Cold wax block for controlling wall thickness of tenon teeth of hollow turbine working blade and casting method implemented by applying cold wax block

A technology of wax blocks and blades, which is applied in the field of cold wax blocks, can solve the problems of shrinkage control and over-tolerance of the wall thickness of tenons and teeth, and achieve the effects of avoiding core deviation, improving matching, and uniform wall thickness of tenons and teeth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

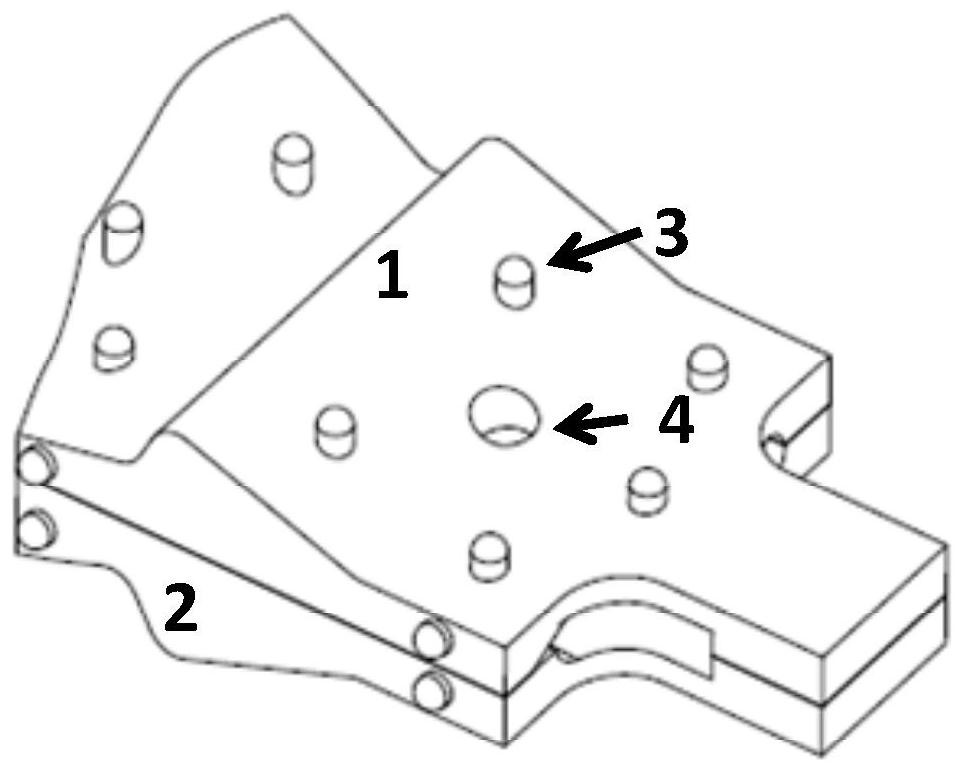

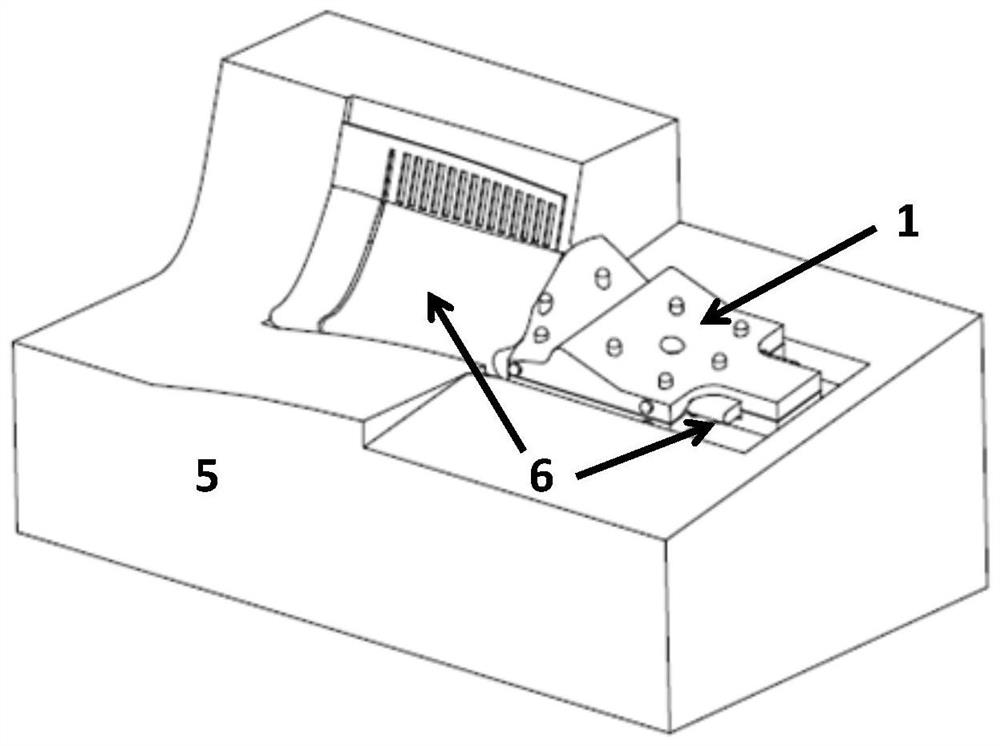

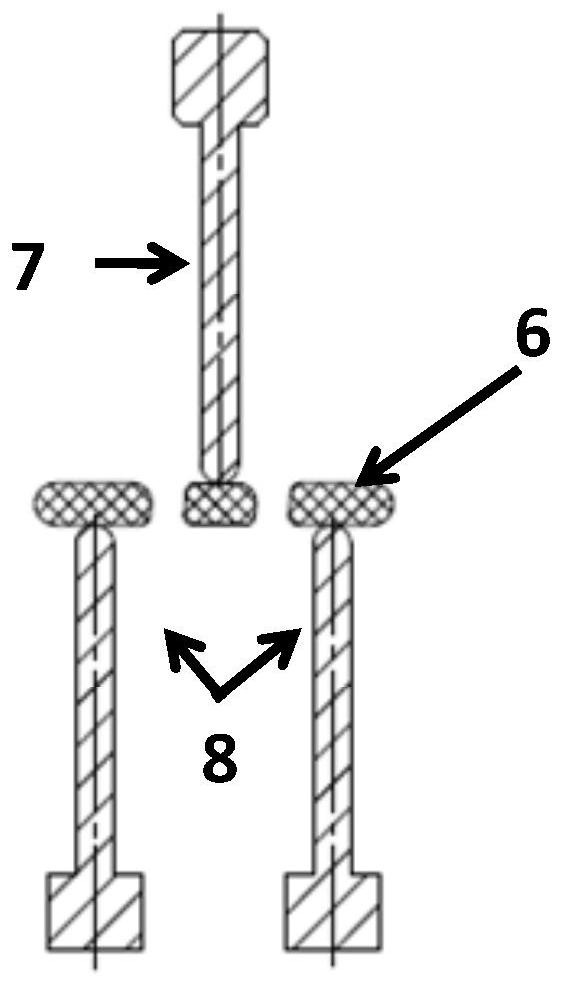

[0021] A cold wax block for controlling the wall thickness of the mortise teeth of a hollow turbine working blade, characterized in that the shape of the cold wax block matches the shape of the root section of the blade, and the cold wax block includes an upper die cold wax block and a lower die cold wax block. The wax block, the lower surface of the upper mold cold wax block and the upper surface of the lower mold cold wax block can be fastened together, and the upper surface of the upper mold cold wax block and the lower surface of the lower mold cold wax block are provided with a positioning component. Because of the positioning of the cold wax block in the external mold, the surfaces of the upper and lower mold cold wax blocks are all provided with through holes.

[0022] The positioning part is a protrusion located on the upper surface of the upper mold cooling wax block and the lower surface of the lower mold cooling wax block.

[0023] The protrusion is a cylindrical st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com