Spiral-type surface finishing and trimming cutter

A technology for surface finishing and trimming tools, used in rotary cutting tools, tools for lathes, manufacturing tools, etc., can solve problems such as threatening operation safety, weakening strength, cutting setback, etc., to reduce operational safety hazards and improve strength. , Optimize the effect of the bezel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

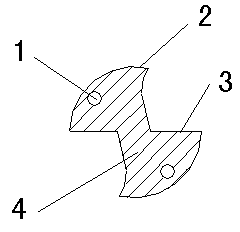

[0009] Depend on figure 1 As we know, the six-edge spiral surface finishing tool is composed of a clamping part 1, a deep cutting edge part 2, an arc serrated blade part 3 and a tapered blade part 4. The clamping part 1 is longer than the common one, and the deep blade is A circular arc surface is added to the front end of the mouth part 2 . The circular-arc sawtooth blade part 3 is the rear part of the knife tip, and is in the shape of six-edged circular-arc spiral serrations. The tip of the tapered blade portion 4 is conical, and the blade is a high-density helical cutting edge with a shallow cutting edge and a thinner diameter.

[0010] The structure of the present invention uses the six-blade machining of the middle end mill type when machining general workpiece burrs and requires fast machining speed. It has the deepest cutting edge and the highest cutting efficiency in the whole tool. When processing curved surfaces and planes that are difficult to process, use arc bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com