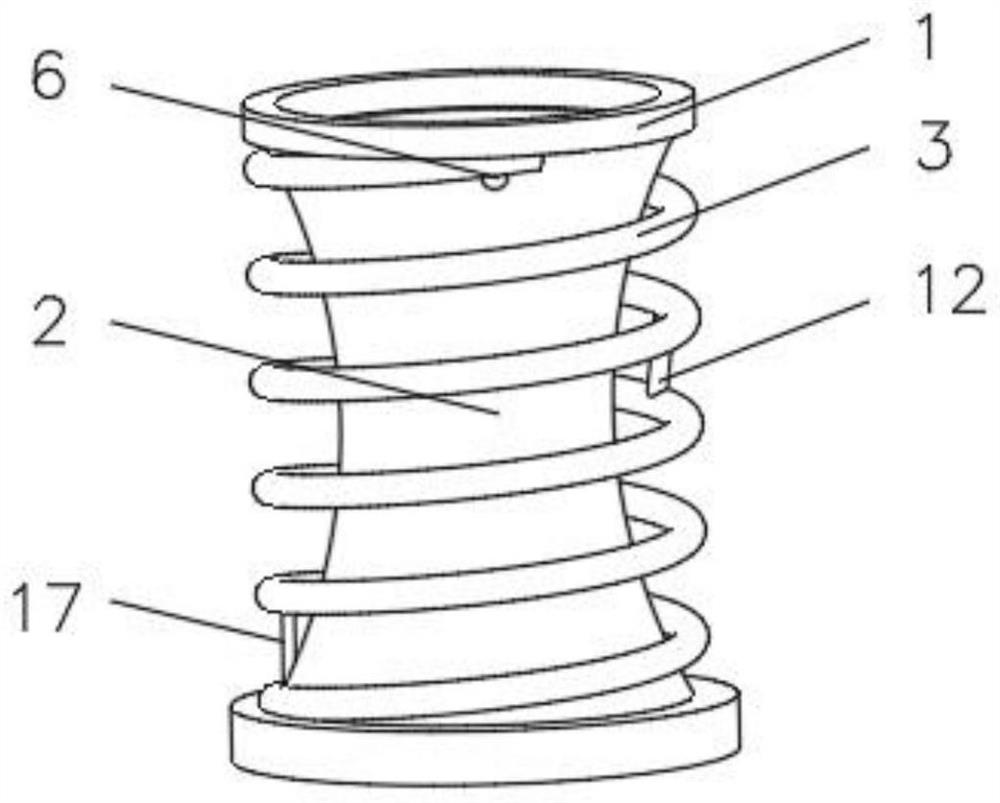

Express logistics packaging device

PendingCN112278473AImprove fitRealize the wrapping functionWrapper twisting/gatheringAdhesive beltLogistics management

The invention discloses an express logistics packaging device. The express logistics packaging device comprises a top frame, wherein the bottom of the top frame is fixedly connected with a placing frame; a spiral pipe is arranged outside the placing frame in a sleeving mode; the spiral pipe is in a corrugated shape; one end of the top of the spiral pipe is fixedly connected with the top frame; oneend, far away from the top frame, of the spiral pipe is fixedly connected with a bottom frame; sliding grooves are symmetrically formed in one side of the spiral pipe; sliding blocks are connected into the sliding grooves in a sliding mode; one end, far away from the sliding grooves, of each sliding block is fixedly connected with an elastic rope; one end, far away from the sliding blocks, of each elastic rope is fixedly connected with a fixing rod; one end of each fixing rod is movably connected with an adhesive tape rod; a limiting rod is arranged at the position, close to the bottom frame,of one end of the spiral pipe; and connecting rods are symmetrically arranged at one end of the limiting rod. The invention relates to the technical field of logistics packaging. According to the express logistics packaging device, the function of tightly wrapping the express is achieved, and the packaging efficiency is improved.

Owner:董广伟

a packing carton

ActiveCN109264206BGuaranteed overlapping areaGood lap stabilityContainers preventing decayRigid containersCartonPaperboard

Owner:烟台欧亚塑料包装有限公司

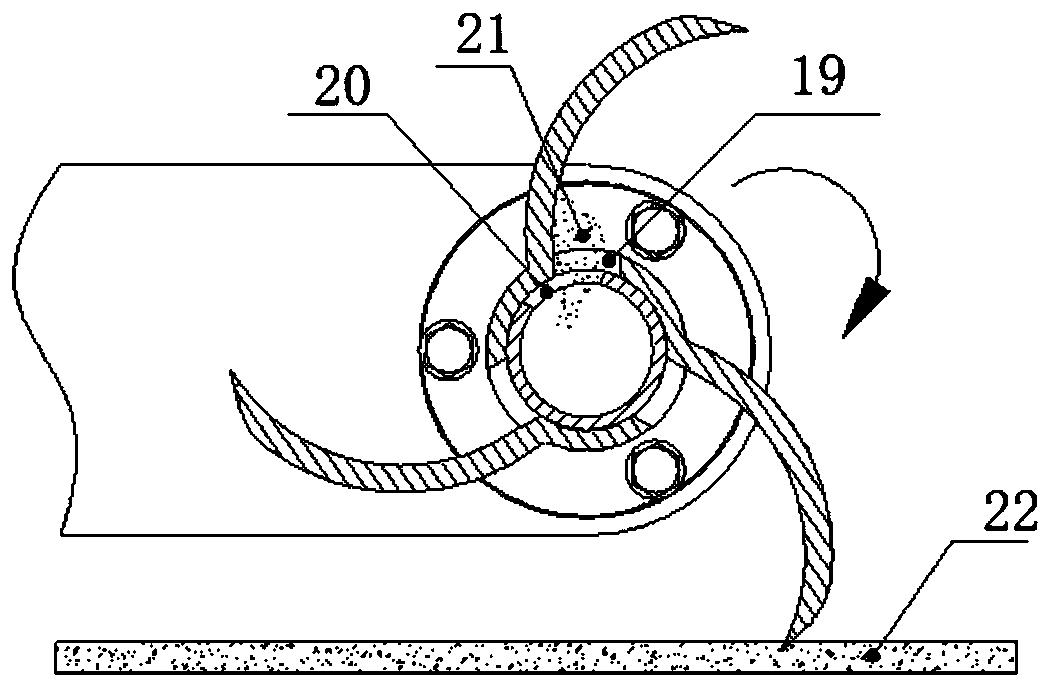

Sample collecting device

PendingCN110926862ATo achieve the purpose of packagingHighly integratedWithdrawing sample devicesEngineeringStructural engineering

The invention discloses a sample collecting device. The device comprises a supporting seat, a hollow cylinder, a rotary outer claw and a power part; the hollow cylinder is fixed on the supporting seat; the rotary outer claw is sleeved on the hollow cylinder; a feeding hole is formed in the root part of the rotary outer claw; a material conveying opening communicated with the feeding opening is formed in the hollow cylinder; the hollow cylinder is a container for containing a sample; when the sample collecting device works, the power part drives the rotary outer claw to rotate; a sample is brought into the feeding hole by the outer selecting and grabbing claw; when the feeding hole and the conveying hole are communicated with each other, a sample falls into the hollow cylinder under the action of gravity; and after the hollow cylinder is filled with a sample, the rotary outer claw is rotated to enable the feeding port and the conveying port to be staggered, so that the purpose of packaging is achieved, the hollow cylinder is arranged in the rotary outer claw, the integration degree of the device is improved, the occupied space is reduced, the device also has the advantages of beingsimple in structure and convenient to use and maintain, continuous sampling can be achieved through the device, and the working efficiency is high.

Owner:湖南千智机器人科技发展有限公司

A packaging method for densely arranging semiconductor chips for Internet of Things terminals

ActiveCN111092057BFree from crushingPlay the role of elastic adjustmentSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipEngineering

The invention discloses a packaging method for densely arranging semiconductor chips for an Internet of Things terminal, belonging to the field of semiconductor packaging, and a packaging method for densely arranging semiconductor chips for an Internet of Things terminal, including the upper surface of a lower casing There is a placement slot, and two sets of conductive columns are fixedly connected to the upper surface of the lower case, and the two sets of conductive posts are respectively located on both sides of the placement slot, and there are perforations in the lower case, and the perforations are located below the conductive posts. Pins are placed in the center, and the upper ends of the pins are fixedly connected with the conductive columns, the bottom of the placement groove is bonded with adhesive, the chip is placed in the placement groove, and the lower end of the chip is bonded with the adhesive, the upper surface of the chip is It can realize the indirect connection between the chip and the pins by connecting multiple wires to the conductive posts, so as to prevent the pins from being involved in the chip and causing the chip to shake or be damaged. effect without damaging the chip.

Owner:袁晓华

Packing device for carton

PendingCN112389740ASolve the problem of not being able to rotate and packTo achieve the effect of respectively invertingWrapping with article rotationBundling machine detailsClassical mechanicsCarton

The invention relates to the technical field of cartons, in particular to a packaging device for a carton. The packaging device comprises a supporting base, and a conveying plate is arranged at the front end of the upper side of the supporting base; a packaging frame is arranged on the rear side of the conveying plate, and a conveyor belt is arranged on the rear side of the packaging frame; a containing box is arranged below the supporting base, and rotating rollers are arranged on the two sides of the packaging frame; arc-shaped plates are symmetrically arranged on the two sides of the rotating rollers, and a motor is arranged on the side wall of the containing box; a containing cavity is formed in the containing box, and a first bevel gear is arranged in the containing cavity; rotating rods are symmetrically arranged on the inner walls of the containing box, and second bevel gears are symmetrically arranged at the ends of the rotating rods; and the second bevel gears are meshed withthe first bevel gear. According to the packaging device, the defects in the prior art are overcome; through the second bevel gears on the two sides of the packaging frame, the effect of automaticallyrotating the carton through rotation of the bevel gears is achieved, the existing mode that the carton needs to be rotated manually and packaged is improved, and the working efficiency is improved.

Owner:澧县广和包装有限公司

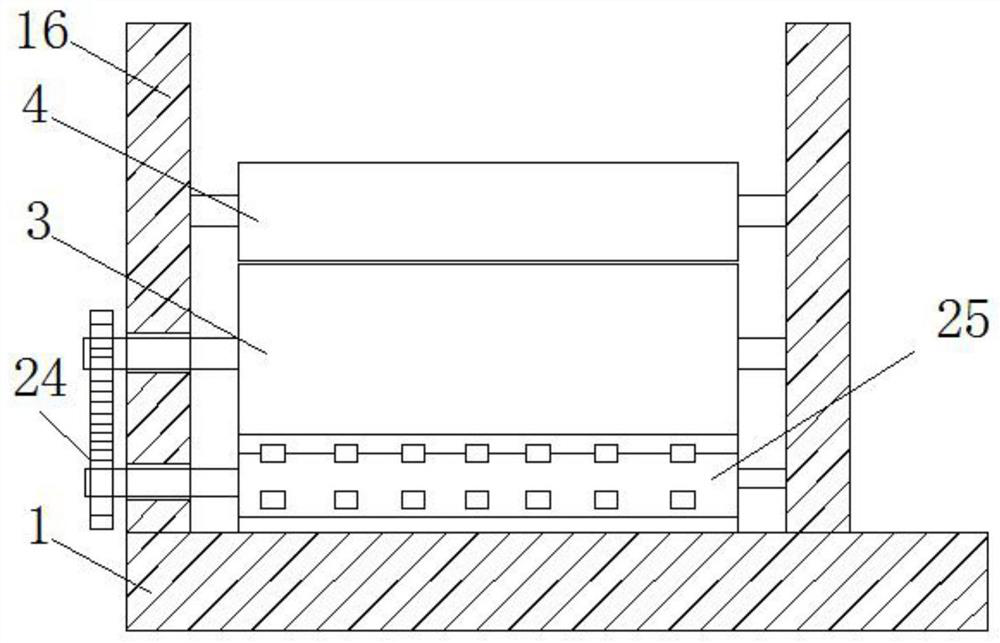

Subpackaging device for rare earth inspection

PendingCN114229122ATo achieve the purpose of packagingAvoid shakingSolid materialEngineeringStructural engineering

The sub-packaging device for rare earth inspection comprises a base, the two sides of the base are connected with racks, a support is connected between the ends of the racks, and a discharging mechanism is arranged between the racks and the support; and the conveying assembly is arranged on the base. According to the rare earth subpackaging device, the containing box can be conveyed through the conveying assembly and can be conveyed to the discharging mechanism, discharging can be conducted through the discharging mechanism, rare earth falls into the containing box, and therefore the purpose of subpackaging the rare earth is achieved.

Owner:何群星

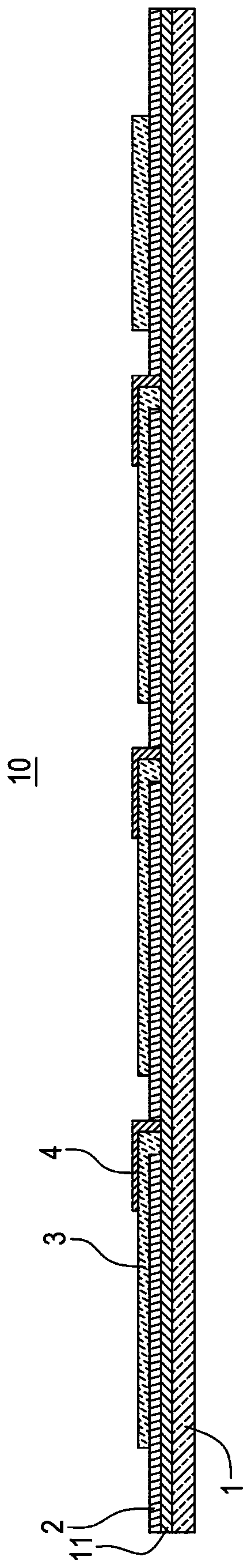

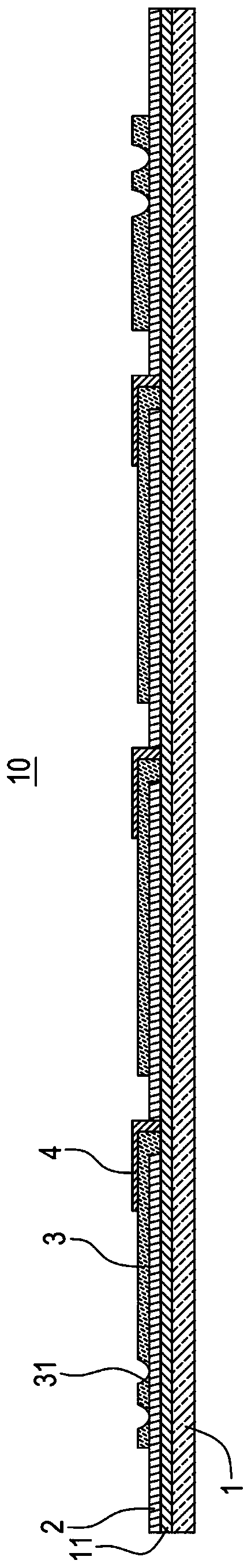

Packaging structure with groove

ActiveCN111276616AThickened package structureTo achieve the purpose of packagingSolid-state devicesSemiconductor/solid-state device manufacturingStructural engineeringPhysics

A packaging structure with groove includes a substrate, a lower conductive layer, an optical element, a sealing layer and a barrier layer. The lower conductive layer is arranged on one face of the substrate. The optical element is arranged on one face of the lower conductive layer. The upper conductive layer is arranged on one face of the optical element. The packaging structure further comprisesa groove defined on an inactive area of the optical element. The sealing layer is arranged on one face of the optical element and on one face of the upper conductive layer. The barrier layer is arranged on one face of the sealing layer. Because the groove is formed on inactive area of the optical element to enhance lateral sealing tightness, extended interface is provided between sealing layer / barrier layer and the substrate, thus enhance the water-resistant and gas-resistant property for package.

Owner:WAYS TECHN CORP +1

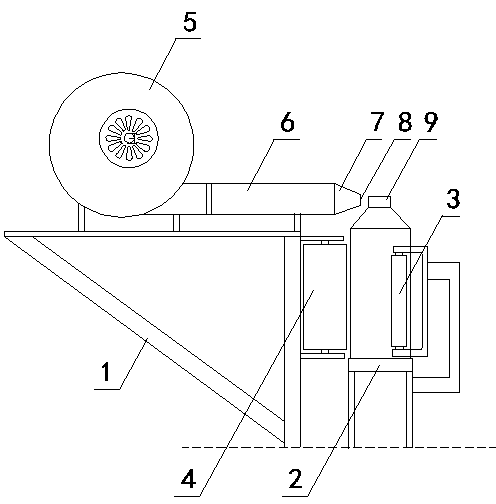

Hot contraction membrane machine capable of providing accurate target directions

InactiveCN103496479APrecise contractionTo achieve the purpose of packagingWrappers shrinkageTemperature controlEngineering

The invention discloses a hot contraction membrane machine capable of providing accurate target directions. When used for packaging products, the hot contraction membrane machine usually plays a role in air isolation, appearance beautifying, dust prevention, abrasion prevention, scattering preventing and prevention of burglary. No hot contraction membrane packaging equipment for part of a product, especially a bottle opening part, exists in the prior art. The hot contraction membrane machine capable of providing accurate target directions comprises a machine frame, a product conveying belt and a bottle gripper arranged at a working position, wherein an air feeder is arranged on the machine frame, an air outlet of the air feeder is connected with a heating pipe, a heating device is arranged inside the heating pipe, the heating pipe is connected with a heat restraining pipe, a temperature control probe is arranged in the heat restraining pipe, and a rotary roller is further arranged below the heat restraining pipe on the machine frame. By means of the measures, air fed by the air feeder is heated in the heating pipe, hot air is sent out from a heat restraining port of the heat restraining pipe, a membrane sleeve on a bottle cap at the working position is accurately heated and contracted, and the purpose of hot contraction membrane packaging at part of a bottle is achieved.

Owner:合浦果香园食品有限公司

A packing machine for binding publications of different specifications for printing and processing

ActiveCN110844152BEasy to tieTo achieve the effect of packagingBinding material applicationBundling machine detailsEngineeringMechanical engineering

The invention relates to the technical field of printing processing, and discloses a packing machine for binding publications of different specifications for printing processing, which includes a stand, and a first empty slot is opened inside the stand; The rocker at the bottom of a threaded rod makes it rotate, the upper slide bar moves to the position where the publications are piled up, the side slide bar moves to the left synchronously, the side slide bar moves from above the block and squeezes the block recess, and the stop block When disengaged, the stopper returns to its original position, which has the effect of limiting the position of the side slide bar, so that the upper slide bar moves downward, and the side slide bar moves to the left, and the publication is positioned and squeezed, so that the rope can pass from the platform to the upper slide bar. The grooves pass through to bundle the publications, so as to achieve the effect of packaging. By moving the first slider up and down, the height of the upper slider and the range of side sliders can be increased, so as to achieve different sizes and different Stack height publications for packaging purposes.

Owner:SHAANXI JINYE SCREEN PRINTING +2

Packaging equipment for plastic box

PendingCN114735259ARealize automatic feeding processTo achieve the purpose of packagingPackagingAcute anglePackaging Case

The packaging equipment comprises a rack, a packaging assembly and a driving part located on one side of the packaging assembly are arranged above the rack, the packaging assembly comprises a pressing plate capable of vertically moving, an opening is formed in one side of the pressing plate, and the pressing plate is arranged on the rack; the inner side of the opening is provided with a material conveying rail fixedly mounted on the rack, and the driving part is used for driving the pressing plate to vertically move; a packaging box is placed on the material conveying rail, an object to be packaged is placed in a box body of the packaging box, and the driving component drives the pressing plate to move downwards to press a box cover of the packaging box, so that the box body and the box cover of the packaging box are closed. According to the automatic feeding packaging box, automatic feeding of objects to be packaged is achieved, the purpose of packaging the objects through the packaging box is achieved, in addition, in the process, the box cover can be pushed through the cover pushing assembly to enable the included angle between the box body and the box cover to be changed into an acute angle from an obtuse angle, and therefore it is guaranteed that packaging is conducted smoothly.

Owner:郭进旭

A self-sealing push bag trash bin

ActiveCN112573044BTo achieve the purpose of packagingAchieve the purpose of launchingRefuse receptaclesWrapper twisting/gatheringRefuse collectionProcess engineering

The invention relates to an automatic sealing push-bag garbage bin, which includes a casing, and the casing corresponds to a group of separate garbage cans. By using the garbage capacity detection system to detect the garbage capacity in the casing, the sealing mechanism and the push The mechanism realizes the automatic packaging of full-loaded garbage bags, and automatically pushes the packed garbage out of the shell, which completely replaces the manual sealing of full-loaded garbage bags and taking out the garbage bin in the traditional garbage collection process; making intelligent While intelligently placing garbage and intelligently identifying garbage, the sorting garbage bin further realizes the purpose of automatically sealing bags and packing out the garbage bins, further reducing the allocation of garbage collection staff in the community; realizing the purpose of reducing the cost of staffing, and avoiding The situation of personnel contacting garbage during the packing process can effectively ensure the health of garbage transportation staff.

Owner:广州东软科技有限公司

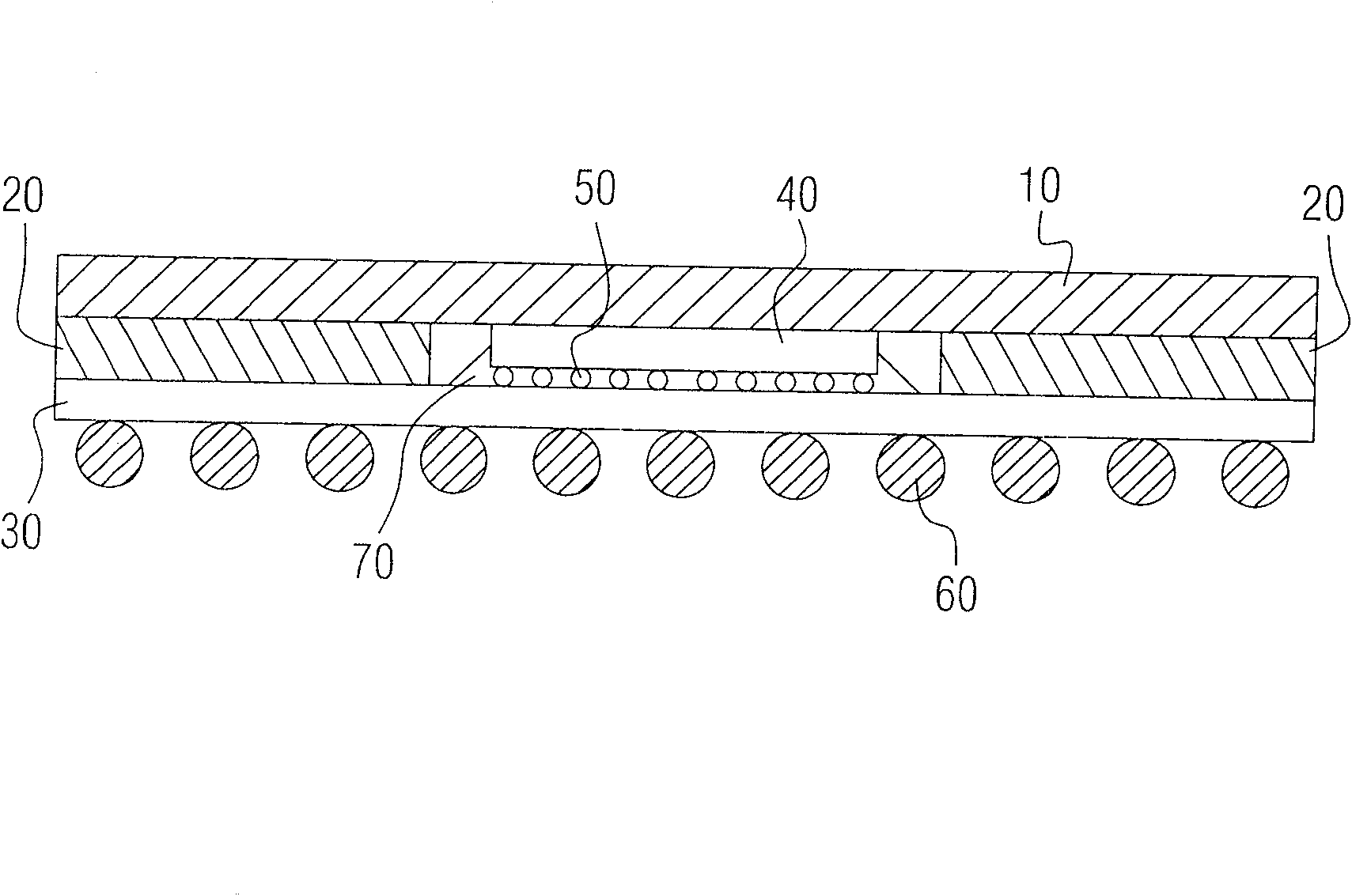

Semiconductor packaging structure with intensification layer and encapsulation method thereof

ActiveCN100521180CHigh mechanical strengthPrevent collapseSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageCopper

The invention discloses a semiconductor package structure with a strengthened layer, at least comprising a conducting wire support with a plurality of pins, a chip with the surface provided with a plurality of metal welding pads, a plurality of conductive convex blocks used to connect the metal welding pads of the chip and the pins of the conducting wire support, and a strengthened layer covering the surfaces of the pins and the conductive convex blocks. The material of the structure contains copper with the melting point higher than that of lead and tin, and is formed through electroplating.

Owner:ADVANCED SEMICON ENG INC

A semiconductor component packaging equipment applicable to different types and specifications

The invention relates to the field of packaging of semiconductor elements, in particular to packaging equipment applicable to semiconductor elements of different types and specifications. The equipment comprises a stepping conveying belt, a guiding device, a limiting device and a feeding device; the guiding device comprises two guiding polish rods which are arranged at one sides of the stepping conveying belt respectively, each guiding polish rod can move vertically through one lifting device, and the limiting device comprises two guide assemblies which are arranged at one sides of the stepping conveying belt respectively; each guide assembly is always located above the stepping conveying belt and can vertically move through a height fine-adjustment device, the two guide assemblies can bemovably arranged face to face or back to back through spacing fine-adjustment devices, and the feeding device is arranged outside one side of the downstream end of the stepping conveying belt. The equipment can be applicable to automatically packaging the semiconductor elements of different types and specifications, and the product output efficiency of manufacturers is greatly improved.

Owner:江苏尖端半导体有限公司

Message forwarding method, device, storage medium and electronic equipment based on SRV6 network

ActiveCN111935014BTo achieve the purpose of packagingIncrease detection functionNetworks interconnectionCommunications systemPrivate network

The invention discloses a message forwarding method and device based on an SRv6 network, a storage medium and an electronic device, an original message is sent by a device A to reach a device B through a plurality of End nodes and at least one NAT device, and the NAT device is located between the two End nodes. The SRH structure is different from a traditional SRH structure, the NAT detection message based on the SR strategy is sent through the End node and is used for public network address learning, meanwhile, an NAT-det type is added into a Next Header of an SRH message extension header, sothat an End operation type End.N of an SRv6 is newly added in an End node; and NAT public network address learning and message packaging during forwarding can be carried out according to different Next Header types, and the problem that in an existing SRv6 communication system, a message cannot be forwarded due to existence of equipment of a private network IP is solved.

Owner:PURPLE MOUNTAIN LAB

Nylon bag zipper packaging device facilitating feeding and discharging

ActiveCN112938033AEasy loadingTo achieve the purpose of packagingPackage recyclingWrapper twisting/gatheringEngineeringMaterials science

The invention relates to the field of packaging equipment, in particular to a nylon bag zipper packaging device facilitating feeding and discharging. The device comprises a special-shaped support frame, a rotary feeding mechanism, a rotary pressing mechanism, a forward pushing mechanism, a pushing mechanism and the like, wherein the rotary feeding mechanism, the rotary pressing mechanism, the forward pushing mechanism and the pushing mechanism are arranged on the special-shaped support frame. According to the device, one side of a nylon bag can be bonded with a nylon bag zipper head through the rotary pressing mechanism, the other side of the nylon bag is directly sealed, compared with a traditional sealing machine, the device is safer, and the purpose of sealing a nylon bag zipper can be achieved.

Owner:临沭县尚润彩印有限公司

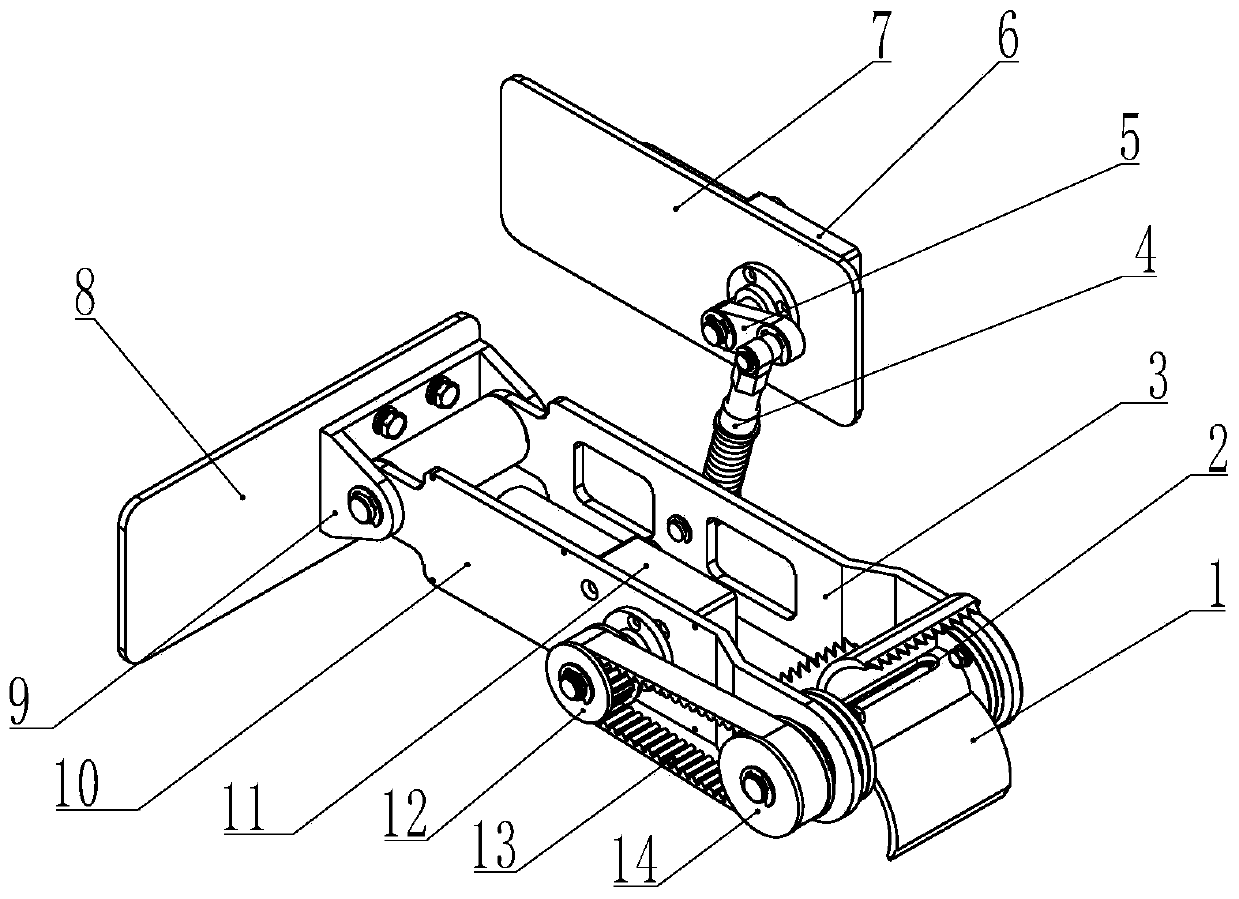

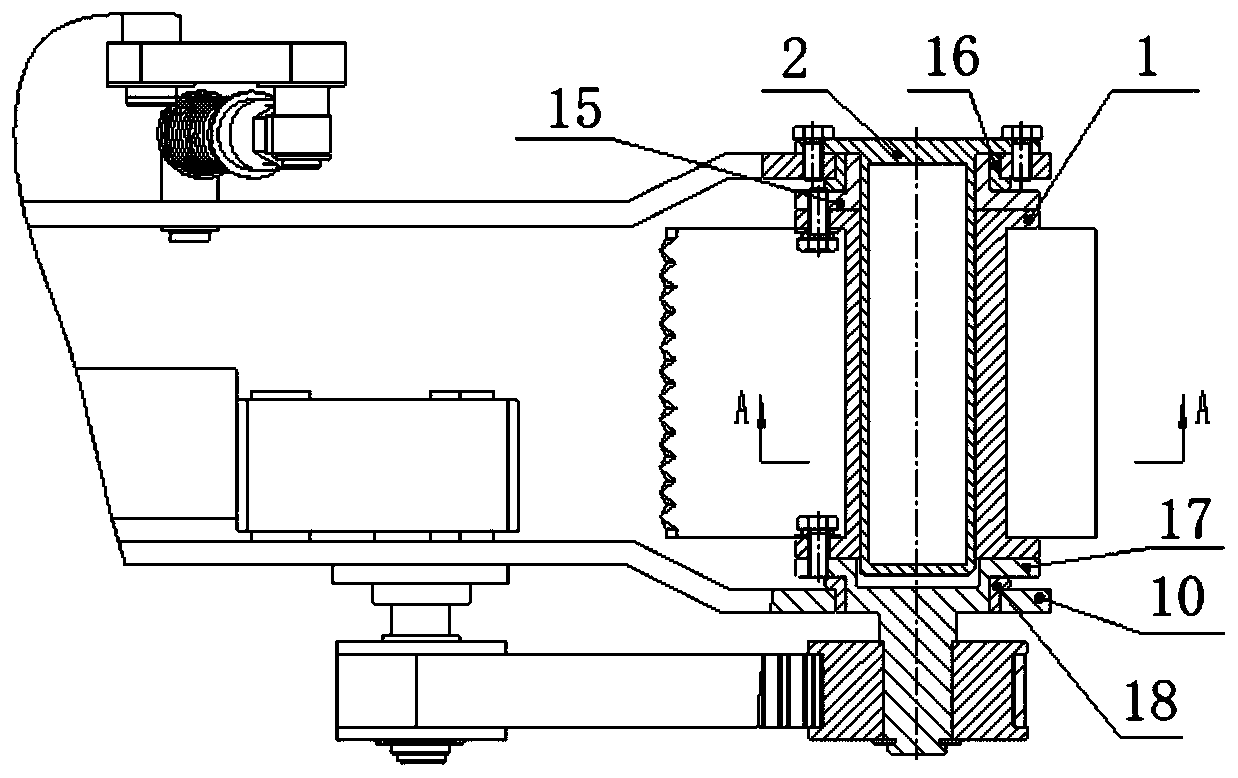

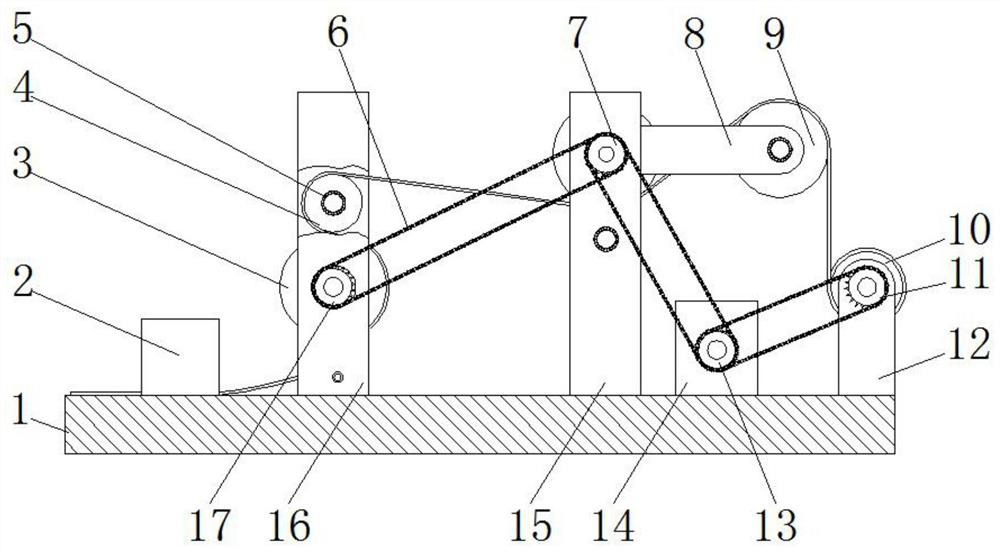

A traction and compaction device for waterproof coiled material

ActiveCN109911679BAvoid breakingAchieve double compactionPackagingWebs handlingGear wheelElectric machinery

The invention belongs to the technical field of compacting of coiled materials and particularly relates to a traction compacting device of a waterproof coiled material. A bottom plate, a scraping therapy box, a pressing roller, a first guiding roller, a bearing, a chain, a first shaft connecting gear, a cross beam, a second guiding roller, a coiling block, a first gear, a first supporting plate, asecond shaft connecting gear, a motor box, a second supporting plate, a third supporting plate, a second gear, a sweeping brush, a strip-shaped channel, a speed reducing motor, a stepping motor, a telescopic rotating shaft, a first round rod, a first spring, an intermediate shaft, a second round rod, a positioning pin, a rolling wheel, an auxiliary roller, an arc-shaped plate, a protrusion, a supporting rod, a second spring and a cam. According to the traction compacting device of the waterproof coiled material, in the process of performing traction compacting of the waterproof coiled material, under mutual cooperation of the scraping therapy box, the sweeping brush and the speed reducing motor, sand remaining on the surface of the coiled material in the previous work procedure is discharged out of through holes in the side edge of the scraping therapy box through the sweeping brush, and it is avoided that the coiled material is broken in the compacting process.

Owner:嘉兴市金鹭喷织有限公司

Rapid packaging equipment for cylindrical lithium ion battery

PendingCN113629330AImprove packaging efficiencyPrevent force deflection and shakingFinal product manufactureCell component detailsPhysicsEngineering

The invention discloses rapid packaging equipment for a cylindrical lithium ion battery. The rapid packaging equipment comprises a vertical rod, a base and a placement disc, supporting columns are installed on the two sides of the bottom end of the base, a cavity is formed in the top end in the base, the placement disc is installed at the top end of the base, limiting grooves are evenly formed in the top end of the placement disc, a connecting plate is installed at the bottom end of the placement disc, a rotating mechanism is arranged at the bottom end of the connecting plate, vertical rods are installed on the two sides of the placement disc, the bottom ends of the vertical rods are fixed to the base, a cross beam is installed at the top ends of the vertical rods, a hydraulic air cylinder is installed at the top end of the cross beam, a connecting block is installed at the bottom end of the hydraulic air cylinder, and a pressing head is installed at the bottom end of the connecting block. The fixing air cylinder is installed at the bottom end of one side of the vertical rod, when the limiting groove rotates to the position under the pressing head, the fixing air cylinder is started, so that the clamping plates can clamp lithium ion batteries of different sizes, and the phenomena of stress deviation and shaking during packaging of the lithium ion batteries are prevented.

Owner:DONGGUAN LILONG BATTERY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com