Automatic food heating and vending machine

A technology of vending machines and vending machines, which is applied in the direction of coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc., and can solve secondary The operation is cumbersome, there are hidden dangers in operation safety, unfavorable consumer experience and other problems, to achieve the effect of reducing hidden dangers in operation safety, reducing heat preservation energy consumption, and improving consumer experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

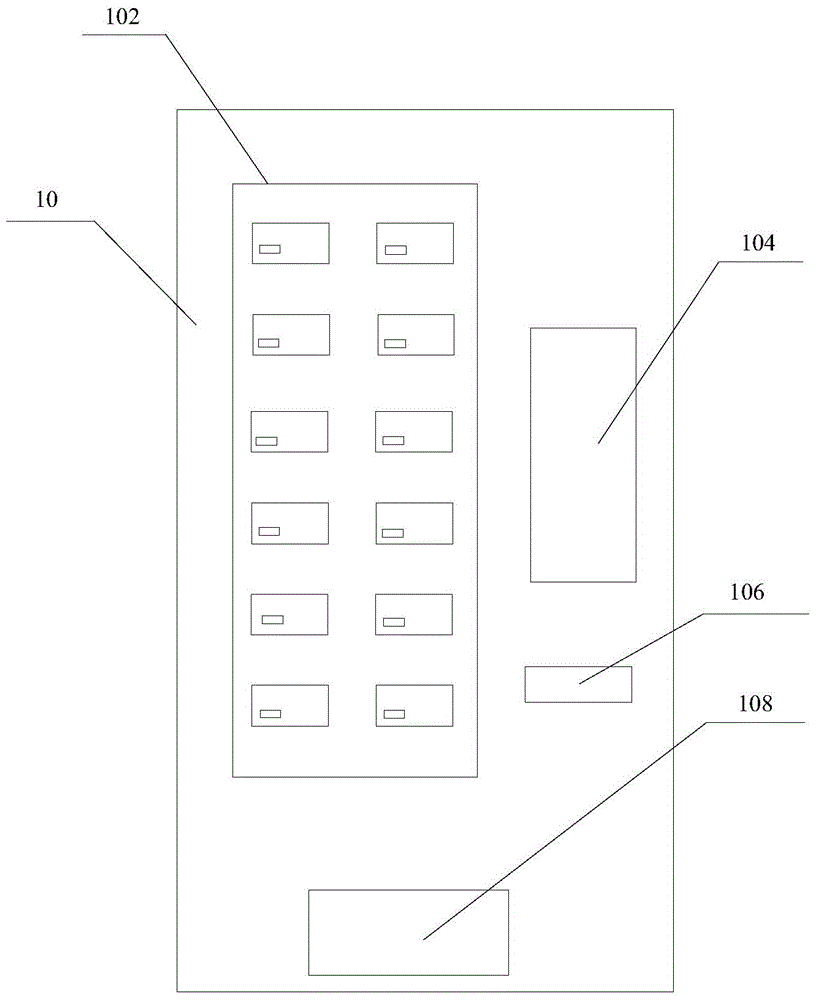

Embodiment 1

[0047] Such as Figure 4 to Figure 6 As shown, according to an embodiment of the present invention, in the above technical solution, preferably, the food heating system 304 includes: a first heating device 3042 connected to a conveying device 3044 for automatically heating the food; The transmission device 3044, one end of the transmission device 3044 is connected to the article storage area 306 of the food heating vending machine 30, and the other end of the transmission device 304 is connected to the pick-up area of the food heating vending machine 30 Port 308, so as to transfer the food from the article storage area 306 to the first heating device 3042 for automatic heating and then transfer to the fetching port 308.

[0048] According to the food heating vending machine 30 of the embodiment of the present invention, by associating and connecting the article storage area 306, the conveying device 3044, the first heating device 3042 and the pick-up port 308, after the cons...

Embodiment 2

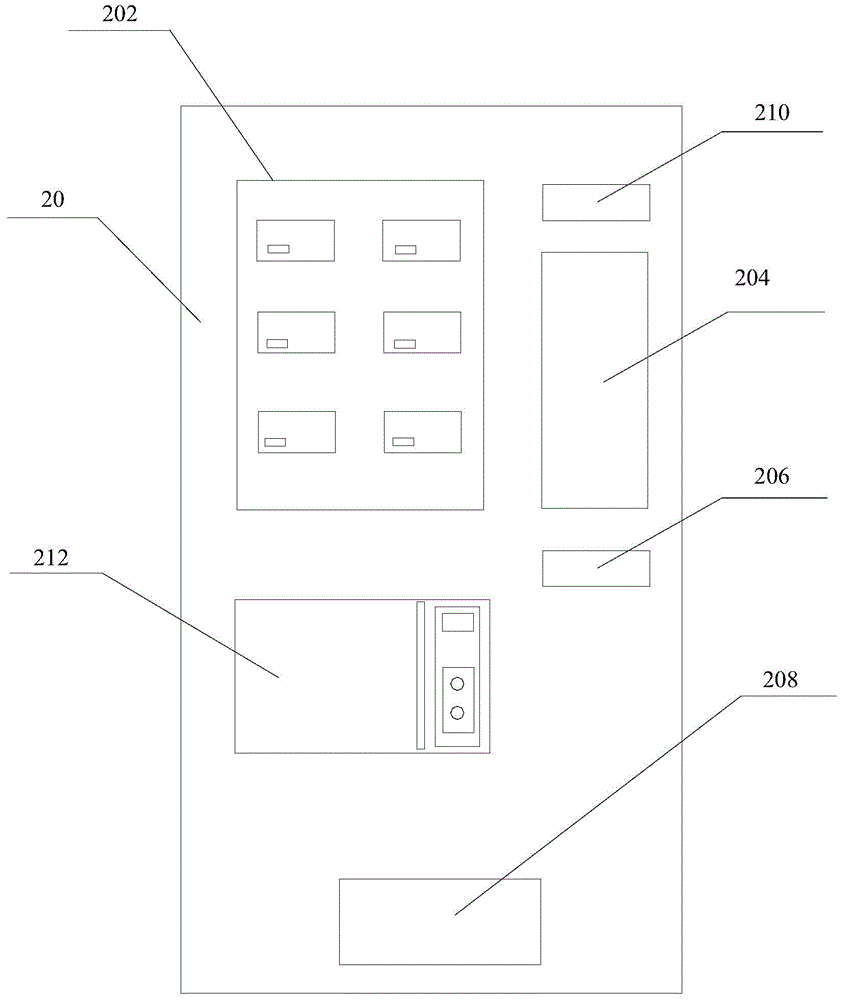

[0056] Such as Figure 4 , Figure 7 and Figure 8 As shown, according to an embodiment of the present invention, in the above technical solution, preferably, the food heating system 304 includes: a second heating device 3041 for automatically heating the food; at least one manipulator 3043 connected to To the manipulator control device 3045; the manipulator control device 3045 is used to control the operation of the manipulator 3043 to move the food from the item storage area 306 of the food heating vending machine 30 to the second heating The device 3041 moves to the pick-up port 308 of the food heating vending machine 30 after heating.

[0057] According to the food heating vending machine 30 of the embodiment of the present invention, after the consumer chooses to heat the purchased food, at least one manipulator 3043 of the vending machine is controlled by the manipulator control device 3045 to work to remove the food from the article storage area 306 Take out and move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com