A kind of solid-liquid reagent reaction experimental method

An experimental method and reagent technology, applied in the field of chemical experimental operation, can solve the problems of easy introduction of impurities, hidden operational safety hazards, and troublesome operation, and achieve the effects of simple and convenient experimental operation, reducing operational safety hazards and preventing pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention provides a kind of solid-liquid reagent reaction experimental method, and this method specifically comprises the following steps:

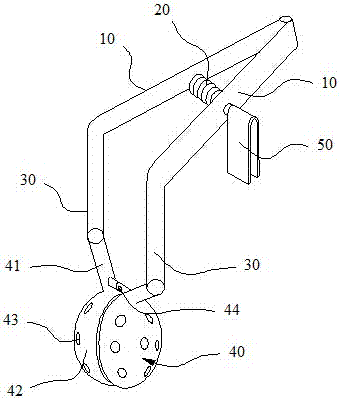

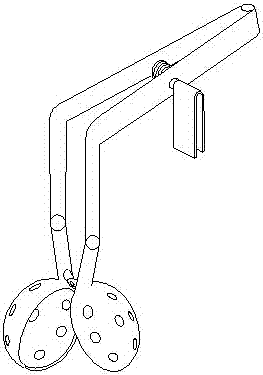

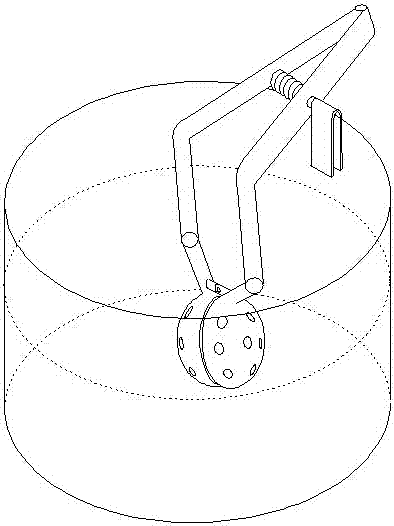

[0023] 1) Prepare the solid reagents and liquid reagents that need to participate in the reaction, as well as a beaker and a solid reagent holder reactor. In the inventive method, adopted special-purpose solid reagent clamping reactor, as figure 1 As shown, the solid reagent clamping reactor has two long support arms 10 with the same length, one end of the two support arms 10 is rotatably connected together, and the middle parts of the two support arms 10 are abutted with compression Spring 20, the ends of the other ends of the two support arms 10 are respectively fixedly connected with a vertical extension arm 30, wherein the middle part of one support arm is hinged with an elastic clamp 50 on the side of the other support arm side; the elastic clamp 50 is An integrally formed U-shaped stainless steel sheet, and its U-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com