Patents

Literature

63results about How to "Reduce operational safety hazards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

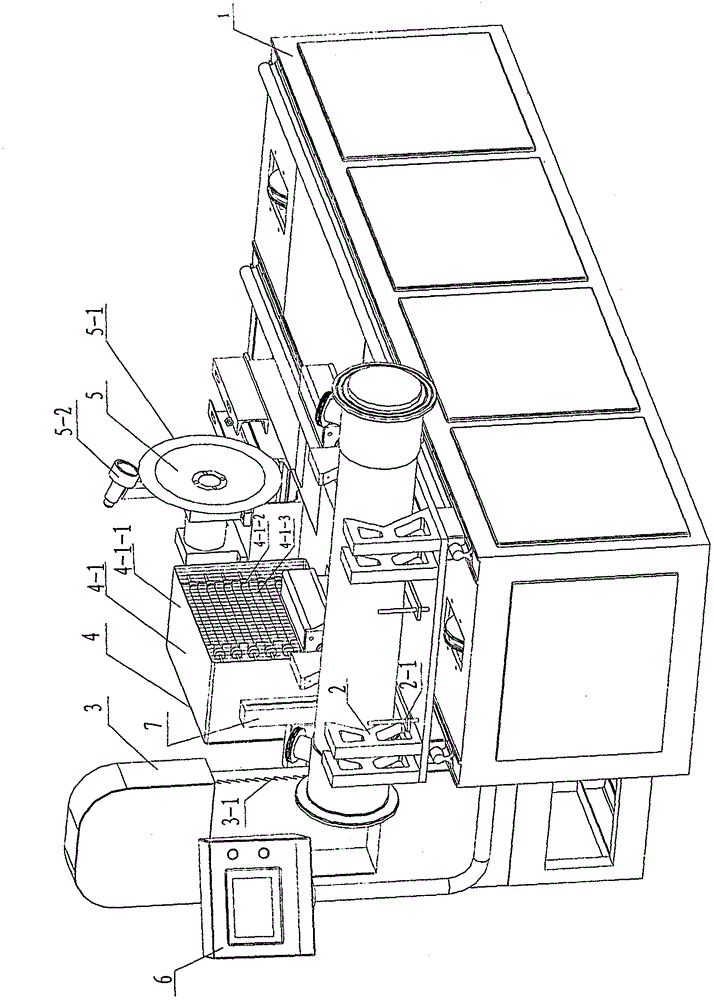

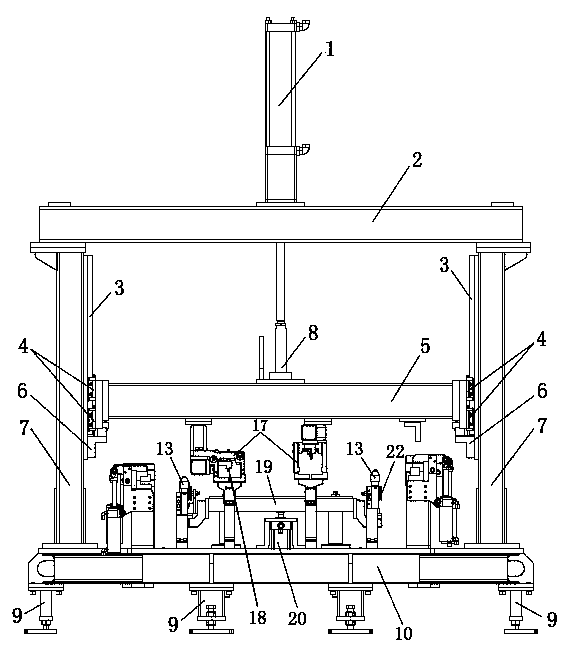

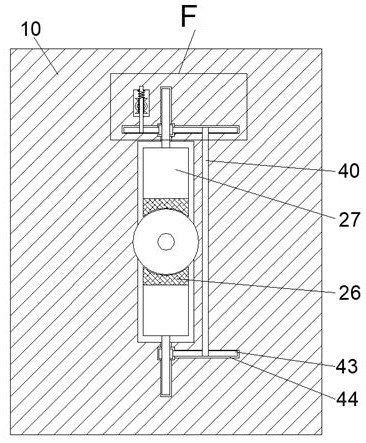

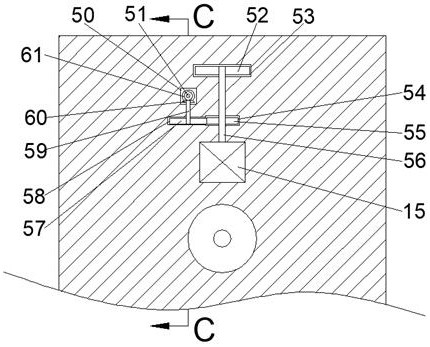

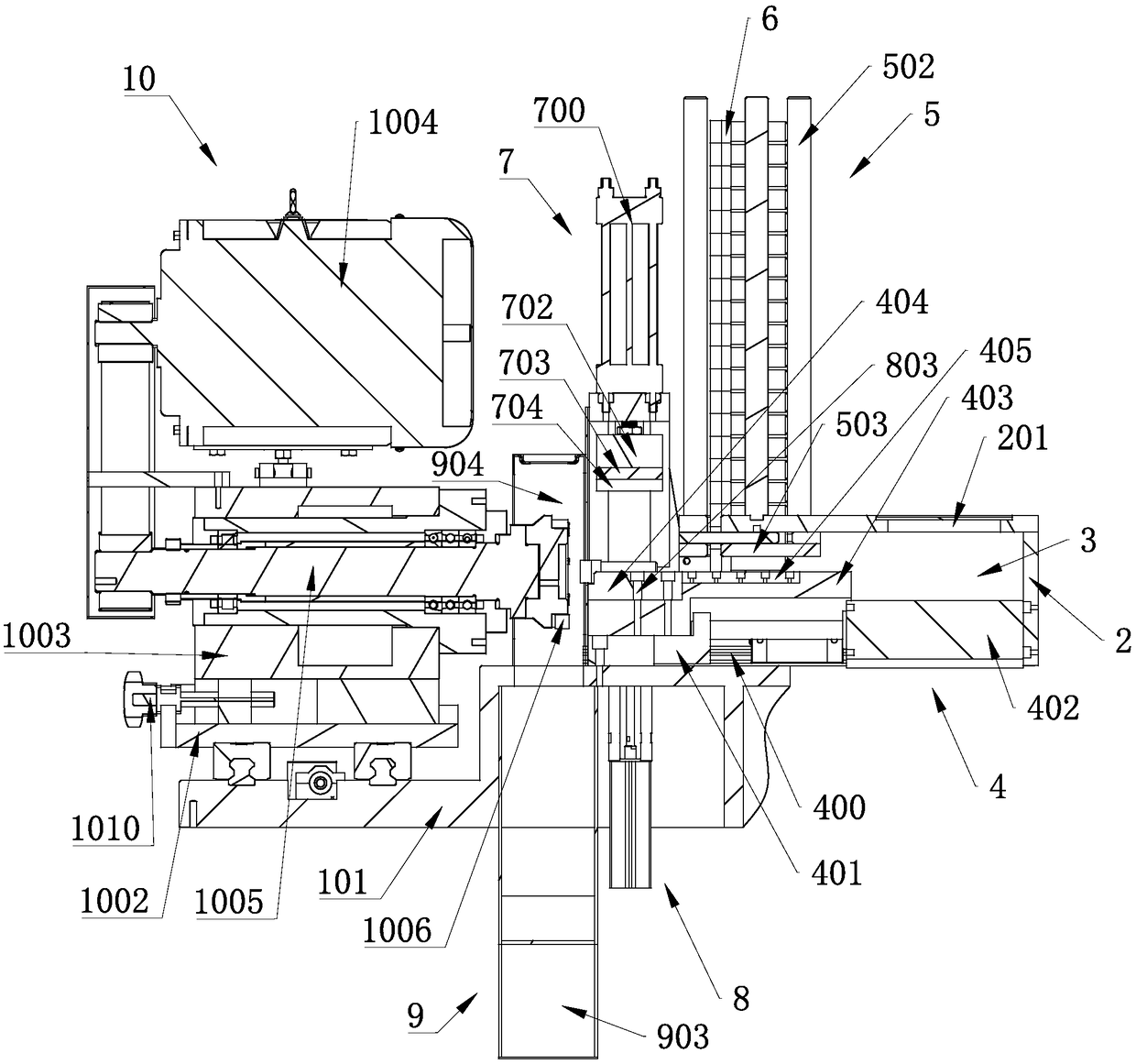

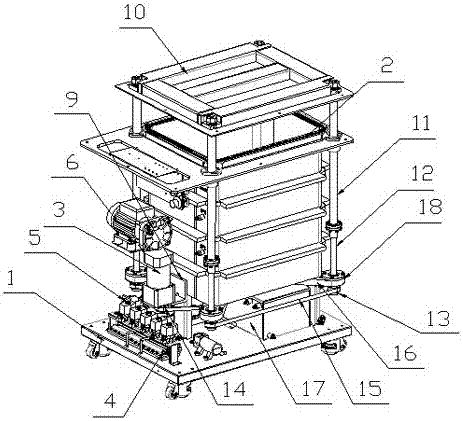

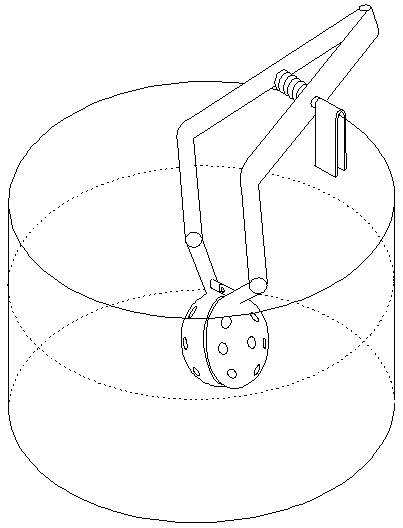

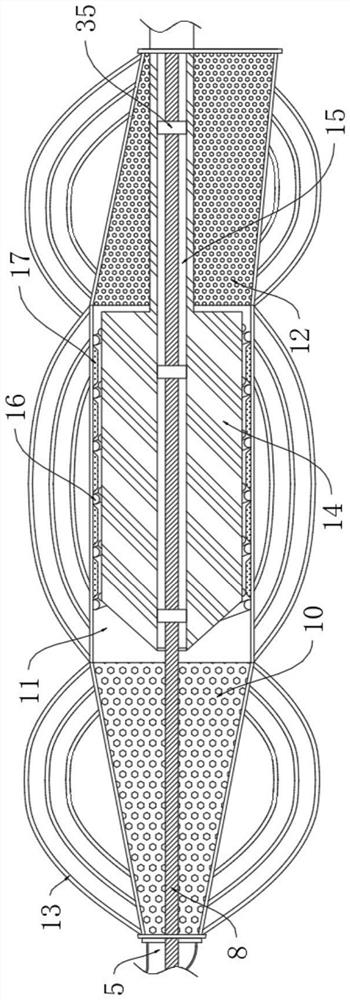

Multifunctional ultrafiltration membrane module cutter

InactiveCN102744742AImprove cutting efficiencyHigh speedMetal working apparatusBiochemical engineeringOperational safety

The invention relates to the technical field of ultrafiltration membrane machining equipment, in particular to a multifunctional ultrafiltration membrane module cutter. The multifunctional ultrafiltration membrane module cutter is provided with a frame with a slide rail; a movable clamping device used for clamping an ultrafiltration membrane module is arranged on the frame; and a rough cutting device, a heating device and a fine cutting device, which are capable of roughly cutting, heating and finely cutting the ultrafiltration membrane module in the clamping device in sequence when the clamping device advances to a certain position, are arranged on one side of the frame. Through the adoption of the technology, technical problems of low efficiency, uneven cutting end surface, easiness for plugging a hole, potential safety hazards in operation and so on of the traditional manual cutting are solved; high production efficiency, even cutting end surface, no blockage of the hole, good use effect and long service life of an ultrafiltration membrane as well as simplicity and convenience in operation are achieved; and the potential safety hazards in operation are lowered.

Owner:施吉中

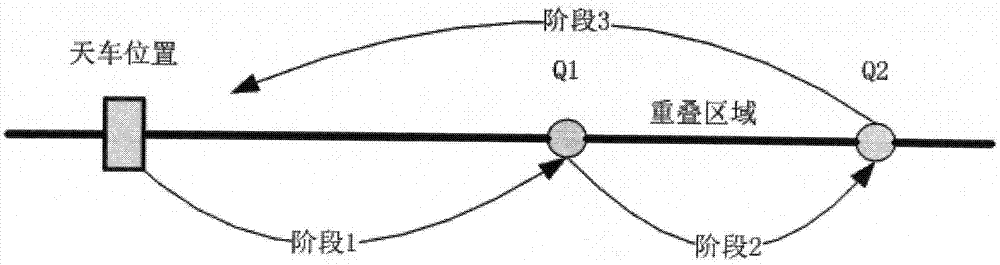

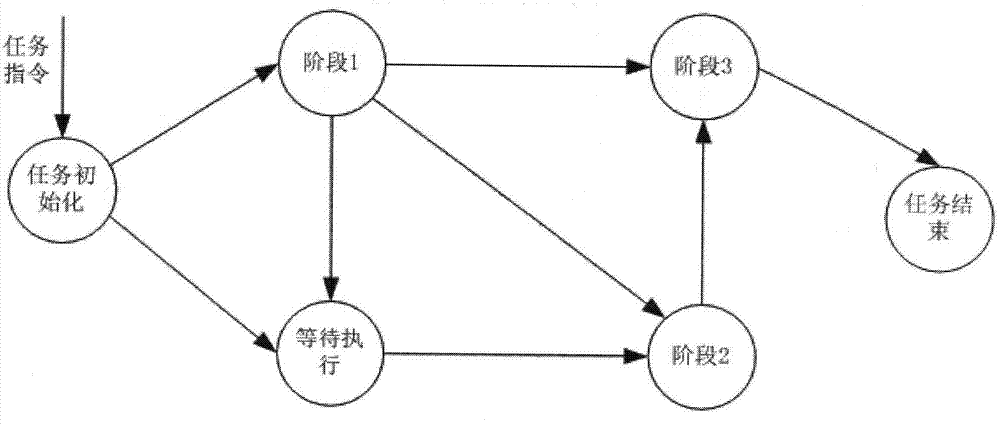

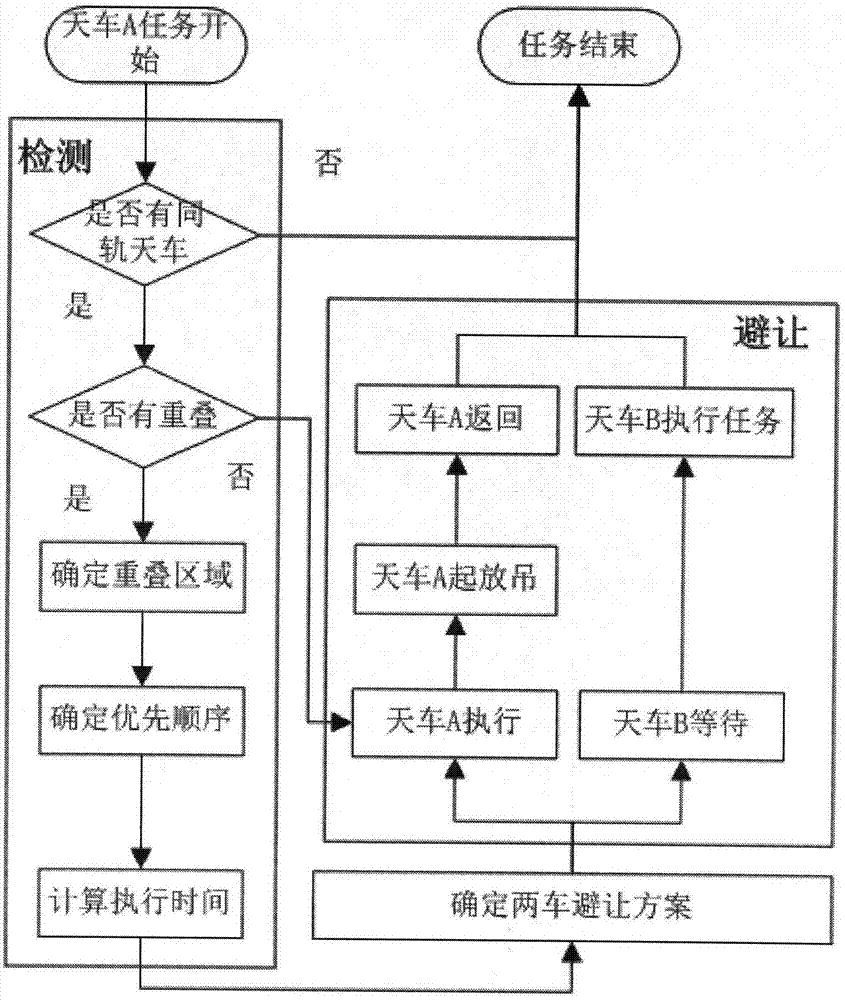

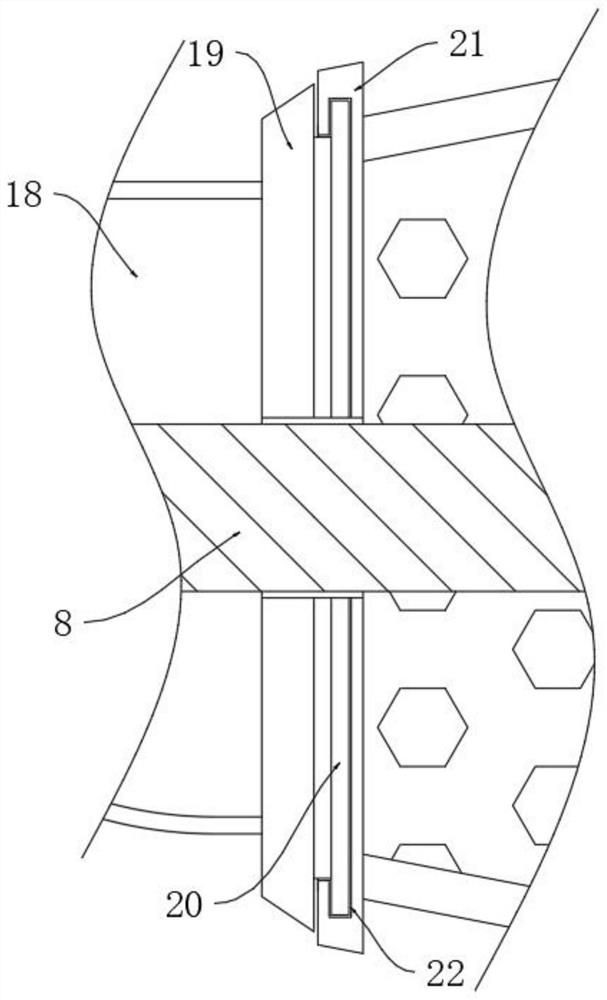

Crown block collision detection and intelligent collision avoidance method

InactiveCN105447619AReduce operational safety hazardsReduce security risksResourcesManufacturing computing systemsCollision detectionControl system

The invention discloses a crown block collision detection and intelligent collision avoidance method. The method specifically comprises the following steps of 1, whether two crown blocks are on the same rail or not is judged; 2, upon detecting the presence of crown blocks on the same rail, the state information and the task information of the crown blocks on the same rail are judged; 3, by means of a collision detection mechanism, whether the collision exists between two crown blocks or not is judged; 4, a crown block A enters an overlapped region firstly and has a high priority, while a crown block B is in the execution waiting state; 5, the crown block B stops outside the safety distance before entering the overlapped region and is switched into the waiting interruption state; 6, after the crown block A executes the hoisting and releasing operation at a target location, the crown block A begins to return; 7, the crown block B executes a task until the completion of the task. According to the invention, the enterprise production efficiency is improved, and the operation potential hazard of crown blocks is lowered. The method can be widely applied to crown block control systems in combination with crown block intelligent control and unmanned crown block autonomous operation in various warehouses and steel-making places.

Owner:HUNAN CHAIRMAN IOT INFORMATION TECH CO LTD

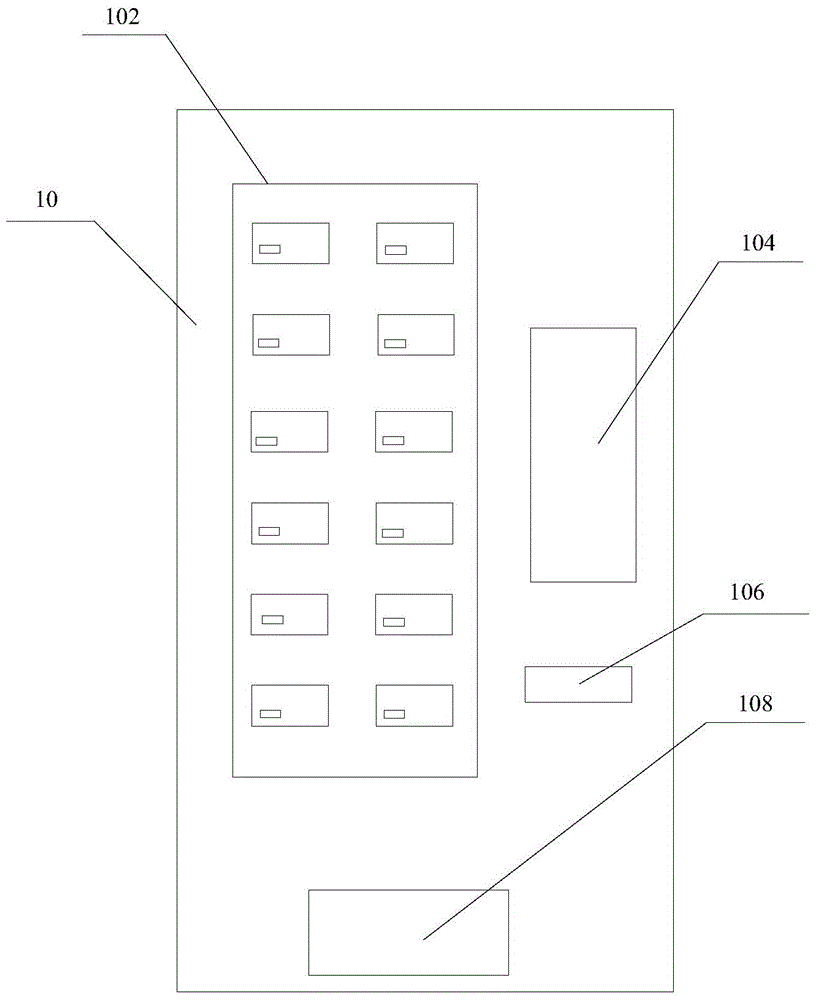

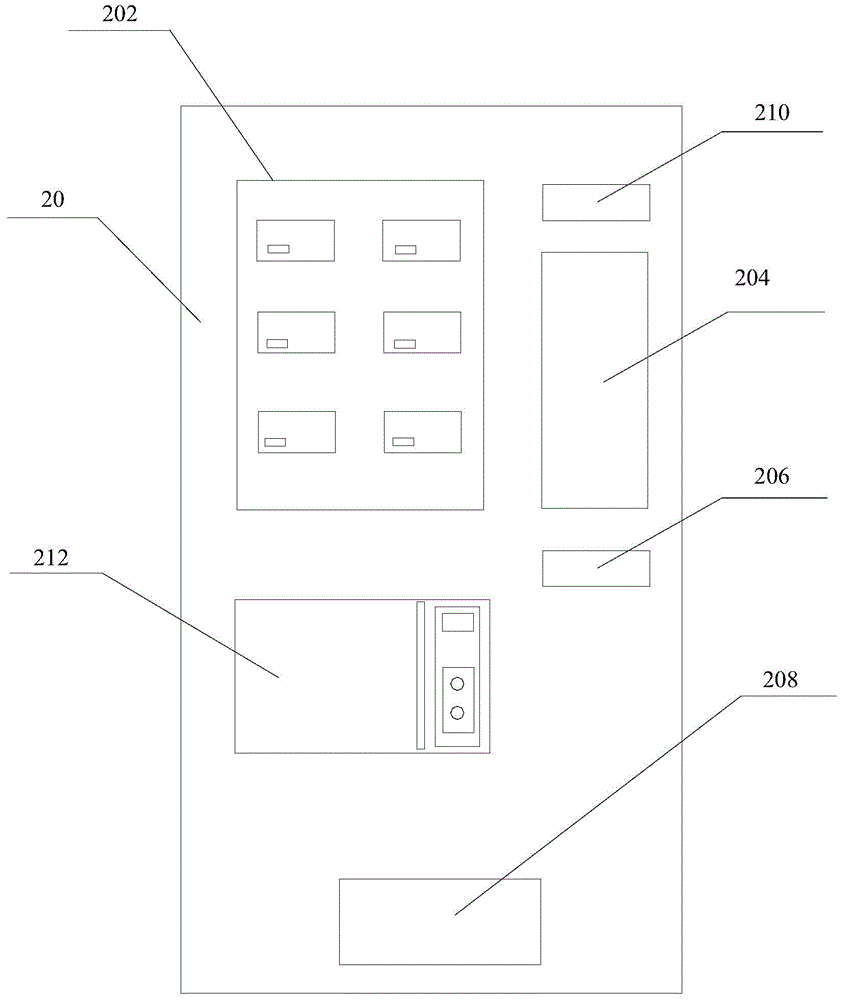

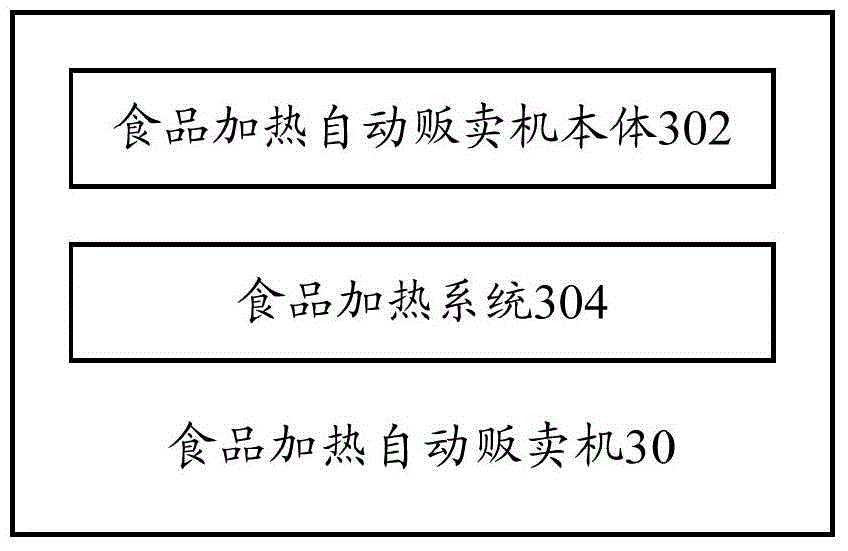

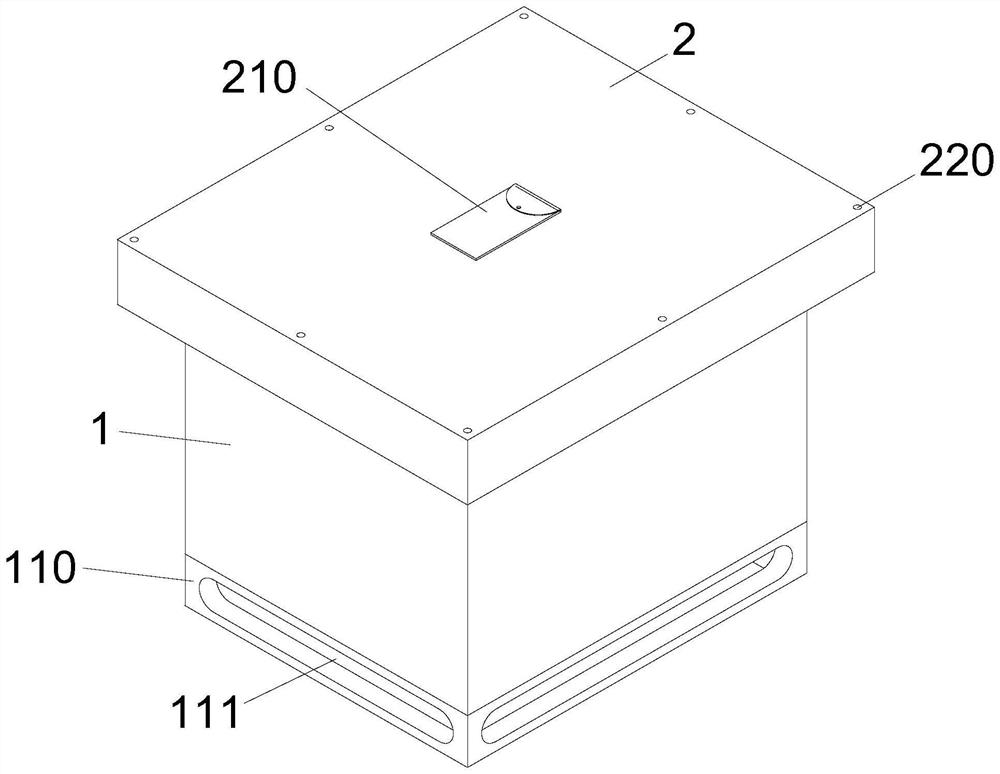

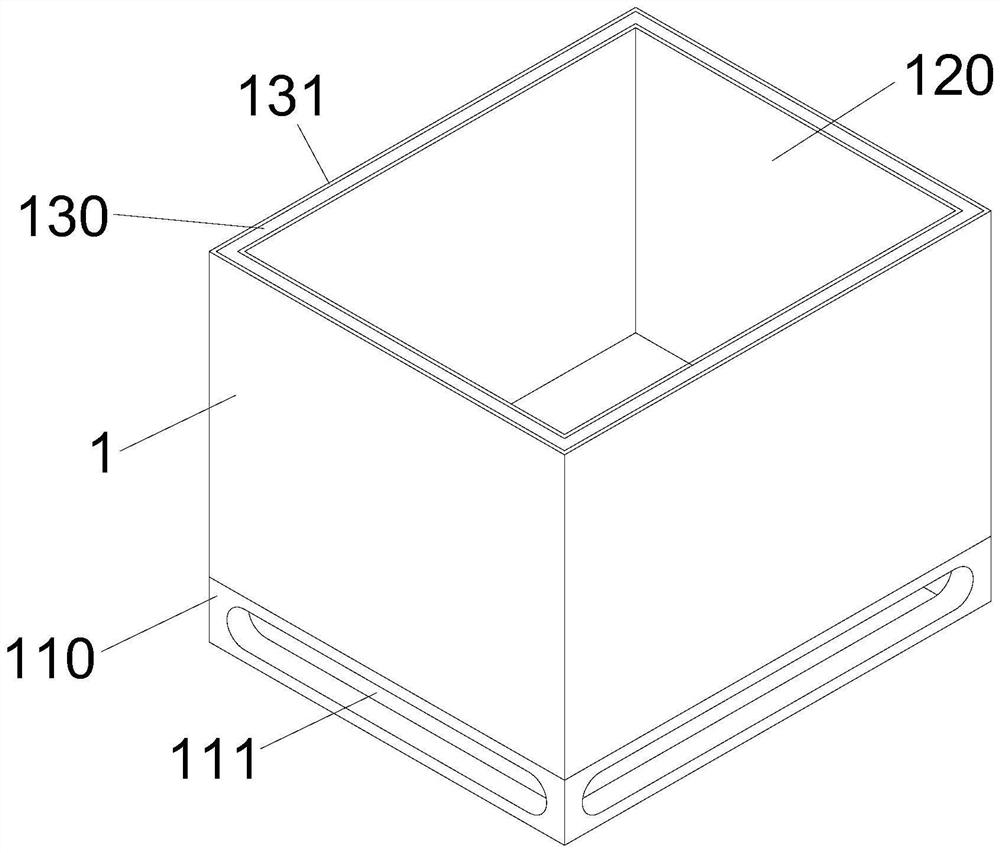

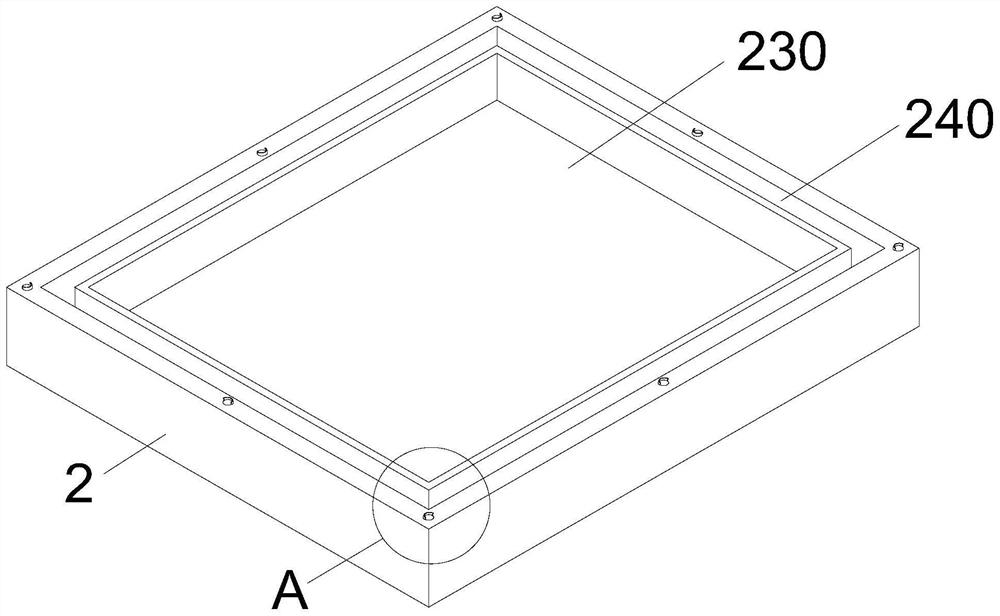

Automatic food heating and vending machine

InactiveCN104637168AQuick and direct accessImprove experienceCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringHeating system

The invention provides an automatic food heating and vending machine comprising an automatic food heating and vending machine body and a food heating system, wherein the food heating system is built in the automatic food heating and vending machine body and is used for automatically heating food. By means of the technical scheme of the invention, no matter a consumer purchases food in any form, the food can be automatically heated, moreover, the operation is simpler and safer, and the heated food can be obtained more quickly and directly, thereby improving the consumer experience and reducing the heat preservation energy consumption at the same time.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

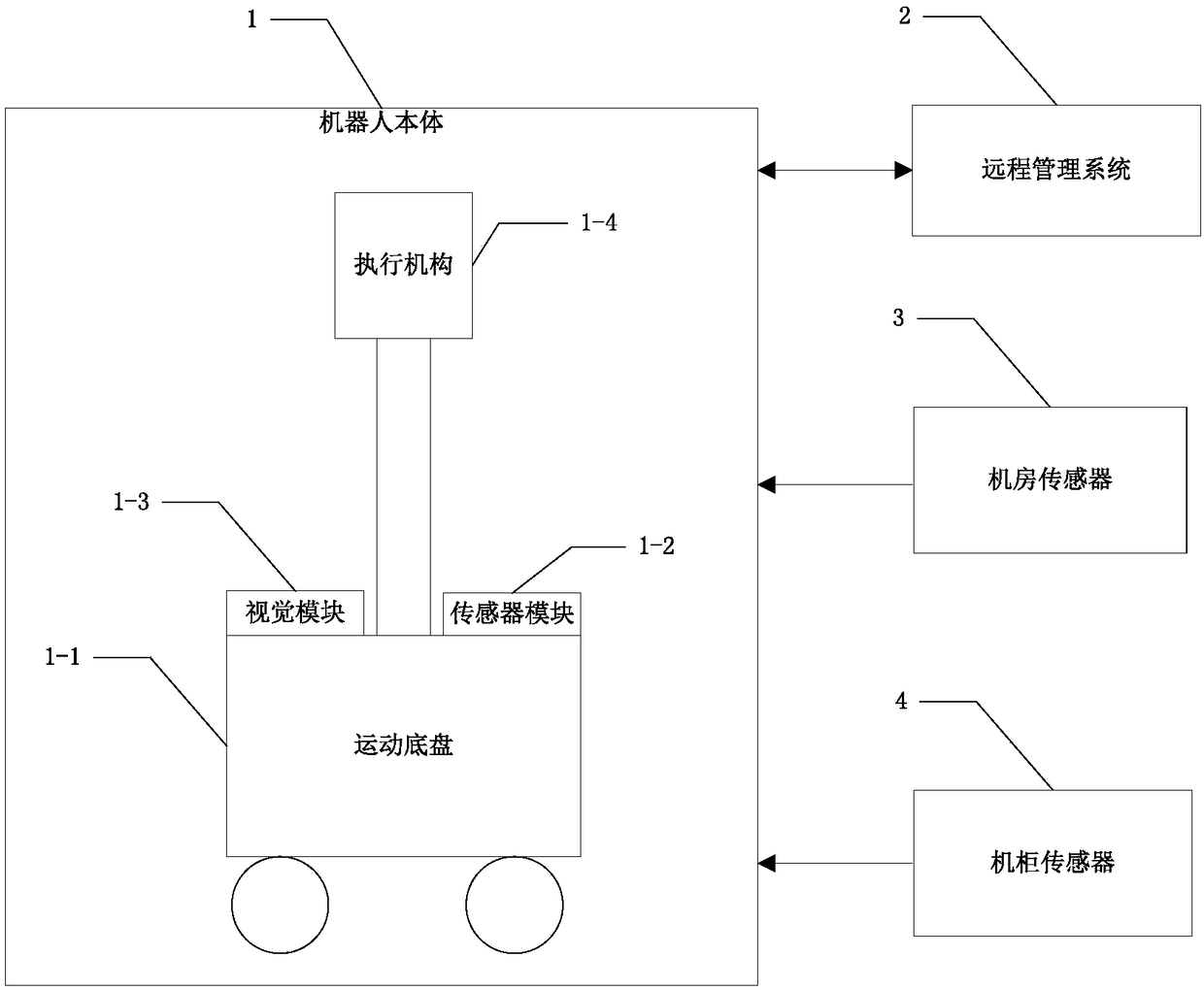

IDC equipment room operation and maintenance robot management system

InactiveCN109189056AReduce in quantityReduce operational safety hazardsMeasurement devicesPosition/course control in two dimensionsFixed positionManagement system

The invention discloses an IDC equipment room operation and maintenance robot management system. The IDC equipment room operation and maintenance robot management system comprises a robot body, a remote management system, an equipment room sensor and an equipment cabinet sensor; the equipment room sensor is deployed in a fixed position of the equipment room, and sends information obtained by the equipment room sensor in the position to the robot body; the equipment cabinet sensor is arranged on the equipment cabinet, and sends information obtained by the equipment cabinet sensor to the robot body; the remote management system is interconnected with the robot body, and receives, processes and integrates sensor data transmitted by the robot, so as to detect an environmental condition of theIDC room, operating states of sensors of the equipment cabinet and the equipment room, and an operating state of a server. The IDC equipment room operation and maintenance robot management system provided by the invention has the advantages of low cost and high reliability.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

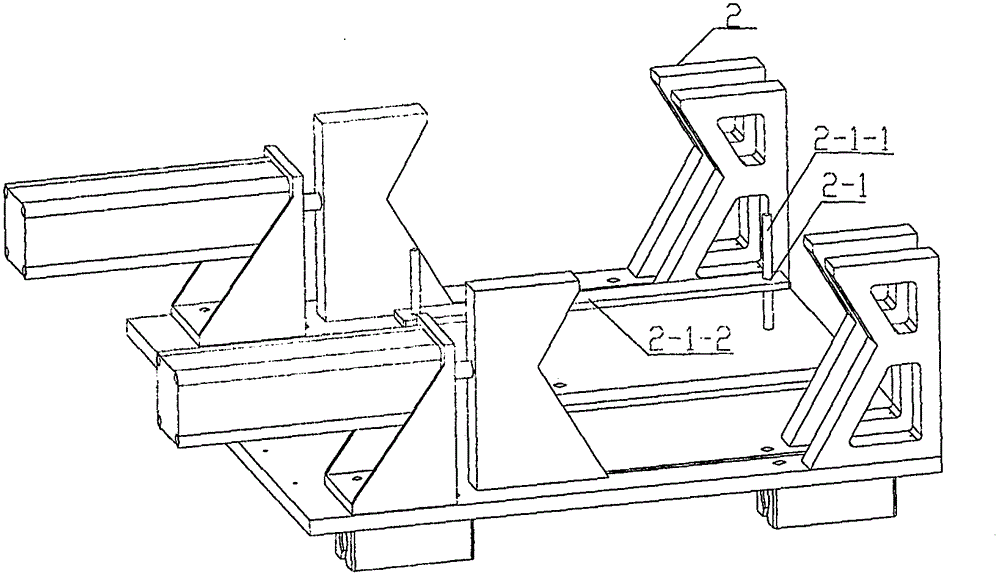

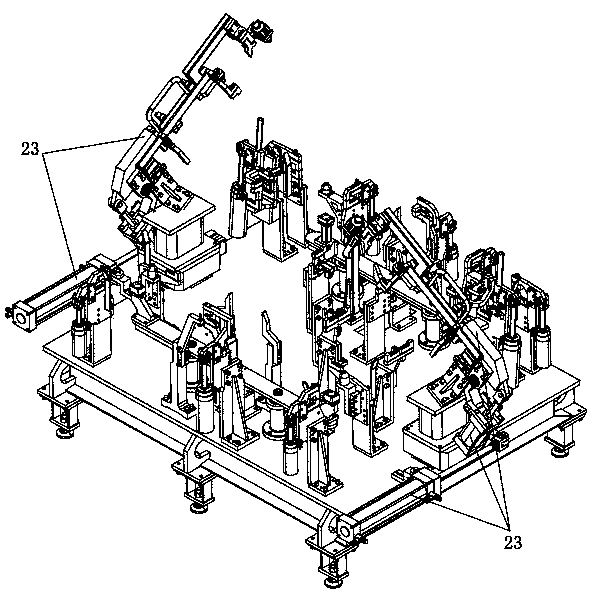

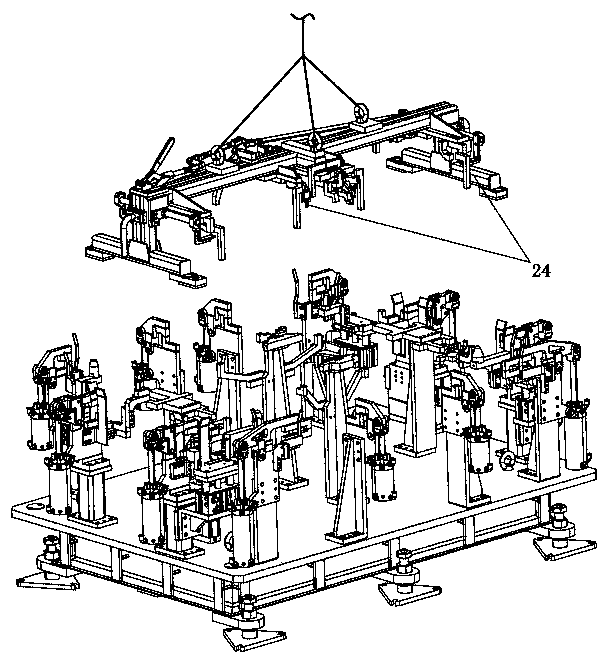

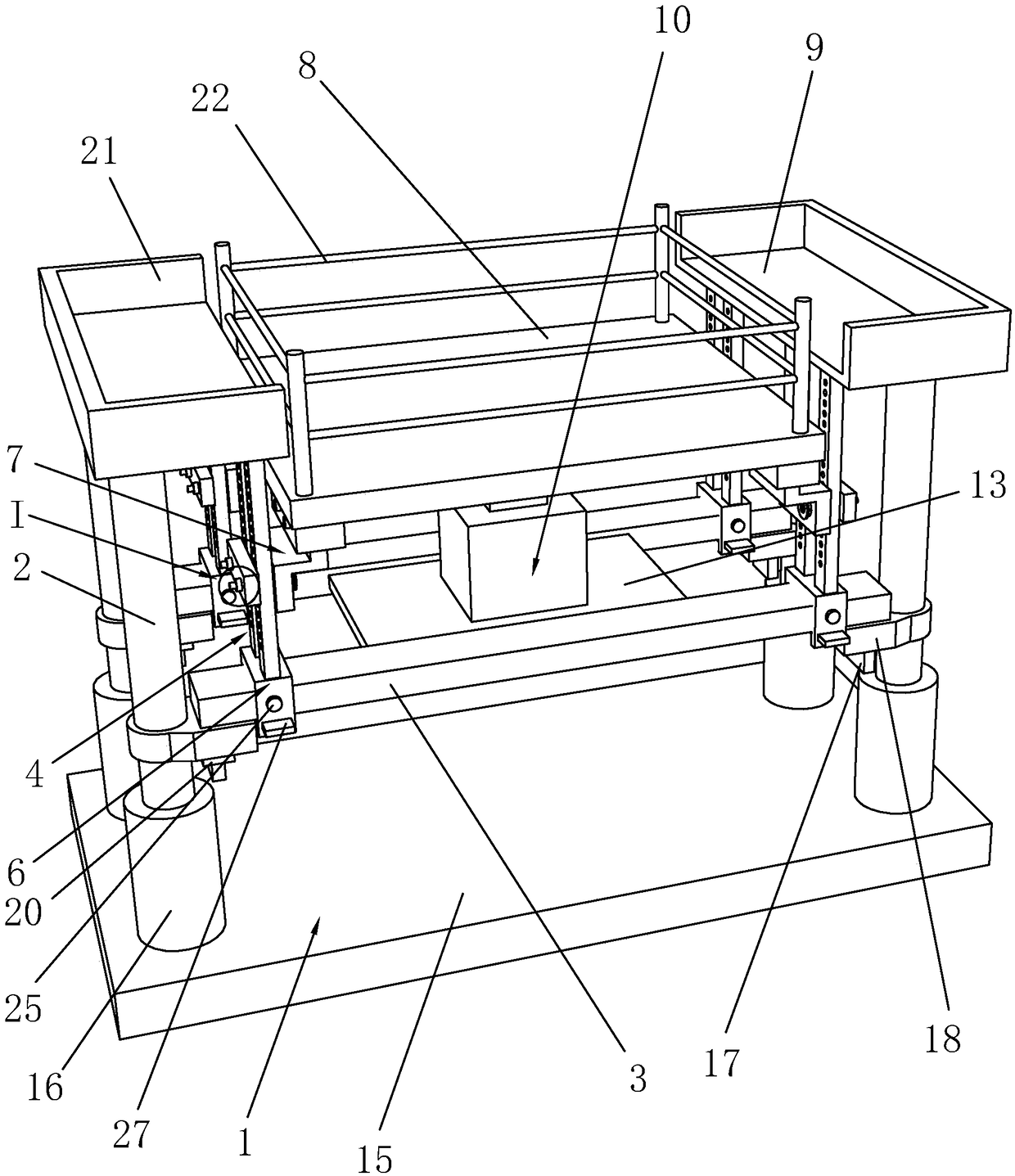

Fixture used for welding of automobile front floor and front row seat installation crossbeam

ActiveCN104308437ASmall working radiusStable structureWelding/cutting auxillary devicesAuxillary welding devicesSelf lockingEngineering

The invention relates to a fixture used for welding of an automobile front floor and a front row seat installation crossbeam. The fixture comprises a front floor positioning clamping device and a front row seat installation crossbeam positioning clamping device, wherein the front floor positioning clamping device and the front row seat installation crossbeam positioning clamping device are arranged on a fixture base. The front row seat installation crossbeam positioning clamping device comprises four upright columns divided into two groups, fixing beams connecting the top ends of the two groups of upright columns and a gantry framework structure formed by the upright columns and the fixing beams. A sliding beam is arranged under the fixing beams, the two ends of the sliding beam are connected with the upright columns in a sliding mode, and the middles of the fixing beams are provided with a self-locking cylinder, and the head of a piston rod of the self-locking cylinder is downward and is fixedly connected with the middle of the sliding beam. The upright columns are provided with limiting blocks, the sliding beam is provided with a cantilever moving in the front-back direction, clamping components are arranged on the cantilever, and positioning pins are disposed on the clamping components. The fixture can precisely position the front row seat installation crossbeam longitudinally and horizontally, the front row seat installation crossbeam does not shake during positioning, stability is good, and safety hidden hazards caused by shaking are avoided.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

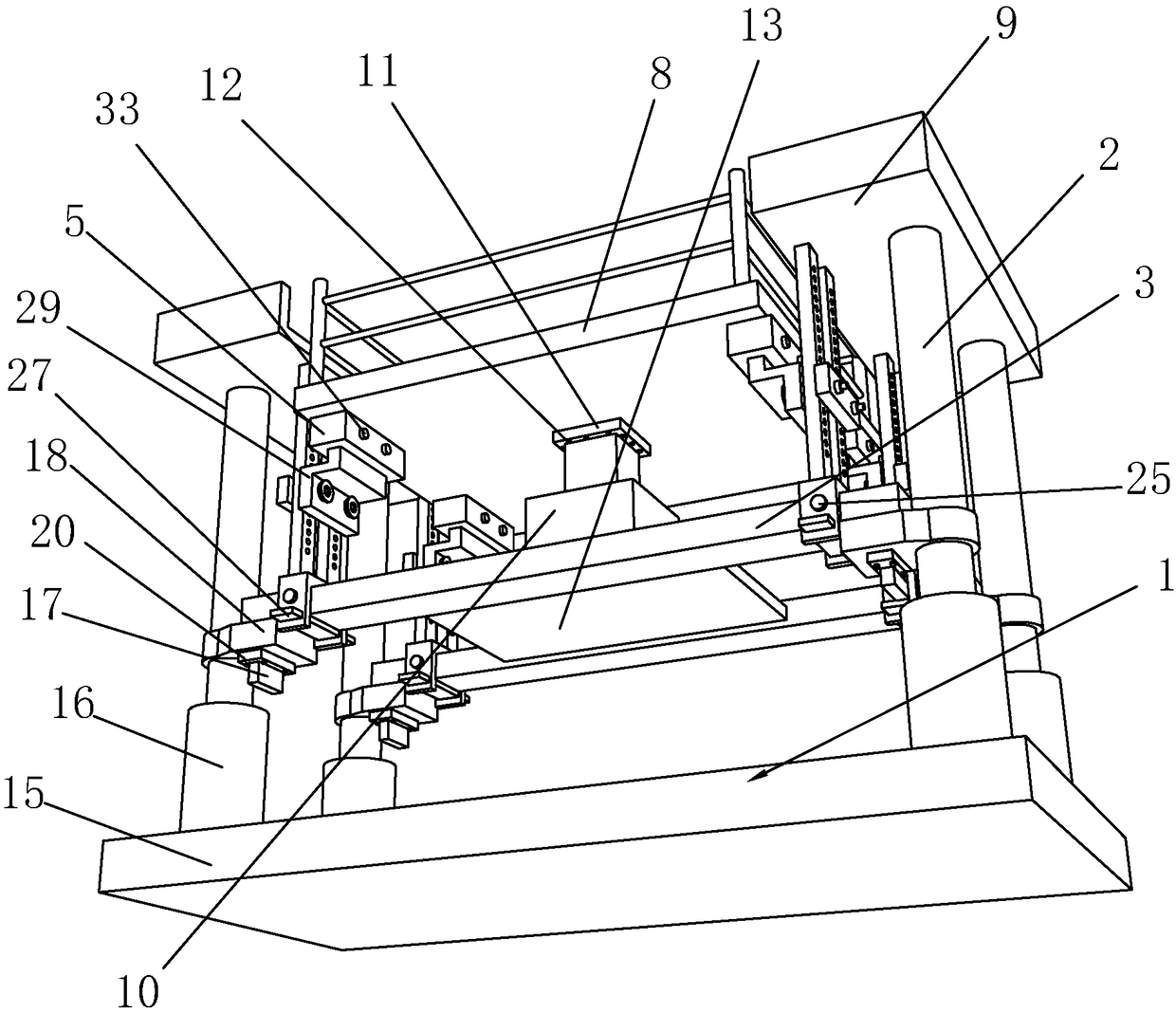

Supporting platform for building construction and installation method of supporting platform

PendingCN109339425ARealize automatic adjustmentImprove structural stabilityScaffold accessoriesUltimate tensile strengthSupport plane

The invention discloses a supporting platform for building construction. The supporting platform includes a supporting frame and a supporting table, the supporting frame comprises a supporting base, supporting columns, connecting rods and an adjusting frame, the supporting columns are uniformly arranged at the corners around the top face of the supporting base, the connecting rods are arranged between the left and right supporting columns correspondingly, the adjusting frame includes a fixing rod piece and an adjusting rod piece, and the supporting table includes a main supporting table and anauxiliary supporting table. An installation method includes the following steps that a, the supporting frame is installed; b, a hydraulic lifting column is installed; c, the supporting table is installed; and d, regular maintenance and overhaul are carried out. According to the supporting platform for building construction and the installation method of the supporting platform, overall design isreasonable, the structure is simple, building and disassembling are convenient, and the overall structural strength and stability of the supporting platform are high; and through design of the main supporting table and the auxiliary supporting table, the functionality and security of the supporting platform are additionally achieved, the main supporting table can facilitate standing of an operator, the auxiliary supporting table can facilitate placement of materials and tools, and meanwhile the height of the main supporting table can be adjusted up and down according to the actual demands.

Owner:ZHEJIANG UNIV OF TECH

Method for comprehensively processing chicken gallbladders by using biological enzyme

InactiveCN108504714ALow costReduce operational safety hazardsAnimal feeding stuffFermentationEconomic benefitsStearic acid

The invention discloses a method for comprehensively processing chicken gallbladders by using a biological enzyme. The method comprises the following steps: heating frozen chicken gallbladders to unfreeze the chicken gallbladders, filtering the chicken gallbladder, adding the obtained filtered bile into a hydrolysis kettle, and adding a bile salt thallus hydrolase to hydrolyze the bile in the chicken gallbladders and complex bile acid, wherein the biological enzyme has the advantages of high efficiency, specificity, safe reaction environment and environmental protection; and processing the obtained hydrolyzed leftovers, hydrolyzing proteins, gallbladder skins and adhered stearic acid in the bile by using the biological enzyme, and performing concentrating spraying to obtain an animal feedprotein additive. The method has the advantages of maximal utilization of biological resources, no generation of three wastes in the operating process, greenness, environmental protection, and good social and economic benefits.

Owner:CHANGDE YUNGANG BIOTECHNOLOGY CO LTD

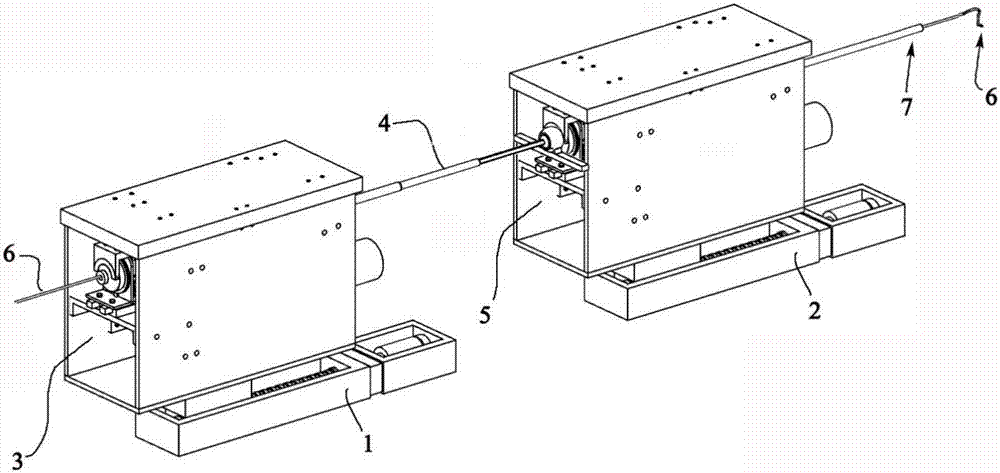

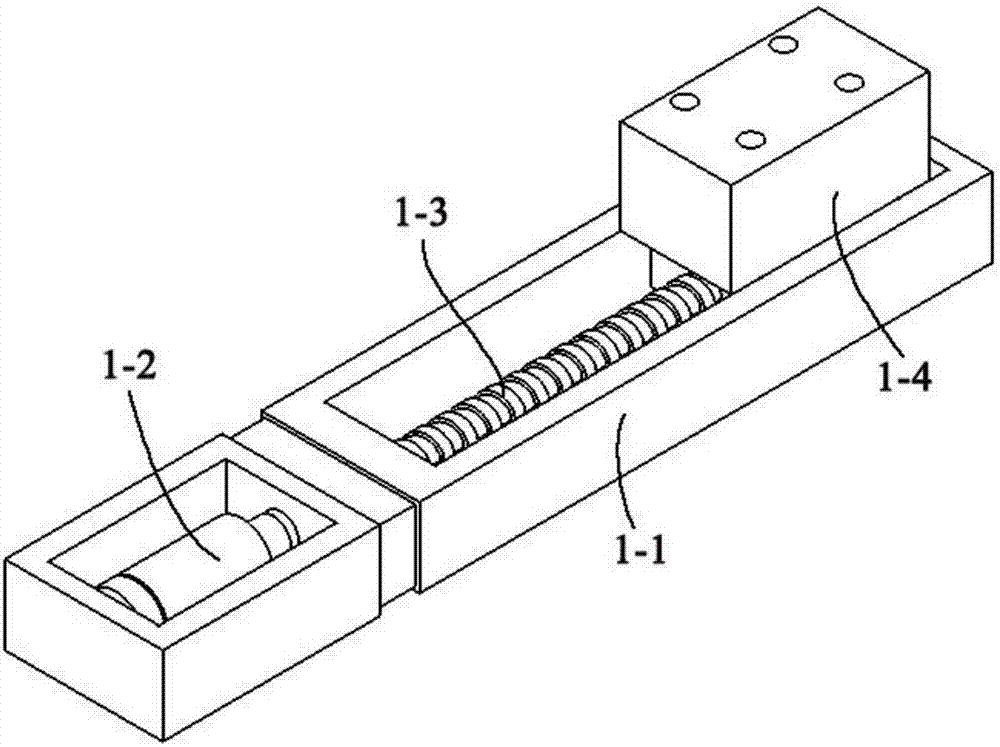

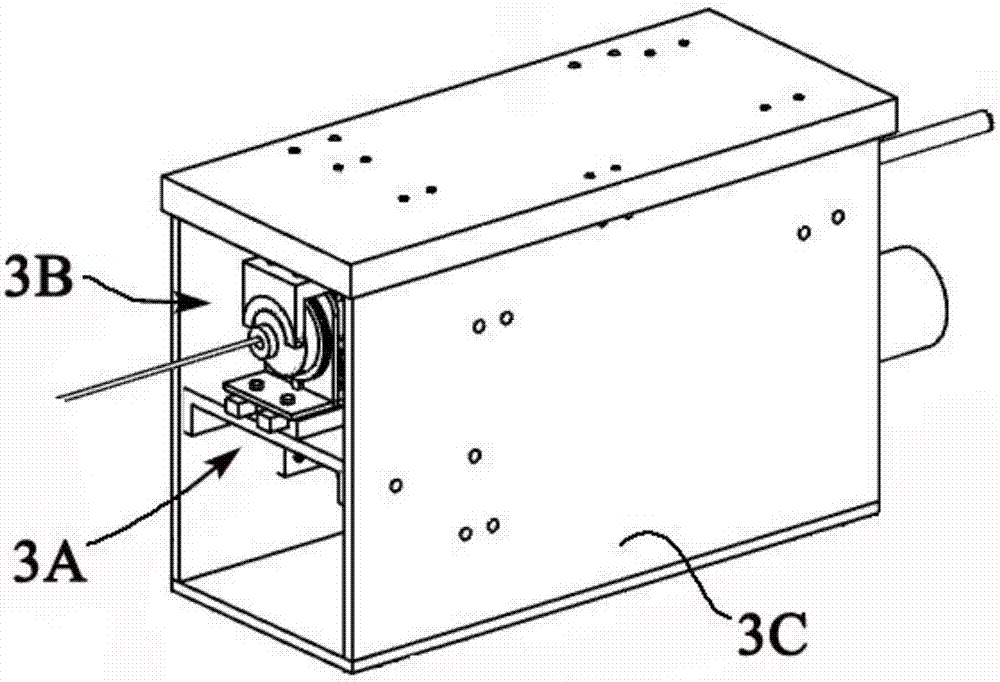

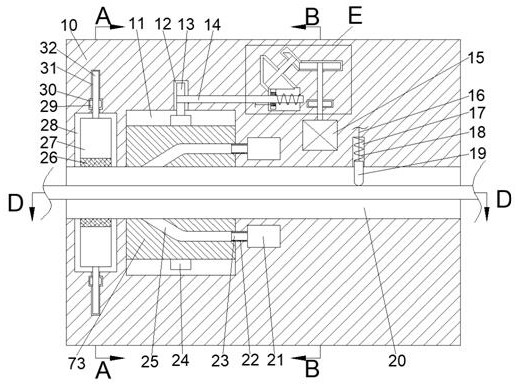

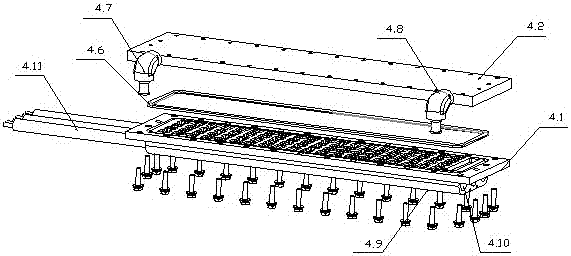

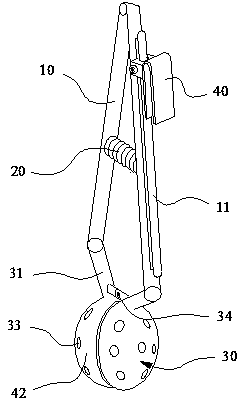

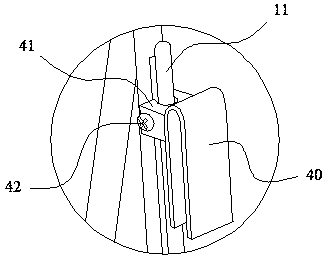

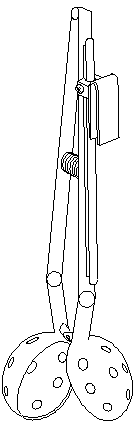

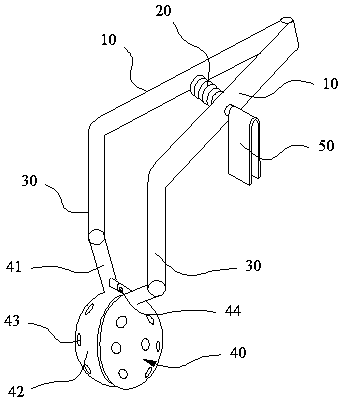

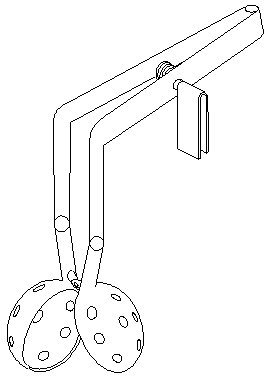

An interventional surgery robot and its control method for collaboratively pushing a catheter guide wire

ActiveCN105662586BImprove operating precisionImprove surgical efficiencyOperating tablesSurgical robotsSurgical robotEngineering

The invention discloses an interventional operation robot where a catheter and a guide wire are cooperatively pushed and a control method thereof and belongs to the technical field of machine manufacturing.The robot comprises a guide wire moving platform, a catheter moving platform, a guide wire operation end, a supporting guide frame, a catheter operation end, the guide wire and the catheter.The two ends of the supporting guide frame are connected with the guide wire operation end and the catheter operation end respectively.The catheter penetrates through the catheter operation end, and the guide wire is arranged in the catheter and penetrates into the guide wire operation end.Meanwhile, the invention further discloses the control method of the robot.By means of the guide wire operation end and the catheter operation end, movement of the guide wire and movement of the catheter are controlled respectively so that the catheter and the guide wire can be operated according to specific operation of a doctor, it is guaranteed that the guide wire and the catheter can be pushed cooperatively in the operation process, operation actions of the doctor can be completely simulated, and the robot has the advantages of being reasonable in structure, convenient to control and the like.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

Extrusion molding mold for automatic coating of wires and cables

InactiveCN111958935ANo risk of burnsReduce operational safety hazardsDomestic articlesCoatingsEngineeringStructural engineering

The invention relates to the field of plastic molds, and discloses an extrusion molding mold for automatic coating of wires and cables. The extrusion molding mold includes a main box body, a cable conveying cavity is formed in the main box body in a left-right penetrating mode, lifting cavities in upper-lower symmetric are formed in the upper side and the lower side of the cable conveying cavity in a communicating mode, nut rotating cavities are formed in the end walls of the sides, away from the cable conveying cavity, of the lifting cavities, and sliding rod cavities are formed in the side,away from the cable conveying cavity, of the nut rotating cavities, wherein the sliding rod cavities extend in the direction of the side close to the cable conveying cavity and penetrate through the nut rotating cavities into the lifting cavities. A mechanism is used for clamping the head of a coating layer to instead of manually pinching by hand, so that an operator is prevented from the risks ofscalding, the potential safety hazard of worker is greatly reduced, meanwhile, a rotating coating mechanism enables the wires and cables to be coated more tighter, the coating effect is greatly increased, meanwhile, according to the diameter of the wires and cables, the rotation speed of the coating layer is automatically adjusted, and thus it is ensured that the coating layers of the wires and cables of different diameters can achieve a tight coating effect.

Owner:福州约春向科技有限公司

Bimetallic catalytic reforming catalyst containing LTL type molecular sieve

InactiveCN108236964AHigh reactivityReduce device operation safety hazardsMolecular sieve catalystsNaphtha reformingIon exchangeChemistry

The invention relates to a catalytic reforming catalyst containing an LTL type molecular sieve. The catalytic reforming catalyst comprises the following components: (1) a catalyst carrier composed of10-100wt% of an LTL type molecular sieve and 0-90wt% of a binding agent; (2) lanthanide metal ions exchanging and replacing 5-100mol% of positive ions in the LTL type molecular sieve, wherein the content of the lanthanide metal ions is higher than or equal to 5mol% of the total amount of the positive ions, and the content of H<+> in the LTL type molecular sieve is less than 5mol% of the total amount of the positive ions; (3) a VIIIB group metal contained on the catalyst, wherein the content of the VIIIB group metal accounts for 0.1-50wt% of carrier; and (4) Sn or Re contained on the catalyst,wherein the content of Sn or Re accounts for 0.1-5wt% of the carrier. The catalytic reforming catalyst provided by the invention can realize dehydrogenation, dehydrocyclization, aromatization and thelike and has relatively high reaction activity, selectivity and stability.

Owner:PETROCHINA CO LTD

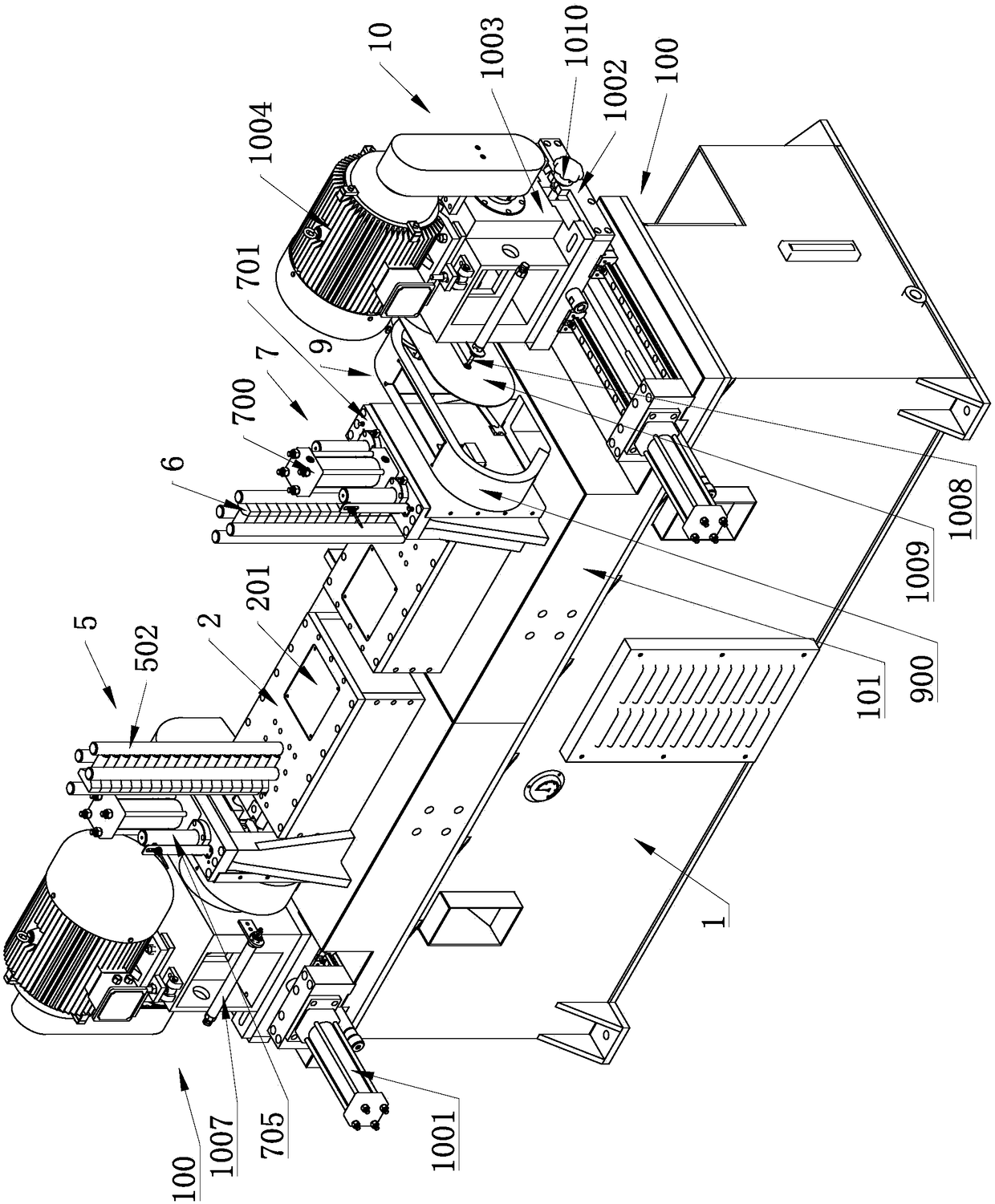

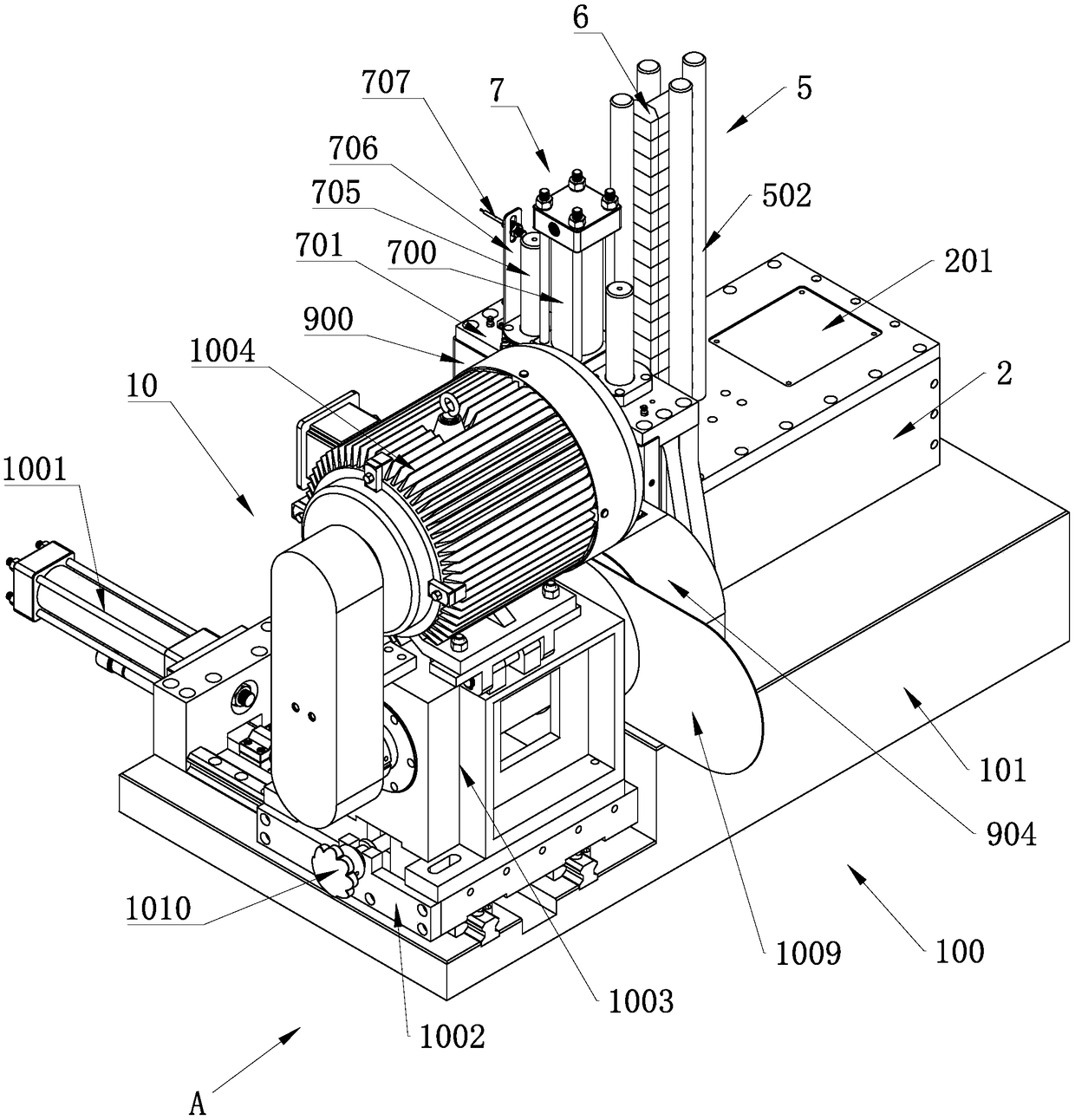

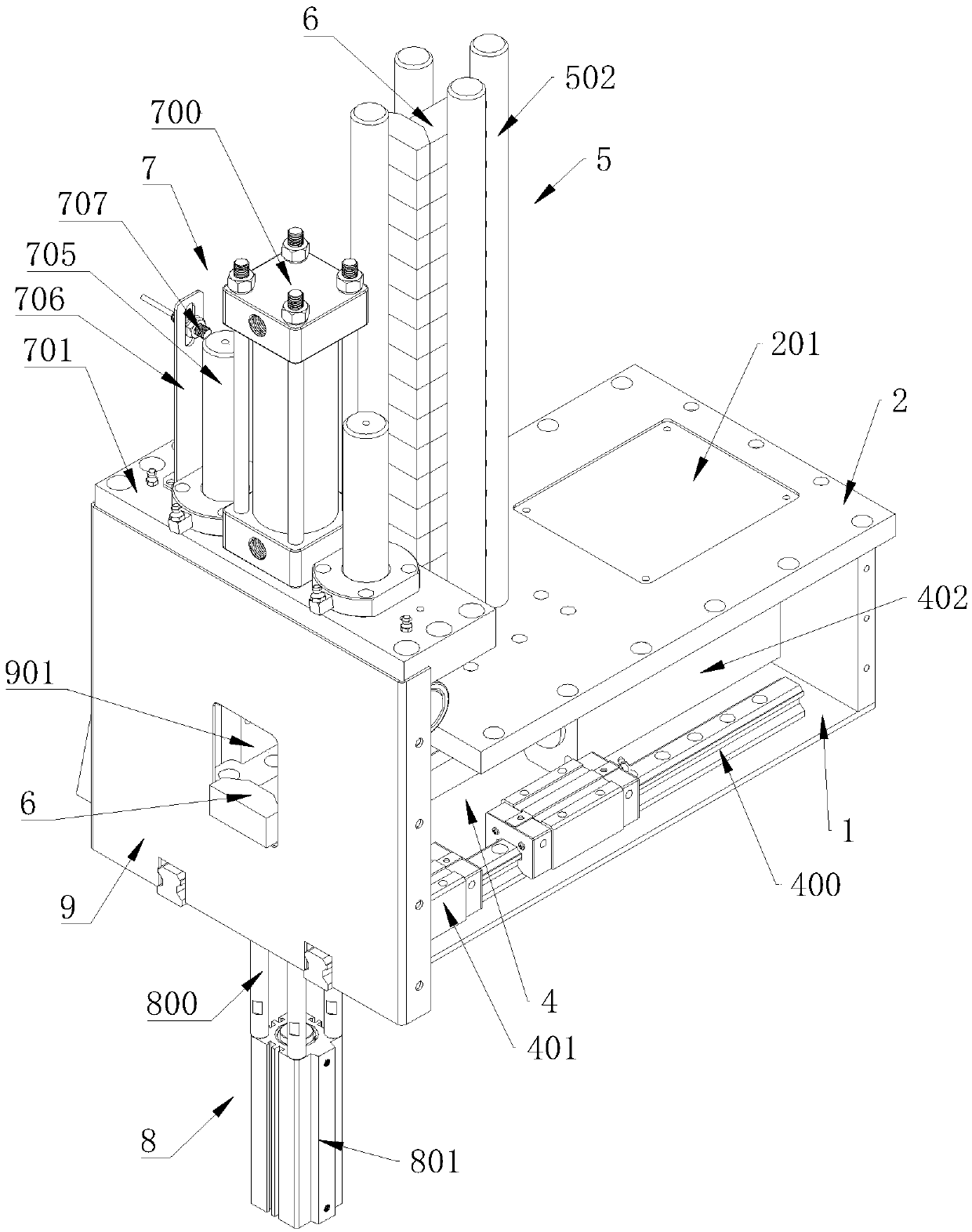

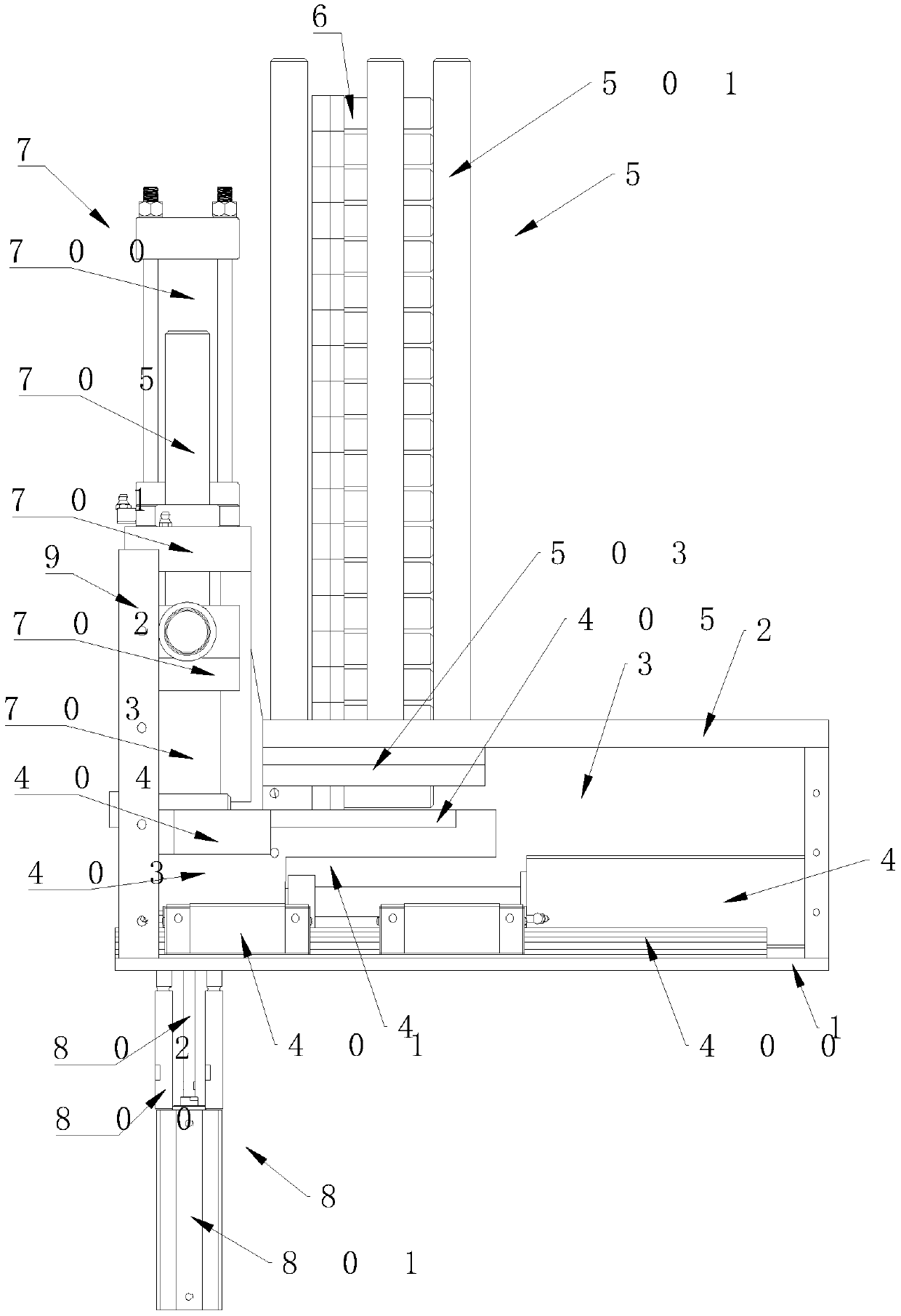

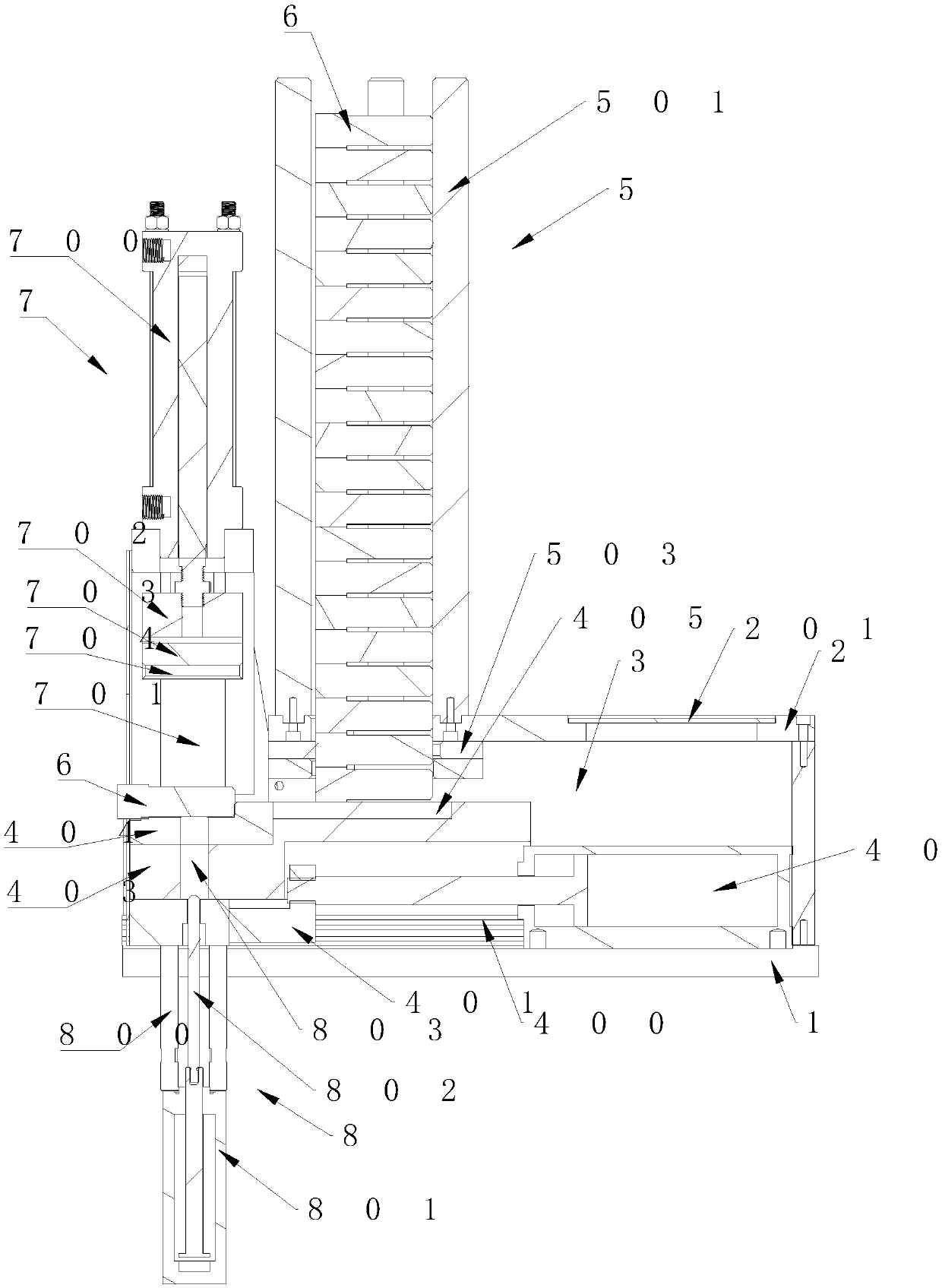

End face machining method of bolts and end face machining machine achieving method

PendingCN109352044AImprove push effectEasy to replaceMilling equipment detailsMetal working apparatusEngineeringOperation safety

The invention discloses an end face machining method of bolts and an end face machining machine achieving the method. The method comprises the following steps that bolts to be machined are guided andconveyed one by one; the guided and conveyed bolts to be machined are pushed to the machining station, and in the pushing process, a pushing mechanism used for pushing the bolts to be machined to abutagainst next bolts to be machined; the to-be-machined bolts pushed to the machining station are located and clamped; composite end face machining is carried out; an end face machining device used formachining the end face and a clamping mechanism used for clamping are reset; the machined bolts are conveyed in an ejected manner; the bolts conveyed in an ejected manner are conveyed; and the pushing mechanism is reset to push the next bolts to be machined. According to the method, assembly automatic guiding, conveying, pushing, clamping, locating and machining of the bolts, and ejected conveying and outputting of the machined bolts are achieved, the potential safety hazards in the operation of the bolt clamping process and labor intensity of personnel are reduced, and meanwhile the work continuity and the working efficiency are improved greatly.

Owner:张家港市润泰机械有限公司

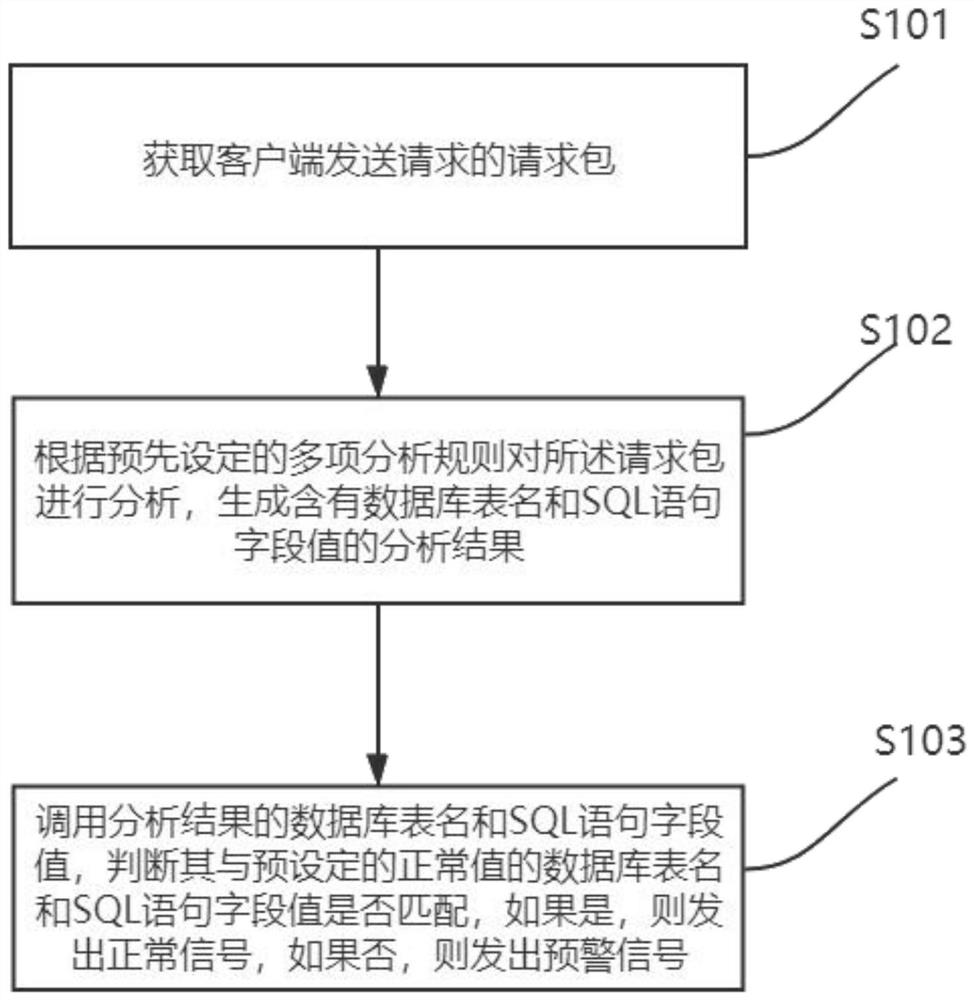

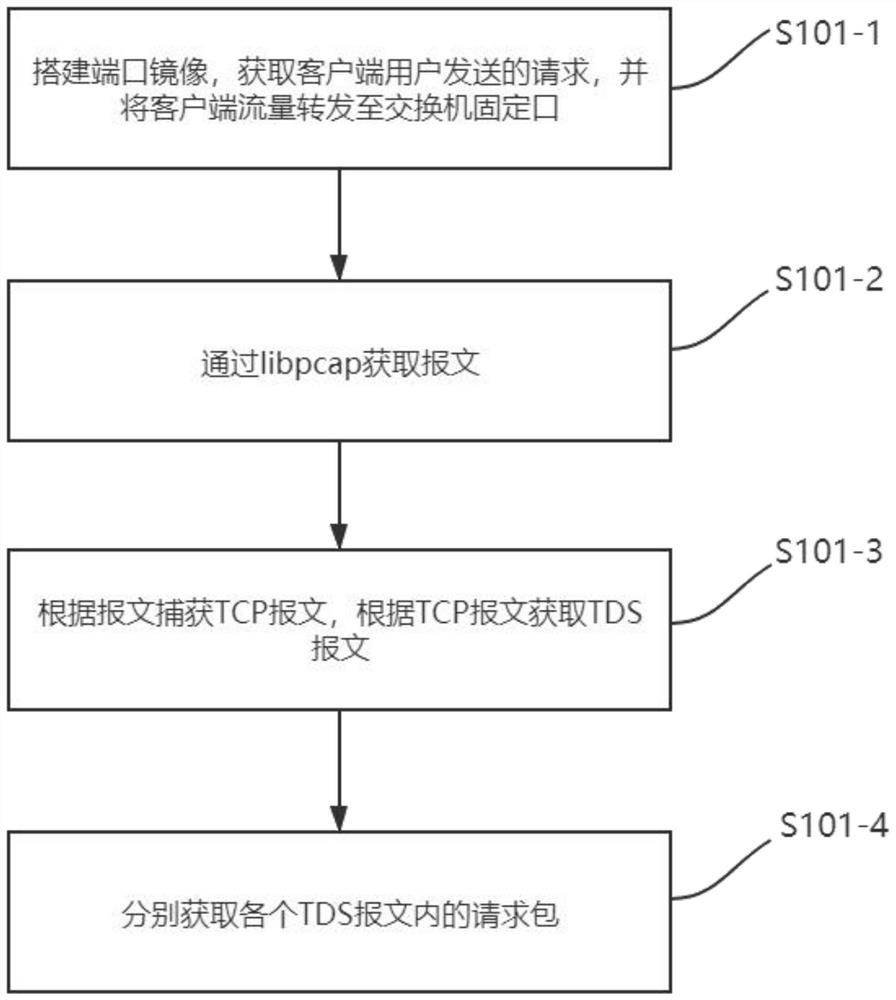

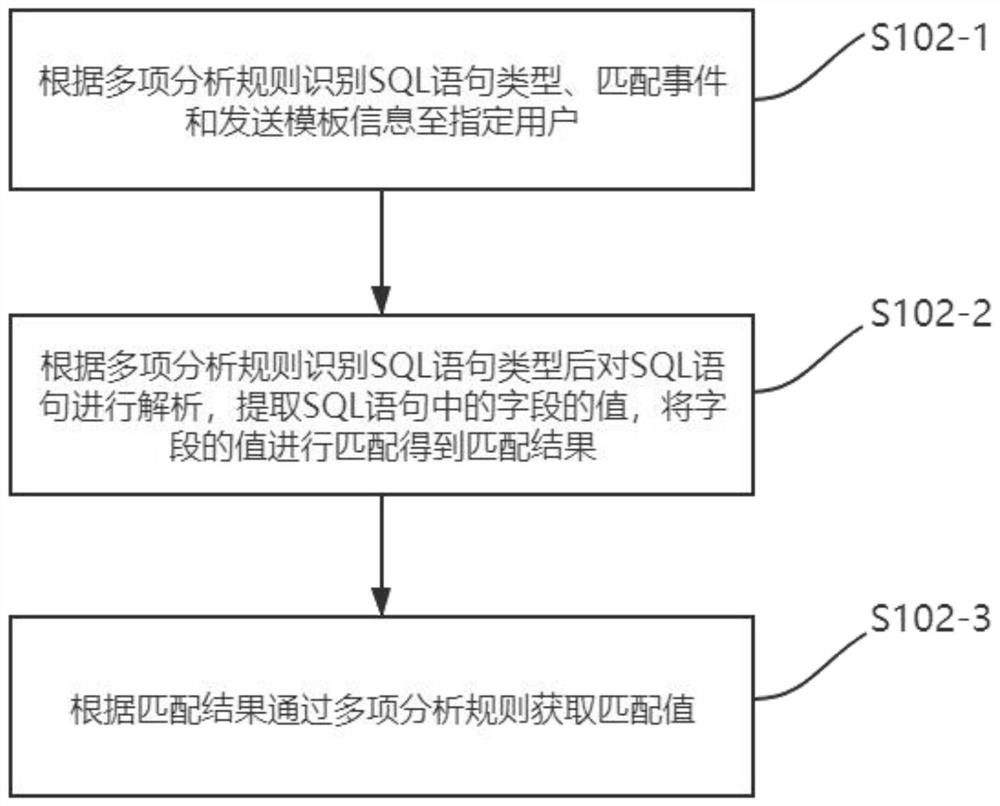

Clinical risk early warning method and system based on libpcap

PendingCN112217809AKnow accessReduce operational hazardsEpidemiological alert systemsTransmissionEarly warning systemThird party

The invention discloses a clinical risk early warning method based on libpcap. The method comprises the following steps of a, obtaining a request packet of a request sent by a client; b, analyzing therequest packet according to a plurality of preset analysis rules to generate an analysis result containing a database table name and an SQL statement field value; and c, calling the database table name and the SQL statement field value of the analysis result, judging whether the database table name and the SQL statement field value are matched with the database table name and the SQL statement field value of a preset normal value or not, if so, sending a normal signal, and if not, sending an early warning signal. The invention further discloses a clinical risk early warning system based on the libpcap. According to the method, potential safety hazards of internal personnel operation can be reduced, potential safety hazards of third-party maintenance personnel are reduced, potential safetyhazards of system account sharing are reduced, and potential safety hazards of users with the highest authority are reduced.

Owner:遂宁浩洋商贸有限公司

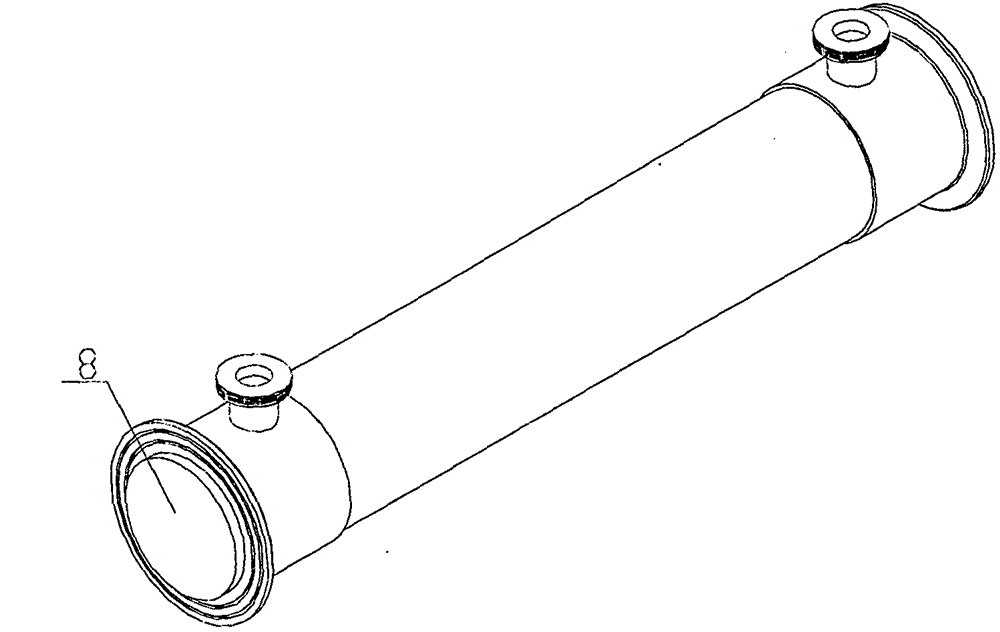

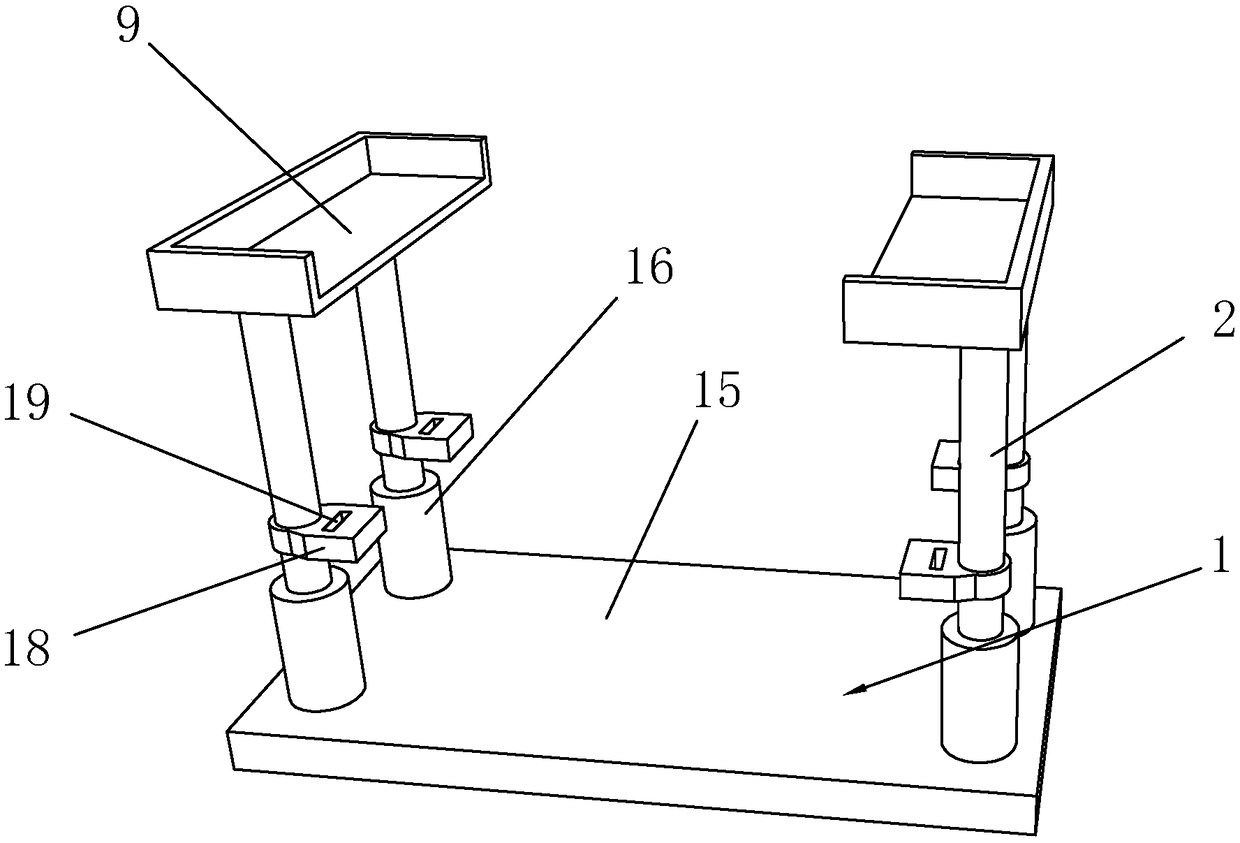

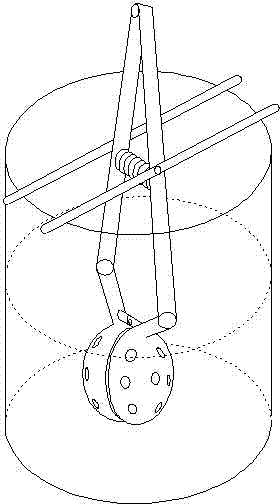

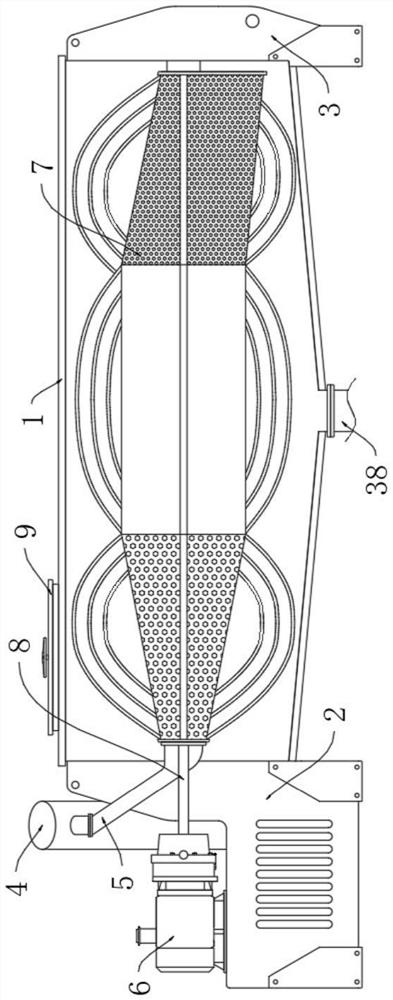

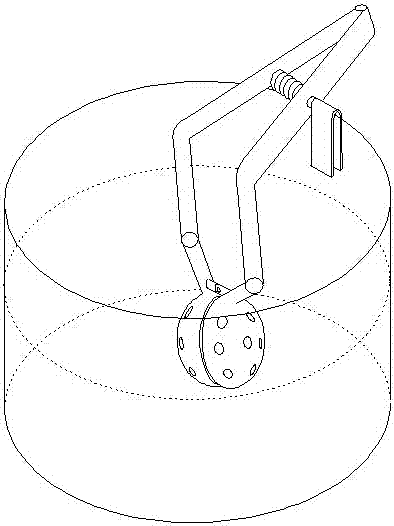

Full-automatic hoisting type vertical sterilizer

PendingCN107080852AEasy accessReduce operational safety hazardsLavatory sanitoryHeatElectric machineDistilled water

The invention relates to a full-automatic hoisting type vertical sterilizer. The full-automatic hoisting type vertical sterilizer is characterized by comprising a bottom plate, a barrel body, a speed reducing motor and a steam generator, wherein a water tank for storing distilled water is mounted on the bottom plate; the steam generator is mounted on the bottom plate; a water pump located on the bottom plate is used for conveying the distilled water in the water tank into the steam generator; a gas outlet of the steam generator is communicated with the inner part of the barrel body through a pipeline; a vacuum pump, which is communicated with the barrel body, is mounted on the barrel body and is used for vacuumizing; an exhaust opening in the barrel body is used for cooling and exhausting through a condenser mounted on the bottom plate; a door cover capable of being hoisted is mounted on the barrel body; the door cover is hoisted under the action of a speed reducing motor. The full-automatic hoisting type vertical sterilizer has the advantages that materials are convenient to fetch; meanwhile, the potential safety hazards of operation are reduced and the efficiency is improved.

Owner:JIANGYIN BINJIANG MEDICAL EQUIP

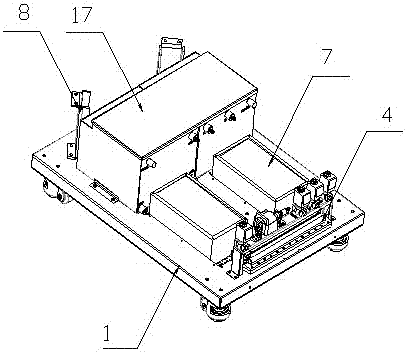

Bolt pre-processing assembly

PendingCN109514334AImprove push effectEasy to replaceWork clamping meansPositioning apparatusEngineeringOperation safety

The invention discloses a bolt pre-processing assembly. The bolt pre-processing assembly comprises an installation body. A support body is arranged on the installation body. An installation cavity isformed between the support body and the installation body. A material pushing mechanism is slidably installed on the portion, positioned in the installation cavity, of the installation body. A bolt guiding mechanism communicated with the installation cavity is arranged on the support body. A clamping mechanism is arranged on the portion, at one end of the support body, of the installation body. The clamping mechanism is arranged in the pushing direction of the material pushing mechanism. A material jacking mechanism for jacking and conveying bolts pushed by the material pushing mechanism is arranged on the material pushing mechanism. By adopting the bolt pre-processing assembly, the mechanical guiding, pushing, clamping and positioning of the bolts and the jacking and conveying work afterthe bolt processing is completed are realized, and compared with a traditional manual bolt transferring and clamping mode, by the adoption of the bolt pre-processing assembly, the potential safety hazard of operation in the bolt clamping process is greatly reduced, and the labor intensity of workers is greatly reduced as well; and meanwhile the work continuity and work efficiency are effectively improved.

Owner:张家港市润泰机械有限公司

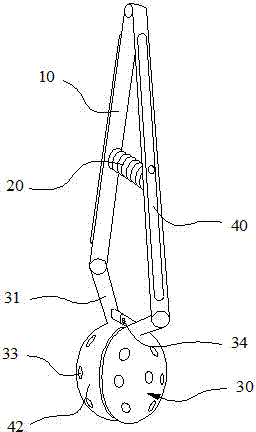

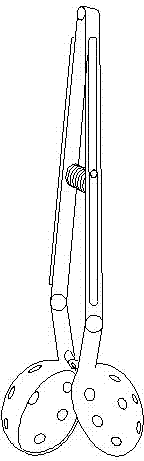

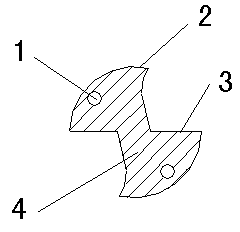

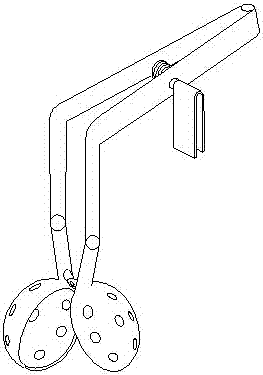

Operation method of solid and liquid reagent reaction experiment

InactiveCN104492347AControl samplingEasy to operateLaboratory glasswaresChemical/physical processesChemical reactionLiquid state

The invention provides an operation method of a solid and liquid reagent reaction experiment. The method is characterized in that a specially-designed solid-state reagent clamping device is adopted, sampling of solid-state reagents can be controlled by virtue of the solid-state reagent clamping device by only needing simple operations of holding and loosening two clamping arms, a clamping state of the solid-state reagents can be stably maintained, so that under the consideration of a specific operation process, the solid-state reagent clamping device is mounted on a beaker mouth in which liquid-state reagents are held by virtue of support rods on the two clamping arms, and thus, the solid-state reagents and the liquid-state reagents are converged and reacted; moreover, the solid-state reagent clamping device can be taken out of a beaker anytime so as to stop the reaction, and therefore, solid-liquid separation is convenient to operate, other impurities are not introduced, the harm to operation personnel is avoided, the operation potential safety hazard is reduced, and the problems that the solid-liquid separation is difficult to operate in the solid and liquid reagent reaction experiment in the prior art, the impurities are easily introduced and the operation potential safety hazard happens are solved well.

Owner:CHONGQING YUEFA COMMODITY

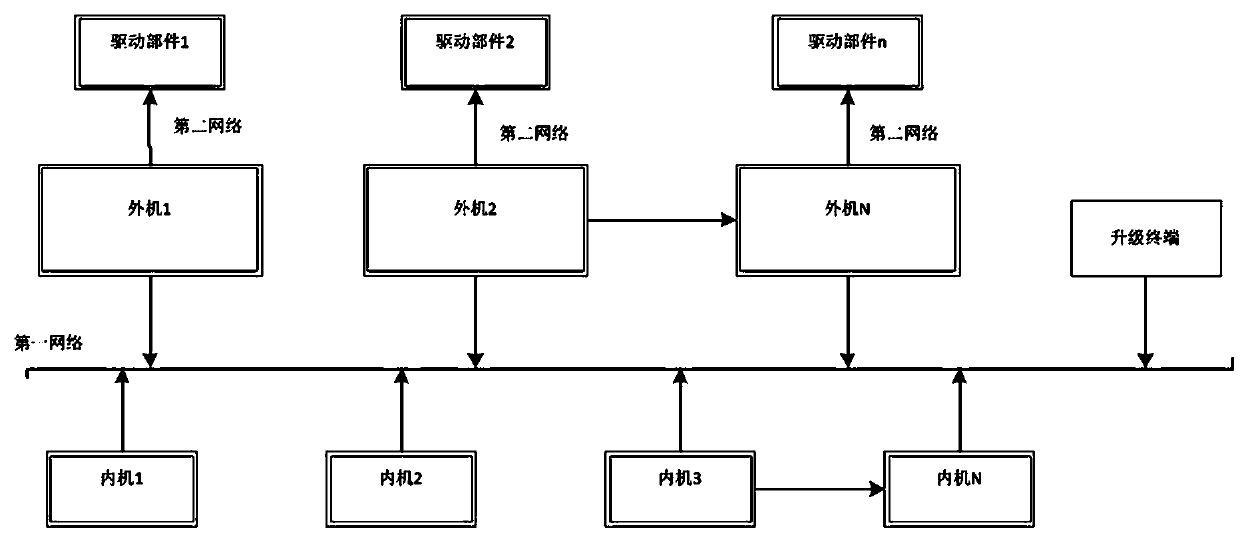

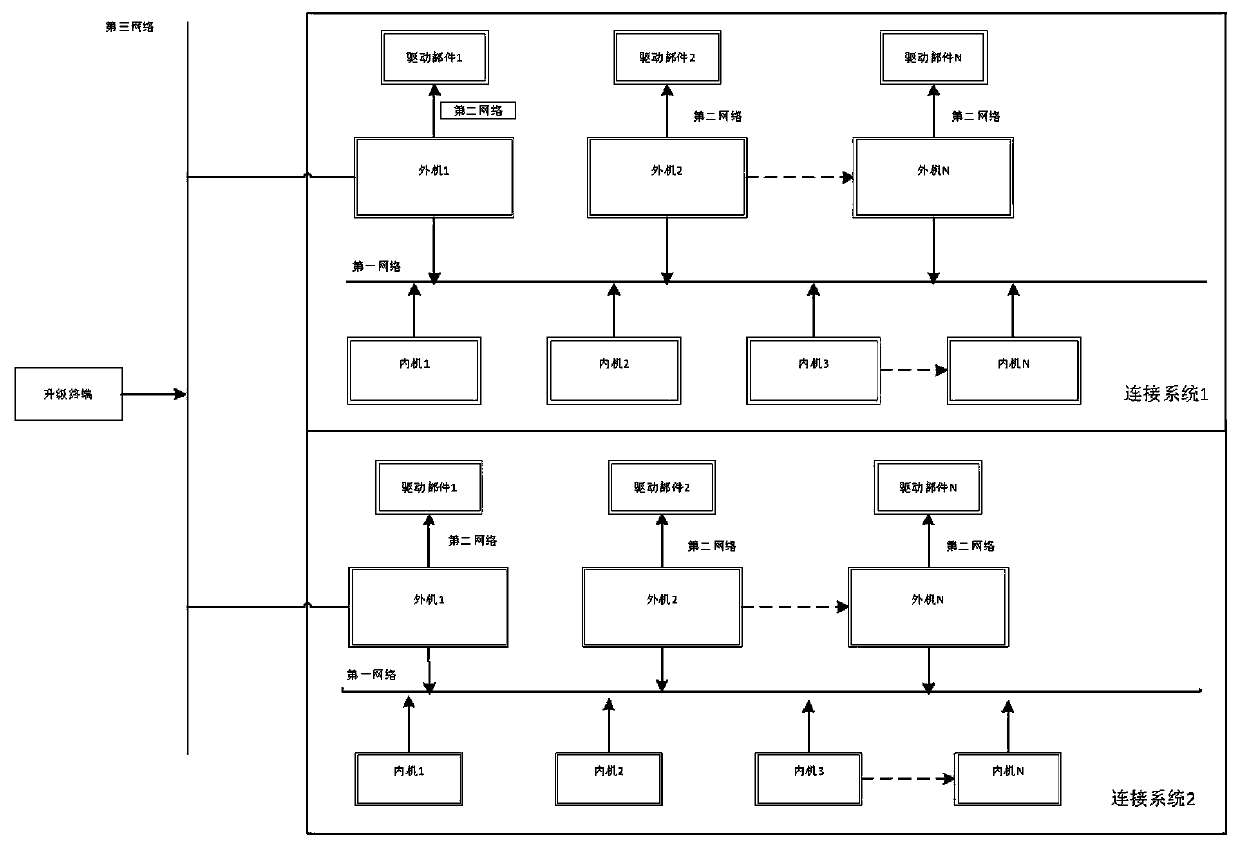

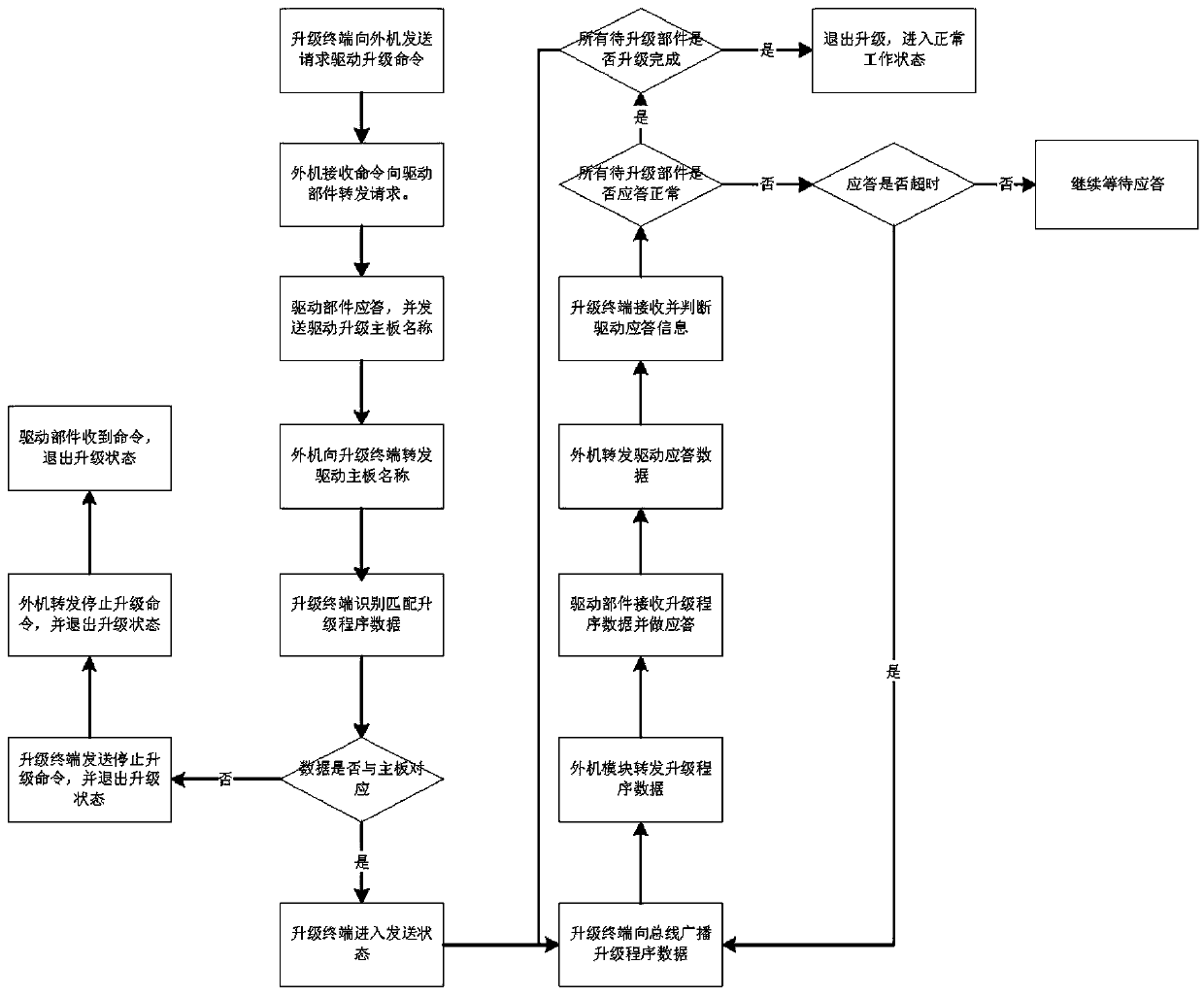

Software upgrading method of air conditioning system

InactiveCN110990040AReduce programming error rateImprove maneuverabilityTransmissionSoftware deploymentProcess engineeringAir conditioning

The invention discloses a software upgrading method of an air conditioning system. The method comprises the following steps that: an upgrading terminal loaded with upgrading program data is connectedwith the network of the air conditioning system, and the air conditioning system enters an upgrading state; the upgrading terminal acquires the identification data of a to-be-upgraded part in the airconditioning system; whether at least one piece of upgrading program data is uniquely matched with the to-be-upgraded part or not is judged, if at least one piece of upgrading program data is uniquelymatched with the to-be-upgraded part, the upgrading terminal sequentially broadcasts each piece of upgrading program data to each outdoor unit through a bus, and the upgrading program data are forwarded to the connecting parts of the outdoor units through outdoor unit protocol conversion; the to-be-upgraded part judges whether the upgrading program data are upgrading program data matched with theto-be-upgraded part, if the upgrading program data are the upgrading program data matched with the to-be-upgraded part, upgrading is conducted, and response data of successful upgrading are sent to the upgrading terminal through outdoor unit protocol conversion; and if the corresponding to-be-upgraded part is successfully upgraded, the upgrading terminal informs the air conditioning system of quitting the upgrading state. By means of the method, the multiple outdoor units of a multi-split air conditioner can be upgraded, and the upgrading process of operators is simplified.

Owner:GREE ELECTRIC APPLIANCES INC

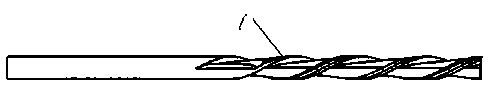

High-strength edge trimmer milling cutter

The invention discloses a high-strength edge trimmer milling cutter. A spiral-groove-shaped cutting edge is formed on the high-strength edge trimmer milling cutter, the spiral angle of the spiral-groove-shaped cutting edge is 30 degrees, and the cutting edge angle of the spiral-groove-shaped cutting edge is 60 degrees. The high-strength edge trimmer milling cutter has the advantages that the cutting edge shape and the cutting edge angle are rationalized to facilitate cutting of plates of the milling cutter and further to improve production efficiency; meanwhile, the strength of the milling cutter is improved, and accordingly the service life of the high-strength edge trimmer milling cutter is prolonged and potential risks of operation are reduced.

Owner:DANYANG CITY EAGLE TOOLS

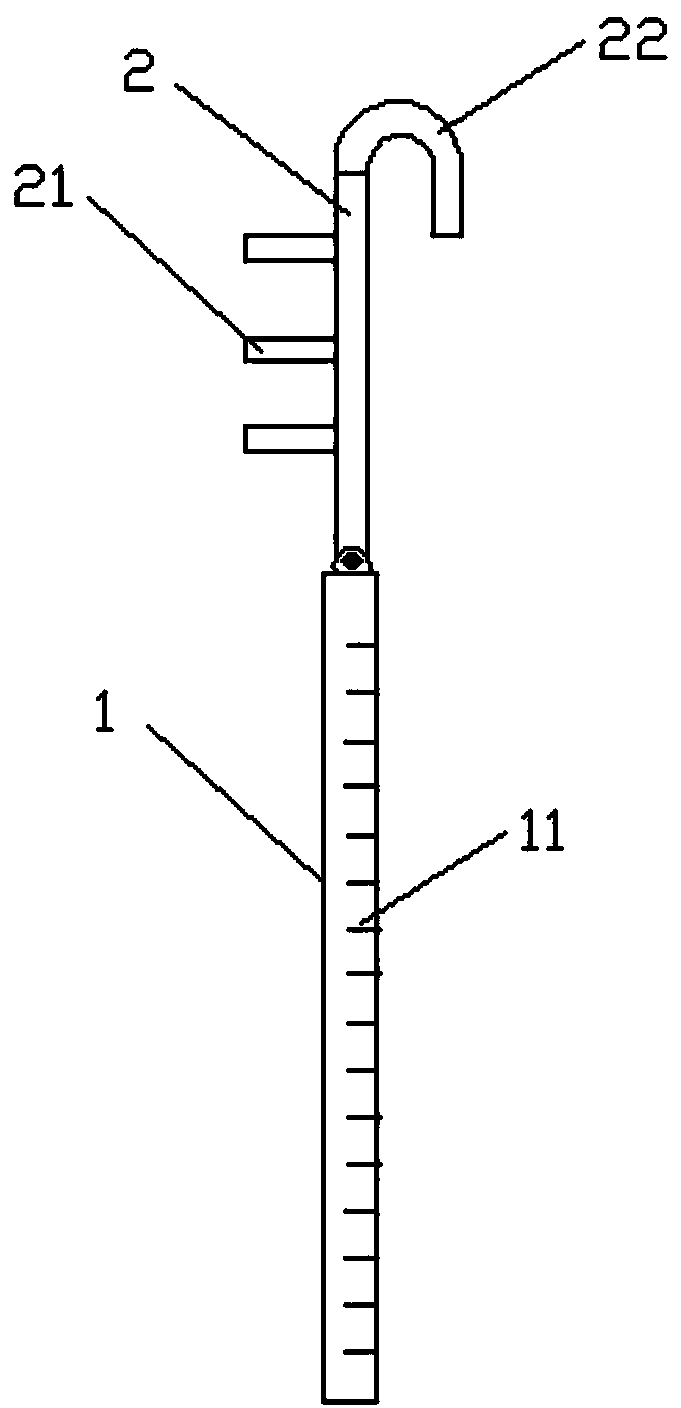

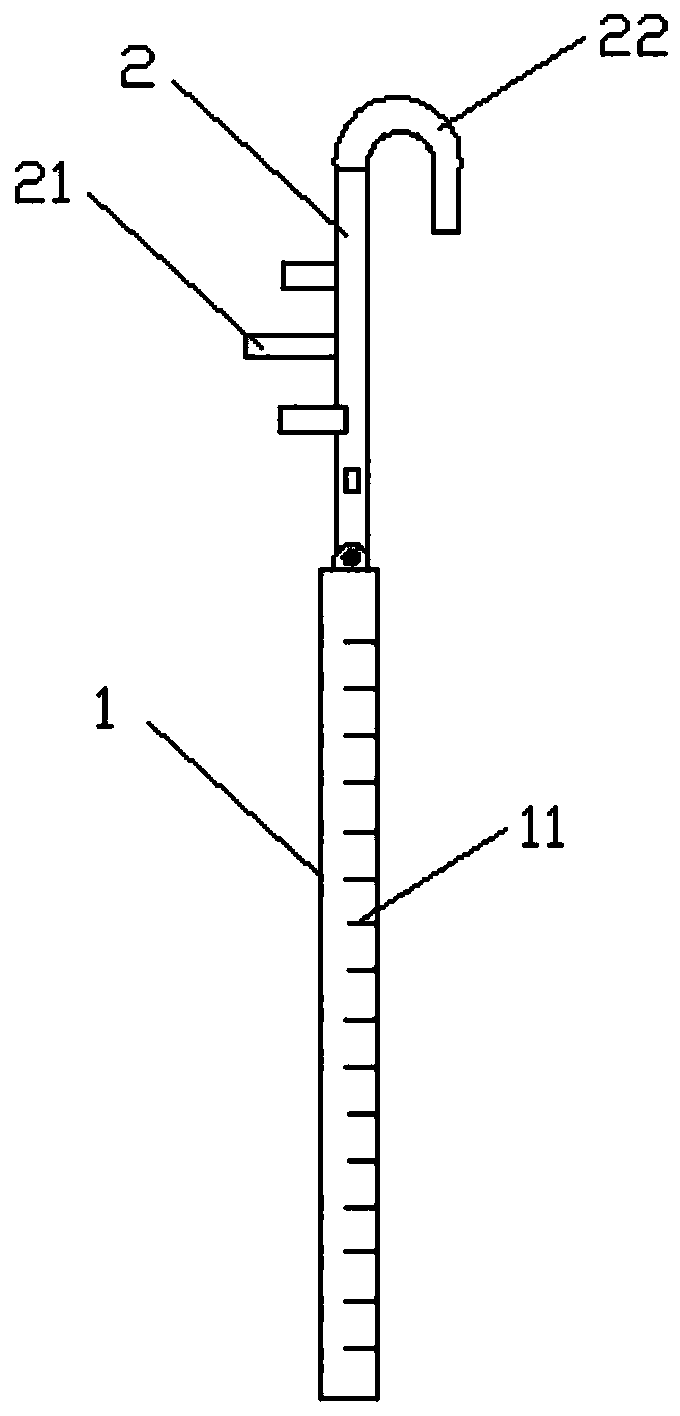

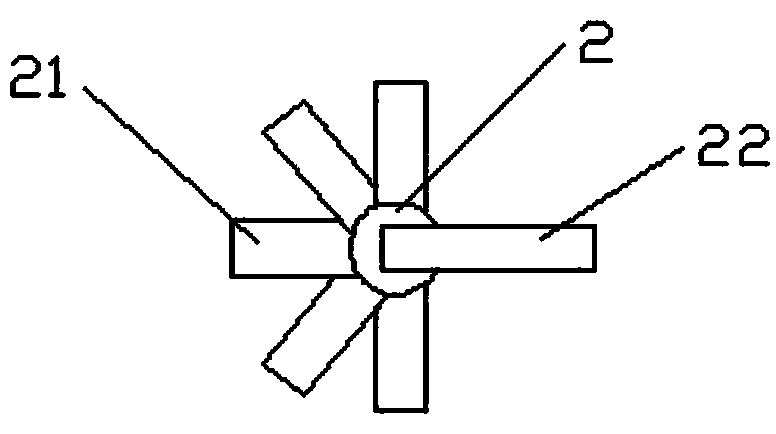

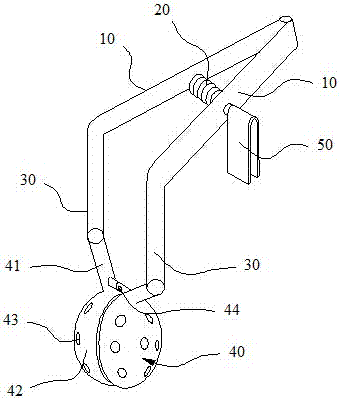

Processing device for articles hung on power transmission line

ActiveCN103683103ALow costImprove securityApparatus for overhead lines/cablesEngineeringForeign body

The invention discloses a multifunctional processing device for foreign materials on a power transmission line. The multifunctional processing device for the foreign materials on the power transmission line comprises an insulating operating rod, wherein an operating tool bit is connected to the front end of the insulating operating rod, the insulating operating rod and the operating tool bit are connected through a tooth-shaped connector, and different included angles can be formed between the insulating operating rod and the operating tool bit through rotation motion when the tooth-shaped connector is connected. The multifunctional processing device for the foreign materials on the power transmission line can be used for processing the foreign materials which are not tightly wound on an electric wire, and can also be used for processing thin ropes which are wound on the electric wire, the different angles of the tool bit can be adjusted so that the foreign materials can be processed more conveniently and more easily, the power transmission line cannot be easily damaged, the distance between a worker and the processed foreign materials or between the worker and the power transmission line can be measured, the worker can be kept away from the power transmission line, and personal safety of the worker is ensured.

Owner:STATE GRID CORP OF CHINA +1

Waterproof high-toughness corrugated carton and production device thereof

PendingCN114852461AIncrease heightIncrease bottom waterproof performancePackage recyclingConveyorsWater sourceCarton

The waterproof high-toughness corrugated carton comprises a carton body, a storage inner cavity is formed in the inner wall of the carton body, the top of the storage inner cavity is formed in a penetrating mode, the carton body comprises a carton body paperboard, the inner wall and the outer wall of the carton body paperboard are each provided with a carton body waterproof coating, and a carton cover is arranged at the top of the carton body; a plurality of water accumulation holes uniformly penetrate through the top of the tank cover, and water guide rings are arranged on the outer walls, located at the bottom end of the tank cover, of the water accumulation holes. The water accumulation hole in the top of the box cover is matched with the water guide ring to guide rainwater or other water sources falling on the top of the box cover to the outer end away from the box body, and the waterproof coating is matched to improve the overall waterproof performance of the corrugated box and the box cover. According to the corrugated carton creasing machine, a paperboard can be automatically conveyed into the creasing machine, manual operation is not needed, meanwhile, the operation that the paperboard is conveyed into the creasing machine, creasing operation is stopped and the paperboard subjected to creasing operation is conveyed to the creasing machine can be completed in cooperation with a stepping motor, the corrugated carton creasing operation efficiency is improved, and meanwhile the operation potential safety hazards are reduced.

Owner:天长市天翔包装有限公司

Solid-liquid reagent reaction experiment operation method

ActiveCN104383857AControl samplingEasy to operateLaboratory glasswaresChemical/physical processesChemical reactionLiquid state

The invention provides a solid-liquid reagent reaction experiment operation method which is characterized in that a specially-designed solid reagent clamping reactor is adopted, and through simple operation of squeezing and releasing two clamping arms, the solid reagent clamping reactor can be controlled to sample the solid reagent and stably keep clamping the solid reagent; therefore, in combination with the specific operating process, the solid reagent clamping reactor is clamped and hung over the mouth of a beaker holding liquid reagent through elastic clips sleeving slide tracks of the clamping arms, so that the solid reagent and the liquid reagent are in contact and react, and the clamping arm of the solid reagent clamping reactor can be lifted or dropped at any time to enable the solid reagent and the liquid reagent to be separated or contact again. The method has the advantages that the operation is very convenient, other impurities cannot be brought in, the potential safety hazards of operation can be reduced, and the problems that in the prior art, solid-liquid separation is troublesome, impurities are brought in easily, potential safety hazards of operation exist in a solid-liquid reagent chemical reaction experiment can be well solved.

Owner:重庆顶煌日用品有限公司

Solid-liquid reagent reaction experiment method

ActiveCN104383856AControl samplingEasy to operateLaboratory glasswaresChemical/physical processesChemical reactionLiquid state

The invention provides a solid-liquid reagent reaction experiment method which is characterized in that a specially-designed solid reagent clamping reactor is adopted, and through the simple operation of pinching and releasing two supporting arms, the solid reagent clamping reactor can be controlled to sample the solid reagent and stably keep clamping the solid reagent; therefore, in combination with the specific operating process, the solid reagent clamping reactor is clamped and hung over the mouth of a beaker holding liquid reagent through elastic clips hinged to the supporting arms, so that the solid reagent and the liquid reagent can be in contact with each other and react, and the solid reagent clamping reactor can be rotated around the hinge parts of the supporting arms and the elastic clips at any time to enable the solid reagent and the liquid reagent to be separated. The method has the advantages that other impurities cannot be brought in, the probability of damage to operators is low, the potential safety hazards of operation can be reduced, and the problems that solid-liquid separation is troublesome, impurities are easily brought in, potential safety hazards of operation exist in a solid-liquid reagent chemical reaction experiment in the prior art can be well solved.

Owner:重庆顶煌日用品有限公司

Spiral-type surface finishing and trimming cutter

InactiveCN103909279AEasy to cutHigh strengthTurning toolsRotary cutting toolsSurface finishMilling cutter

The invention discloses a spiral-type surface finishing and trimming cutter which is composed of a clamping portion, a deep cutting edge portion, a circular-arc sawtooth blade portion and a conical blade portion. The clamping portion is longer than a common one, and a circular arc face is additionally arranged at the front end of the deep cutting edge portion. The spiral-type surface finishing and trimming cutter is characterized in that the circular-arc sawtooth blade portion is the rear portion of a cutter point and is in the shape of a six-blade circular-arc-shaped spiral sawtooth. Compared with the prior art, the spiral-type surface finishing and trimming cutter has the advantages that cutting edge shape and cutting edge angle are reasonably optimized for bringing convenience to a milling cutter to cut a plate, and production efficiency is improved; strength of the milling cutter is improved, so that service life of the milling cutter is prolonged, and potential safety hazards in operation are reduced.

Owner:范朝民

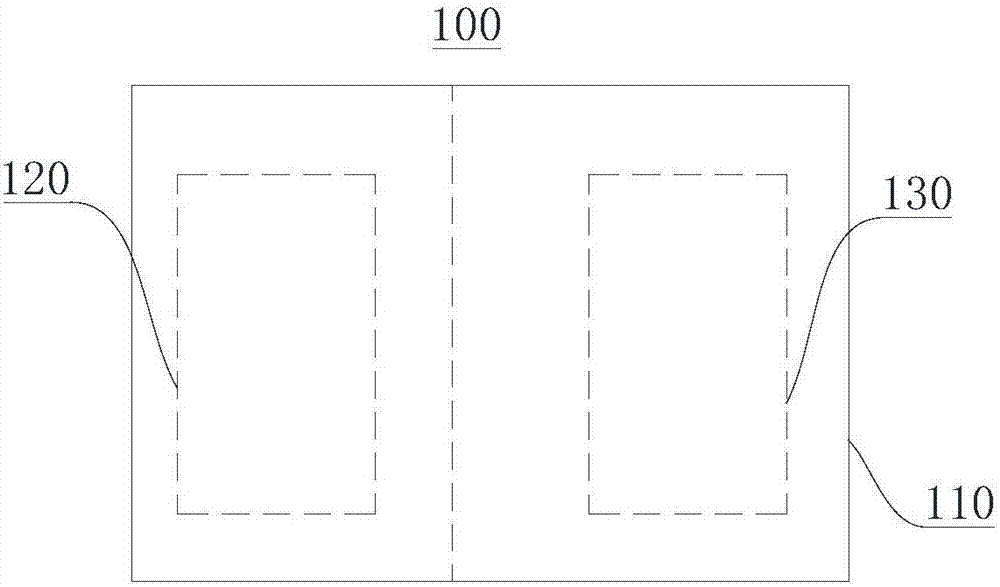

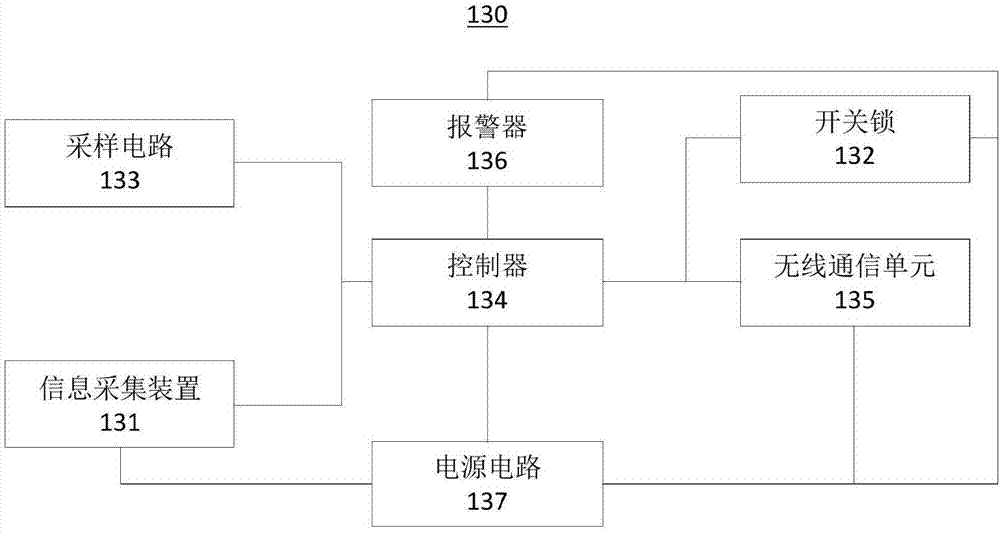

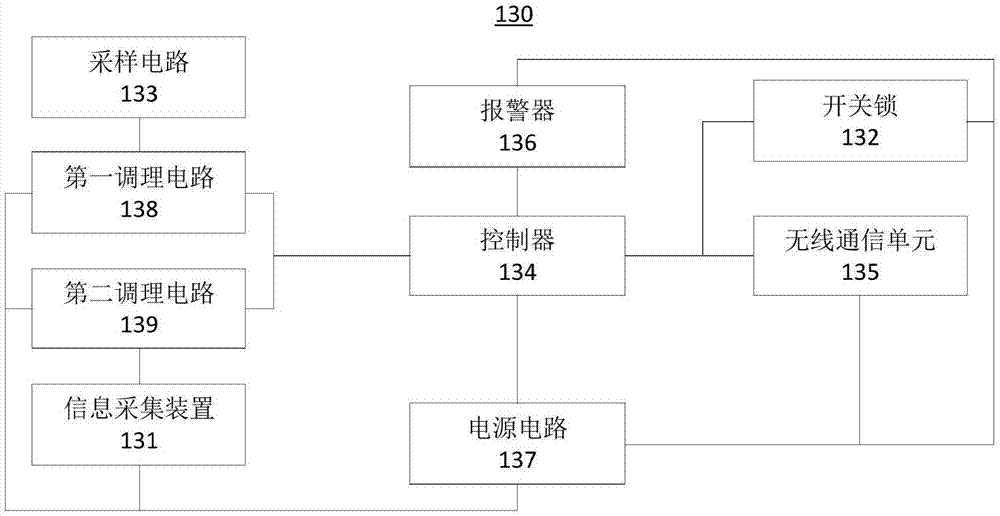

Intelligent column switch and control system

InactiveCN107959349AReduce volumeReduce installationCircuit arrangementsSustainable buildingsInformation repositoryCommunication unit

The invention relates to an intelligent column switch and control system, and belongs to the electric power automation technical field; the intelligent column switch comprises a housing, a switch bodyarranged in the housing in an insulated mode, and a control terminal; the control terminal comprises an information acquisition device, a switch lock, a sampling circuit, a power supply circuit, a controller, a wireless communication unit, and an alarm device; the controller is used for preprocessing a wireless signal received from the wireless communication unit, thus obtaining preprocessed information, and determining whether the preprocessed information contains the first information or not; if yes, the first information is coupled with a pre-stored ID information database; if the couplingis finished, operations corresponding to a control order carried by the wireless signal are executed. The intelligent column switch can remotely send the control order according to manager demands, thus opening or closing, adjusting and calibrating parameters, simplifying field maintenance work load, and maximumly reducing the operation safety troubles.

Owner:国网山东省电力公司蒙阴县供电公司

Catalytic reforming catalyst containing LTL type molecular sieve

InactiveCN108239554ANo cloggingReduce operational safety hazardsNaphtha reformingCatalytic reformingMolecular sieve

The invention relates to a catalytic reforming catalyst containing an LTL type molecular sieve. The catalytic reforming catalyst comprises the following components: (1) a catalyst carrier composed of10-100wt% of an LTL type molecular sieve and 0-90wt% of a binding agent; (2) lanthanide metal ions exchanging and replacing 5-100mol% of positive ions in the LTL type molecular sieve, wherein the content of the lanthanide metal ions is higher than or equal to 5mol% of the total amount of the positive ions, and the content of H<+> in the LTL type molecular sieve is less than 5mol% of the total amount of the positive ions; and (3) at least one VIIIB group metal contained on the catalyst, wherein the content of the VIIIB group metal on the catalyst accounts for 0.1-50wt% of the carrier. The catalytic reforming catalyst provided by the invention can realize dehydrogenation, dehydrocyclization, aromatization and the like and has relatively high reaction activity, selectivity and stability.

Owner:PETROCHINA CO LTD

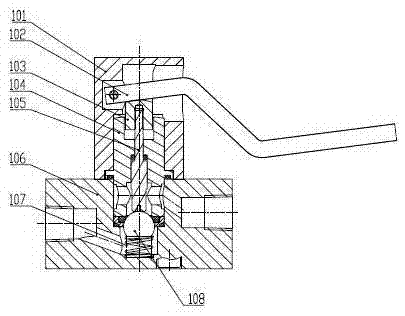

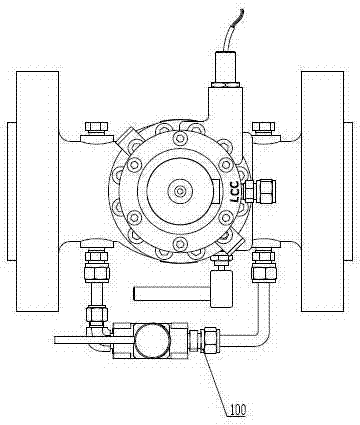

Automatic-reset bypass valve

InactiveCN105443801AReduce operational safety hazardsAvoid flowMultiple way valvesValve housingsPhysicsSpring steel

The invention relates to a novel reset bypass valve. The novel reset bypass valve comprises an upper valve body, a reset wrench, an ejection cap, a guide sleeve, an ejector rod, a valve body, a spring and a steel ball, and is characterized in that the spring is installed in a groove in the bottom of the valve body, and the steel ball is arranged on the spring and is in contact with an O-shaped sealing ring below the guide sleeve for sealing; and the upper valve body and the valve body are fastened through screws, and the ejector rod, the election cap and the reset wrench are installed in the valve body. When the novel reset bypass valve works, the reset wrench and the ejector rod are pressed down, the steel ball is pressed down to be separated from the O-shaped sealing ring, and gas enters a downstream portion; and on the contrary, the steel ball and the O-shaped sealing ring are tightly pressed through the force of the spring, and sealing is achieved. The novel reset bypass valve has the beneficial effects that when the reset wrench is pressed down to enable the steel ball to be separated from the O-shaped sealing ring, gas passes through the bypass valve; when the reset wrench is released, the steel ball is pushed to the original position by the spring, the steel ball and the O-shaped sealing ring are attached for sealing, gas flow is blocked, and the automatic reset function is achieved; and the possibility that as an operator forgets to close the bypass valve, gas continues to flow towards the downstream portion is avoided, and potential safety hazards of operation are reduced.

Owner:TIANJIN BTER FLUID CONTROL VALVE +1

Mixing device for composite bio-fertilizer production and use method of mixing device

InactiveCN112892259AAchieve smashRealize the effect of mixed simultaneous operationRotary stirring mixersTransportation and packagingElectric machineryMixing effect

The invention discloses a mixing device for composite bio-fertilizer production and a use method thereof, the mixing device comprises a mixing cavity and a motor base arranged on one side of the mixing cavity, wherein the other side of the mixing cavity is provided with supporting legs, and the middle position of the lower end of the mixing cavity is provided with a discharge pipe; a material screening barrel which is arranged in the mixing cavity, one end of the material screening barrel is provided with a first material screening cavity, the other end of the material screening barrel is provided with a second material screening cavity, the middle position of the material screening barrel is provided with a crushing cavity, the inner diameter of the crushing cavity is provided with material guiding internal threads, and a grinding plate is arranged between the material guiding internal threads; a crushing mechanism which is arranged in the material screening barrel, wherein a stirring shaft groove is formed in the crushing mechanism; the mixing device realizes the effect of simultaneously crushing and mixing materials, so that the problem that the mixing effect is influenced due to the difference of the diameters of various particle materials is effectively avoided.

Owner:李彤

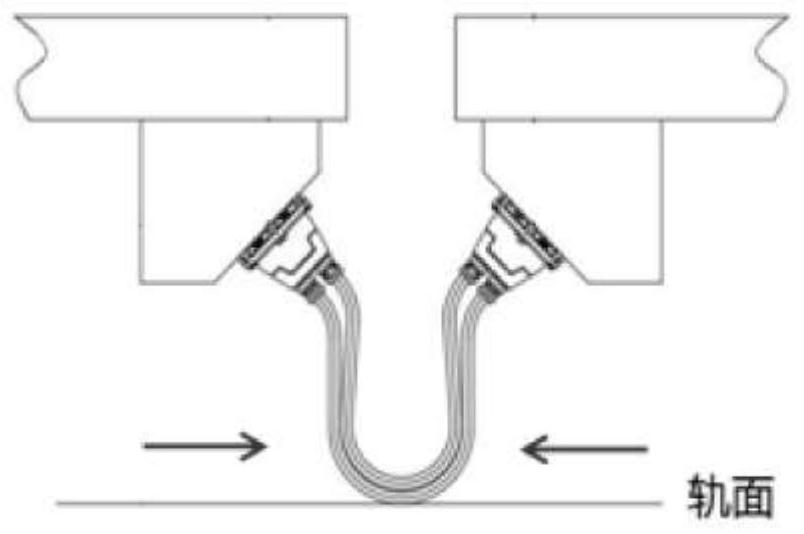

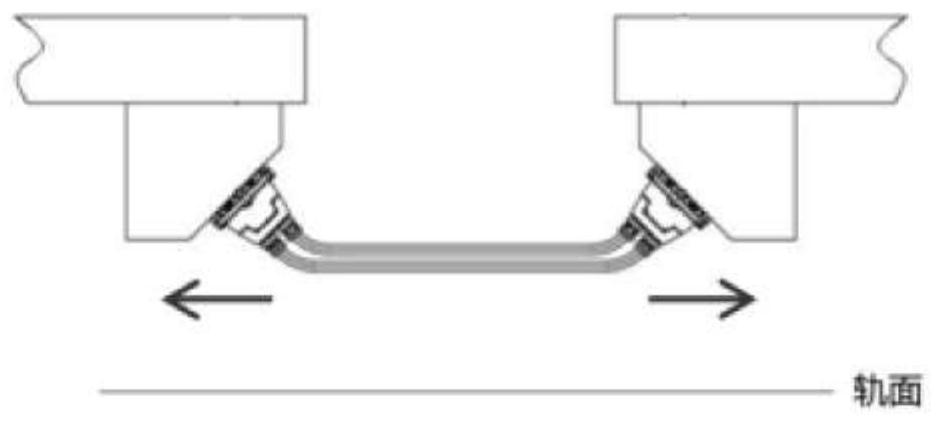

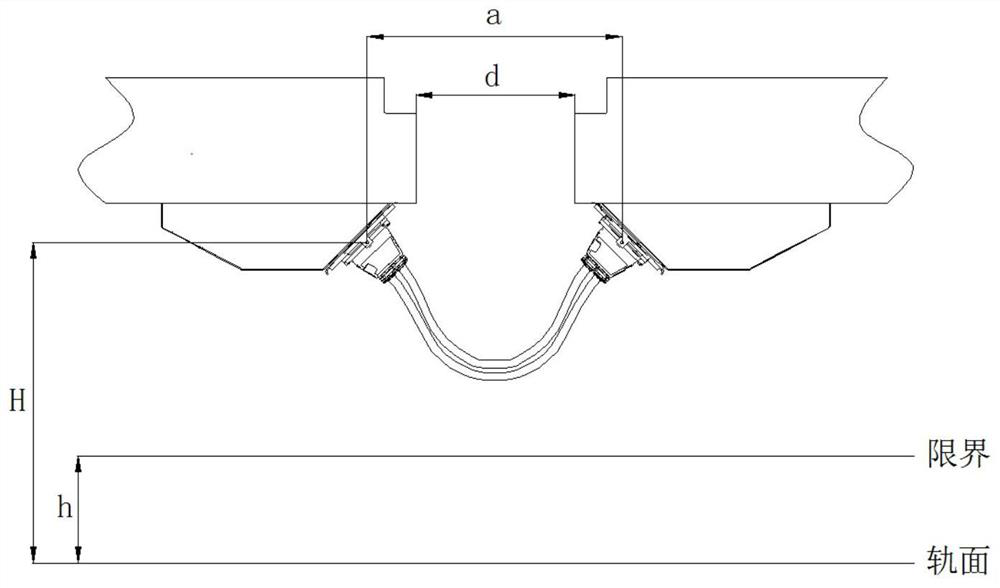

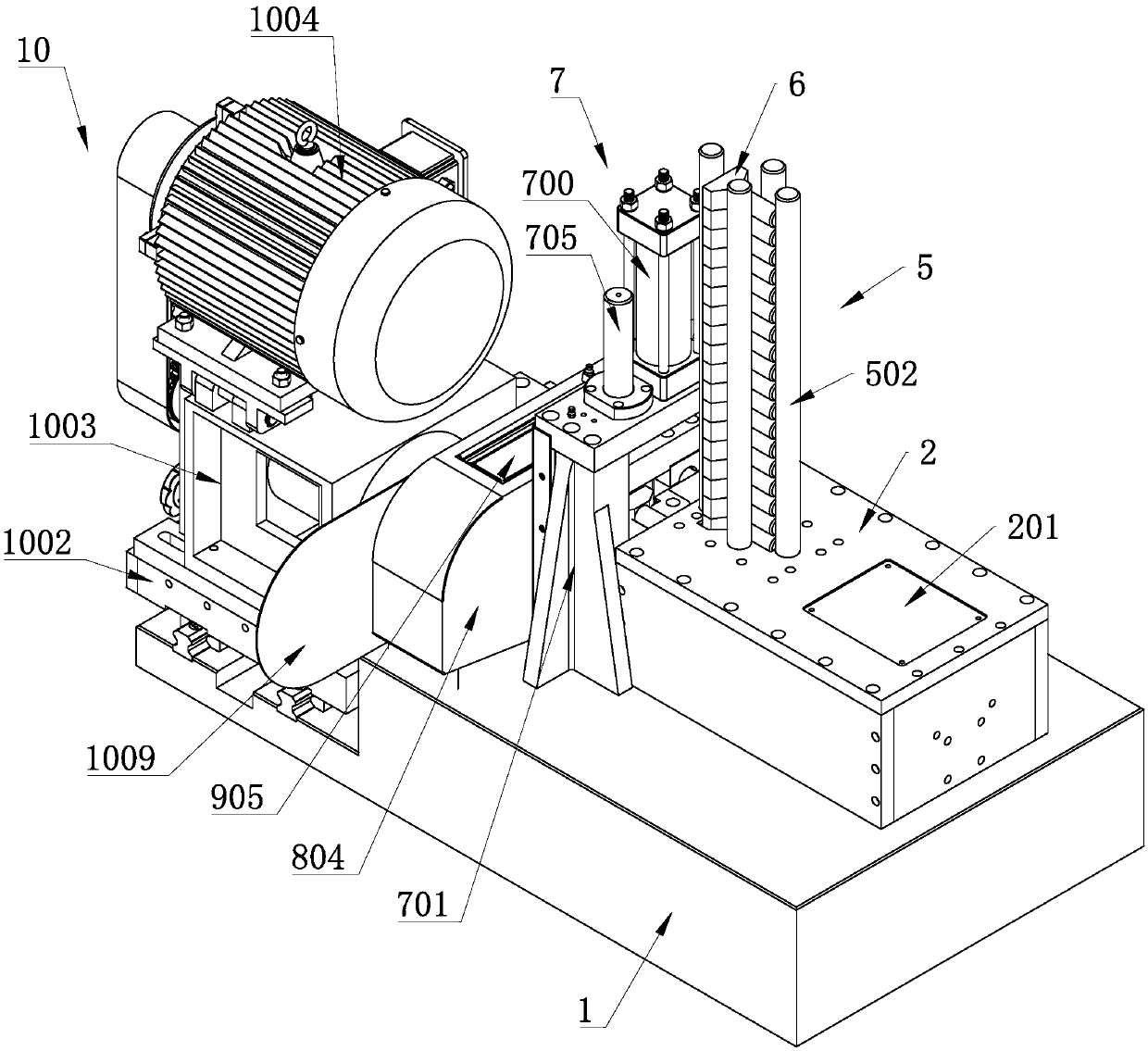

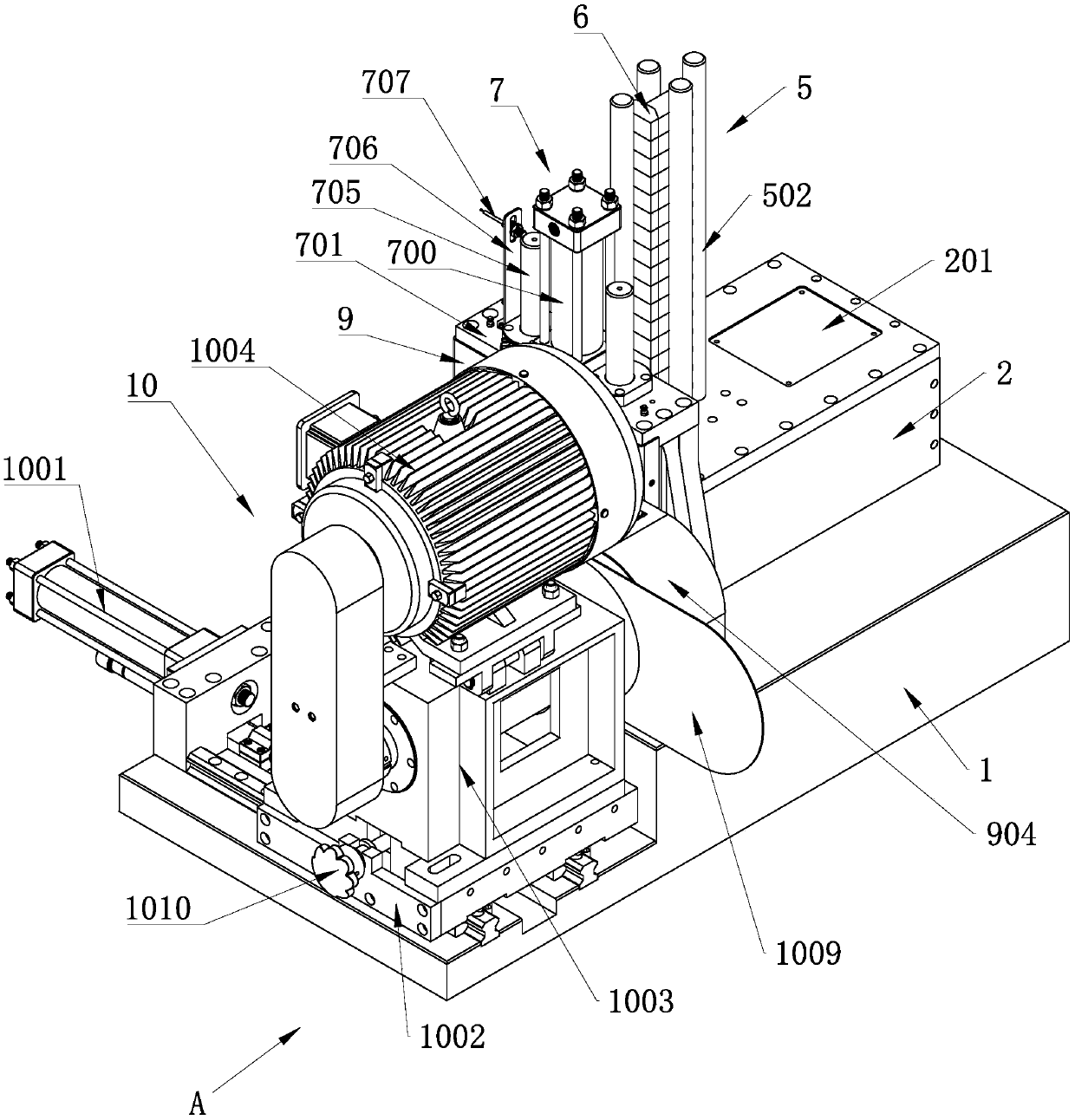

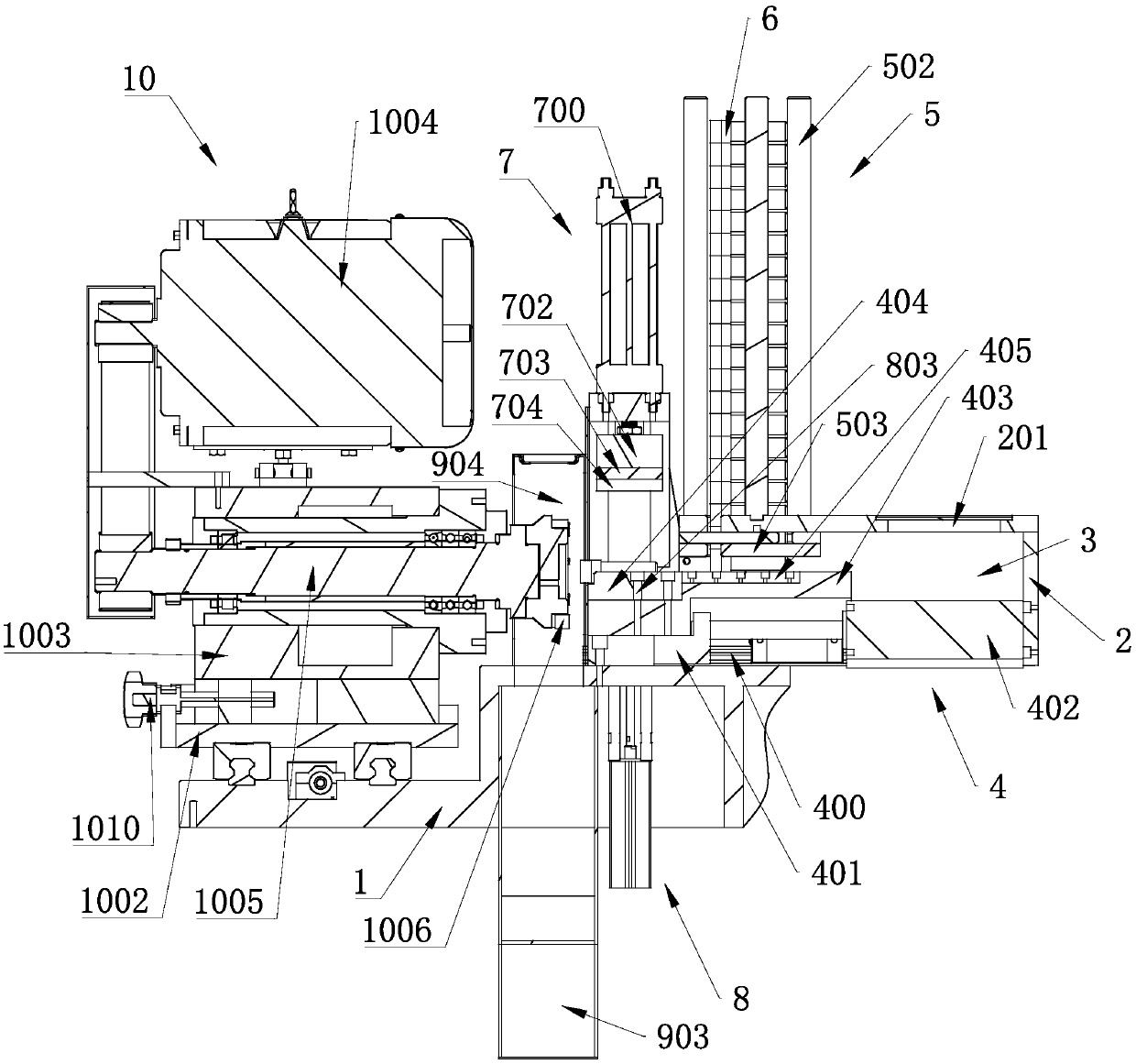

Rail transit vehicle and vehicle end jumper cable length calculation method thereof

PendingCN113806928AReduce operational safety hazardsReduce cost lossCable arrangements between relatively-moving partsDesign optimisation/simulationEngineeringElectric cables

The invention discloses a rail transit vehicle and a vehicle end jumper cable length calculation method thereof. The jumper cable length L meets the following relational expression: L is greater than L1 and less than L2; wherein L1 is the length of the jumper cable calculated according to the maximum linear distance Y of the mounting surfaces of the two vehicle end connectors, and L2 is the length of the jumper cable calculated according to the minimum linear distance y of the mounting surfaces of the two vehicle end connectors. The method can be suitable for various lines with different parameters and is high in universality and operability, the length value, calculated through the method, of the jumper cable is reliable and high in accuracy, potential safety hazards of vehicle operation caused by the improper length of the cable can be effectively avoided, and important reference and application value are provided for calculating the length of the jumper cable between rail transit vehicles.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Bolt end face machining assembly

PendingCN109249068AReduce volumeLow costWork clamping meansMilling equipment detailsEngineeringUltimate tensile strength

The invention discloses a bolt end face machining assembly. The bolt end face machining assembly comprises a mounting body provided with a support, wherein a mounting cavity is formed between the support and the mounting body; a pushing mechanism is arranged on the mounting body in the mounting cavity in a slide manner; an end face machining device is arranged on the mounting body located on the downstream of the pushing mechanism in a slide manner; the slide direction of the end face machining deice is vertical to the slide direction of the pushing mechanism; the support is provided with a bolt conveying mechanism which is communicated with the mounting cavity; the mounting body located between the bolt conveying mechanism and the end face machining device is provided with a clamping mechanism; the pushing mechanism is provided with an ejection mechanism. By adopting the bolt end face machining assembly, mechanical conveying, pushing, clamping positioning of bolts and ejection work after finishing of bolt machining are realized, the operation potential hazard in the bolt clamping process is lowered greatly, and the labor intensity of workers is lowered effectively. Meanwhile, theworking continuity and working efficiency are improved greatly. Moreover, the bolt end face machining assembly has the advantages of small size and low cost.

Owner:张家港市润泰机械有限公司

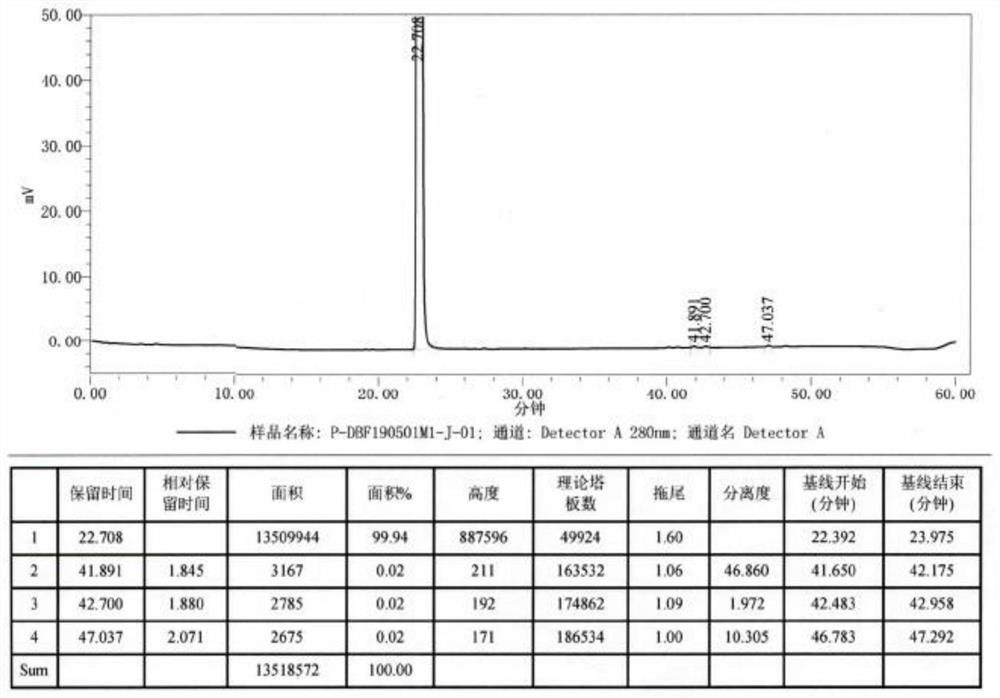

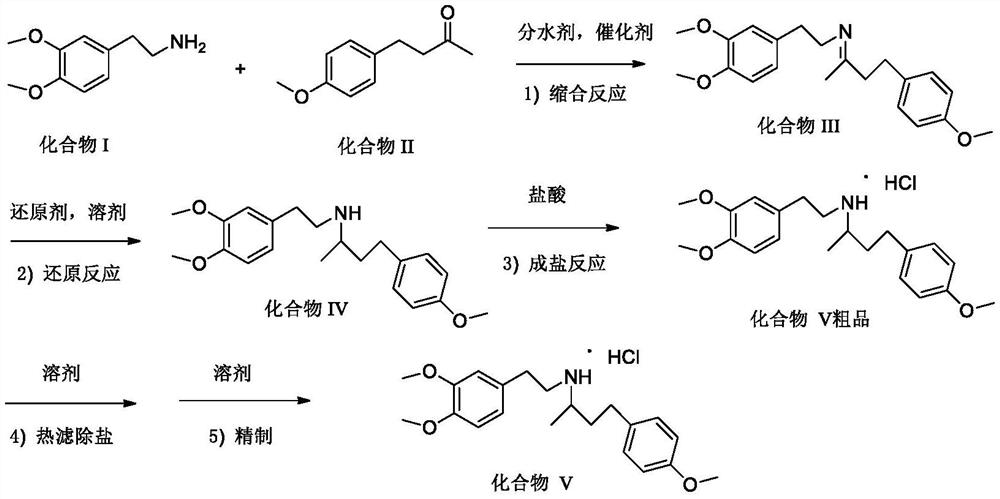

Preparation method of dobutamine hydrochloride intermediate compound

InactiveCN111807975AReduce usageAvoid High Pressure Catalytic Hydrogenation Reaction ConditionsOrganic compound preparationImino compound preparationOxyphenylbutazonePotassium borohydride

The invention discloses a preparation method of a dobutamine hydrochloride intermediate compound. According to the method, 3, 4-dimethoxyphenylethylamine and 4-(4-methoxyphenyl)-2-butanone are adoptedas the starting materials, acetic acid is adopted as a catalyst, cyclohexane is adopted as a reflux water diversion agent, reflux water diversion is performed to obtain a condensation product, potassium borohydride is adopted for further hydrogenation reduction, and hydrochloric acid salification is performed to obtain a crude product of a dobutamine hydrochloride intermediate. Isopropanol is adopted for refluxing and dissolving, an inorganic salt generated in the preparation process of the intermediate is removed through filtering while the solution is hot, and refining is conducted to obtain the dopamine hydrochloride intermediate. According to the method, high-pressure catalytic hydrogenation operation in the prior art is avoided, potential safety hazards are greatly reduced, meanwhile, an expensive metal catalyst is prevented from being used, and the production cost is reduced; and the use of some high-toxicity reagents and genotoxic reagents is avoided.

Owner:QIANFOSHAN HOSPITAL OF SHANDONG +1

A kind of solid-liquid reagent reaction experimental method

ActiveCN104383856BControl samplingEasy to operateLaboratory glasswaresChemical/physical processesChemical reactionLiquid state

Owner:重庆顶煌日用品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com