Anti-dry-burning electric heating faucet valve element and faucet made of same

An electric hot water faucet and anti-dry-burning technology, applied in the field of faucets, can solve the problems of accelerated aging of the water tank, damage to the electric heating tube, reduction of the service life of the faucet, etc., and achieve the effect of preventing dry-burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described and explained below in conjunction with accompanying drawing.

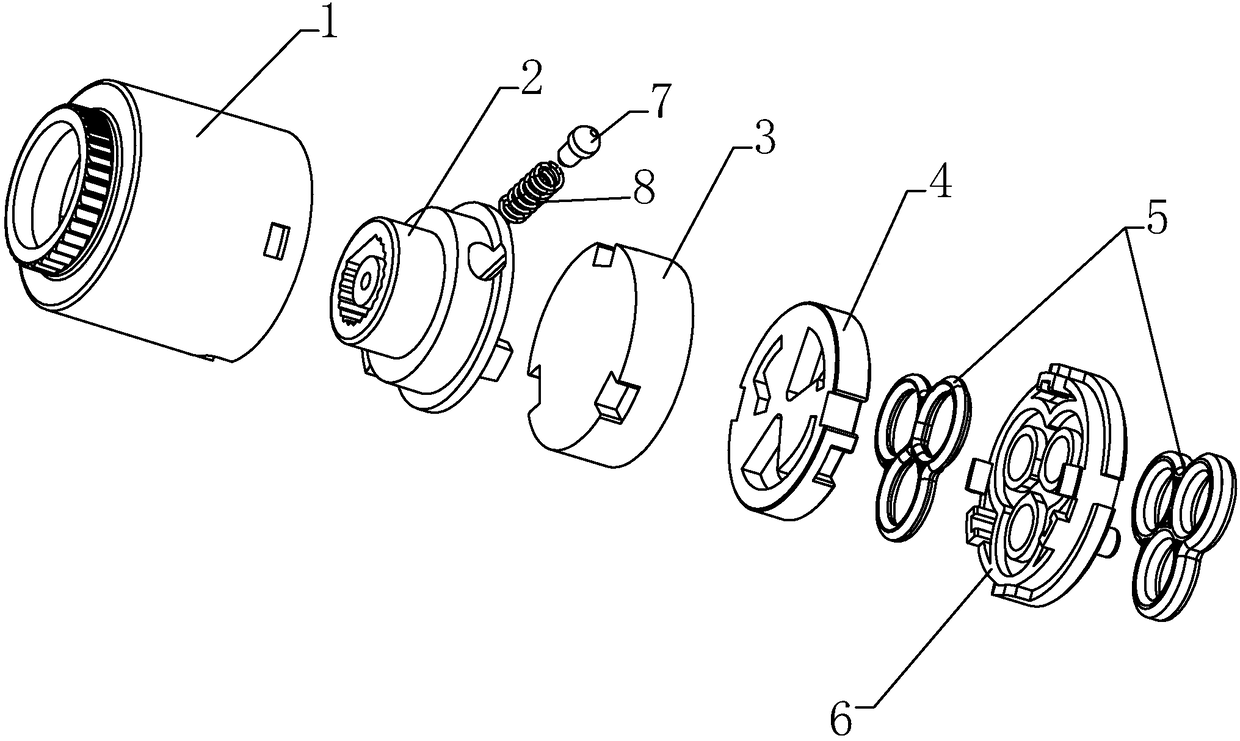

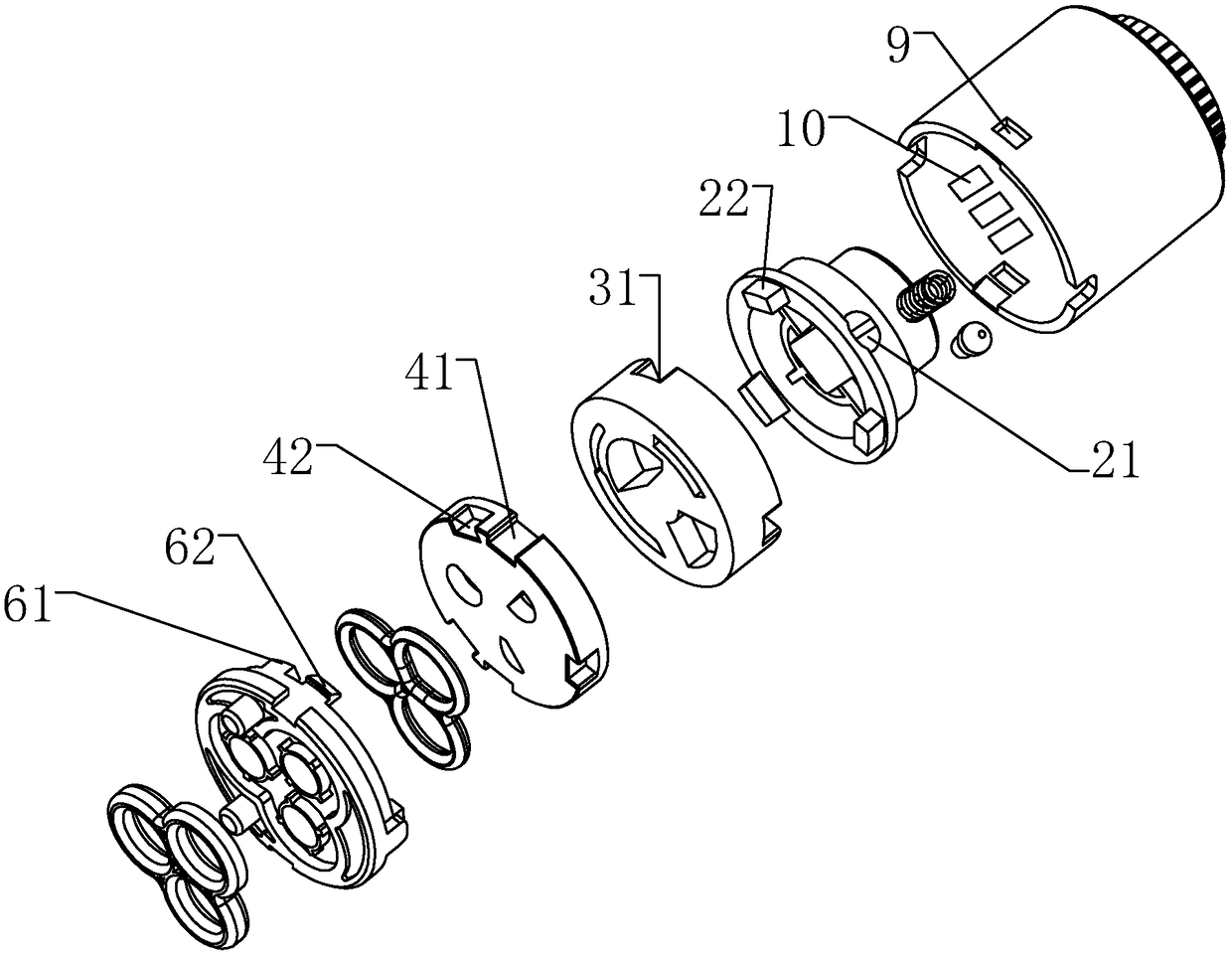

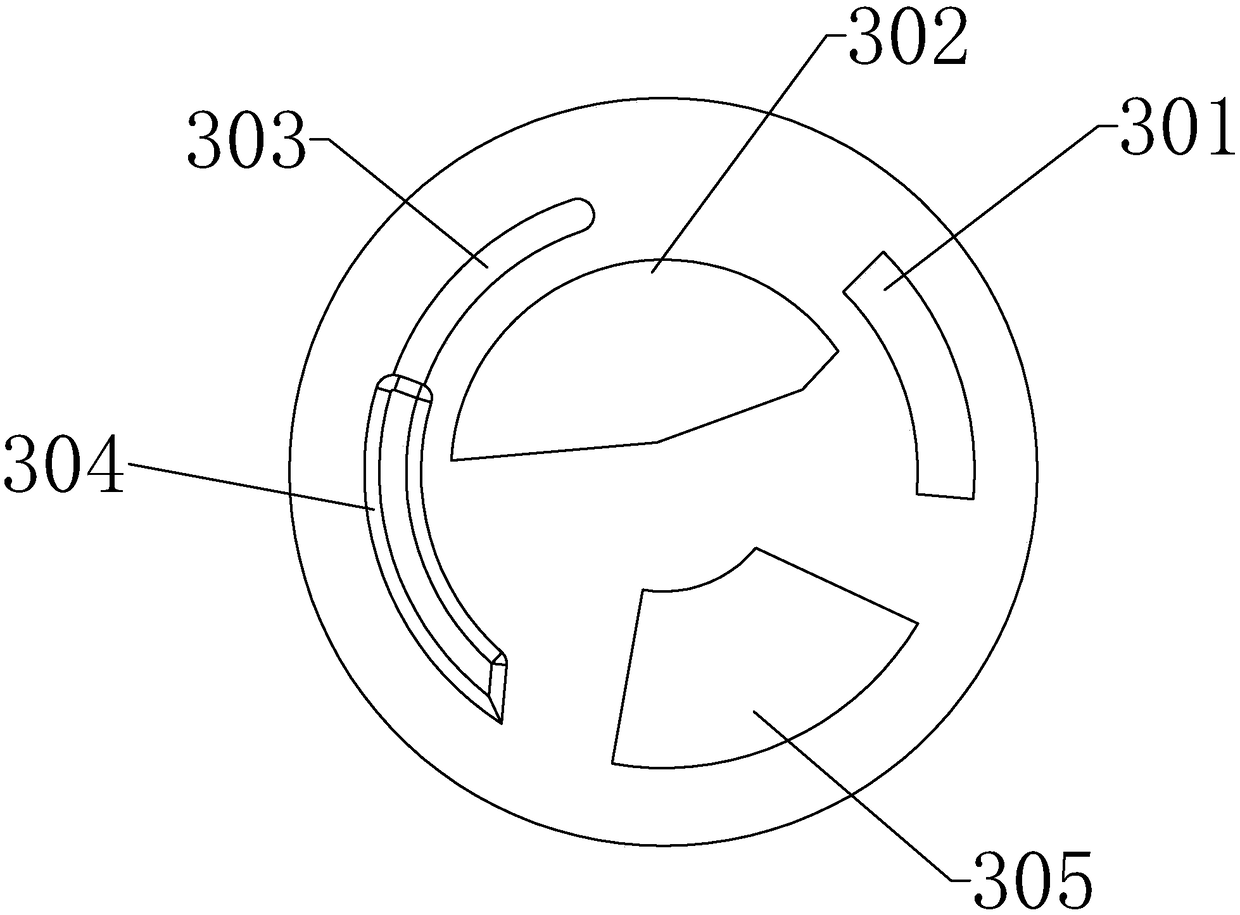

[0021] Such as Figure 1-4 As shown, a valve core of an anti-dry electric hot water faucet comprises a valve core assembly 12 composed of a rotationally fitted housing 1 and a rotor 2, upper and lower ceramic sheets for controlling hot and cold water discharge, and a flat base 6 equipped with a silicone sealing ring 5. , the side of the upper ceramic sheet 3 corresponding to the lower ceramic sheet 4 is provided with a cold water flow control groove 302, a pressure inlet groove 305, a pressure relief groove 301 and a hot water flow control groove, and the upper ceramic sheet 3 and the rotor 2 are buckled and matched The cold water flow control groove 302 and the pressure inlet groove 305 are fan-shaped and relatively arranged; the hot water flow control groove is a groove-like structure, and is arranged on the cold water flow control groove 302 and the pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com