Dual spiral fertilizing part

A screw and component technology, applied in the field of double-layer screw fertilization components, can solve the problems that the fertilization components cannot complete the controllable layered fertilization, the soil blocks the fertilizer discharge port, and the use of labor is too much, so as to meet the requirements of agronomic base fertilizer and reduce the use of chemical fertilizers The effect of high fertilizer use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

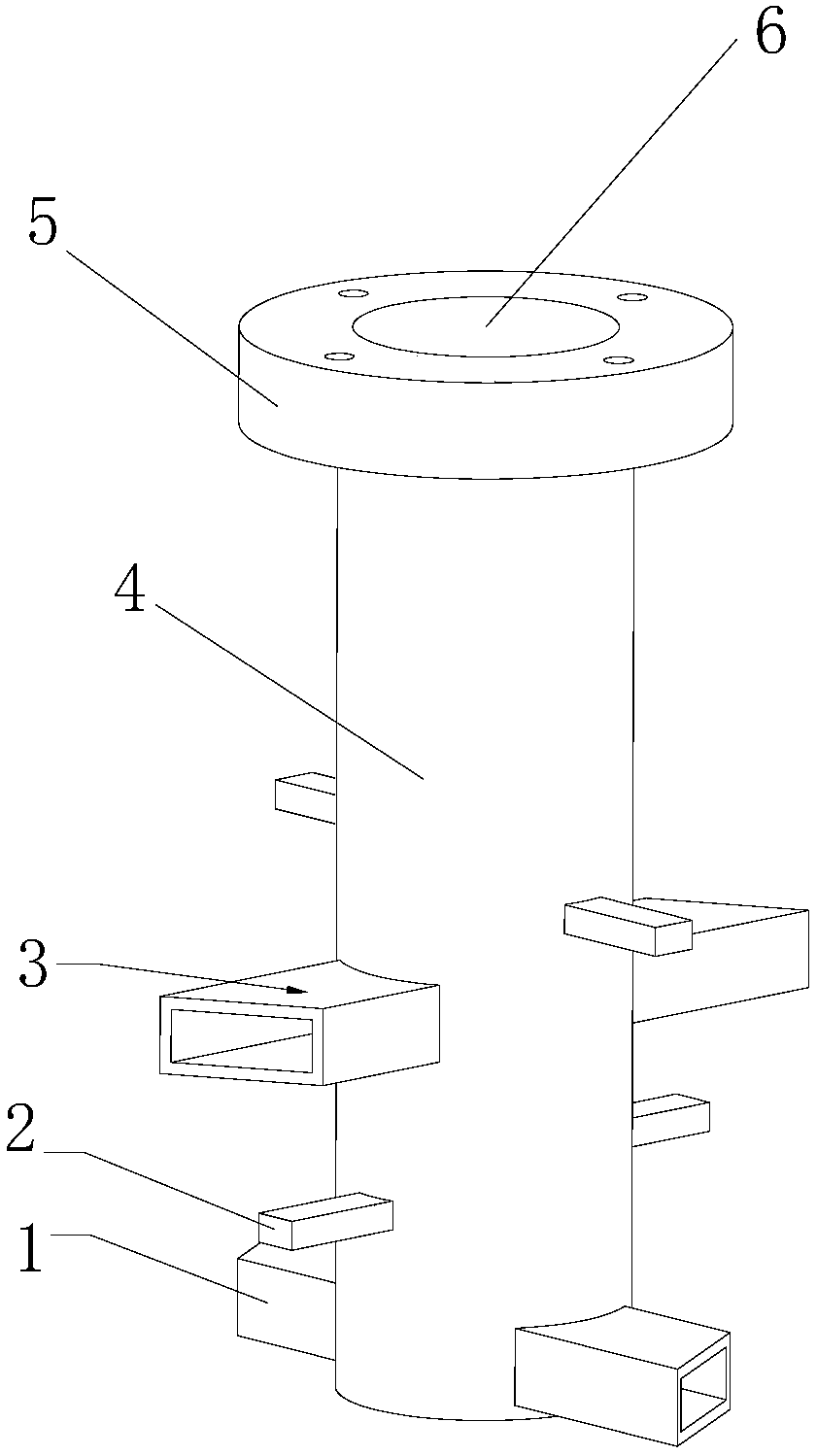

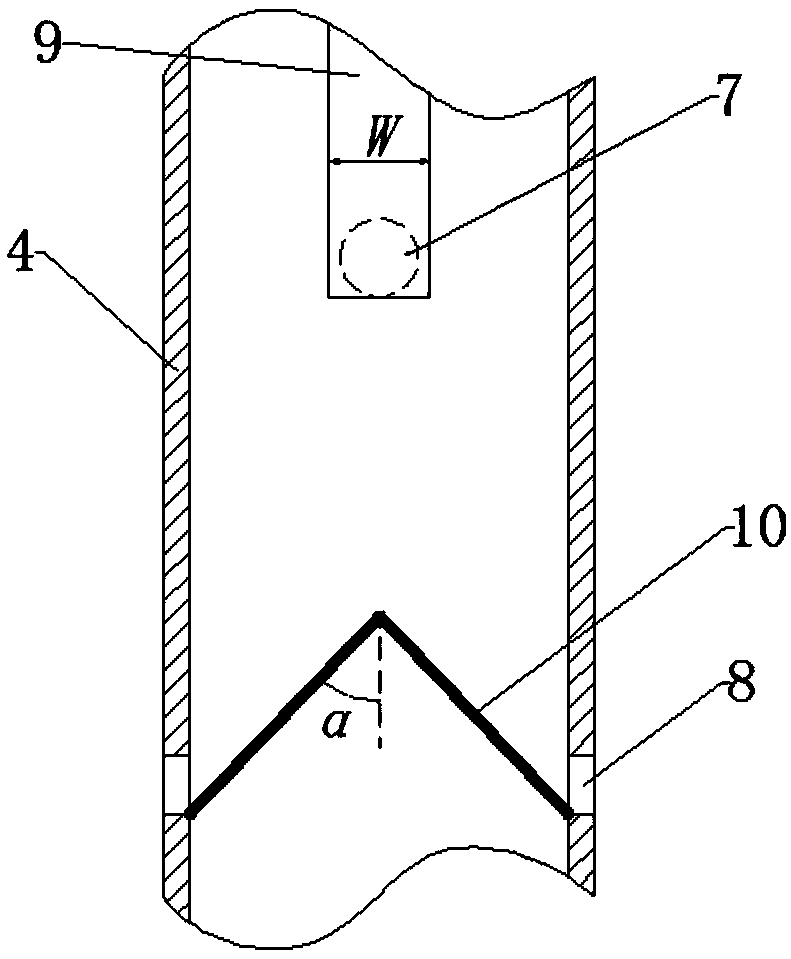

[0018] The double-layer spiral fertilization parts of the present embodiment, as figure 1 and figure 2 As shown, it includes a main fertilizer discharge pipe 4 that is vertically arranged and is a hollow structure. The top opening of the main fertilizer discharge pipe 4 is a fertilizer inlet 6, and the bottom opening of the main fertilizer discharge pipe 4 is a bottom fertilizer discharge port. The main fertilizer discharge pipe 4 The upper and lower rows of through holes are provided on the side wall of the upper row of through holes, and the upper row of through holes 7 are fixedly connected with the upper layer of fertilizer discharge pipe 3, that is, the entrance of the upper layer of fertilizer discharge pipe 3 is connected with an upper row of through holes 7, and the upper layer of fertilizer discharge pipe The outlet of 3 extends to the direction away from main fertilizer pipe 4. The lower row of through holes 8 is fixedly connected with the lower fertilizer discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com