Packaging carton

A carton and cardboard technology, applied in the field of logistics and transportation, can solve the problems of instability, increased cost, poor buffer capacity, etc., and achieves the effects of small space occupation, odor removal, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

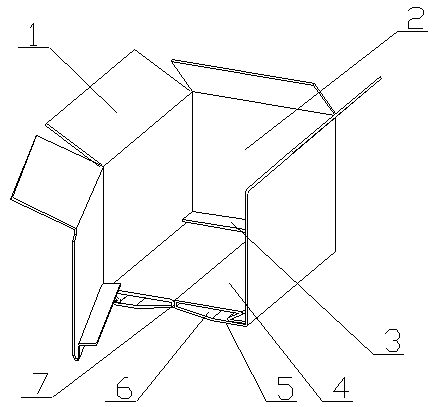

[0024] A packaging carton of the present invention is achieved in the following way: a packaging carton of the present invention consists of top cardboard (1), side cardboard (2), edge lap (3), inner bottom board (4), outer bottom board (5), Composed of a hollow area (6) and an adhesive layer (7), the inner bottom plate (4) is placed on the outer bottom plate (5), the outer bottom plate (5) is bent from the middle, and one side is higher than the other side,

[0025] The two sides of the inner bottom plate (4) are bent downward to connect with the two sides of the outer bottom plate (5), and a hollow area (6) is placed between the inner bottom plate (4) and the outer bottom plate (5) , the inner bottom plate (4) and the outer bottom plate (5) are combined to form a bottom plate, one side of the bottom plate is bent inward, the hollow area (6) is an inverted trapezoidal structure, and the other side of the bottom plate is provided with an adhesive Layer (7), the two base plates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com