A semiconductor component packaging equipment applicable to different types and specifications

A kind of packaging equipment and semiconductor technology, applied in the direction of packaging, transportation and packaging, single objects, etc., can solve the problems of unable to meet the packaging work of multiple types and specifications of semiconductor components, and reduce output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

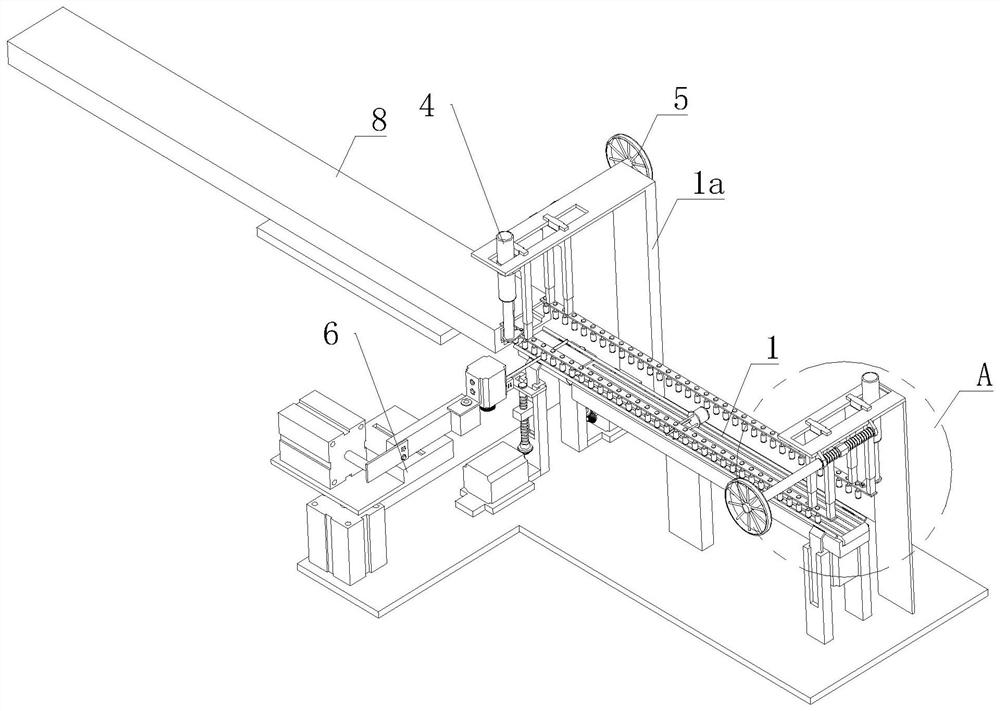

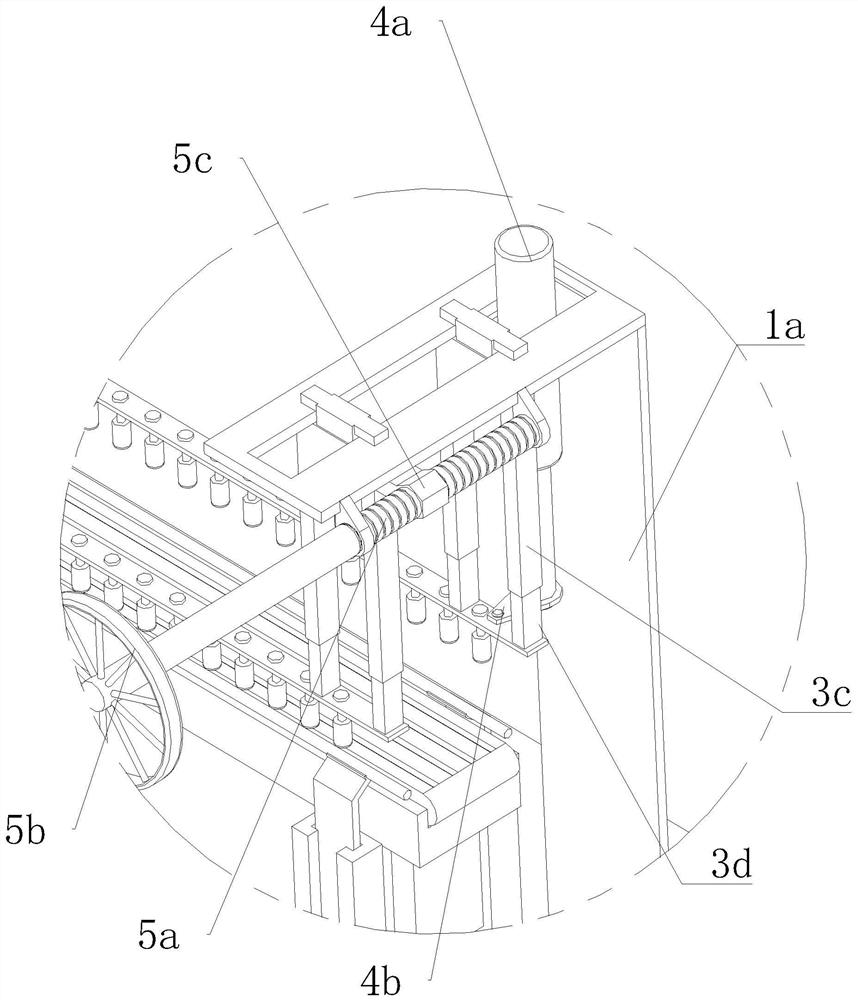

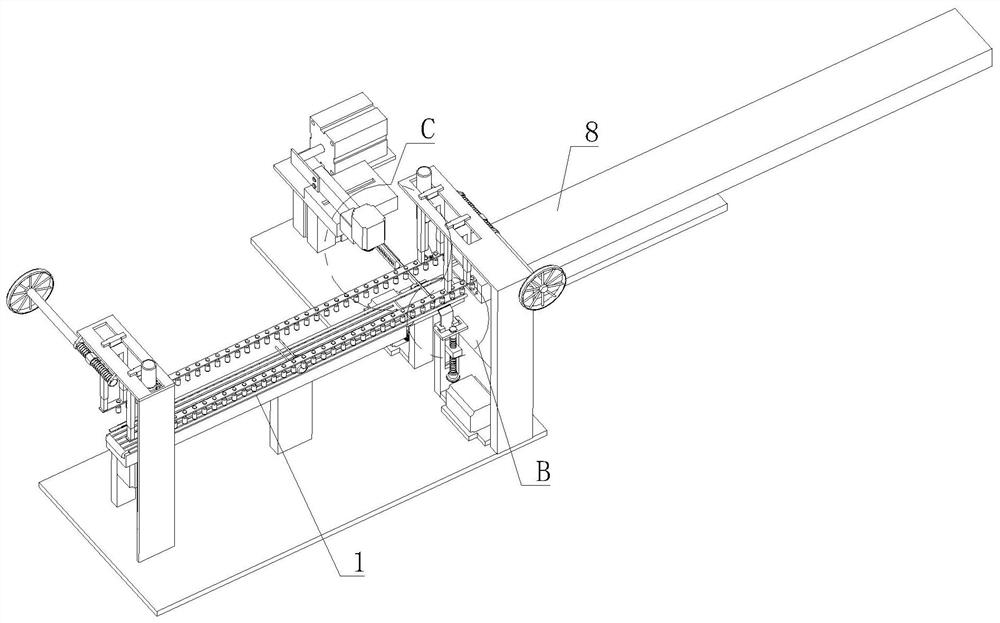

[0039] refer to Figure 1 to Figure 14 The one shown can be applied to semiconductor component packaging equipment of different types and specifications, including a stepping conveyor belt 1, a guiding device, a limiting device and a feeding device 6, and the guiding device includes two respectively arranged on the stepping conveyor belt 1- The light guide rods 2 on the side, each guide light rod 2 can be vertically movable through a lifting device, and the limit device includes two guide assemblies respectively arranged on one side of the stepping conveyor belt 1, each guide assembly is always located at the stepping Above the type conveyor belt 1, each guide assembly can be vertically movable through a height fine-tuning device 4, and the two guide assemblies can also be moved toward or away from each other throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com