Transformer iron core overturning device and operating method thereof

A technology of a transformer core and a flipping device, which is applied in the manufacture of inductors/transformers/magnets, electrical components, circuits, etc., can solve the problems of poor flipping stability, low work efficiency, and heavy labor for workers, and achieve stable flipping and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

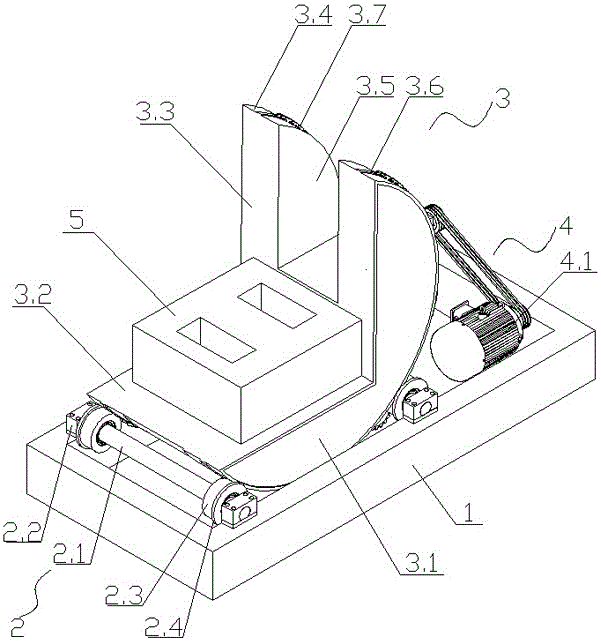

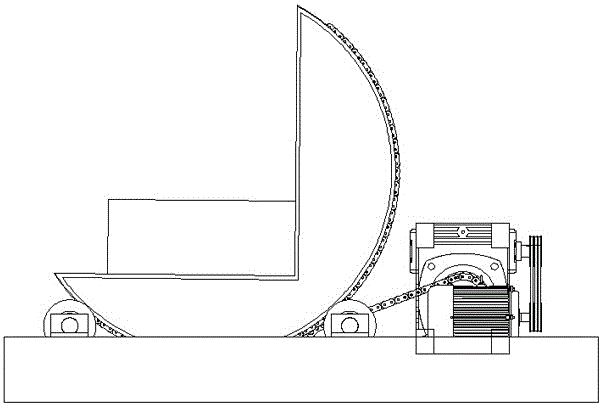

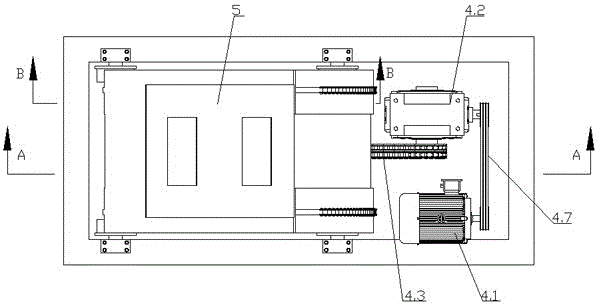

[0033] see Figure 1~Figure 6 , a transformer core turning device related to the present invention, which includes a base 1, a bracket 2, a turning frame 3 and a power mechanism 4;

[0034] The bracket 2 includes two left and right rotating support shafts 2.1 longitudinally arranged, the front and rear ends of the rotating support shaft 2.1 are fixed on the bearing seat 2.2, the bearing seat 2.2 is fixed on the base 1, and the front and rear sections of the rotating support shaft 2.1 Each section is equipped with a supporting roller 2.3, and the front edge of the front supporting roller 2.3 and the rear edge of the rear supporting roller 2.3 are provided with a stopper 2.4;

[0035] The flip frame 3 includes a flip frame main body 3.1, the flip frame 3.1 has a first support plane 3.2 and a second support plane 3.3 perpendicular to each other, the flip frame 3.1 also has a driving surface 3.4 of an arc segment, and the second support plane 3.3 corresponds to The flip frame mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com