Hot contraction membrane machine capable of providing accurate target directions

A heat-shrinkable film, precise technology, applied in the direction of wrapping paper shrinkage, packaging, wrapping paper, etc., can solve the problems of high use cost and high manufacturing cost, and achieve the effect of low use cost, low manufacturing cost and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

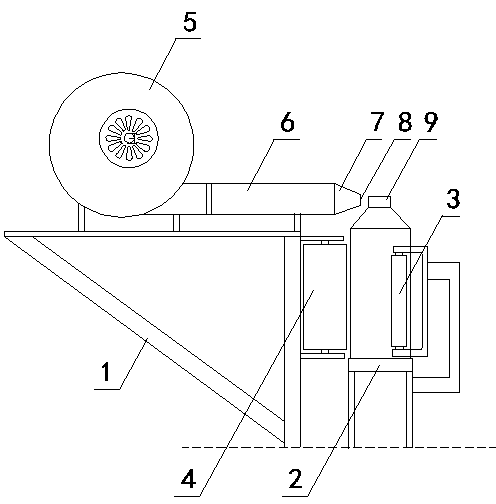

[0014] Such as figure 1 Shown, the present invention comprises following structure: frame 1, conveyer belt 2, bottle gripper 3, rotating roller 4, air blower 5, heating pipe 6, bundle heat pipe 7, bundle hot mouth 8.

[0015] Such as figure 1 As shown, a blower 5 is installed on the frame 1, and the blower 5 has its own power. Heating is obtained in the heating tube 6, and the other end of the heating tube 6 is connected with the beam heat pipe 7, and the temperature control probe is installed in the beam heat tube 7, and the heating device in the heating tube 6 is controlled by the temperature control probe and the temperature controller to work. The tube 6 is sent to the beam heat pipe 7 and sent to the working position from the beam heat port 8 . The rotating roller 4 and the bottle gripper 3 located at the working position are installed on the frame 1, both of which hold the bottled product 9 together, the rotating roller 4 is driven by an additional power to rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com