Flip chip packaging structure with girth member and packaging method thereof

A flip-chip packaging and reinforcement technology, which is applied in the field of flip-chip packaging and its packaging, can solve problems such as inability to bond primer materials with solder bumps, chip substrates, poor packaging, and inability to solve packaging problems. Flux cleaning effect, reduction of poor coplanarity, and good encapsulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Hereinafter, preferred embodiments are specifically cited and described in detail in conjunction with the accompanying drawings:

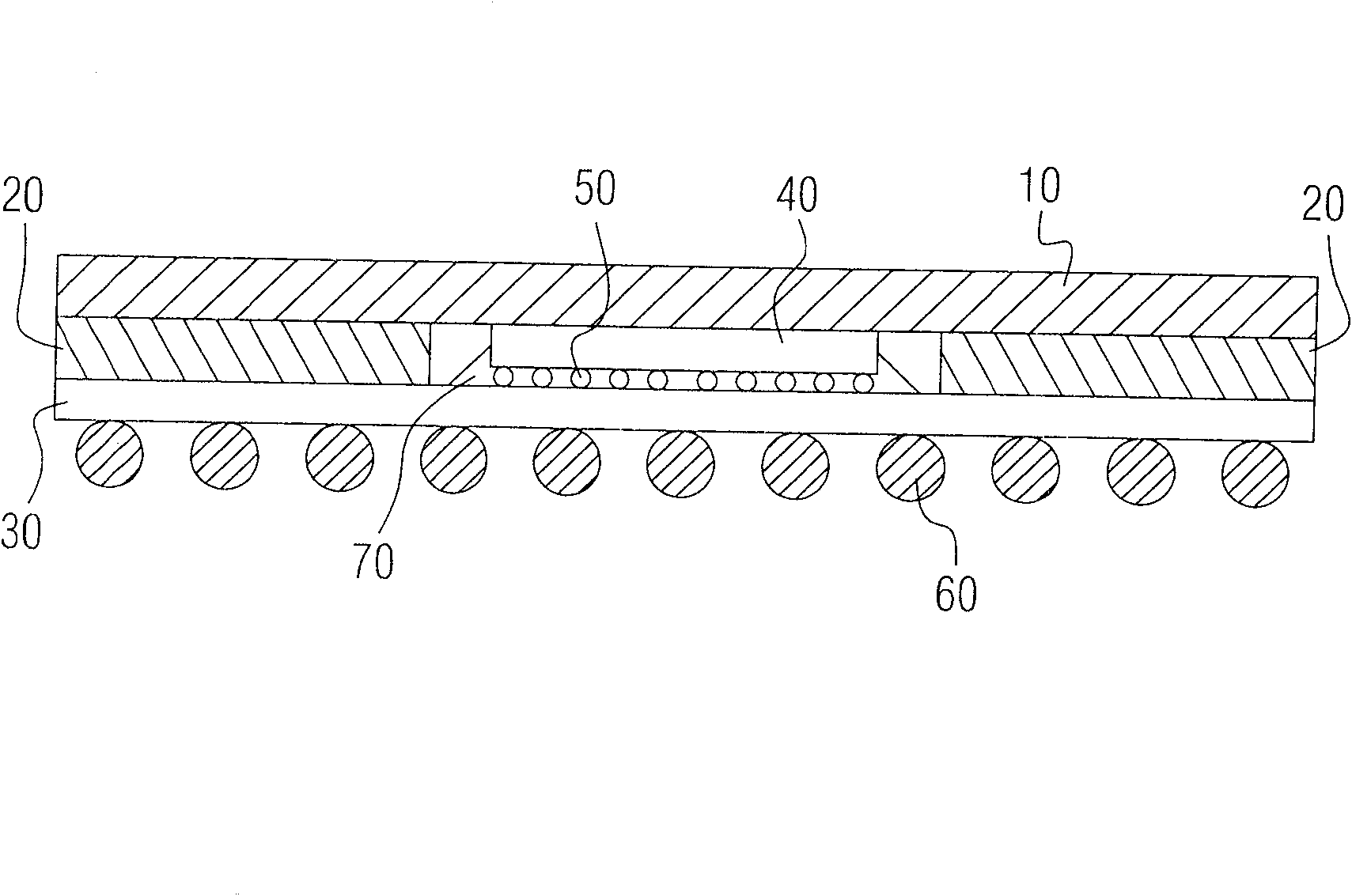

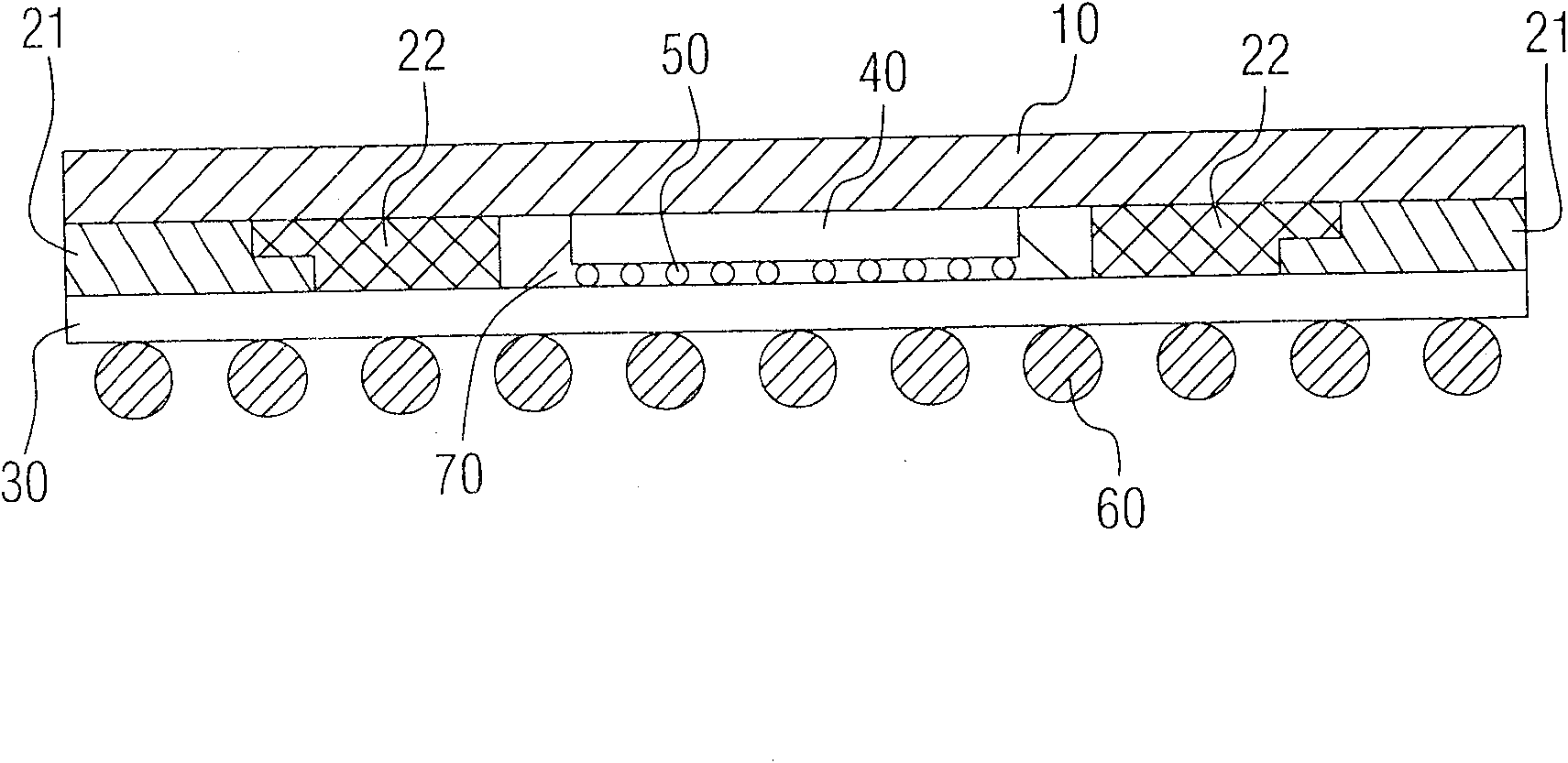

[0019] Please refer to image 3 as shown, image 3 It is a structural diagram of the flip-chip package of the present invention. The flip-chip package structure of the present invention includes: a package carrier 30, a first reinforcement, and several welding bumps 50, wherein the package carrier 30 is a circuit substrate; the first reinforcement The part 21 is arranged on one of the surfaces of the package carrier 30, the first reinforcement has an upper surface and a lower surface, and the first reinforcement is arranged on the upper surface of the package carrier with its lower surface, because the first The lower surface of the reinforcing element is larger than its upper surface, so that the first reinforcing element 21 is designed in two stages; and several welding bumps 50 are used to electrically connect the chip 40 and the package...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com