Device and method for trip-type ditching toward-target hole fertilization in orchard

The technology of a fertilizing device and a fertilizing device is applied in the field of agricultural machinery, which can solve the problems of high efficiency, seasonality and labor intensity, environmental pollution, etc. The effect of automatic operation, simple and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

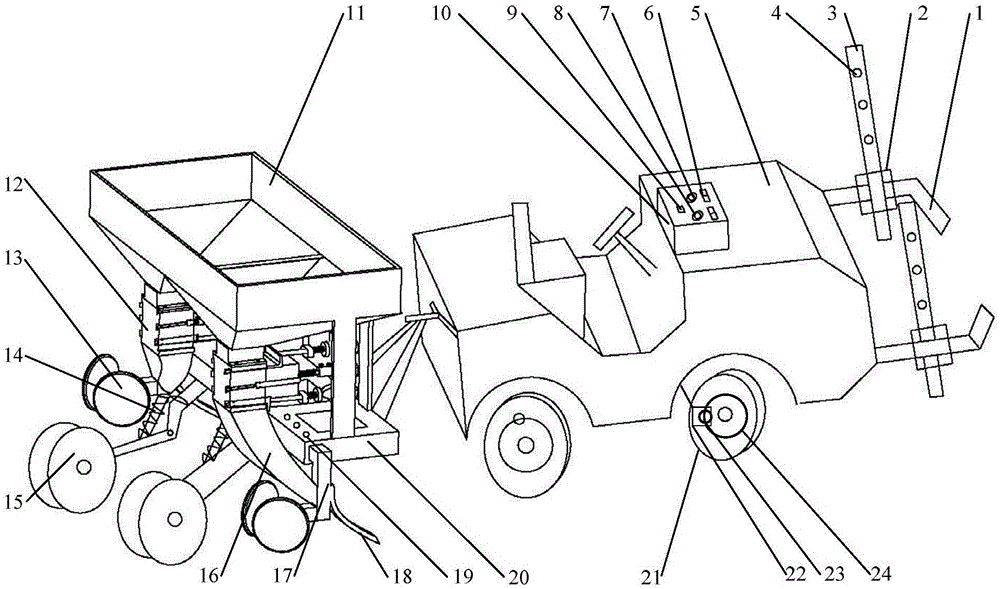

[0044] Such as figure 1 As shown, it is a schematic diagram of the main structure of an orchard strip ditching device for fertilizing target holes according to the present invention, including a hole fertilizer discharge device, a ditching device, a detection device and a controller 10 . Among them, the hole fertilizer discharge device is supported by the base frame 20, and includes a fertilizer box 11 and a hole fertilizer discharge device 12. The fertilizer box 11 is fixedly connected with the bottom frame 20, and the bottom of the fertilizer box 11 is set in a conical shape, which is beneficial for the fertilizer to fall into the hole for fertilizer discharge. In the device 12, the hole fertilizer discharge device 12 is installed through the mounting holes corresponding to the bolts and the fertilizer box 11. Fertilizer enters the rear side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com