Packaging structure with groove

A packaging structure and sealing layer technology, applied in photovoltaic power generation, instruments, electrical components, etc., can solve the problems of unfavorable effective area and space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The technical content and detailed description of the present invention are now described as follows in conjunction with the accompanying drawings:

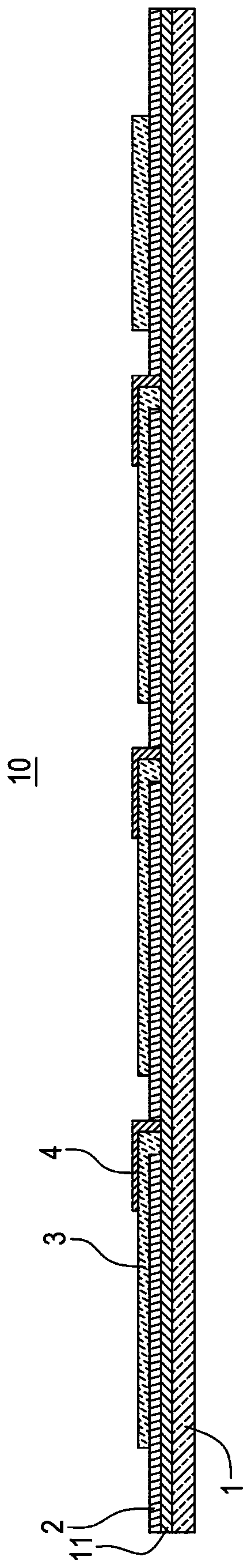

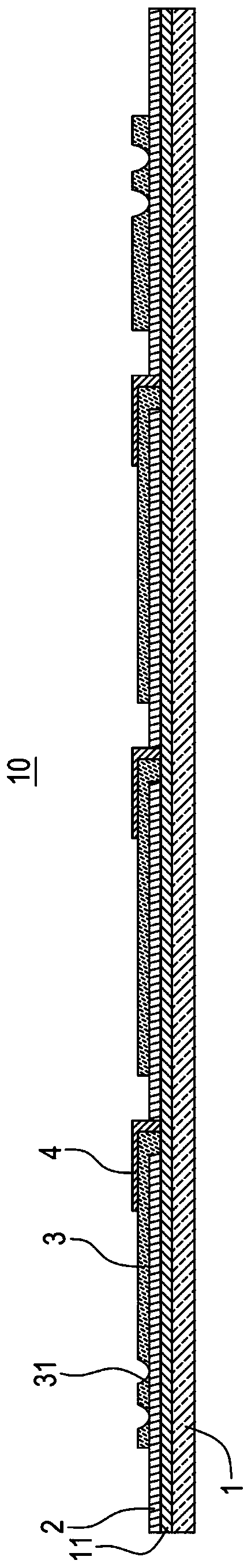

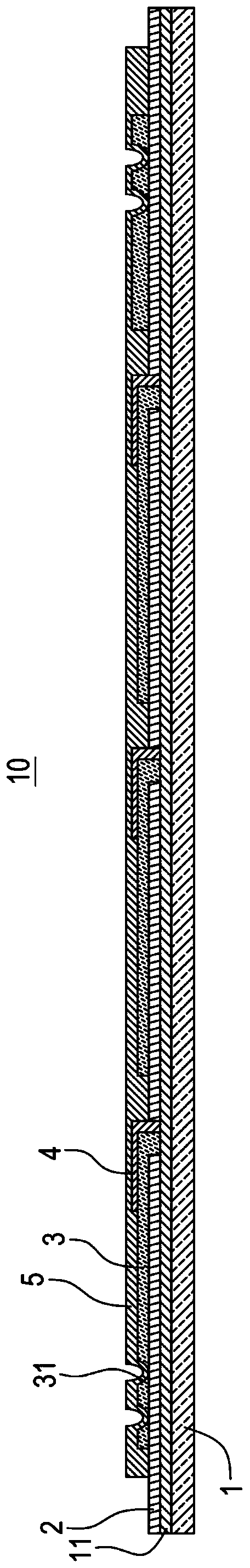

[0054] see figure 1 , a schematic diagram of the thin component package structure of the first embodiment of the present invention. As shown in the figure: the groove packaging structure of the present invention is a packaging structure of grooves made on a thin component 10. The thin component 10 includes: a substrate 1, a lower conductive layer 2, an optical component 3 and an upper conductive layer 4.

[0055] The substrate 1 is a transparent plastic or transparent glass substrate. The light-transmitting plastic is polyimide (Polyimide, PI), polyimide and inorganic mixture (hybrid PI), polyethylene terephthalate (Polyethyleneterephthalate, PET), polyethersulfone (Polyethers

[0056] Ulfone, PES), polyethylene naphthalate (Polyethylene naphthalatc, PEN)

[0057], Cyclo olefin polymer (Cyclo olefin polymer, COP), glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com