Vertical type self-pressurization and temperature rising rubber regeneration device

A recycled rubber, vertical technology, applied in the field of rubber manufacturing, can solve the problems of unstable quality, equipment damage, unstable temperature and shear force, etc., and achieve the effect of reducing production costs, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

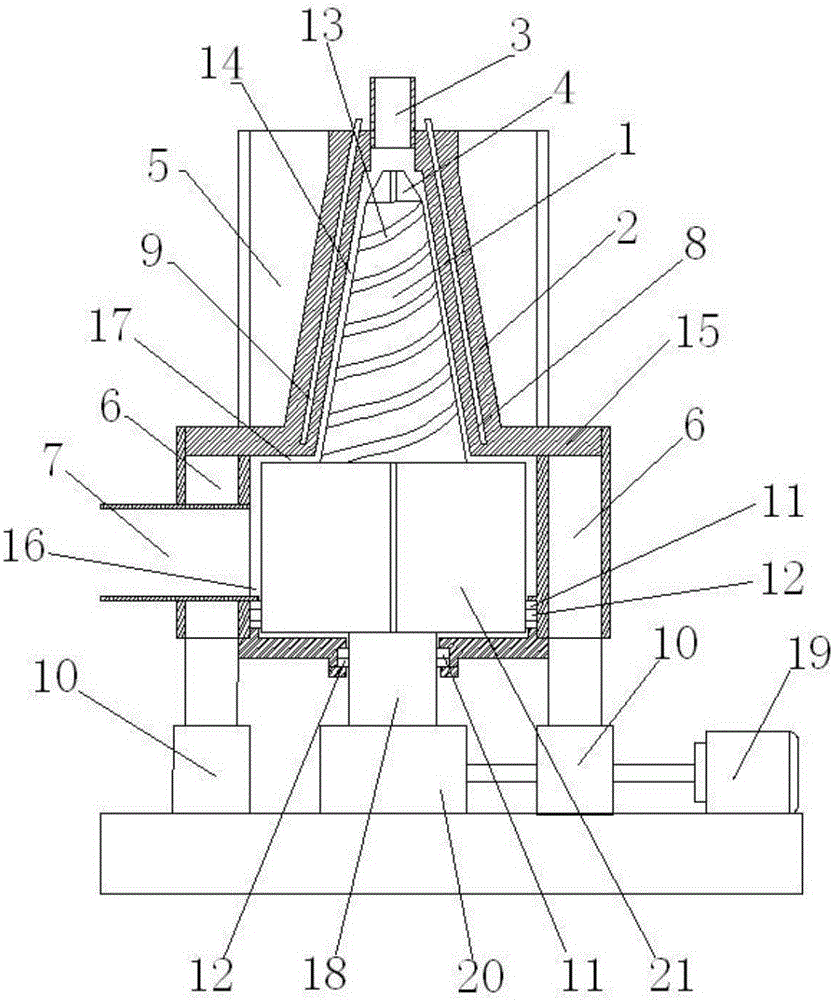

[0017] Such as figure 1 As shown in the figure, a vertical self-pressurization and heating regenerated rubber device includes a tapered main shaft 1, a main shaft sleeve 2, a feed port 3, an internal temperature control cooling zone 5 of the main shaft sleeve, a material distribution puller 4, and a rubber material processor. 21. Rubber material cooling zone 6, discharge port 7, driving device, preheating electric heating rod 8, temperature detector 9, numerical control unit, pressure sensor, current sensor, hydraulic pressure regulator 10, numerical control unit, pressure sensor, current Sensor, graphite self-lubricating copper sleeve 11 and high temperature and high pressure resistant packing 12. The conical body of the tapered main shaft 1 is provided with a spiral groove 13 from top to bottom. The inside of the main shaft sleeve 2 is a conical cavity 14 that accommodates the tapered main shaft 1 and is consistent with the shape of the tapered main shaft 1. The top of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com