Nylon bag zipper packaging device facilitating feeding and discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

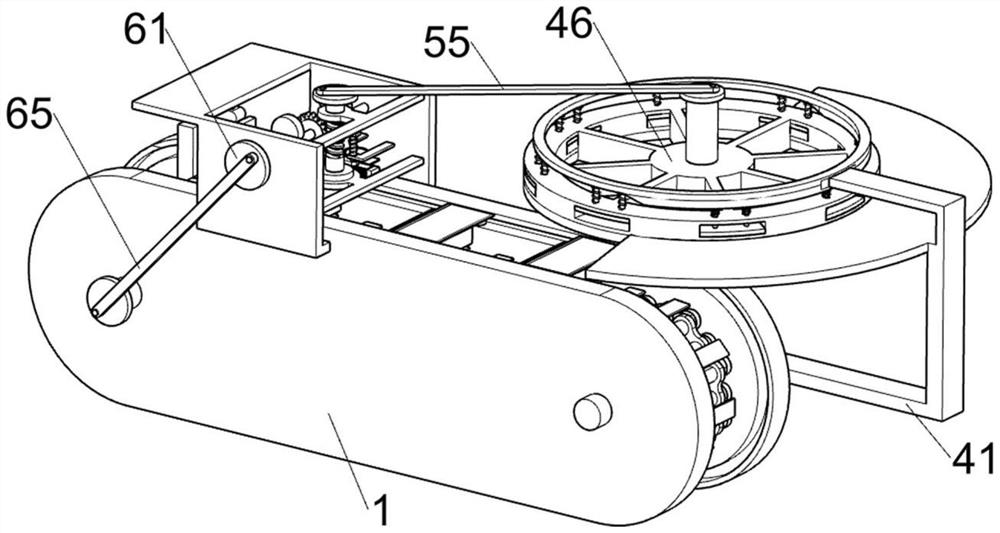

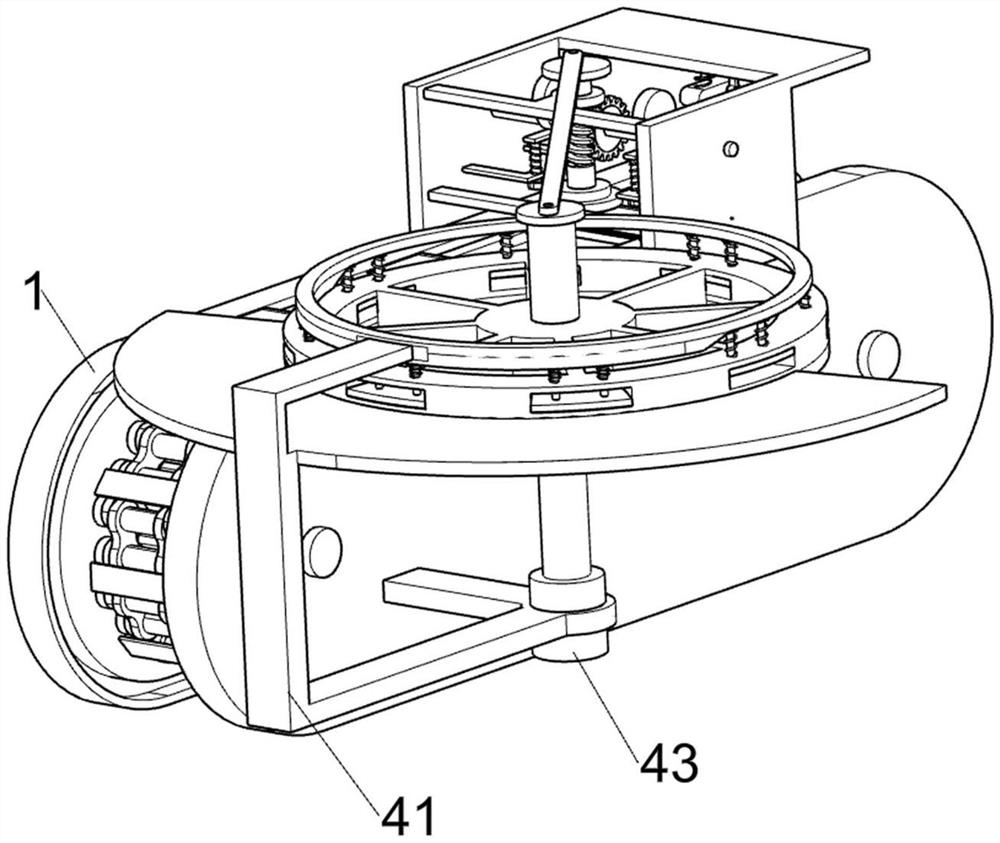

[0027] A nylon bag zipper packaging device that is convenient for loading and unloading, such as Figure 1-9 As shown, it includes a special-shaped support frame 1, a rotary feeding mechanism 4, a rotary pressing mechanism 5, a forward pushing mechanism 6 and a pushing mechanism 7, the rotary feeding mechanism 4 is located on the special-shaped supporting frame 1, and the rotary pressing mechanism 5 Set on the special-shaped support frame 1, the rotary pressing mechanism 5 is used to bond one side of the nylon bag to the zipper pull of the nylon bag, and directly seal the other side of the nylon bag. The forward pushing mechanism 6 is set on the special-shaped support frame 1, The nylon bag can be conveyed through the mutual cooperation of the rotating feeding mechanism 4 and the forward pushing mechanism 6. The pushing mechanism 7 is arranged on the special-shaped support frame 1, and the pushing mechanism 7 is used for releasing the nylon bag zipper pull.

[0028] The rotary...

Embodiment 2

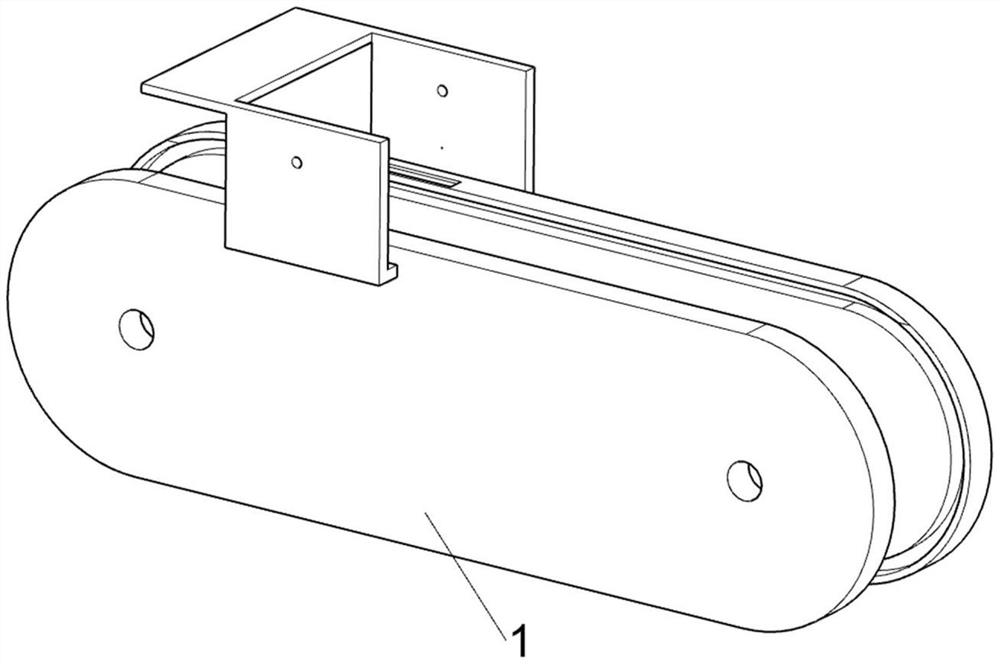

[0035] On the basis of Example 1, such as Figure 9 As shown, it also includes a flattening mechanism 8. The flattening mechanism 8 is arranged on the special-shaped support frame 1. The flattening mechanism 8 is used to squeeze the finished nylon bag more smoothly. The flattening mechanism 8 includes a small round head drive shaft Frame 81, fourth transmission shaft 82, swing lever 83, second return spring 84, wedge-shaped block plate 85, pressure roller frame 86 and belt shaft pressure roller 87, and a pair of small round head transmissions are fixedly connected to the bottom of one side of special-shaped support frame 1. Axle frame 81, small round head transmission shaft frame 81 is used to support the fourth transmission shaft 82 and its upper device, and the fourth transmission shaft 82 is rotatably connected between the two small round head transmission shaft frames 81 bottoms, the fourth transmission shaft 82 The middle part is fixedly connected with a swing rod 83, thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com