Long-acting slow-release fertilizer used in planting early stage of Pseudostellaria heterophylla and preparation method thereof

A technology of slow-release fertilizer and Radix Radix ginseng, which is applied to the field of long-acting slow-release fertilizer and its preparation in the early stage of Radix ginseng planting, can solve the problems such as patents and literature reports of long-acting slow-release fertilizers that have not yet been found, and can reduce the pollution of soil environment. Destruction, good practicality, the effect of solving supplementary long-term problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

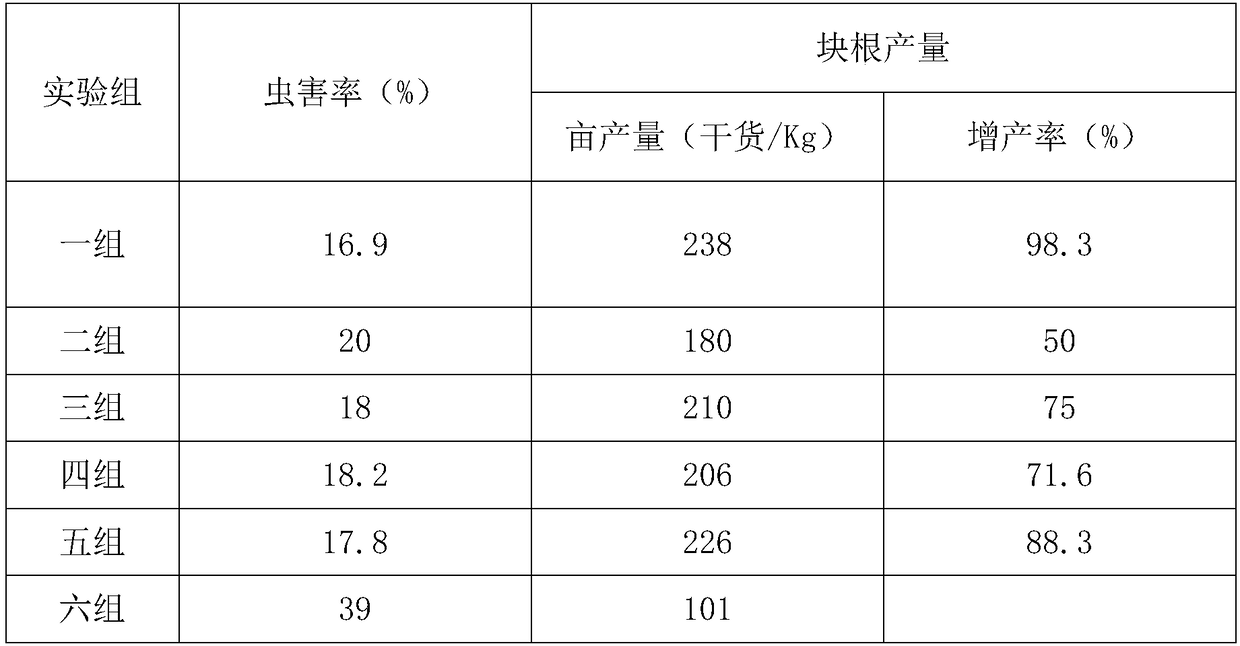

Examples

Embodiment 1

[0017] Embodiment 1: a long-acting slow-release fertilizer used in the early stage of Pseudostellaria heterophylla planting and its preparation method,

[0018] (1) Fertilizer components mixing: take the following fertilizer components: edible fungus processing waste residue fertilizer 120Kg, urea 50Kg, superphosphate 60Kg, potassium sulfate 80Kg, after edible fungus processing waste residue fertilizer is chopped, mix with other components uniform;

[0019] (2) Adsorption: take by weighing 310Kg porous starch, mix the fertilizer component obtained in step (1) with the porous starch, and perform adsorption. After the adsorption, take by weighing and place in the mold the fertilizer to be coated. The individual volume of the mold is 50cm 3

[0020] (3) Coating: Weigh 80Kg stearic acid and 120Kg paraffin, put them in a container, add 30Kg water, heat and melt, lower and maintain the system temperature between 80-90℃, add 200Kg glucose and sucrose 1:1 Keep the temperature of th...

Embodiment 2

[0021] Embodiment 2: a long-acting slow-release fertilizer used in the early stage of Pseudostellaria heterophylla planting and its preparation method,

[0022] (1) Fertilizer components mixing: take the following fertilizer components: edible fungus processing waste residue fertilizer 130Kg, urea 58Kg, superphosphate 70Kg, potassium sulfate 90Kg, after edible fungus processing waste residue fertilizer is chopped, mix with other components uniform;

[0023] (2) Adsorption: take by weighing 348Kg porous starch, mix the fertilizer component obtained in step (1) with the porous starch, and adsorb, take by weighing and place in the mold in proportion to obtain the fertilizer to be coated after the adsorption, The single volume of the mold is 200cm 3

[0024] (3) Coating: Weigh 100Kg stearic acid and 100Kg paraffin, put them in a container, add 36Kg water, heat and melt, reduce and maintain the system temperature between 80-90°C, add 240Kg glucose and sucrose 1:1.5 Keep the temp...

Embodiment 3

[0025] Embodiment 3: a long-acting slow-release fertilizer used in the early stage of Pseudostellaria heterophylla planting and its preparation method,

[0026] (1) Fertilizer components mixing: take the following fertilizer components: edible fungus processing waste residue fertilizer 150Kg, urea 65Kg, superphosphate 80Kg, potassium sulfate 100Kg, edible fungus processing waste residue fertilizer is chopped and mixed with other components uniform;

[0027] (2) Adsorption: take by weighing 395Kg porous starch, mix the fertilizer component obtained in step (1) with the porous starch, and carry out adsorption. After the adsorption, take by weighing and place in the mold the fertilizer to be coated. The individual volume of the mold is 650cm 3

[0028] (3) Coating: Weigh 120Kg stearic acid and 120Kg paraffin, put them in a container, add 36Kg water, heat and melt, lower and maintain the system temperature between 80-90°C, add 240Kg glucose and sucrose 1:1.5 Keep the temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com