Novel grind-type smoothening equipment

A kind of equipment and grinding technology, applied in grinding/polishing equipment, metal processing equipment, grinding machines, etc., can solve the problems of reducing the dimensional accuracy of products, wasting manpower and material resources, etc., to reduce the probability of damage, increase the service life, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

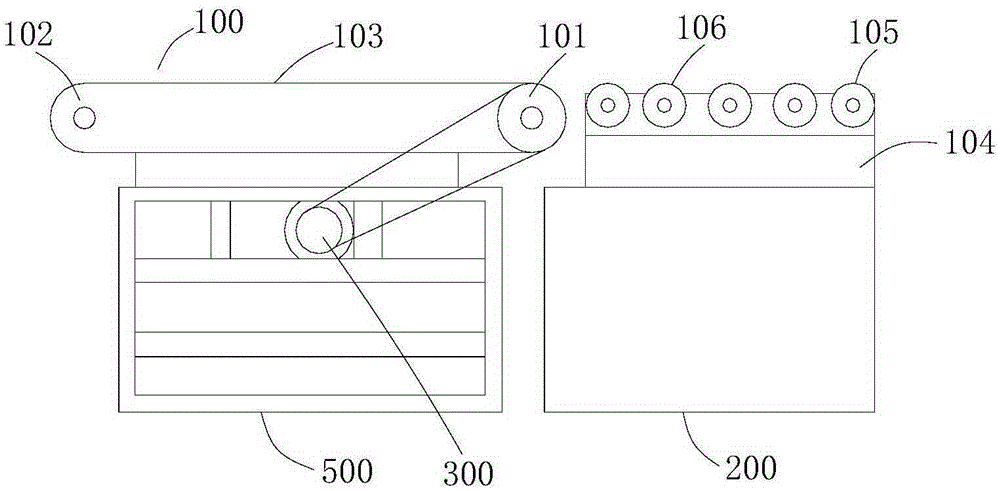

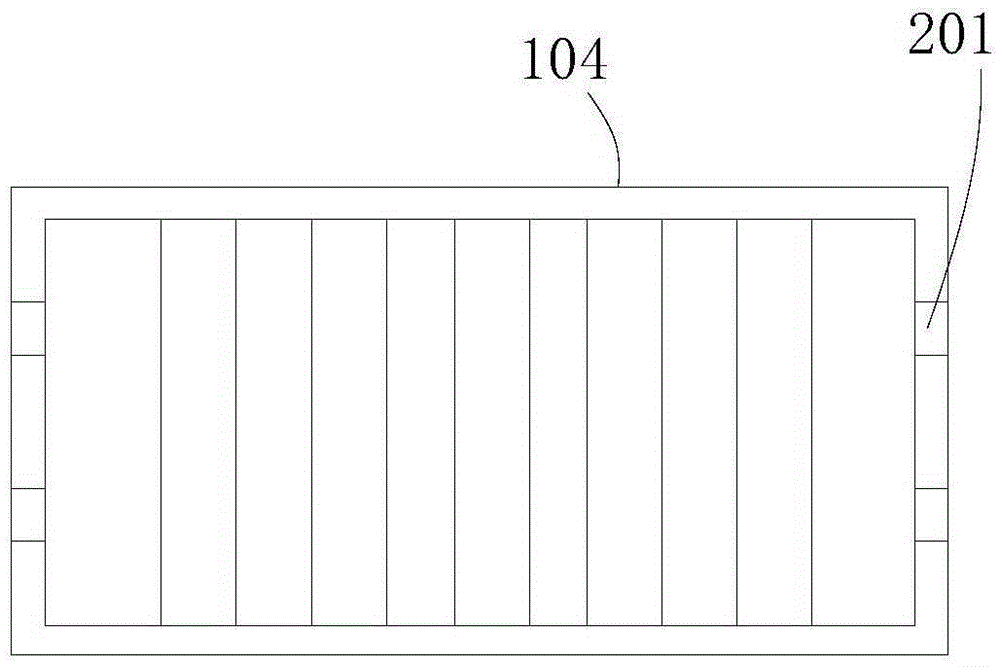

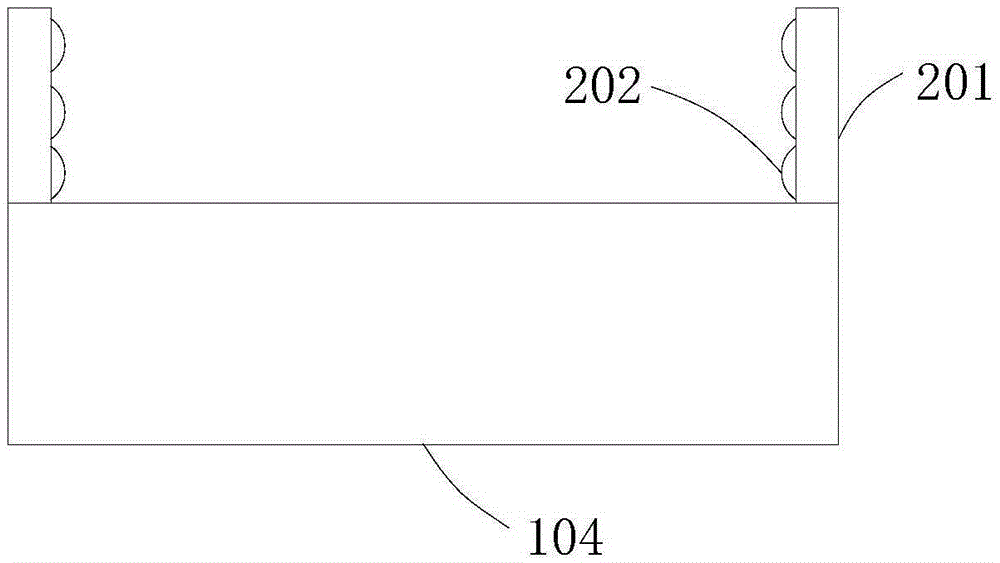

[0051] see Figure 1-6 , this embodiment provides a new type of smoothing equipment for smoothing wooden boards, including a smoothing unit 100, a conveying unit 200, and a power unit 300. The smoothing equipment includes different working units. During use, different The working unit has corresponding functions, which is convenient for workers to operate. At the same time, multiple tasks can be used to operate at the same time, and cooperate with each other to improve work efficiency. In the specific processing process, some workers are responsible for placing the wooden boards on the conveying unit 200, and then, as the conveying unit 200 transports the wooden boards to the smoothing unit 100, another worker is responsible for balancing the wooden boards, grinding the wooden blocks or having a lower height When the wooden pile is used, it is not necessary to carry out the work of keeping the balance, and the workman can accept and place the plank after grinding at the tail e...

Embodiment 2

[0064] see Figure 7-10 , this embodiment also provides a new type of grinding equipment, this embodiment is a further improvement on the basis of the technical solution of the first embodiment, the technical solution described in the first embodiment is also applicable to this embodiment, and the first embodiment has been The disclosed technical solution will not be described repeatedly, as follows:

[0065]The novel grinding equipment also includes a lifting mechanism 400, the output end of the lifting mechanism 400 is located at the bottom of the base 104, and is used to drive the base 104 to move up and down reciprocally. First lower the conveying unit 200 to the lowest position, and then place the planks on the conveying unit 200. The operation of placing the planks is more convenient and quick, saving manpower and material resources. Then, start the lifting mechanism 400, and adjust the conveying unit 200 to a position level with the smoothing belt 103, or slightly high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com