Whole-board packaging mold of flexible board and packaging method of whole-board packaging mold

A flexible board and board sealing technology, which is applied in the manufacturing of electrical components, electrical solid-state devices, semiconductor/solid-state devices, etc., can solve the problems of uneven distribution of colloids, complicated processes, and long production cycles, and can shorten the production cycle and simplify the process. procedures, reducing the effect of the supply chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

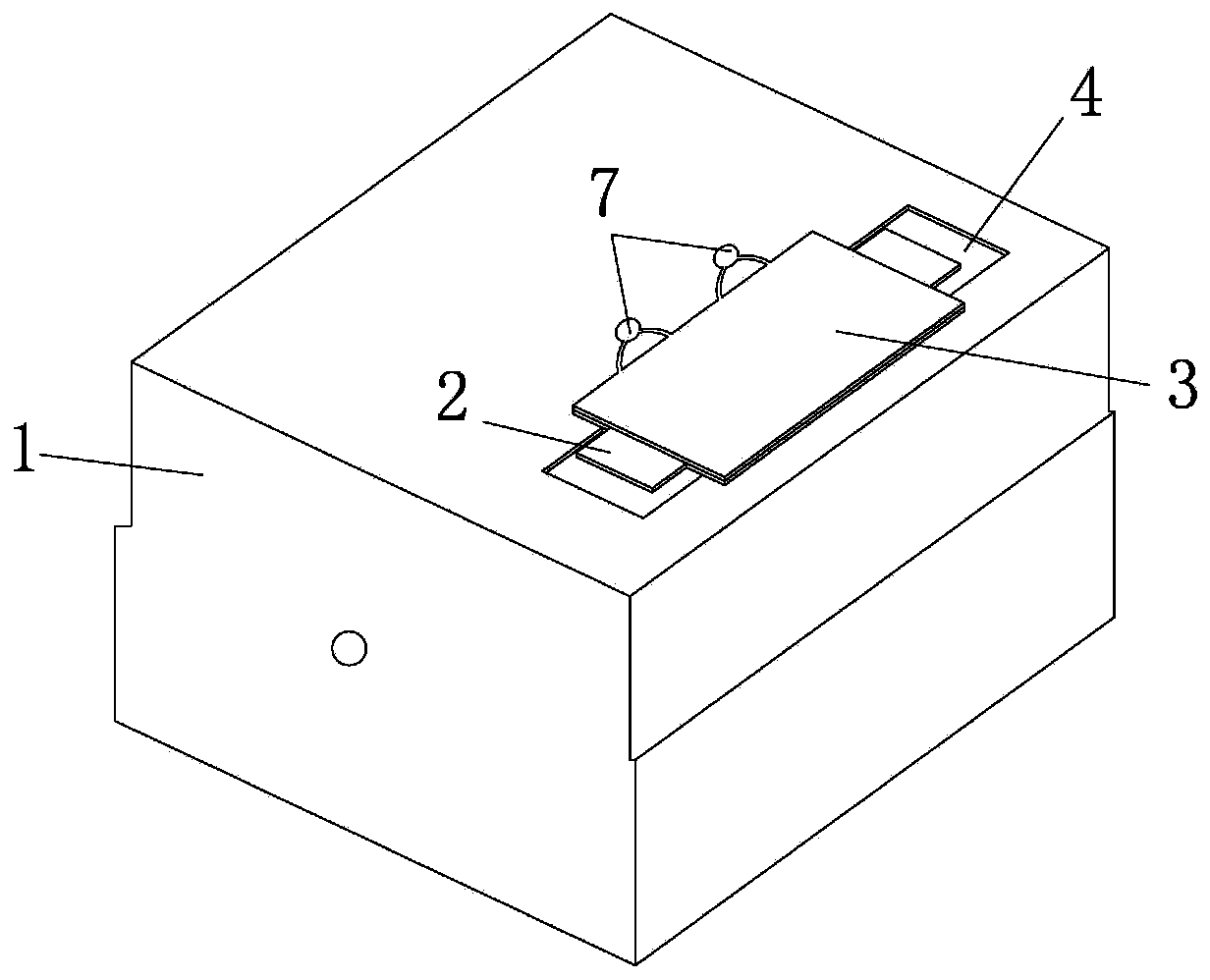

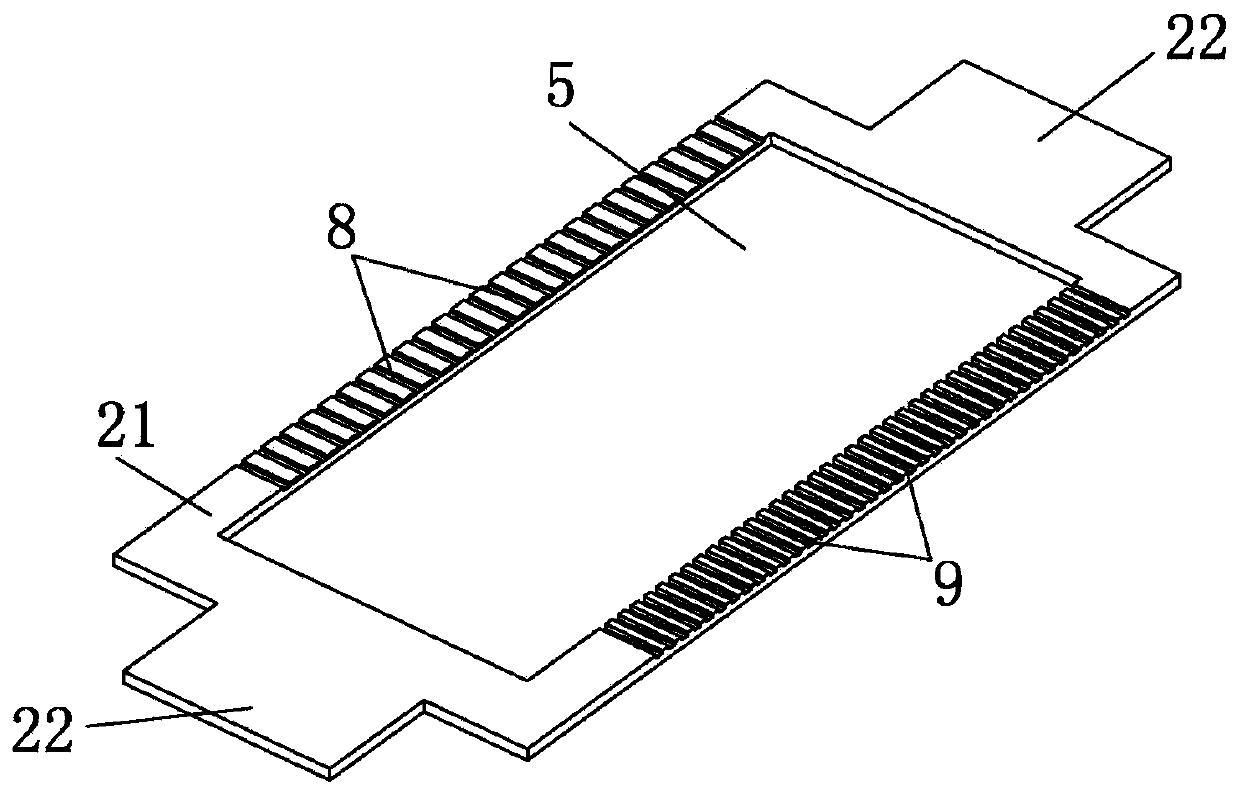

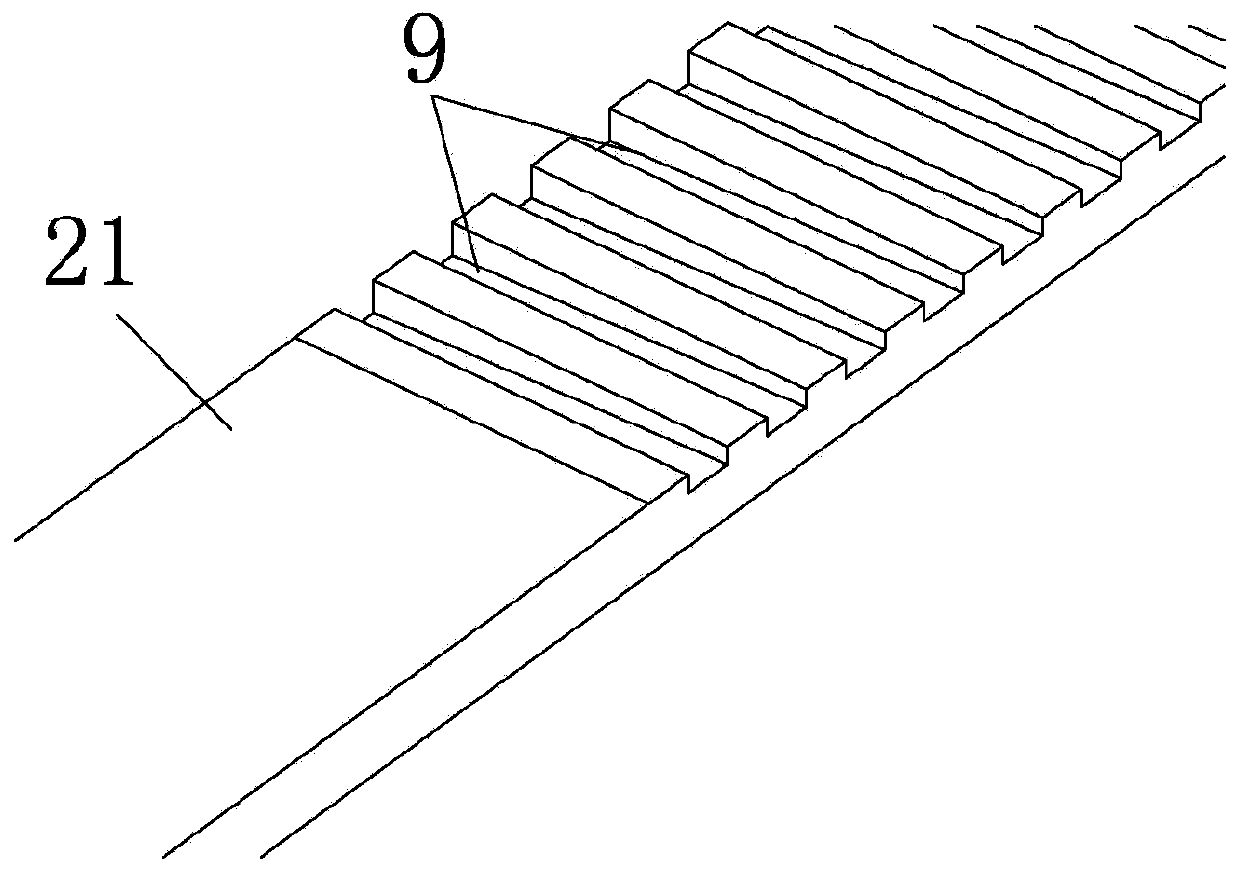

[0033] At present, most of the existing mass production solutions for flexible board LEDs in the industry are to design and produce LED particles and flexible substrates separately, and then assemble and assemble them at last. This kind of production and manufacturing has virtually increased costs, and has disadvantages such as complicated procedures and long production cycles. then arises accordingly. In view of this, in order to effectively solve the technical problems of LED packaging on flexible boards in the industry, the present invention designs a mold and packaging method that can perform whole-board packaging for flexible boards, so as to simplify the process and reduce the production cycle.

[0034] The technical solutions of the present invention will be clearly and completely described below through specific embodiments. Apparently, the described embodiments are only some of the embodiments of the present invention, but not all of them. Based on the embodiments of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com