Lead sheath copper wire shielding composite high-voltage power cable

A technology of copper wire shielding and high-voltage power, which is applied in the direction of power cables, insulated cables, cables, etc. with shielding layer/conductive layer, to achieve the effect of saving costs, ensuring product quality and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

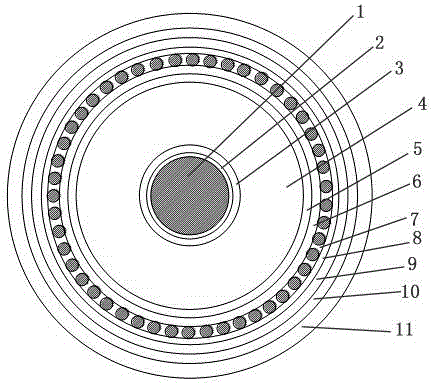

[0014] Such as figure 1 A lead-sheathed copper wire shielded composite high-voltage power cable is shown, the cable includes a conductor 1, a semiconductive tape 2, a conductor shield 3, an insulation layer 4, an insulation shield 5, a semiconductive Buffer tape 6, copper wire shielding tape 7, semi-conductive buffer water-blocking tape 8, lead sheath 9, outer sheath 10; said conductor 1 and semi-conductive tape 2 with four-layer co-extruded structure, conductor shielding layer 3. The insulating layer 4 and the insulating shielding layer 5 constitute the insulating wire core; the thickness ratio of the semiconducting tape 2, the conductor shielding layer 3, the insulating layer 4 and the insulating shielding layer 5 is 1 / 2:1 / 2:1 : 1 / 4, in which the thickness of the insulating layer is 16.0mm; the semi-conductive buffer strip 6 with a thickness of 0.5mm is wrapped around the insulating core, and the copper wire shielding strip 7 is braided outside the semiconducting buffer stri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com