Machining unit suitable for panels of different widths

A kind of plate processing, adapting to different technologies, applied in the field of plate processing, can solve the problem of large labor consumption, achieve the effect of simple structure, convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

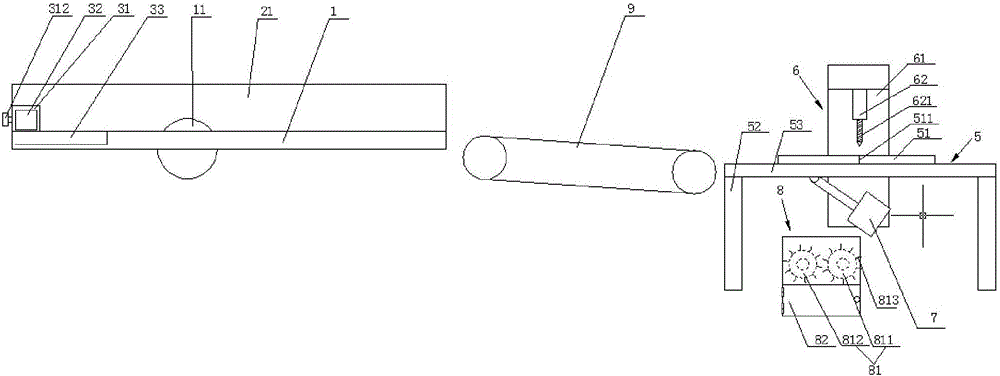

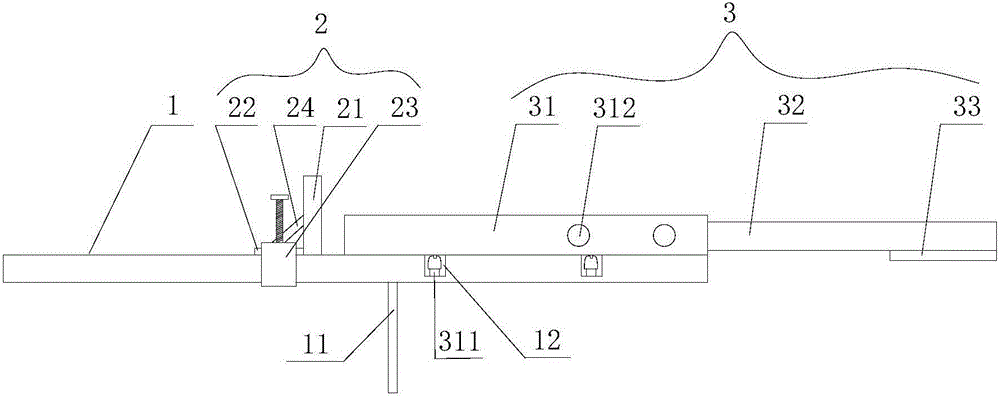

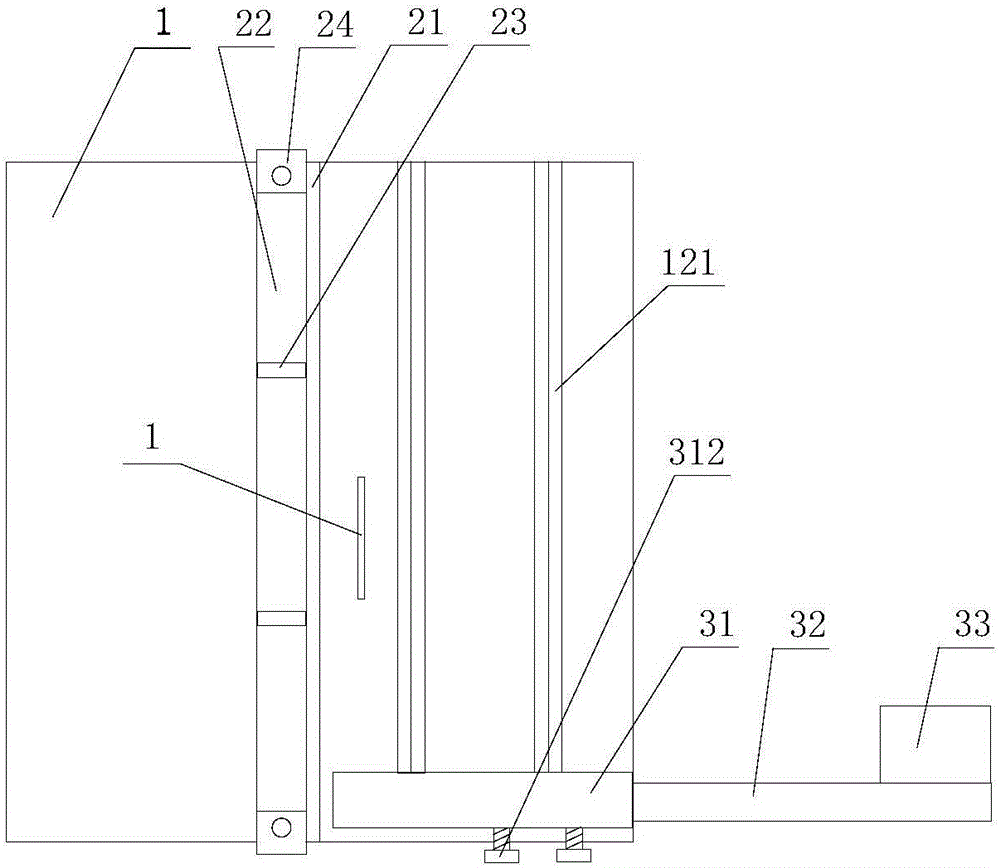

[0041] Such as figure 1 , figure 2 , image 3 As shown, a cutting machine adapted to plates of different widths includes a workbench 1 and a grinding wheel saw 11; a grinding wheel saw groove is arranged on the workbench 1; the grinding wheel saw 11 is located in the grinding wheel saw groove, and the grinding wheel saw 11 is partially extended The upper surface of the workbench-1; the cutting machine also includes a limit device 2 for controlling the width of the saw edge of the plate; the limit device 2 is fixed on the workbench-1 and the distance between the limit device 2 and the grinding wheel saw 11 can be adjusted. spacing; the movement path of the limit device 2 is perpendicular to the saw disc of the grinding wheel saw 11;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com