Patents

Literature

42results about How to "Avoid secondary operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

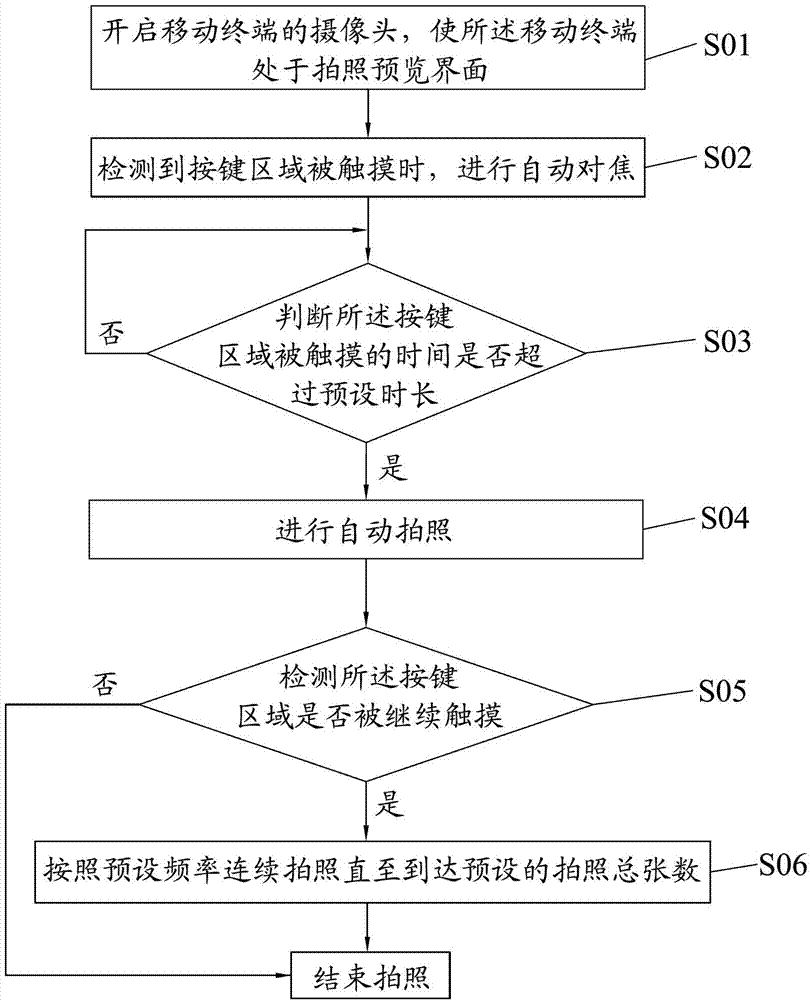

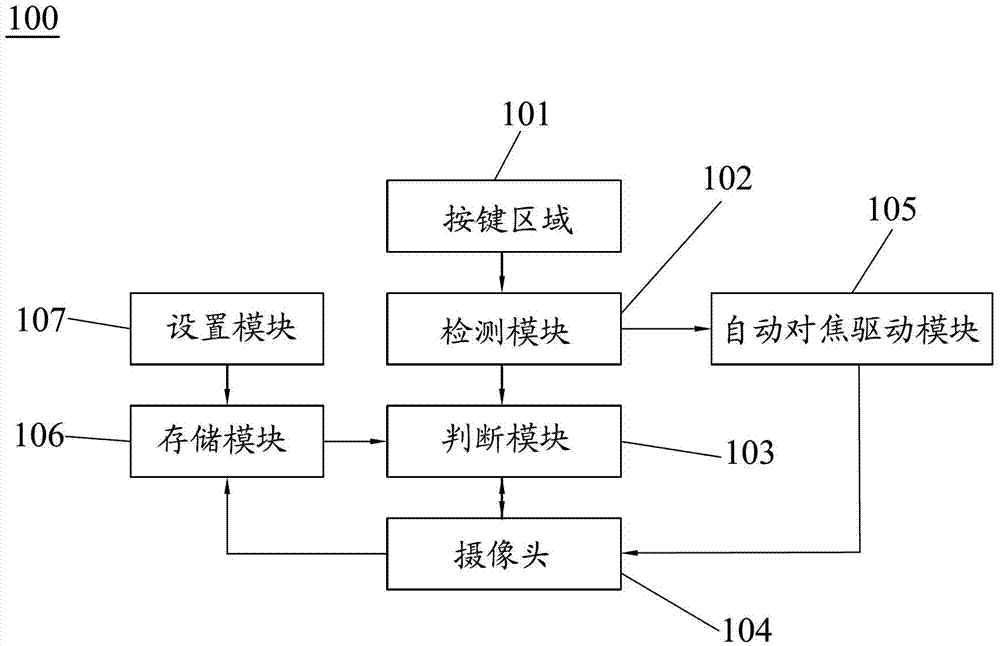

Mobile terminal picture-taking method and mobile terminal

InactiveCN103209256AAvoid ambiguityImprove photo experienceTelevision system detailsColor television detailsKey pressingComputer terminal

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

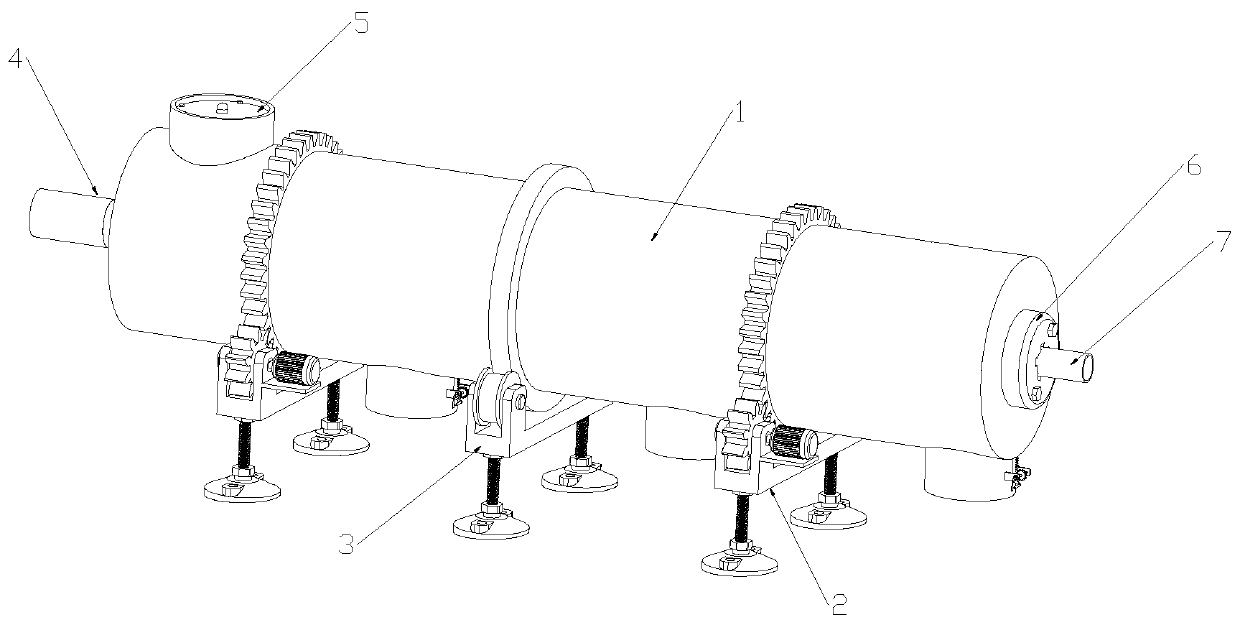

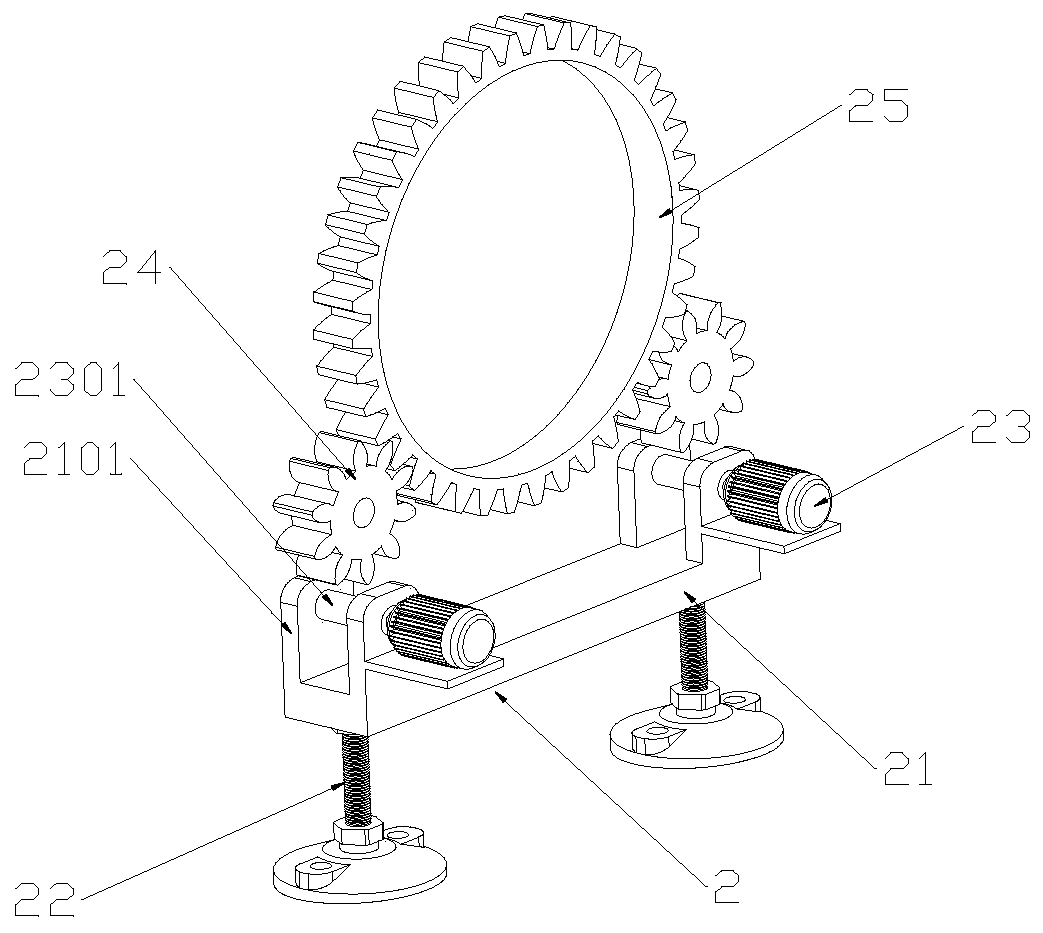

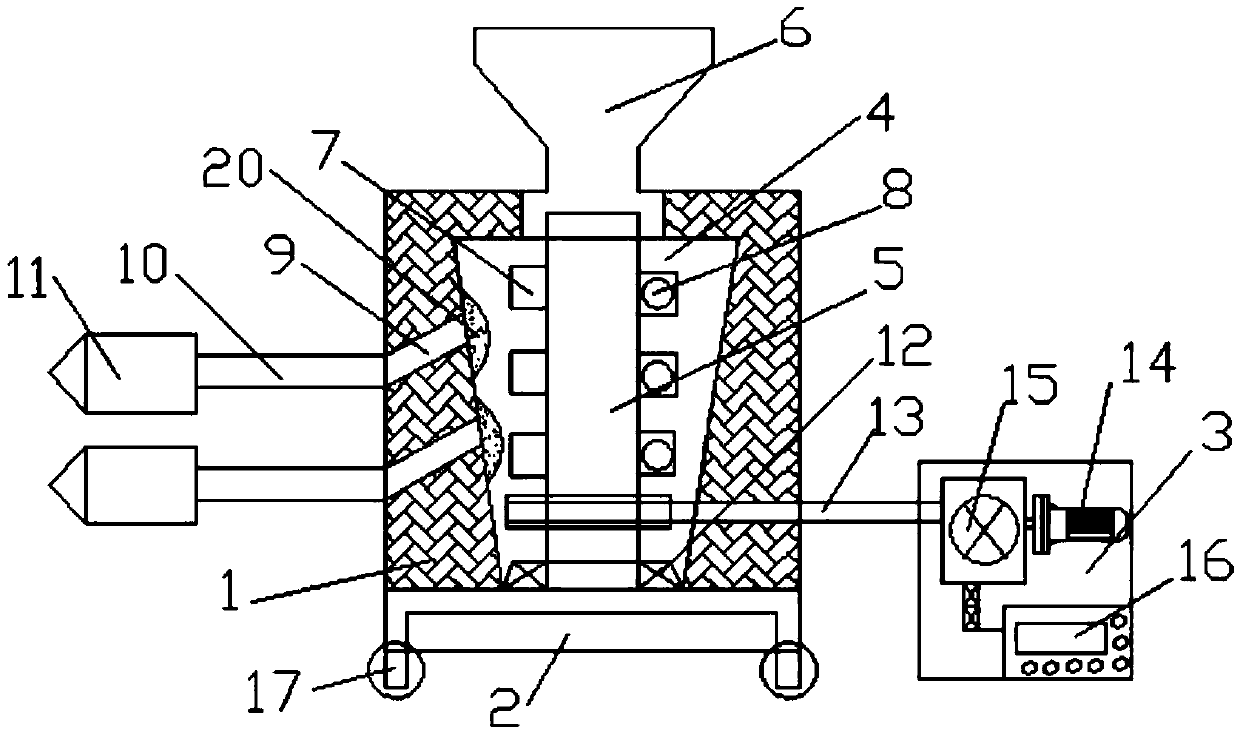

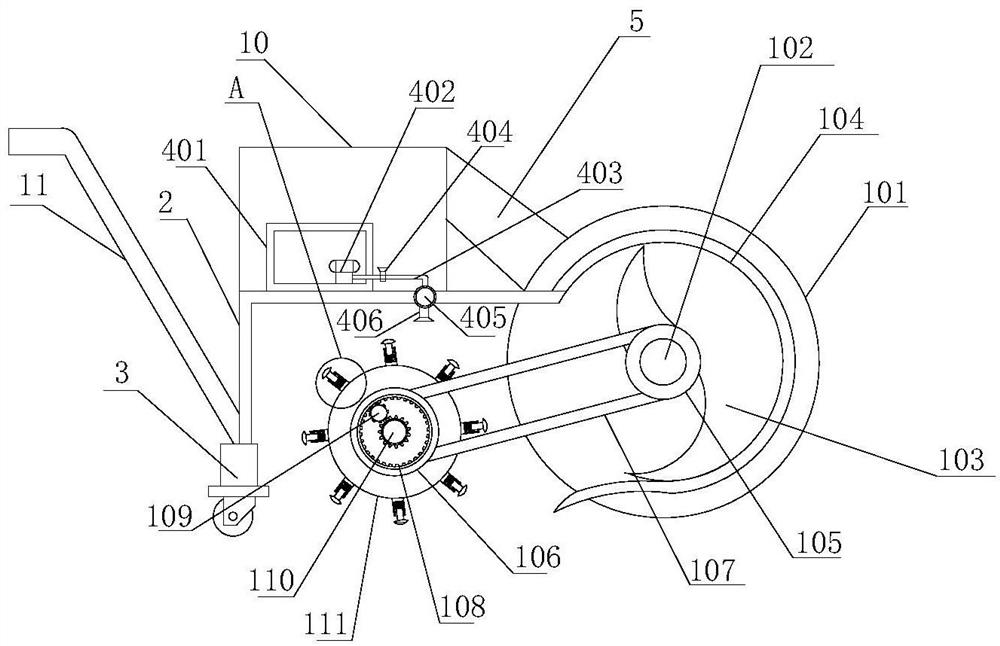

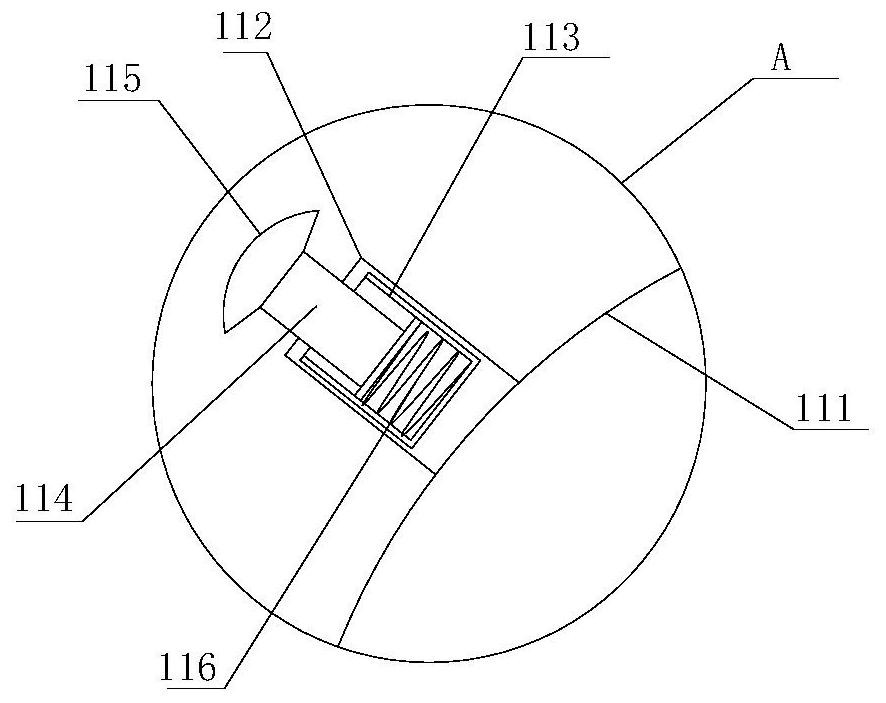

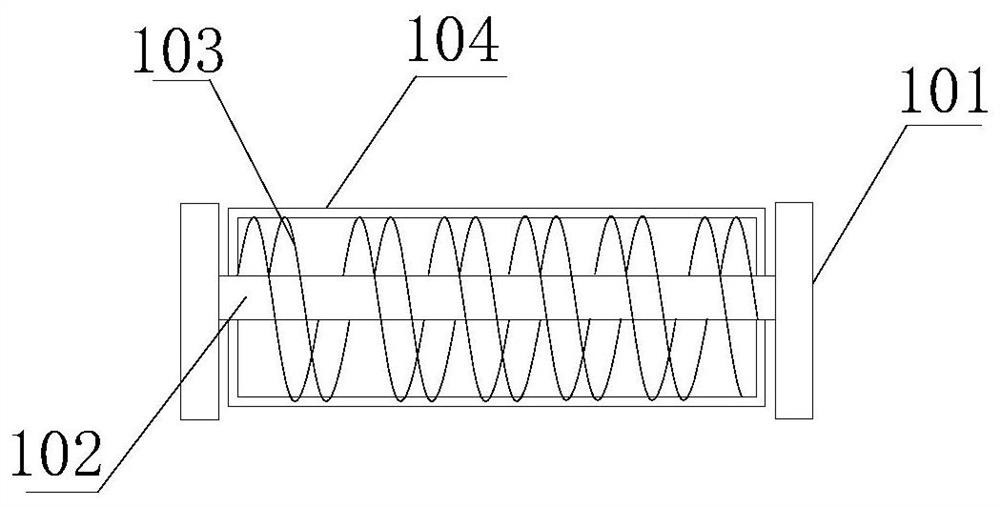

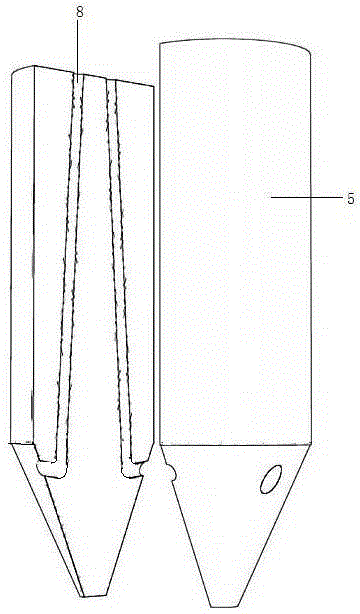

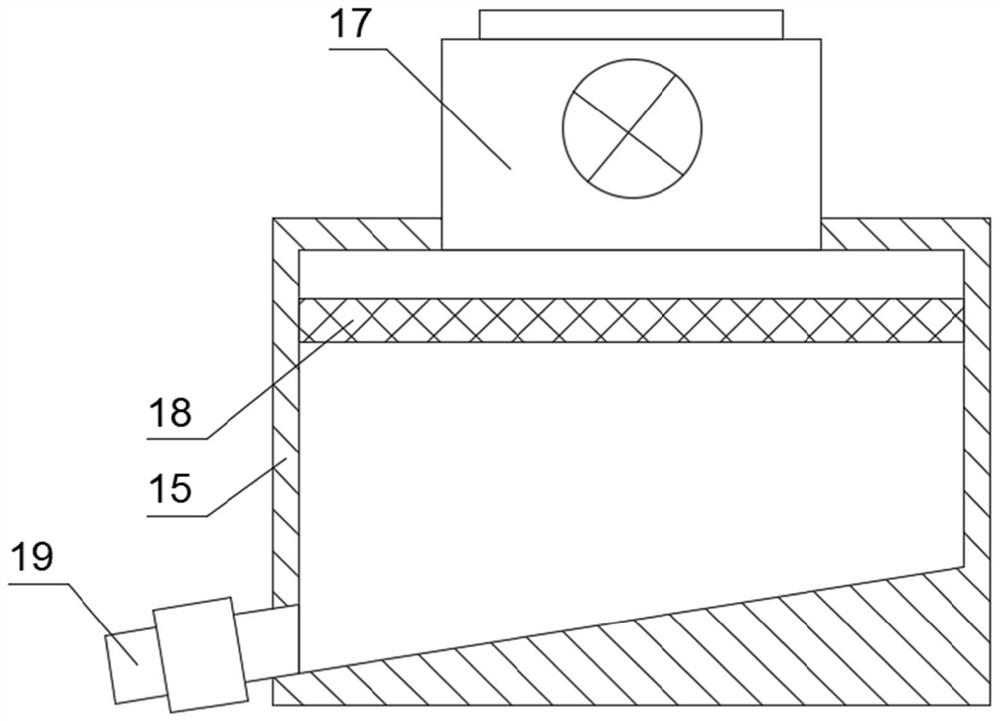

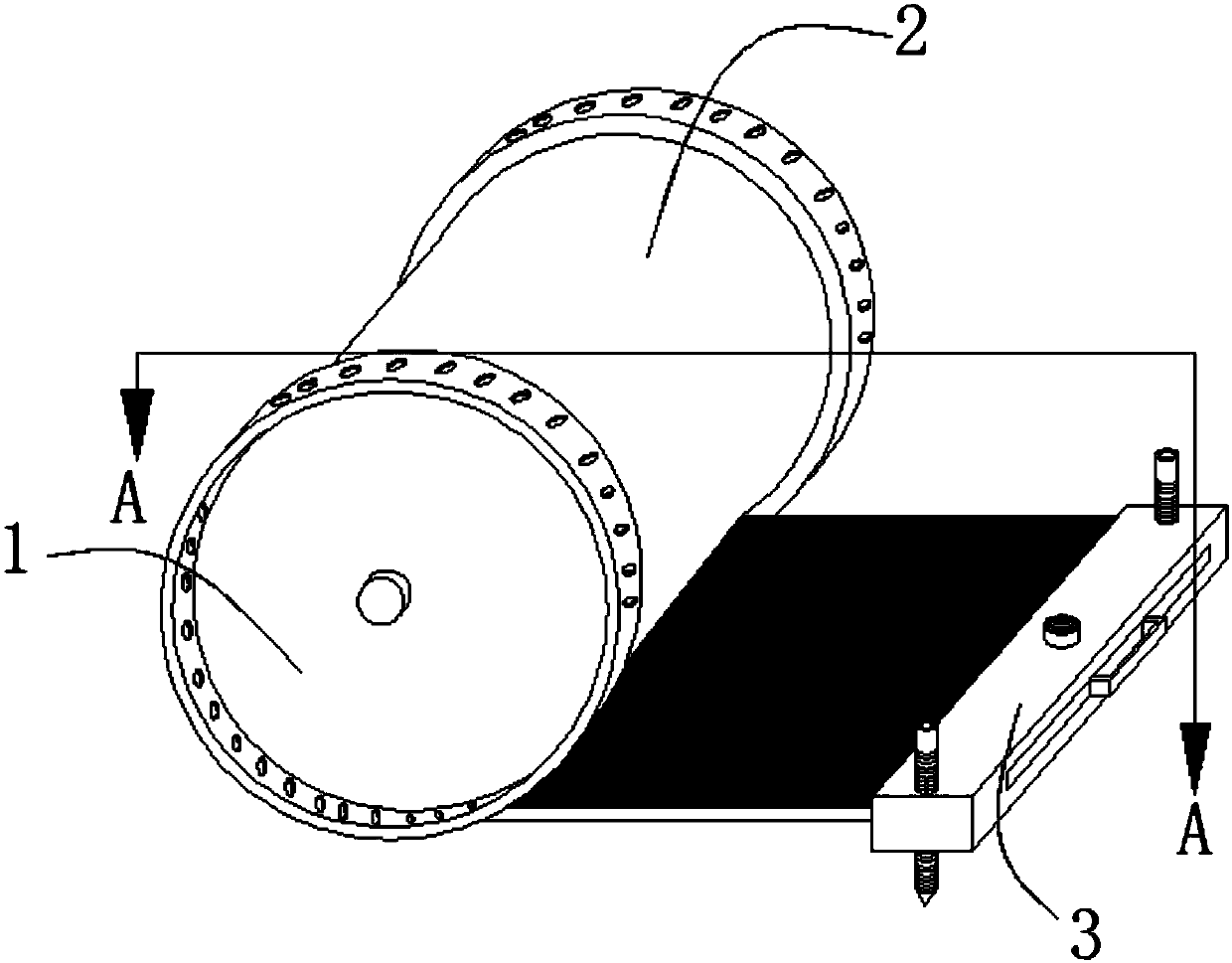

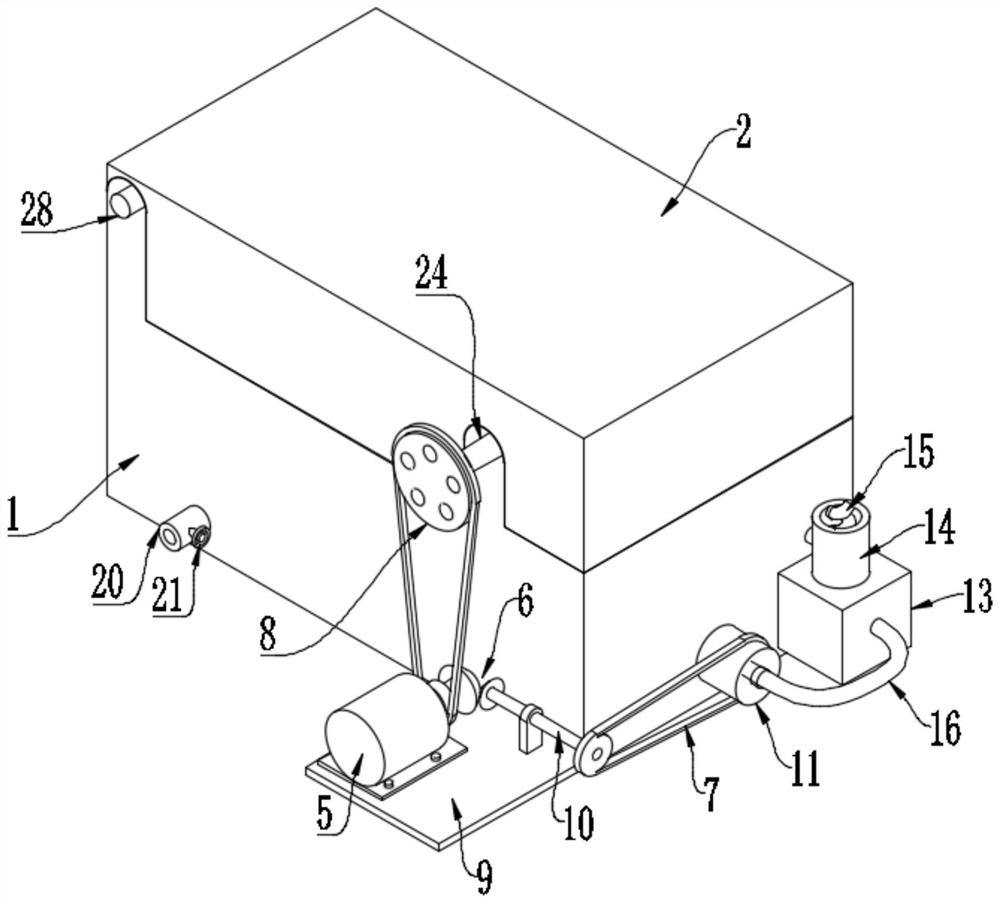

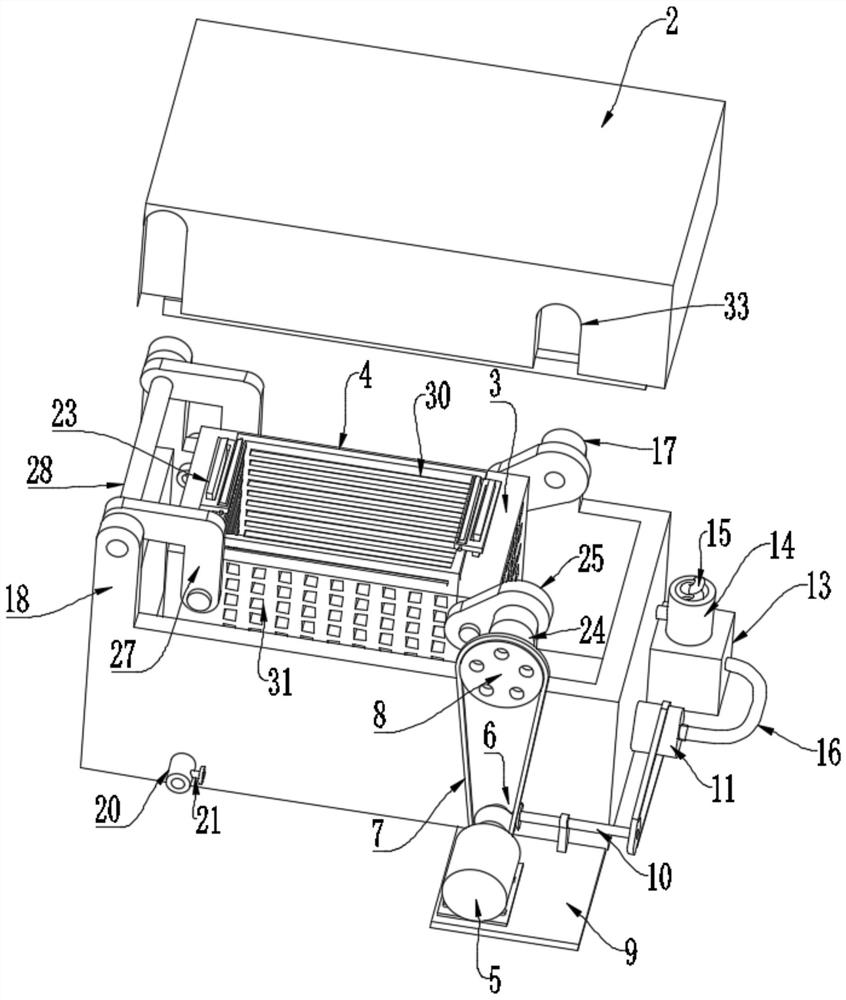

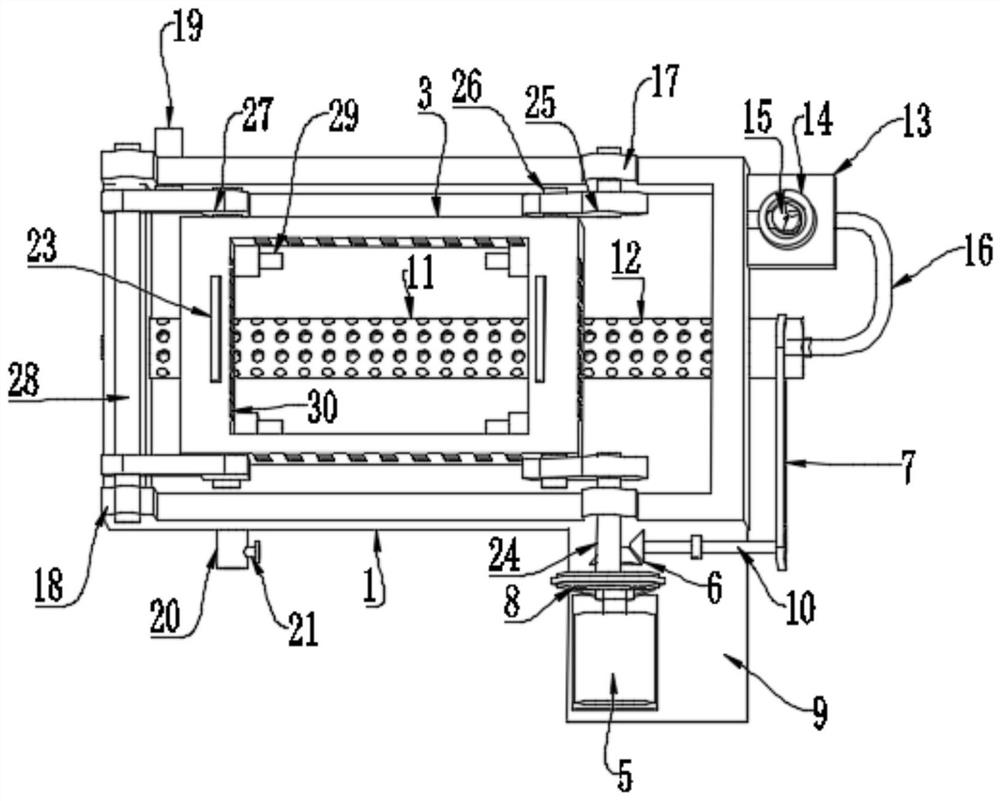

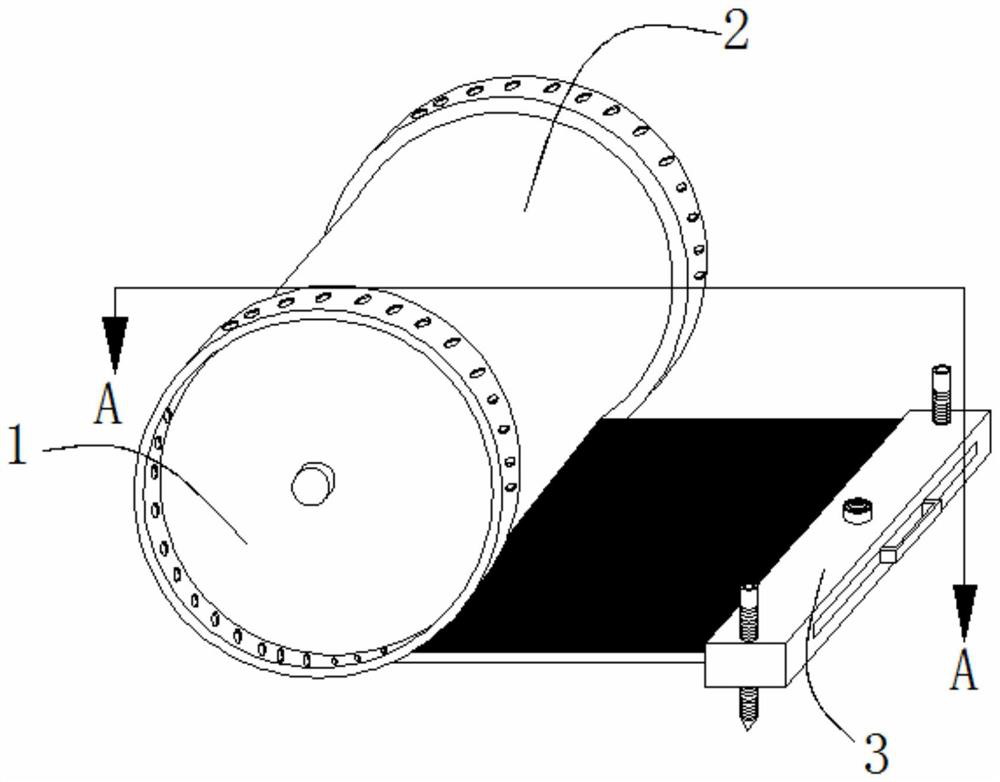

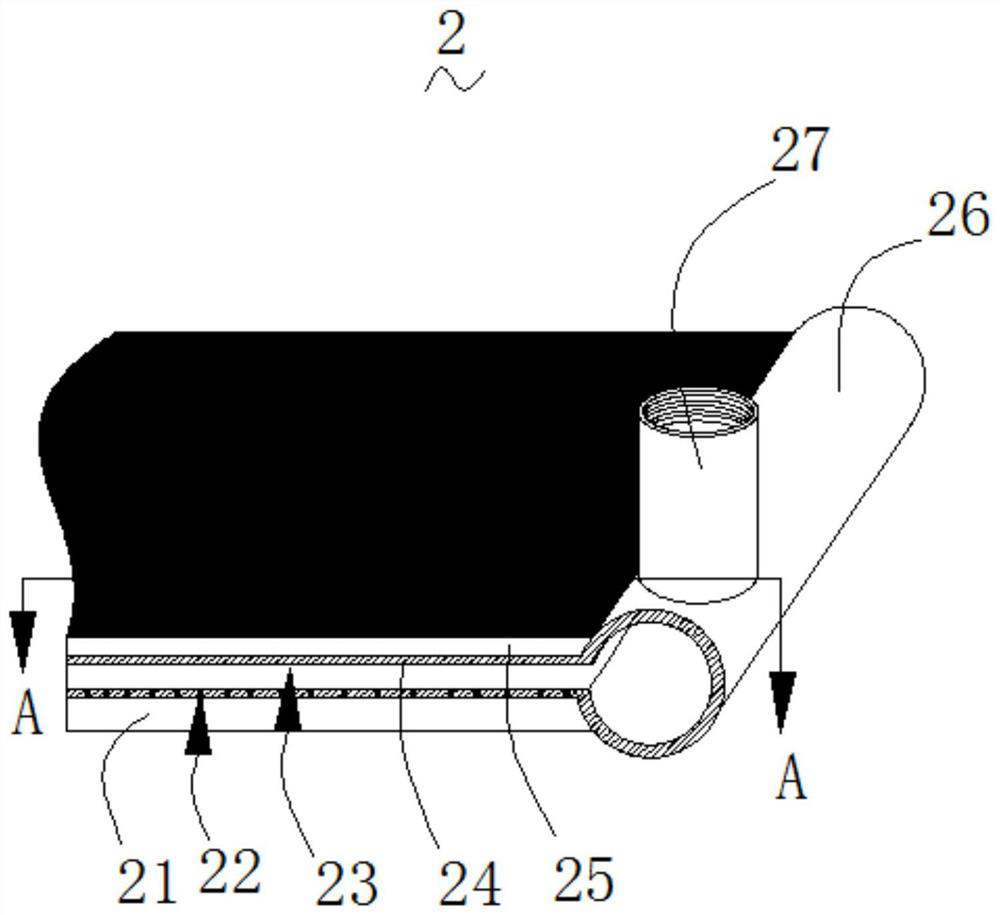

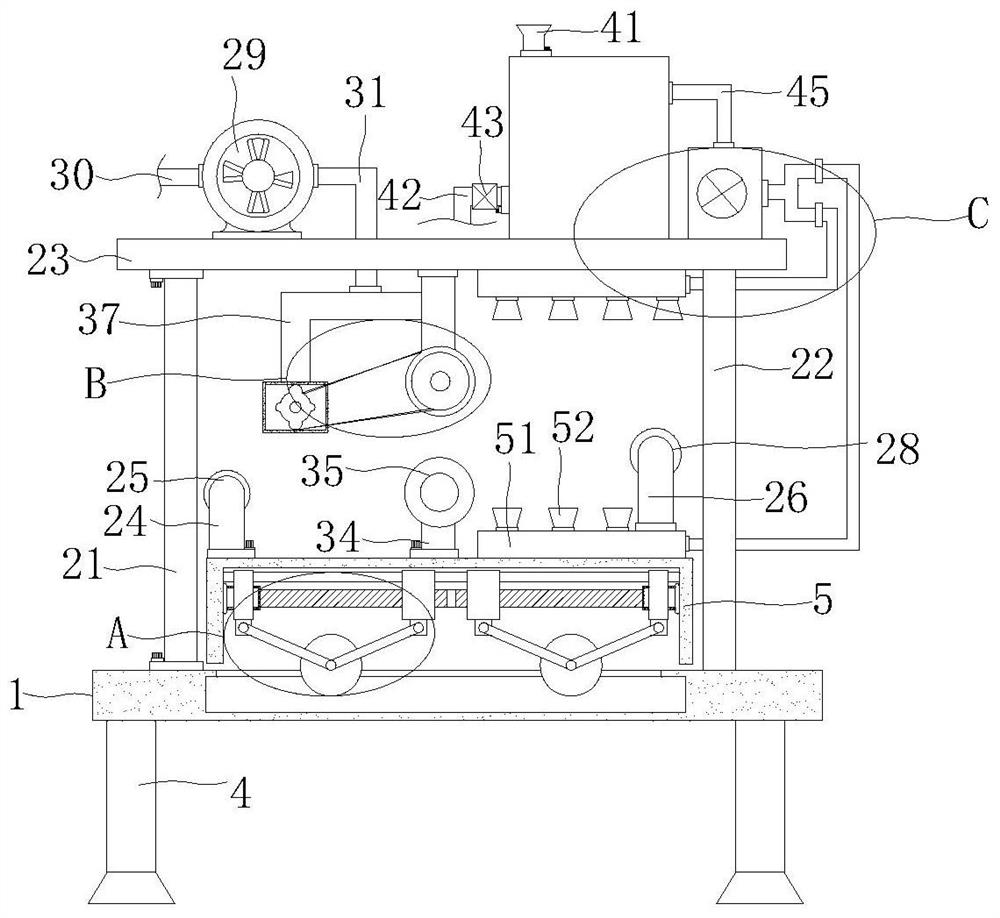

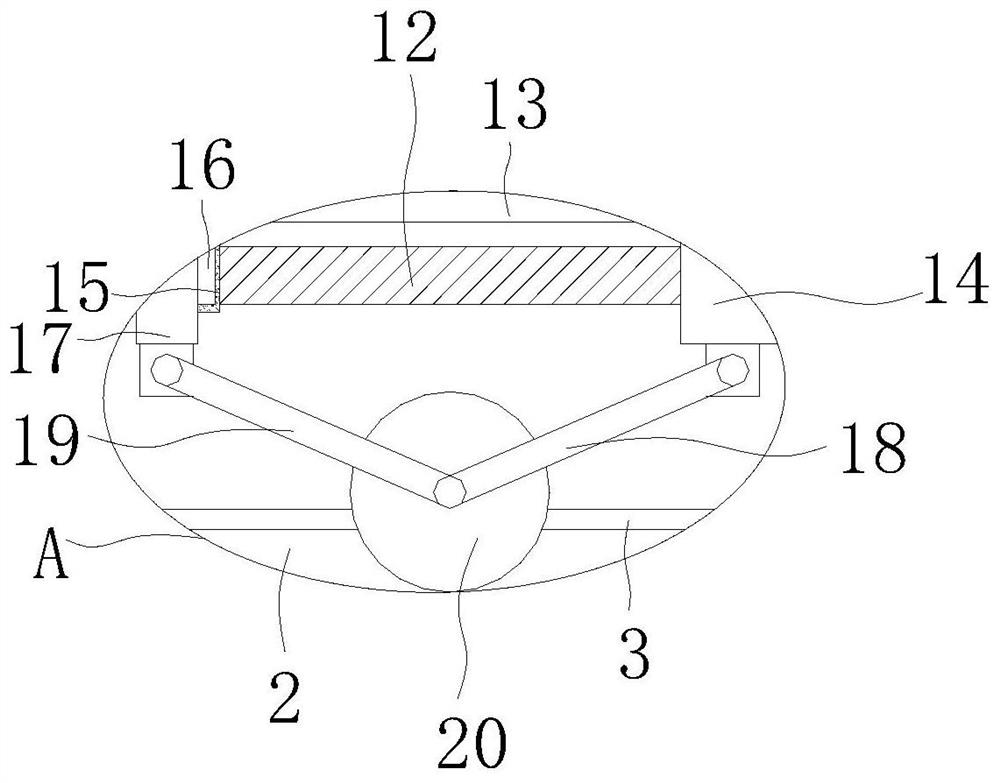

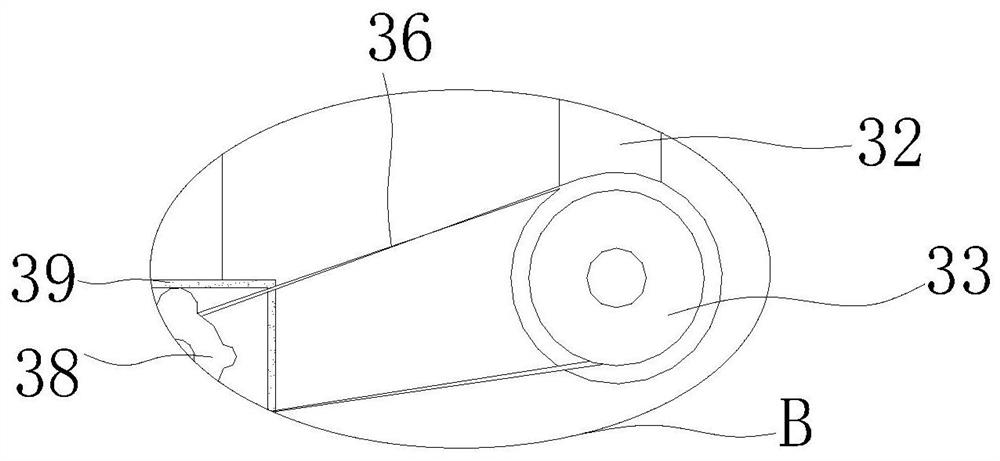

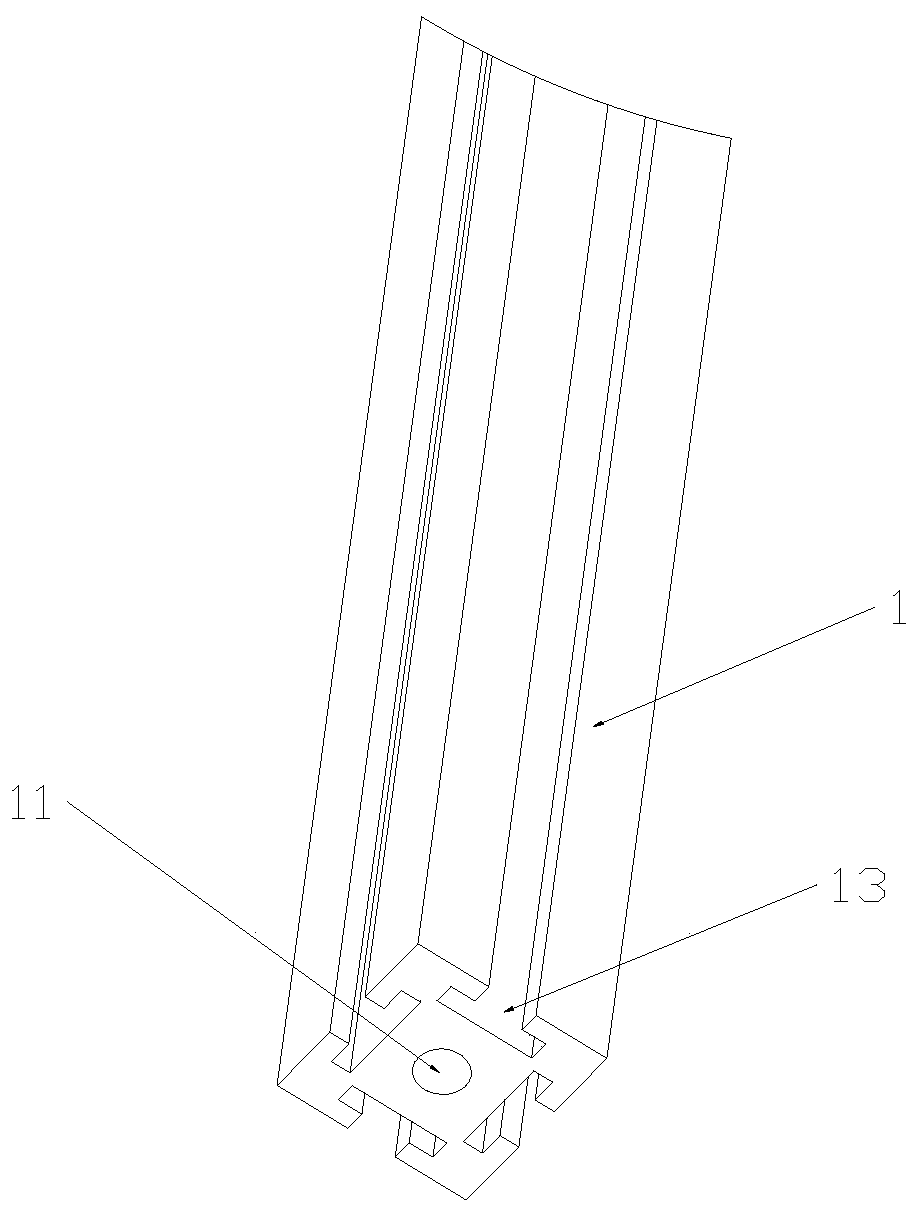

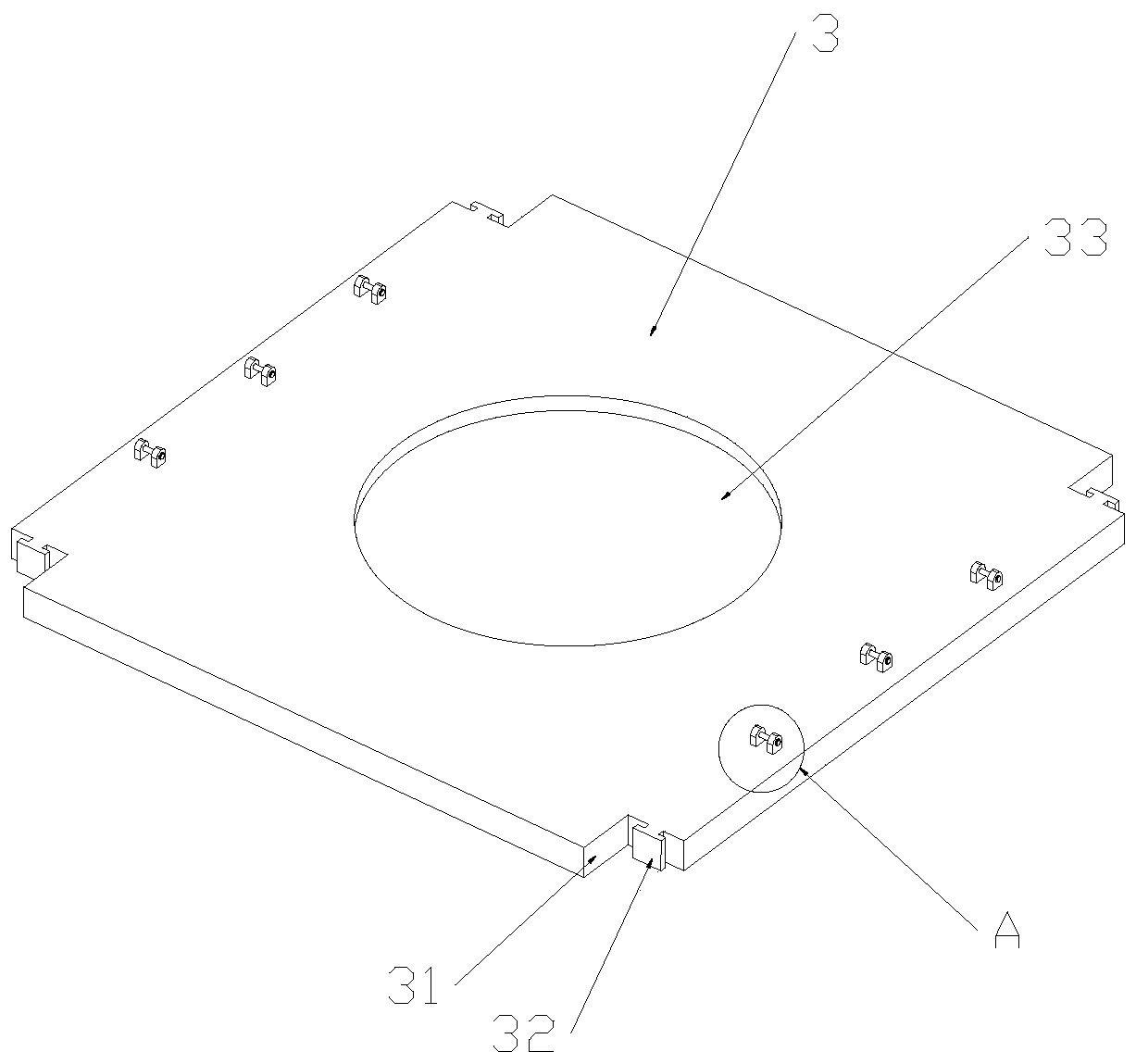

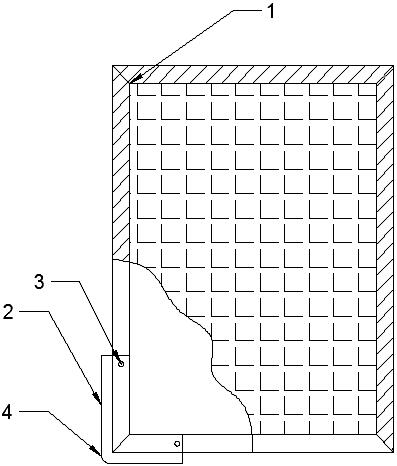

Energy-saving and environment-friendly coal slime drying machine and use method thereof

ActiveCN110030810ASimple structureReduce volumeSievingGas current separationPulp and paper industryCoal

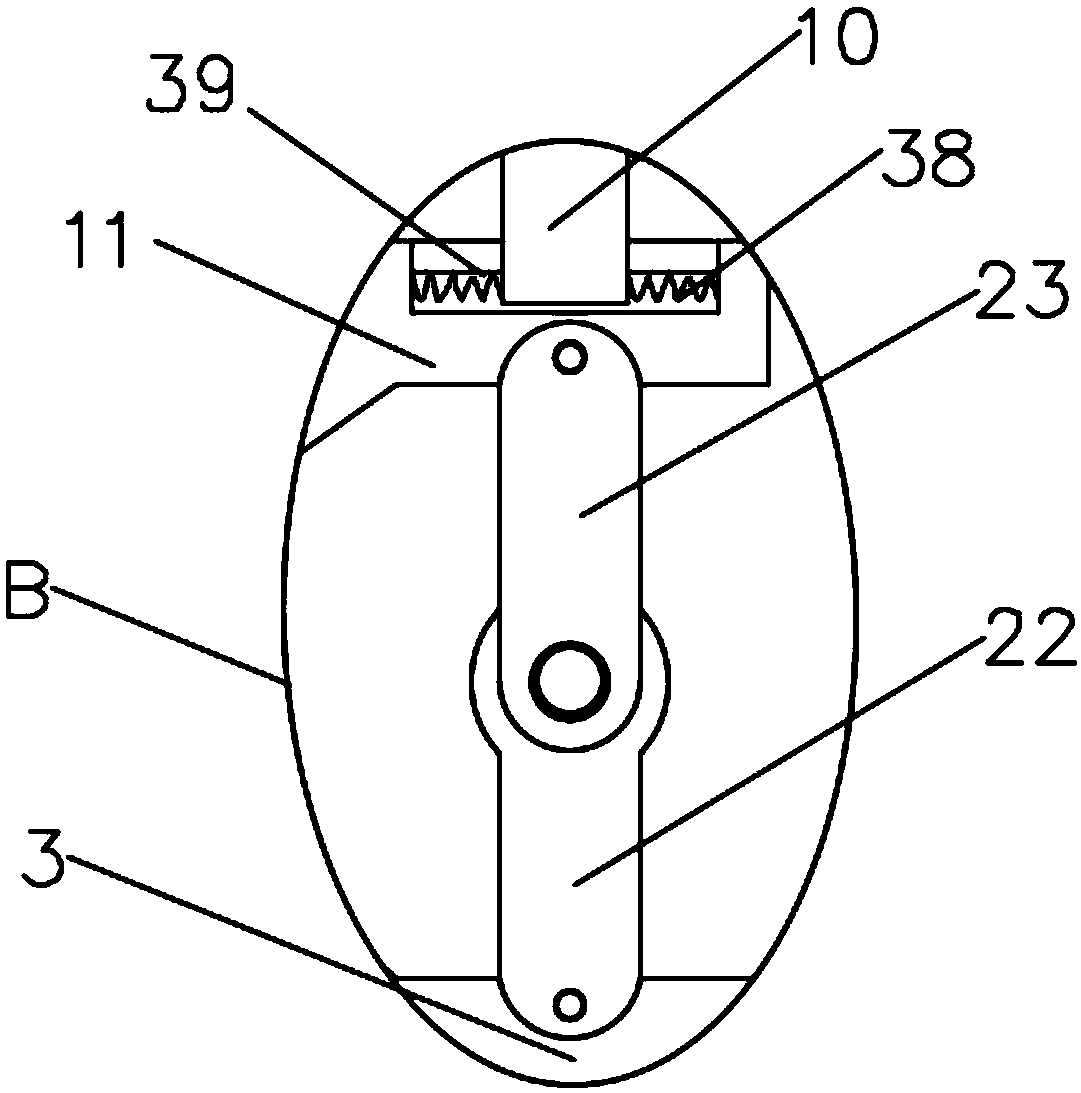

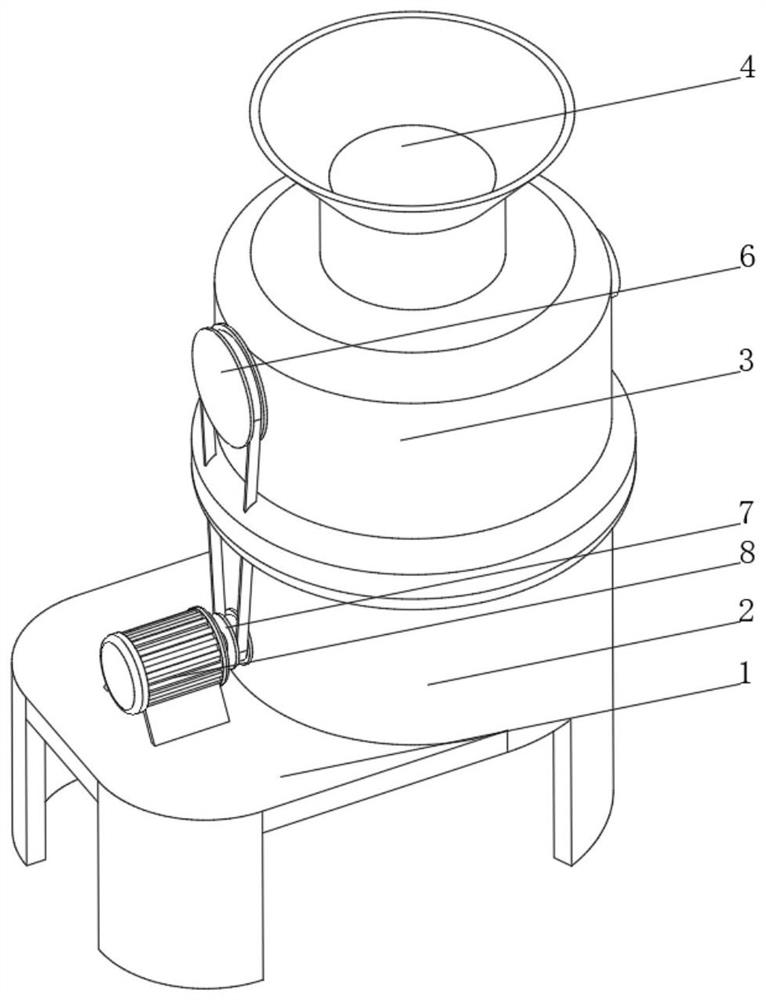

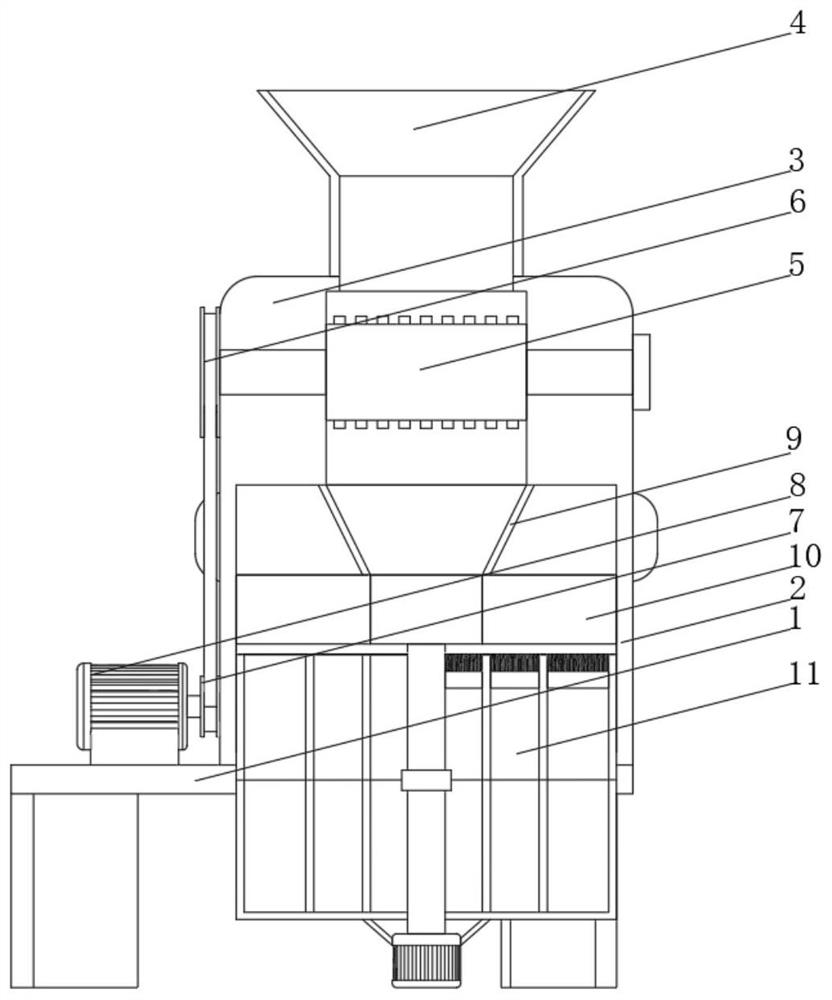

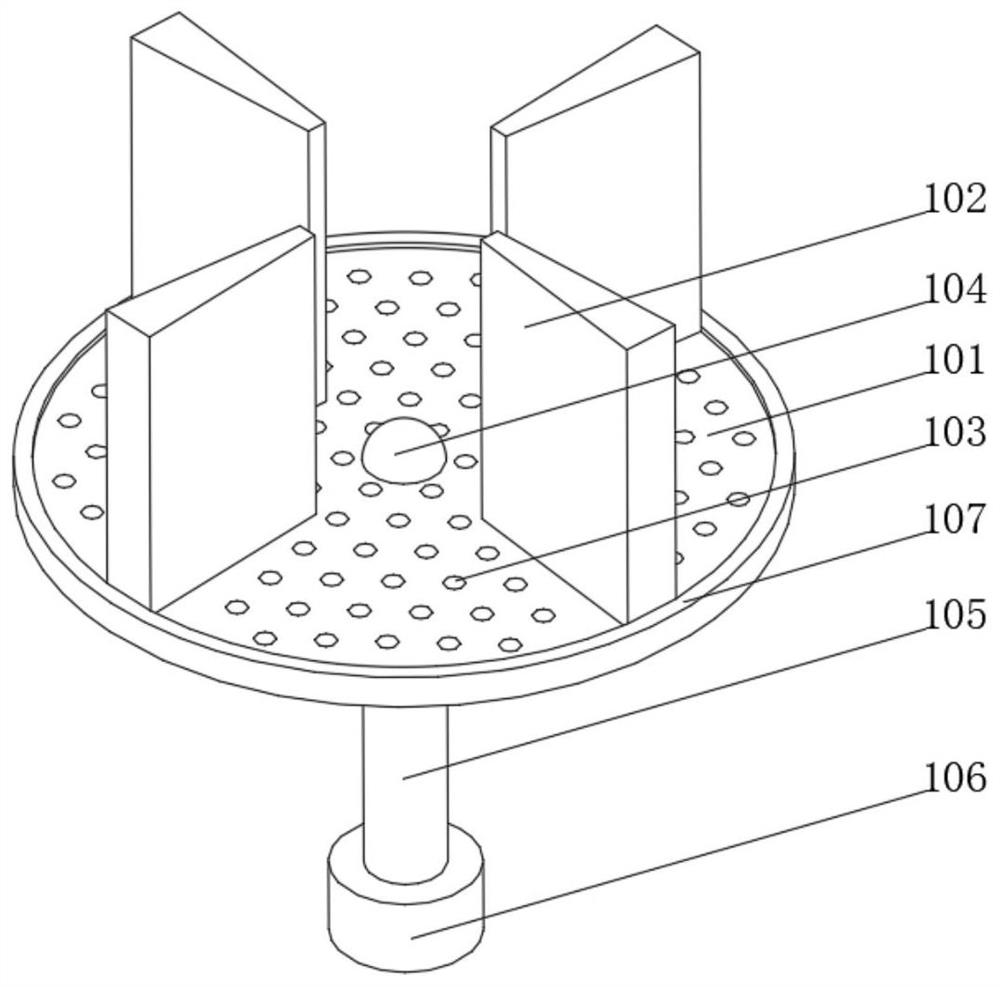

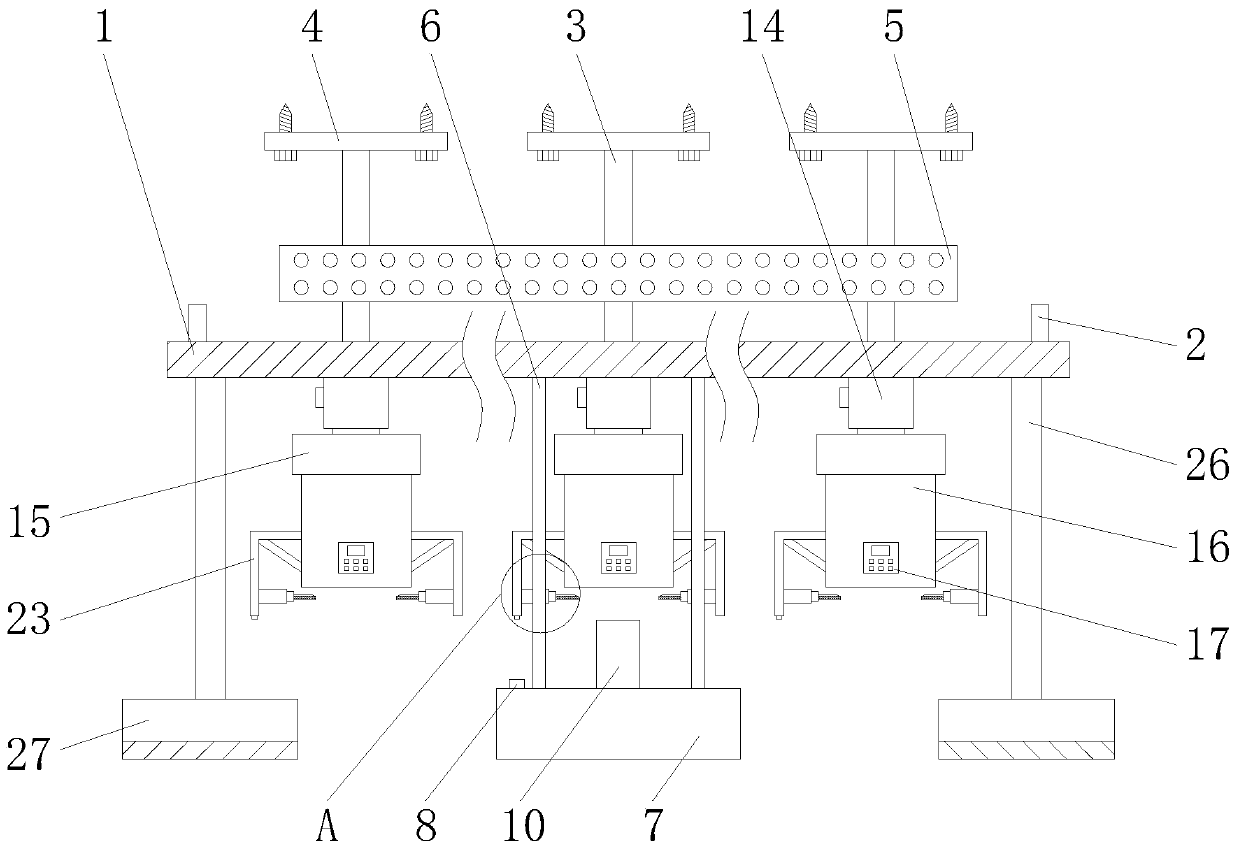

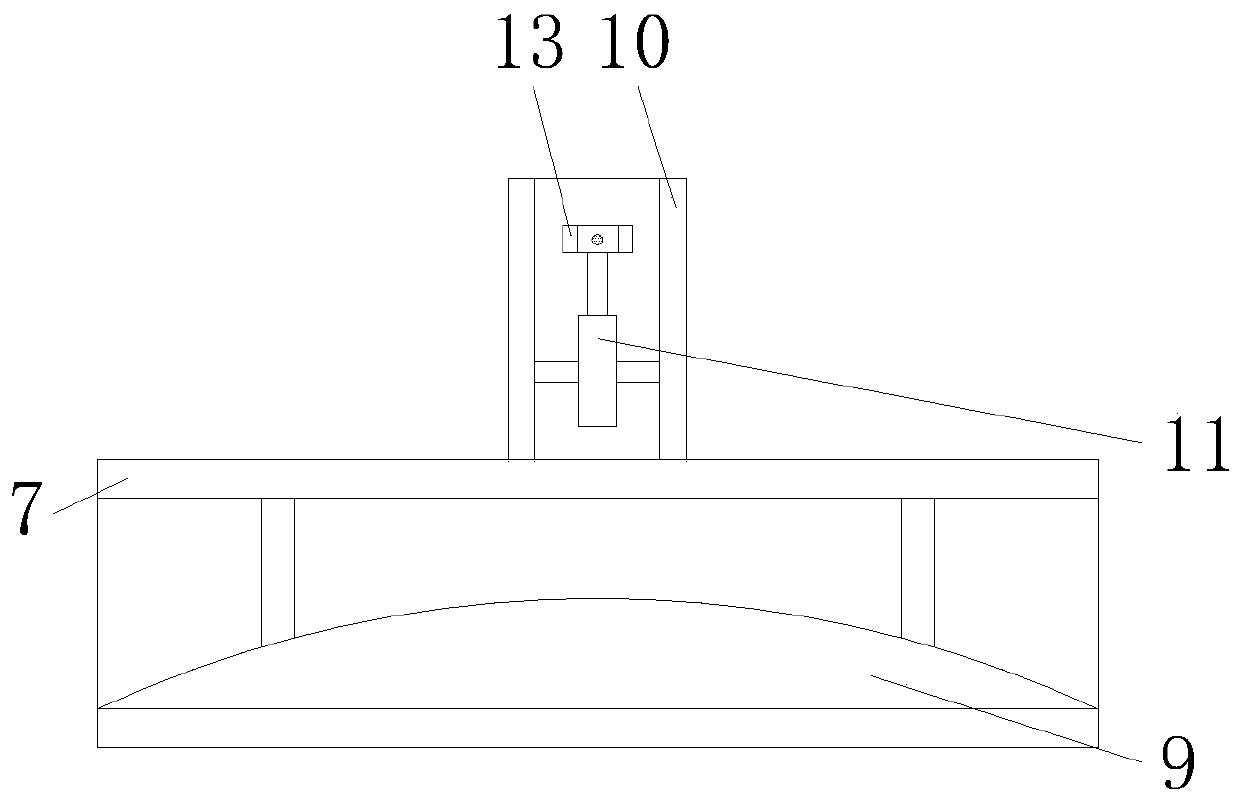

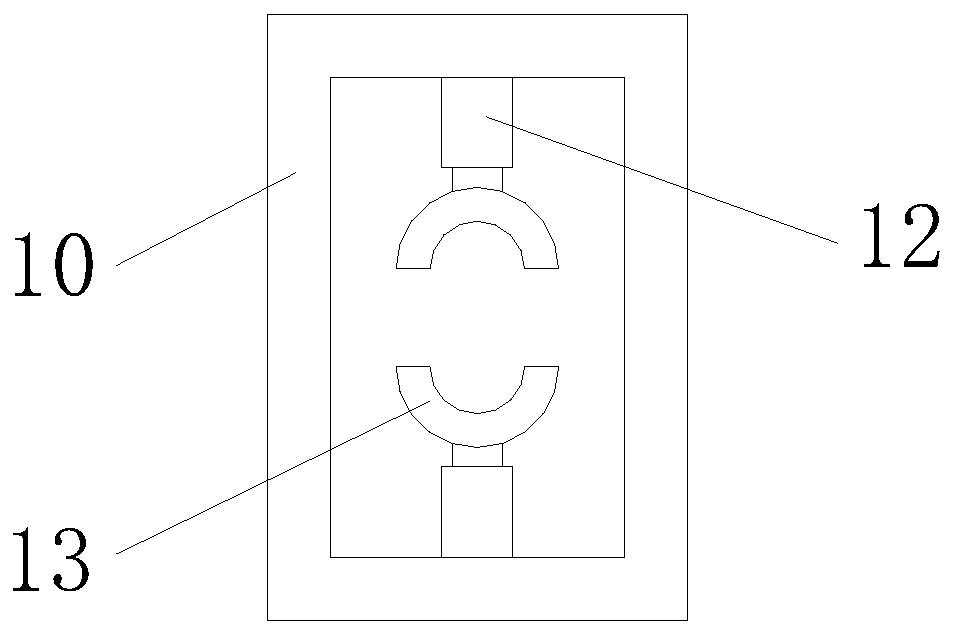

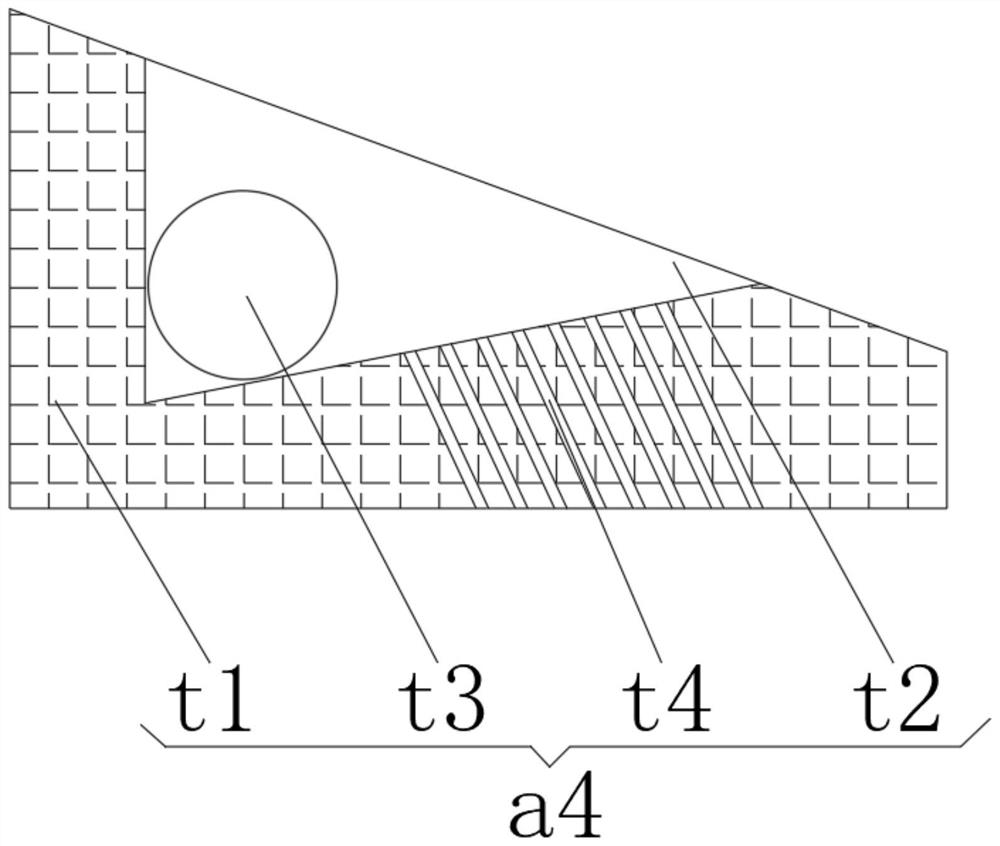

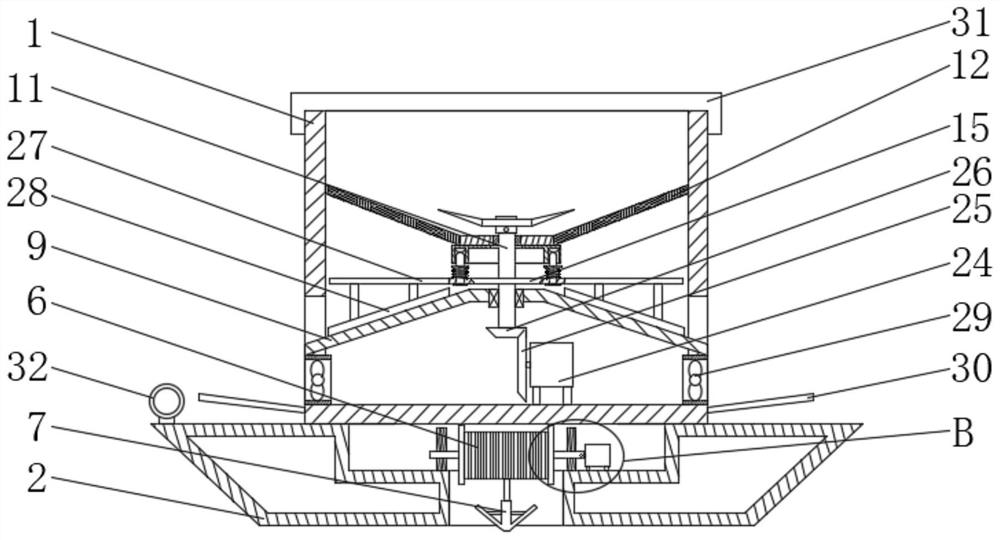

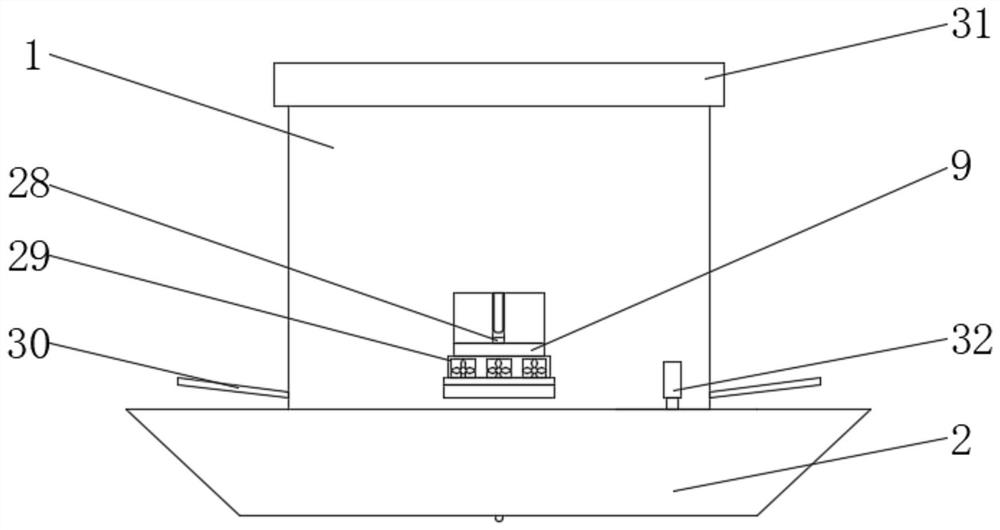

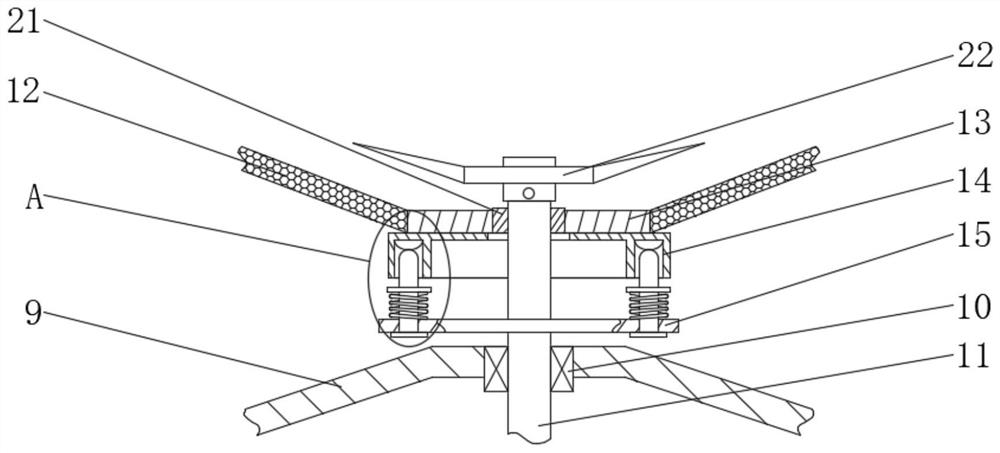

The invention discloses an energy-saving and environment-friendly coal slime drying machine and a use method thereof. The energy-saving and environment-friendly coal slime drying machine comprises a roller arranged obliquely, and driving mechanisms and a limiting mechanism are arranged at the bottom end of the roller; an air inlet mechanism is arranged at a side end of the roller, and a feeding mechanism is fixed to the top of one end of the roller; a fixing disc is welded to one end of the inner wall of the roller, a drainage mechanism is rotatably arranged at the middle position of the fixing disc, the drainage mechanism comprises a drainage rod, a first limiting plate is arranged at one end of the drainage rod, and a second limiting plate is arranged at the other end of the drainage rod; an air outlet pipe connected to tail gas treatment equipment is arranged at the side end of the second limiting plate; and discharging mechanisms distributed parallelly are arranged at the bottom ofthe roller, and the discharging mechanisms are arranged right below drainage paddles. According to the energy-saving and environment-friendly coal slime drying machine and the use method thereof, through the transmission of third gears and racks, and under the action of gravity and spiral material leading paddles, materials with small particle sizes can be obtained, and the purpose of screening in the roller is finally realized; and the structure is simple, the manufacturing cost is reduced, and the energy-saving and environment-friendly coal slime drying machine and the use method thereof are suitable for small-scale production and have good popularization practicability.

Owner:ANHUI UNIV OF SCI & TECH

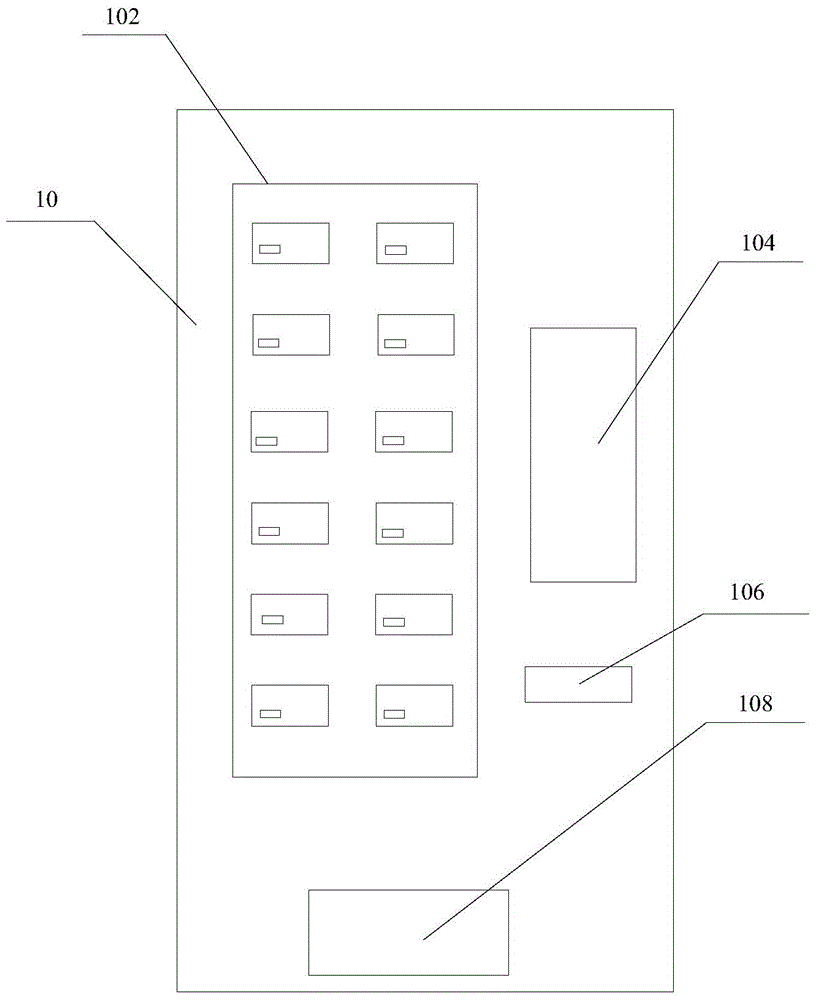

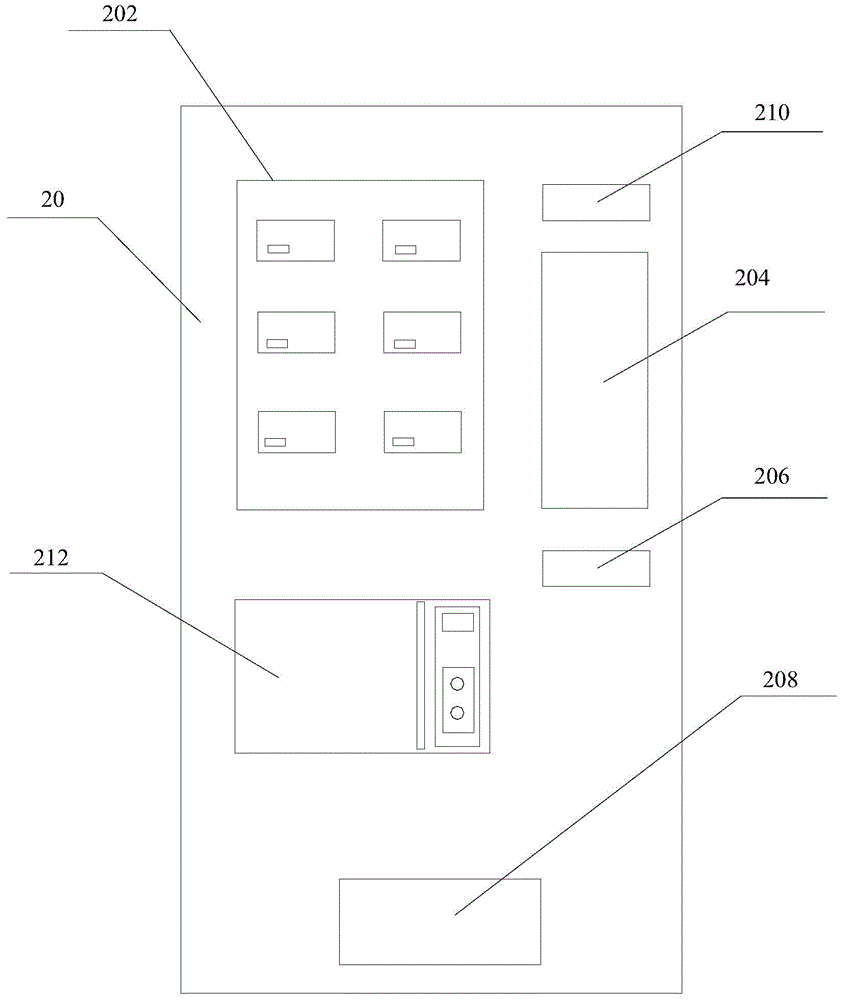

Automatic food heating and vending machine

InactiveCN104637168AQuick and direct accessImprove experienceCoin-freed apparatus detailsApparatus for dispensing discrete articlesEngineeringHeating system

The invention provides an automatic food heating and vending machine comprising an automatic food heating and vending machine body and a food heating system, wherein the food heating system is built in the automatic food heating and vending machine body and is used for automatically heating food. By means of the technical scheme of the invention, no matter a consumer purchases food in any form, the food can be automatically heated, moreover, the operation is simpler and safer, and the heated food can be obtained more quickly and directly, thereby improving the consumer experience and reducing the heat preservation energy consumption at the same time.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

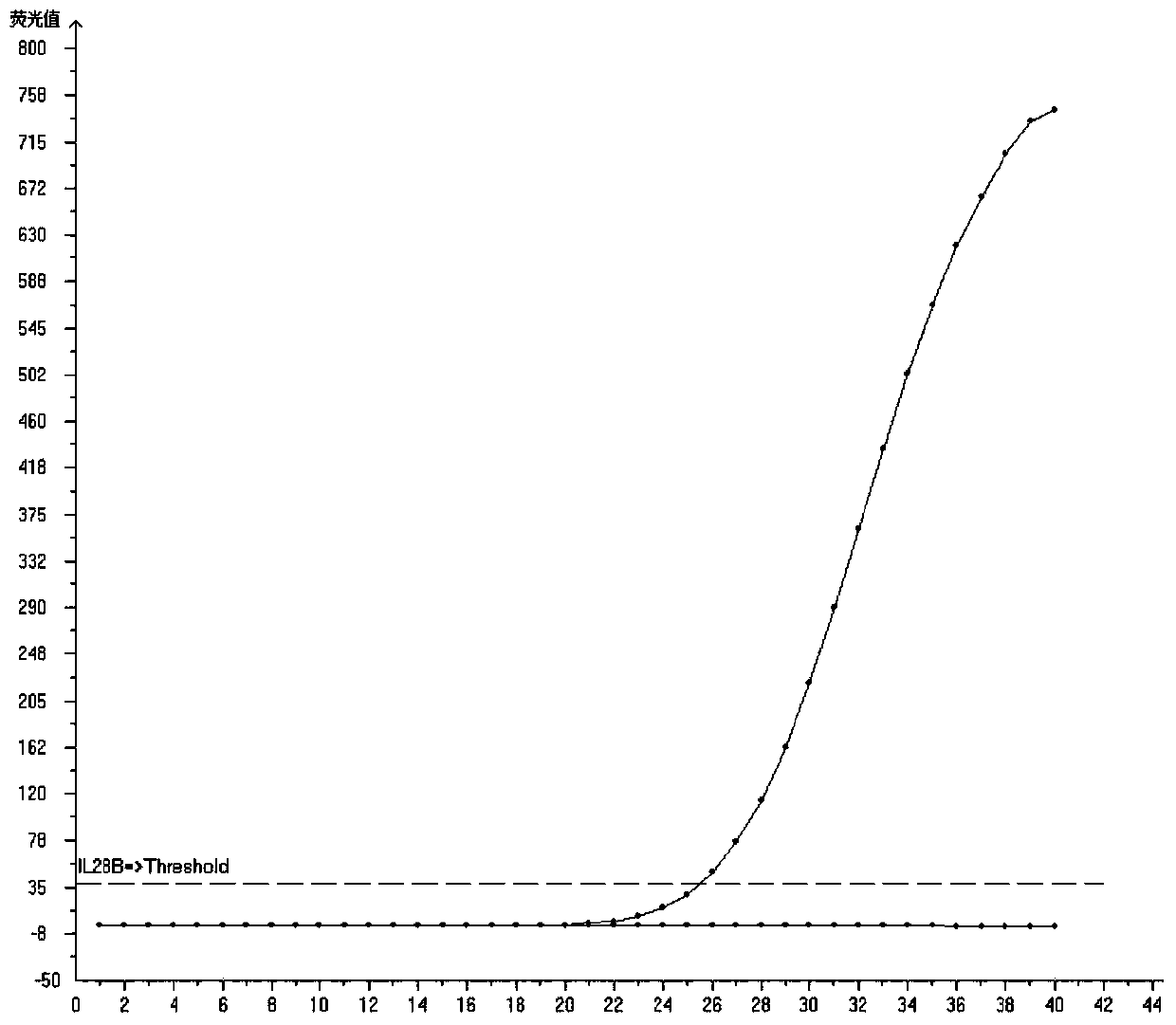

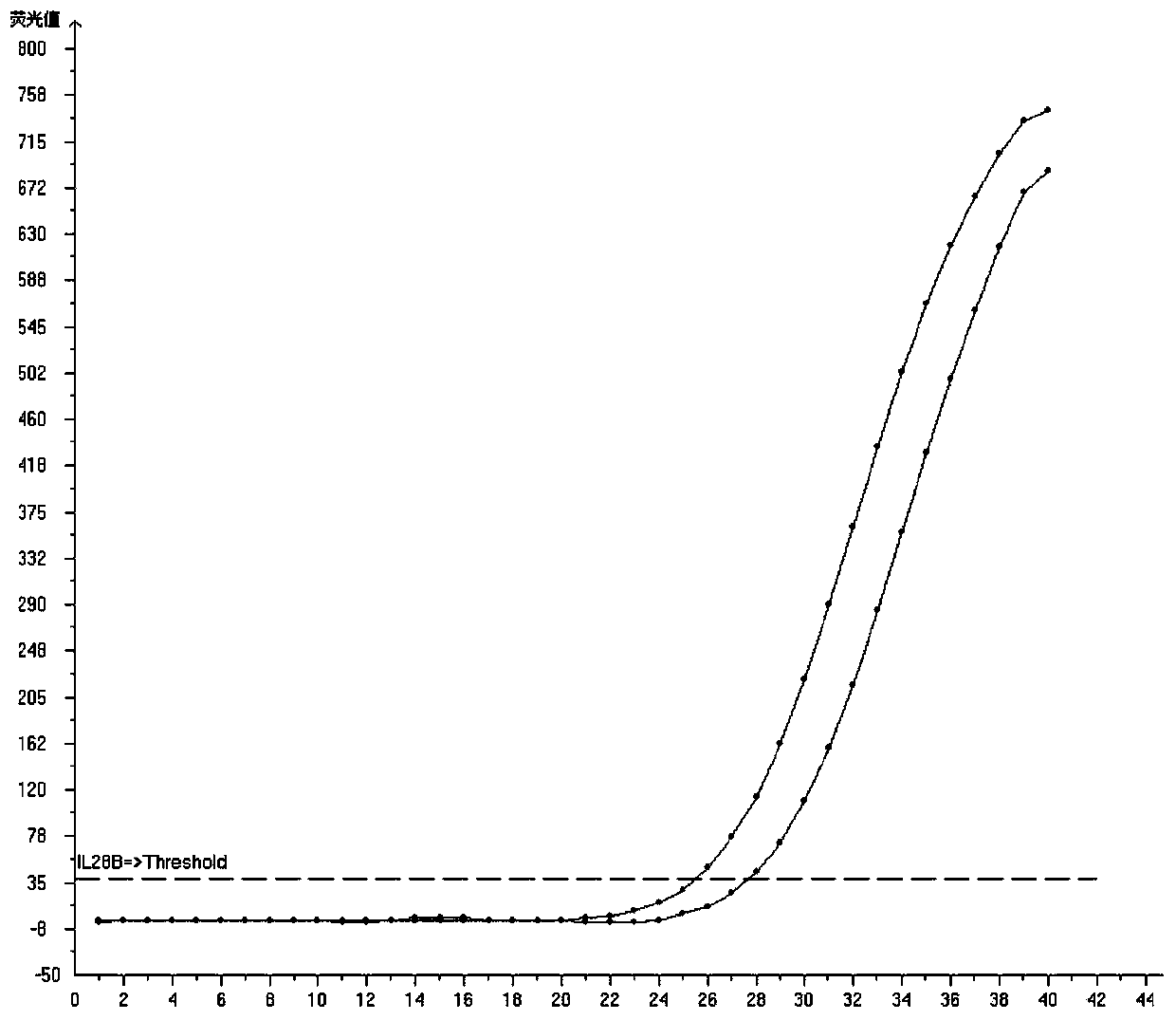

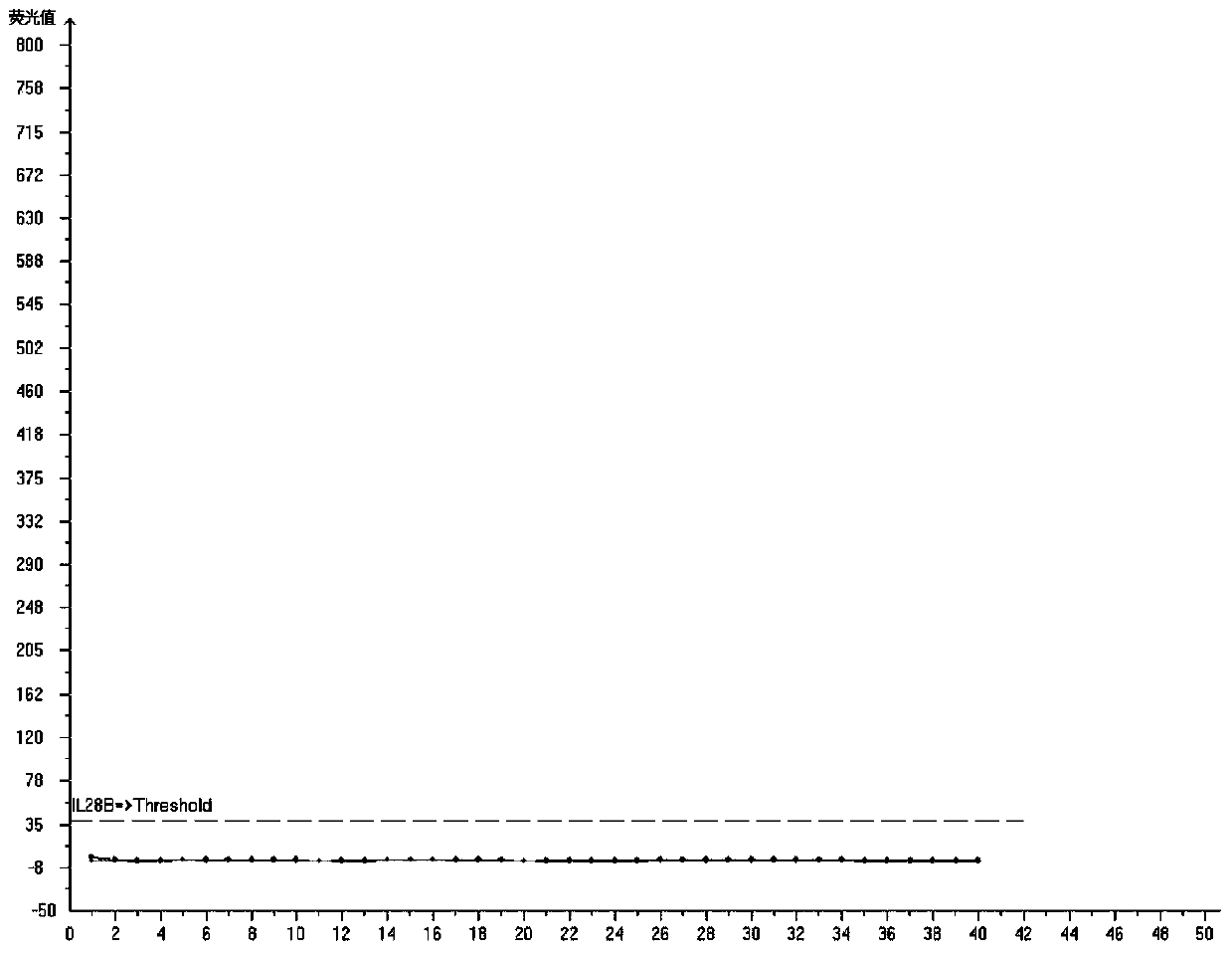

Human chromosome gene IL28B site polymorphism detection kit, and detection method and application thereof

InactiveCN103993076AEasy to operateImprove automationMicrobiological testing/measurementDNA/RNA fragmentationPolymorphism DetectionPollution

The invention provides a human chromosome gene IL28B site polymorphism detection kit, and a detection method and application thereof. The kit comprises at least one group of primers and probes in group a, group b and group c. The primers and the probes comprise: a: 860L1, 860L2, 860R, 860P; b: 275L1, 275L2, 275R, 275P; and c: 917L1, 917L2, 917R, 917P. 5' terminals of 860P, 275P and 917P are labeled as FAM, and 3' terminals are labeled as DACYL. The invention also discloses the detection method and application of the kit. The method is relatively simple and rapid, and is easy for realizing whole-course automation; secondary pollution of PCR products is avoided, and pollution is reduced; the cost is relatively low and relatively economic; and present popularized equipment in the market can be utilized, and no new investment is needed.

Owner:厦门安普利生物工程有限公司 +1

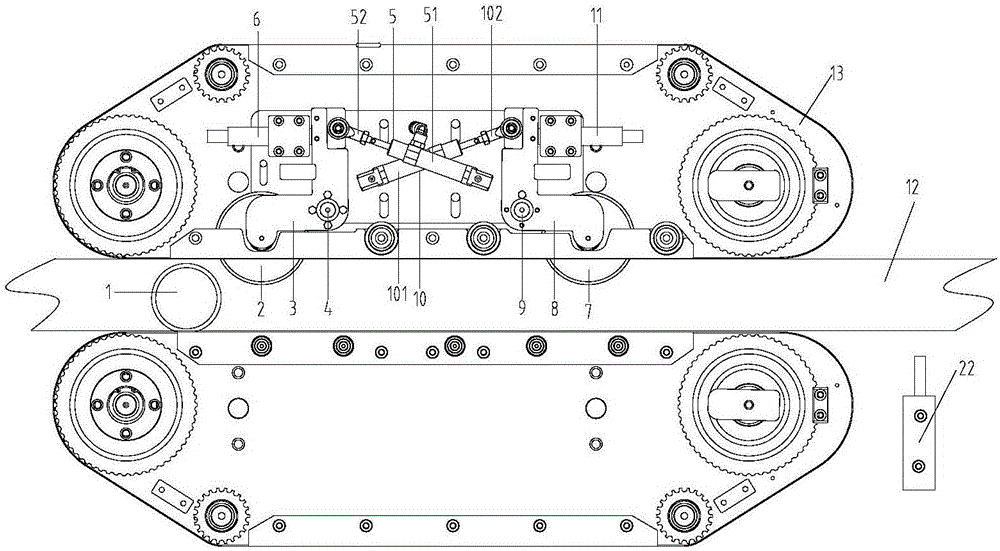

Method and device for detecting air leakage of beverage bottle

InactiveCN107525639AJudgment method is accurateAvoid secondary operationsMeasurement of fluid loss/gain rateEngineeringAssembly line

The invention relates to the field of bottle airtightness detection, and discloses a method and device for detecting air leakage of a beverage bottle. According to the invention, one conveying assembly is used for conveying the beverage bottle, and double cams are employed for pressure detection. The two cams are respectively provided with two independent pressure detection devices. When a to-be-detected beverage bottle enters a detection region, the to-be-detected beverage bottle sequentially passes through the two cams, and the pressure detection devices respectively read the data for two times and transmit the data to a controller. The controller judges whether the air pressure in the to-be-detected beverage bottle changes or not through the comparison of the data, and judges whether the to-be-detected beverage bottle leaks air or not. According to the above scheme of the invention, the device can guarantee the production speed of an industrial assembly line, and also can guarantee the detection accuracy.

Owner:苏州苏尔码自动化科技有限公司

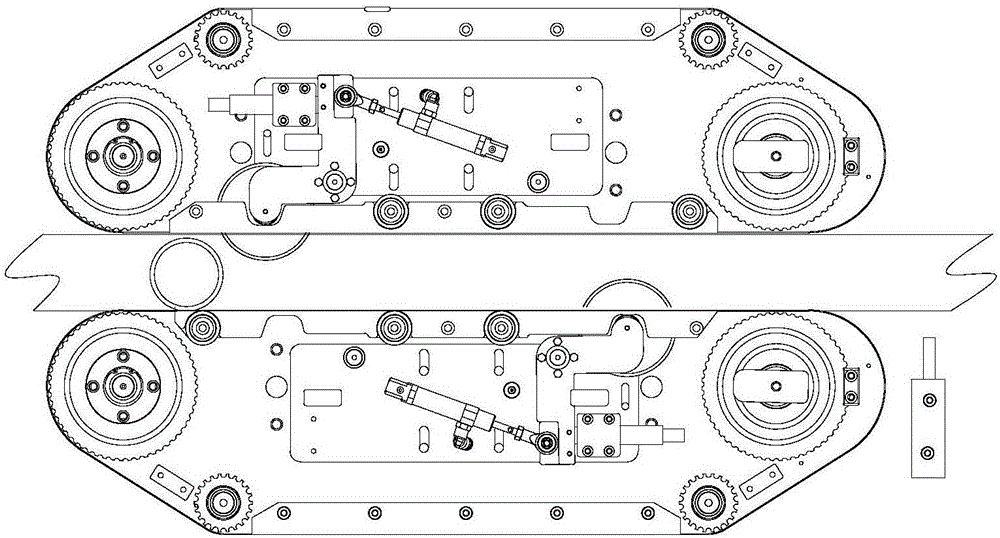

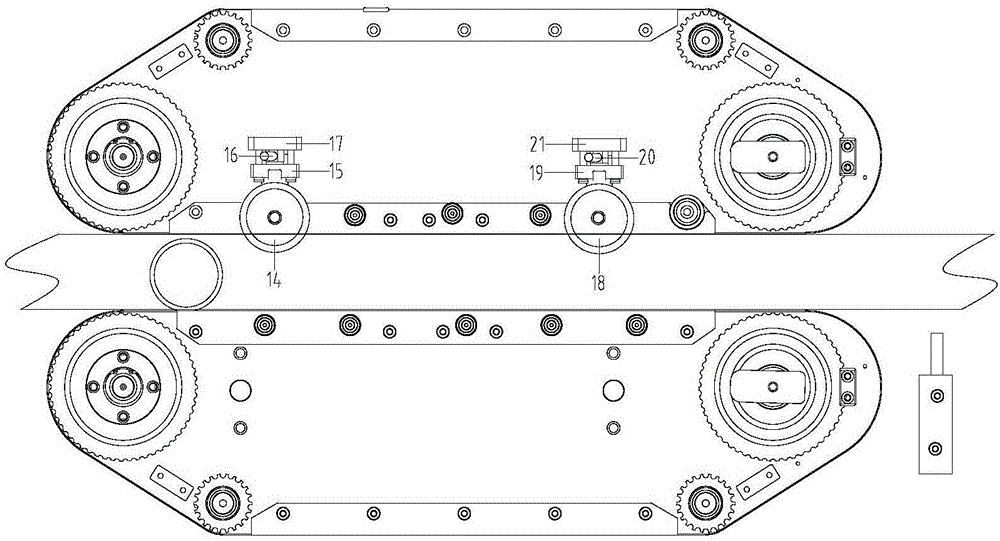

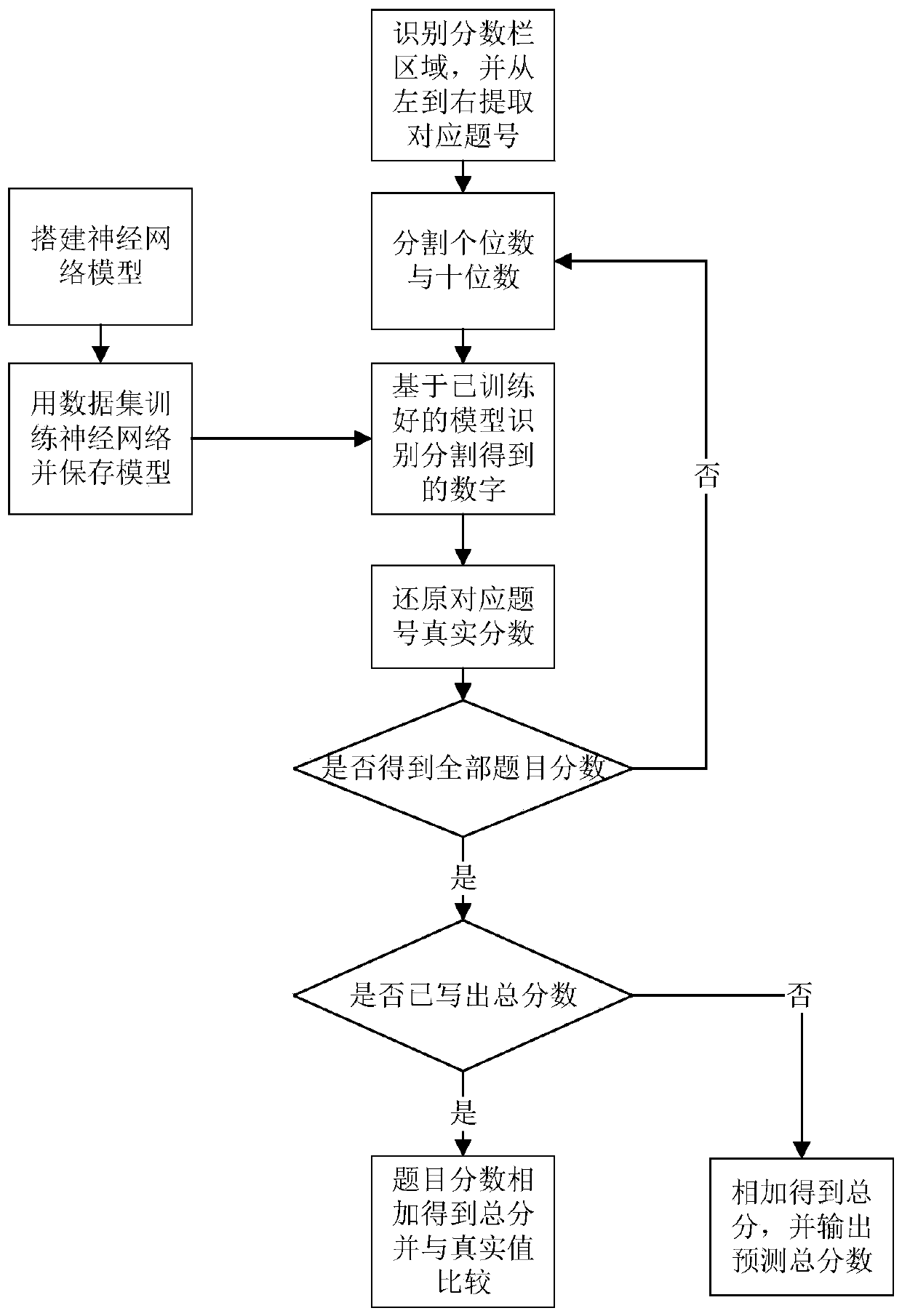

Intelligent paper test paper total score identification method and system

ActiveCN110443235AHigh speedReduce the burden onImage enhancementImage analysisPattern recognitionRapid identification

The invention discloses an intelligent paper test paper total score identification method and system, which are applied in the field of teacher test paper scoring for improving efficiency , in the method, numbers are accurately segmentedthrough a segmentation algorithm, a unit digit and a ten digit of a score of a corresponding question number in a score region picture are segmented and marked toobtain a marked score region picture, and real numbers are restored. The method is applied to the specific field of paper scoring of teachers and corresponds to a question number score extraction mode. In order to help a teacher group to increase the speed in paper scoring and reduce the burden and pressure of the teacher group, on the premise of changing the score of each question, the corresponding question number score of a score calculation column is recognized through a handwritten numeric recognition neural network, and the scores are added to obtain a total score. A total score calculation result is obtained through rapid identification and rapid calculation, the paper scoring speed is greatly increased, and therefore secondary operation is avoided.

Owner:FOSHAN UNIVERSITY

Steel raw material nano crusher

The invention discloses a steel raw material nano crusher which comprises a machine body, a base and a driving device. The machine body is fixed on the base, a transmission main shaft is vertically arranged on the axis location inside a crushing drum, the lower end of the transmission shaft is installed on a bearing seat in the machine body, multiple crushing discs are symmetrically and movably connected to the two ends of the transmission main shaft respectively, the lower end of the transmission main shaft is connected with the driving device through a belt conveying device, multiple powder outlet channels are arranged on the side wall of the crushing drum, and one end of each powder outlet channel is located below a filter device. According to the steel raw material nano crusher, the multiple crushing discs are arranged inside the crusher, the crushing effect is effectively guaranteed, screen mesh is arranged inside the crushing drum, screening is conducted on the steel raw material particle size in the crushing process, secondary operation is avoided, the structure is simple, operation is convenient, moving is convenient and rapid, and the defects of an existing crusher are effectively overcome.

Owner:铜陵百荣木业有限公司

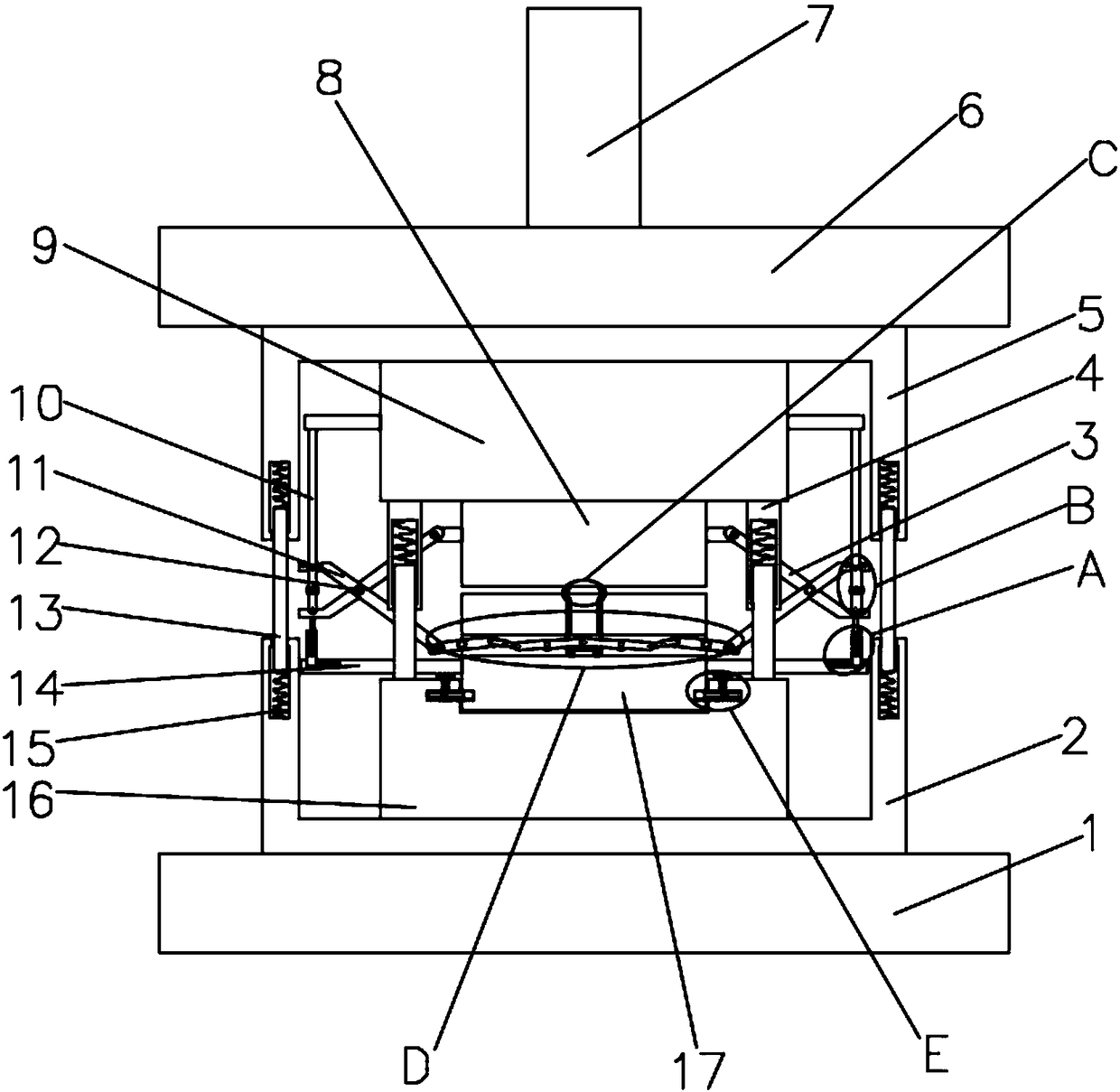

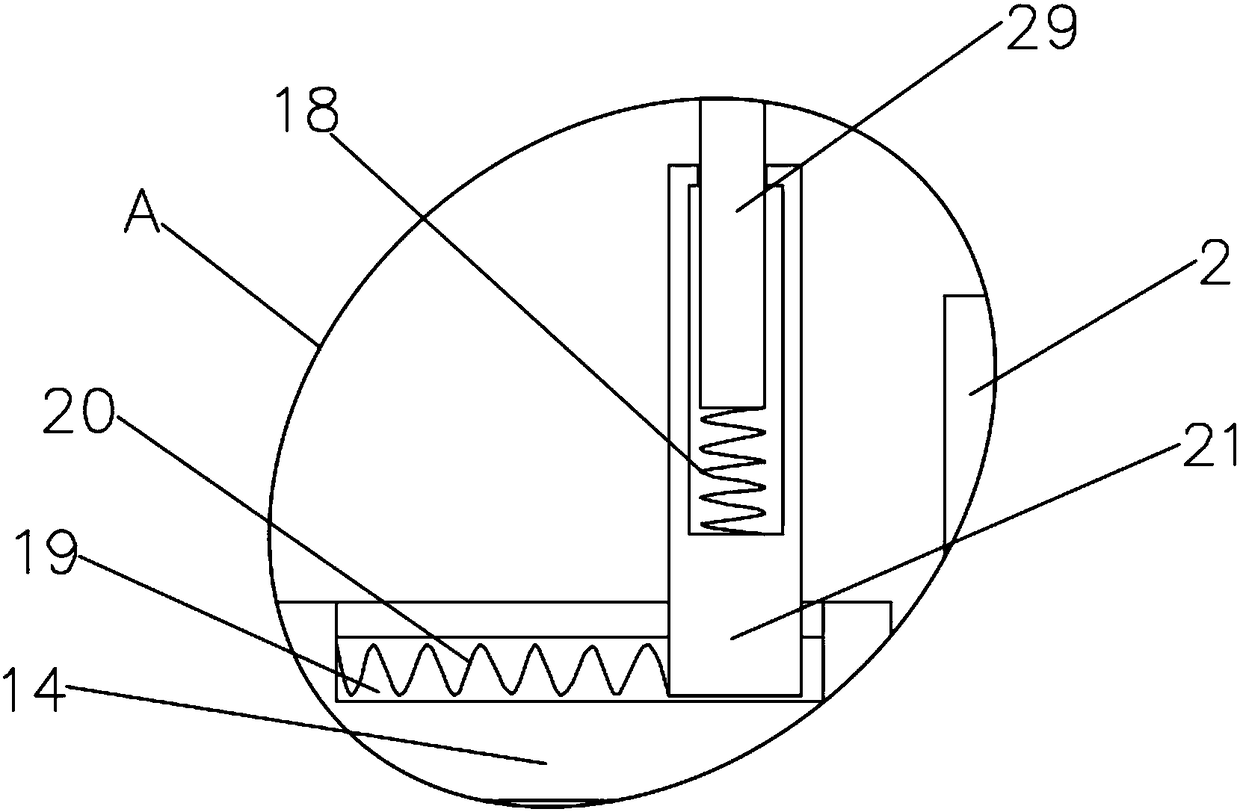

Stamping and hole flanging device

The invention discloses a stamping and hole flanging device. The stamping and hole flanging device comprises a first pressing block and a second pressing block, the second pressing block is arranged at the bottom of the first pressing block, and the end, away from the first pressing block, of the second pressing block is provided with a first fixing body. A base is arranged at the bottom of the first fixing body, a groove is formed in the first fixing body, and the second pressing block is inserted on the groove. Clamping devices are symmetrically arranged on the two sides of the groove, the second pressing block is fixedly connected to the groove through clamping devices, and the end, away from the second pressing block, of the first pressing block is fixedly connected with a second fixing body. The upper portion of the second fixing body is provided with a top seat, and the top seat is connected with an oil cylinder. According to the stamping and hole flanging device, operation is easy, through mutual cooperation of the clamping devices, a movable device, a connecting device, a linkage device and an adjusting device, the two sides of a metal sheet can be stamped simultaneously, secondary operation is avoided, the work efficiency can be improved while the production cost is saved, and the stamping and hole flanging device is provided for a user.

Owner:MAANSHAN WANXIN CASTING

Construction waste crushing device

The invention discloses a construction waste crushing device which comprises a supporting base. The top of the supporting base is fixedly connected with a treatment barrel, the top of the treatment barrel communicates with a crushing barrel, the top of the crushing barrel communicates with a feeding port, and the inner wall of the crushing barrel is rotationally connected with a crushing roller. One end of the crushing roller penetrates through the crushing barrel and is fixedly connected with a driven belt wheel, the side face of the driven belt wheel is connected with a driving belt wheel through a belt, one side of the driving belt wheel is fixedly connected with a driving motor, the bottom of the crushing barrel communicates with a guide pipe, the bottom of the guide pipe communicates with a treatment rotary disc, and the part, located at the bottom of the treatment rotary disc, of the inner wall of the treatment barrel is fixedly connected with a classification device. The invention relates to the technical field of construction waste crushing. According to the construction waste crushing device, classification operation is conveniently achieved while crushing is conducted, secondary operation on disintegrating slag is avoided, use is easy and convenient, the disintegrating slag can be divided into multiple different grades according to use requirements, and flexibility is good.

Owner:蒋传华

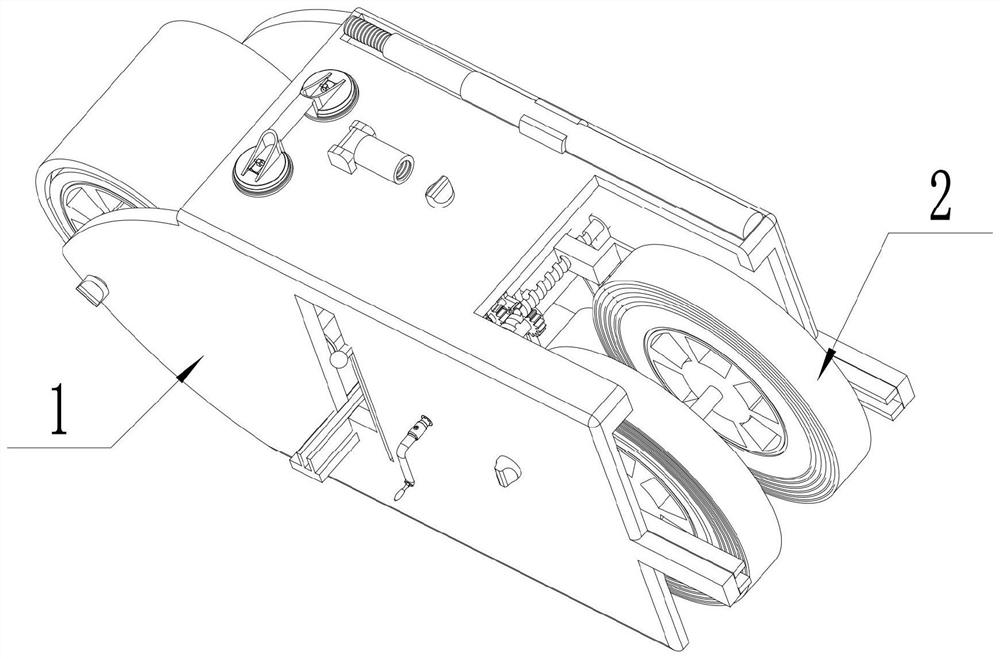

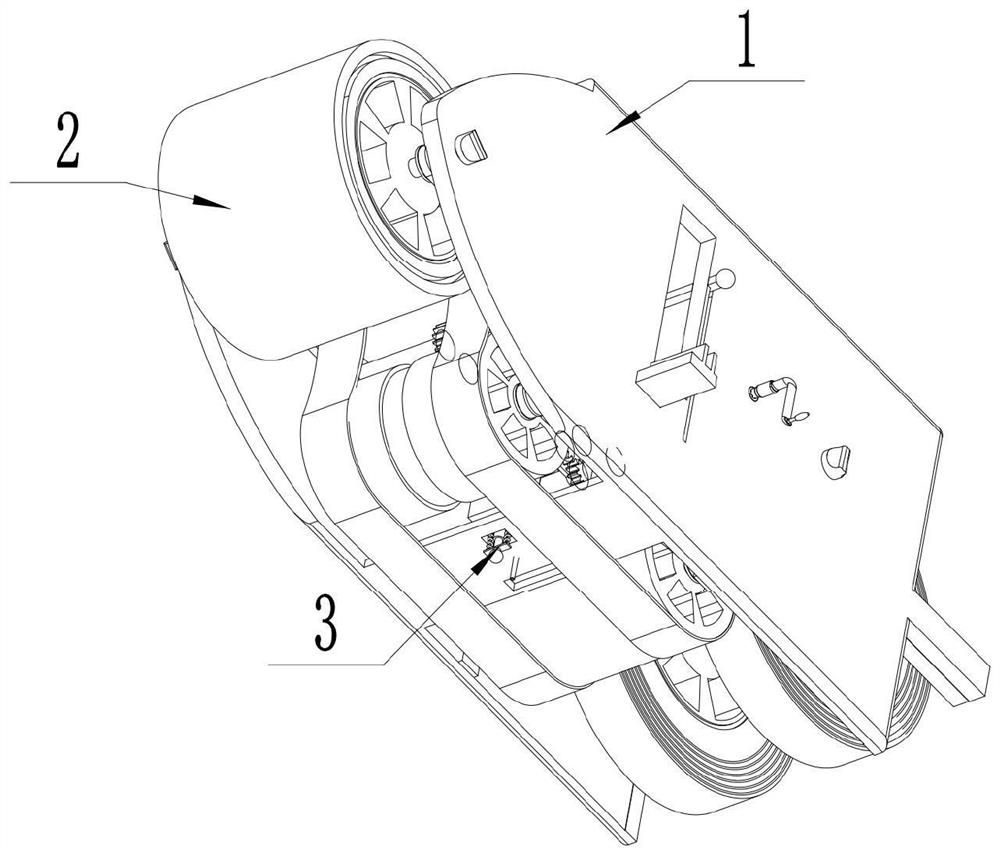

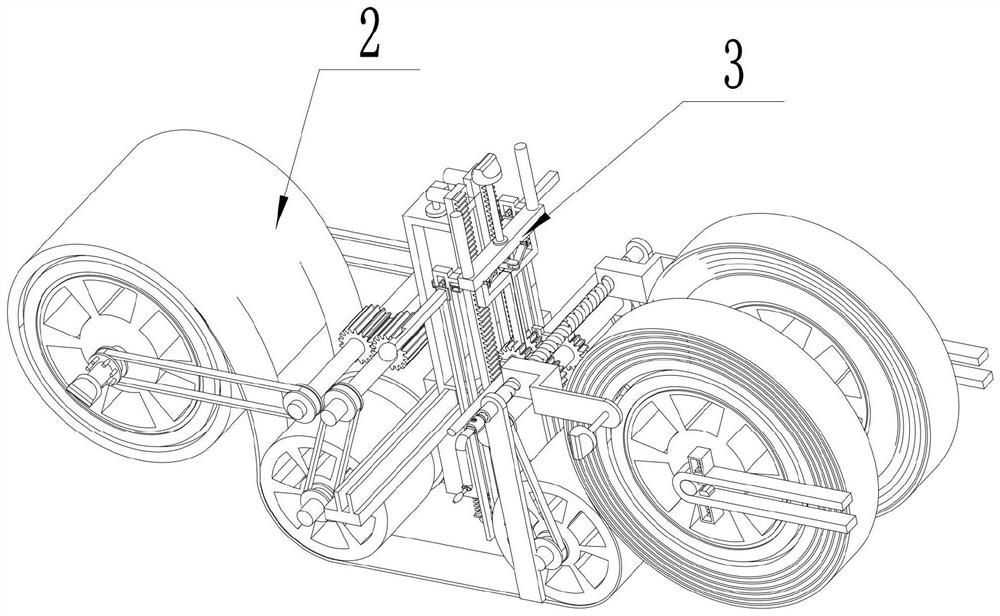

Construction waste treatment device

PendingCN112681197AFast cleaningReduce the amount of manual laborRoad cleaningPressesElectric machineryRefuse Disposals

The invention relates to the technical field of garbage treatment equipment, and discloses a construction waste treatment device. A construction waste treatment device comprises a cleaning device, the rear end of the cleaning device is fixedly connected with a second housing, a dust falling device is arranged at the top of the second housing, the right end of the cleaning device communicates with a material guide pipe, a motor is fixedly installed at the top of the material guide pipe, and the surface of the output end of the motor is sleeved with a first belt wheel. The first belt wheel and a second belt wheel are in transmission connection through a belt, the surface of the driving shaft is sleeved with the second belt wheel, and a spiral blade is fixedly installed on the surface of the driving shaft and arranged in the material guide pipe. By arranging the cleaning device, the construction waste is cleaned and collected in the moving process of the pushing device, so that the cleaning speed of the construction waste is greatly increased, and meanwhile, the manual labor amount in the construction waste cleaning process can be effectively reduced.

Owner:湖南伟隆建设工程有限公司

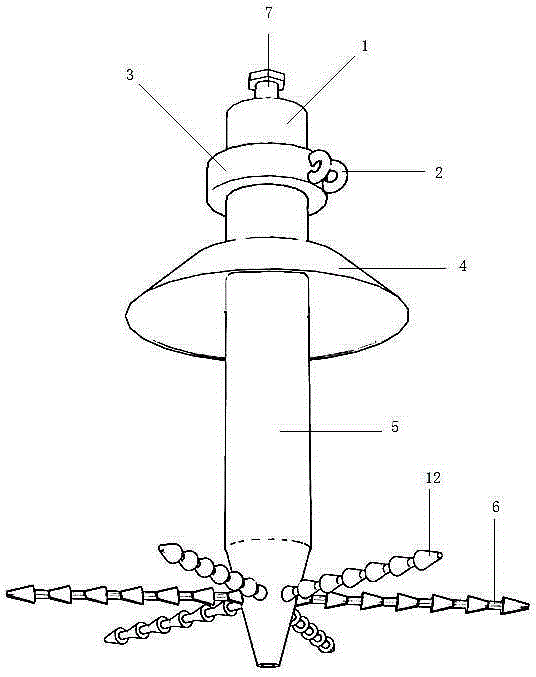

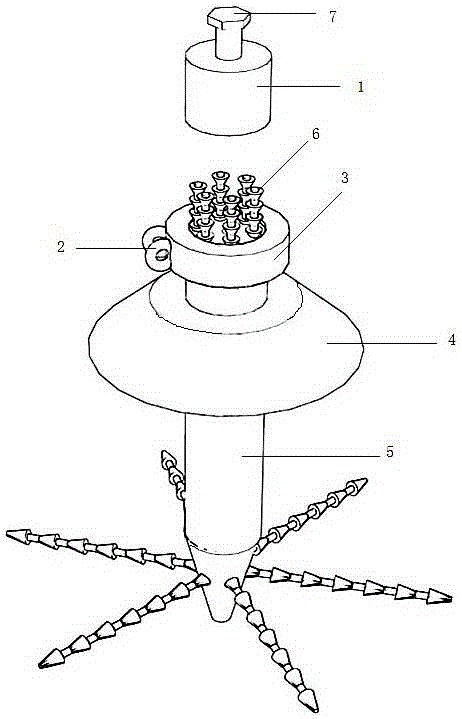

Tree-root-shaped telegraph pole inclined pull line fixator

InactiveCN105239571AWill not deformImprove stabilityTowersBulkheads/pilesElectric power transmissionTree root

The invention discloses a tree-root-shaped telegraph pole inclined pull line fixator and relates to the technical field of outdoor electric power transmission equipment. The tree-root-shaped telegraph pole inclined pull line fixator comprises a pointed pile, and the upper end of the pointed pile is fixedly sleeved with a knocking ring; the upper end face of the knocking ring is higher than the upper end face of the pointed pile; a pull line ring is welded to the outer side face of the knocking ring; at least four channels are annularly and evenly distributed on the upper end face in the pointed pile; each channel is in the shape of L in the vertical direction; a non-return drill rod is arranged in each channel in a penetrating manner; each non-return drill rod is evenly provided with circular-truncated-cone-shaped protrusions in the length direction; the lower ends of the non-return drill rods penetrate the channels and extend out of the pointed pile; the knocking ring is connected with a top cap through internal threads; and the top cap is matched with the upper portion of the pointed pile in a sealing manner. The tree-root-shaped telegraph pole inclined pull line fixator has the beneficial effects that a traditional method that an inclined pull line is fixed through a cement pouring clod is changed, the traditional method can be effectively replaced, man hours and the labor amount are reduced, engineering equipment and raw materials are saved, changes of the terrain are avoided, and the shape is attractive.

Owner:DONGYING POWER SUPPLY COMPANY STATE GRID SHANDONG ELECTRIC POWER +2

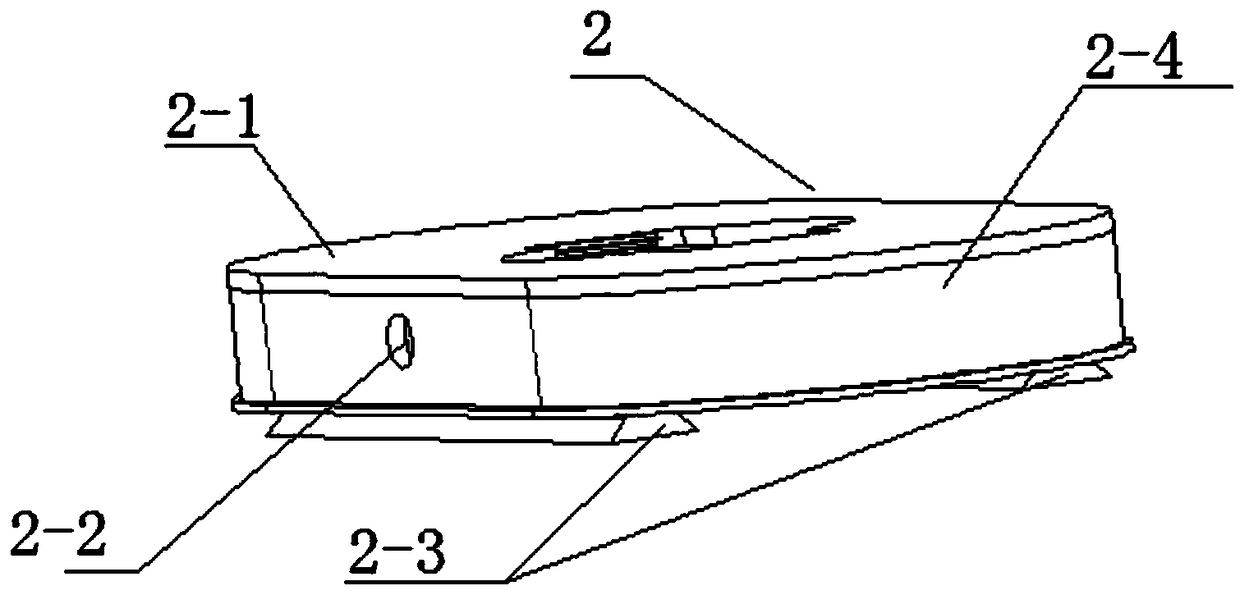

Surface cleaning device for fence plate after production

PendingCN112090816AEasy to cleanSimple structureDirt cleaningCleaning using toolsBristleSurface cleaning

The invention discloses a surface cleaning device for fence plate after production, and belongs to the technical field of fence cleaning. The surface cleaning device comprises a supporting plate frame; two sets of symmetrical sliding blocks are fixedly connected to the two ends of the top of the supporting plate frame, a bidirectional electric push rod is mounted at the top of the supporting plateframe, and two sets of symmetrical supporting seats are fixedly connected to the telescopic ends of the two sides of the bidirectional electric push rod; and sliding grooves are formed in the bottomsof the supporting seats, the sliding blocks are slidably connected with the sliding grooves, and two sets of symmetrical side frames are fixedly connected to the sides, away from each other, of the two sets of supporting seats. The surface cleaning device is simple in structure and convenient to operate, two sets of brush bristles simultaneously clean the two sides of the fence plate through cooperation of a motor and a belt, the two sides of the fence plate are conveniently cleaned at the same time, and cleaning efficiency is improved; and the distance between the two sets of brush bristlesis adjusted through the bidirectional electric push rod, a fan is matched with a filter net to collect waste, collection is facilitated while cleaning is conducted, secondary operation is avoided, thetime and labor are saved, fence plates of different sizes can be cleaned conveniently, and wide application is facilitated.

Owner:福建省创鑫木业有限公司

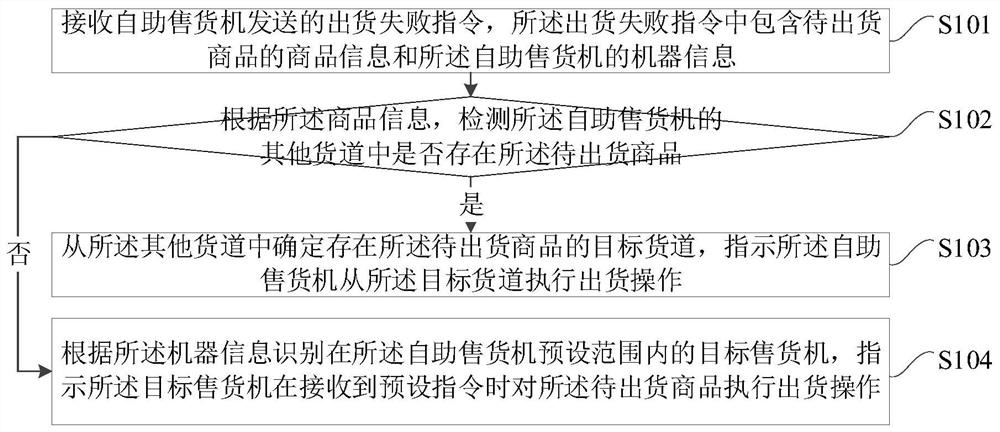

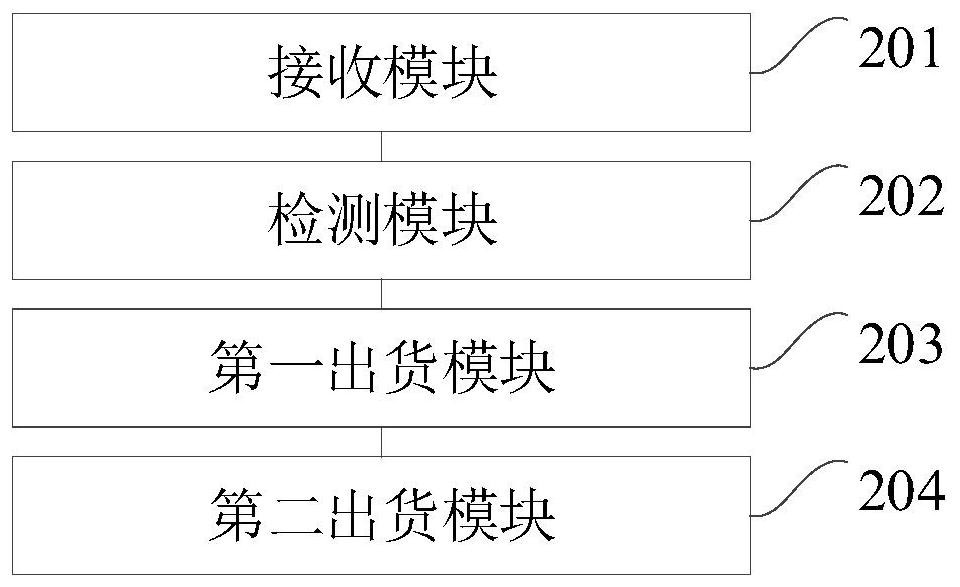

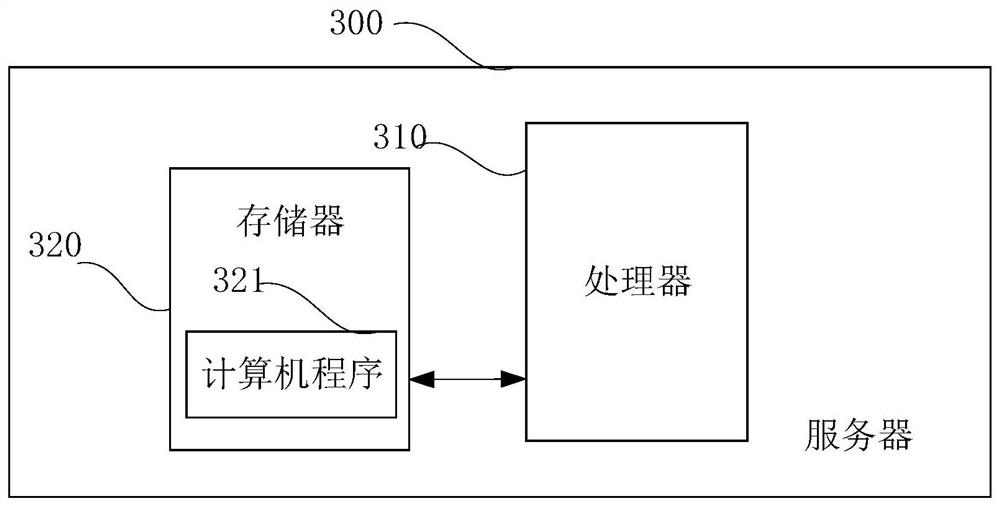

Method and device for processing delivery failure of vending machine

InactiveCN111696259AAvoid secondary operationsIncrease success rateCoin-freed apparatus detailsApparatus for dispensing discrete articlesOperating systemReliability engineering

The embodiment of the invention is suitable for the technical field of vending machines, and provides a vending machine delivery failure processing method and device, and the method comprises the steps: receiving a delivery failure instruction sent by a vending machine, and the delivery failure instruction comprises the commodity information of a to-be-delivered commodity and the machine information of the vending machine; detecting whether the to-be-delivered commodity exists in other commodity channels of the vending machine or not according to the commodity information; if the commodity tobe delivered exists, determining that a target commodity channel of the commodity to be delivered exists from the other commodity channels, and indicating the vending machine to execute a delivery operation from the target commodity channel; and if not, identifying a target vending machine within a preset range of the self-service vending machine according to the machine information, and indicating the target vending machine to execute a delivery operation on the to-be-delivered commodity when receiving a preset instruction, thereby improving the success rate of customer purchase.

Owner:SHENZHEN YOUBAOSI TECH CO LTD

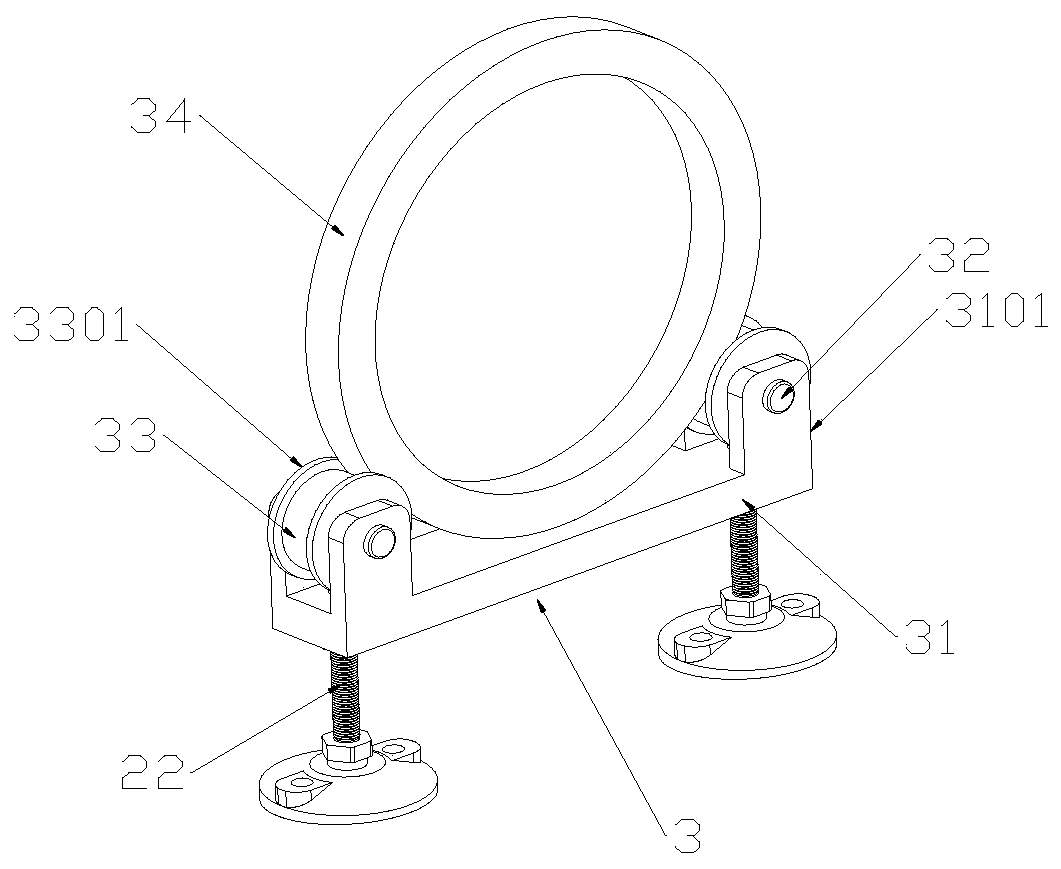

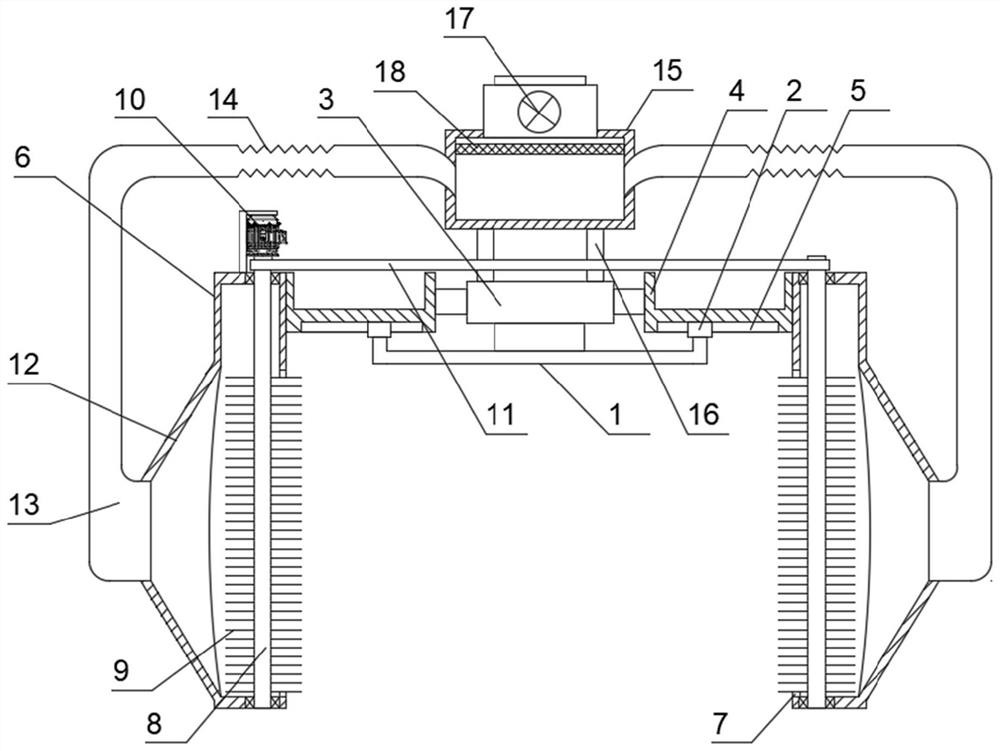

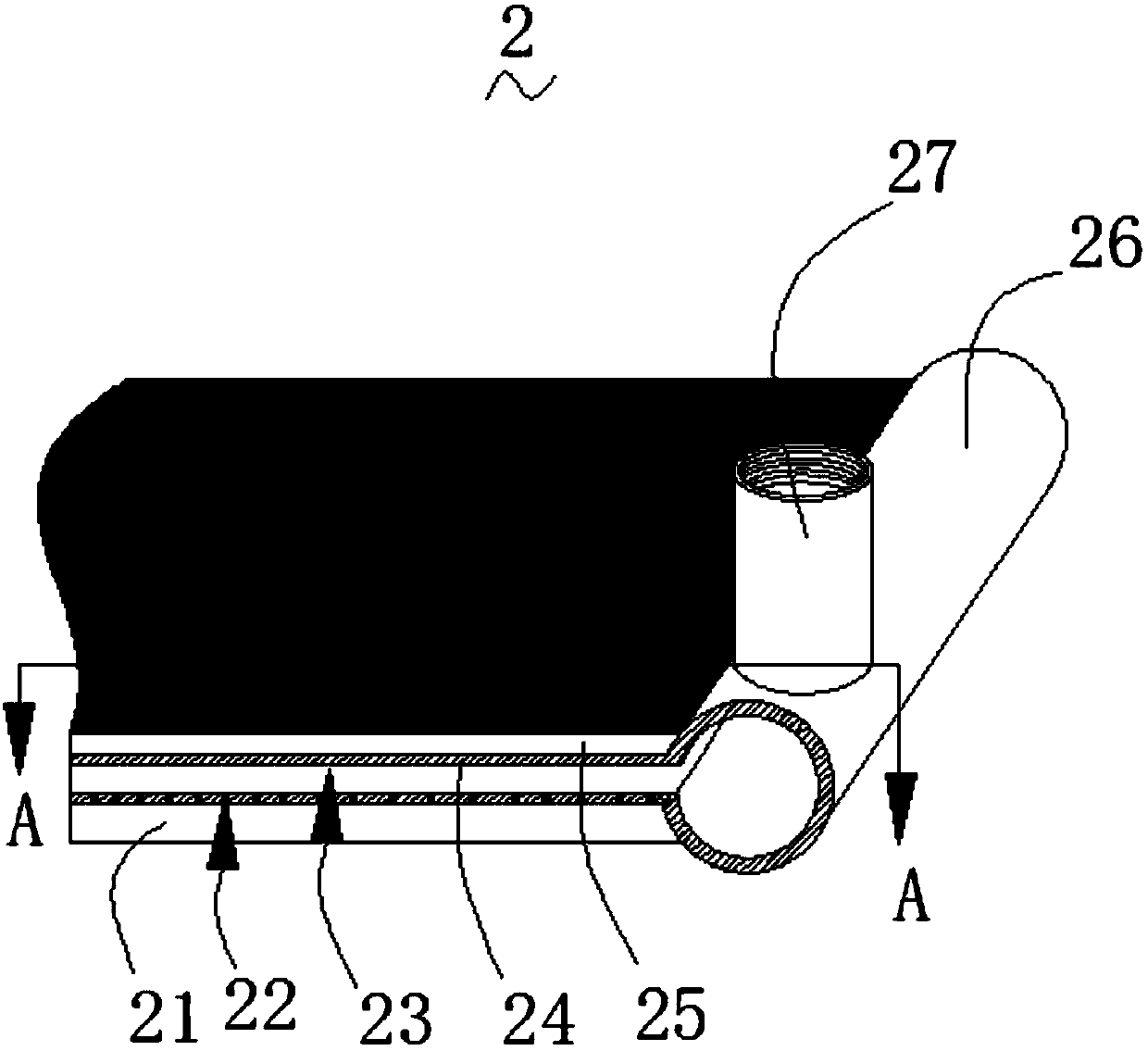

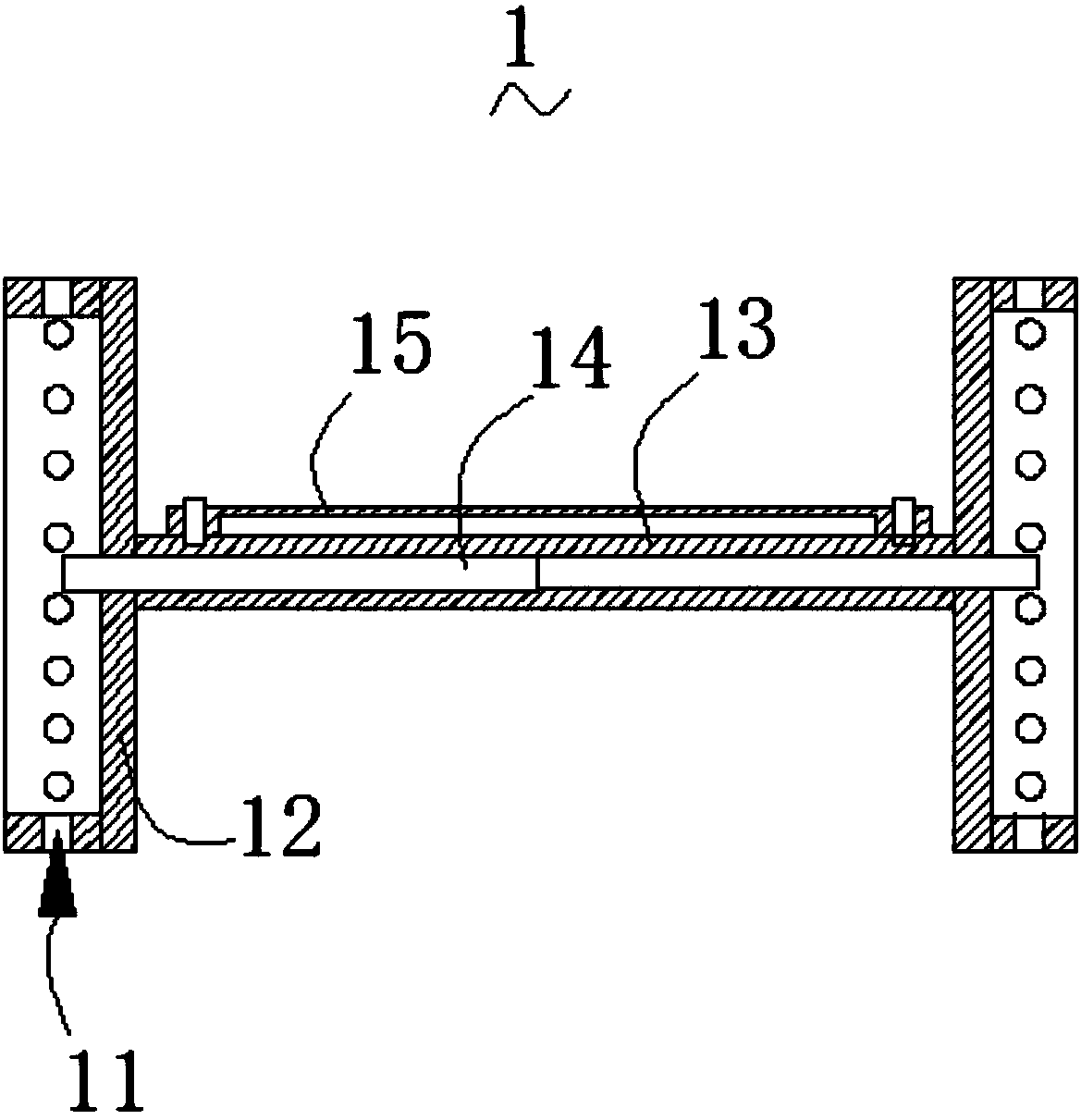

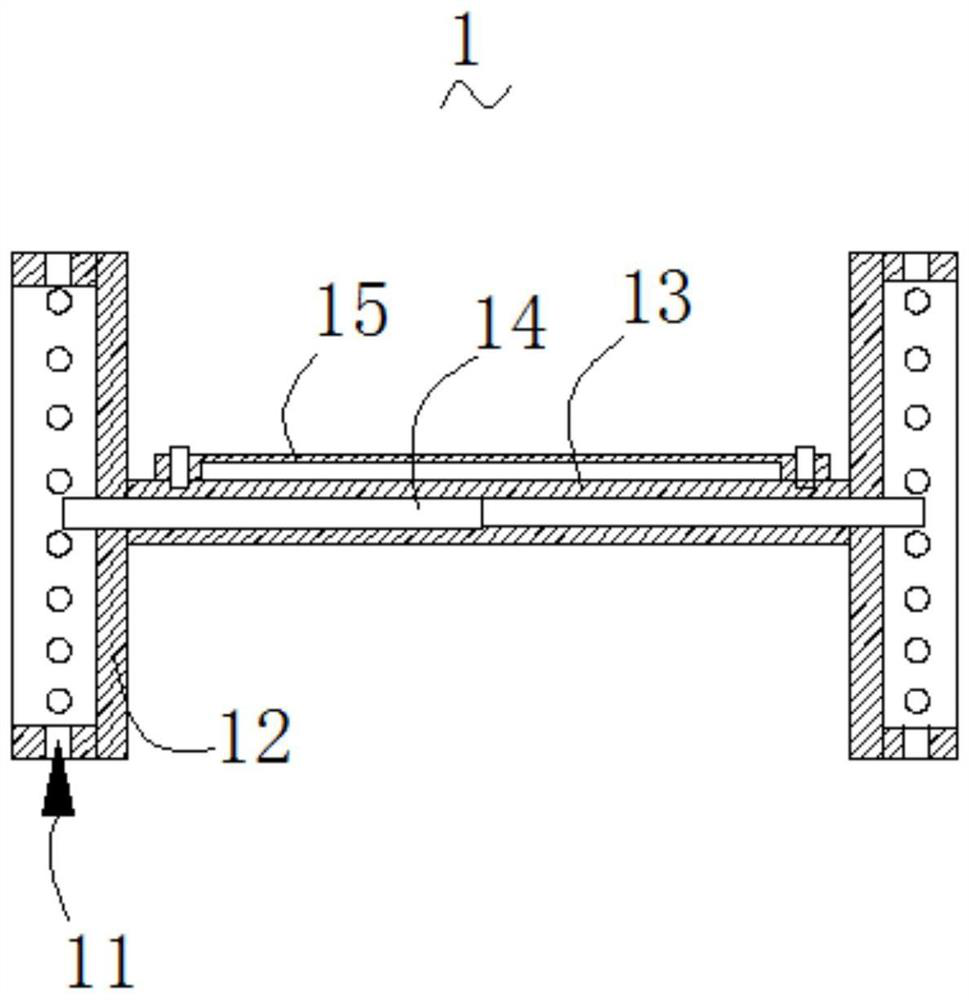

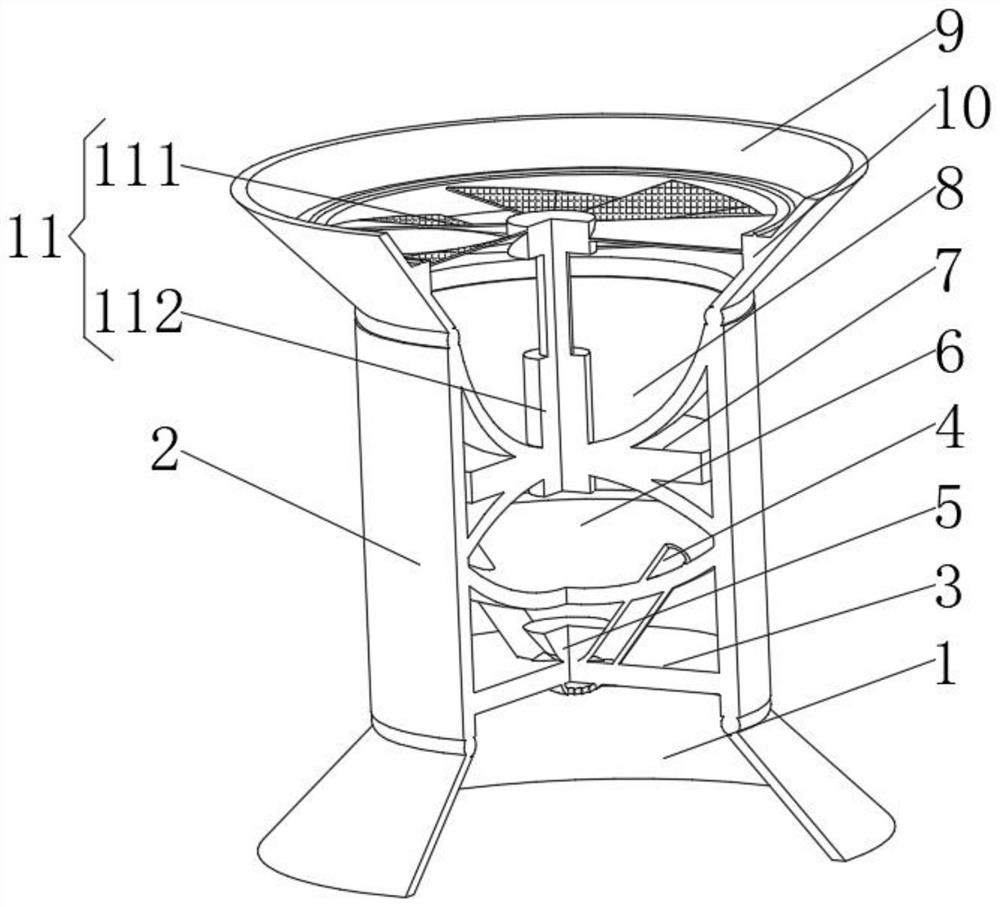

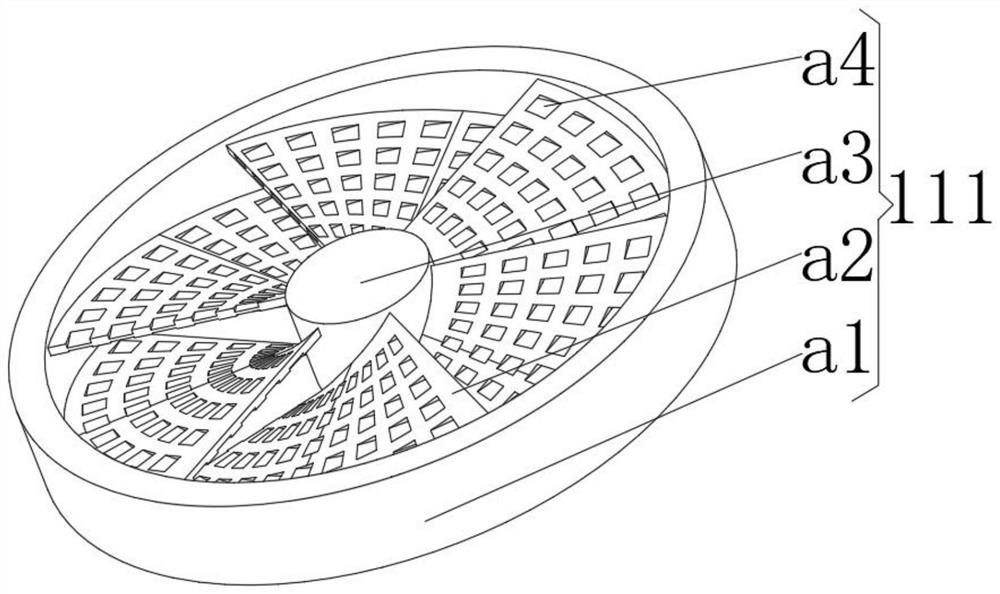

Water-saving device used for uniform watering of concrete

ActiveCN109927159AIncrease the speed of solidificationImprove construction qualityCeramic shaping apparatusWater savingWater source

The invention provides a water-saving device used for uniform watering of concrete. The water-saving device used for uniform watering of the concrete comprises a winding mechanism, a watering mechanism and a fixing mechanism. The winding mechanism comprises a connection shaft and a fixing strip. The watering mechanism comprises a sponge layer, dropping holes, drainage grooves, a drainage layer, aflow distribution pipe and a connection pipe. The sponge layer is fixed to the drainage layer. The drainage grooves which are evenly distributed and the dropping holes which are evenly distributed areformed in the drainage layer. The dropping holes are formed in the side, face, close to the sponge layer, of the drainage layer and communicate with the drainage layer. The other end of the drainagelayer and the other end of the sponge layer are connected with the flow distribution pipe. The flow distribution pipe communicates with the drainage grooves. The flow distribution pipe is connected tothe connection pipe. The fixing mechanism comprises a limiting groove, a limiting hole, a fixing lead screw and a fixing supporting rod. The water-saving device used for uniform watering of the concrete is good in water saving performance, high in heat preservation performance, uniform in watering, low in water source evaporation speed and convenient to operate.

Owner:路港集团有限公司

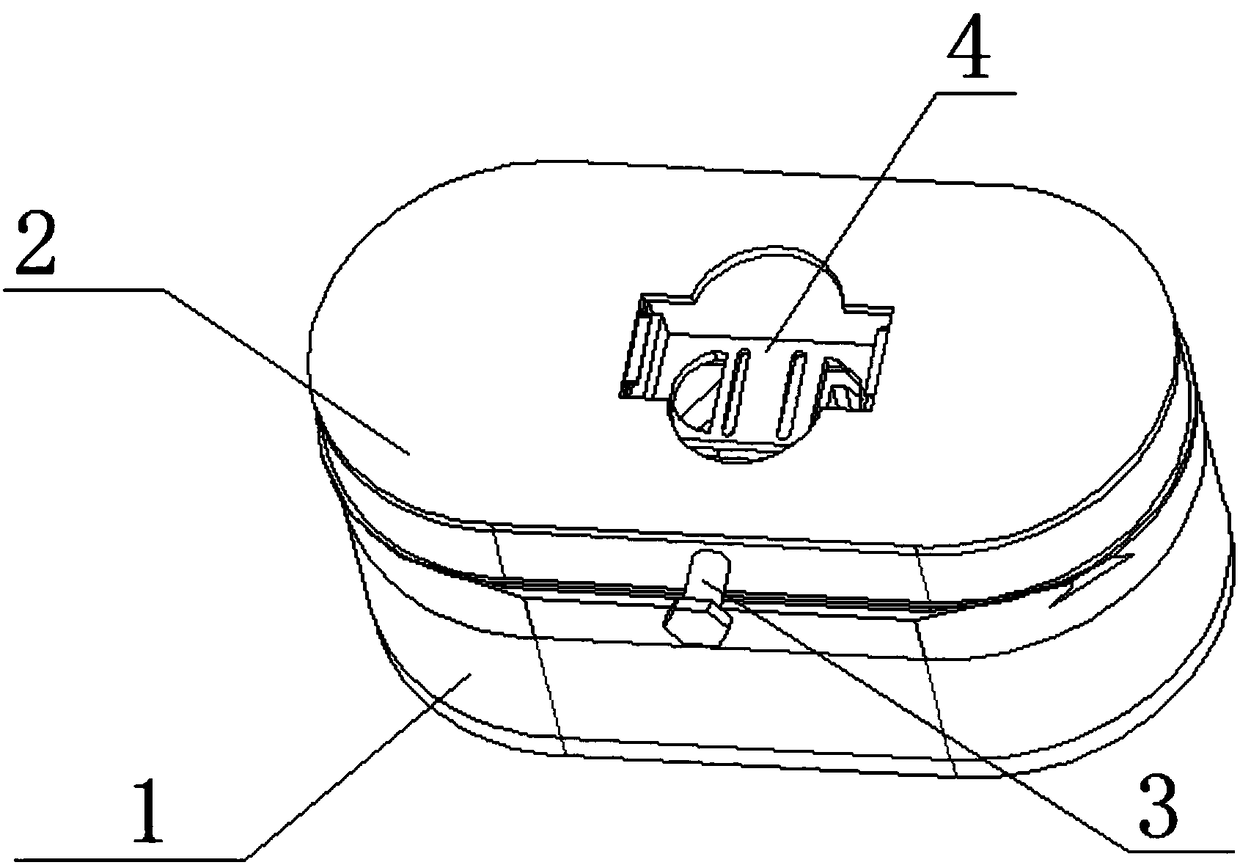

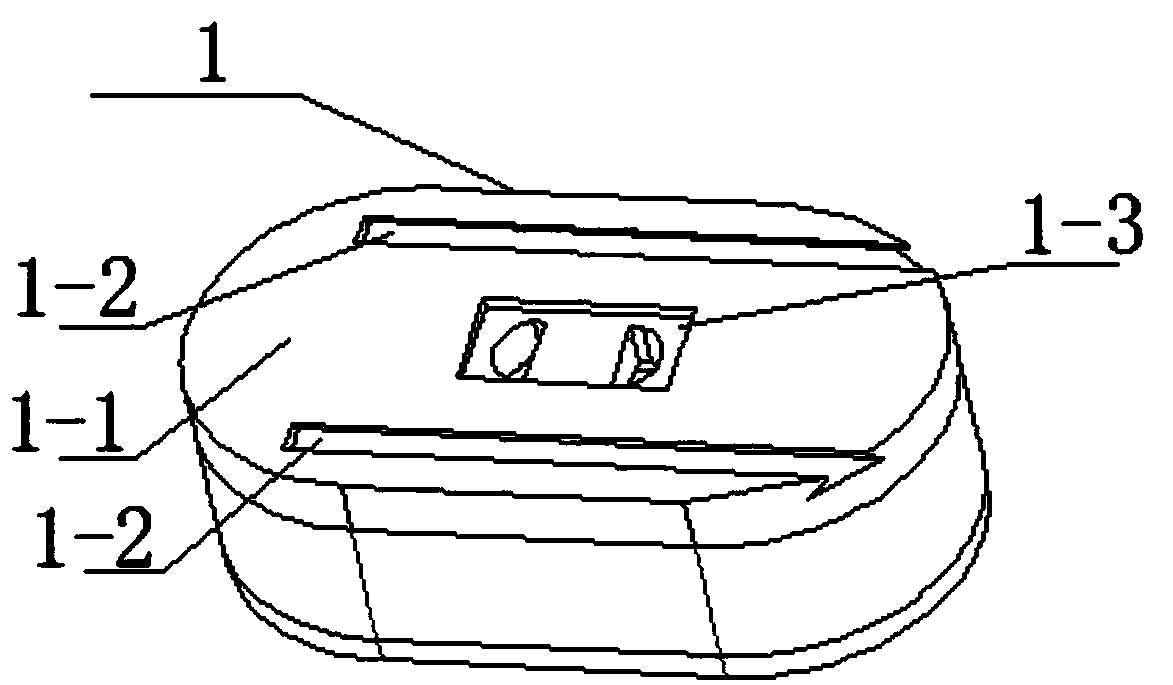

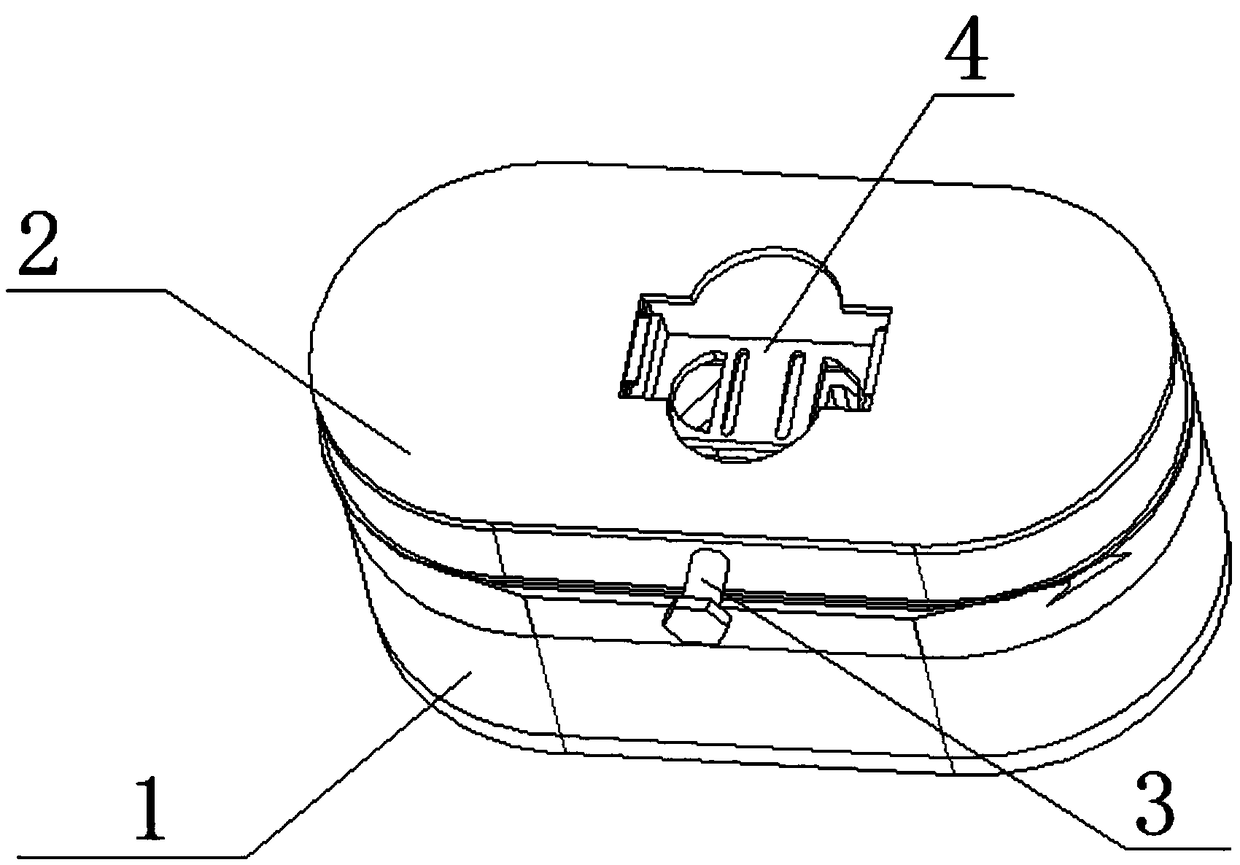

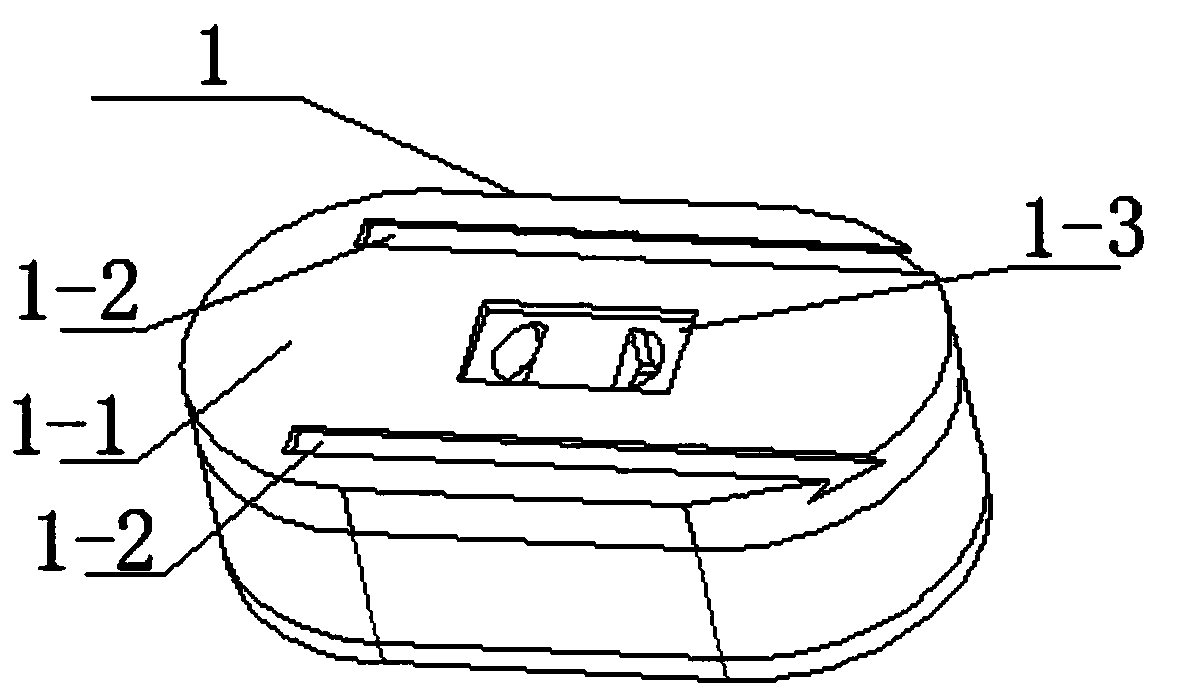

Fixing device for plug power-on

The invention relates to the field of power distributor connectors, in particular to a fixing device for plug power-on. The device comprises a power distributor base, a fixing device shell, a fixing device control structure and a fixing device carrier structure. The fixing device shell is slidingly connected to the power distributor base, the fixing device control structure is rotatably connectedin the fixing device shell, the fixing device control structure is in linkage with the fixing device carrier structure, and the fixing device carrier structure is fixedly connected in the fixing device shell. The fixing device for plug power-on has the advantages that the fixing device and a power distributor can be manually disassembled, the device is extremely easy to install and use, a plug canbe fixed by the device during plug power-on at the same time, and the device is convenient to use; meanwhile, the plug does not need to be unplugged by hands in the process of unplugging the plug, byrotating a hand rotation block, the plug can be automatically ejected, and the situation is avoided that electric shock is caused when the wet hand unplugs the plug.

Owner:WENZHOU TECELLENT MACHINERY CO LTD

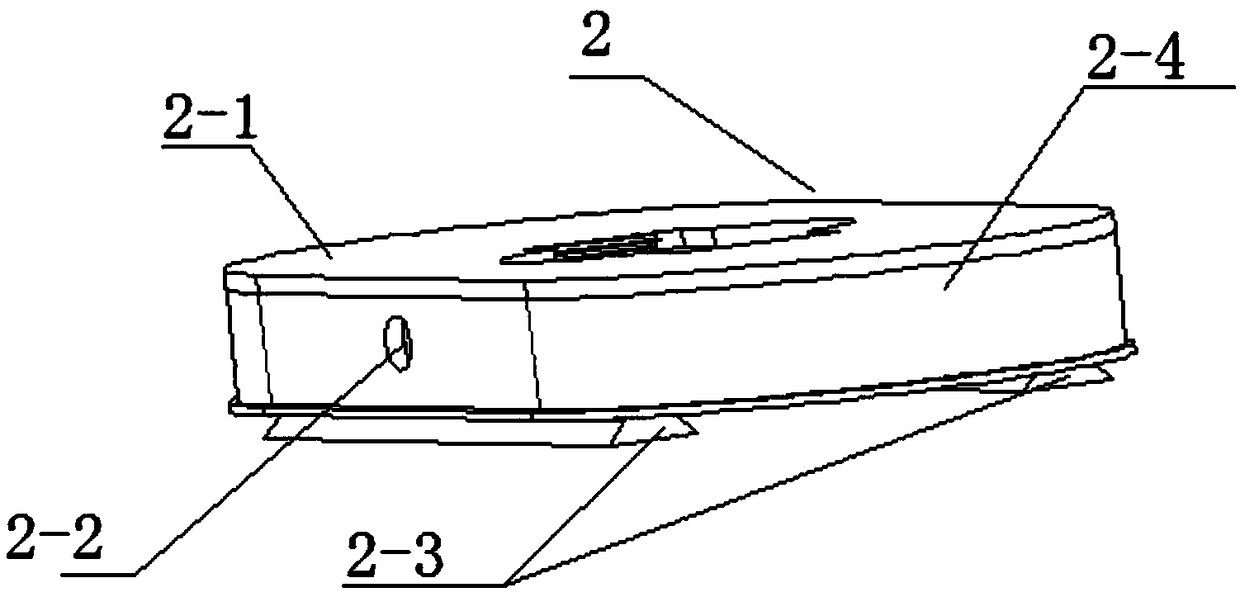

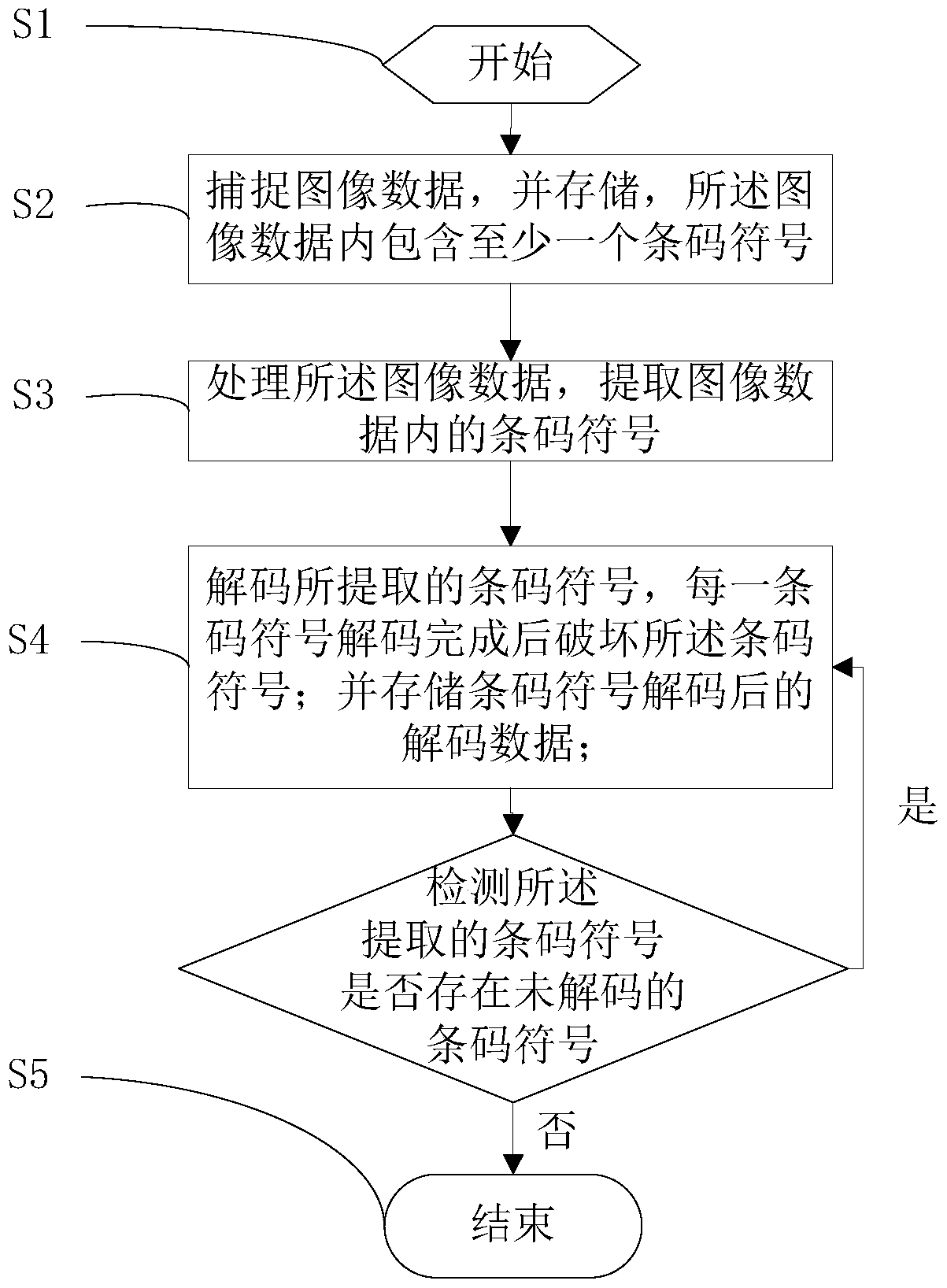

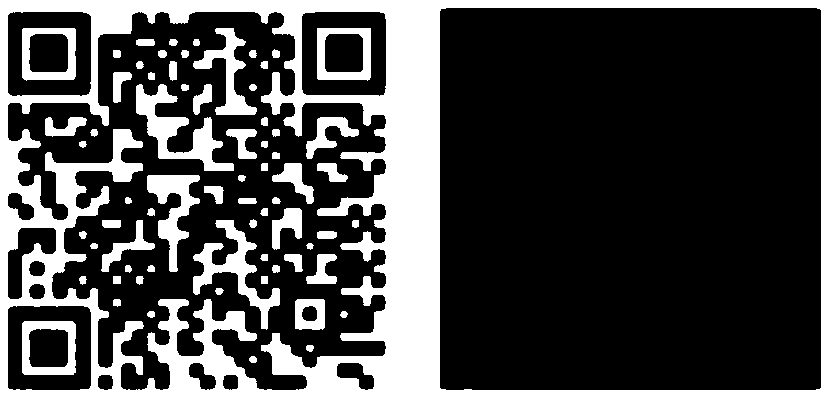

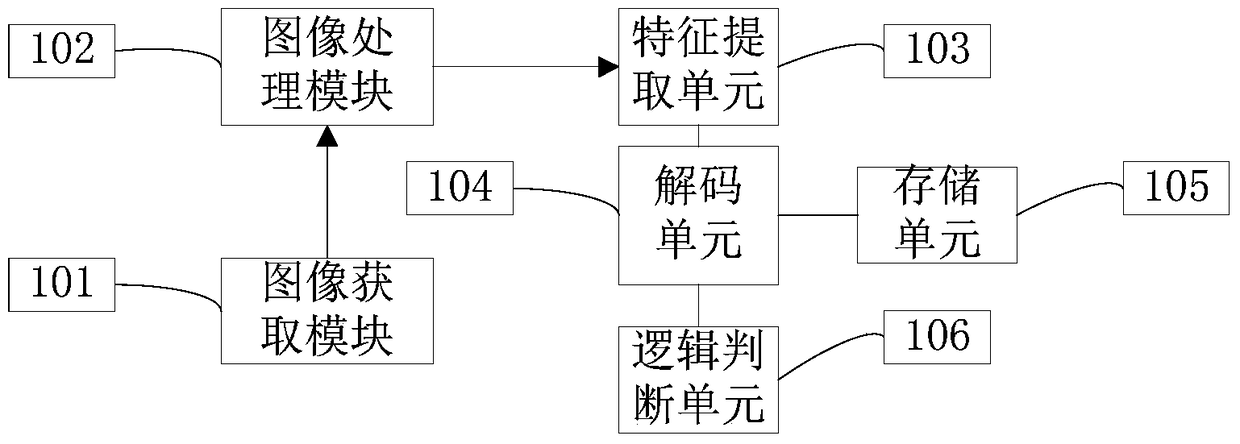

A barcode reading method for a high-pixel image and a barcode reading device for a high-pixel image

ActiveCN105787403BSpeed up barcode decodingImprove decoding speedSensing by electromagnetic radiationComputer graphics (images)Data information

The invention relates to a barcode reading method and device of a high-pixel image. The method includes the following steps that: S1, the method is started; S2, image data are captured and stored, wherein the image data contain at least one barcode symbol; S3, the image data are processed, and the barcode symbols in the image data are extracted, and are stored; S4, the extracted barcode symbols are decoded, after the decoding of each barcode symbol is completed, the barcode symbols are destroyed, and decoding data obtained after the barcode symbols are decoded are stored, and whether the extracted barcode symbols contain decodable barcode symbols is detected, if the extracted barcode symbols contain decodable barcode symbols, the step S4 is cycled; and S5, the method is terminated. The barcode reading method and device of the high-pixel image of the invention can obtain high-pixel image data and automatically read barcode data information on the high-pixel image. With the barcode reading method and device of the high-pixel image adopted, a plurality of barcodes on the high-pixel image can be automatically identified, and barcode data can be obtained with one step.

Owner:NEWLAND DIGITAL TECH CO LTD

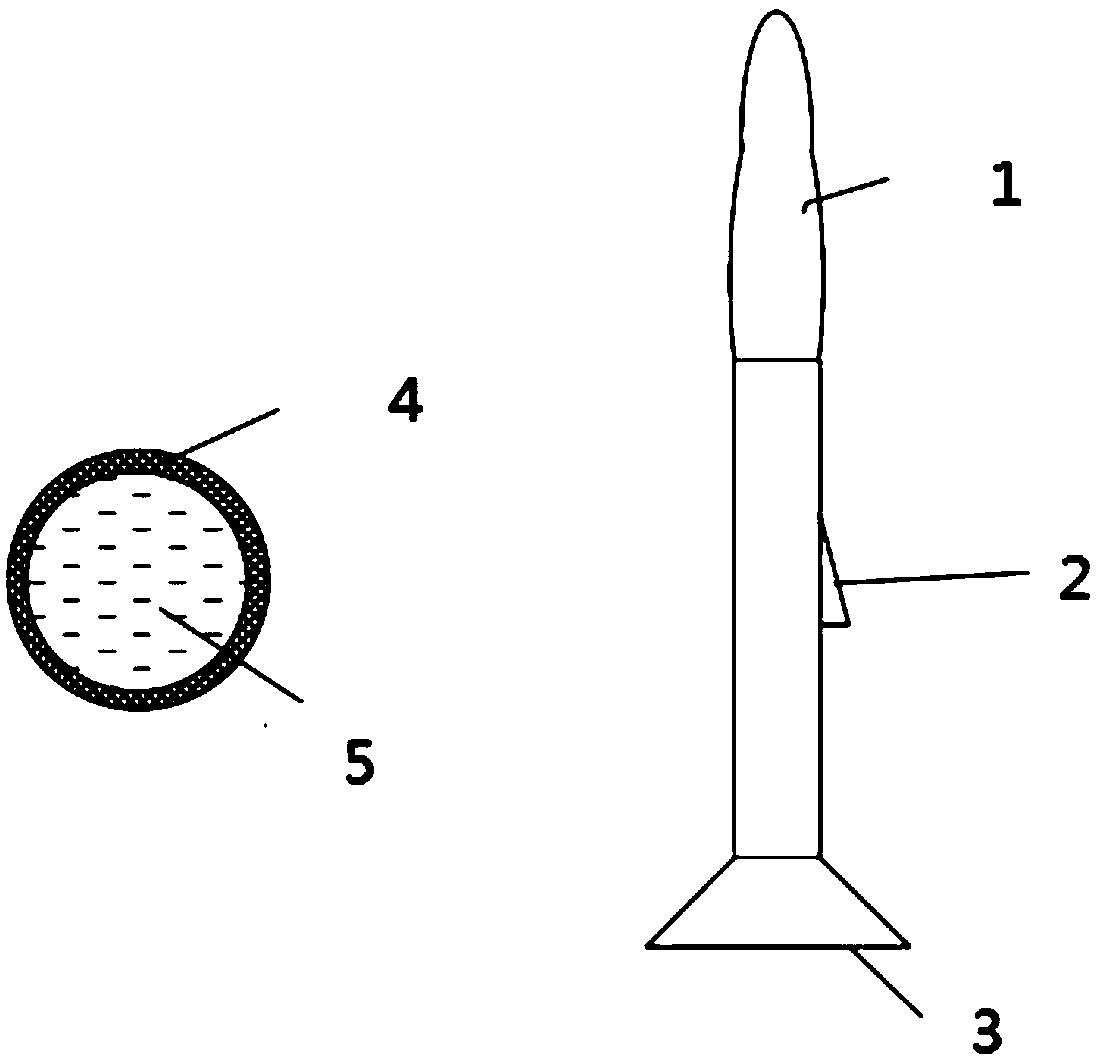

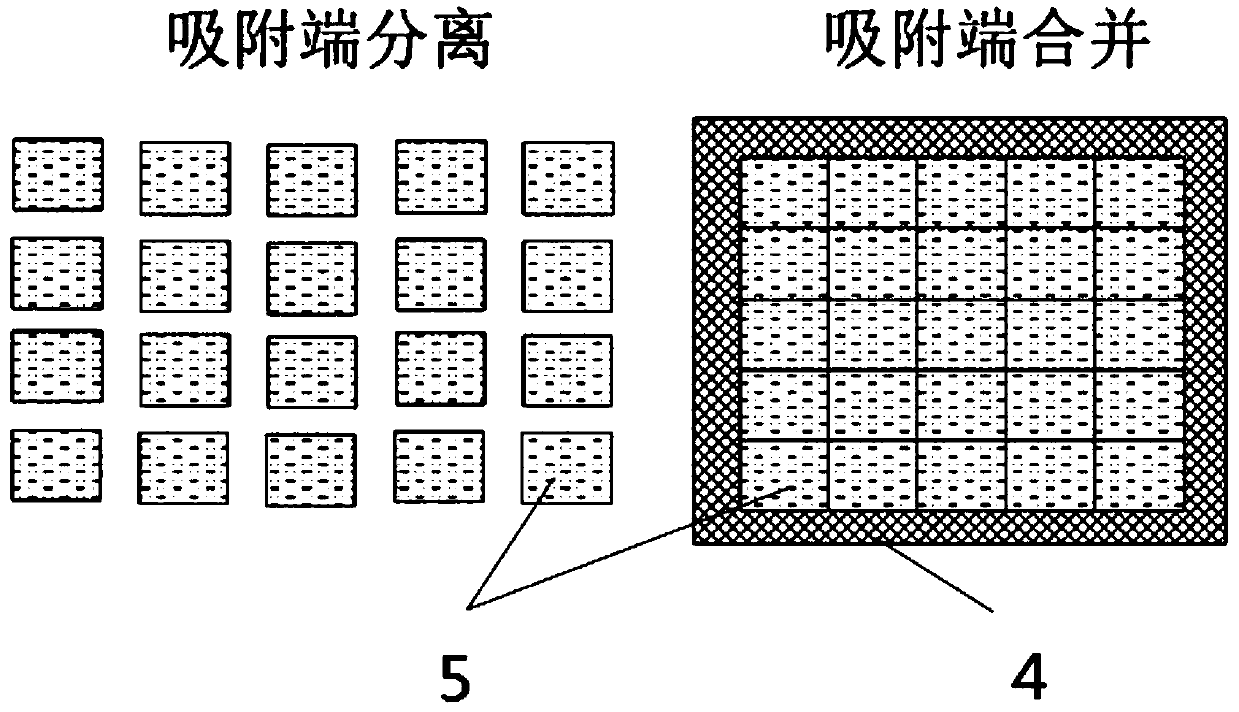

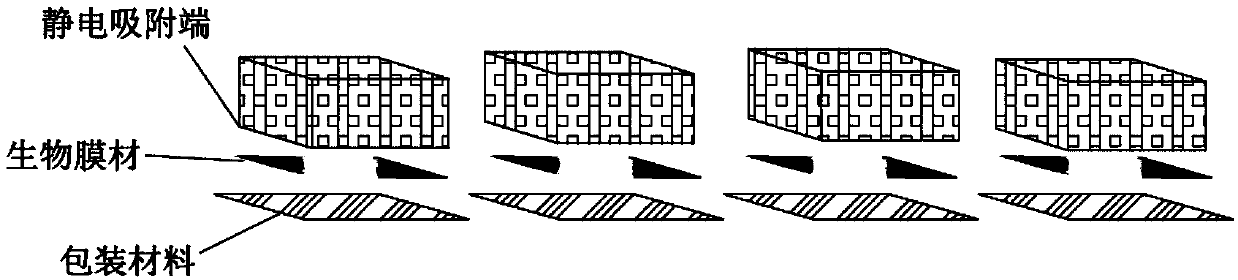

Natural biofilm material moving method

ActiveCN108861614AAvoid breakingQuick Coverage RepairNon-mechanical conveyorsBiofilmTherapeutic effect

The invention provides a natural biofilm material moving method which comprises the following steps: a, starting an electrostatic generator, so that a natural biofilm material can be adsorbed to an adsorption end surface; and b, after moving the natural biofilm material to a target position, starting the electrostatic elimination operation, so that the natural biofilm material can be divorced fromthe adsorption end surface and can reach the target position accurately. By adoption of the natural biofilm material moving method provided by the invention, the scale production operation steps canbe simplified during the production process, the operation slowness caused by electrostatic adsorption and the material damage caused by improper operation can be avoided, the production efficiency and the finished product ratio can be improved, and the cost can be reduced; and during the clinic use process, a wound surface of a patient can be quickly and accurately covered and repaired, the secondary operation caused by material edge warping and material overlapping can be avoided, the operation efficiency can be improved, the pain of the patient can be relieved, and the treatment effect canbe improved.

Owner:CHENGDU QINGSHAN LIKANG PHARMA CO LTD

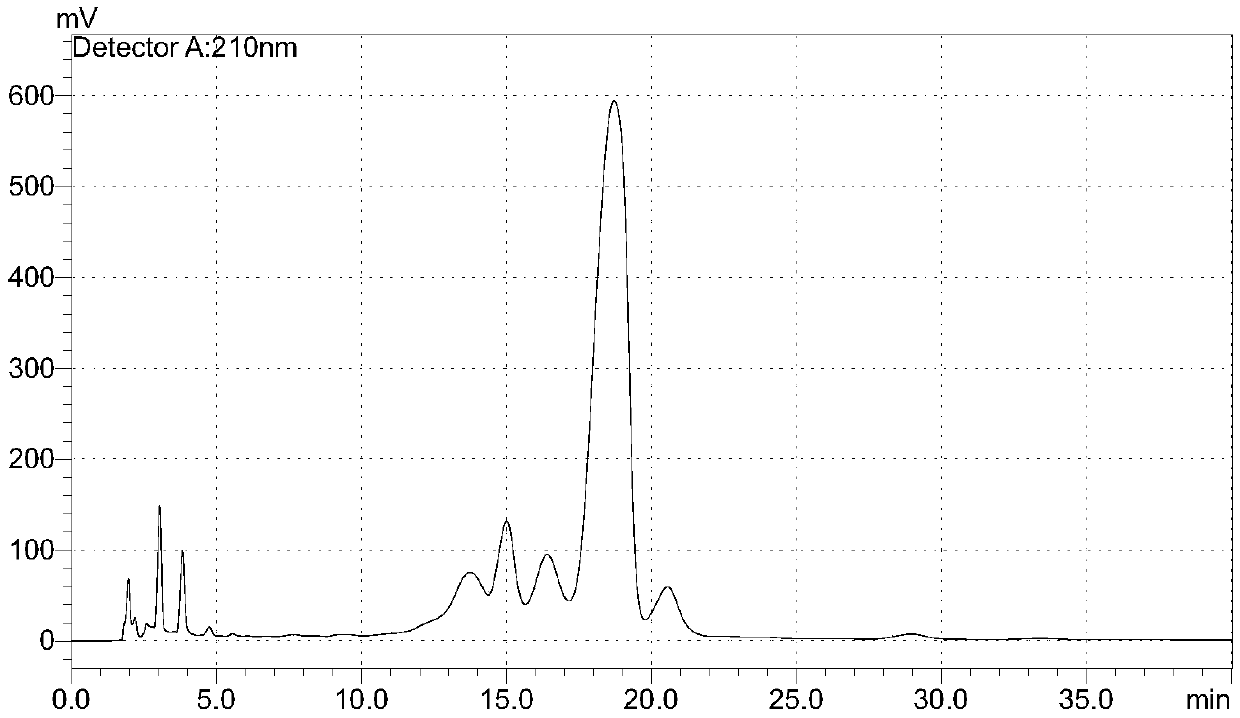

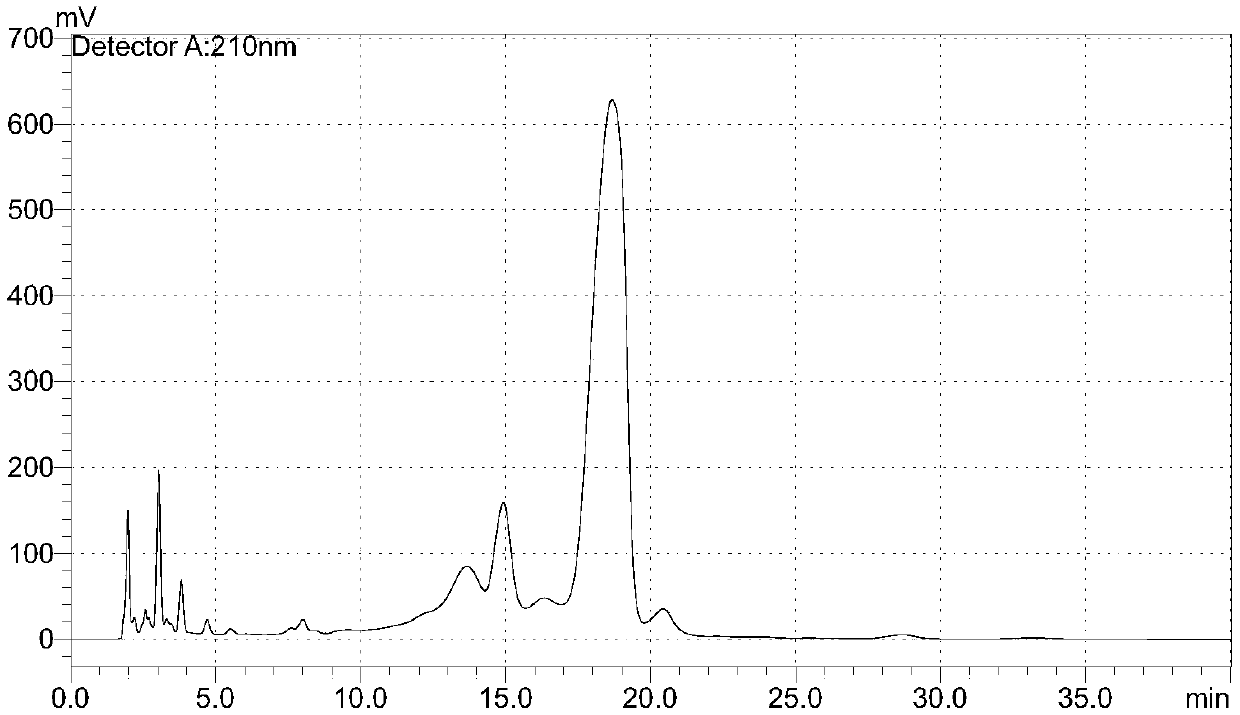

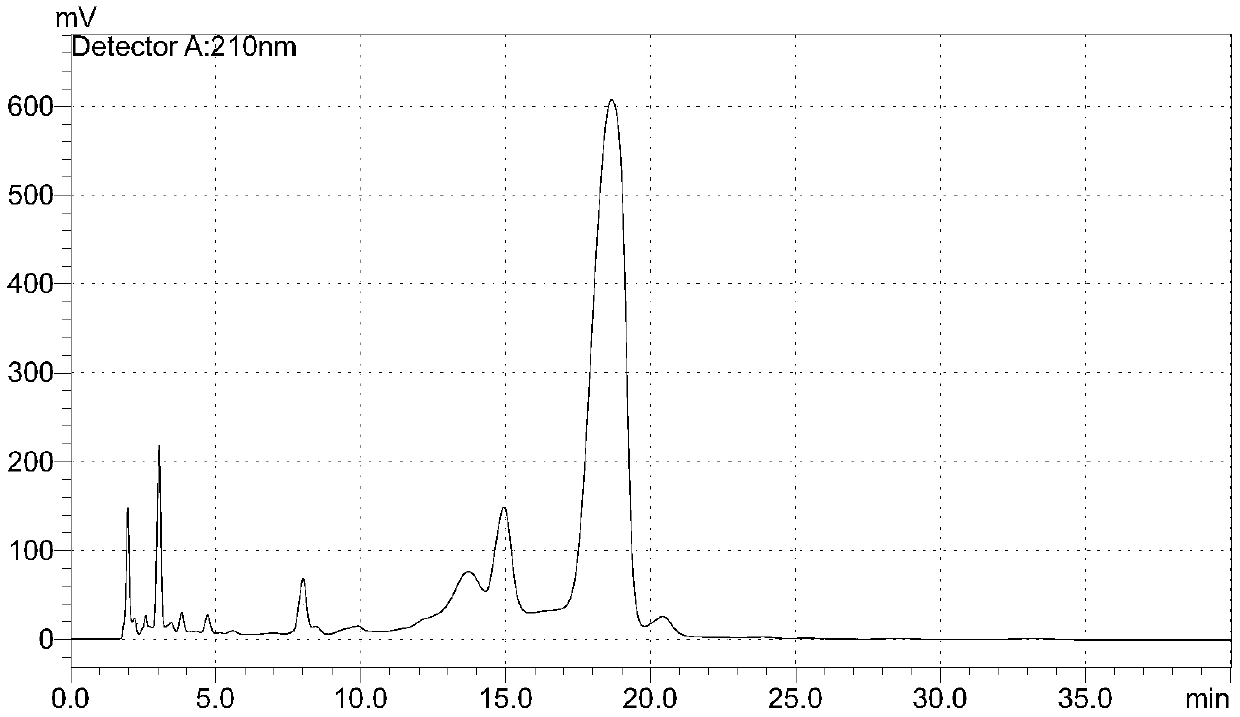

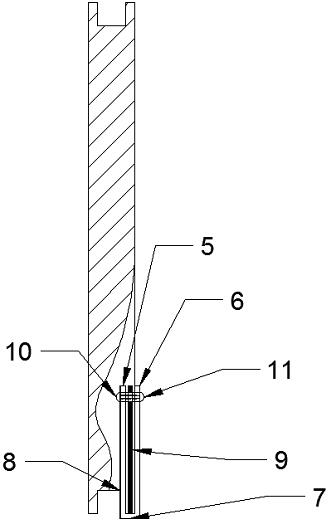

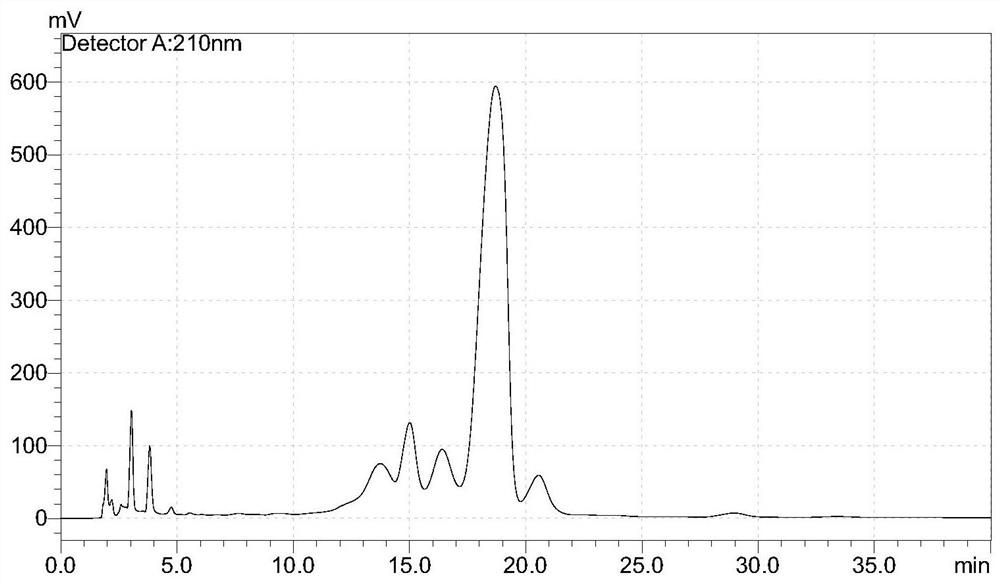

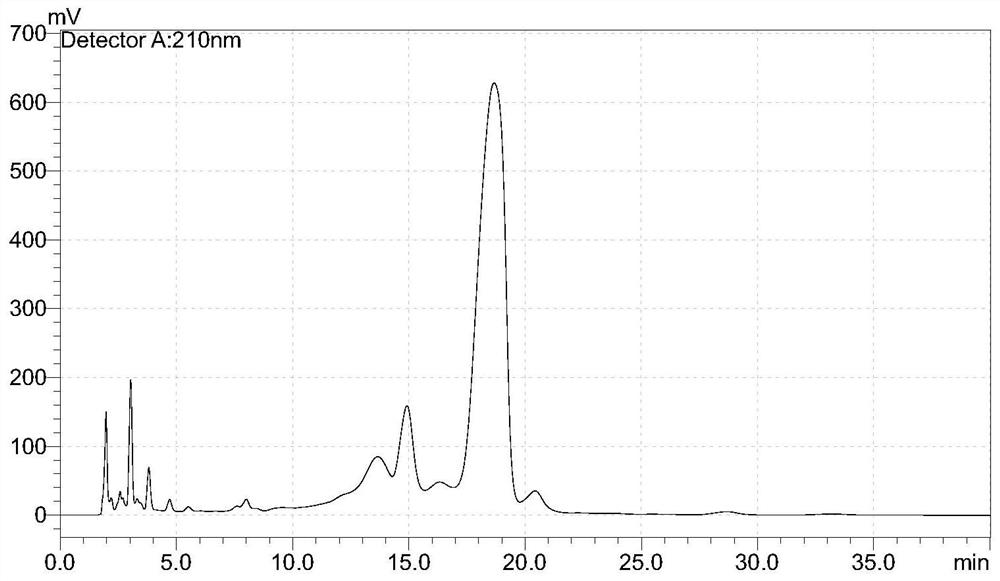

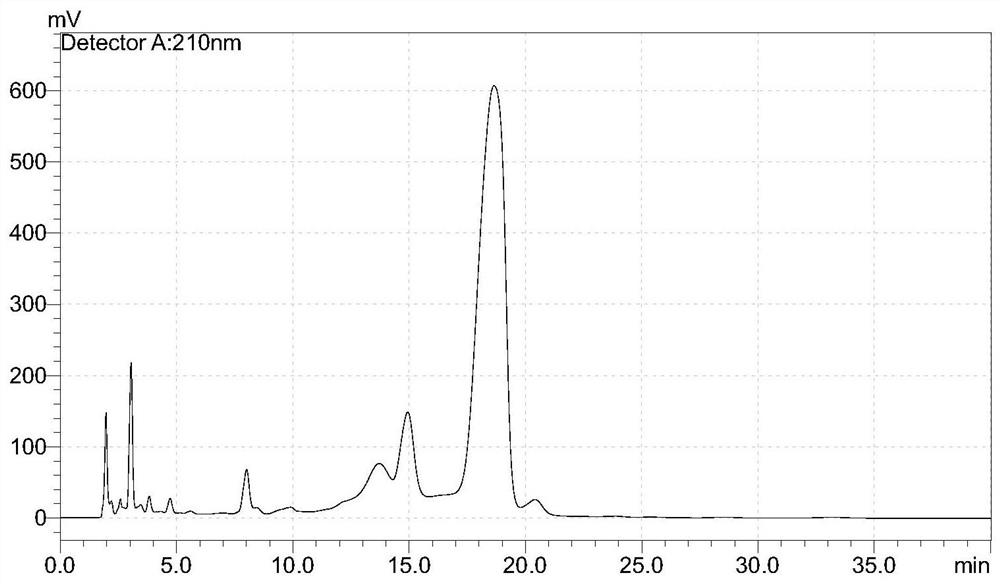

Graphene mixed filler, preparation method thereof, graphene mixed filler chromatographic column and application

ActiveCN111450573ALow costAvoid secondary operationsIon-exchange process apparatusOrganic chemistryPhysical chemistryGraphite

The invention provides a graphene mixed filler and a chromatographic column. The mixed filler comprises a graphene material and a chromatography medium filler, wherein the weight ratio of the graphenematerial to the chromatography medium filler is (1-50): 100, the particle size of the graphene material is 500-5000 meshes, and the particle size of the chromatography medium filler is 200-500 meshes. According to the invention, the special property (the pi-pi electron conjugative effect) of the graphene is adopted to achieve the column adsorption of the compound having the pi conjugated electronstructure, and the lower layer column has the conventional impurity separation effect so as to further separate, purify and adsorb the impurities, such that the multiple operations are avoided, and the chromatography cost and the operation time of the target product can be effectively reduced.

Owner:福州奥尼多生物科技有限公司

A Convenient Ultrasonic Automatic Cleaner

ActiveCN112427401BEasy to placeEasy to collectDrying gas arrangementsDrying solid materialsElectric machineryEngineering

The invention discloses an easy-to-operate ultrasonic automatic cleaner, which comprises a cleaning tank, the cleaning tank is provided with a receiving frame, an ultrasonic transducer and a shaft cylinder, the receiving frame is connected with the cleaning tank, and the receiving frame has no Bottom, the receiving frame is provided with a cleaning frame, the cleaning frame is used to hold the parts to be cleaned, and the cleaning frame follows the receiving frame. At the same time, using the cooperation of the motor convex plate, etc., the parts to be cleaned in the cleaning frame are continuously turned over, shaken, rubbed against each other, and collided, making it easier to peel off dirt and dust, complete and rapid cleaning, and a drying drum is set in the cleaning tank , It can be dried evenly in the rolling type directly after cleaning, avoiding cumbersome secondary operations. In summary, the shaking type cleaning is fast and complete. The cleaning and drying are carried out step by step, which is more convenient to use. It adopts automatic cleaning Drying integrated design, easy to operate.

Owner:莱芜成威电子材料有限公司

Handheld portable seam beautifying machine

The invention discloses a handheld portable seam beautifying machine. The machine comprises a shell part, an adhesive tape winding and unwinding part and an adhesive squeezing part, wherein the shell part comprises a handheld rod, a rotatable joint, a connectable rod and a shell mechanism. According to the machine, a hand rocker is manually rotated to drive a different-direction lead screw to rotate, then two distance adjusters are enable to move towards each other in opposite directions on the different-direction lead screw, positions of the two distance adjusters are adjusted, positions of two adhesive tapes are adjusted, a distance of the adhesive tapes can be adjusted at any time according to a size of a gap, adjustment is simple, the machine is easy to use and hold, a flattening wheel A makes contact with the ground, when the machine is moved, the flattening wheel A rotates, the adhesive tapes which are put down can be flattened and attached to the ground, the adhesive tapes are automatically smoothened, it is guaranteed that the attached adhesive tapes do not incline, secondary operation is avoided, time is saved, the handheld portable seam beautifying machine is convenient to carry, trouble and labor are saved, and the working efficiency is greatly improved.

Owner:陕西微阅信息技术有限公司

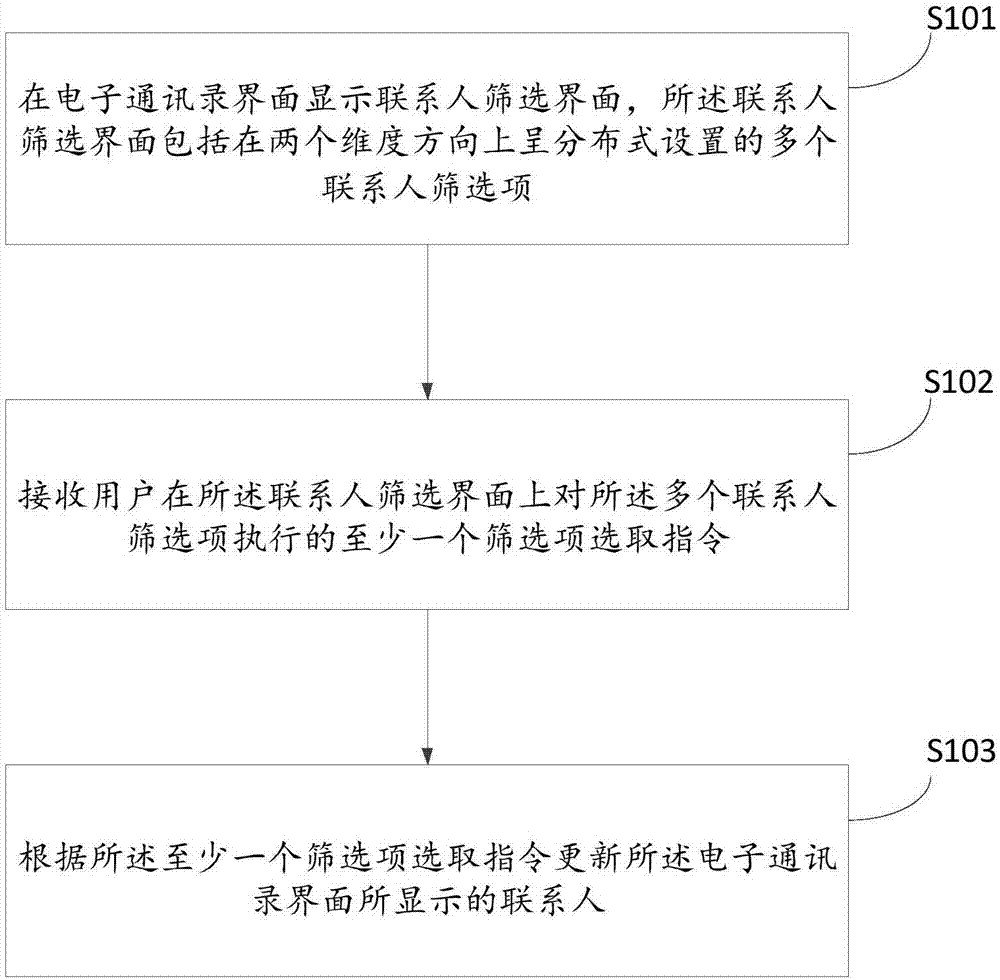

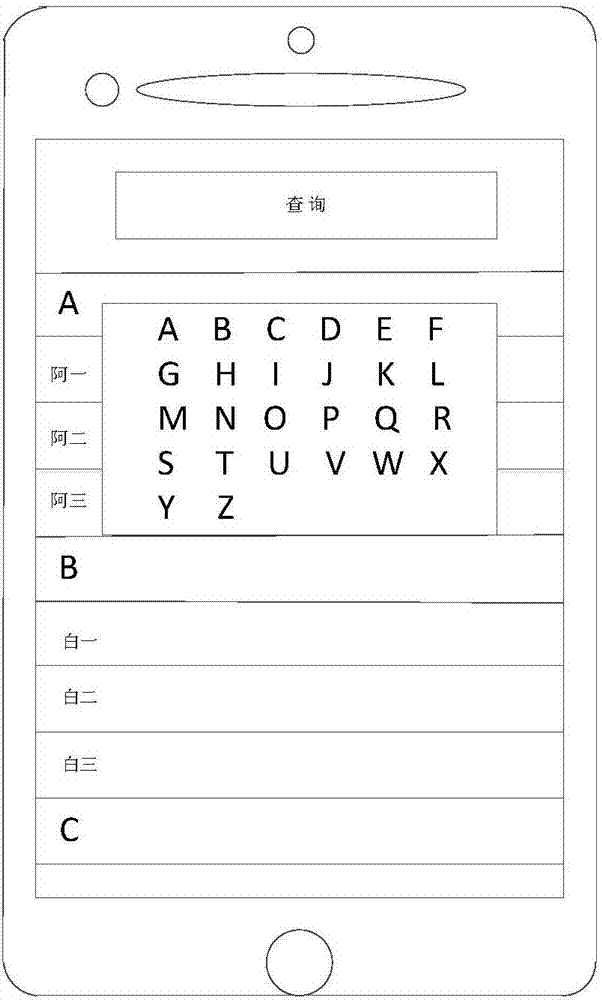

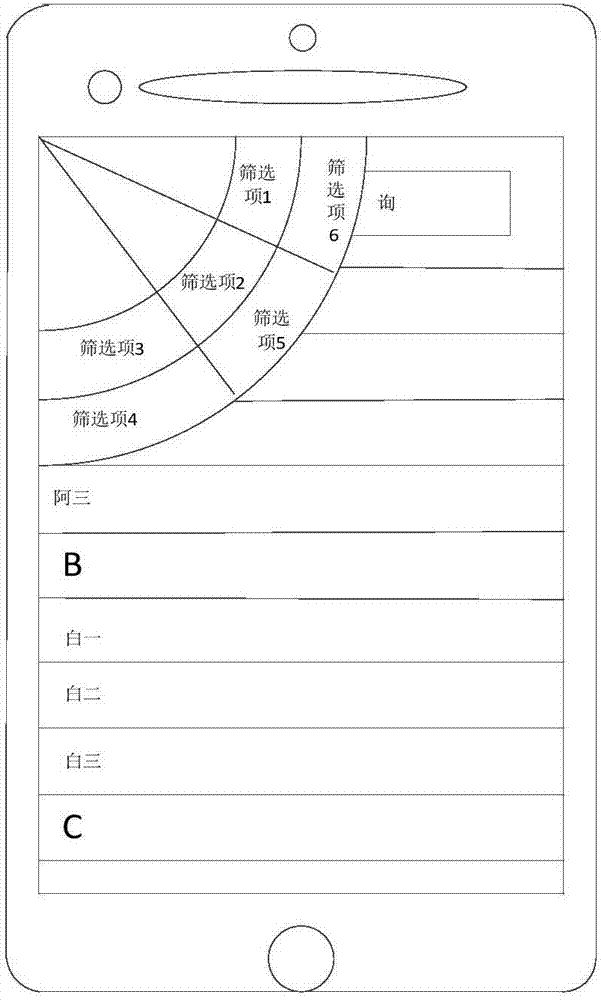

Electronic contact list inquiring method

InactiveCN107277215AAvoid secondary operationsImprove operating experienceSubstation equipmentHuman–computer interactionItem selection

The embodiment of the invention provides an electronic contact list inquiring method, and solves the problems that the present electronic contact list contact person inquiring mode is inconvenient and slow and poor in user experience. The electronic contact list inquiring method comprises the steps that a contact person screening interface is displayed on an electronic contact list interface, wherein the contact person screening interface includes multiple contact person screening items which are distributed in two dimensional directions; at least one contact person screening item selection instruction performed on multiple contact person screening items on the contact person screening interface by the user is received; and the contact persons displayed on the electronic contact list interface are updated according to at least one contact person screening item selection instruction.

Owner:SHENZHEN TINNO WIRELESS TECH +1

A water-saving device for uniform watering of concrete

ActiveCN109927159BIncrease the speed of solidificationImprove construction qualityCeramic shaping apparatusWater savingWater source

The invention provides a water-saving device used for uniform watering of concrete. The water-saving device used for uniform watering of the concrete comprises a winding mechanism, a watering mechanism and a fixing mechanism. The winding mechanism comprises a connection shaft and a fixing strip. The watering mechanism comprises a sponge layer, dropping holes, drainage grooves, a drainage layer, aflow distribution pipe and a connection pipe. The sponge layer is fixed to the drainage layer. The drainage grooves which are evenly distributed and the dropping holes which are evenly distributed areformed in the drainage layer. The dropping holes are formed in the side, face, close to the sponge layer, of the drainage layer and communicate with the drainage layer. The other end of the drainagelayer and the other end of the sponge layer are connected with the flow distribution pipe. The flow distribution pipe communicates with the drainage grooves. The flow distribution pipe is connected tothe connection pipe. The fixing mechanism comprises a limiting groove, a limiting hole, a fixing lead screw and a fixing supporting rod. The water-saving device used for uniform watering of the concrete is good in water saving performance, high in heat preservation performance, uniform in watering, low in water source evaporation speed and convenient to operate.

Owner:路港集团有限公司

A fixing device for plug connection

The invention relates to the field of power distributor connectors, in particular to a fixing device for plug power-on. The device comprises a power distributor base, a fixing device shell, a fixing device control structure and a fixing device carrier structure. The fixing device shell is slidingly connected to the power distributor base, the fixing device control structure is rotatably connectedin the fixing device shell, the fixing device control structure is in linkage with the fixing device carrier structure, and the fixing device carrier structure is fixedly connected in the fixing device shell. The fixing device for plug power-on has the advantages that the fixing device and a power distributor can be manually disassembled, the device is extremely easy to install and use, a plug canbe fixed by the device during plug power-on at the same time, and the device is convenient to use; meanwhile, the plug does not need to be unplugged by hands in the process of unplugging the plug, byrotating a hand rotation block, the plug can be automatically ejected, and the situation is avoided that electric shock is caused when the wet hand unplugs the plug.

Owner:WENZHOU TECELLENT MACHINERY CO LTD

A high-efficiency hair sticking device for garment production and processing

ActiveCN111021030BQuality improvementAvoid incomplete sticky hairMechanical cleaningPressure cleaningIndustrial engineeringPulley

The invention discloses an efficient hair sticking device for garment production and processing, and relates to the technical field of garments. The high-efficiency hair sticking device for garment production and processing includes a support seat, a first chute is provided in the support seat, an opening is provided on the top of the support seat, and support legs are welded and installed at the bottom of the support seat, and the number of support legs is Four groups, the first bracket and the second bracket are welded and installed above the support base, the first bracket and the second bracket are adjacently arranged, and a top plate is arranged above the support base, and the top plate is fixedly connected with the first bracket and the second bracket, A pulley is slidably installed in the first chute, and the quantity of the pulley is two groups. A workbench is arranged above the support seat, and a third fixing rod is welded and installed on the bottom of the top plate. The invention is easy to use, is beneficial to increase the quality of clothing sticking wool, avoids incomplete clothing sticking wool, prevents workers from being troubled, and is beneficial to increasing the portability of use.

Owner:佛山市顺德区贝奇服装有限公司

Lid pulling equipment for barreled water

InactiveCN109761177AImprove stabilityAvoid secondary operationsFlanged caps removalFixed frameEngineering

The invention discloses lid pulling equipment for barreled water. The lid pulling equipment comprises a conveying device, frames are fixedly connected to the two sides of the middle of the bottom of the conveying device, a fixing frame is arranged below the conveying device, the two sides of the top of the fixing frame are connected with the bottoms of the two frames, the left side of the top of the fixing frame is fixedly connected with a receiver, a vertical shell is connected to the center of the top of the fixing frame in a through manner, the front and back sides of an inner cavity of thevertical shell are fixedly connected with first cylinders, the output ends of the first cylinders are fixedly connected with second cylinders, and one ends of the two second cylinders are in slidingconnection to the front and back surfaces of the inner cavity of the vertical shell through slide ways. According to the lid pulling equipment for barreled water, empty barrels in different types canbe effectively fixed, the stability of the lid pulling equipment is increased, the lid pulling equipment can pull out barrel lids on the empty barrels in different types, the stopping or jamming condition of the equipment can be avoided, and a worker is prevented from performing secondary operation on the empty barrels.

Owner:湖南湘星环保水处理设备有限公司

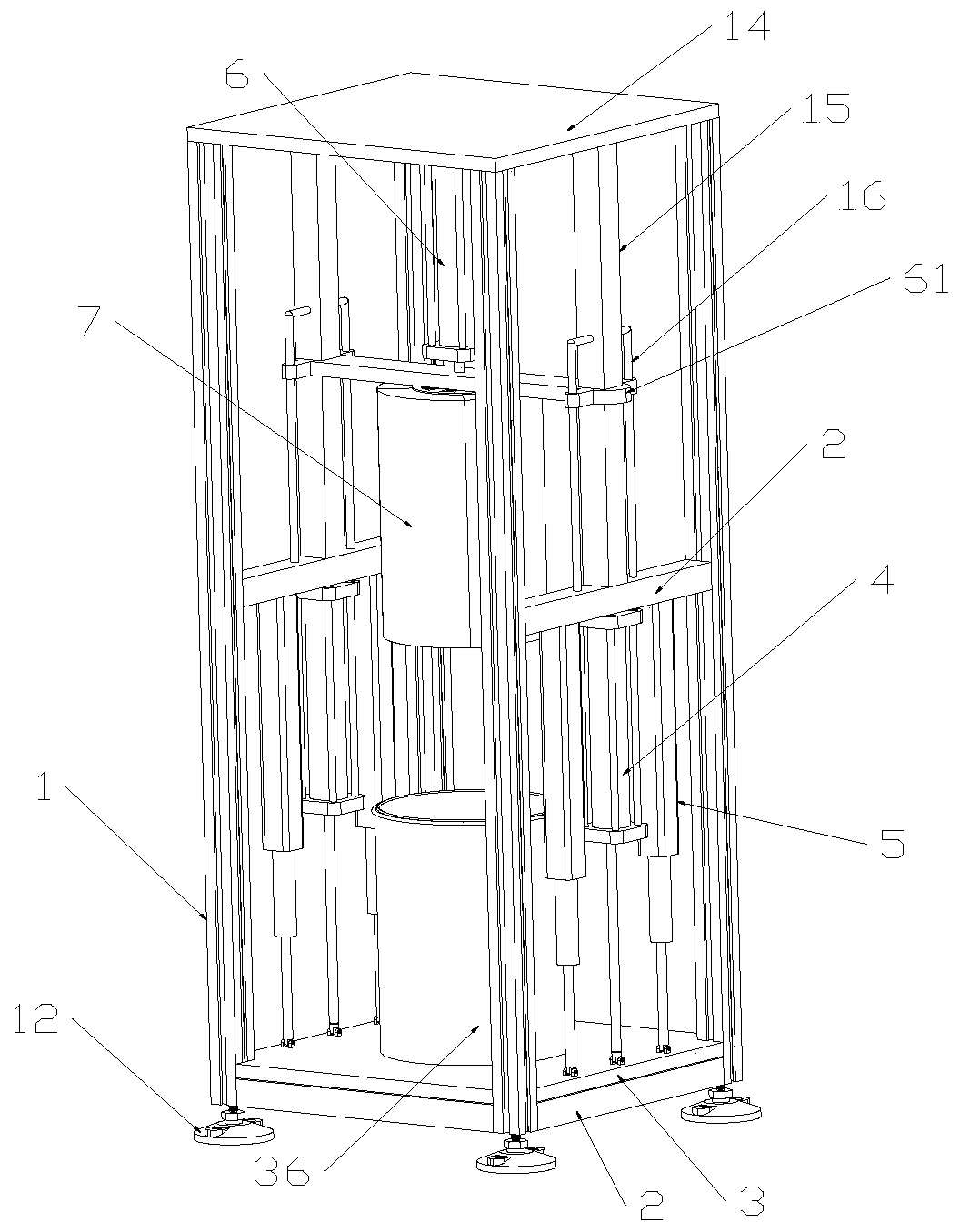

An automatic stacking machine for lined barrels

Owner:安徽洁纯生物科技有限公司

Rainwater purifier

InactiveCN112897790AEnsure normal collection storageImprove acquisitionSpecific water treatment objectivesWater/sewage treatment by magnetic/electric fieldsWater leakageEnvironmental engineering

The invention discloses a rainwater purifier which comprises a water leakage base, a water drainage pipe is movably connected to the middle position of a bottom sealing plate, a magnetic cone is movably connected to the middle position of the top of the water drainage pipe, and a shuttle-shaped purification box is movably connected to the lower middle position of the inner surface of a purification cylinder; an internal energy mechanism is movably connected to the position, located above the shuttle-shaped purification box, of the inner surface of the purification cylinder, a hemispherical purification box is movably connected to the top of the inner surface of the purification cylinder, a flow guide funnel is movably connected to the top of the purification cylinder, and a limiting rail is movably connected to the middle of the inner surface of the flow guide funnel; and the side, away from the flow guide funnel, of the limiting rail is movably connected with a flow guide mechanism. The invention belongs to the technical field of purifier. Rainwater is purified in a multi-layer precipitation mode, the number of precipitated impurities is reduced, reduction of the storage size of the rainwater is avoided, normal collection and storage of the rainwater are ensured, the rainwater collection and purification amount of the equipment is increased, and long-time continuous work of the equipment is ensured.

Owner:安春荣

Medicament feeding machine for sewage treatment

InactiveCN113401952AWide range of dosingAvoid secondary operationsSievingScreeningAnimal scienceTreatment pond

The invention provides a medicament feeding machine for sewage treatment, which comprises a box body, the lower end of the box body is fixedly connected with a floating box, the interior of the floating box is fixedly connected with two symmetrically-distributed support frames, the interiors of the two support frames are jointly and rotatably connected with a driving shaft, the outer side of the driving shaft is fixedly connected with a wire roller, a connecting wire is wound on the outer side of the wire roller, one end of the connecting wire is fixedly connected with a fixing anchor, a self-locking motor is fixedly connected to the interior of the floating box, and an output shaft of the self-locking motor is connected with the driving shaft through a bolt. The floating box, the wire roller, the fixing anchor and other structures are additionally arranged at the lower end of the box body, when agents are fed, the box body can float on the treatment pond through the floating box, the box body can be fixed in a treatment pond through the fixing anchor, water flow in the treatment pond can drive the floating box to swing, and therefore the agent feeding range is wider.

Owner:安徽清泓环境科技有限公司

Door and window protective sleeve

PendingCN112211539AEasy to assembleReduce resistanceSealing arrangementsEngineeringStructural engineering

The invention provides a door and window protective sleeve. The door and window protective sleeve comprises a door and window frame, wherein a protective sleeve main body is arranged at the splicing position of the door and window frame, the protective sleeve main body is L-shaped, a mounting hole is formed in the protective sleeve main body, a fixing device is arranged in the mounting hole, a chamfer is arranged at the bending position of the protective sleeve main body, the protective sleeve main body comprises a first side plate and a second side plate, the first side plate is connected with the second side plate through a connecting plate, a sealing wool top is arranged on the first side plate, and an adsorption strip is arranged on the connecting plate. The protective sleeve main bodycan be quickly sheathed at the splicing position of the door and window frame through a channel formed by the first side plate, the second side plate and the connecting plate, and the protective sleeve main body is fixedly connected with the door and window frame through the fixing device, so that the assembly operation of the protective sleeve is simple, the production efficiency is improved, the sealing wool top can achieve a good sealing effect, the resistance during the movement of the door and window frame is reduced, the stability of a door and window is ensured, the adsorption strip can eliminate excess collision force or supplement the insufficient force during closing, and secondary operation is avoided.

Owner:常州西林盛业建筑门窗有限公司

A kind of graphene mixed filler and its preparation method and graphene mixed filler chromatography column and application

ActiveCN111450573BLow costAvoid secondary operationsIon-exchange process apparatusOrganic chemistryElectronic structurePhysical chemistry

The inventor provides a graphene mixed filler and a chromatographic column, wherein the mixed filler includes a graphene material and a chromatographic medium filler, and the weight ratio of the graphene material to the chromatographic medium filler is 1-50 : 100, the particle size of the graphene material is 500-5000 mesh, and the particle size of the chromatography medium filler is 200-500 mesh. Use the special properties of graphene (π-π electron conjugation effect) to achieve column adsorption of compounds with π-conjugated electronic structures. At the same time, the lower column has the effect of separating conventional impurities, which can be further separated and purified to absorb impurities and avoid Multiple operations are performed, which can effectively reduce the chromatography cost and operation time of the target product.

Owner:福州奥尼多生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com