Dead-corner-free efficient drilling equipment for power distribution cabinet production

A drilling equipment with no dead angle technology, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., can solve the problems of manpower consumption and low efficiency, and achieve improved work efficiency and a high degree of automation , design reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

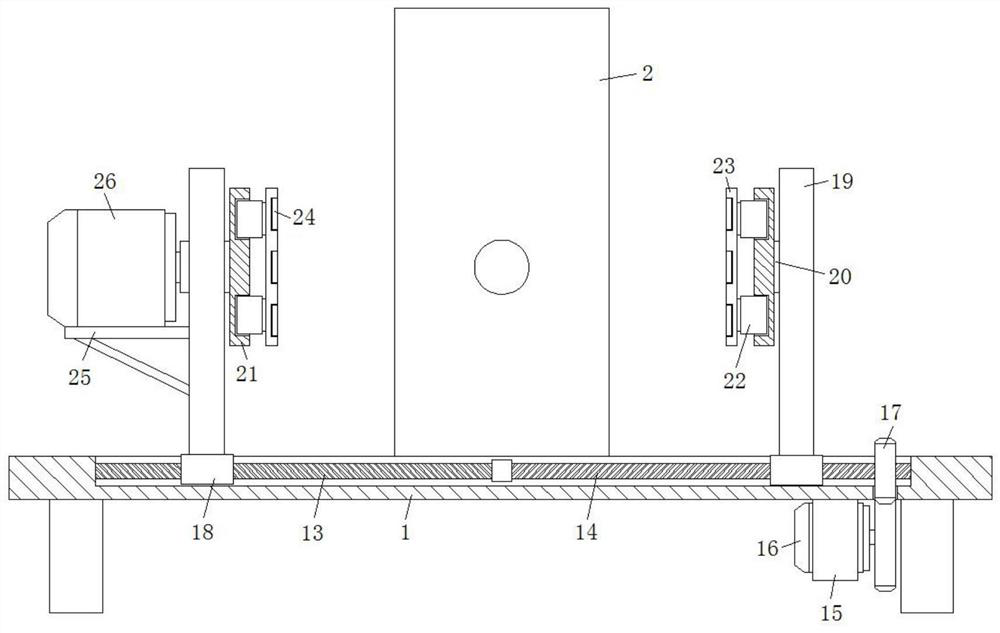

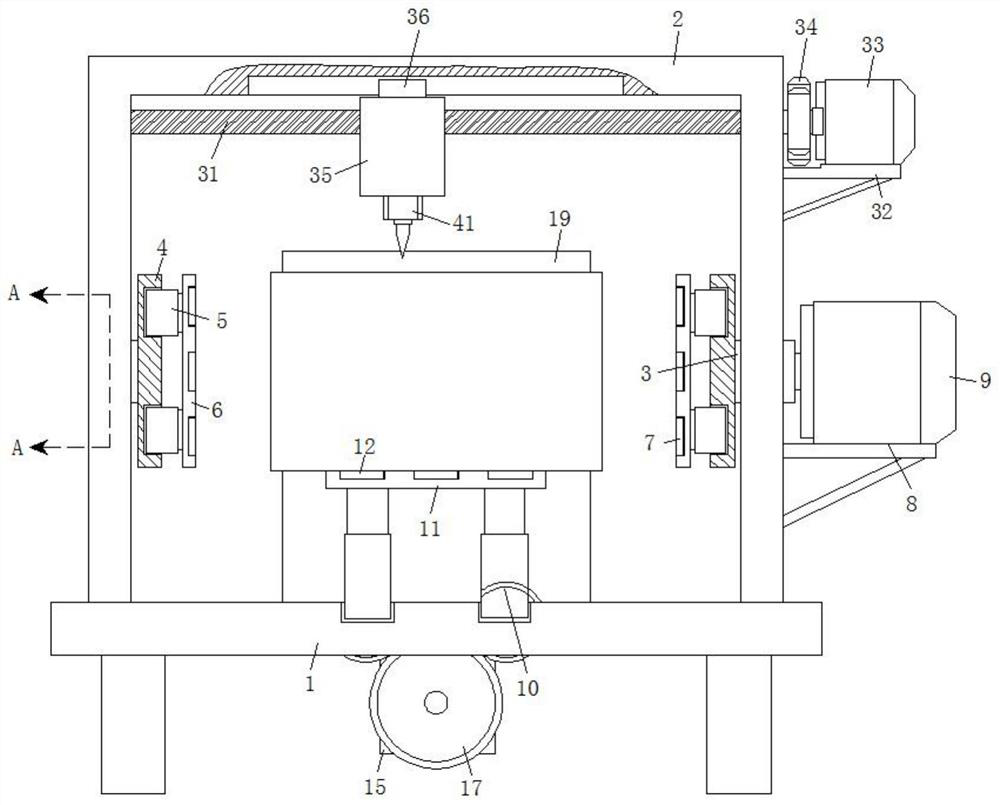

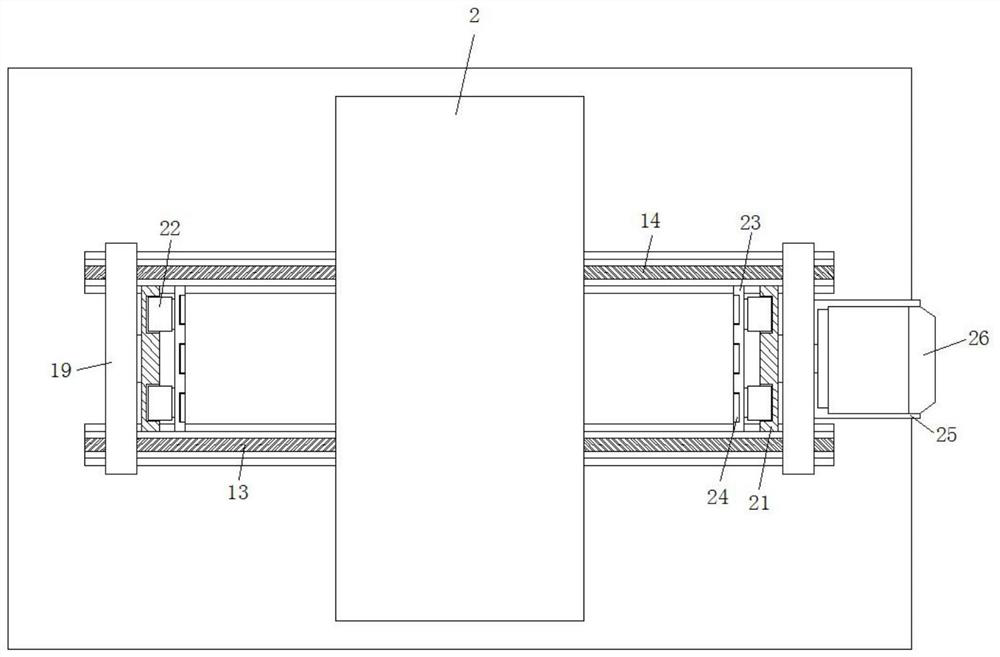

Embodiment 1

[0032] refer to Figure 1-7 , a high-efficiency drilling equipment with no dead angle for the production of power distribution cabinets, including a workbench 1, a mounting frame 2 is fixed in the middle of the top surface of the workbench 1 by screws, and the inner walls on both sides of the mounting frame 2 are rotatably connected with mounting columns-3 through rolling bearings , one end of the mounting column-3 is fixed with a mounting plate-4, and the upper and lower sides of the mounting plate-4 are away from the mounting column-3. The output end of the telescopic rod-5 is fixedly connected with an adsorption plate-6 through screws, and the other end of the adsorption plate-6 is fixed with an electromagnetic block-7 inside, and one side of the installation frame 2 is also fixedly connected with a horizontal frame-8 through screws, and the horizontal frame The top surface of -8 is fixedly connected with servo motor-9 by screws, the output end of servo motor-9 is fixedly c...

Embodiment 2

[0035] Such as figure 1 with 7 As shown, the present embodiment is basically the same as Embodiment 1. Preferably, a circular hole 27 is provided at the rotating connection between the mounting column 3 and the mounting plate 4 and the mounting column 20 and the mounting plate 21, and the circular hole 27 The inner wall is provided with a cylindrical groove 28, and the inner wall of the cylindrical groove 28 is slidably connected with a block 29, and an extruding spring 30 is fixedly connected between the block 29 and the bottom surface of the cylindrical groove 28, and the outer wall of the first mounting column 3 and the second 20 of the mounting column is also opened. There are draw-in slots, and the clamp blocks 29 are placed in the draw-in slots. The cylindrical slots 28 and the draw-in slots are all provided with four and evenly distributed on the inner wall of the circular hole 27 and the outer wall of the second mounting column 20.

[0036] In this embodiment, the con...

Embodiment 3

[0038] Such as Figure 1-7 As shown, this embodiment is basically the same as Embodiment 1. Preferably, electric telescopic rod one 5, electromagnetic block one 7, servo motor one 9, cylinder 10, electromagnetic block two 12, servo motor two 16, electric telescopic rod two 22 The control terminals of the electromagnetic block three 24, the servo motor three 26, the servo motor four 33, and the electric telescopic rod three 37 are all electrically connected with the controller, and the model of the controller is MAM-320.

[0039] In this embodiment, all the driving components in the device are electrically connected to the controller, so as to realize convenient control of the driving components, and further make the device run more stably.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com