A die-casting equipment for processing thin-walled parts with convenient exhaust

A technology for processing and die-casting thin-walled parts is applied in the field of die-casting and forming equipment for thin-walled parts processing. High efficiency, safe and convenient use, and the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

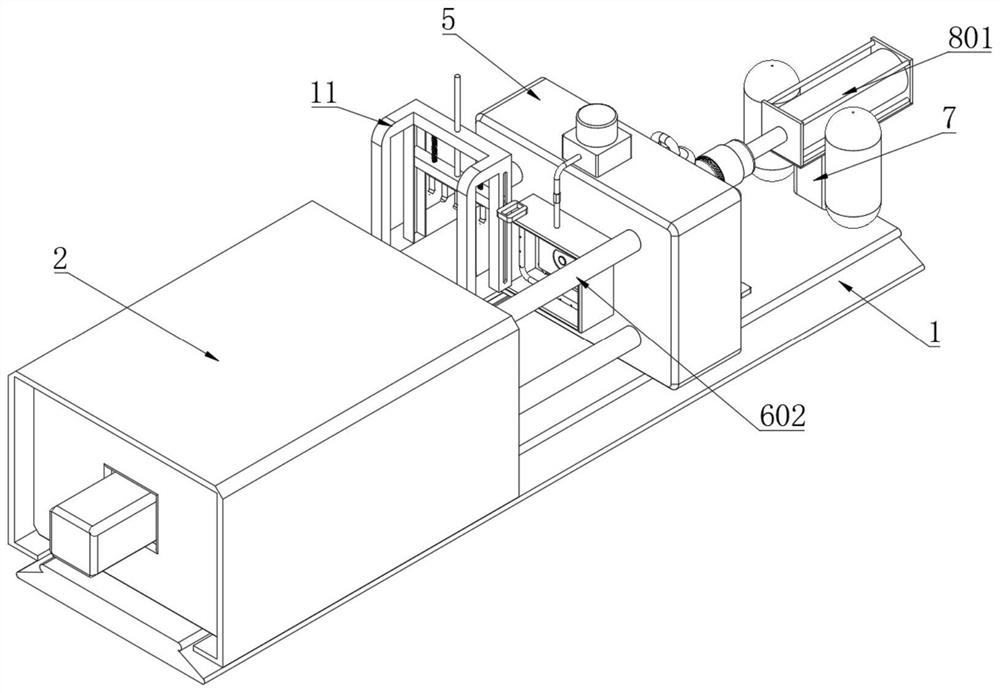

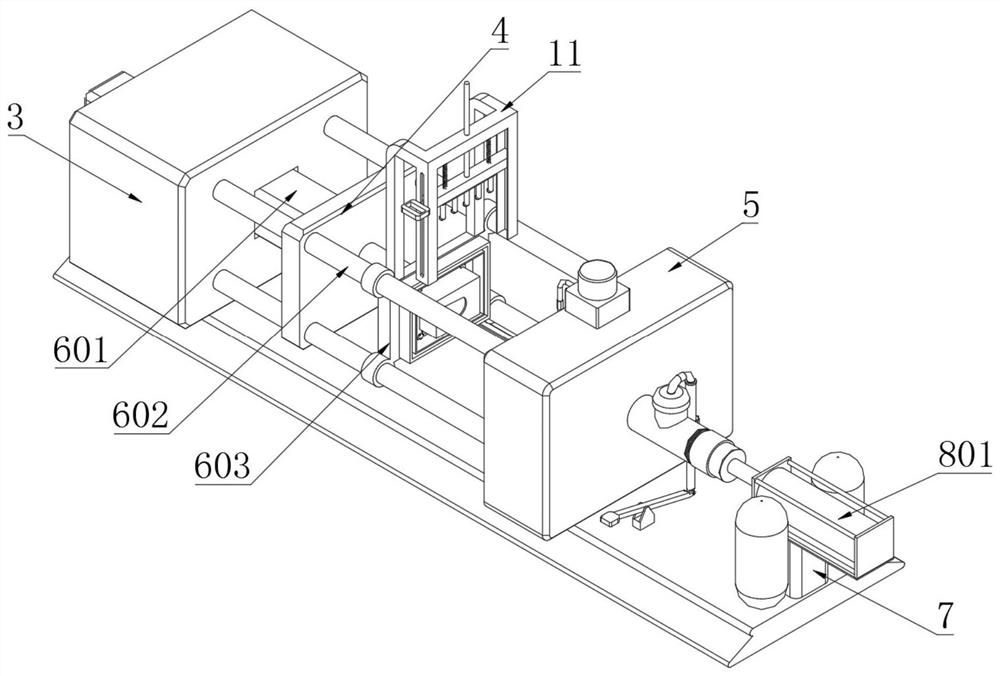

[0056] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a die-casting equipment for processing thin-walled parts that is convenient for exhausting, including a base 1, a protective shell 2 is fixedly connected to the top side of the base 1, and the inner side of the protective shell 2 Embedded with a control box 3, the top of the base 1 is fixedly connected to a support plate 4 at a position on one side of the control box 3, and the top of the base 1 is fixedly installed on the side away from the protective shell 2. Air component 6;

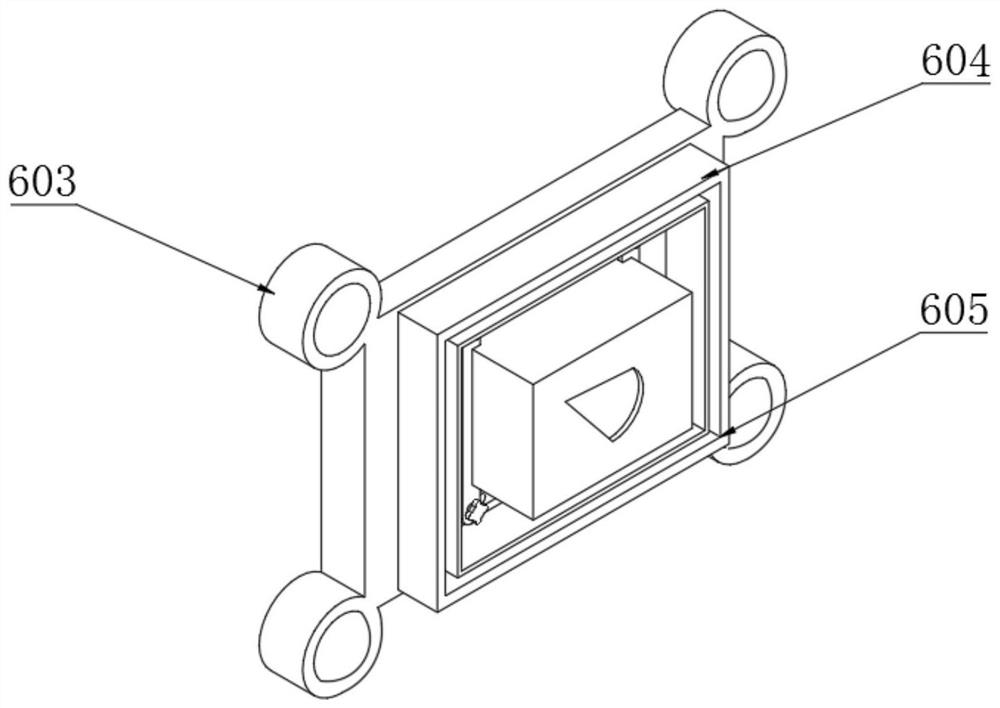

[0057] The exhaust assembly 6 includes a cylinder 601, a sliding guide rod 602, a sliding seat 603, a sealing block 604, a sealing groove 605, a sealing box 606, an annular suction pipe 607, a suction hole 608, an exhaust pipe 609, a one-way valve 610 and Air pump 611;

[0058] The inner side of the control box 3 is embedded with a cylinder 601, and the control box 3 is connected with a sliding guide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com