Packing box structure and manufacturing method thereof

A packaging box and cavity structure technology, applied in packaging, transportation and packaging, containers and other directions, can solve the problems of complex packaging box assembly, and achieve the effect of easy recycling and reuse, high reliability, and guaranteeing connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS

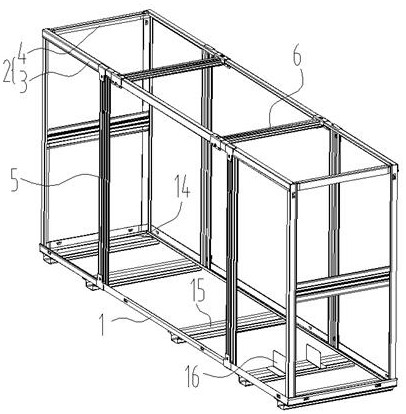

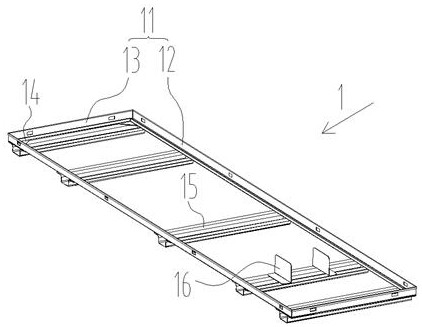

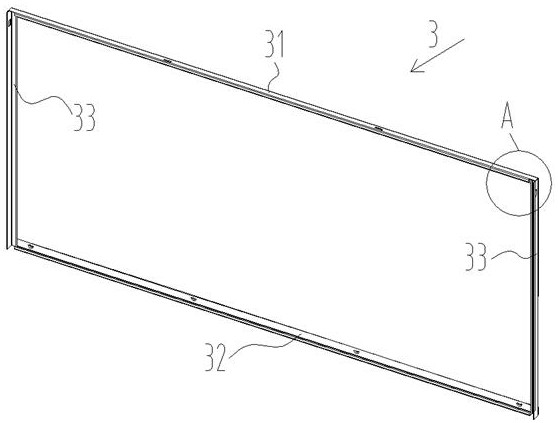

[0034] See Figure 1-4 , Specific embodiment of the box structure, comprising a horizontal bottom frame 1; the bottom frame 1 by a plurality of end to end in a circle of the bottom frame 11 constituting the rib, the rib cross section of the bottom frame 11 having an opening portion U-shaped cavity structure, the bottom frame 11 through the opening rib portions socket connection facade frame 2, two adjacent vertical frame 2 in the two similar end elevation frame, a vertical frame of any cross section having an opening portion U-shaped frame the vertical cavity structure and the opening through which the vertical frame portion connected to the other socket.

[0035] Embodiment of the package structure embodiment, between adjacent facade frame 2 are connected by way of socket, socket also connected by way of a facade between the frame 2 and the bottom frame, substantially without using bolts, screws or other tools, assembly hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com