Construction waste crushing device

A crushing device and construction waste technology, which is applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of troublesome operation, inability to sort and collect debris, reuse and reclassify debris, etc., and achieve good self-cleaning ability, It is convenient to collect and clean up debris, and the effect is simple and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

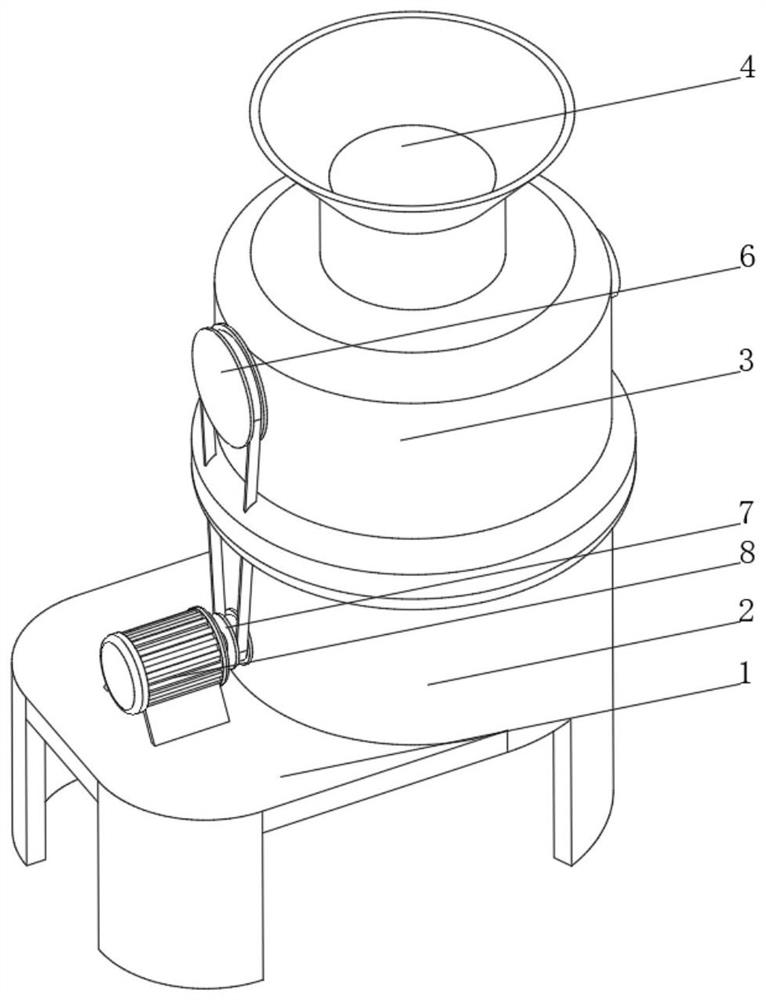

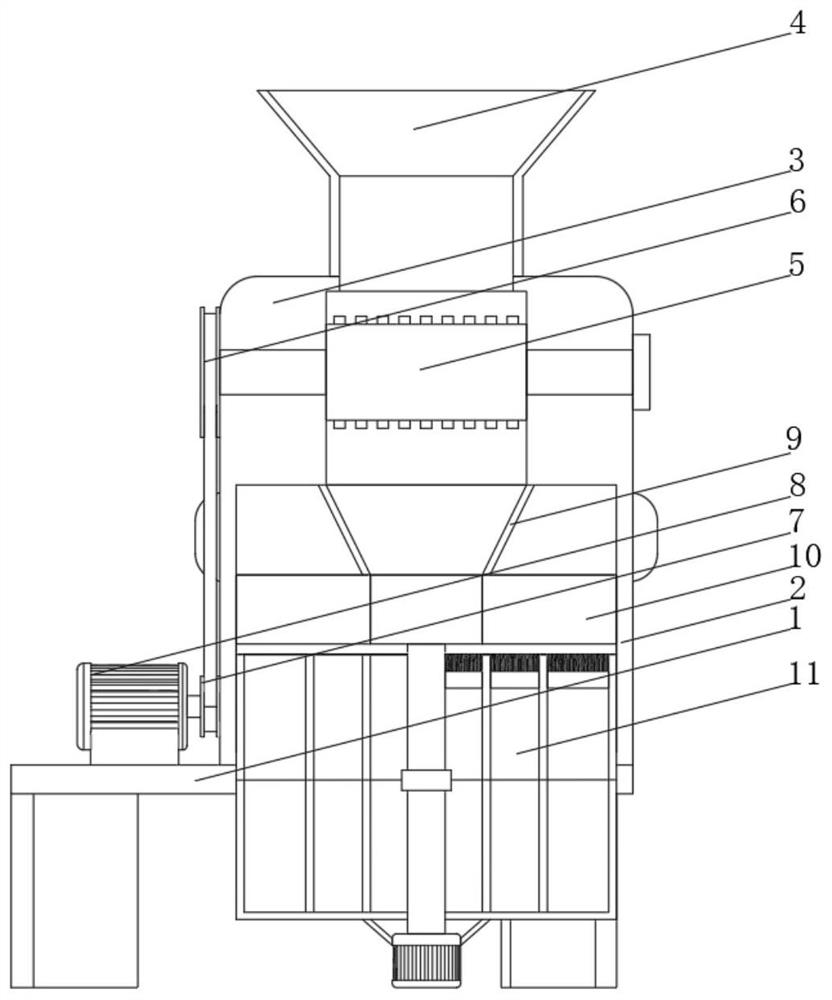

[0032] see Figure 1-4 , the present invention provides a technical solution: a construction waste crushing device, including a support base 1, a processing cylinder 2 is fixedly connected to the top of the support base 1, a crushing cylinder 3 is connected to the top of the processing cylinder 2, and a feeding material is connected to the top of the crushing cylinder 3 Port 4, the inner wall of the crushing cylinder 3 is connected with the crushing roller 5 in rotation, one end of the crushing roller 5 penetrates the crushing cylinder 3 and is fixedly connected with the driven pulley 6, the side of the driven pulley 6 is connected with the driving pulley 7 through the belt, and the driving pulley One side of 7 is fixedly connected with a drive motor 8, the bottom of the crushing cylinder 3 is connected with a guide pipe 9, and the bottom of the guide pipe 9 is connected with a processing turntable 10, and the part of the inner wall of the processing cylinder 2 at the bottom of...

Embodiment 2

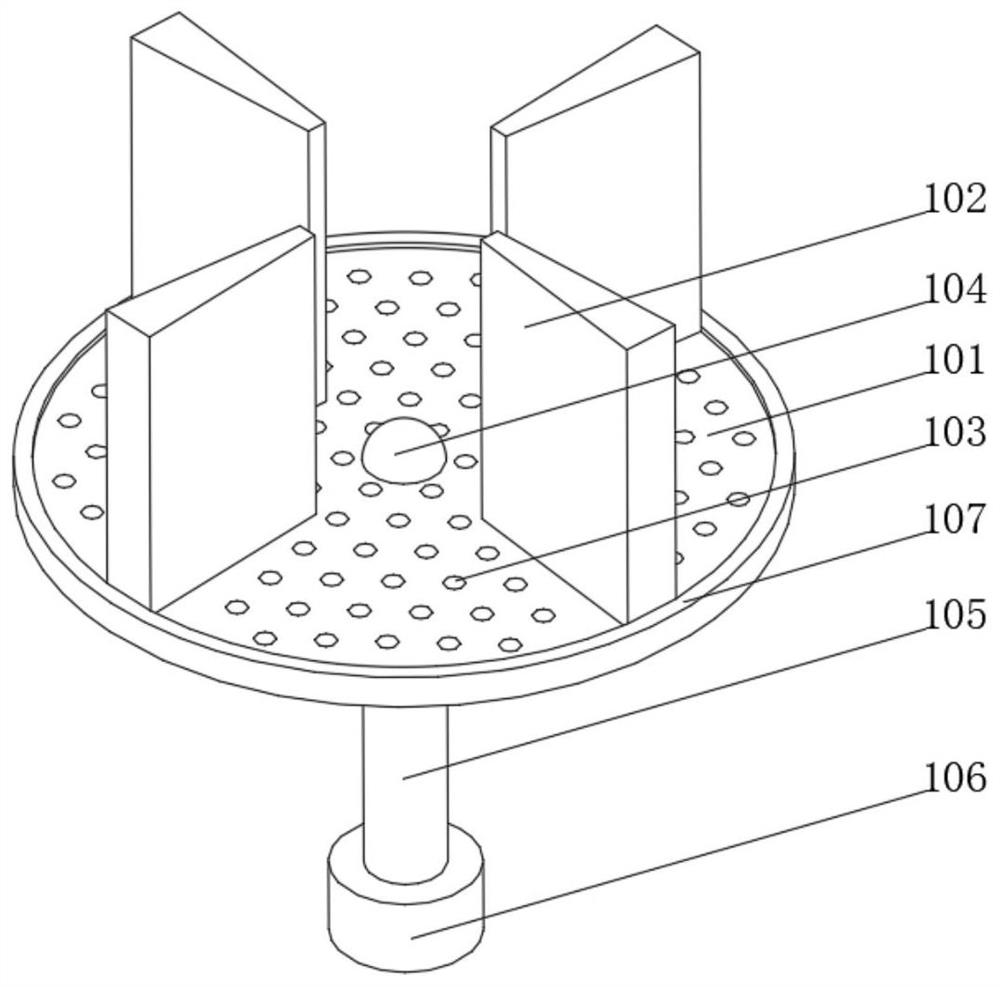

[0035] see Figure 1-6On the basis of Embodiment 1, the present invention provides a technical solution: the classification device 11 includes a classification outer cylinder 111, the inner wall of the classification outer cylinder 111 is fixedly connected with a classification inner cylinder 112 through a support rod, and the classification outer cylinder 111 and the classification inner cylinder 112 The top of one side of the inner wall is fixedly connected with a cleaning brush 113, and the bottom of the outer wall of the classification outer cylinder 111 is fixedly connected with a storage tube 115 through a fixing device 114, and the bottom of the storage tube 115 is fixedly connected with a rotating motor 116, and the drive shaft of the rotating motor 116 is fixedly connected with a drive shaft. The rotating shaft 117, the top of the driving rotating shaft 117 runs through the receiving cylinder 115 and extends to the inside of the classification inner cylinder 112. The f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com