Automatic-reset bypass valve

A technology of automatic reset and bypass valves, which is applied in the direction of multi-way valves, valve details, valve devices, etc., can solve the problem that the safety shut-off valve loses the actual function of cutting off the gas source, and achieves the effect of reducing operational safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

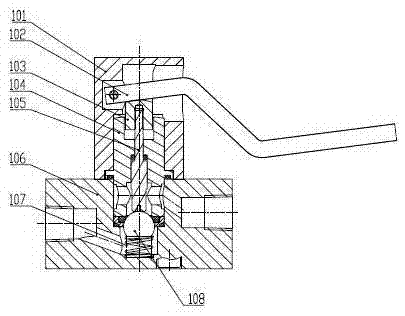

[0012] see attached figure 1 , an automatic reset bypass valve, comprising an upper valve body, a reset wrench, a top cap, a guide sleeve, a push rod, a valve body, a spring, and a steel ball. The spring is placed in the bottom groove of the valve body, steel balls are placed on the spring, the guide sleeve and the valve body are sealed with an O-shaped sealing ring, the ejector rod and the top cap are installed inside the guide sleeve, and the upper valve body is installed outside the guide sleeve , The upper valve body and the valve body are fastened with screws, and the upper valve body is equipped with a reset wrench that can move up and down. When working, press the reset wrench, press the steel ball through the top cap and the ejector rod to break away from the O-ring, so that the gas can smoothly pass through the bypass valve and enter the downstream. When the reset wrench is loosened, under the action of the spring force, The steel ball will move upward to push the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com