Patents

Literature

34results about How to "No risk of burns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oven control method and oven using the same

InactiveCN108201368AEasy to useShorten the timeProgramme controlComputer controlProcess engineeringExcess heat

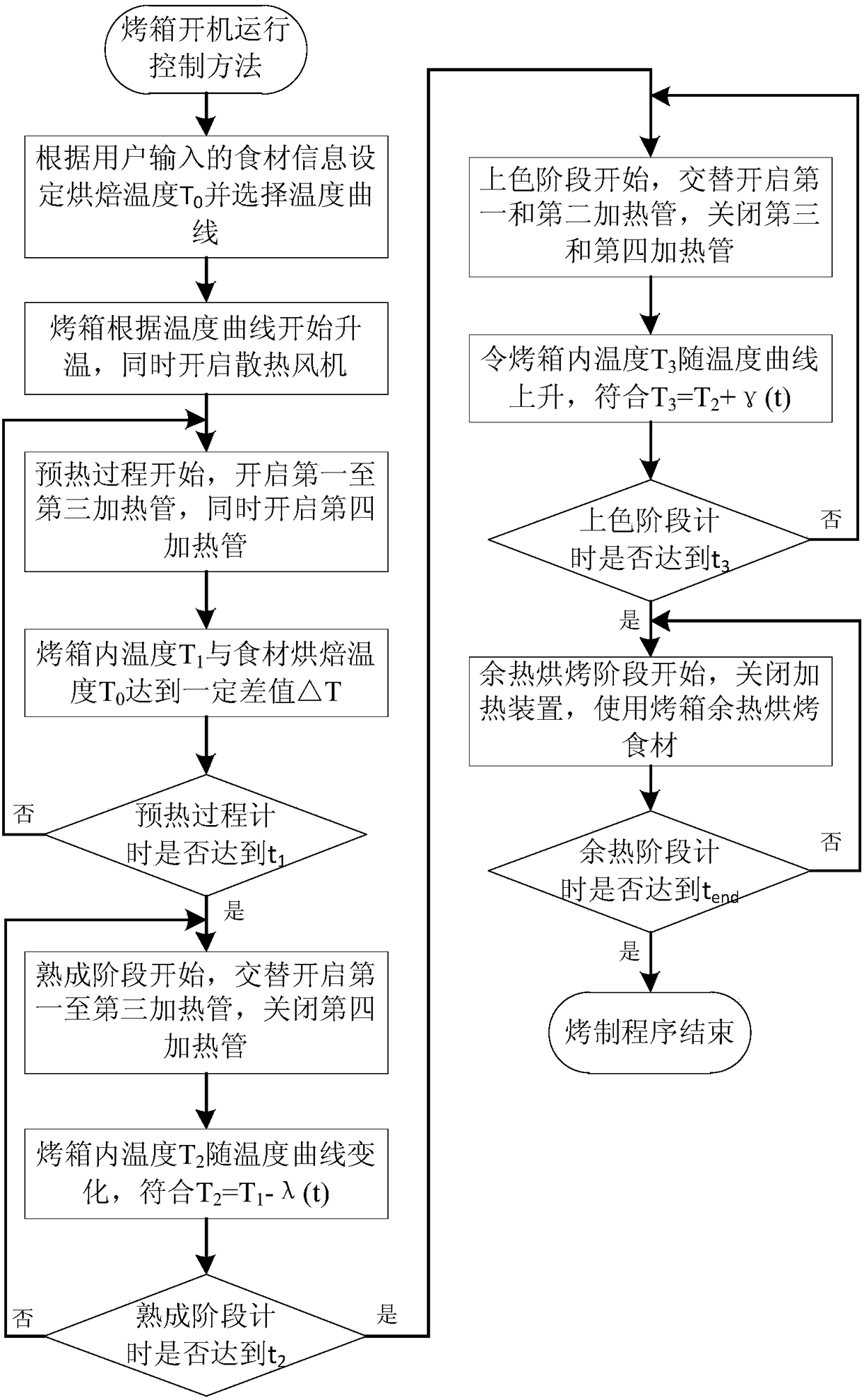

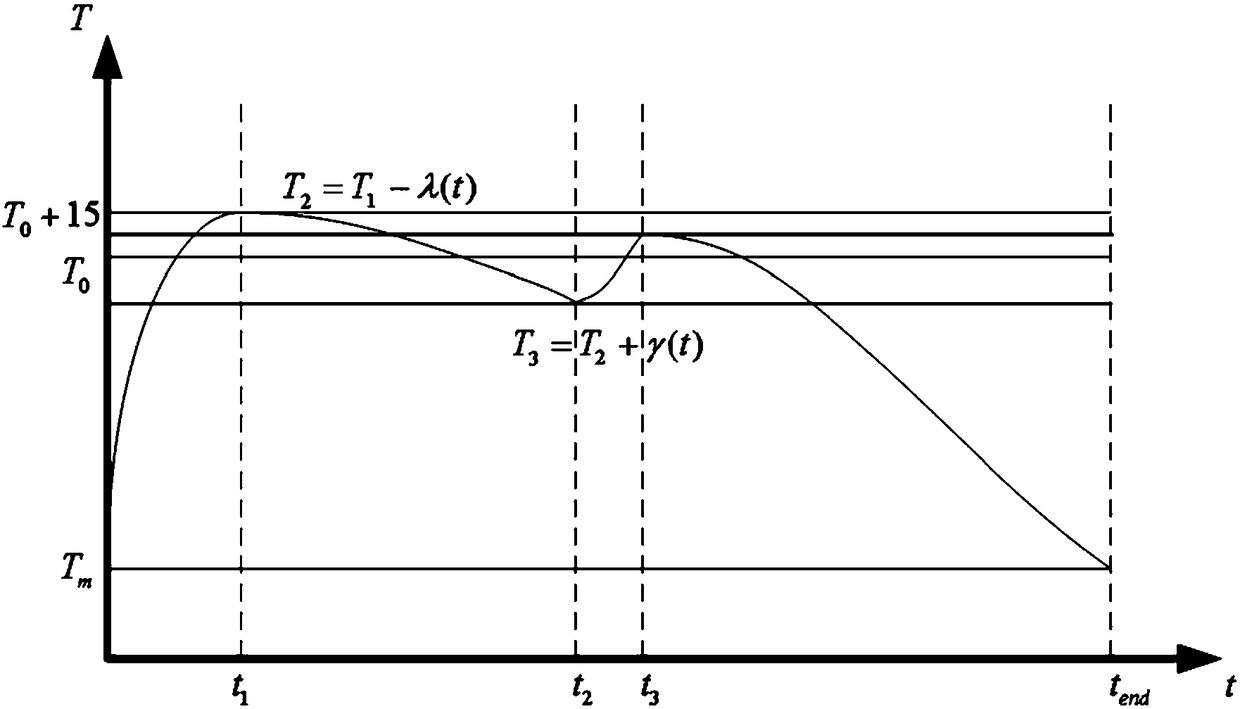

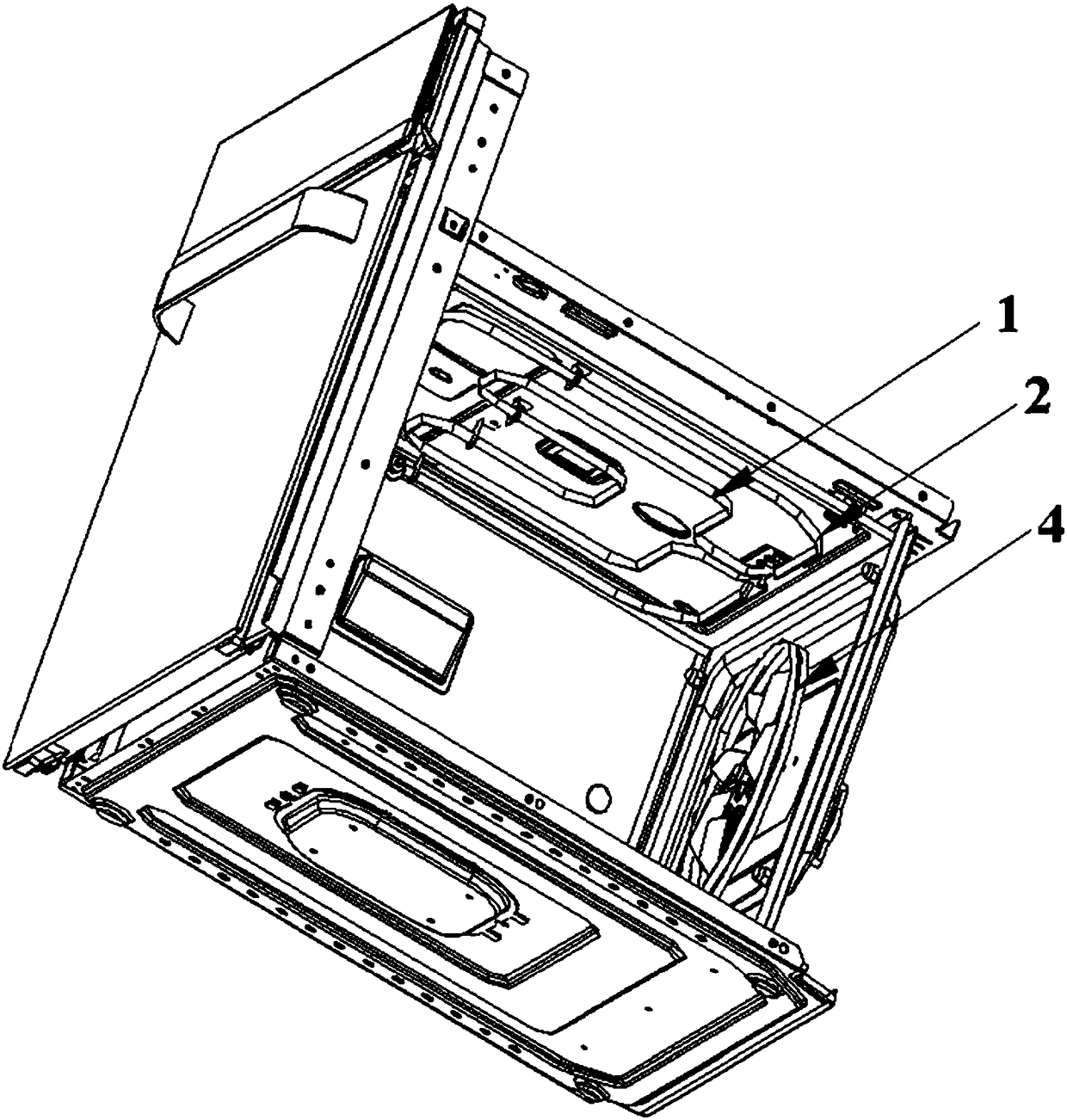

The invention relates to the field of household electrical appliances, and particularly relates to an oven control method and an oven using the same. According to the method, corresponding temperaturecurves are called by the oven according to the food material information input by a user, and heating devices in the oven are controlled to be alternately started or shut down according to the temperature curves, so that the preheating and baking processes of food materials put into the oven in advance are completed; the oven comprises the heating devices and a heat dissipation fan, and the baking of the food materials and the discharging of excess heat and moisture are completed by the oven through controlling the heating devices and the heat dissipation fan. By means of the oven control method, automatic baking of the food materials is achieved, the user does not need to wait for preheating and other baking processes in front of the oven, and time is saved while temperature loss and therisk of burning caused by the frequently opening of an oven door cover are prevented.

Owner:QINGDAO HAIER WISDOM KITCHEN APPLIANCE CO LTD

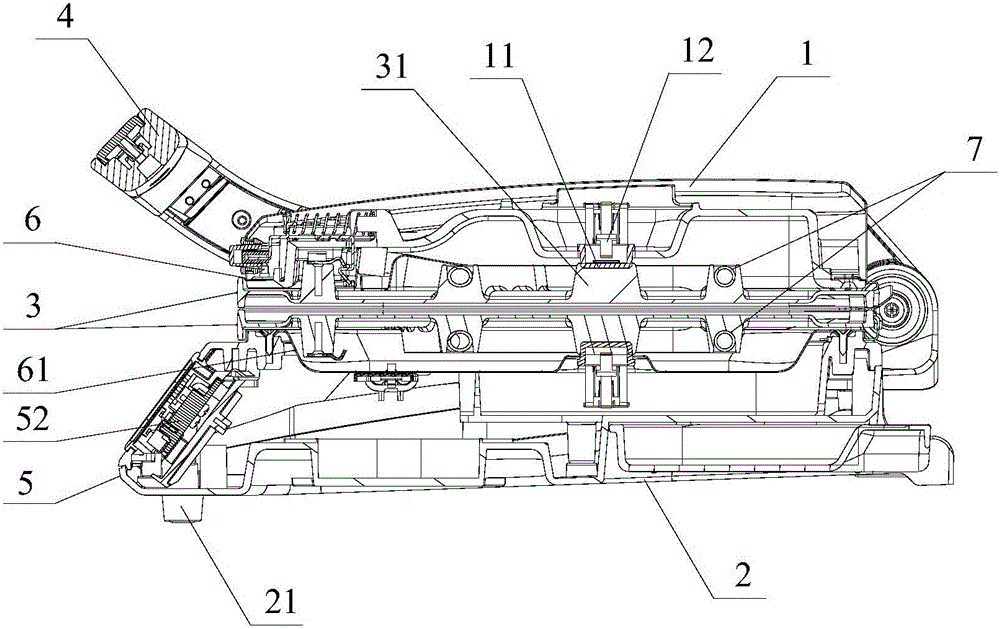

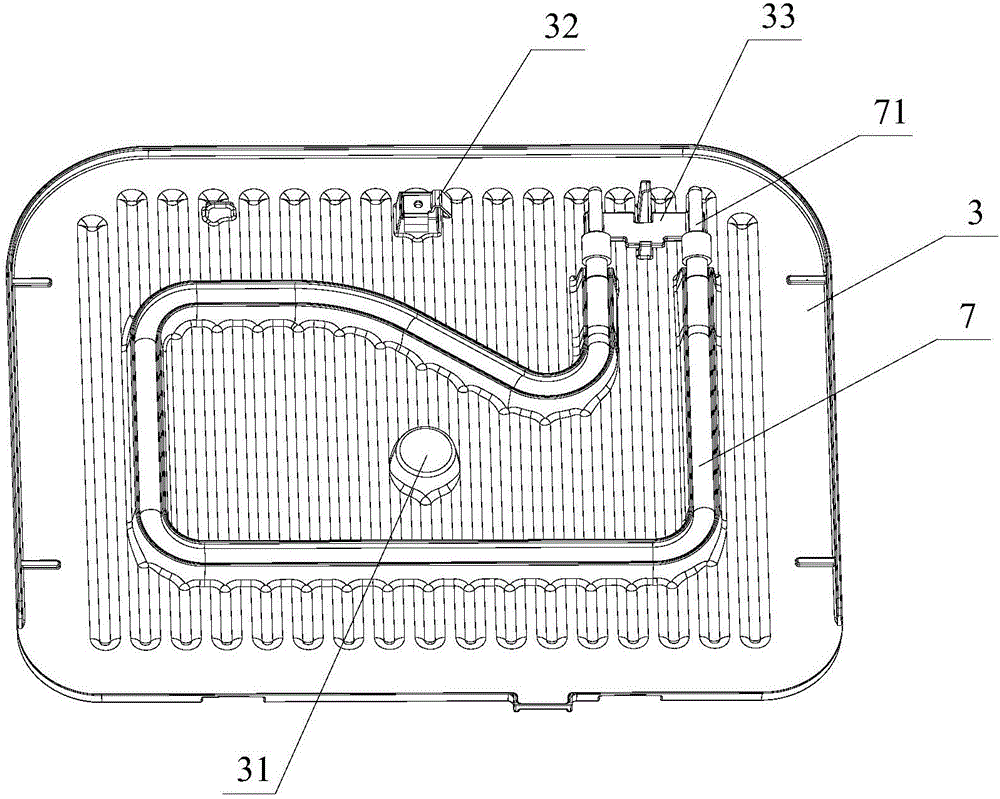

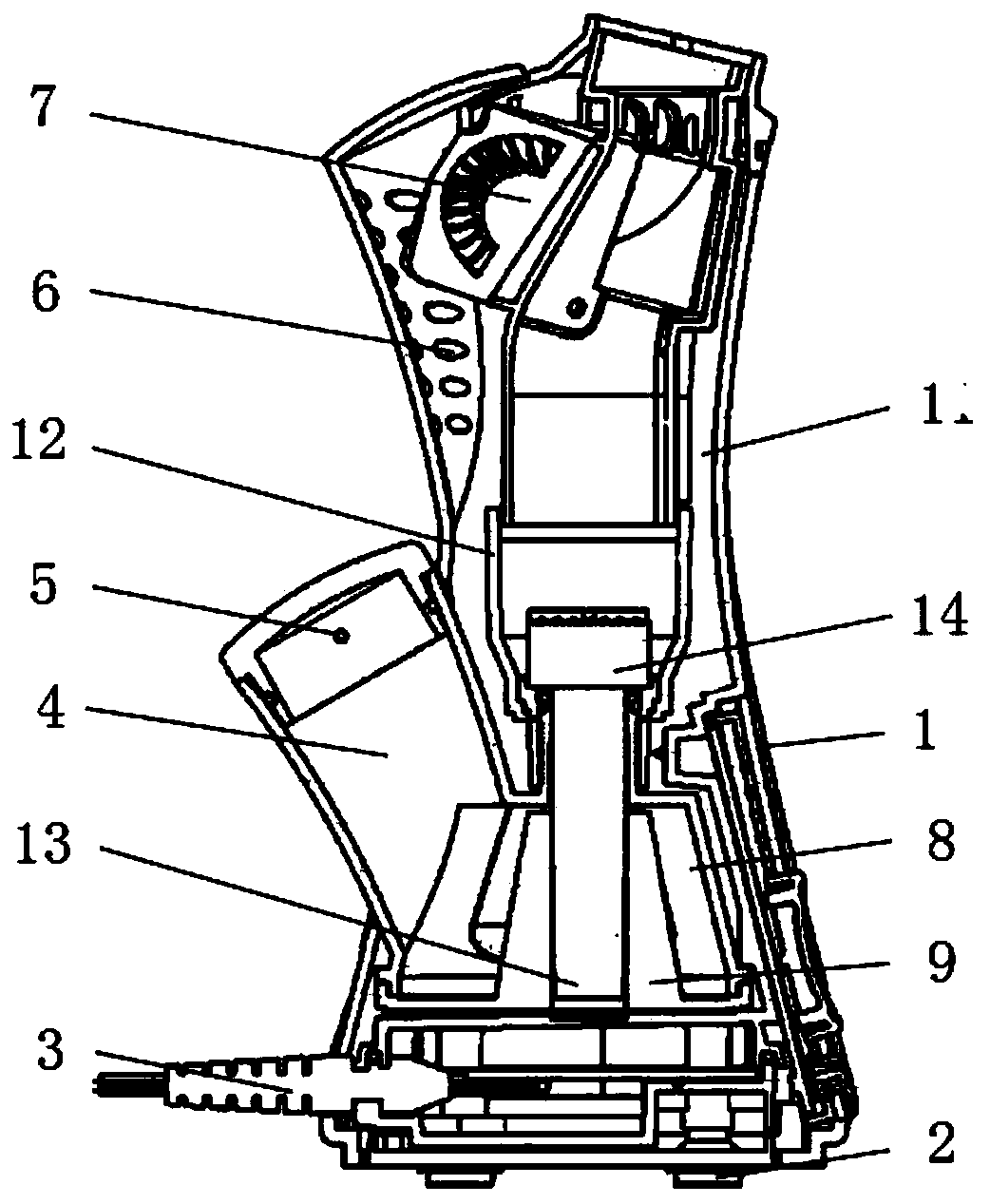

Heating frying-baking device

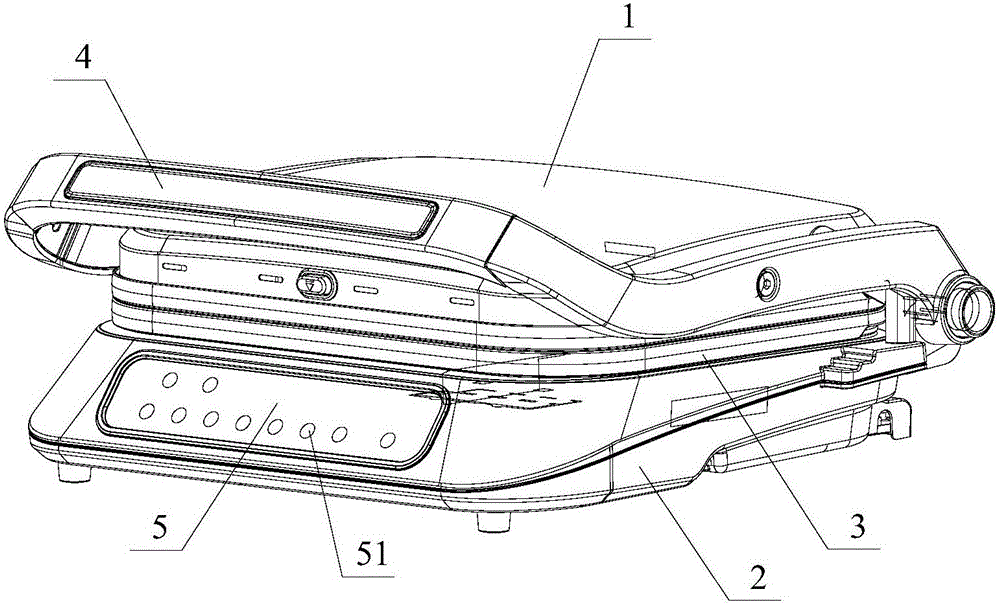

The invention discloses a heating frying-baking device, comprising an upper shell assembly and a lower shell assembly which are mutually articulated, and a lifting lever handle rotationally connected with the upper shell assembly, wherein a baking tray assembly is arranged between the upper shell assembly and the lower shell assembly, the baking tray assembly comprises a baking tray, which comprises an upper baking tray and a lower baking tray which are oppositely arranged, the outer sides of the upper and lower baking trays are respectively detachably connected with the upper and lower shell assemblies by latch structures, the middle parts of the upper and lower baking trays make elastic contact with the upper and lower shell assemblies by contact point structures, and when the upper and lower baking trays are in elastic contact with the upper and lower shell assemblies, a circuit is connected; two groups of electrical heated tubes are arranged, and are respectively riveted and pressed in the upper baking tray and the lower baking tray. According to the heating frying-baking device, the baking trays can be detachably connected by the latch structures, can be detached off at anytime to be cleaned in a dish-washing machine, and convenience and rapidness are realized; the contact point structures guarantee that the circuit is connected only when the baking trays are mounted in place, the safety of the frying-baking device in use is improved, and safety loopholes such as electric leakage are avoided; the electrical heated tubes are riveted and pressed in the baking trays, when food is baked, the heat utilization ratio is high, and quick cooking and baking can be realized.

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

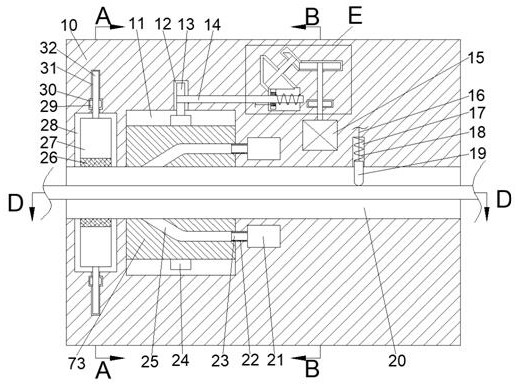

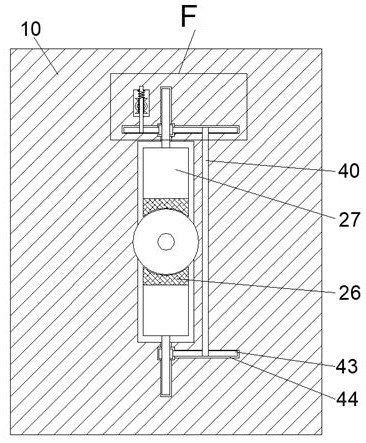

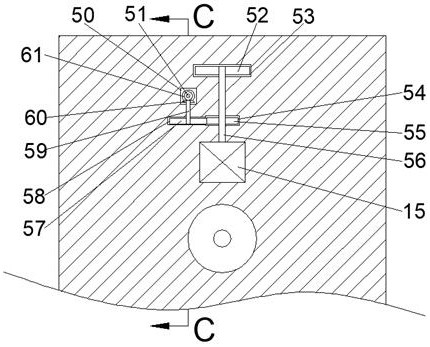

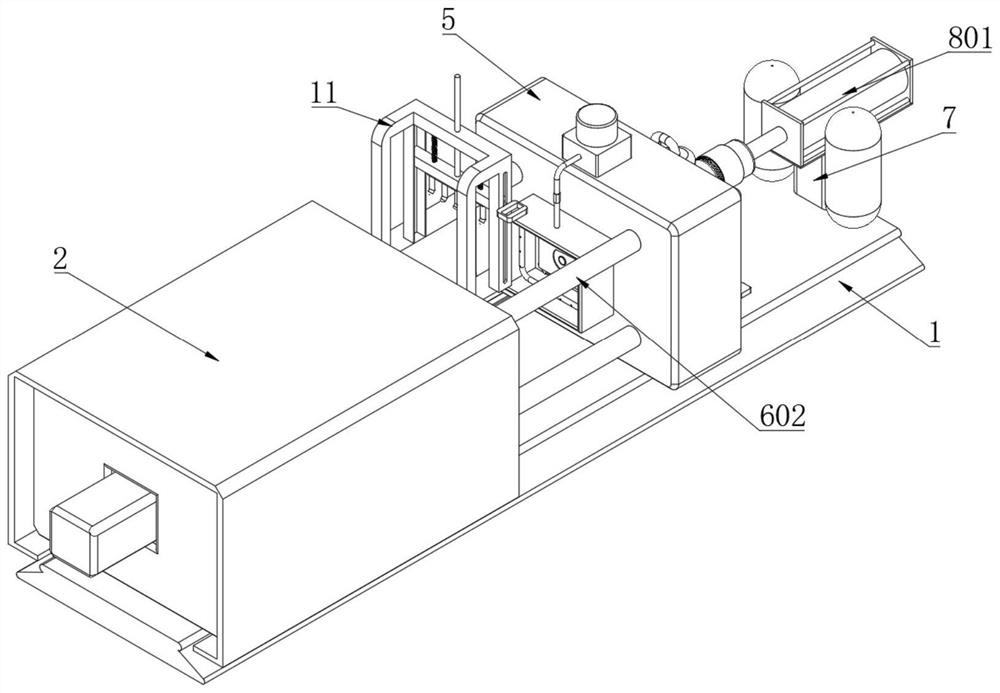

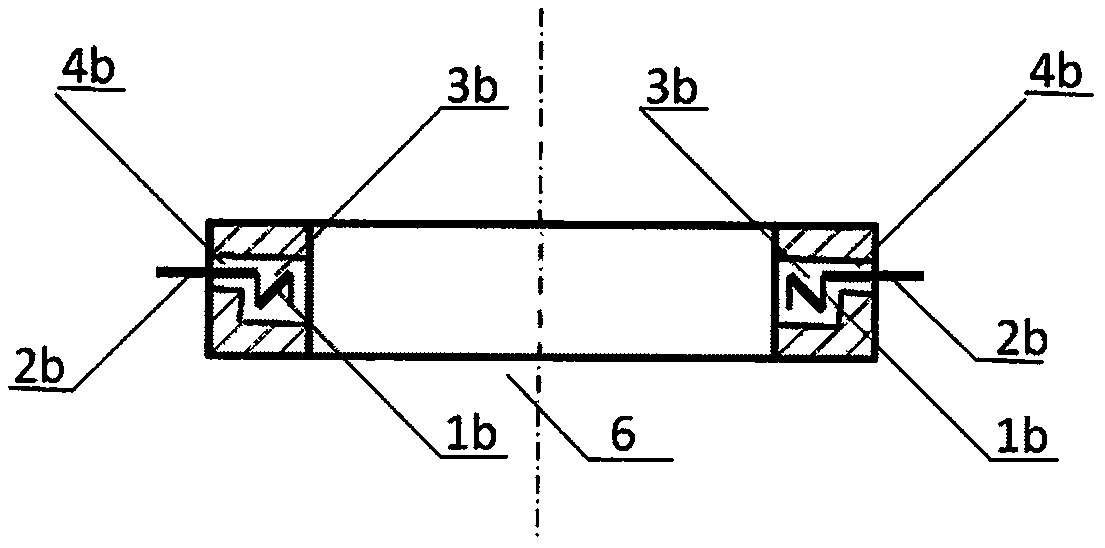

Extrusion molding mold for automatic coating of wires and cables

InactiveCN111958935ANo risk of burnsReduce operational safety hazardsDomestic articlesCoatingsEngineeringStructural engineering

The invention relates to the field of plastic molds, and discloses an extrusion molding mold for automatic coating of wires and cables. The extrusion molding mold includes a main box body, a cable conveying cavity is formed in the main box body in a left-right penetrating mode, lifting cavities in upper-lower symmetric are formed in the upper side and the lower side of the cable conveying cavity in a communicating mode, nut rotating cavities are formed in the end walls of the sides, away from the cable conveying cavity, of the lifting cavities, and sliding rod cavities are formed in the side,away from the cable conveying cavity, of the nut rotating cavities, wherein the sliding rod cavities extend in the direction of the side close to the cable conveying cavity and penetrate through the nut rotating cavities into the lifting cavities. A mechanism is used for clamping the head of a coating layer to instead of manually pinching by hand, so that an operator is prevented from the risks ofscalding, the potential safety hazard of worker is greatly reduced, meanwhile, a rotating coating mechanism enables the wires and cables to be coated more tighter, the coating effect is greatly increased, meanwhile, according to the diameter of the wires and cables, the rotation speed of the coating layer is automatically adjusted, and thus it is ensured that the coating layers of the wires and cables of different diameters can achieve a tight coating effect.

Owner:福州约春向科技有限公司

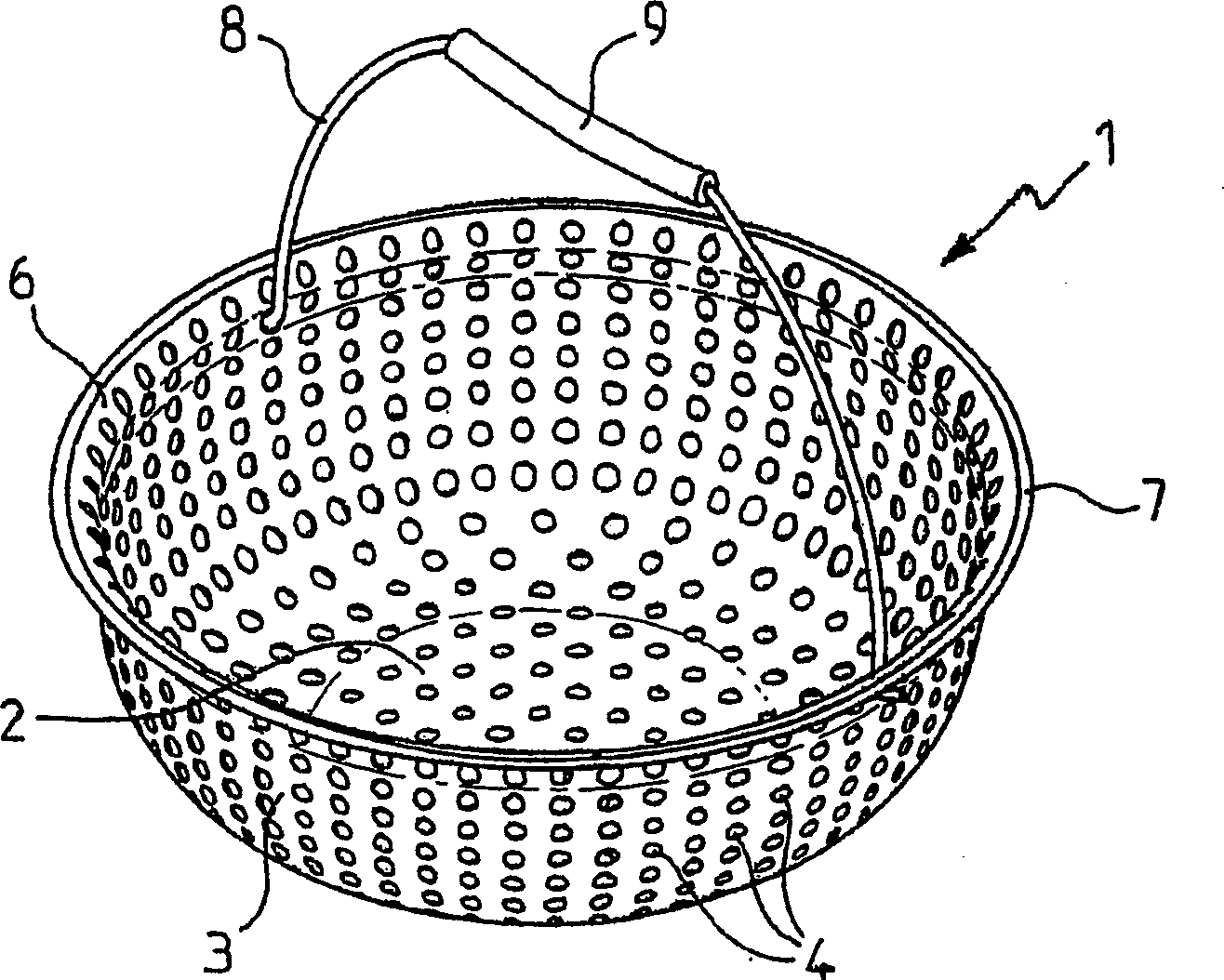

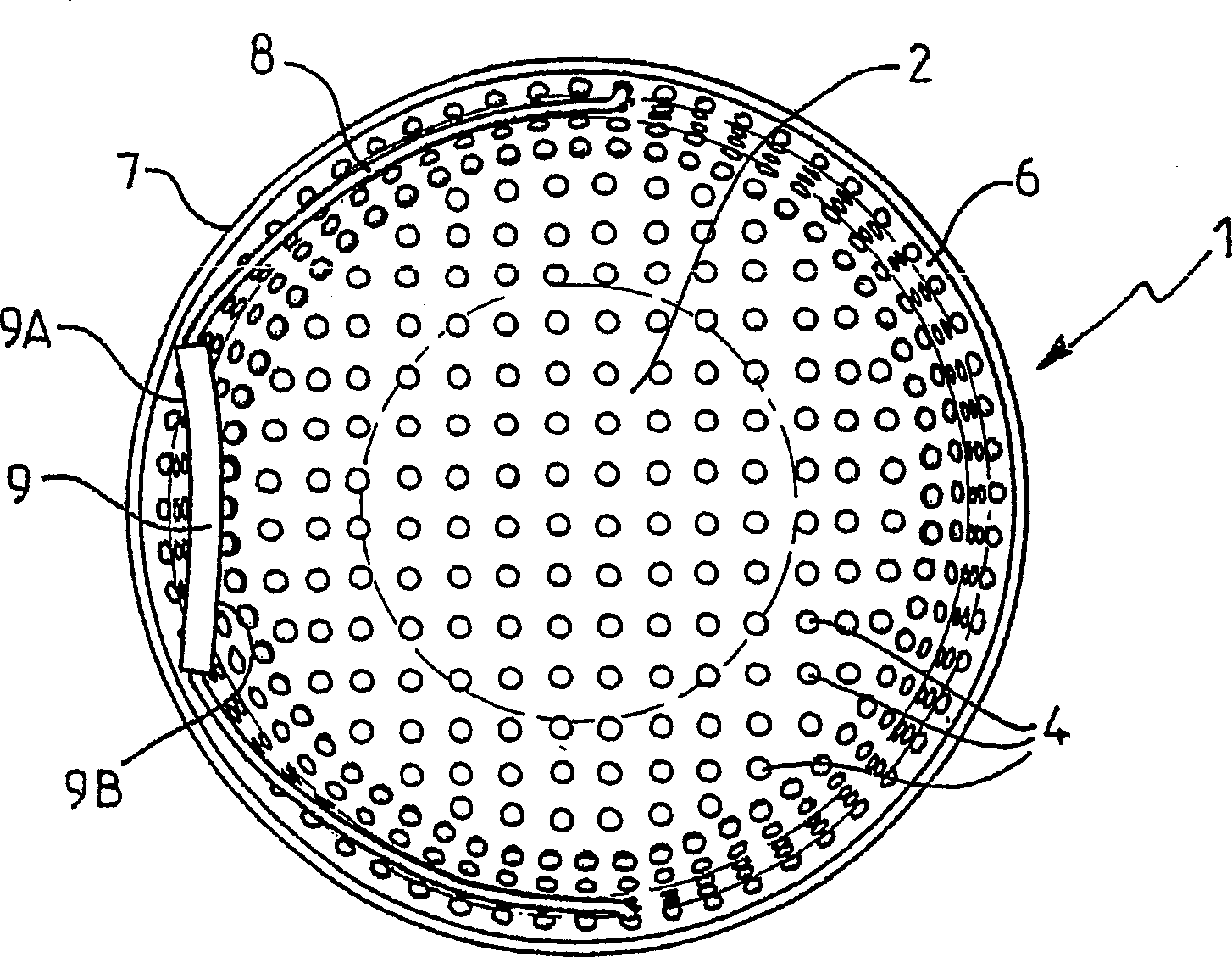

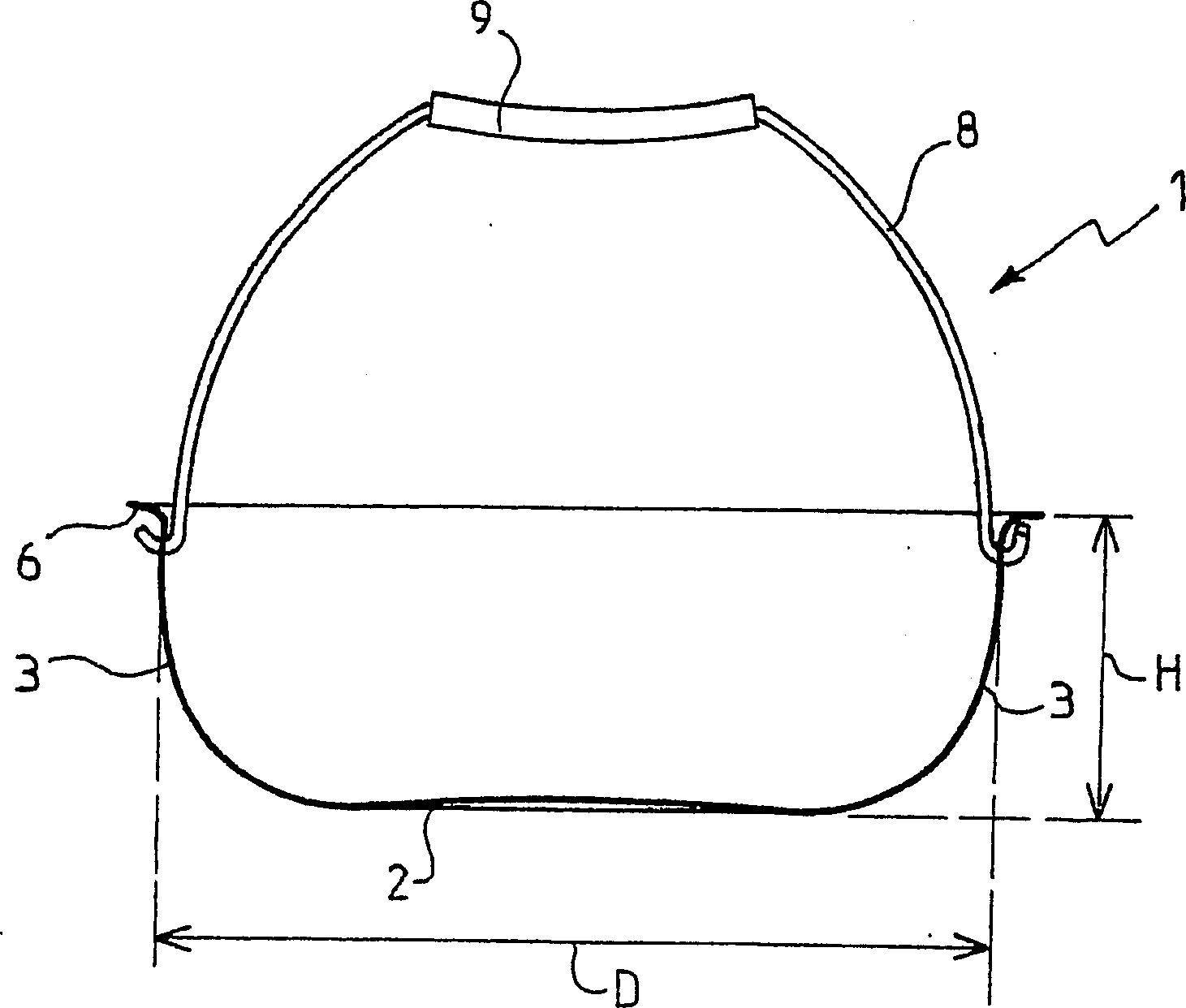

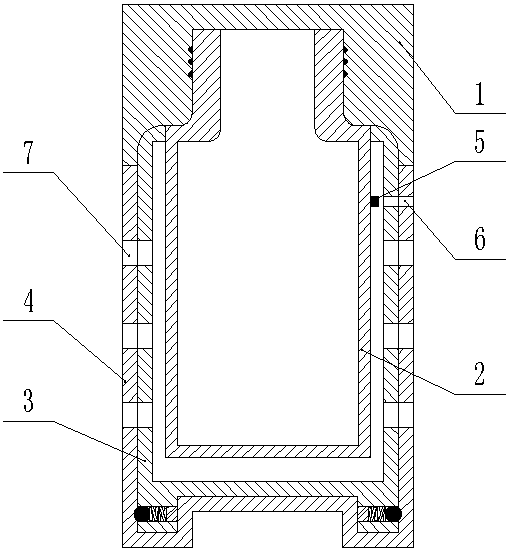

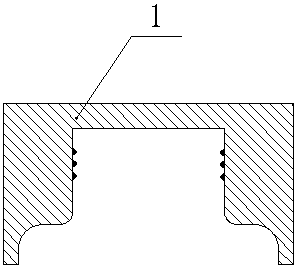

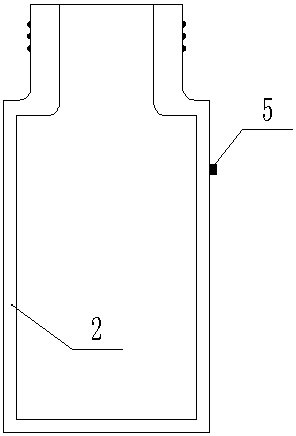

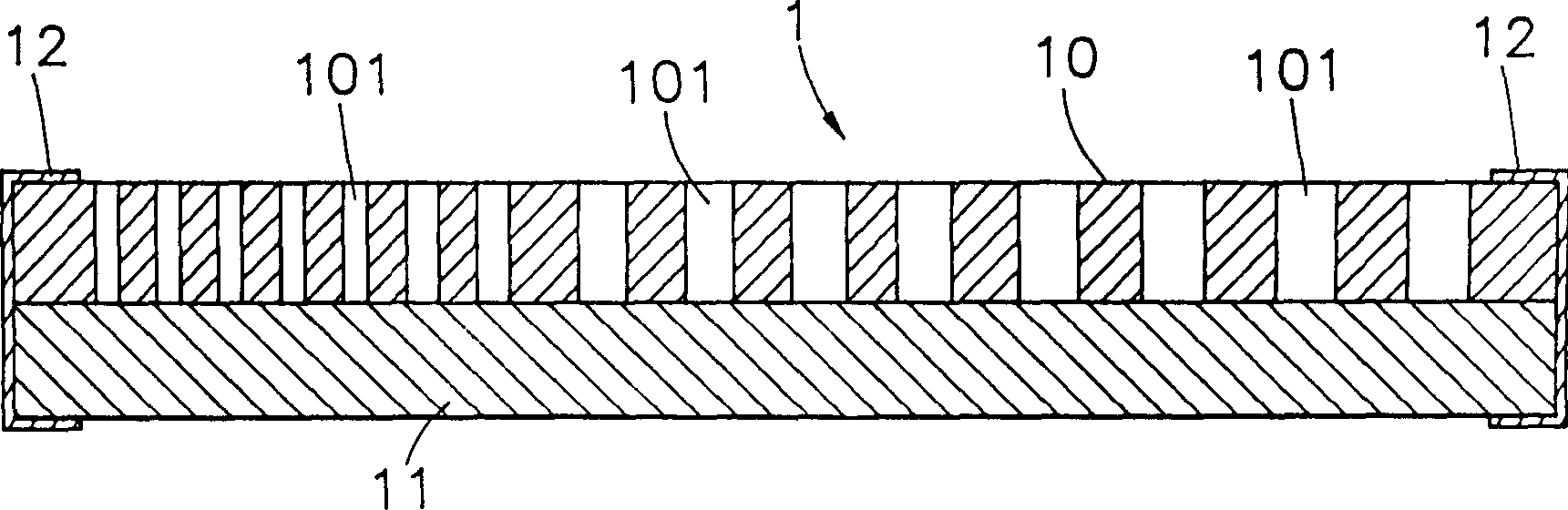

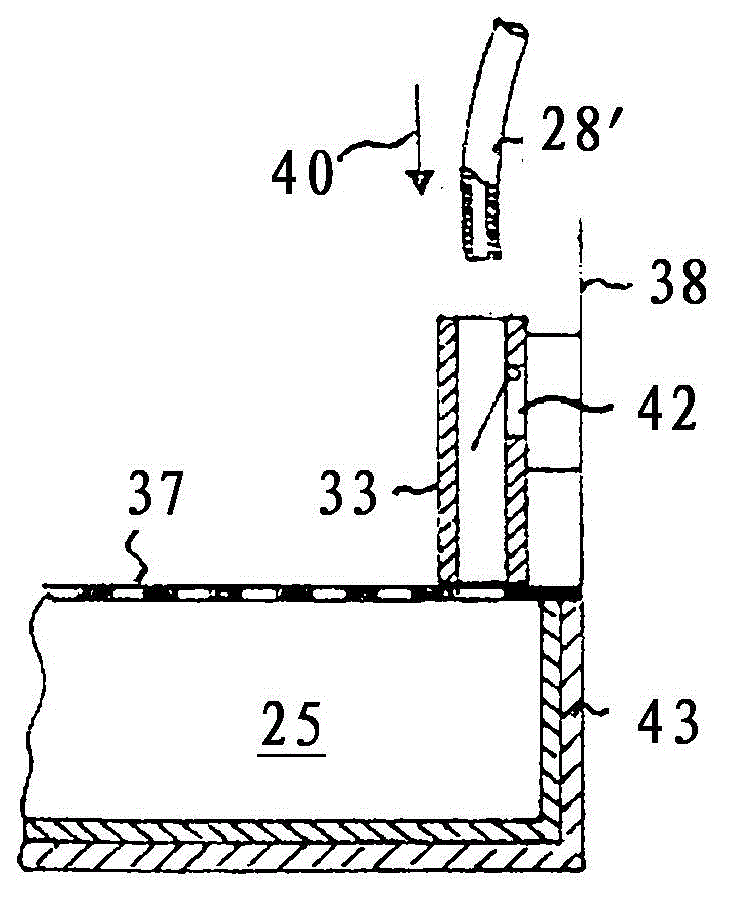

Food cooking basket for pressure cooker, pressure cooker for receiving cooking basket and method for making a cooking basket by swaging

InactiveCN1487806AShorten the timeEasy to manufacturePressure-cookersCooking insertsEngineeringMaterial Perforation

The present application provides a food-cooking basket for pressure cooking in a pressure cooker, the basket being made of a sheet of rigid material defining a bottom (2) and side walls (3) of the basket (1). The sheet is provided with perforations (4), which are provided at least through the side walls (3) and represent at least 30% of the total area of the sheet. The invention is applicable to pressure cooking appliances.

Owner:SEB SA

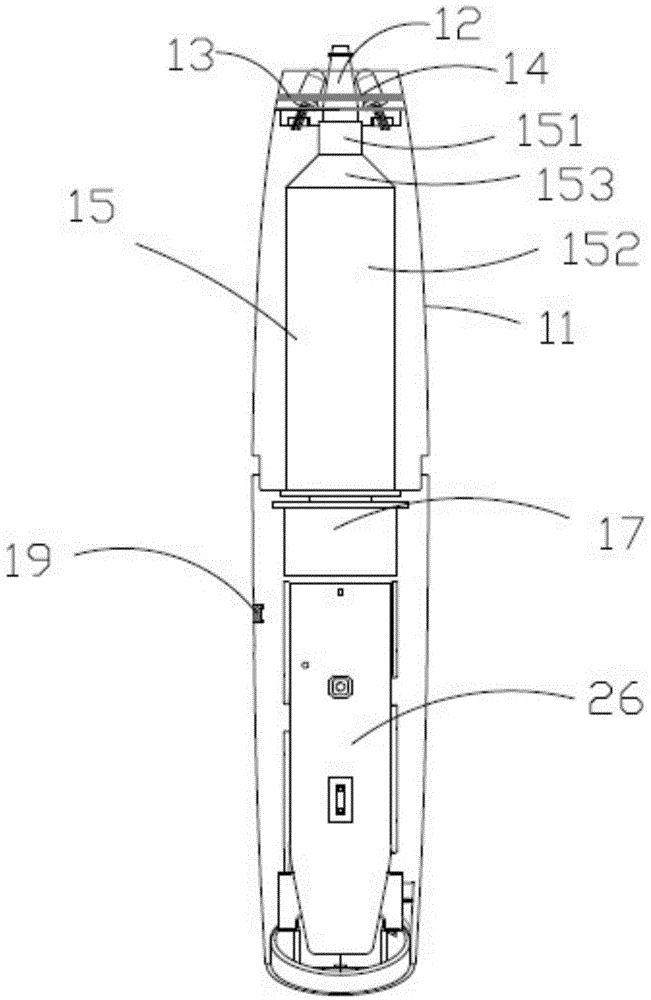

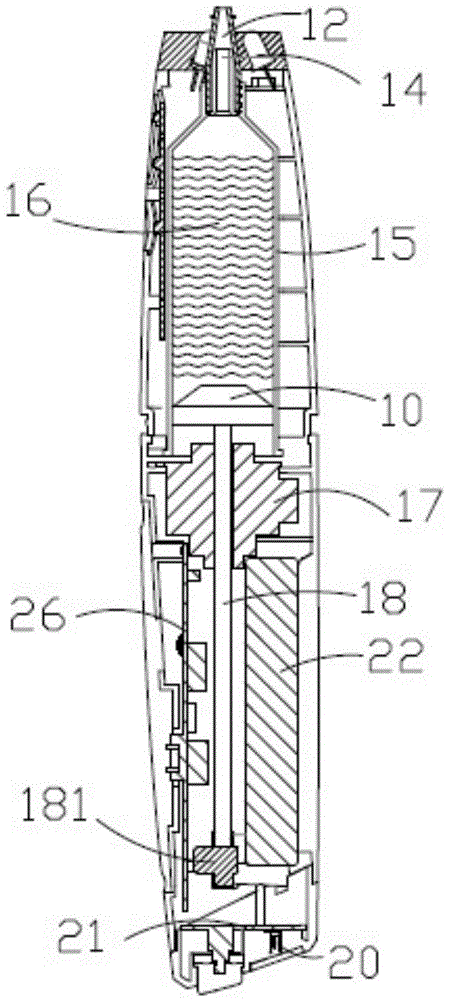

A vacuum cup capable of rapidly cooling

The invention discloses a vacuum cup capable of rapidly cooling, comprising a cup cover, an inner liner, an outer shell 1, an outer shell 2 and a heat dissipation hole. The inner liner and the outer shell 1 are welded together, and an air insulation layer is arranged between the inner liner and the outer shell 1. A shell 2 is arranged adjacent to an outer side of the shell 1, and a heat dissipation hole is machined on the shell 1 and the shell 2. A cup cover is arranged above the inner liner, the outer shell and the outer shell. The cup has the beneficial effects that the cooling and heat preservation functions of the thermos cup are controlled by opening and closing the heat dissipation hole, the heat dissipation hole can be opened only before drinking water is needed, the cup cover neednot be unscrewed, and the operation is convenient and there is no risk of scald.

Owner:HANDAN COLLEGE

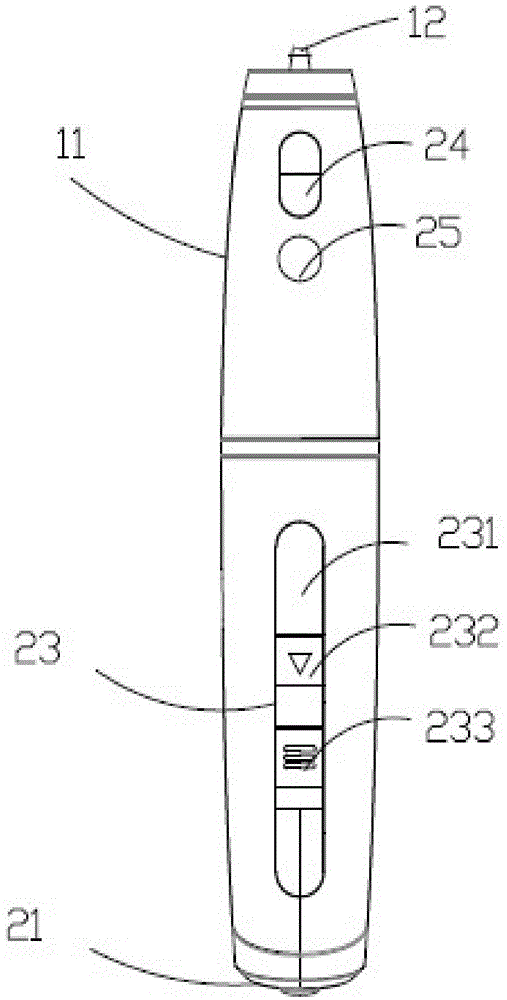

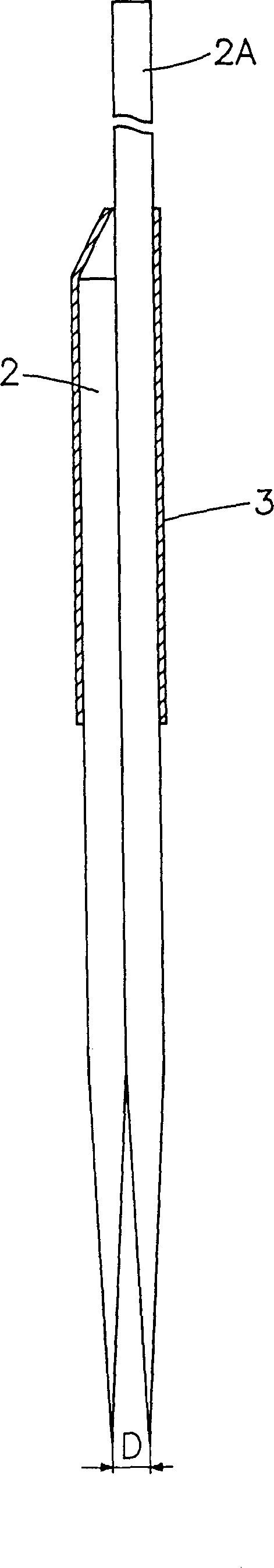

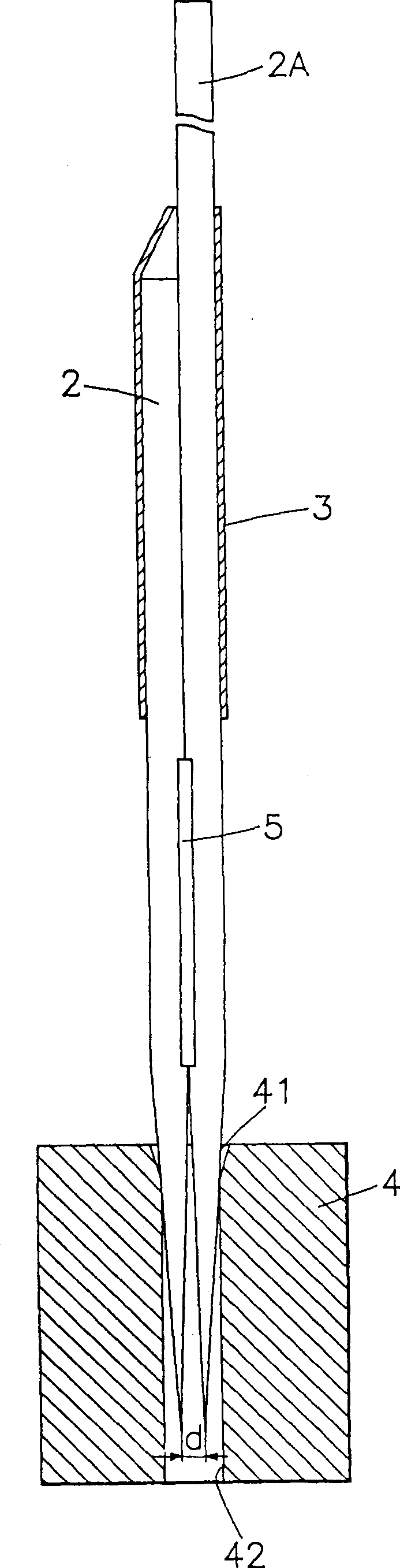

Blue light photocuring 3D printing pen

InactiveCN105643924ALight curing temperature requirements are lowShorten the timeAdditive manufacturing apparatusAdditive manufacturing with liquidsResistUltraviolet

The invention relates to a blue light photocuring 3D printing pen comprising a shell, an ink cartridge, a pen point, photosensitive resin and a plurality of blue light LEDs, wherein the ink cartridge is arranged in the shell; the pen point is arranged at the front end of the ink cartridge and extends out of the shell; the photosensitive resin is placed in the ink cartridge; the plurality of blue light LEDs are arranged around the pen point; the photosensitive resin flows out of the pen point; the blue light LEDs are used for irradiating and curing the photosensitive resin; and the wavelength of each blue light LED ranges from 465nm to 485nm. The blue light photocuring 3D printing pen is low in photocuring temperature requirement and does not need high temperature in the using process, so that the energy consumption is reduced by 90%, and the danger that a user is scalded does not exist; in addition, blue light LED lamps are high in curing speed so that the time is saved, and molding is easily realized; light emitted from the blue light LED lamps belongs to visible light, does not contain ultraviolet, has no skin burning effects and cannot generate atmospheric pollution and wastewater pollution; and a cured product is good in performance, and resists wear, solution and impact.

Owner:NANJING BAICHUAN XINGYUAN LASER TECH

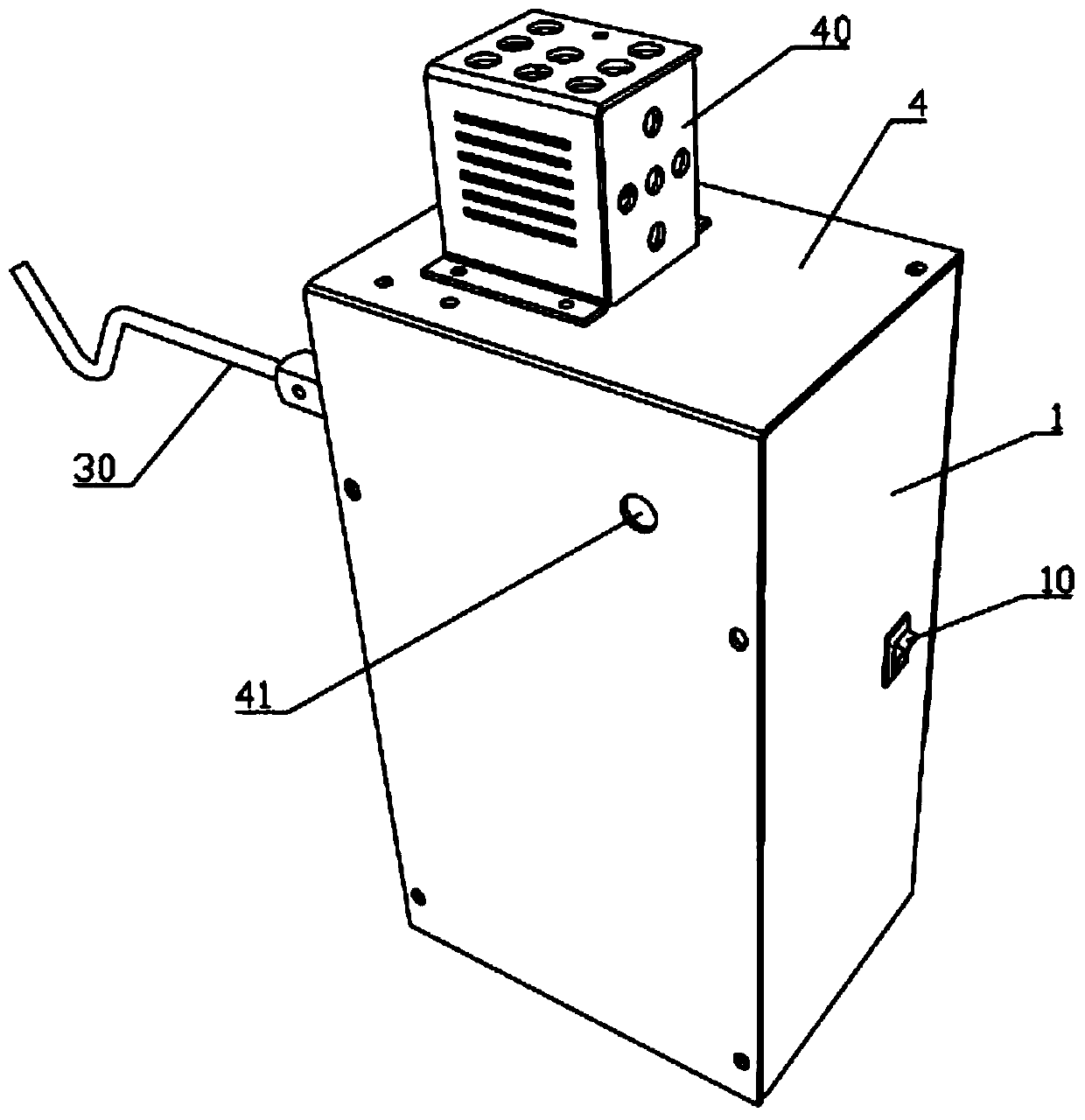

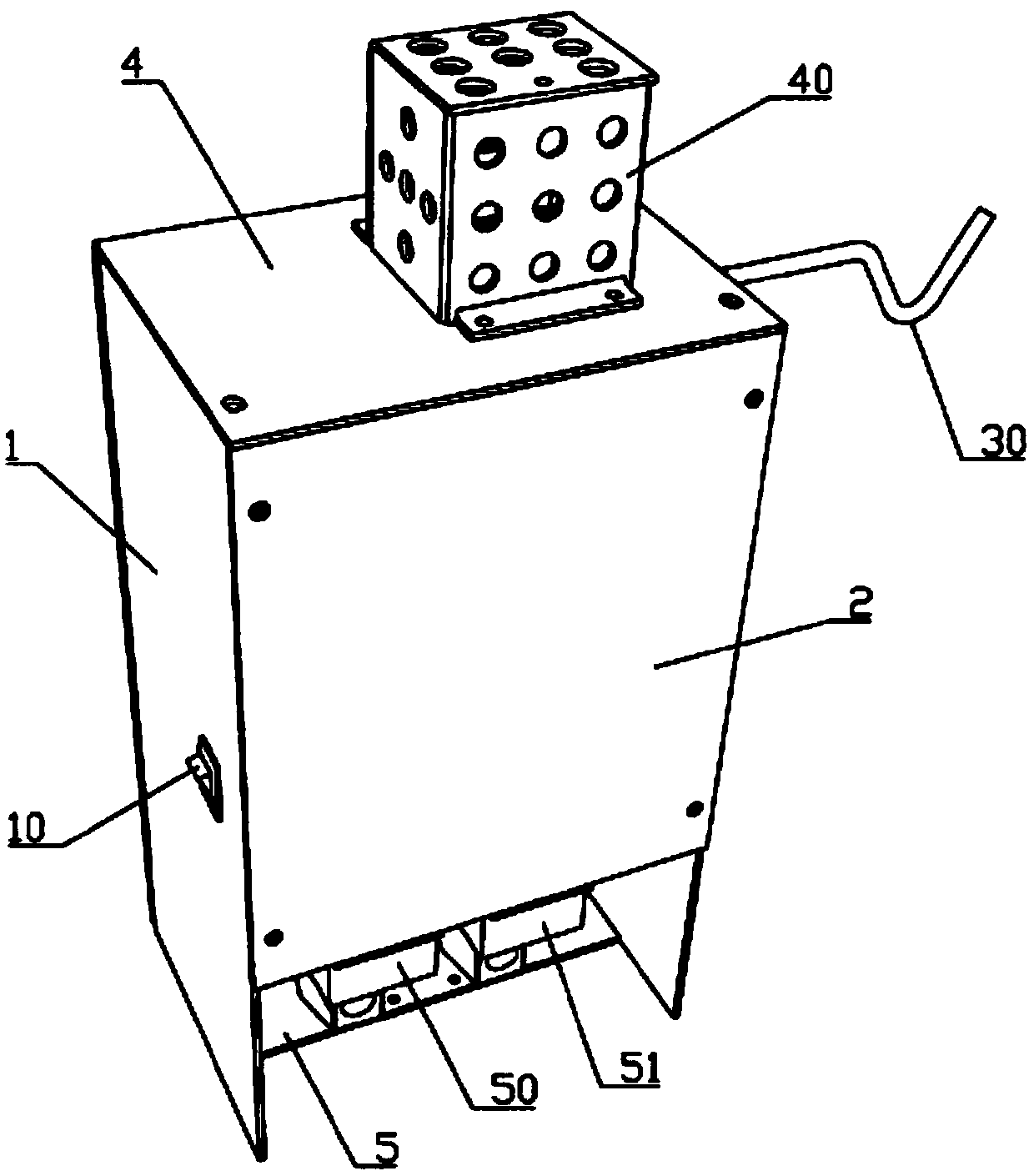

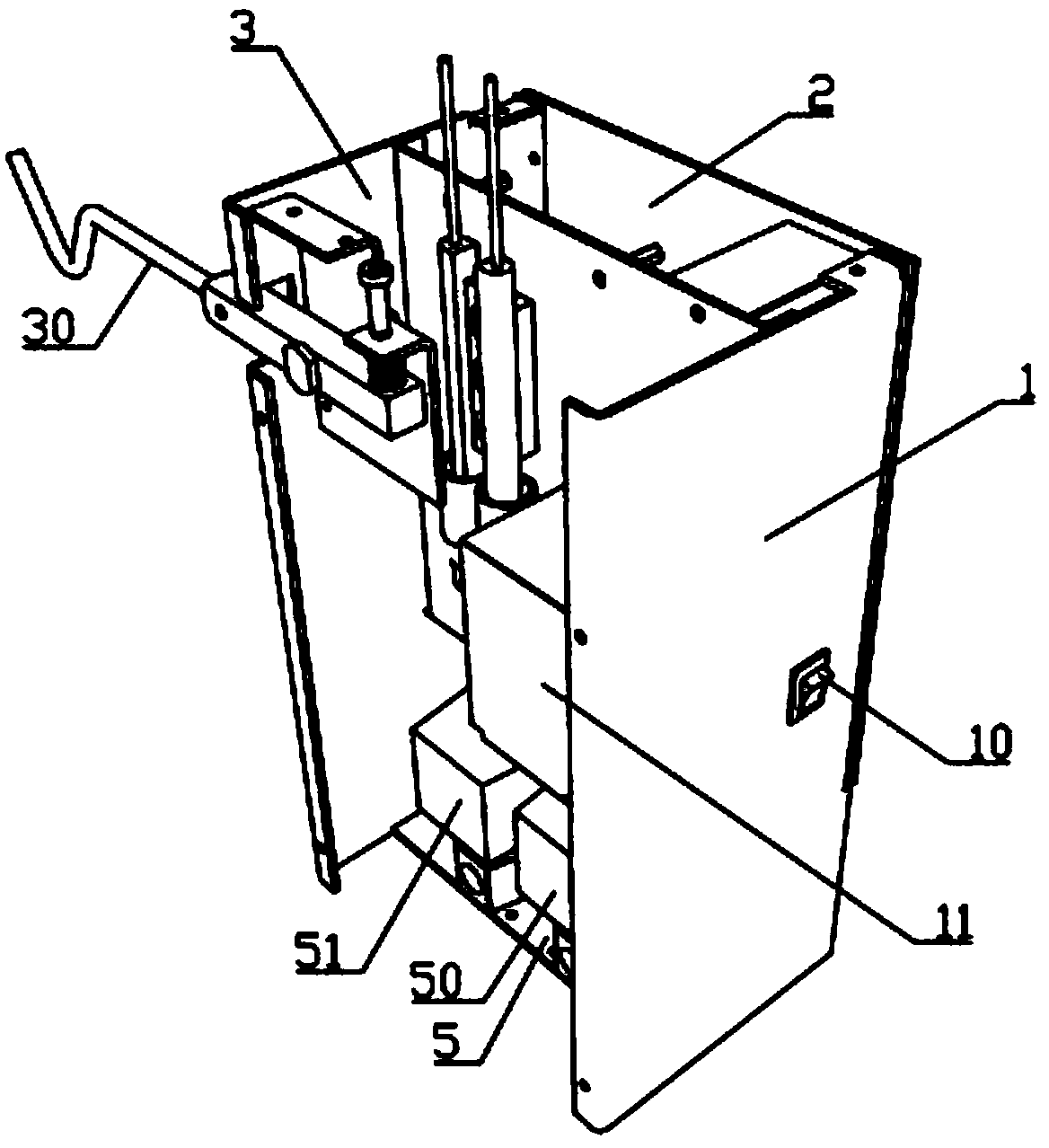

Automatic ignition and flameout gas-saving ignition device

The invention belongs to the technical field of welding and particularly relates to an automatic ignition and flameout gas-saving ignition device. The device comprises a right side panel, a rear sidepanel, a left side panel and an L-shaped panel, wherein the right side panel, the rear side panel, the left side panel and the L-shaped panel are detachably connected and constructed into a box-shapedstructure with the lower portion being open; the right side panel is provided with a switch, a partition plate is connected to the upper middle portion between the right side panel and left side panel, and a controller is arranged on the partition plate; a gap is formed in the upper portion of the front end of the left side panel; a hook assembly is arranged at the position, corresponding to thegap, of the upper portion of the inner wall of the right side panel, and the hook assembly is provided with a vertical plate, a pin, a strip and a hook; the left end of the vertical plate is fixedly connected to the inner wall of the left side panel, the left top end of the vertical plate is vertically folded forward to form a left platform while the right top end of the vertical plate is vertically folded forward to form a right platform; a guiding pillar penetrates through the middle portion of the right platform; and the lower end of the guiding pillar is sleeved with a spring.

Owner:佛山市泓实机械制造有限公司

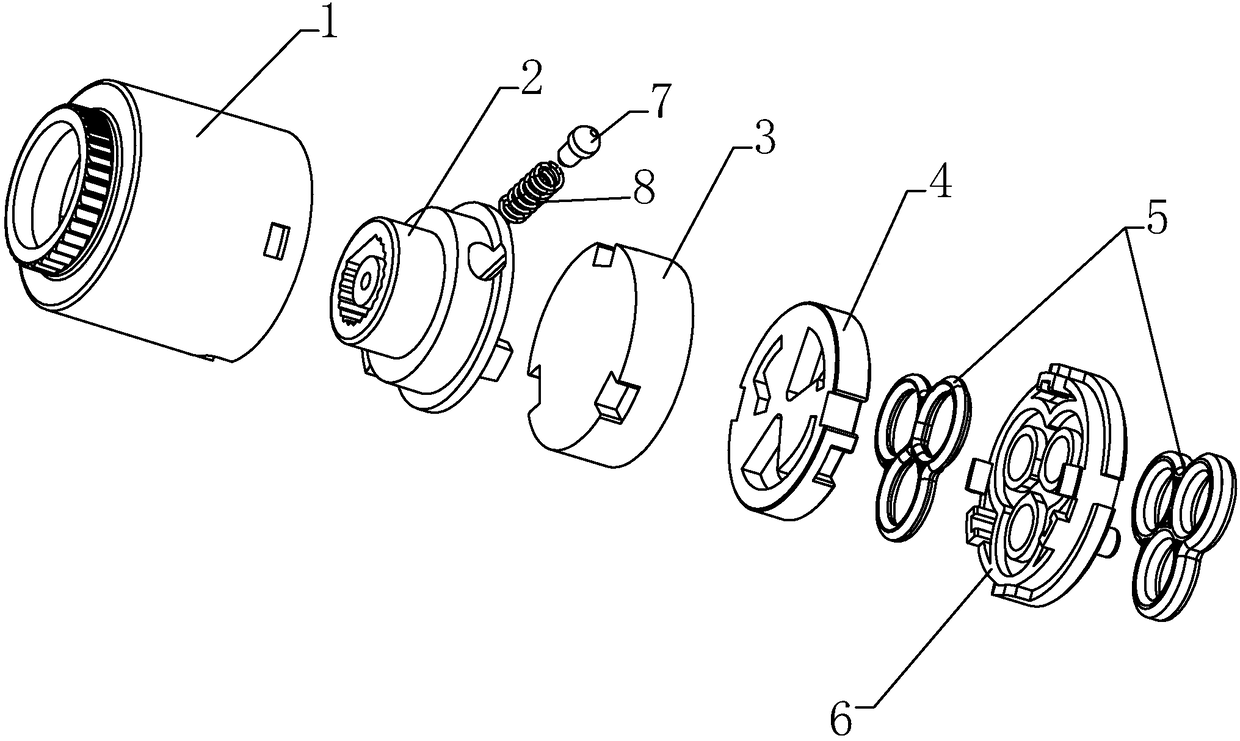

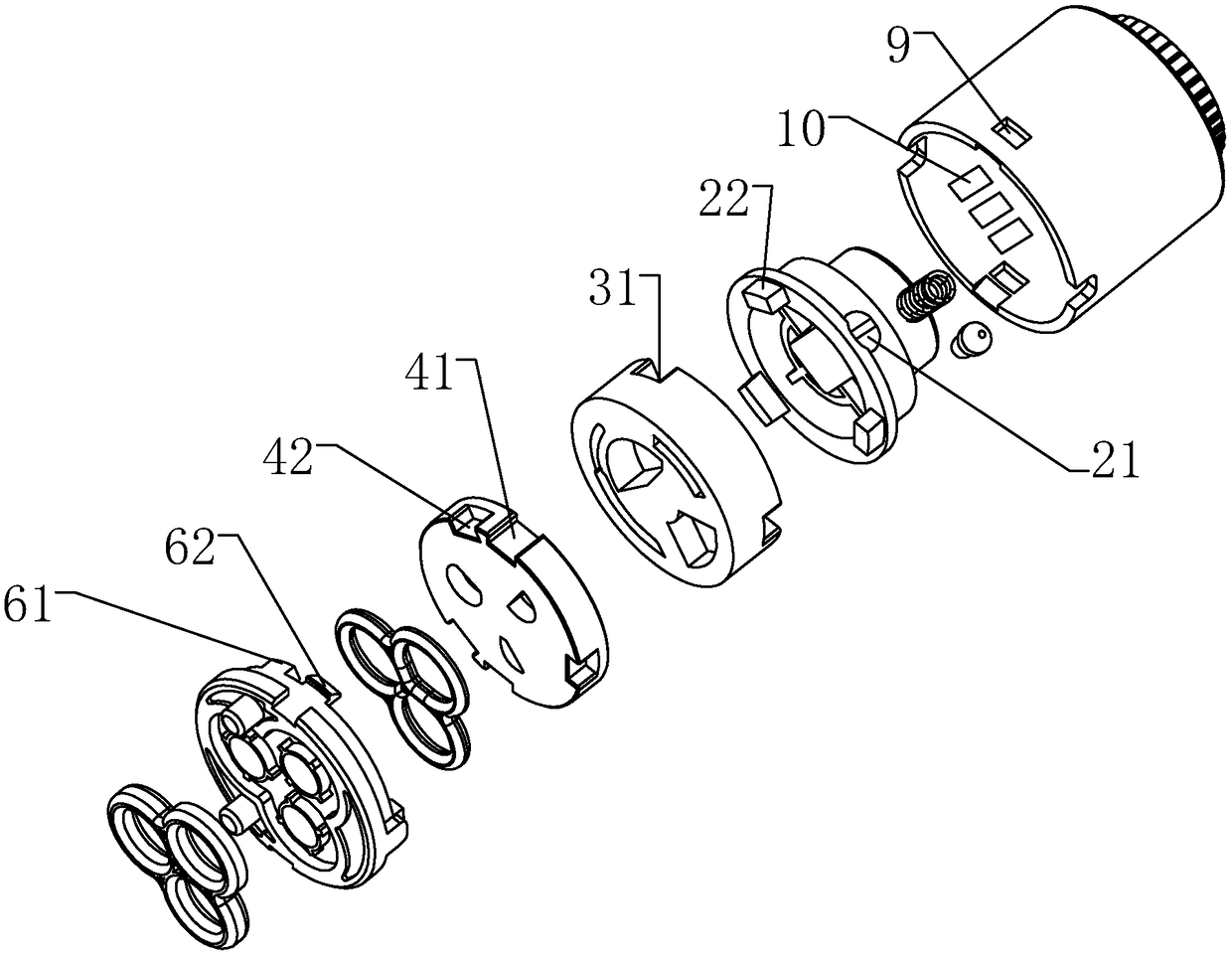

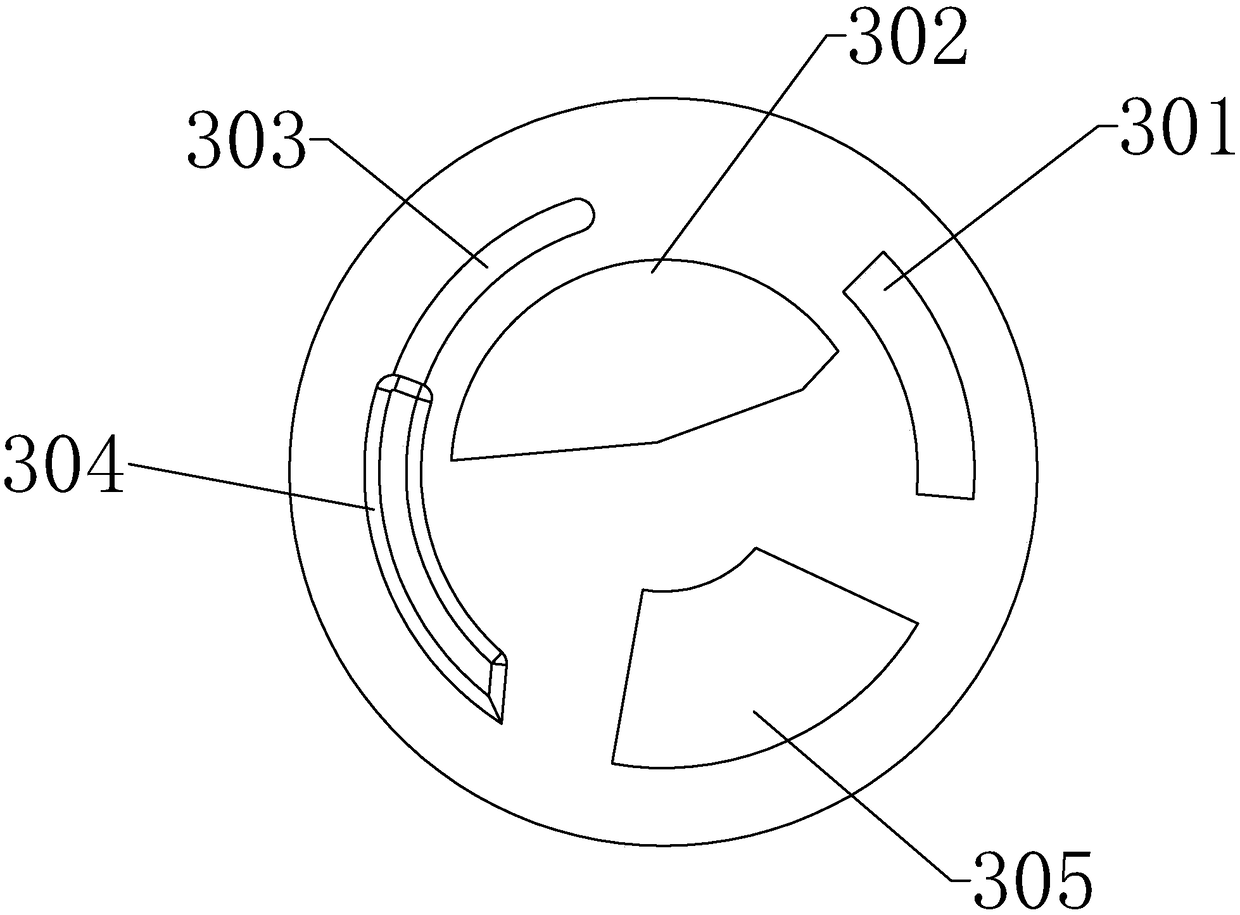

Anti-dry-burning electric heating faucet valve element and faucet made of same

The invention discloses an anti-dry-burning electric heating faucet valve element and a faucet made of the same and relates to electric heating faucets and components thereof. An upper ceramic wafer of the valve element is matched with a rotor in a buckled manner; a lower ceramic wafer is fixedly buckled to a flat foot base, and the flat foot base is fixedly buckled to an outer shell; and a cold water flow control groove, a pressure input groove, a pressure relief groove and a hot water flow control groove which are formed in the upper ceramic wafer are matched with a water inlet slotted hole,a water tank communicating slotted hole and an adhesive film cavity slotted hole which are formed in the lower ceramic wafer in a rotary manner, so that cold water and hot water are controlled. The anti-dry-burning electric heating faucet valve element is applicable to all the current electric heating faucets which are under water pressure control. A switching valve is connected with the rotor ina rotary manner and can only be switched on in one direction. The faucet outputs the cold water in the first place and then slowly conducts heating to output the hot water, and the scald risk is avoided; and therefore, when heating is conducted through electric heating tubes, the water tank is filled with water all the time, and the dry-burning phenomenon is avoided. The pressure relief groove isadopted to effectively cut off a switch in the adhesive film cavity slotted hole, and in other words, work of the electric heating tubes is cut off; and furthermore, the dry-burning phenomenon is stopped.

Owner:ZHEJIANG CHIXIN IND CO LTD

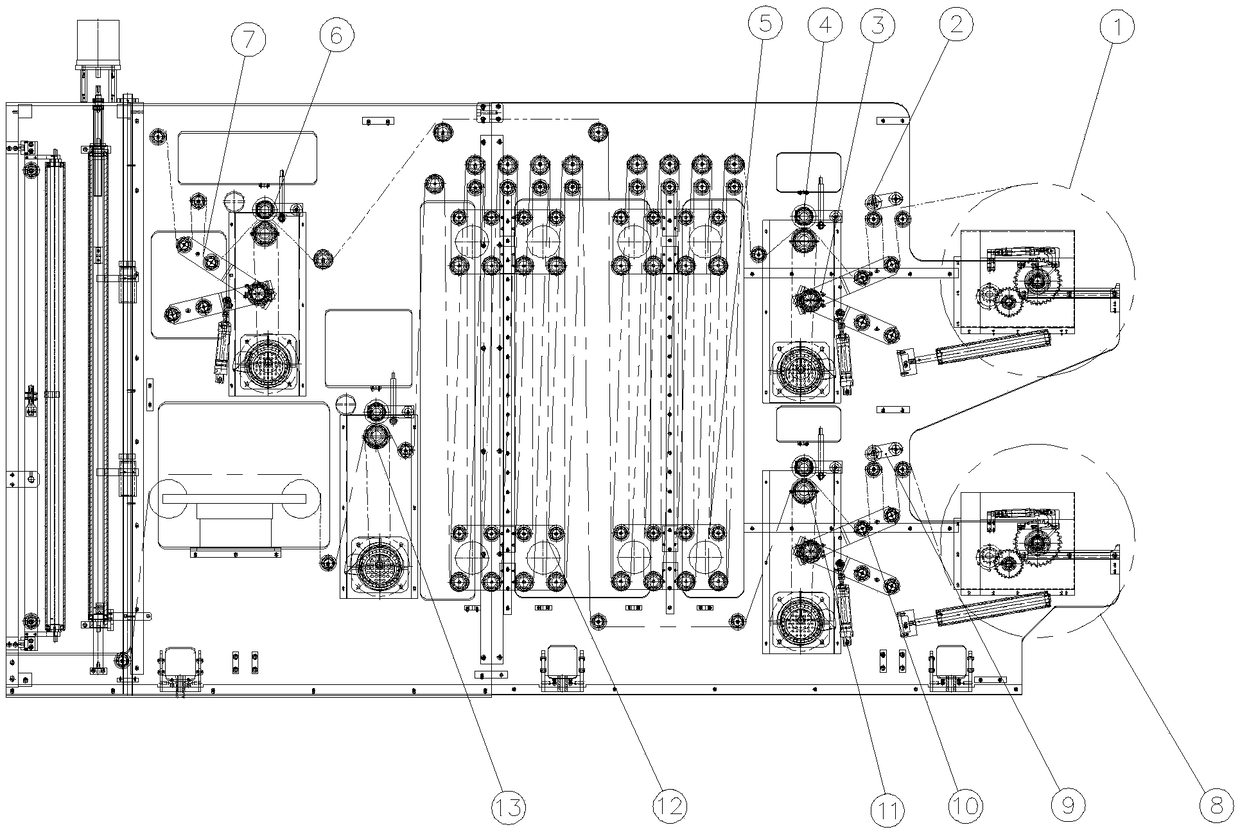

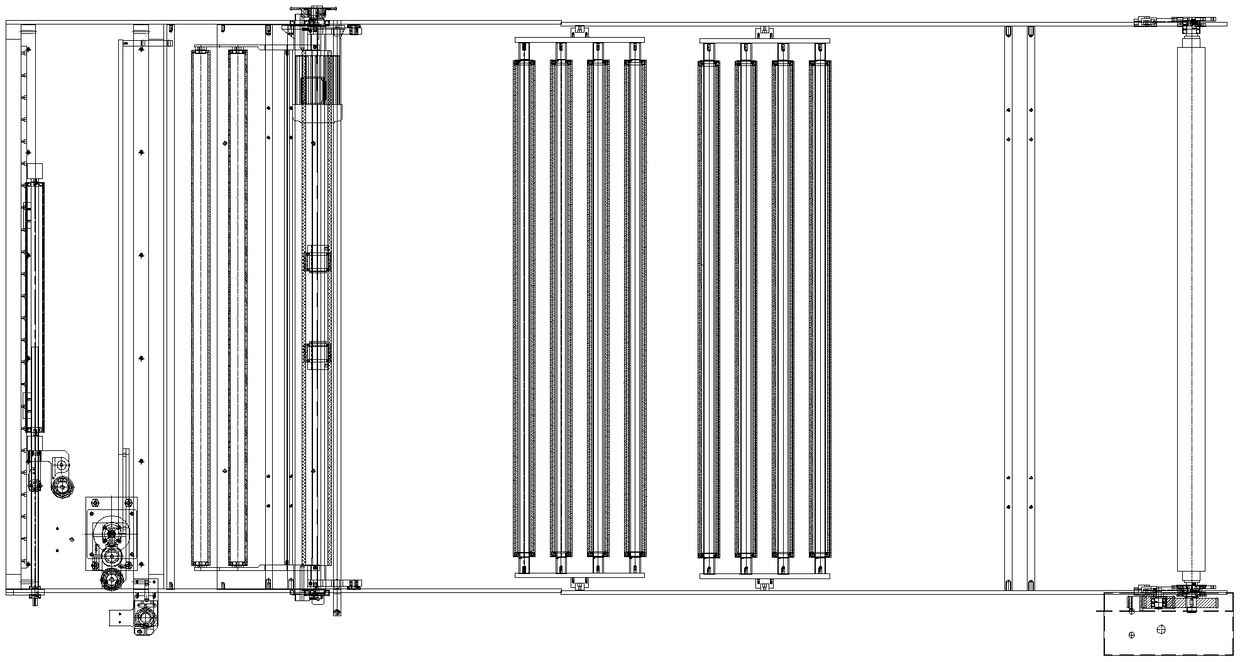

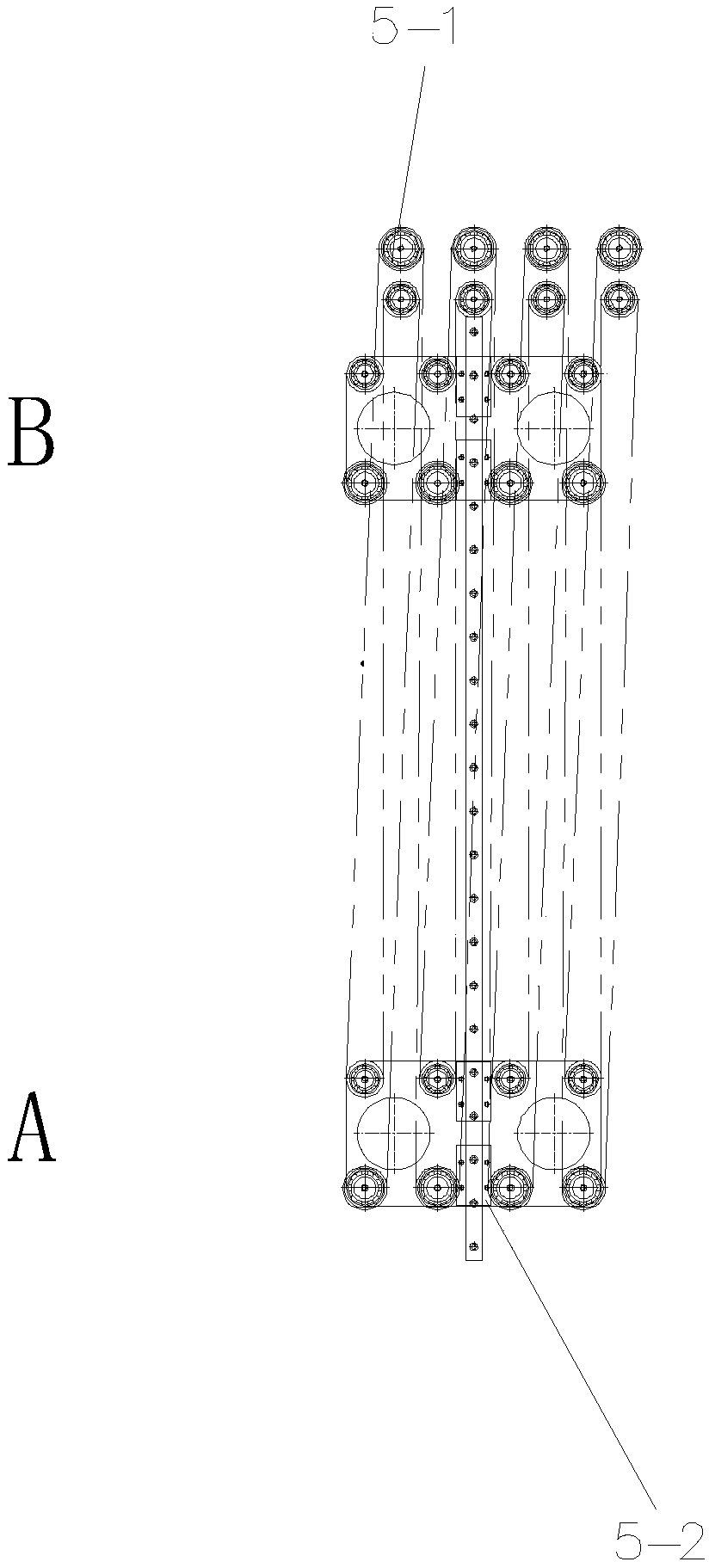

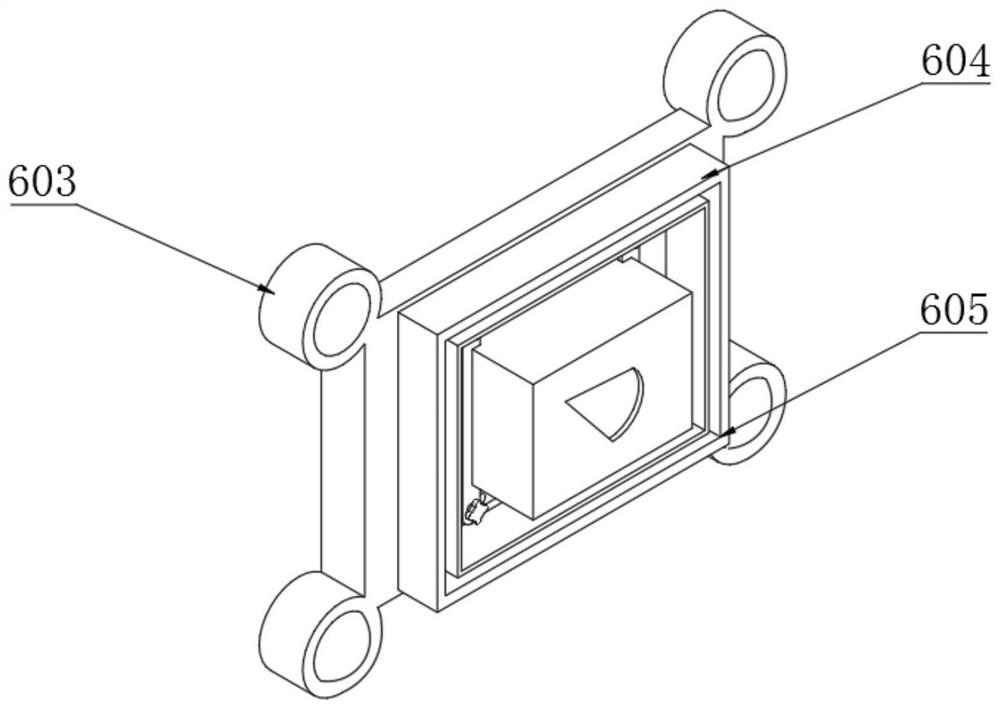

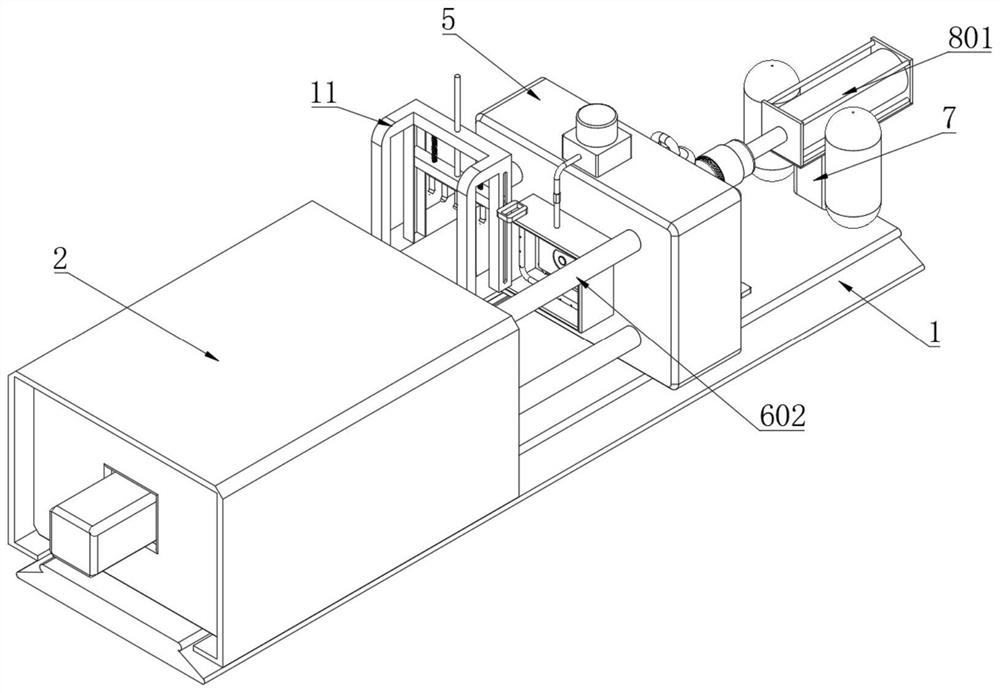

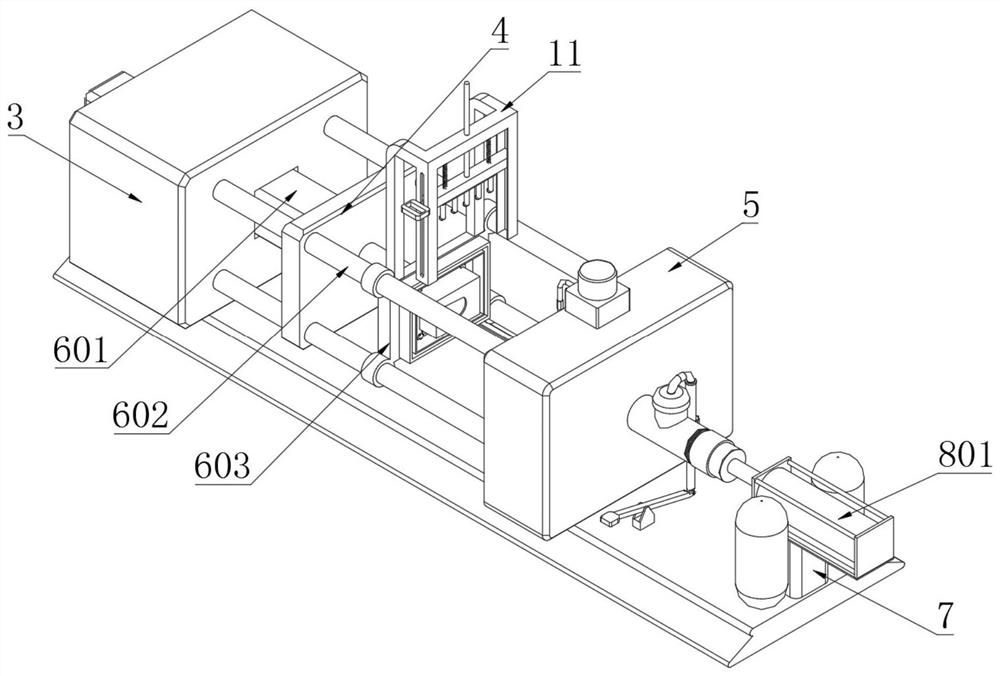

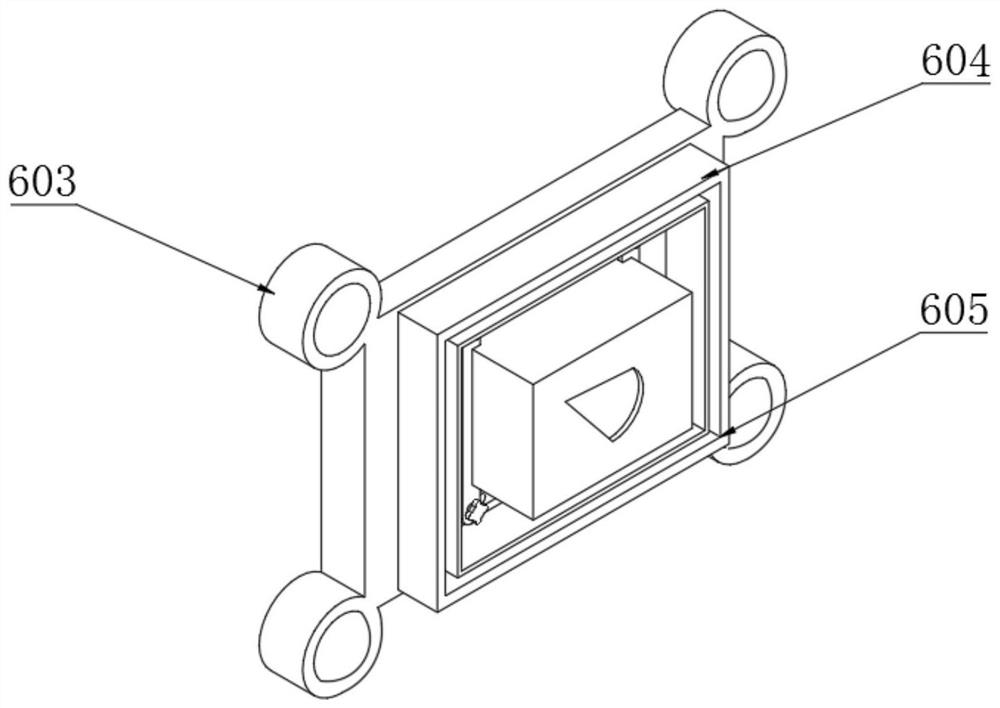

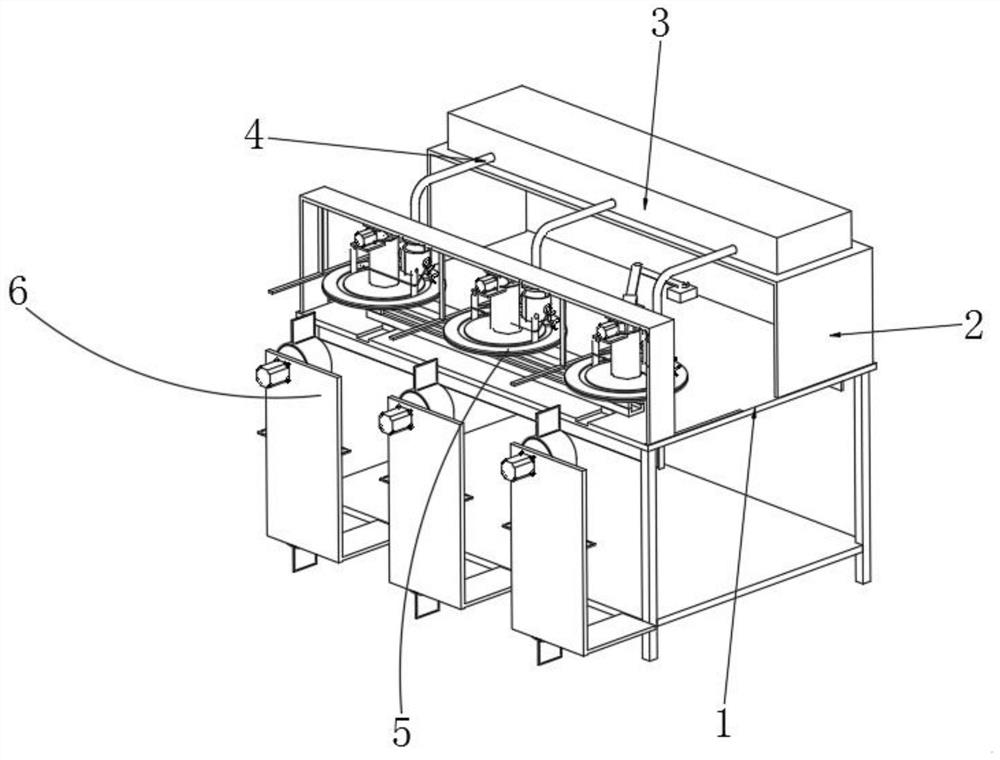

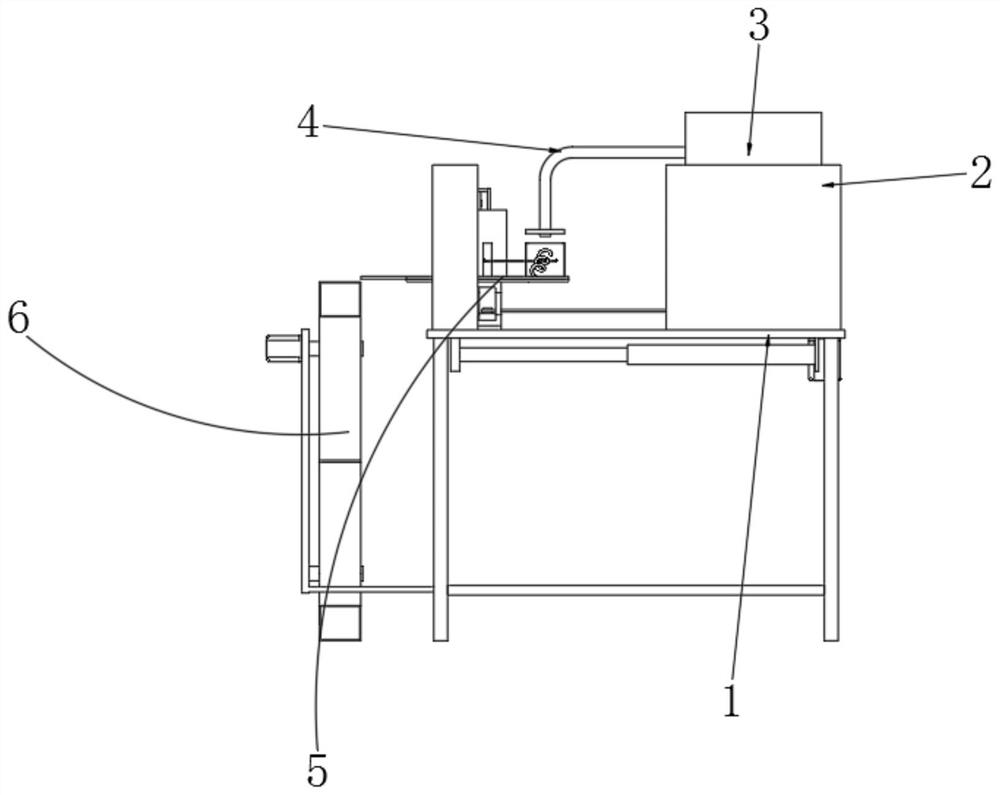

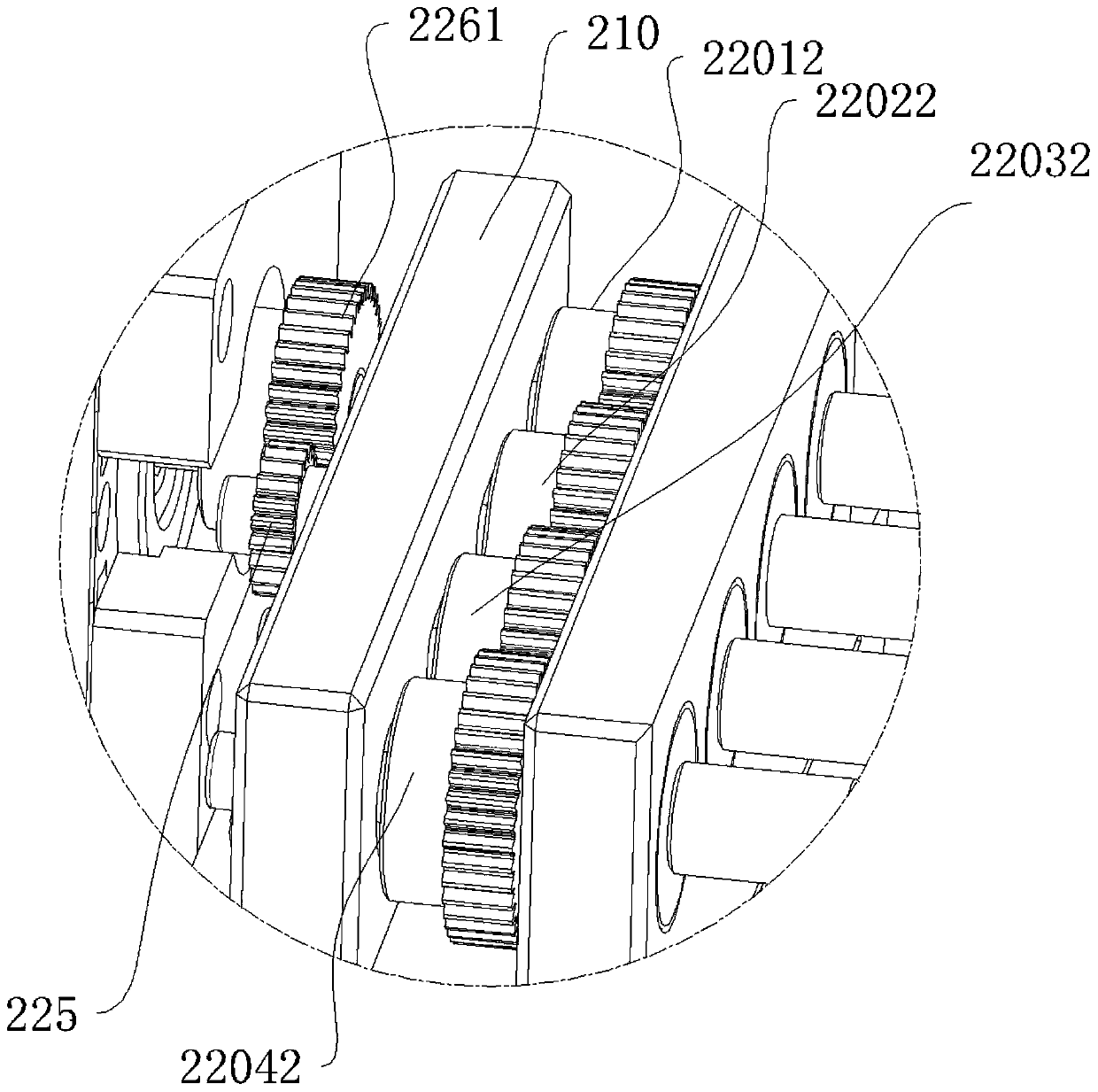

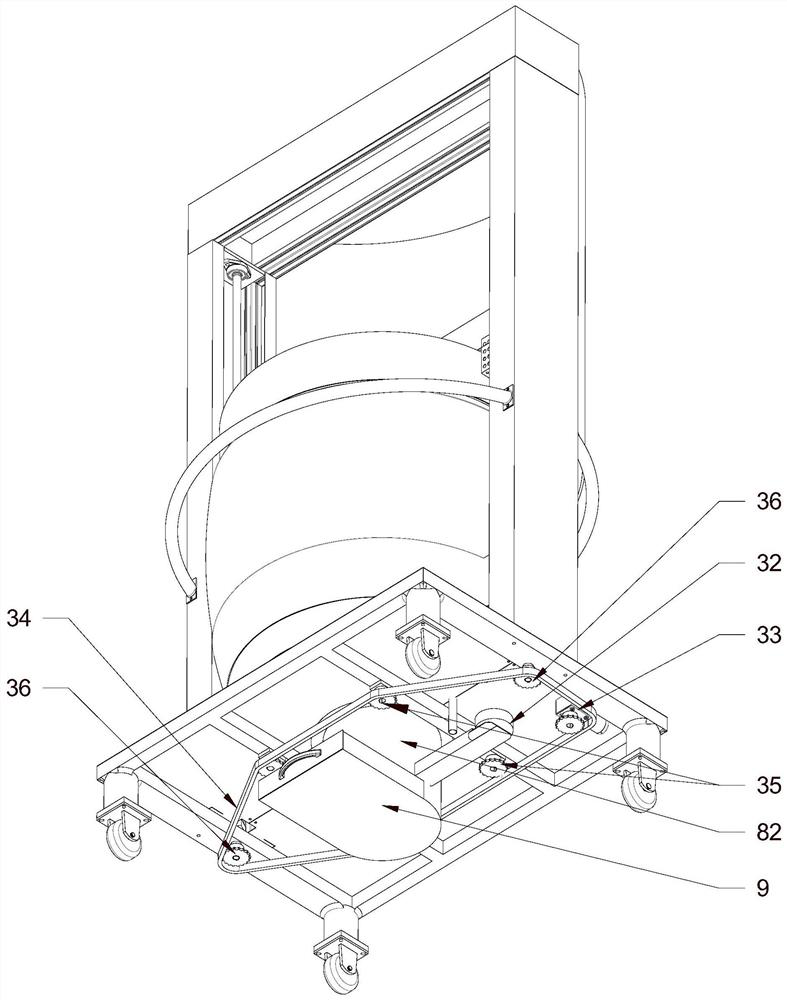

Double-emptying double-storing non-stop material connecting device

InactiveCN108792720ANo risk of burnsReduce wasteBag making operationsPaper-makingEngineeringMechanical engineering

The invention discloses a double-emptying double-storing non-stop material connecting device, and particularly relates to the field of the packaging and bagmaking industry. An upper film unwinding device is in transmission connection with an unwinding pneumatic shaft through a gear; an encoder is arranged on the rear side of the upper film unwinding device; a first swing arm, a continuous tractiondevice, a storage device, a traction device and a second swing arm are sequentially connected through a film coil; a lower film unwinding device is arranged under the upper film unwinding device andcomprises a lower encoder, a lower swing arm, a lower continuous traction device, a lower storage device and a lower traction device; and the lower encoder, the lower swing arm, the lower continuous traction device, the lower storage device and the lower traction device are sequentially connected through a film coil. According to the device, storage structures are arranged in the upper unwinding device and the lower unwinding device, and the machine has no need to be shut down when a film is replaced, so that the risk of scaling the film on the machine can be avoided, the waste is reduced, andthe production cost is reduced.

Owner:巨鼎机械(上海)有限公司

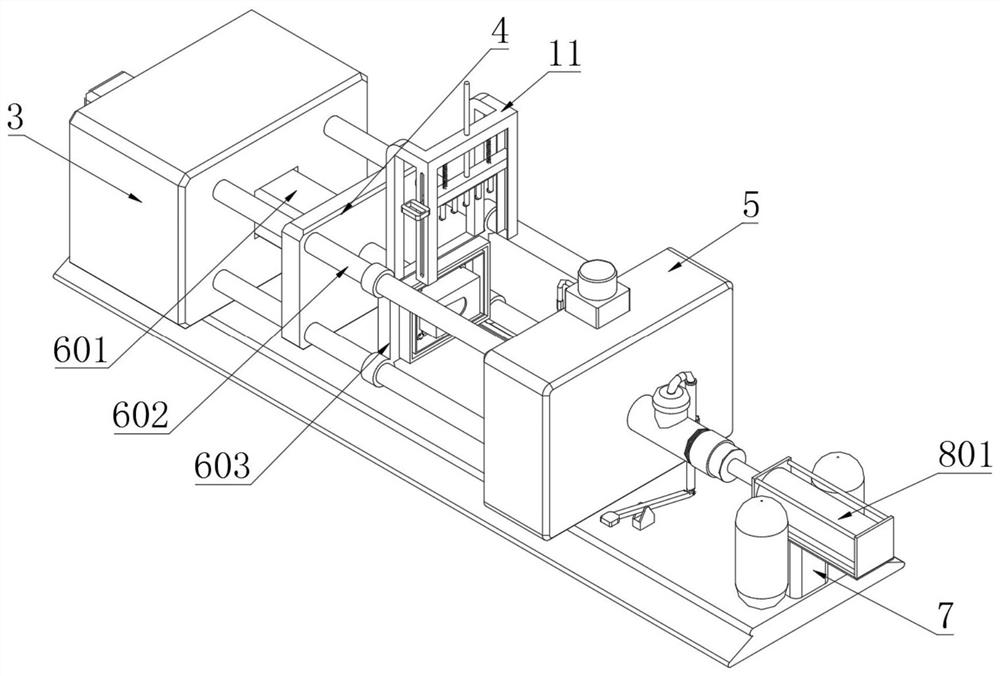

Die-casting forming equipment facilitating exhausting and used for thin-walled workpiece machining

The invention discloses die-casting forming equipment facilitating exhausting and used for thin-walled workpiece machining, the die-casting forming equipment comprises a base, a fixing base is fixedlyinstalled on the side, away from a protective shell, of the top end of the base, an exhaust assembly is installed on the side end face of the fixing base, a sealing box is fixedly welded to the end face, close to a control box, of the fixing base, an annular air suction pipe is embedded into the inner side of the sealing box, an exhaust pipe is fixedly connected to the outer side of the top of the annular air suction pipe, and an air extracting pump is fixedly installed at the top end of the fixing base. The die-casting forming equipment is scientific and reasonable in structure and safe andconvenient to use, the sealing box and a sealing block can be clamped into a whole by being closed, and moreover, the annular air suction pipe and air suction holes are uniformly distributed in the inner side of the sealing box, so that the exhaust efficiency can be improved, air can be prevented from flowing back into the sealing box, air in a die during die casting can be effectively avoided, sand holes and air holes in a formed die casting are avoided, and the success rate of die casting is increased.

Owner:江苏富航钢结构有限公司

Method for combining multiple brow-streaking needles into a whole

InactiveCN1149054CEfficient workReduce human errorSurgeryPackaging toiletriesBiomedical engineeringEngineering

A method for combining multiple brow-streaking needles into a whole includes putting a refractory plate with through hole on a refractory pad, clamping them together, putting short needles in through hole, wrapping, the another end of short needles by a thermoshrinking sleeve tube, inserting a long needle to make the tips of short and long needles in a line, heating in oven to make the needles close, inserting the needles group in a locating hole, and point welding.

Owner:黄得时

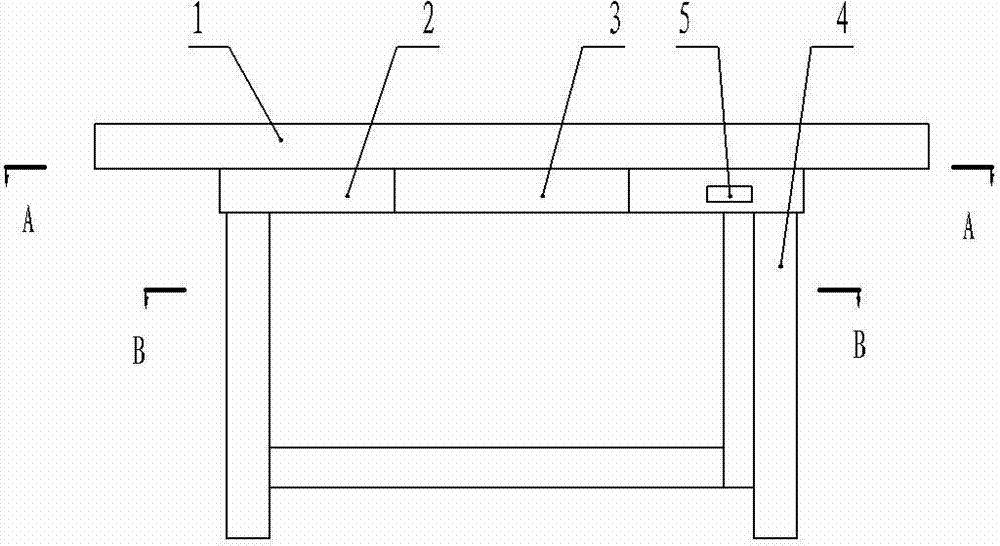

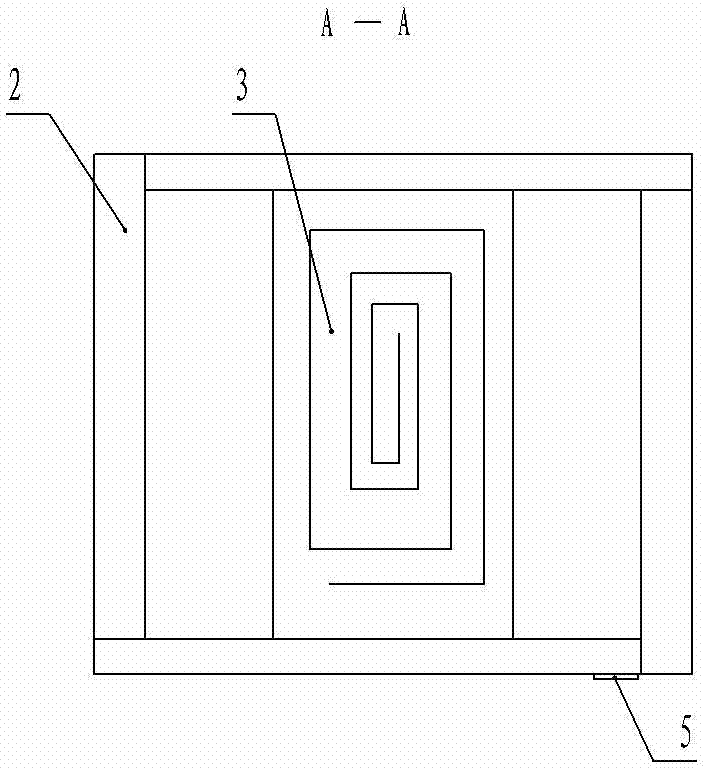

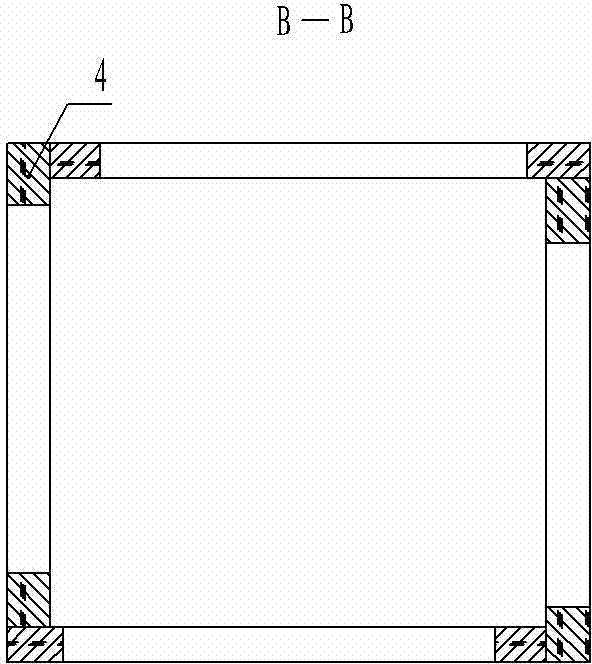

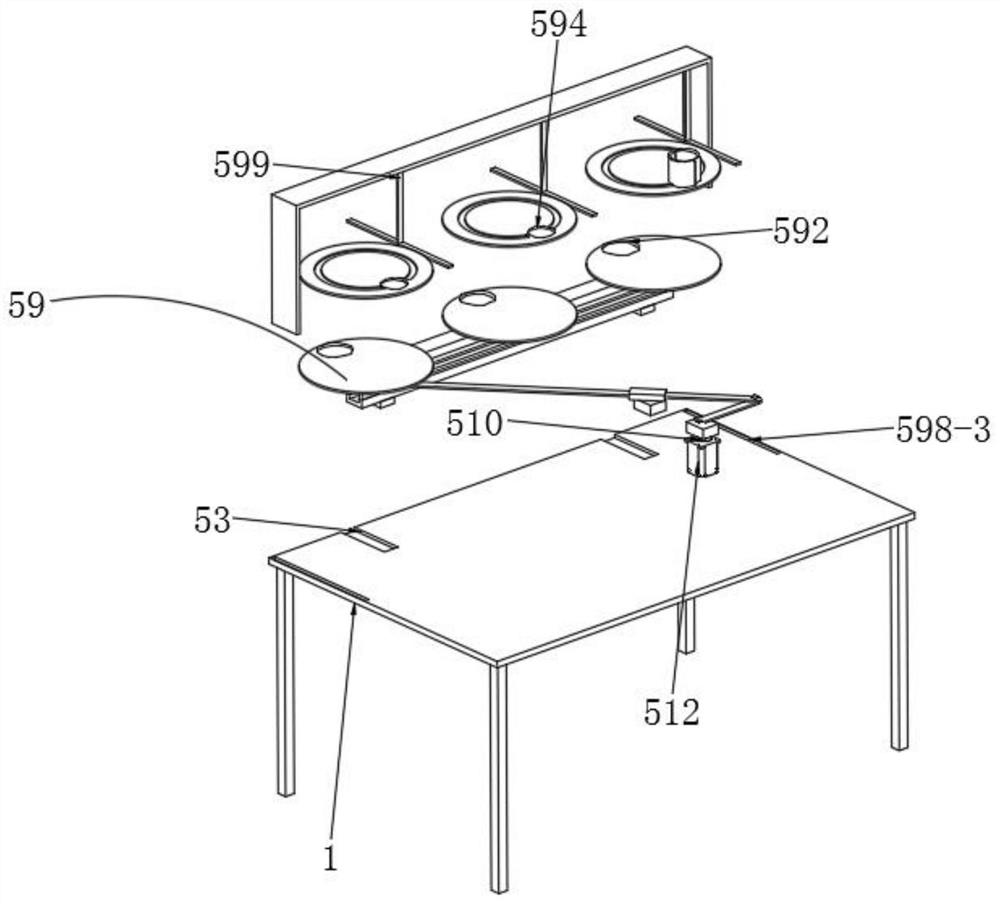

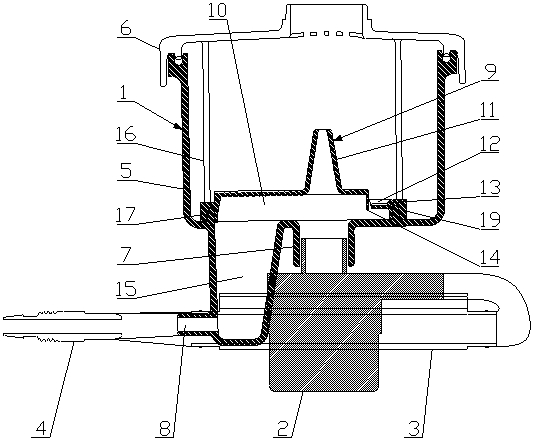

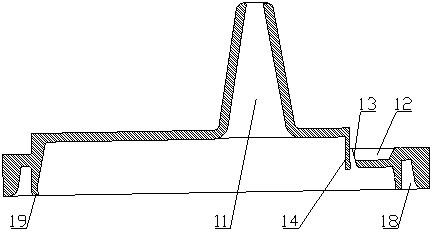

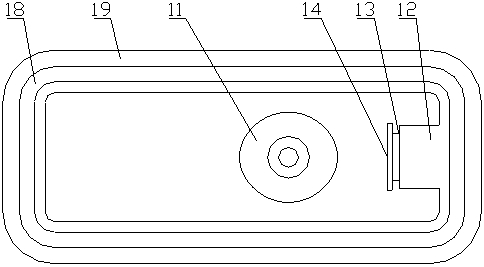

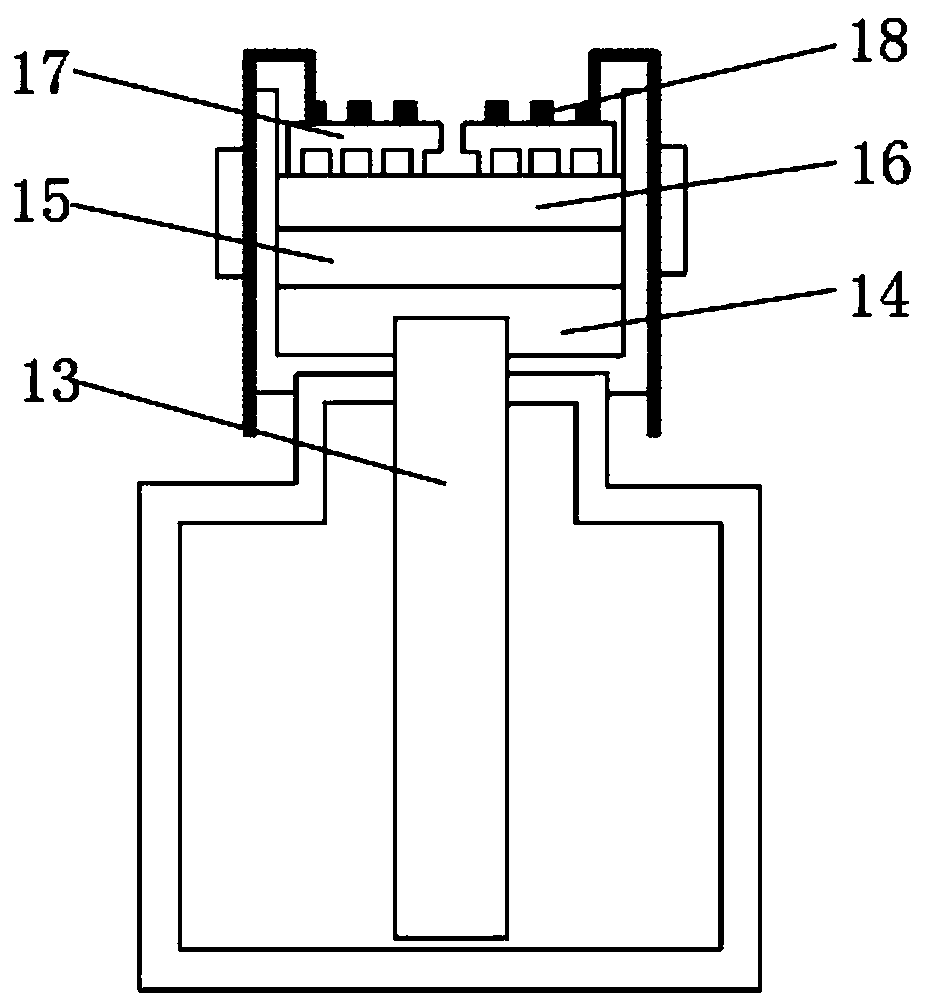

Induction hot pot table

InactiveCN103584505AImprove heating efficiencyNo risk of burnsFoldable tablesStowable tablesArchitectural engineeringInduction cooking

The invention discloses an induction hot pot table and relates to the technical field of tableware. The induction hot pot table comprises a tabletop plate nd a support table rack. An electromagnetic heater is disposed between the tabletop plate and the support table rack and fixed in a support frame. The support frame is movably pressed onto the support table rack in a sleeving manner. The tabletop plate is pressed onto the support frame in a sleeving manner. The bottom of the tabletop plate is tightly attached to the electromagnetic heater. Through the application of the induction hot pot table, the problems that dining with an induction cooker as a hot pot heat source is inconvenient and is adverse to cleaning the tabletop of the dining table are solved.

Owner:李新

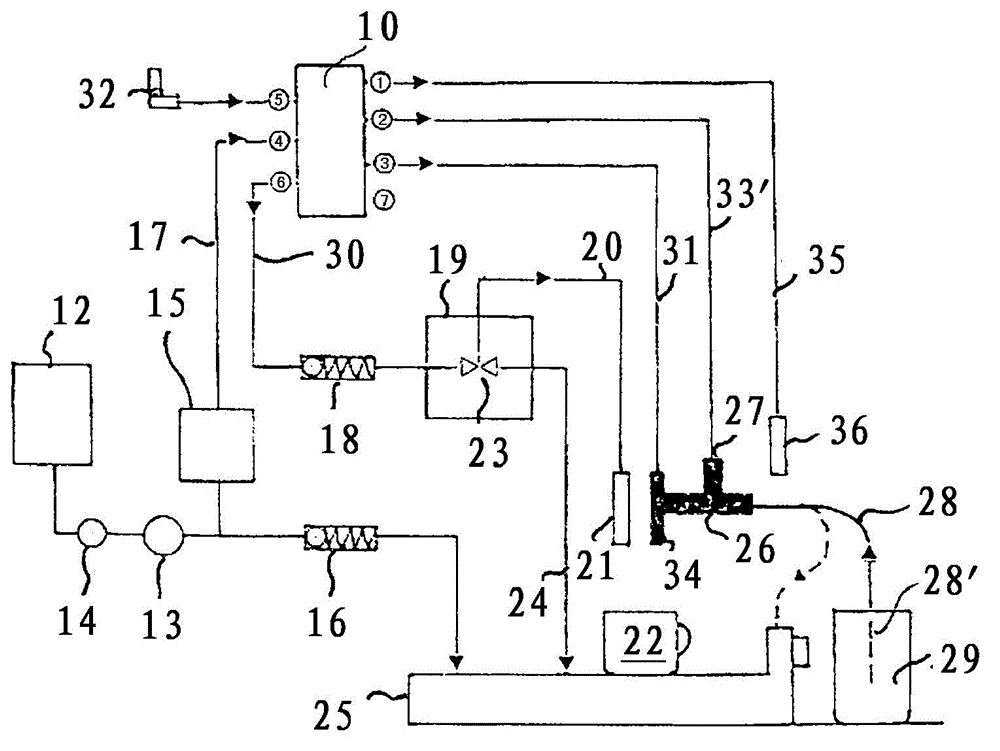

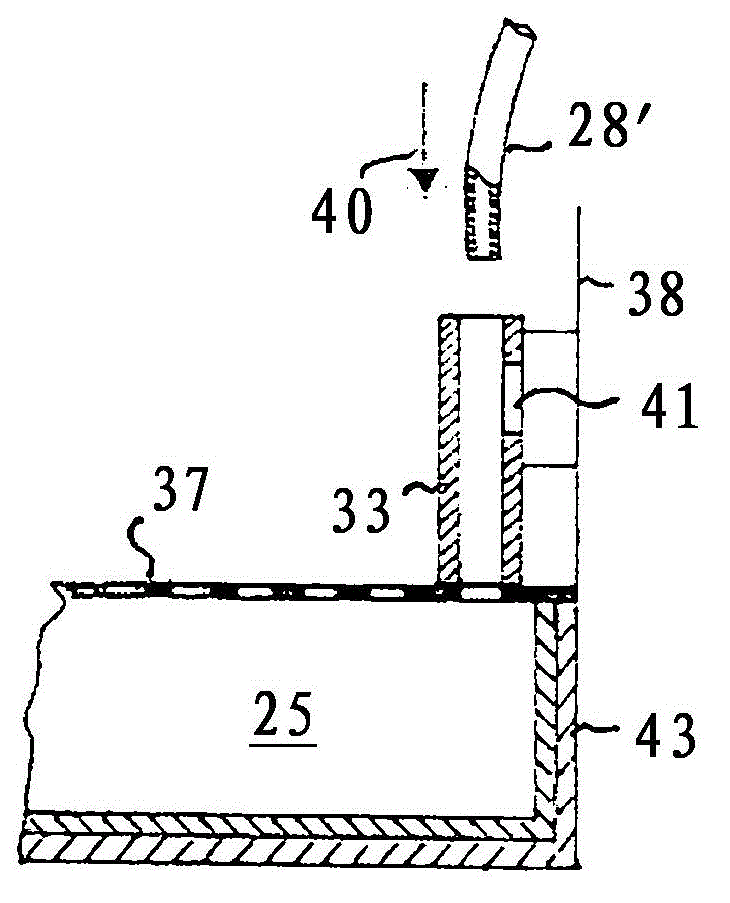

Coffee machine with frothing device and method for cleaning milk suction line

#CMT# # / CMT# The coffee machine has a foaming device (26), in which an inner milk channel to a foaming chamber is provided. The rinsing water from the continuous-flow water heater (15) is conveyed to a bypass air inlet (27) of the foaming device through a controlled valve assembly. The milk inlet end (28') of the milk inlet pipe (28) is directly or indirectly connected with a residual water dish (25) of the coffee machine in a fluid conducting manner. #CMT# : # / CMT# An independent claim is also included for a method for rinsing a milk inlet pipe connected to a foaming device, particularly a coffee machine. #CMT#USE : # / CMT# Coffee machine, particularly fully automatic espresso machine. #CMT#ADVANTAGE : # / CMT# The rinsing water from the continuous-flow water heater is conveyed to a bypass air inlet of the foaming device through a controlled valve assembly, and the milk inlet end of the milk inlet pipe is directly or indirectly connected with a residual water dish of the coffee machine in a fluid conducting manner, and hence ensures simple structure and simple handling of the coffee machine without danger and effective cleaning and rinsing of the milk intake hose. #CMT#DESCRIPTION OF DRAWINGS : # / CMT# The drawing shows a schematic view of the functional elements of the coffee machine. 15 : Continuous-flow water heater 25 : Residual water dish 26 : Foaming device 27 : Bypass air inlet 28 : Milk inlet pipe 28' : Milk inlet end.

Owner:EUGSTER FRISMAG

Antistatic flame-retardant textile

InactiveCN101724965BImprove flame retardant performanceImprove spinnabilityWoven fabricsYarnYarnPolymer science

The invention provides antistatic flame-retardant textile which is weaved by antistatic flame-retardant yarn. The antistatic flame-retardant yarn is blended by modacrylic fiber with chloride and cotton fiber. The antistatic flame-retardant textile also can be weaved in such a way that conductive fiber is weaved in when the antistatic flame-retardant yarn is blended by modacrylic fiber with chloride and cotton fiber with conductive fiber. The antistatic flame-retardant textile further can be weaved by the antistatic flame-retardant yarn which is blended by modacrylic fiber with chloride, cotton fiber and conductive fiber. The invention has the advantages of low price, sot hand feel, good comfort, air permeability, permanent fire resistance, low content of formaldehyde, good strength and excellent antistatic performance.

Owner:汕头市奥山服饰有限公司

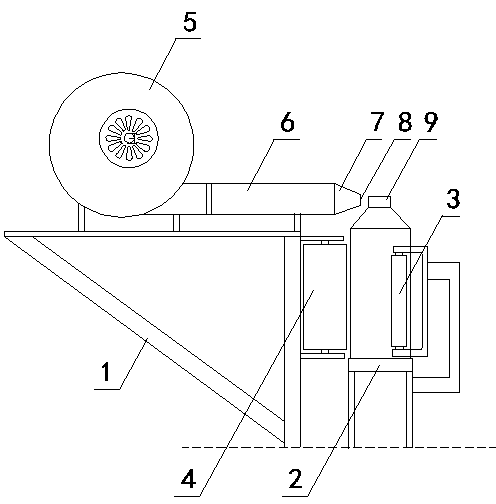

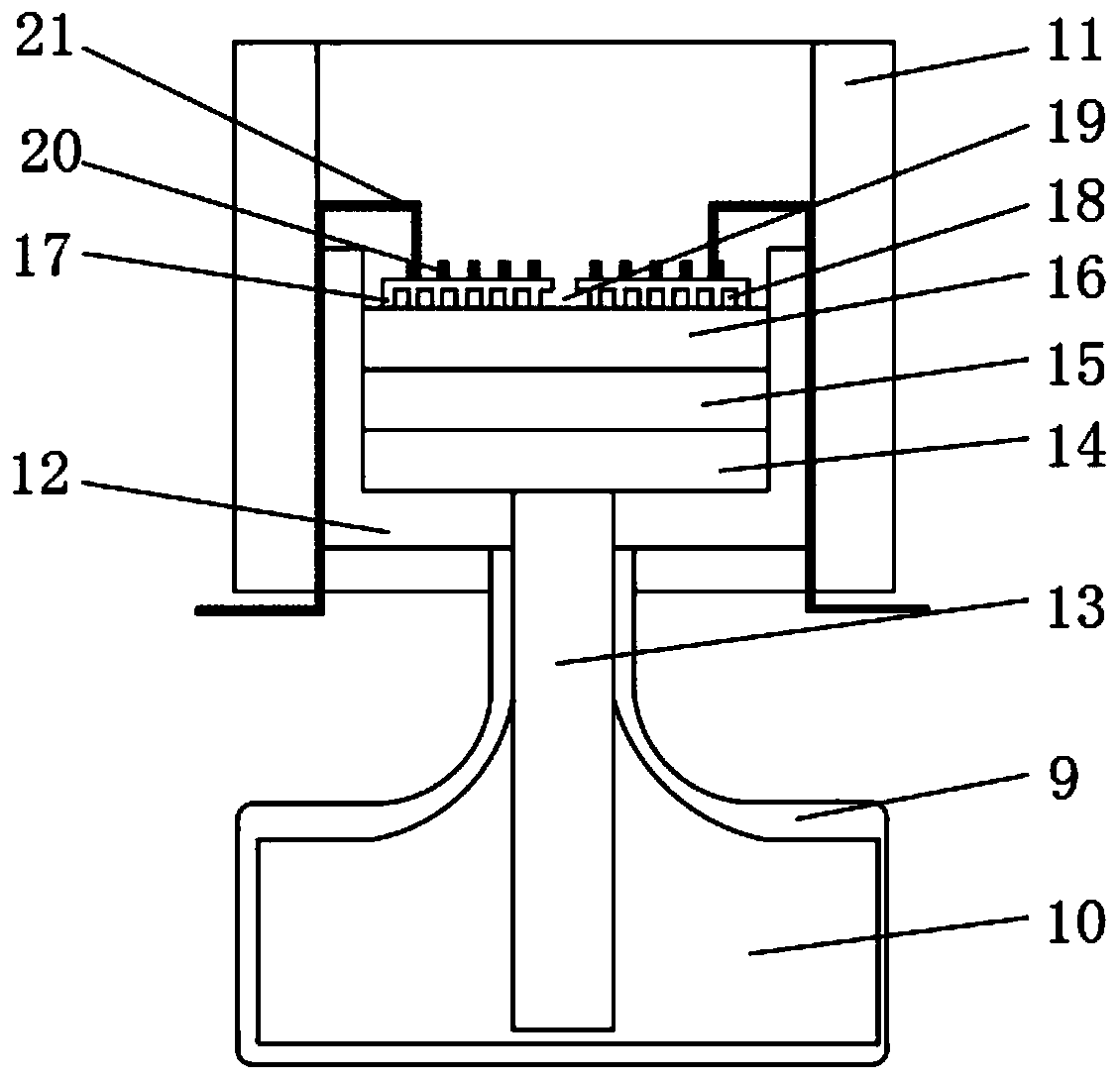

Electric heating Stirling engine

PendingCN108730068AImprove efficiency programNo risk of burnsHot gas positive displacement engine plantsElectricityEngineering

The invention discloses an electric heating Stirling engine. An electric heating device 5 is arranged at the inner bottom of a heating cylinder 20. An insulating heat-preservation material 12 is arranged at the outer bottom of the cylinder, and a piston 21 sliding in an airtight mode is arranged in the cylinder. The piston is hinged to a crankshaft 9 through a connecting rod 10. A piston 23 whichslides in an airtight mode and is hinged to the crankshaft 9 through a connecting rod 11 is arranged in an air cylinder 22. A cooler 7 is arranged on the outside of the air cylinder. The electric heating device 5 is electrified and working gas in the cylinder 20 is heated, a fly wheel 8 is started, the piston 21 and the piston 23 slide up and down along axes of the piston 21 and the piston 23 correspondingly, and the whole engine continues running. The electric heating device can also be arranged outside the cylinder, and the insulating heat-preservation material is used for wrapping the electric heating device and the cylinder, and it can be guaranteed that all electric energy can be converted into heat energy of the working gas. The electric heating Stirling engine has the characteristics that all the electric energy is converted into the heat energy of the working gas, the power of the Stirling engine can be obtained by testing the power of mechanical motion of the fly wheel and thelike, and the engine has experimental reference significance to improving of the design.

Owner:金虎杰

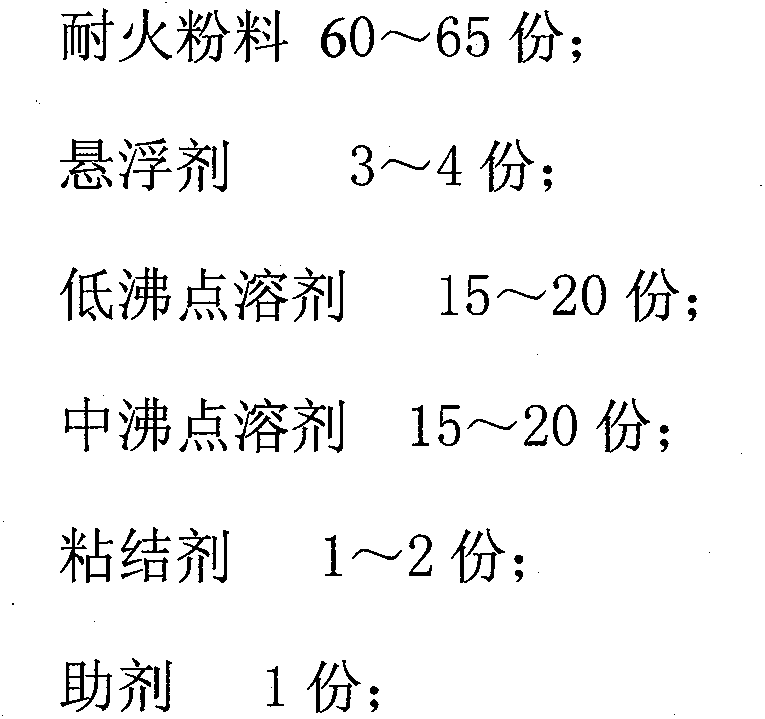

A kind of fast-drying alcohol-based spray casting coating and its spraying method

The invention discloses a quickly dried alcohol based spraying casting coating and a spraying method thereof. The quickly dried alcohol based spraying casting coating comprises the following components in parts by weight: 60-65 parts of fire resistant powder material, 3-4 parts of suspension agent, 15-20 parts of low boiling point solvent, 15-20 parts of medium boiling point solvent, 1-2 parts of bonding agent and 1 part of assistant. The quickly dried alcohol based spraying casting coating can fully meet the spraying usage requirement; according to different castings, different fire resistant materials are used so as to meet the production requirements of different castings.

Owner:杨俊新

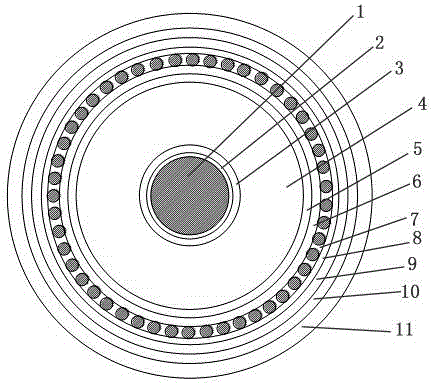

Lead sheath copper wire shielding composite high-voltage power cable

InactiveCN104966581ASolve the role of bearing single-phase fault short-circuit currentNo risk of burnsPower cables with screens/conductive layersInsulated cablesBuffer stripElectrical conductor

The invention discloses a lead sheath copper wire shielding composite high-voltage power cable. The lead sheath copper wire shielding composite high-voltage power cable includes a conductor, the conductor and a semiconductive belting, a conductor shielding layer, an insulating layer and an insulation shielding layer which adopt a four-layer structure form an insulating wire core, the insulating wire core is wrapped by a semicondcutive buffer strip of a thickness of 0.5mm, a copper wire shielding tape is woven outside the semiconductive buffer strip and is wrapped by a semiconductive buffer water-blocking tape, then a lead sheath is extruded outside the semiconductive buffer water-blocking tape, finally an outer sheath is extruded, and a surface of the outer sheath is coated with a graphite layer. Starting from cost saving and environmental pollution, the invention designs the lead sheath copper wire shielding composite high-voltage power cable under the condition of satisfying extra-high-voltage cable laying environment, effectively solves the problem that the shielding layer bears the function of single-phase fault short-circuit current, and can also bear tensile force that needs bearing in vertical laying, and the biggest advantage is that in a production process, a risk of burning a main insulating wire core does not exist, thereby guaranteeing product quality and service life.

Owner:WUXI SHUGUANG CABLE

A die-casting equipment for processing thin-walled parts with convenient exhaust

The invention discloses a die-casting molding equipment for processing thin-walled parts which is convenient for exhausting. It includes a base. A fixing seat is fixedly installed on the side of the top of the base away from the protective shell, and an exhaust assembly is installed on the side end surface of the fixing seat. The end face of the fixed seat close to the control box is fixedly welded with a sealed box, an annular suction pipe is embedded in the inner side of the sealed box, and an exhaust pipe is fixedly connected to the outer position of the top of the annular suction pipe. An air suction pump is fixedly installed on the top of the air pump. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. By closing the sealing box and the sealing block, the two can be clamped into a whole, and because the inner side of the sealing box is evenly arranged with annular air suction The pipe and air suction hole can improve the exhaust efficiency, prevent the air from flowing back into the sealed box, effectively avoid the air in the mold during die casting, and ensure that the molded die casting will not have trachoma and pores, which improves the success rate of die casting.

Owner:江苏富航钢结构有限公司

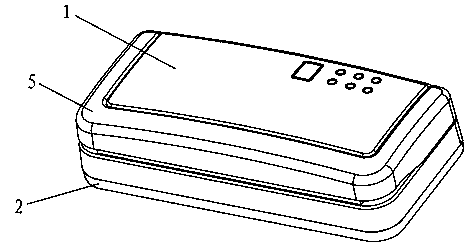

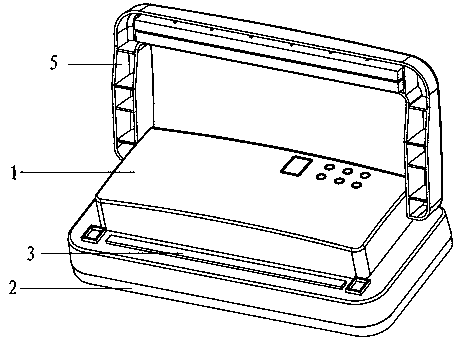

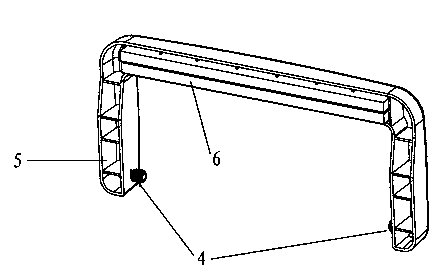

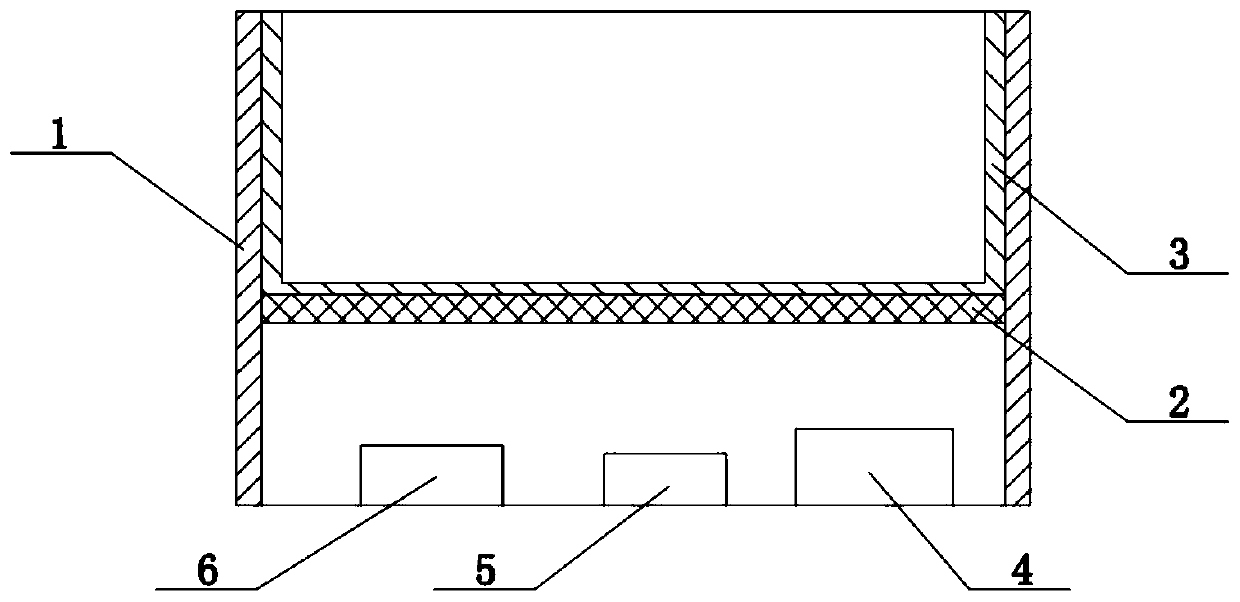

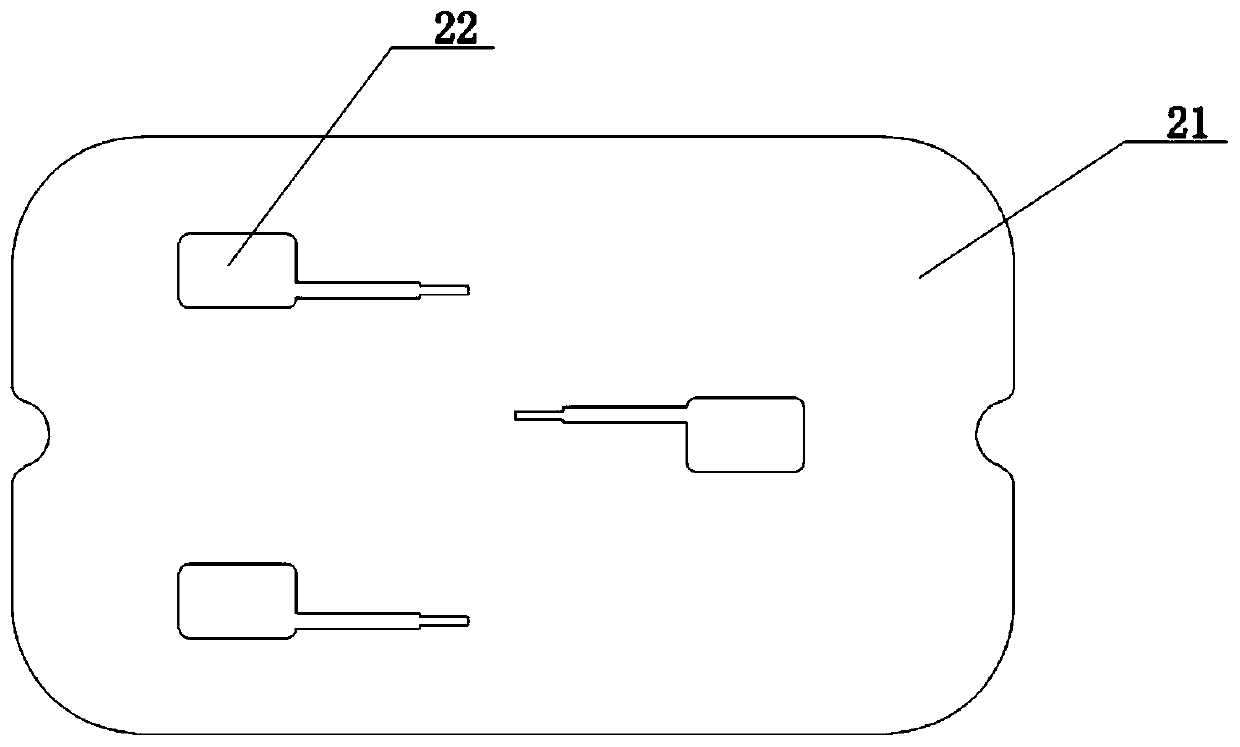

Small vacuum packaging machine

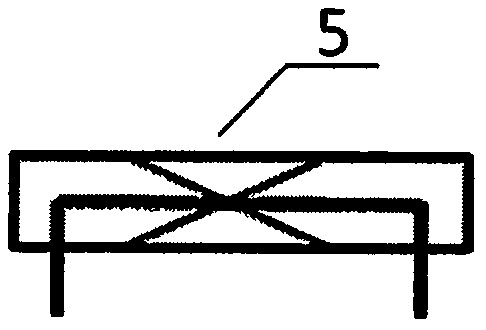

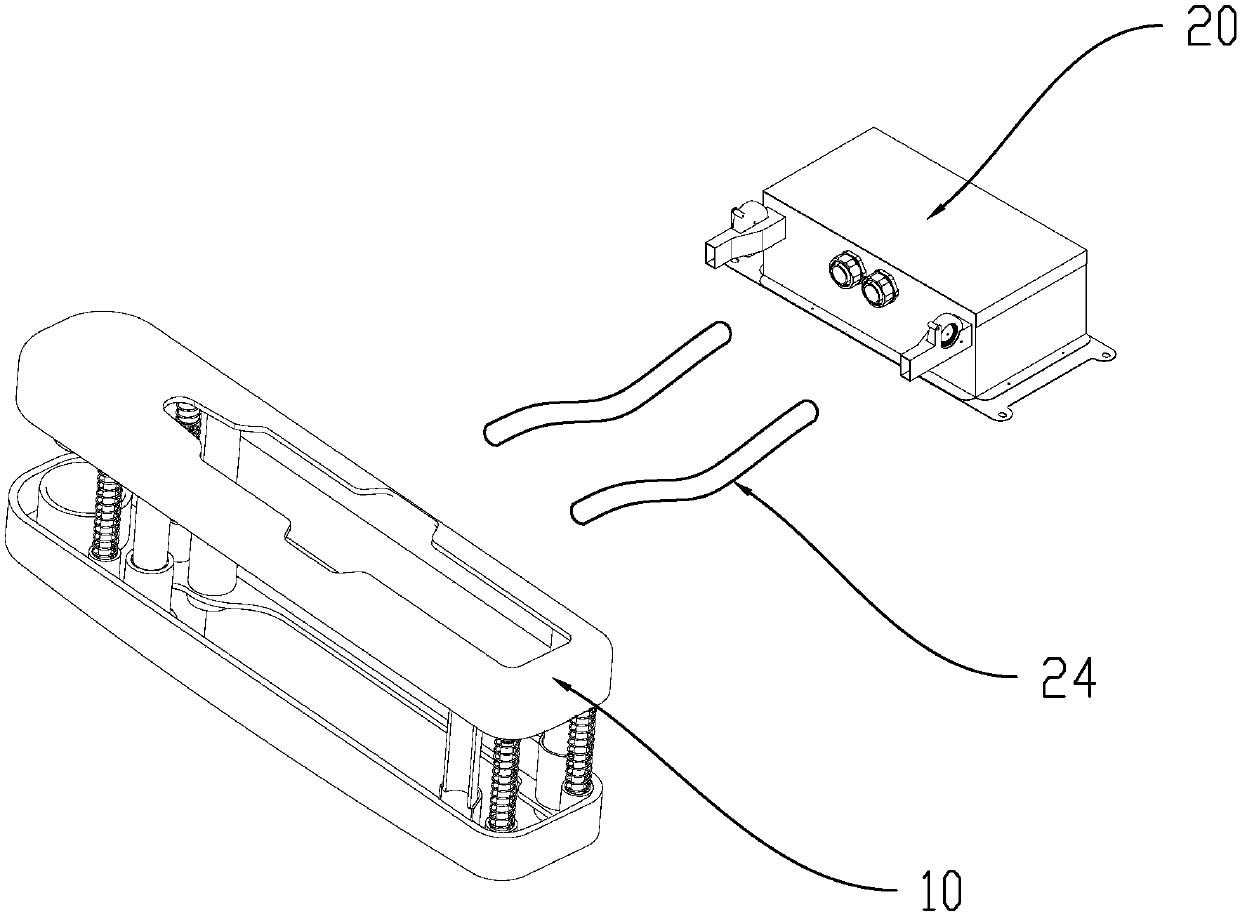

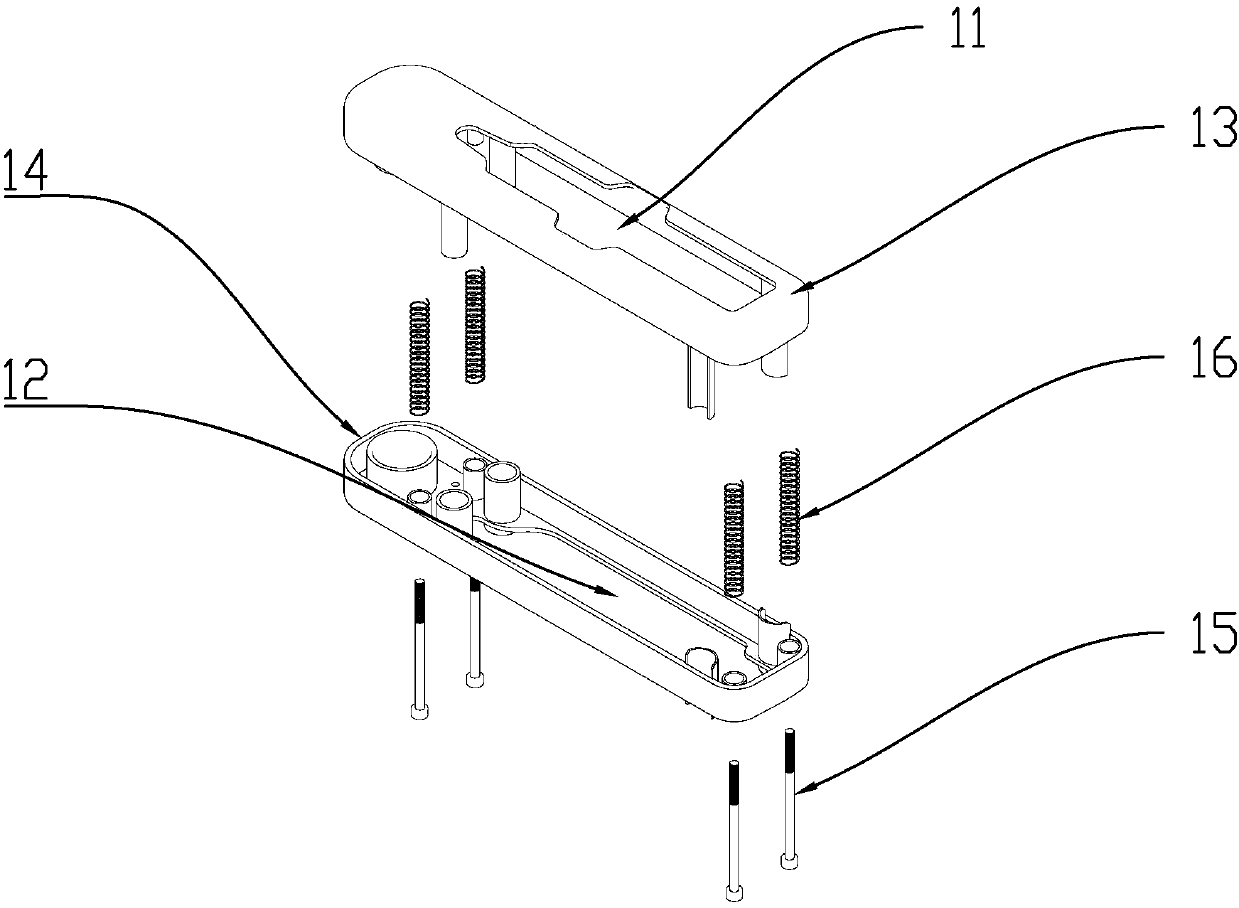

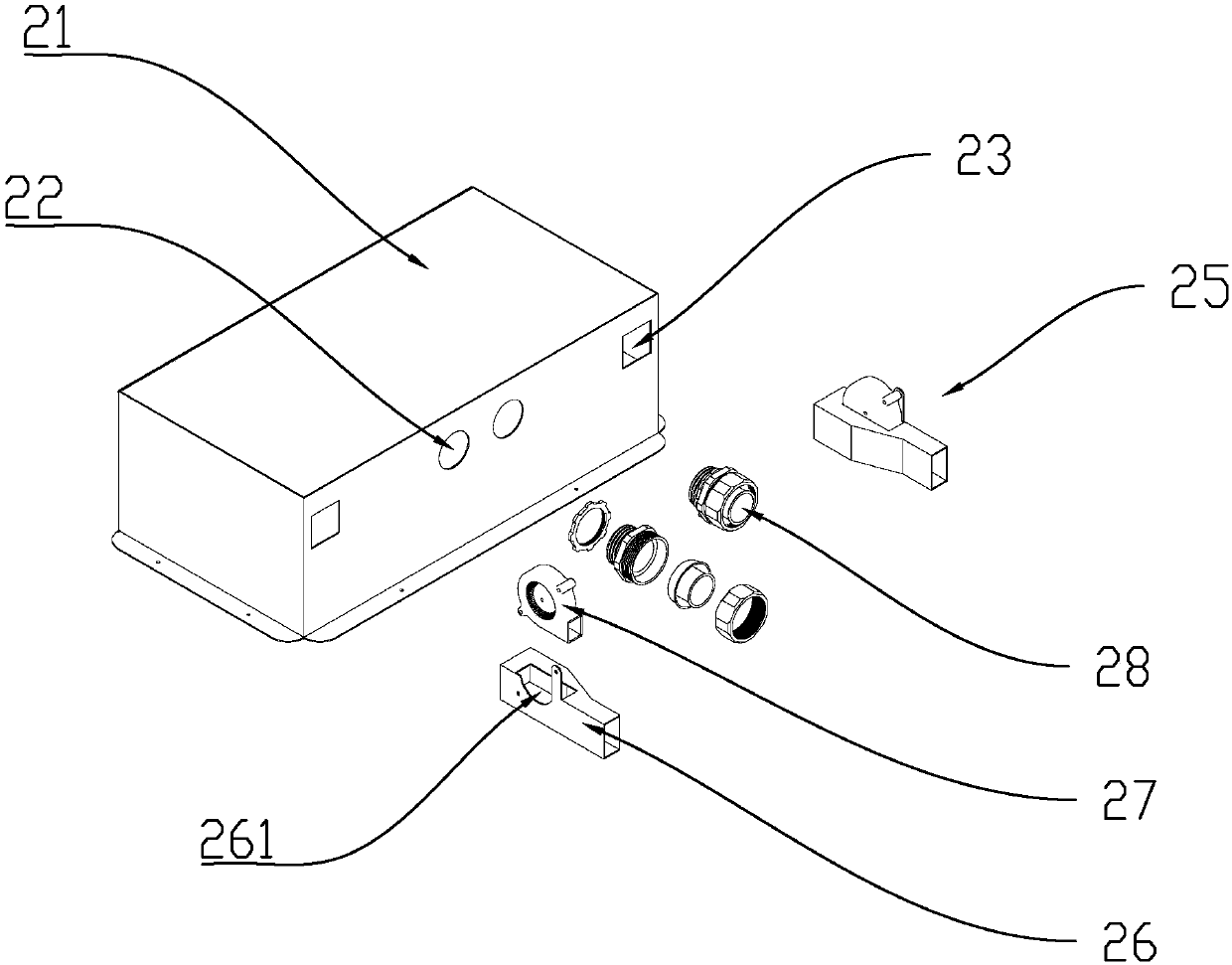

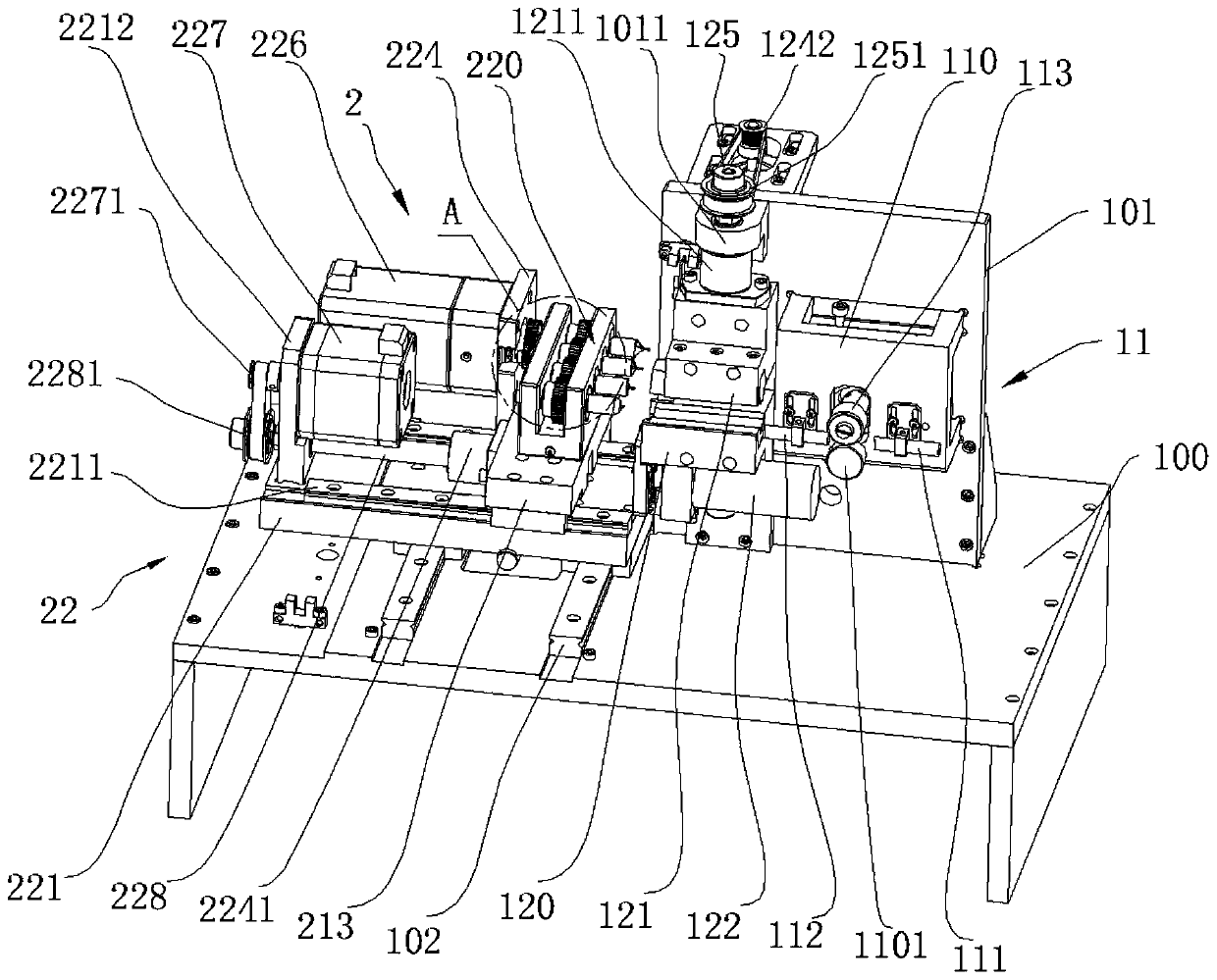

InactiveCN103448941AAvoid taking up a lot of spaceAvoid the risk of burnsPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringFastener

An embodiment of the invention discloses a small vacuum packaging machine which comprises an upper shell, a bottom shell, a heating wire and a gland mechanism. The bottom shell is positioned at the bottom of the upper shell, the heating wire is positioned on the surface of the upper shell, and the gland mechanism is vertically movably connected with the upper shell. The gland mechanism comprises a gland, guide rods, elastic parts, heat-resistant rubber and locking fasteners, the guide rods are positioned at two ends of the bottom of the gland, the elastic parts are sleeved on the guide rods, the heat-resistant rubber is positioned at the bottom of the gland, and the locking fasteners are positioned on side walls of the gland and are connected with the guide rods; guide holes and locking holes are formed in the surfaces of the upper shell, the guide holes are assembled with the guide rods, and the locking holes are assembled with the locking fasteners. The small vacuum packaging machine has the advantage of small occupied space, and potential safety hazards can be prevented when the small vacuum packaging machine is used.

Owner:王为墩

Automatic blanking device based on cake production

InactiveCN113331227ALow costHigh degree of automationBaking ovenBaking processesElectric machineryManufacturing engineering

The invention discloses an automatic blanking device based on cake production, which comprises a workbench and a folding frame fixed on one side of the top of the workbench, a material box is fixed on the top of the folding frame, one end of the material box is communicated and fixed with a material pipe, an automatic blanking unit is arranged on the top of the workbench, and a blanking protection mechanism is arranged on one side of the workbench; the invention relates to the technical field of cake production and processing. According to the automatic blanking device based on cake production, the automatic blanking unit is arranged at the top of the workbench, a first motor is used for providing power output, a sliding plate moves and rotates in a sleeve plate through the rotating process of a rotating plate, intermittent pushing of a transverse frame can be achieved, and the transverse frame recovers to the initial state; the formed cake can be moved to the discharging hole to fall down, the cake is prevented from being adhered to the inner wall of the die holder in cooperation with the anti-adhesion assembly, and compared with an existing cake production technology, manual taking-out is not needed, cost is saved, and the automation degree is high.

Owner:马占洪

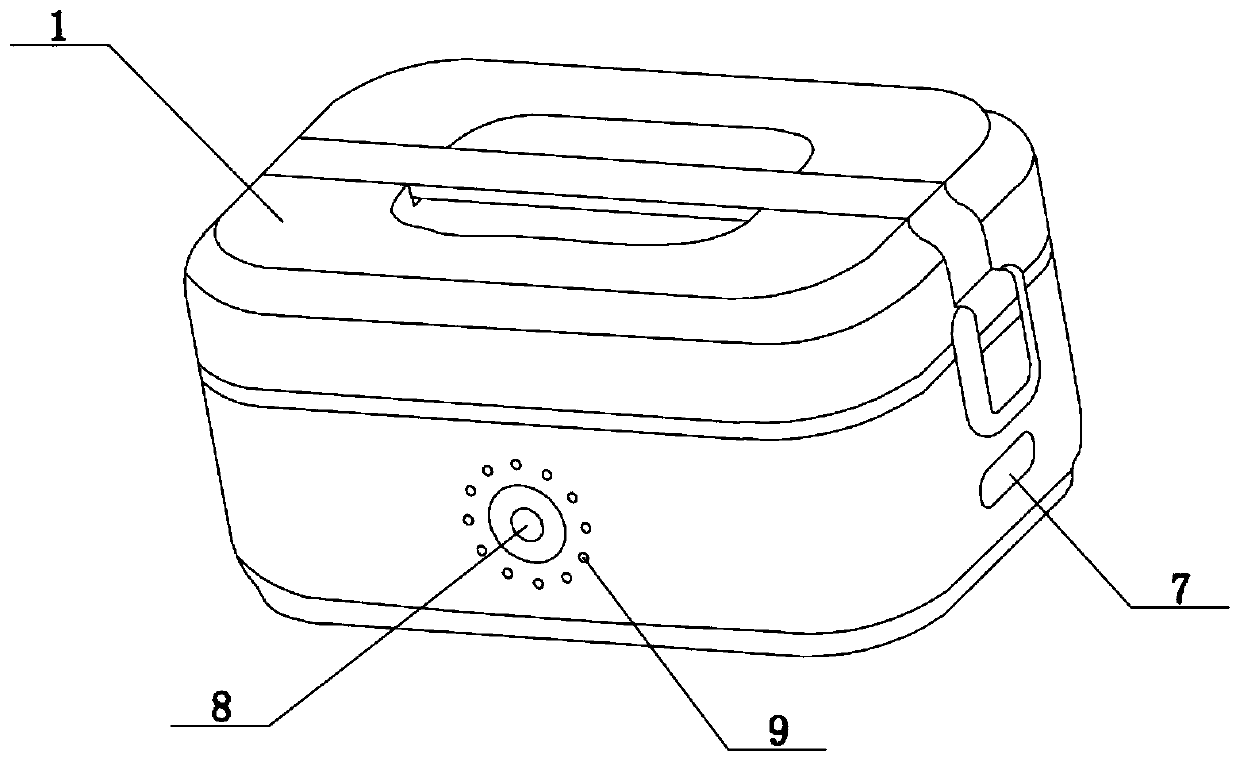

Lunch box heated by batteries

PendingCN109984437AReduce energy storage requirementsAccurately display powerPursesLuggageElectricityHeat conducting

The invention discloses a lunch box heated by a batteries and relates to the technical field of food heating. The lunch box comprises a box body, a heating sheet, a metal lunch box and a battery pack,wherein the heating sheet is arranged in the box body, the periphery of the heating sheet is tightly connected with the side wall of the box body, the metal lunch box is detachably arranged in the box body, the lower end face of the metal lunch box is attached to the heating sheet, the heating sheet comprises a heat conducting sheet and PTC heating sheets, the heat conducting sheet is provided with a plurality of PTC heating sheets, and the PTC heating sheets are treated by a common negative electrode. The heat conducting sheet is the negative electrode for the PTC heating sheets, the batterypack is arranged between the heating sheet and the bottom of the box body, and the battery pack is electrically connected with the heating sheet. The lunch box is reasonable in design, the heating piece is directly in contact with the metal lunch box container for heating, water is not needed, the voltage is completely harmless to a human body, the batteries are arranged in the lunch box, the lunch box is convenient to carry and use, steam is not generated in the heating process, the risk of scalding is avoided, foods are sealed in the metal lunch box in the heating process, no smell diffuses, and no noise is generated in the heating process.

Owner:深圳市喜拉科技有限公司

Energy-saving water heating blanket main machine easy to produce

PendingCN114608058AReduce the temperatureSave energyElectric heating systemCentral heating componentsProcess engineeringSoft materials

The invention discloses an energy-saving water heating blanket main machine easy to produce, and belongs to the technical field of water heating blankets. Comprising a shell, a water distribution assembly, a water tank, a water pump and a pipeline heater, a soft bottom cover is arranged at the bottom in a box body and located over a water pump connector and a water return opening in a covering mode, the outer edge of the soft bottom cover is pressed and fixed to the bottom of the box body through a cover plate, and an inner circulation cavity is formed by the soft bottom cover and the bottom of the box body; an exhaust pipe is arranged on the soft bottom cover and located above the water pump connector in an upward protruding mode, and a water supplementing groove is formed in the exhaust pipe in a downward concave mode. The side, close to the water pump connector, of the water supplementing groove is opened to form a water supplementing opening, the water supplementing opening and the water returning opening are located on the two sides of the water pump connector respectively, a one-way valve plate capable of closing the water supplementing opening is arranged on the lower side of the soft bottom cover and located on the inner side adjacent to the water supplementing opening, and the soft bottom cover and the one-way valve plate are integrally formed through soft materials. When the inner circulation cavity does not need water replenishing, the one-way valve plate seals the water replenishing opening due to the impact force of backwater; when the inner circulation cavity needs water replenishing, the one-way valve is separated from the water replenishing opening.

Owner:成都彩虹电器(集团)中南有限公司

Hot contraction membrane machine capable of providing accurate target directions

InactiveCN103496479APrecise contractionTo achieve the purpose of packagingWrappers shrinkageTemperature controlEngineering

The invention discloses a hot contraction membrane machine capable of providing accurate target directions. When used for packaging products, the hot contraction membrane machine usually plays a role in air isolation, appearance beautifying, dust prevention, abrasion prevention, scattering preventing and prevention of burglary. No hot contraction membrane packaging equipment for part of a product, especially a bottle opening part, exists in the prior art. The hot contraction membrane machine capable of providing accurate target directions comprises a machine frame, a product conveying belt and a bottle gripper arranged at a working position, wherein an air feeder is arranged on the machine frame, an air outlet of the air feeder is connected with a heating pipe, a heating device is arranged inside the heating pipe, the heating pipe is connected with a heat restraining pipe, a temperature control probe is arranged in the heat restraining pipe, and a rotary roller is further arranged below the heat restraining pipe on the machine frame. By means of the measures, air fed by the air feeder is heated in the heating pipe, hot air is sent out from a heat restraining port of the heat restraining pipe, a membrane sleeve on a bottle cap at the working position is accurately heated and contracted, and the purpose of hot contraction membrane packaging at part of a bottle is achieved.

Owner:合浦果香园食品有限公司

Rising backflow device of automatic gas tracking obstacle and moxa-moxibustion physiotherapy device

PendingCN107595615AGet the most out of physical therapyNo risk of burnsDevices for heating/cooling reflex pointsEngineeringMoxibustion

The invention relates to a rising backflow device of automatic gas tracking obstacle, which comprises a picker and a negative pressure extracting mechanism linked to the picker; the upper part of thepicker is provided with an upper opening, and the bottom part is provided with a lower opening for gas access; the upper opening of the picker is an air inlet so that the gas rising is blocked; the negative pressure extracting mechanism extracts air from the air inlet and enters the picker, thus the air and gas are formed to be a vortex which is extracted by negative pressure, thus the gas is risen to the lower part of the obstacle. The negative pressure extracting mechanism can extract moxa smoke, thus there is no smoke in the space and a user cannot be choked; the moxa smoke is risen to thebuttock part of the user and effected on perineum point of the user, thus the user is free from the risk of burning and scalding during the physical therapy period; the rising backflow device is convenient to operate, able to display the effect of the moxa-moxibustion physiotherapy, and suitable for vigorously popularization.

Owner:ZHONGXINHAO IND & TRADE DEV SHENZHEN CITY

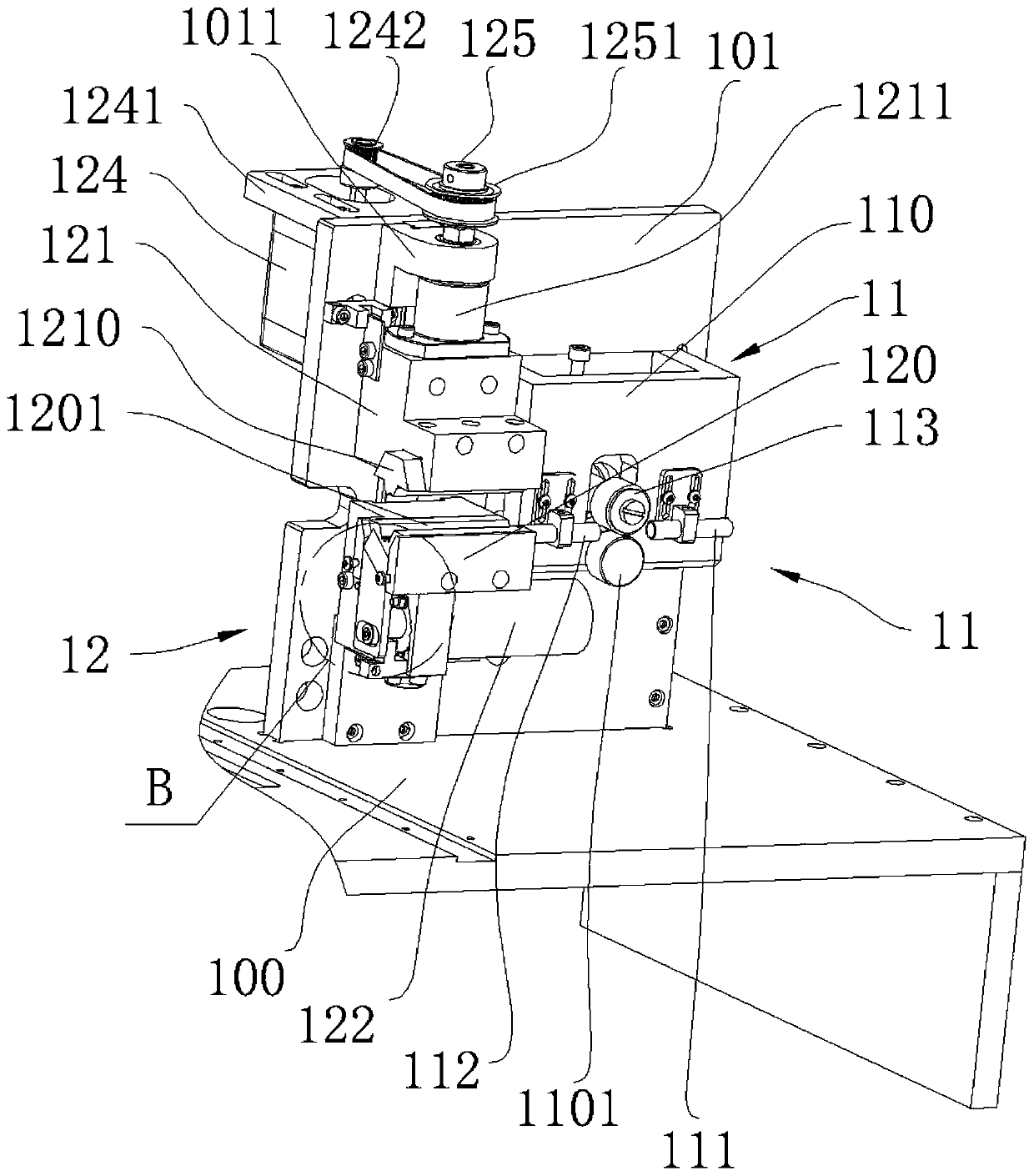

Automatic flanging machine

The invention discloses an automatic flanging machine, and belongs to the technical fields of machining equipment. The automatic flanging machine mainly comprises a clamping mechanism and a flanging mechanism, the clamping mechanism and the flanging mechanism are arranged on the worktable, the clamping mechanism comprises a transfer mechanism and a cutting mechanism, the transfer mechanism comprises an adaptive roller and a driven roller, the cutting mechanism comprises a bearing seat, a pressing table and a cutting blade, the pressing table is movably arranged above the bearing seat, and thecutting blade is movably arranged on one side of the bearing seat. The flanging mechanism comprises a bearing assembly and a flanging assembly, the bearing assembly comprises a base arranged on the flanging assembly, and the flanging assembly comprises a longitudinal feeding table, a transverse feeding table and a flanging roller set, the flanging roller set is arranged on the base, and the flanging roller set comprises a first forming roller, a second forming roller, a shaping roller and a ringing roller, and the first forming roller, the second forming roller, the shaping roller and the ringing roller are rotatably arranged on the base. According to the automatic flanging machine, a silicone hose can be automatically flanged through cold extrusion, safety is improved, and meanwhile the flanging effect is good.

Owner:NANJING RUNZE FLUID CONTROL EQUIP CO LTD

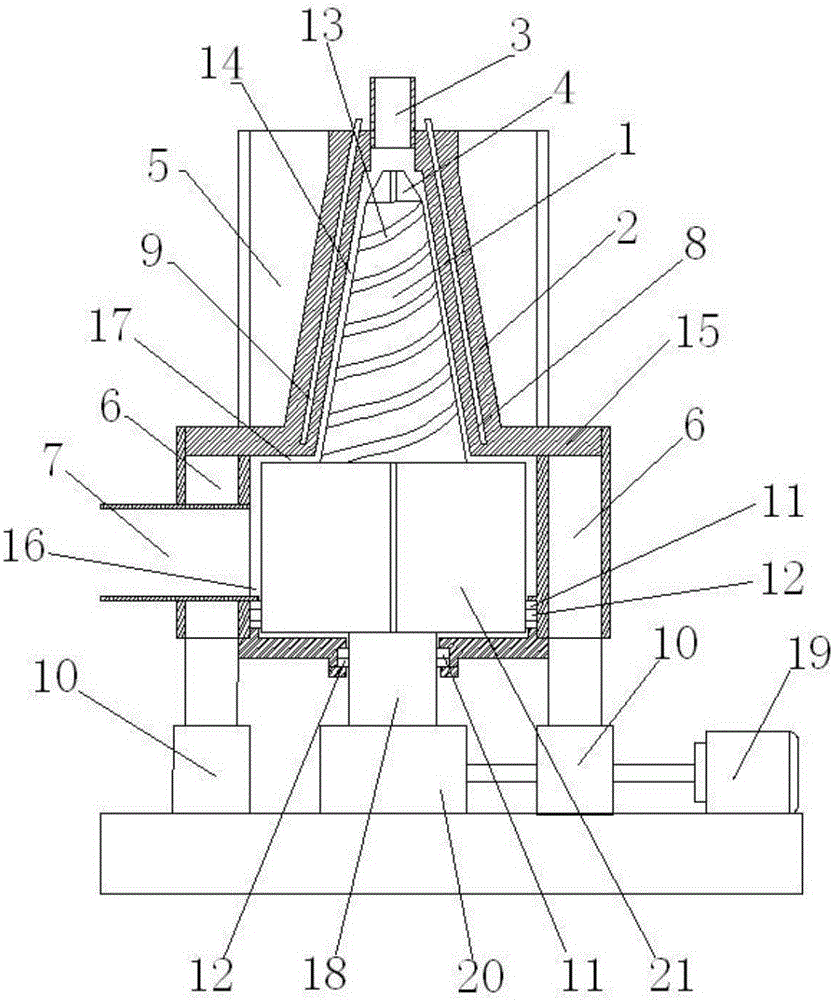

Vertical type self-pressurization and temperature rising rubber regeneration device

ActiveCN105949502AEfficient use ofReduce energy consumptionPlastic recyclingTemperature controlAgricultural engineering

The invention relates to a vertical type self-pressurization and temperature rising rubber regeneration device. A tapered body of a tapered main shaft is provided with a spiral groove from top to bottom; a tapered cavity, which is used for containing the tapered main shaft and is the same as the tapered main shaft in appearance, is formed in a main shaft sleeve; a feeding hole is formed in the top of the main shaft sleeve; the lower end of the main shaft sleeve horizontally and outward protrudes to form an annular table body; the main shaft sleeve sleeves the tapered main shaft; the gap between the tapered main shaft and the main shaft sleeve is gradually reduced from top to bottom; the lower end of an inner temperature control cooling region of the main shaft sleeve is fixed on the annular table body and the inner temperature control cooling region of the main shaft sleeve is arranged at the outer part of the main shaft sleeve in a surrounding manner; a material splitting pulling sheet is fixed at the top of the tapered main shaft; the lower end of the tapered main shaft is connected with the upper end of a sizing material treating device; a sizing material temperature lowering and cooling region is arranged around the sizing material treating device and at the lower part of the annular table body. The vertical type self-pressurization and temperature rising rubber regeneration device has the advantages of wide applicability, good energy-saving performance and low carbon, low production cost, high convenience for installation and maintenance, good safety, stable quality, high yield and no environment pollution.

Owner:山西礼信橡胶科技有限公司

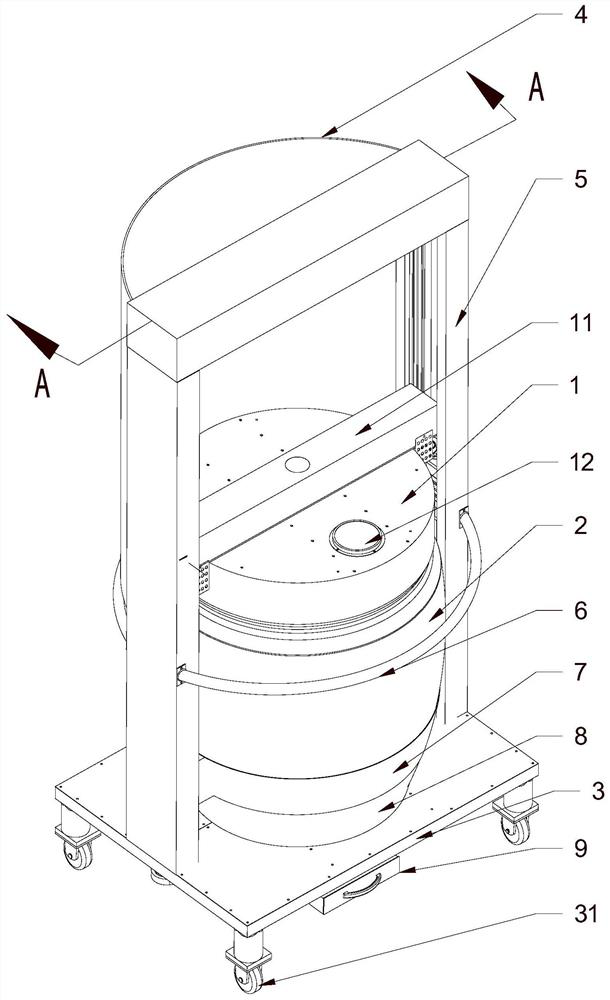

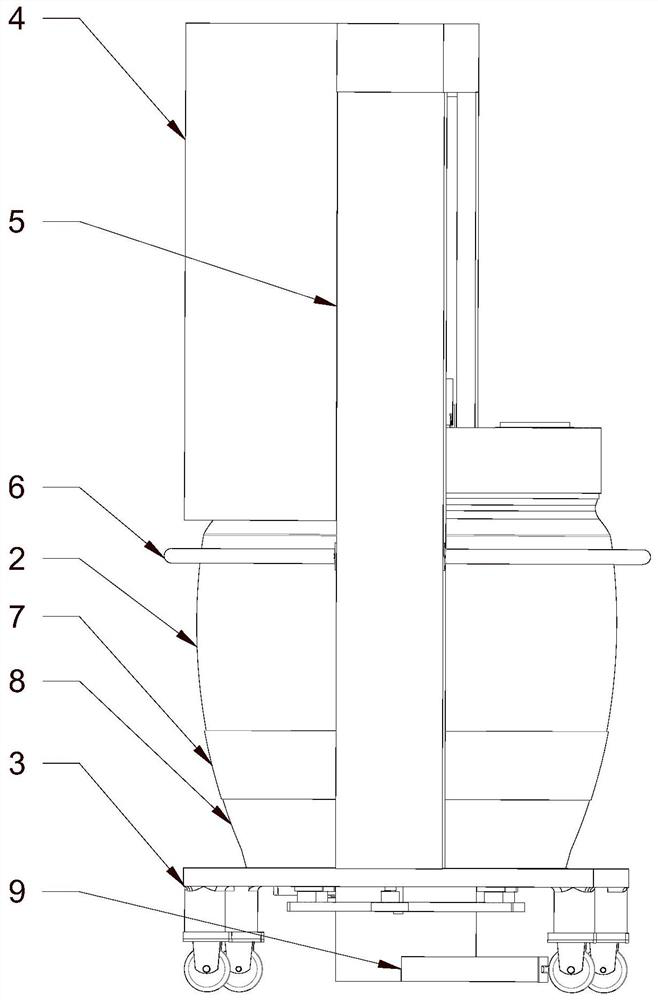

Cured meat baking equipment

InactiveCN111838220ASimple structureEvenly bakedBaking ovenSpecial goods bakingEngineeringPortal frame

The invention relates to cured meat baking equipment which comprises a cured meat chamber, a hook frame is arranged in the cured meat chamber, a plurality of hooks are arranged on the hook frame, a motor drives a transmission mechanism to enable the hook frame to rotate, and the cured meat baking equipment is characterized by further comprising a base and a portal frame, the base is fixed to the bottom of the portal frame, and the cured meat chamber is defined by an upper cover, a cured meat cylinder and the base; wherein a first lifting mechanism is respectively connected with the upper coverand a stand column of the portal frame, so that the upper cover can be vertically lifted along the stand column, the second lifting mechanism is respectively connected with the cured meat cylinder and the stand column of the portal frame, so that the cured meat cylinder can be vertically lifted along the stand column, and the transmission mechanism and the hook frame are arranged in the upper cover; and an open fire combustion furnace is arranged on the base. The structure of traditional cured meat baking equipment is improved, open fire baking is reserved, meanwhile, it can be guaranteed that cured meat is baked evenly, and the baking effect is better.

Owner:张文豪

Capillary force vaporizer device instantly generating vapor

InactiveCN109812906AHigh energy consumptionImprove securitySteam generation plantsSpace heating and ventilation detailsNasal Cavity EpitheliumWater vapor

The invention discloses a capillary force vaporizer device instantly generating vapor. The capillary force vaporizer device comprises a device body. Supporting feet are fixedly installed in the cornerpositions of the outer surface at the lower end of the device body, a power line is movably installed at the lower end of the outer surface on one side of the device body, a water adding pipe is fixedly installed in the middle position of the outer surface on one side of the device body, and vapor outflow holes are formed in the position, near the upper end, of the outer surface of the device body. By the adoption of the capillary force vaporizer device instantly generating the vapor, after being sucked through capillary force, liquid is scattered to become small-size liquid in the capillarytube diameter size and heated so as to instant evaporate, air streams are sprayed out continuously and stably, the capillary force vaporizer device can operate without movable parts such as an air pump, meanwhile, the control ability of the gas ejection amount is quite high, due to the fact that the liquid is directly changed into water vapor to enter the oral cavity and the nasal cavity of a person, the problem that a warm and humid environment is provided for microorganisms such as bacteria does not exist, and a safety coefficient is high.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

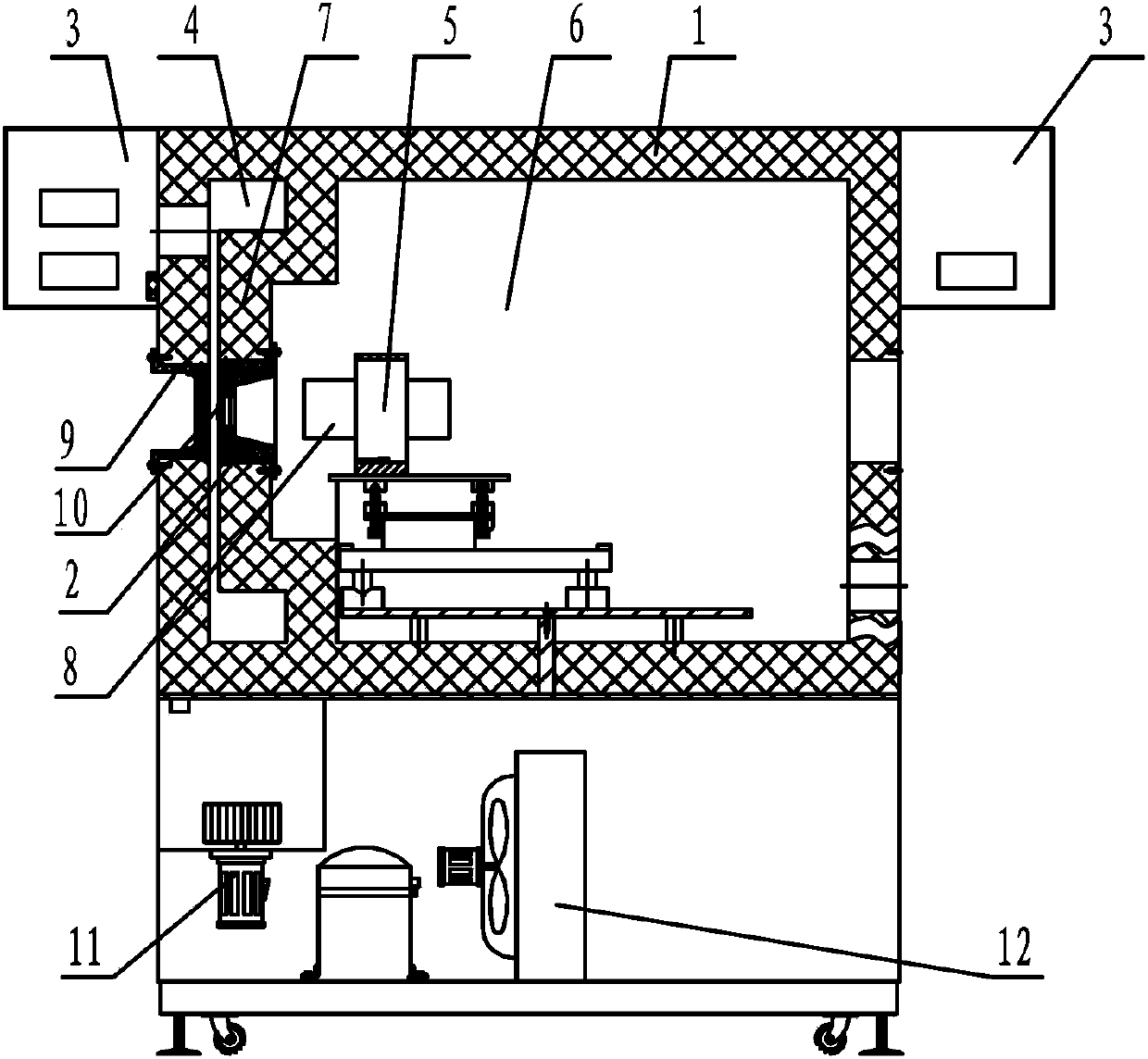

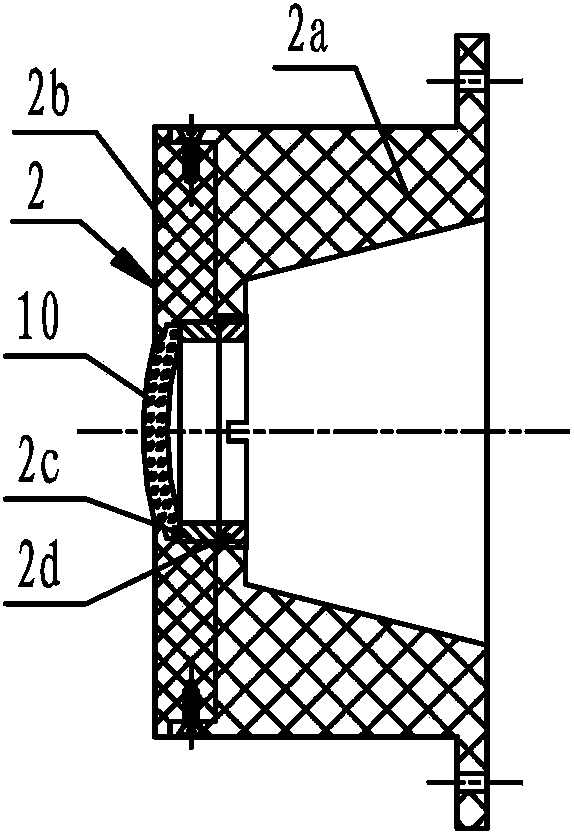

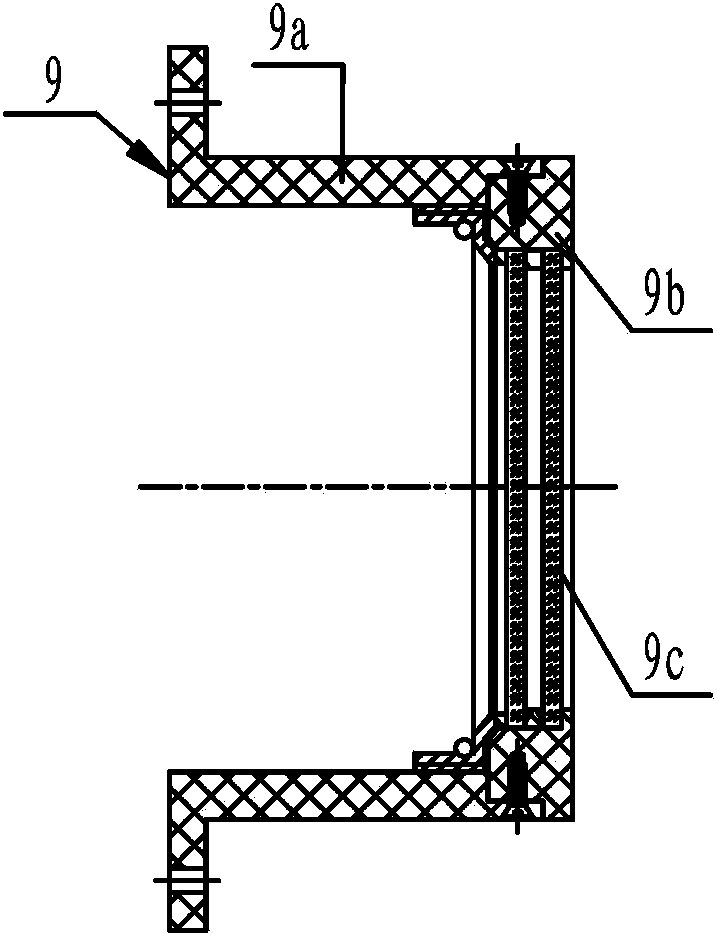

Thermal barrier tester of infrared imaging device

ActiveCN102671720BStable temperatureThe test data is accurateTelevision systemsEnclosures/chambersUltrasound attenuationThermal insulation

The invention discloses a thermal barrier tester of an infrared imaging device, which comprises an incubator, wherein an inner cavity of the incubator is provided with a thermal insulation layer; the thermal insulation layer divides the incubator into a low-temperature region and a high-temperature region; the wall surface of the thermal insulation layer is provided with a fairing fixture, and is used for fixing an optical fairing in the infrared imaging device; an inner cavity of the low-temperature region is internally provided with a mounting rack of the infrared imaging device, and is used for fixing components except for the optical fairing in the infrared imaging device; and the incubator wall of the incubator at the side of the high-temperature region is provided with an observation window which is corresponding to the part of the fairing fixture and acts as a cameral shooting channel of the infrared imaging device. The thermal barrier tester of the infrared imaging device simulates different temperatures of the outer surface of the optical fairing and a cabin of the infrared imaging device by utilizing the high-temperature region and the low-temperature region of the incubator so as to verify the attenuation characteristic of the imaging quality of the infrared imaging device under the thermal barrier condition, the temperature of the optical fairing in the verifying process can be ensured to be constant, the test data is accurate, also the scalding hazard does not exist, and the operation is safe.

Owner:THE GENERAL DESIGNING INST OF HUBEI SPACE TECH ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com