Patents

Literature

33results about How to "Easy to cause blockage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

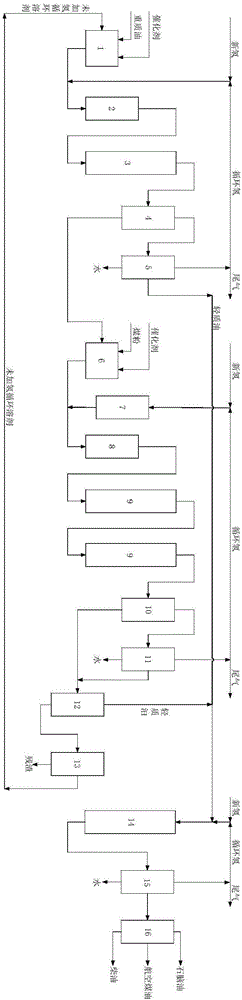

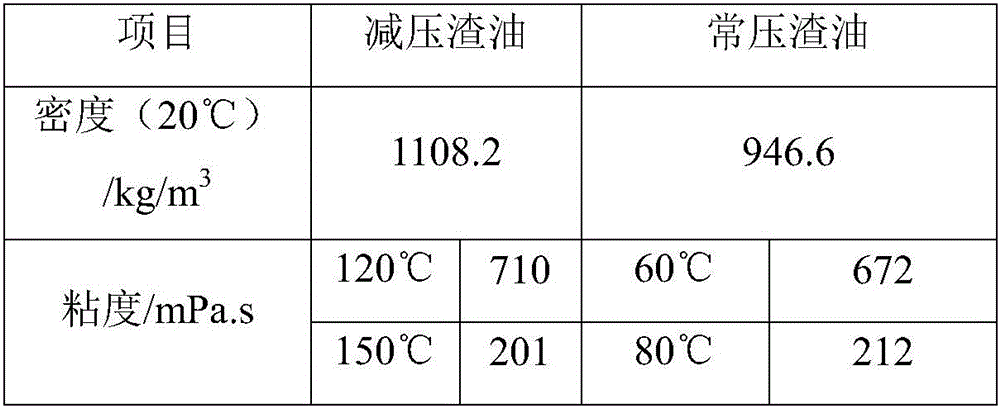

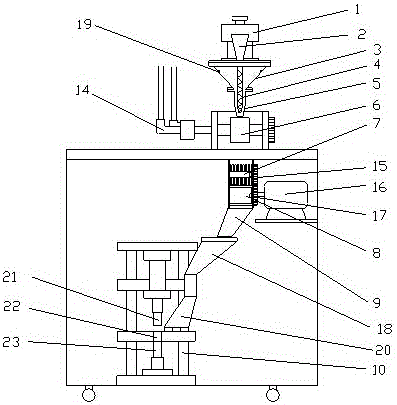

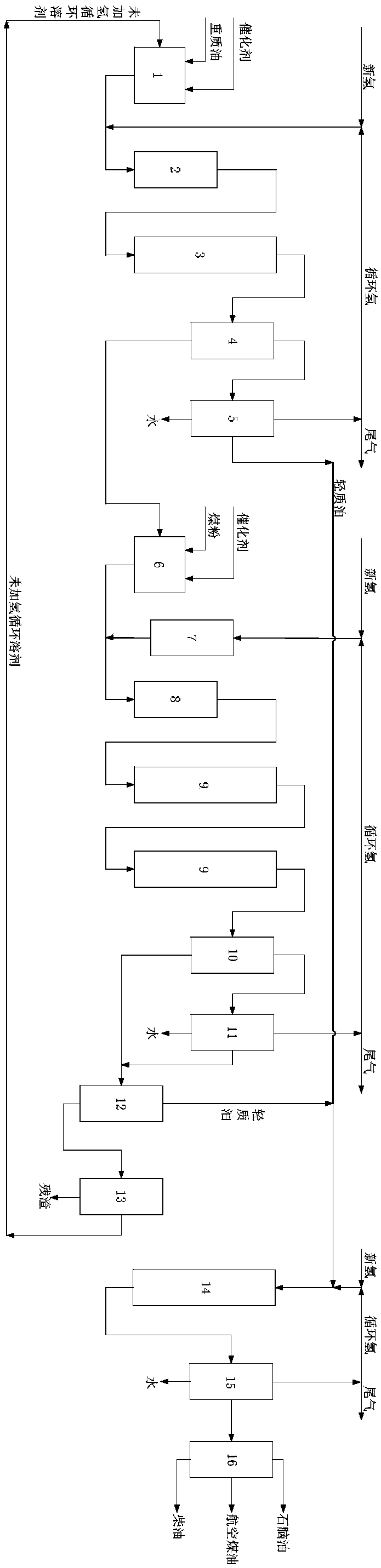

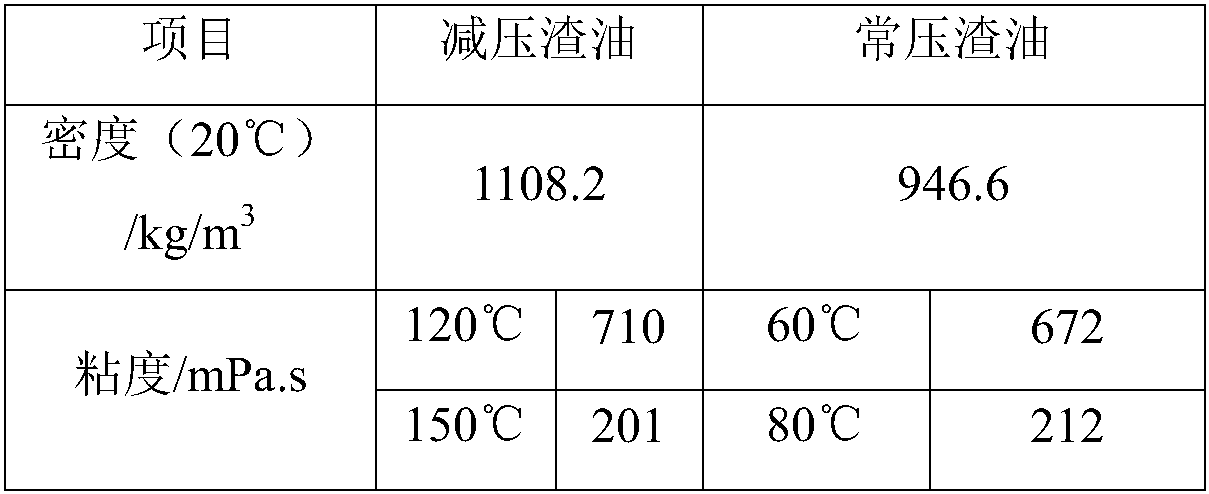

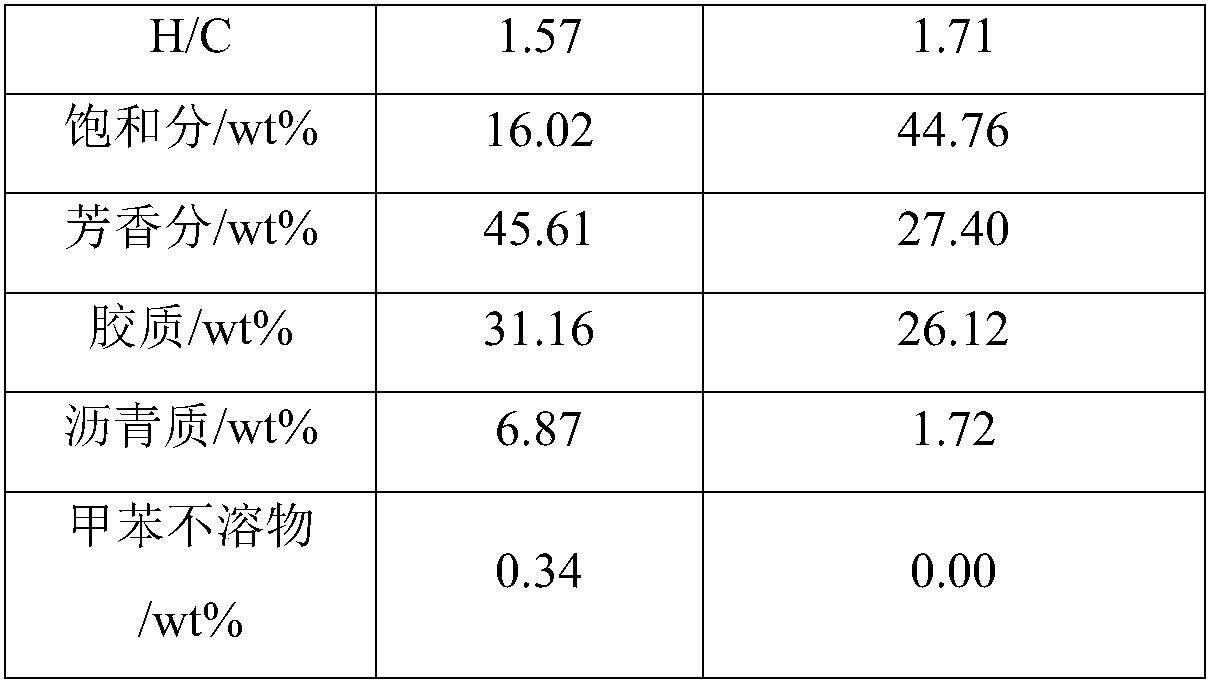

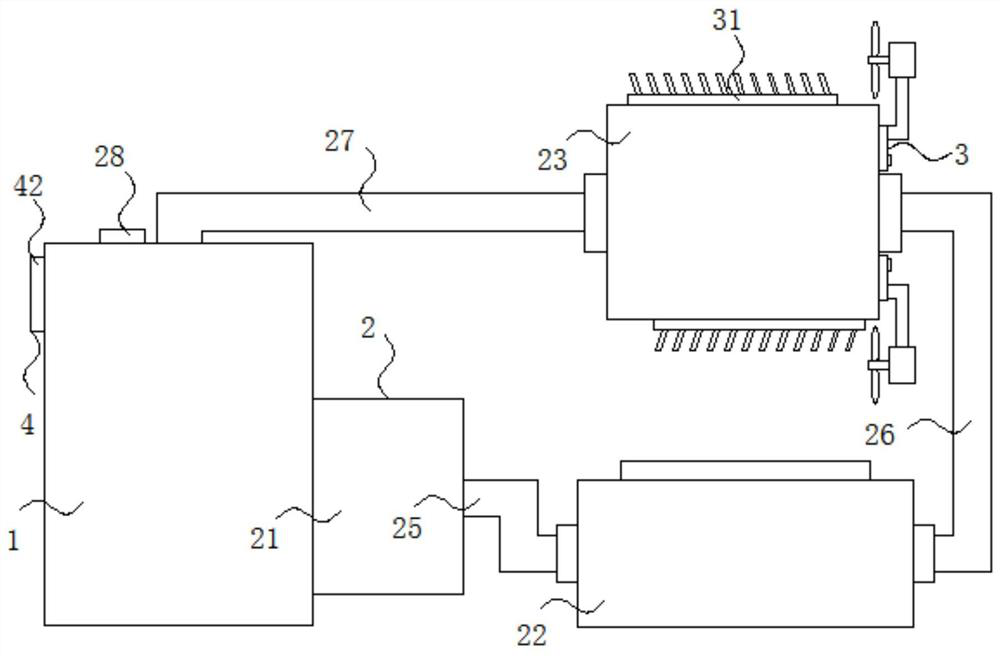

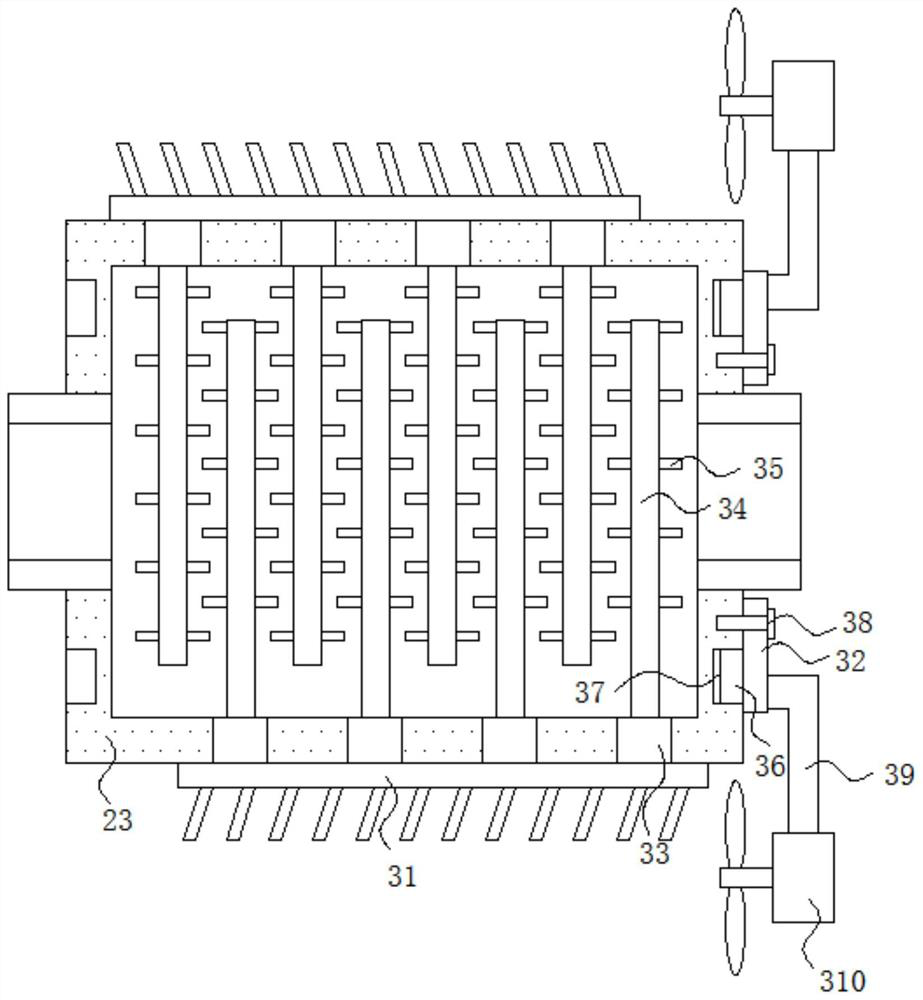

Coal and oil coprocessing method and device

ActiveCN106433775ALow viscosityImprove protectionTreatment with hydrotreatment processesSlurrySolvent

The invention relates to a coal and oil coprocessing method and device. The coprocessing method comprises steps as follows: step one, oil slurry pretreatment: heavy oil, a non-hydrogenated cycling solvent and a first catalyst are mixed, oil slurry is prepared and subjected to first hydrocracking reaction, a first product is obtained and separated, and first light distillate oil and first heavy distillate oil are obtained; step two, coal and oil coprocessing, solvent oil circulation and finished product separation. The coprocessing device comprises an oil slurry pretreatment device, a coal and oil coprocessing device body, a solvent oil circulating device and an oil product quality improving device. According to the coal and oil coprocessing method and device, selectivity for the heavy oil during coal and oil coprocessing is reduced, the percentage amount of pulverized coal in a coal and oil coprocessing process is increased, and the coal and oil coprocessing method and device are more suitable for practical application.

Owner:CCTEG CHINA COAL RES INST

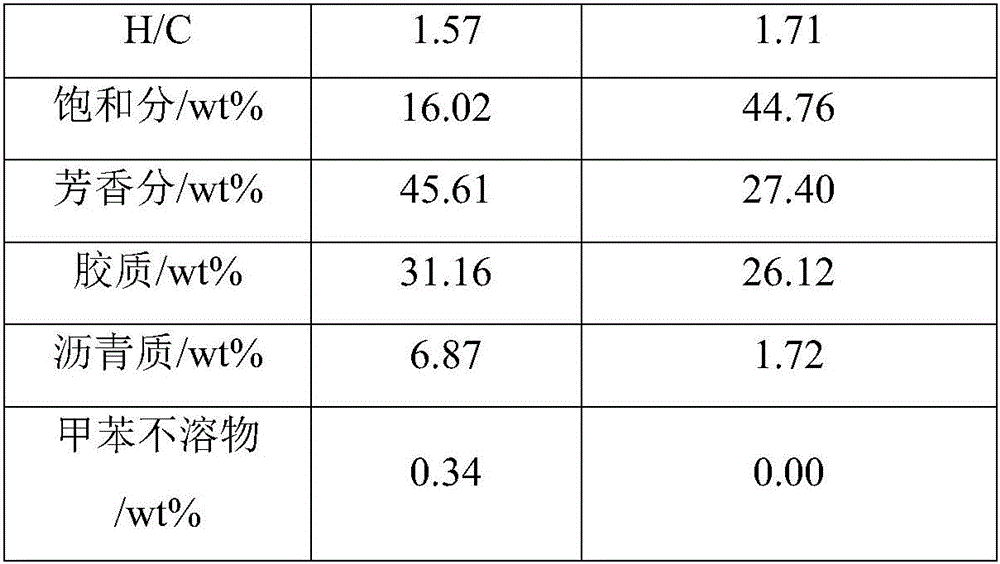

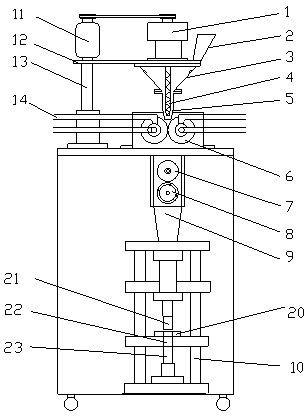

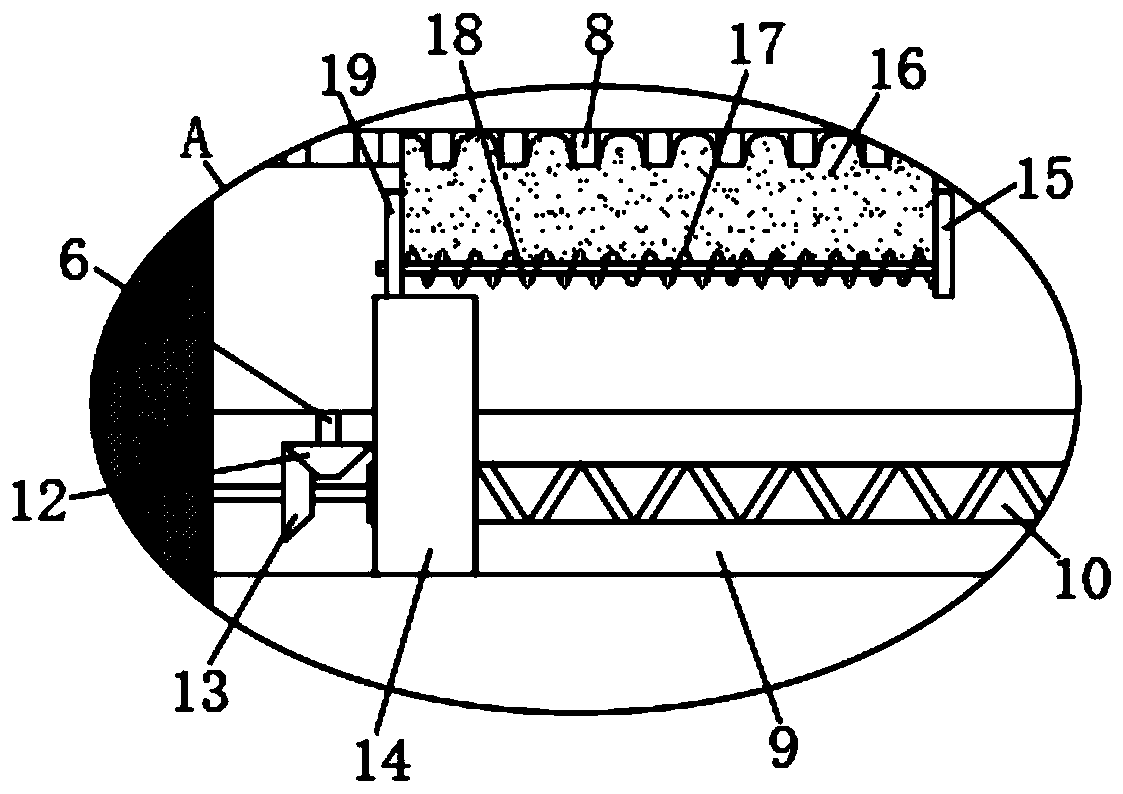

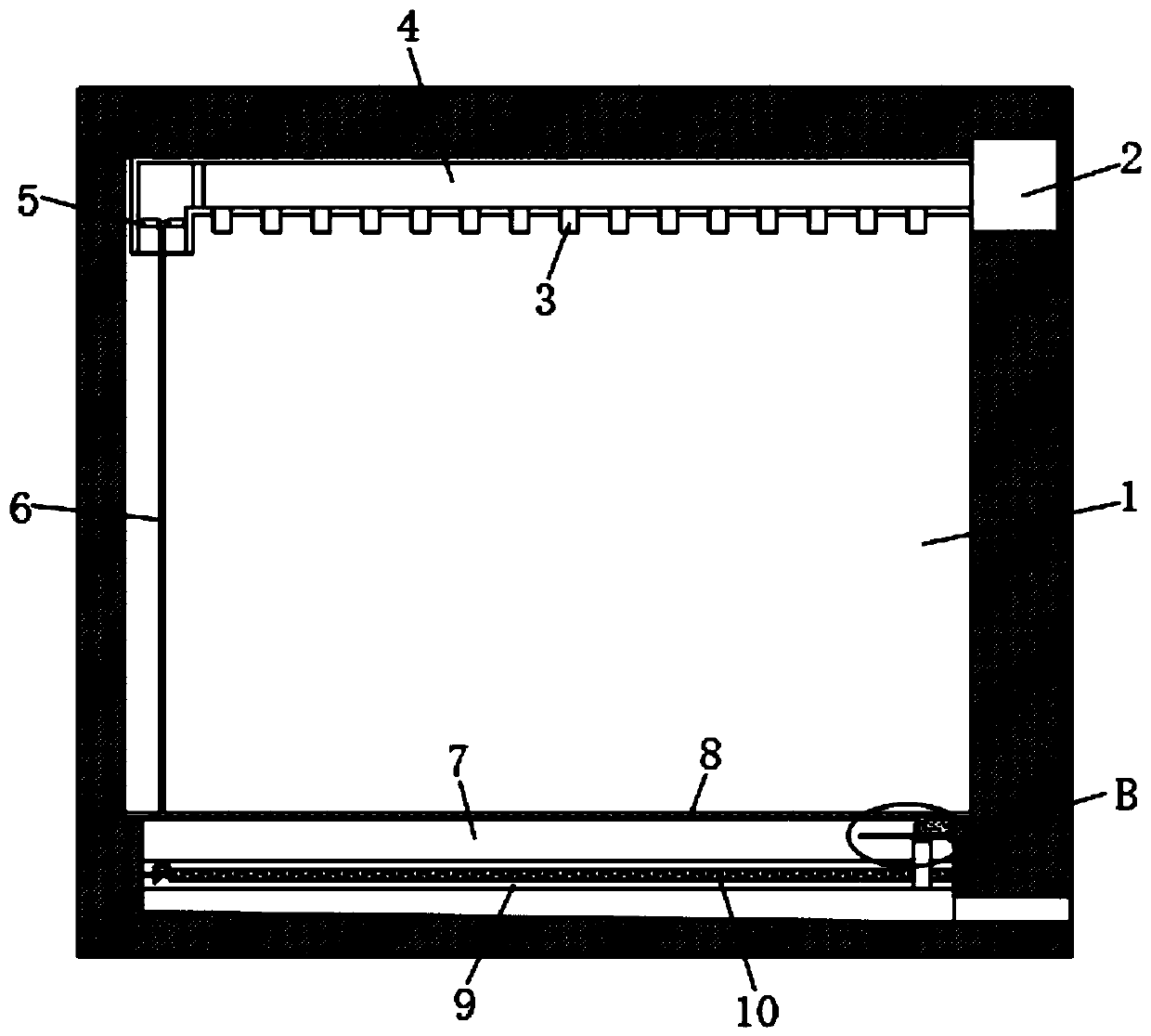

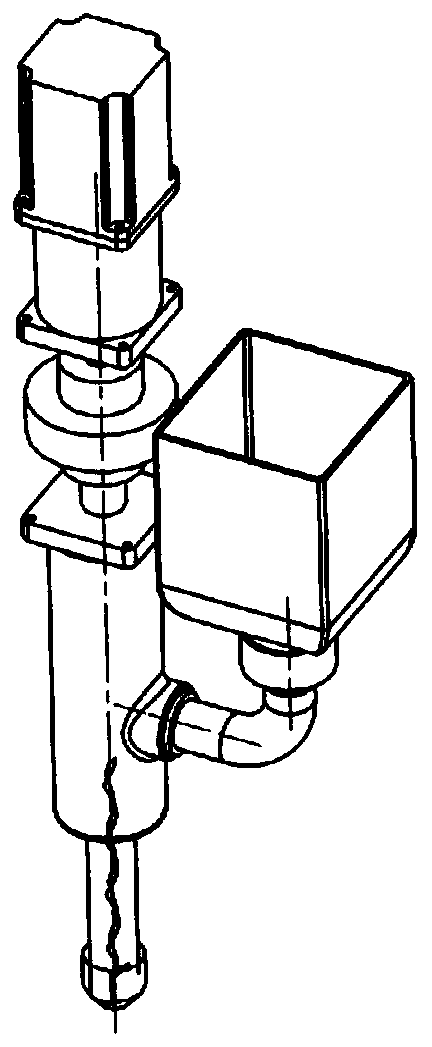

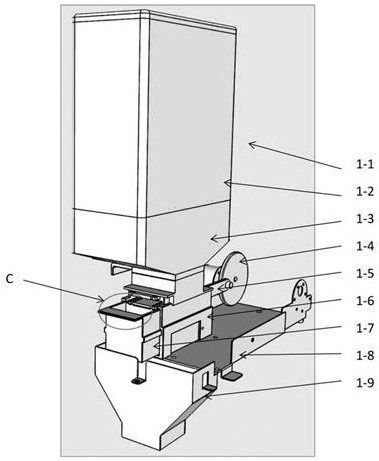

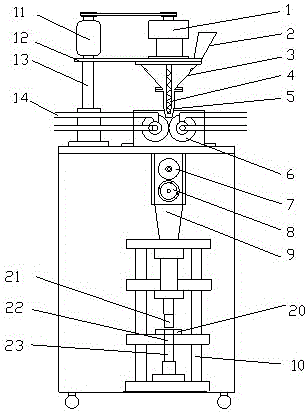

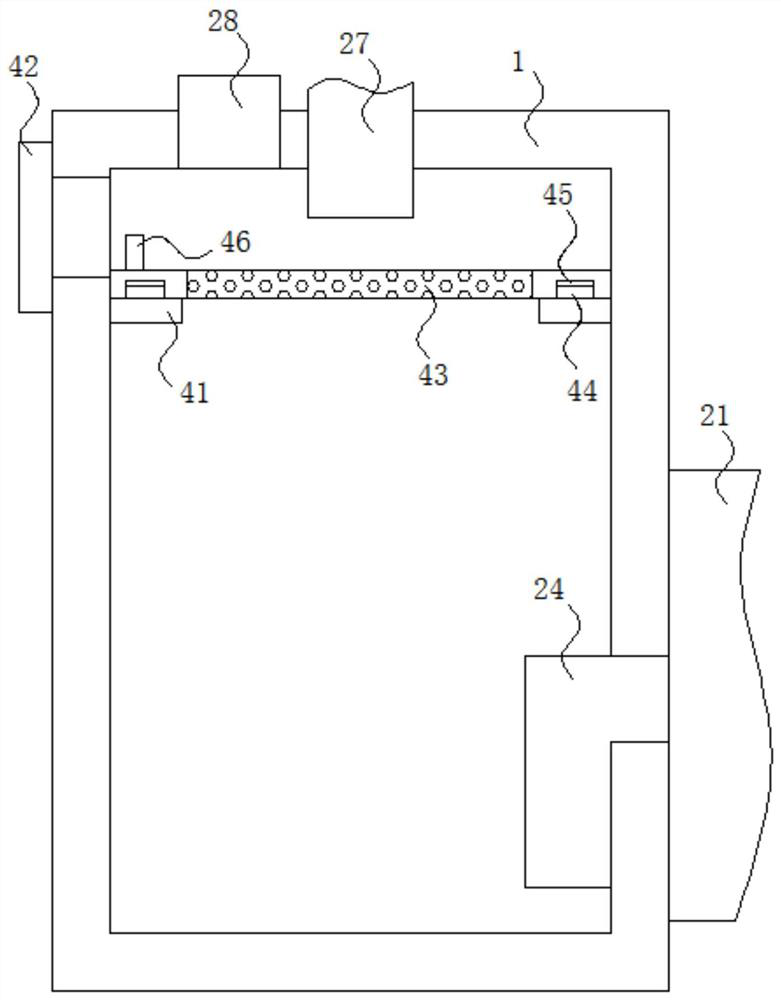

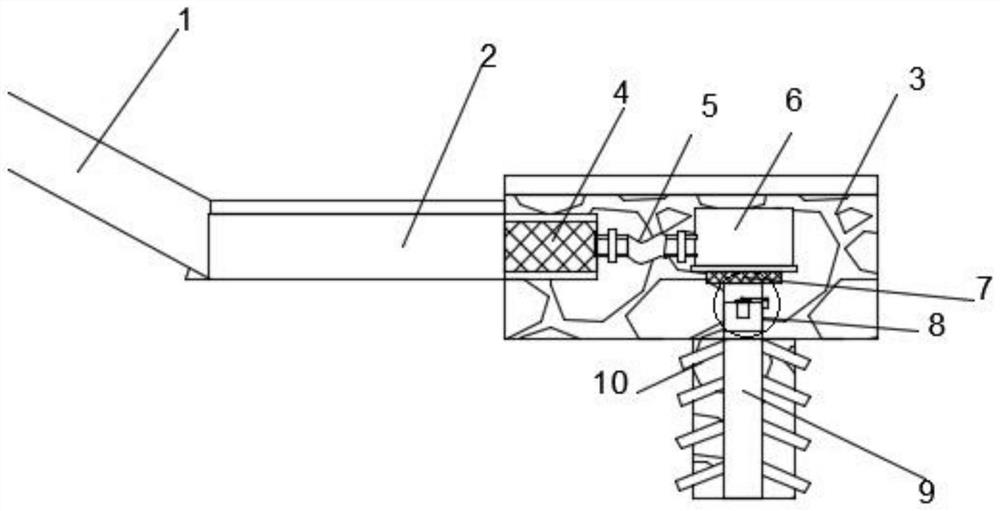

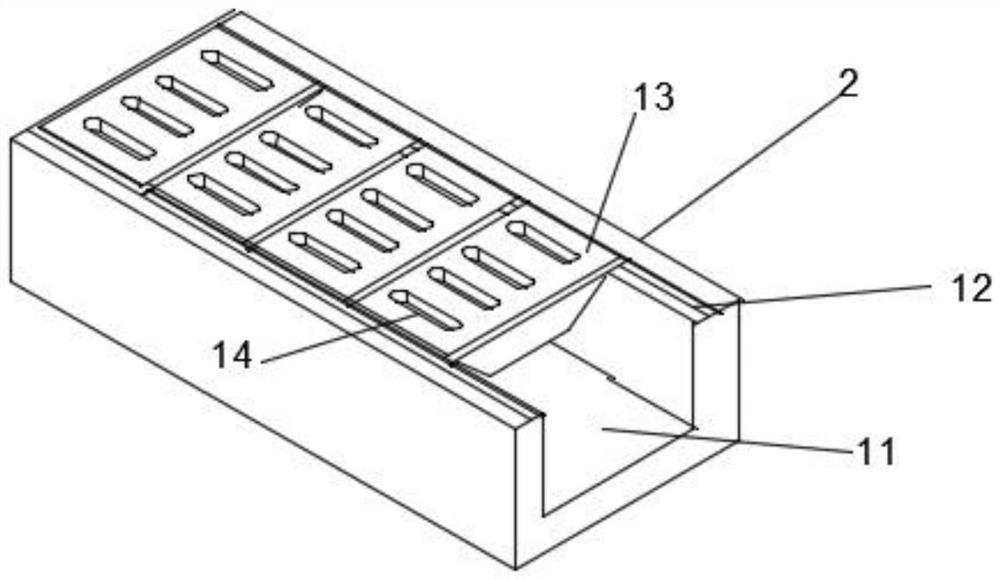

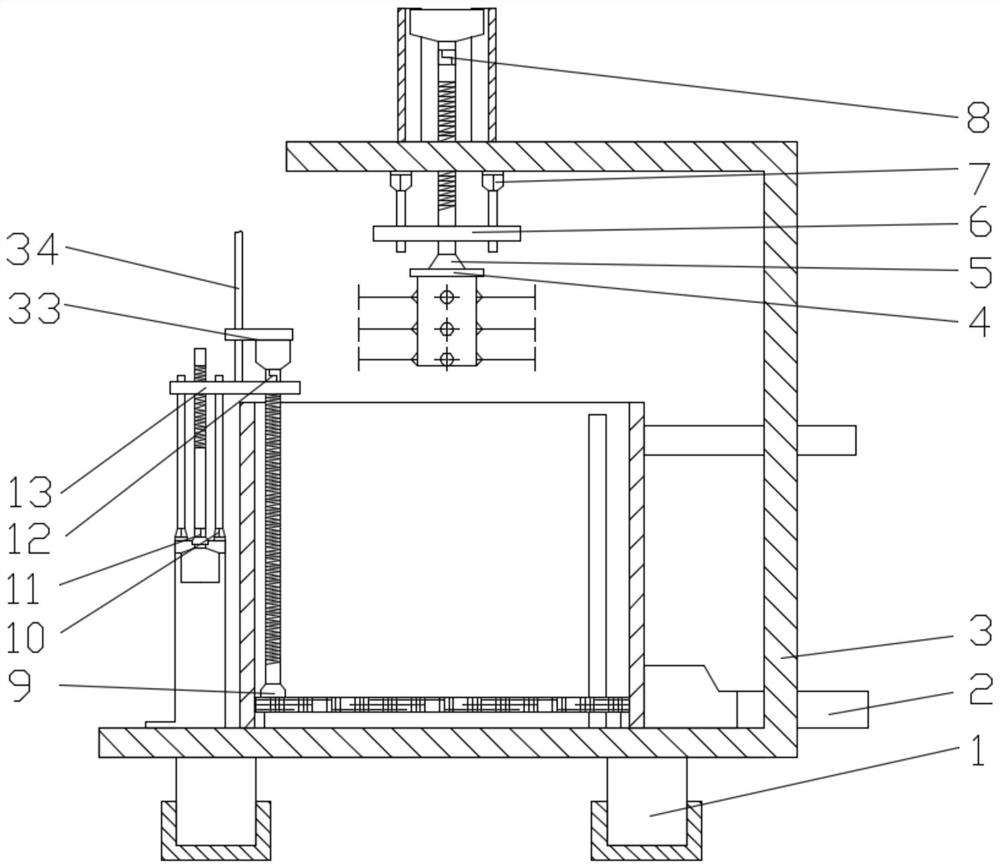

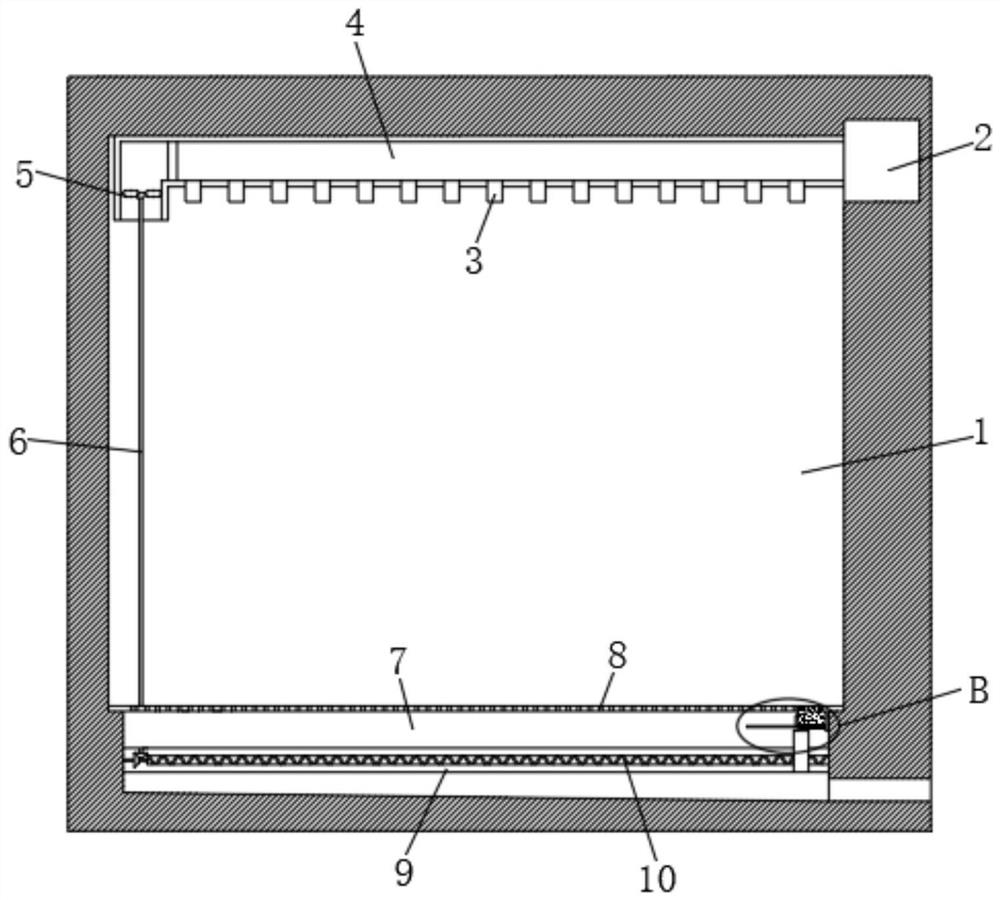

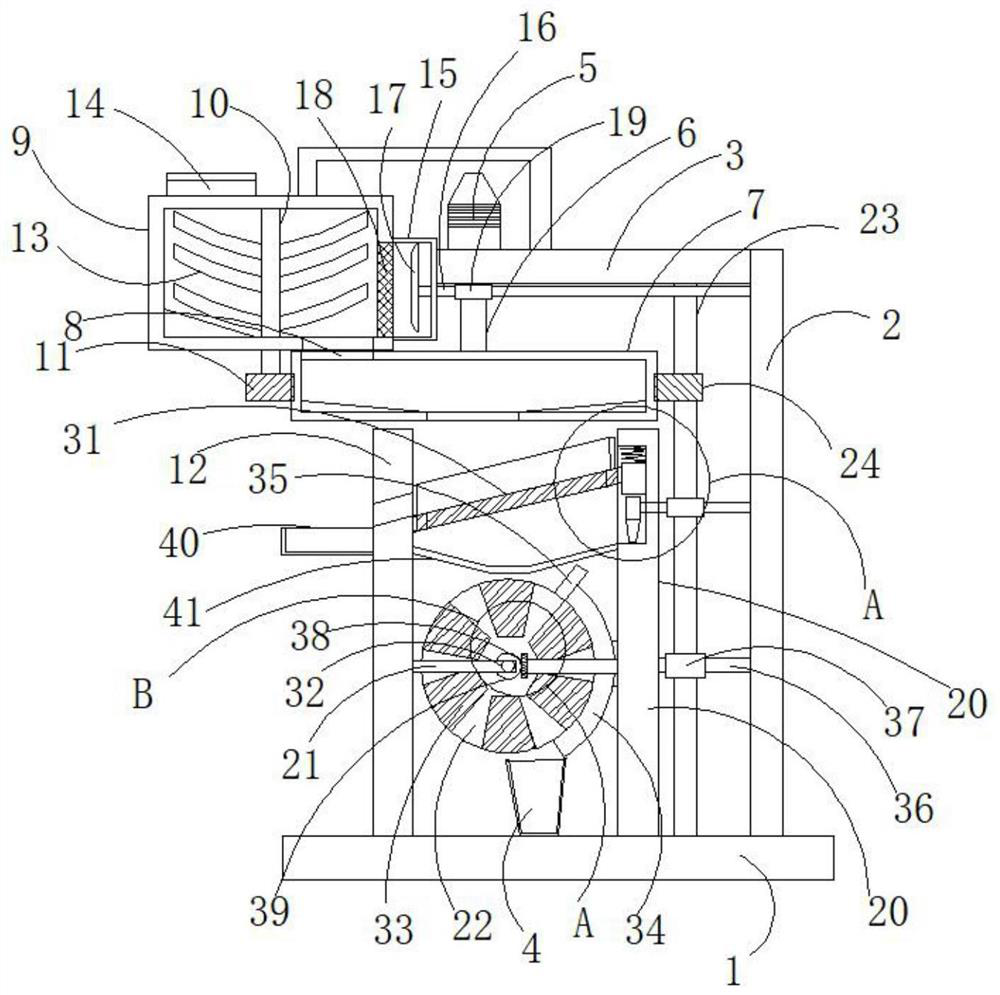

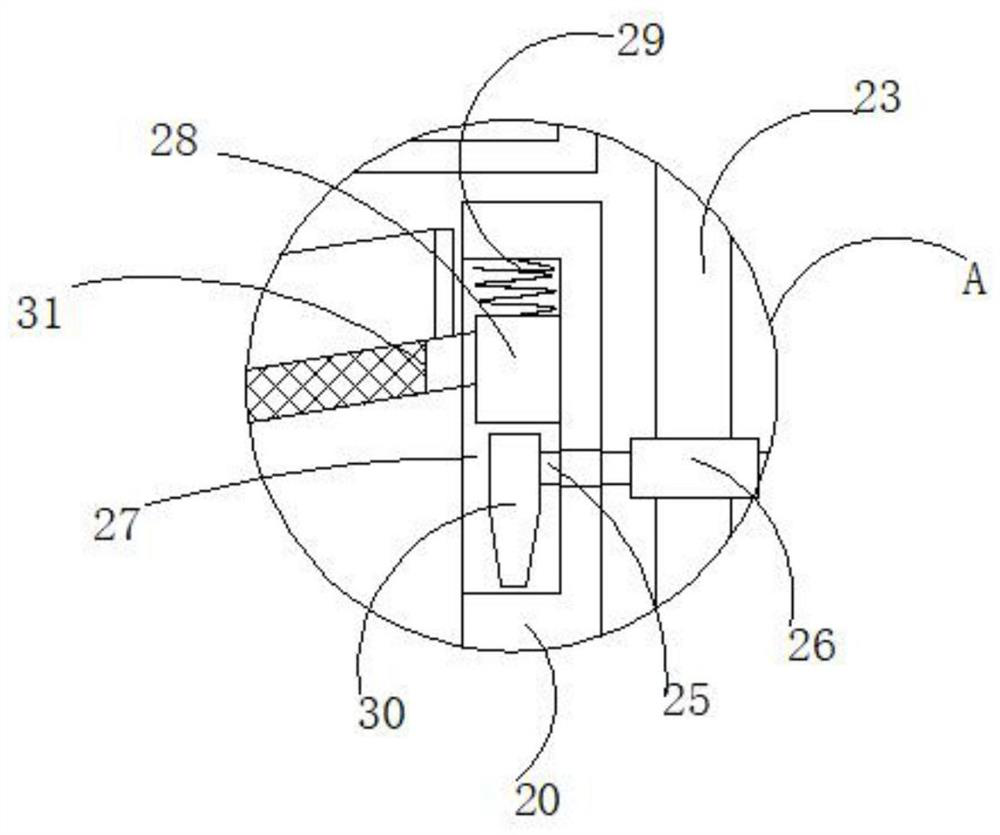

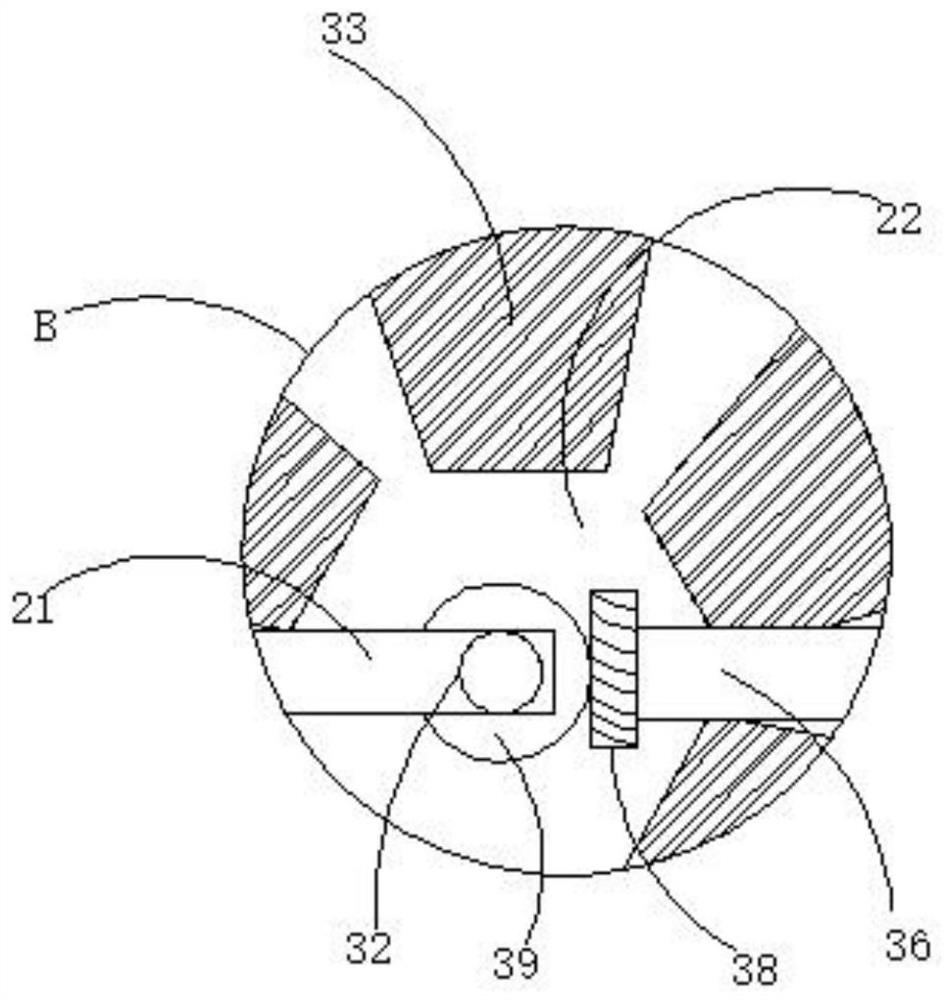

Material screening device

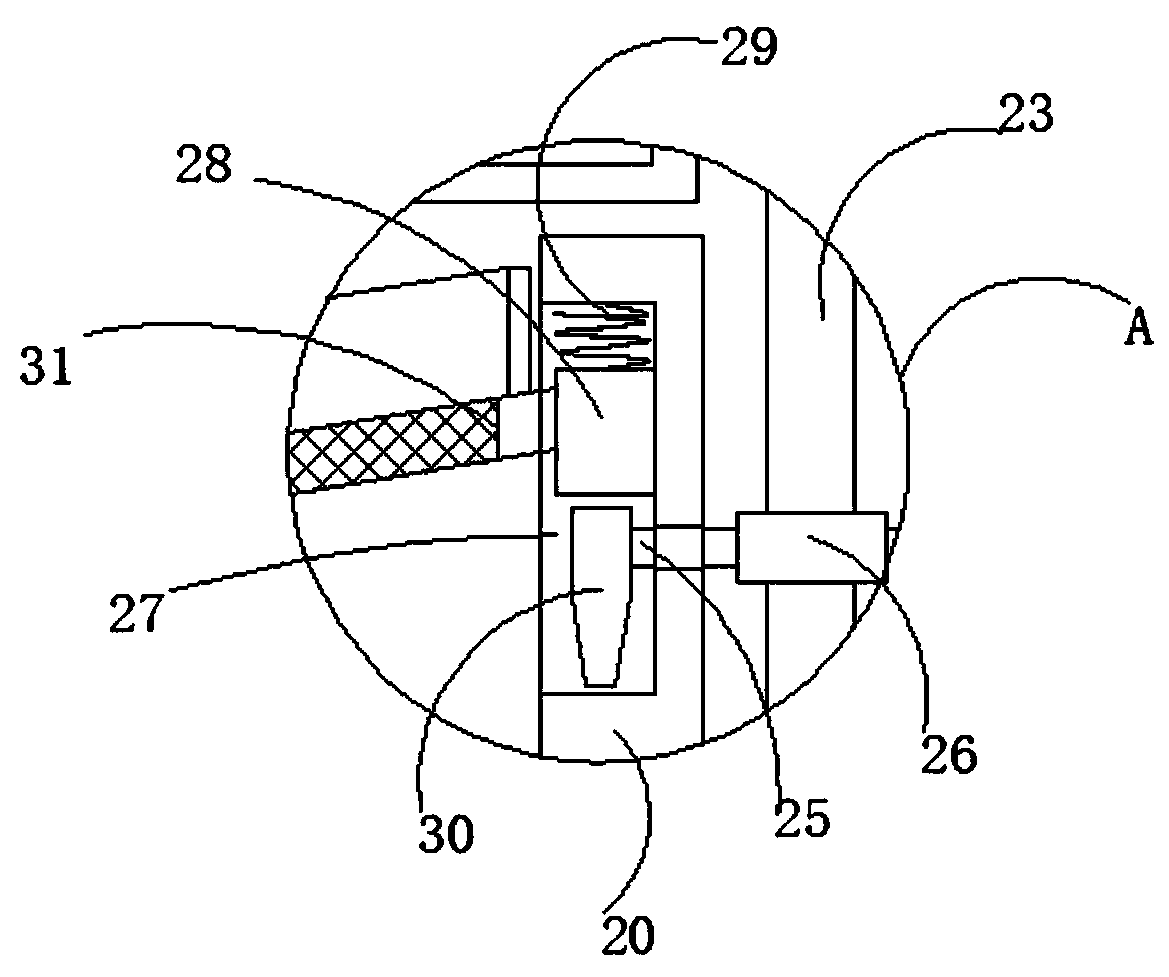

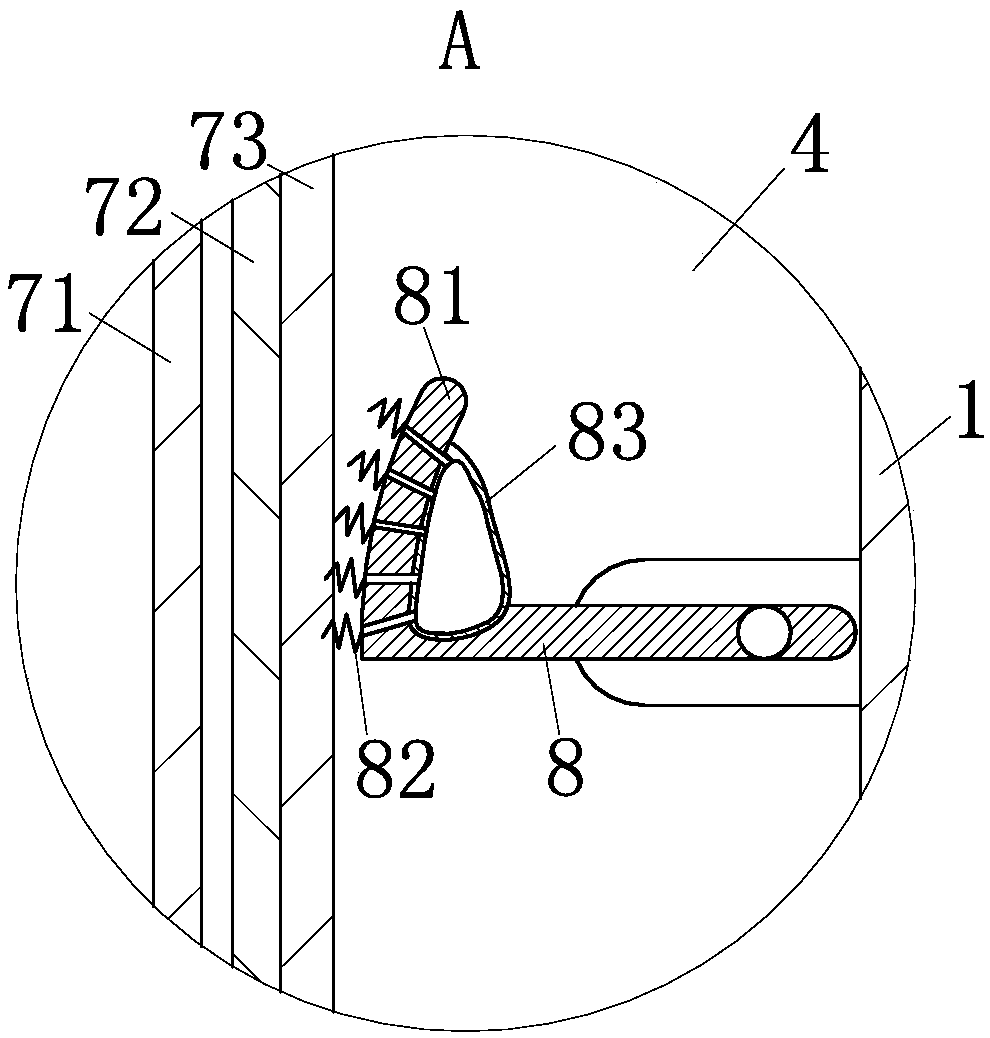

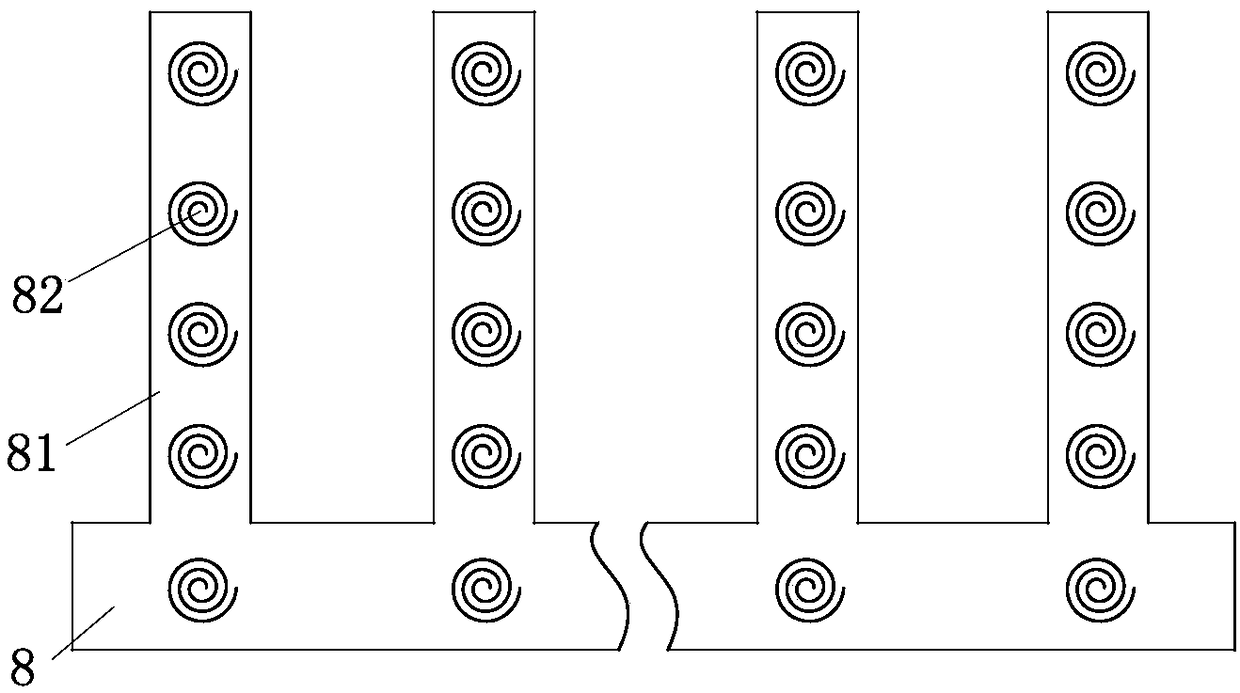

ActiveCN110918454AEasy to cause blockageImprove practicalitySievingDispersed particle filtrationElectric machineDust control

The invention discloses a material screening device. The material screening device comprises a first supporting plate, wherein a second supporting plate is fixed to one side of the top end of the first supporting plate, a third supporting plate is fixed to one end, away from the first supporting plate, of the second supporting plate, the first supporting plate and the third supporting plate are arranged in parallel, a rotating motor is fixed to one side of the top end of the first supporting plate, and an output shaft of the rotating motor penetrates through the third supporting plate and thenis connected with a feeding box of a circular structure in a fixing mode. According to the device, the feeding box can be rotated, intermittent feeding is realized, the situation that feeding is toomuch at a time, so that blockage is easily caused is avoided, meanwhile, through a driving source, stirring and dust removal and intermittent feeding can be carried out, practicability is improved, materials can be subjected to vibrating screening for separated collection, the convenience is improved, the collected materials can fall into collection bags one by one for packing, the practicabilityis improved, various mechanical transmission is achieved through one driving source, and the equipment cost is low.

Owner:安徽省宣城市联通塑业有限责任公司

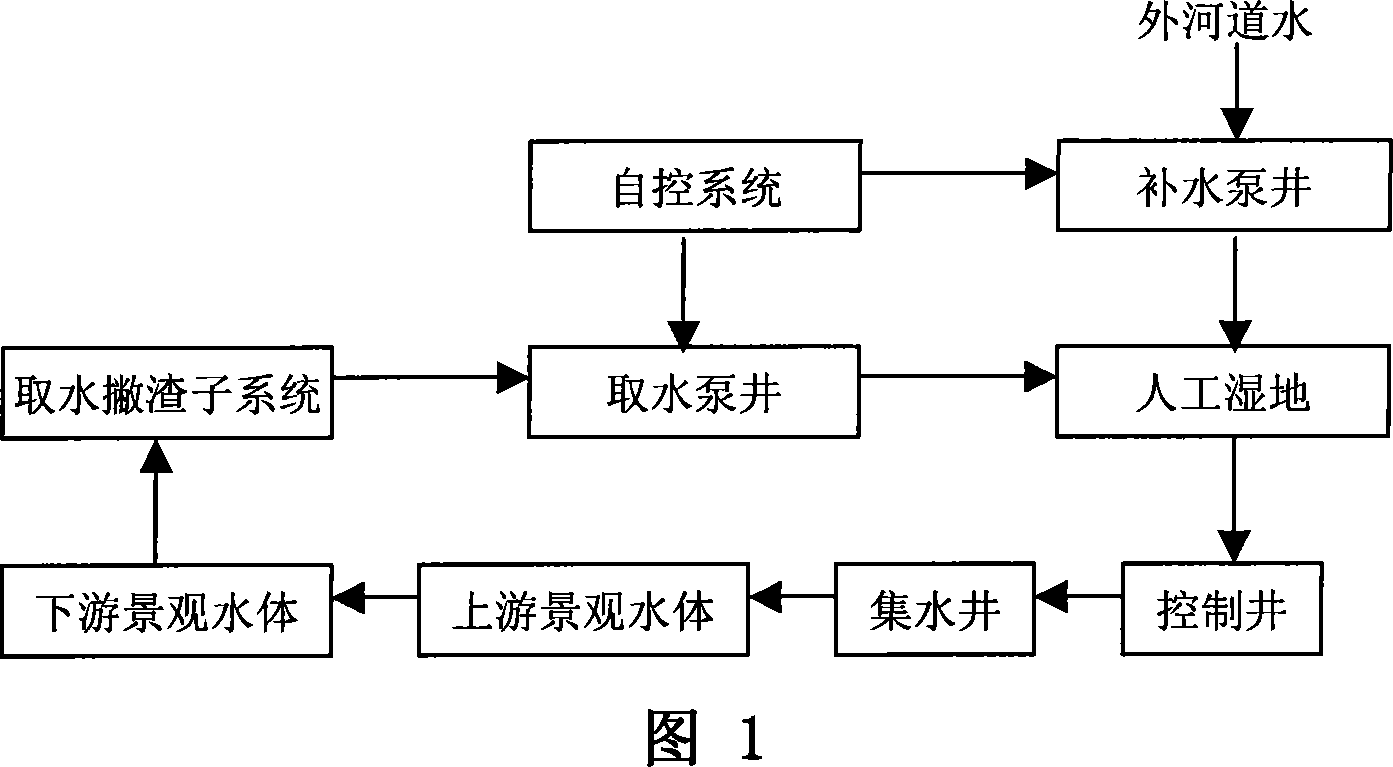

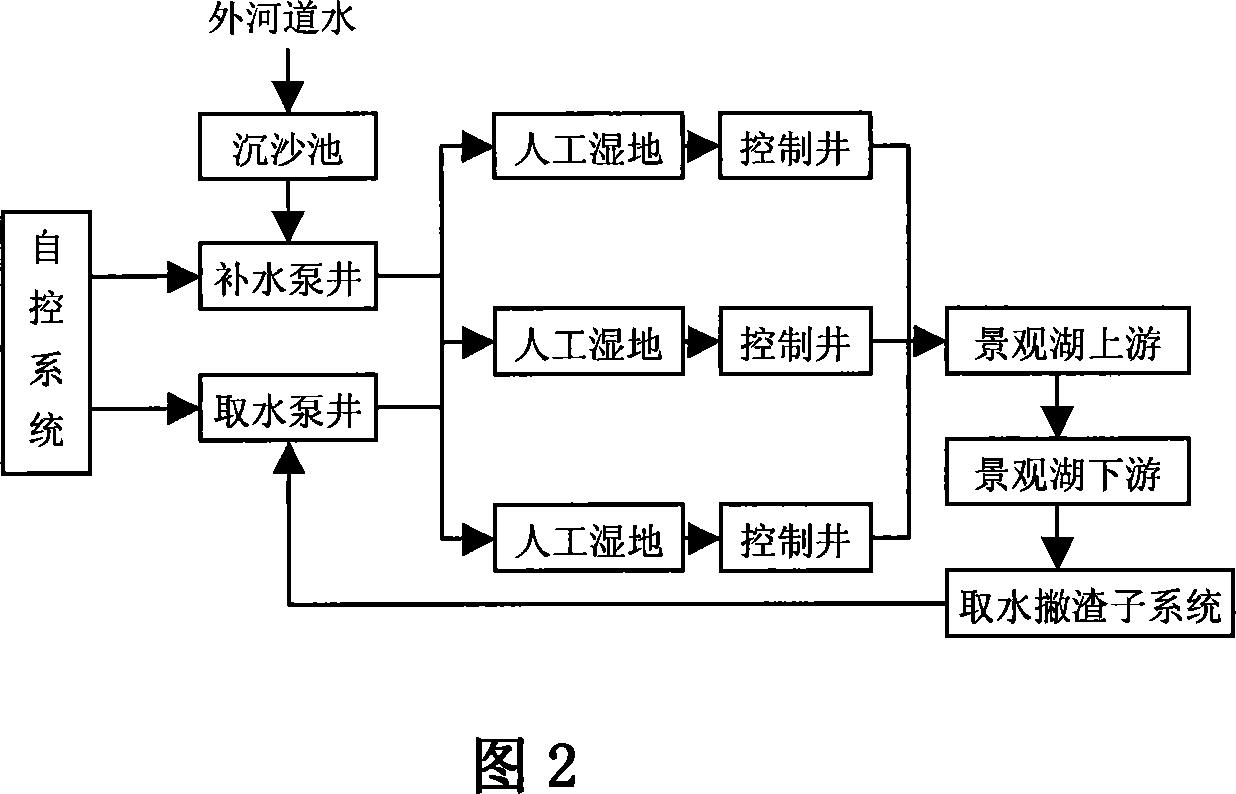

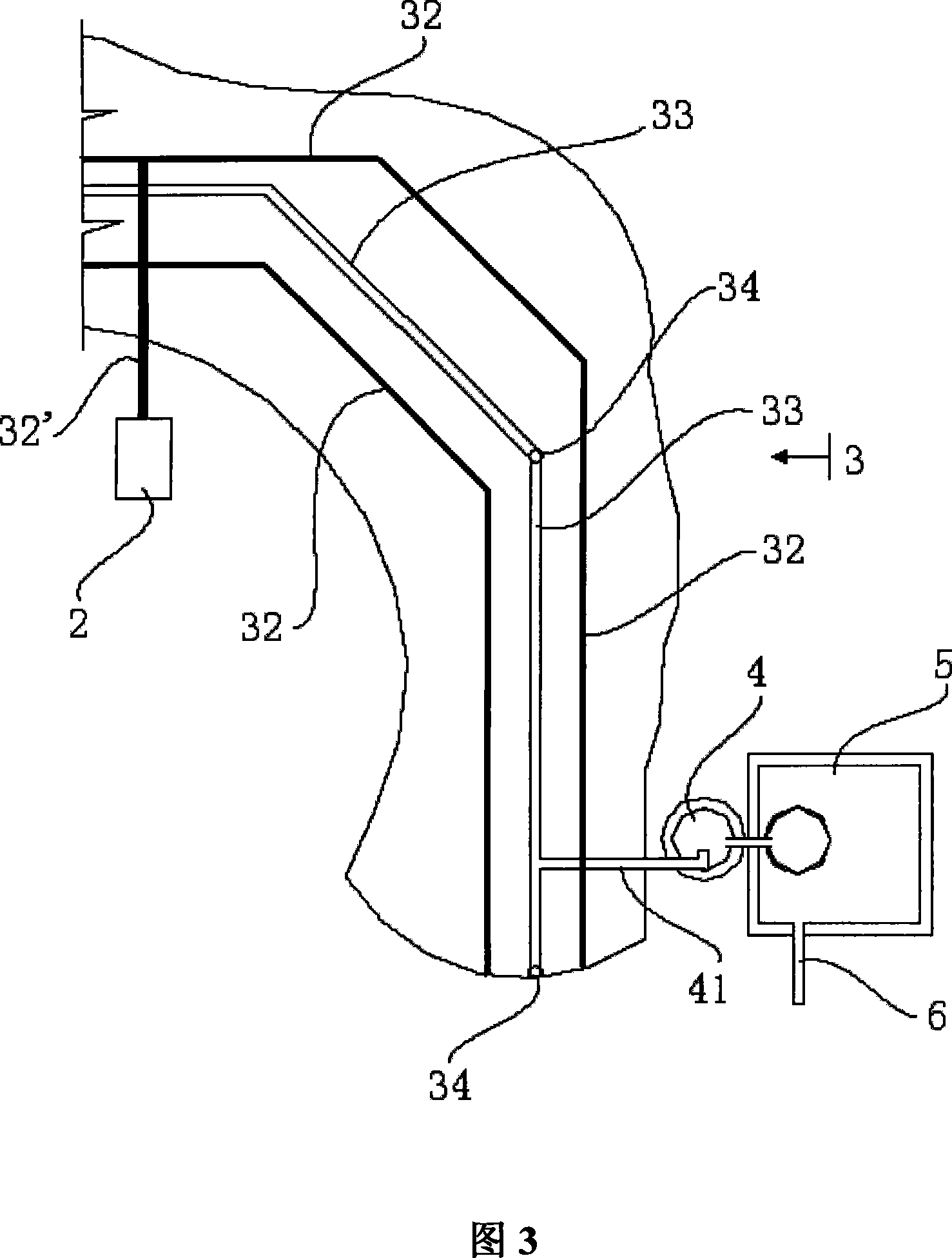

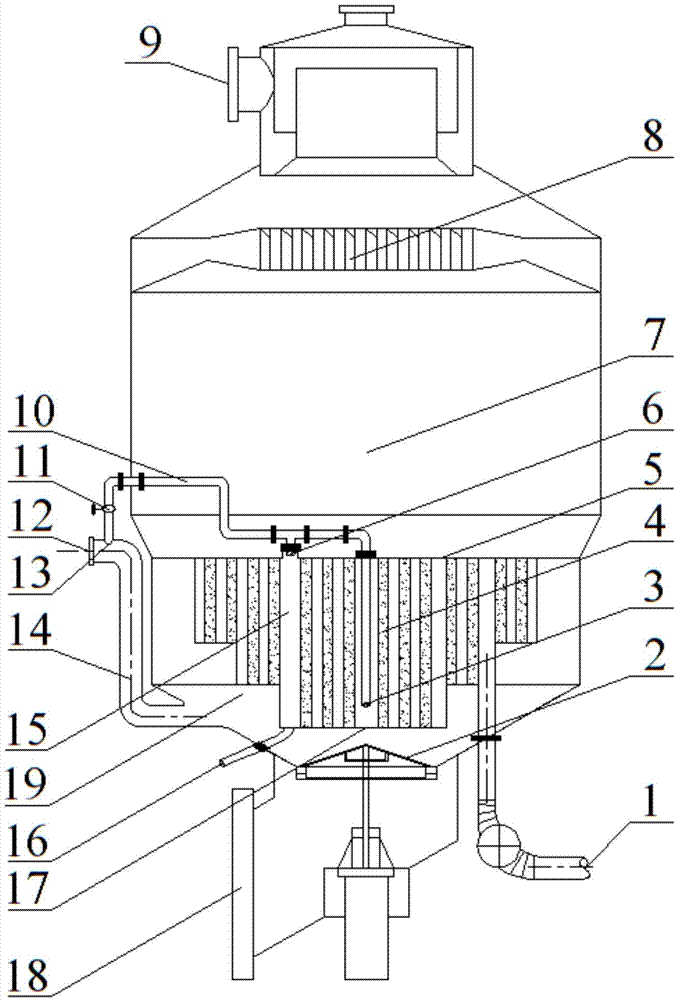

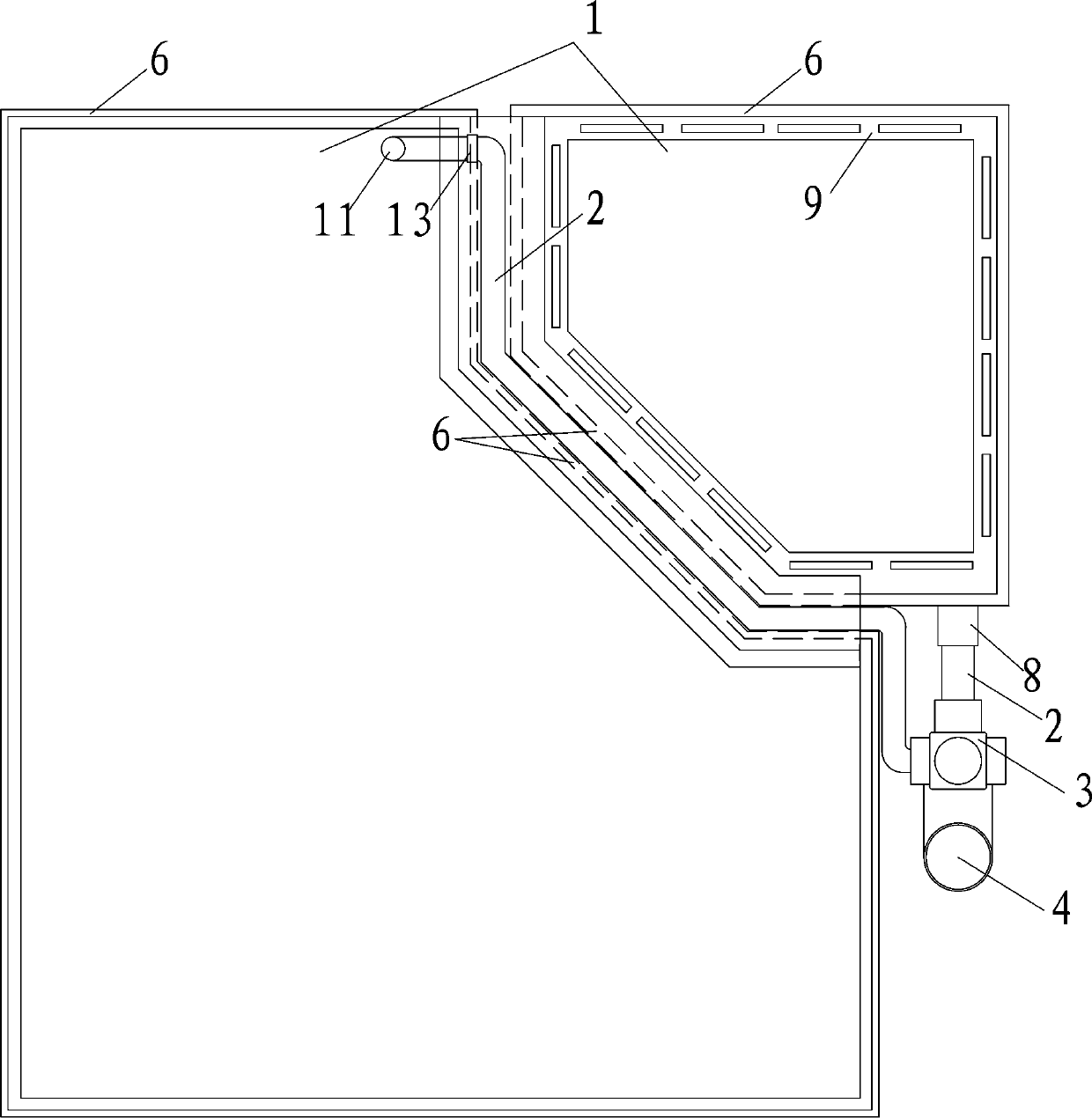

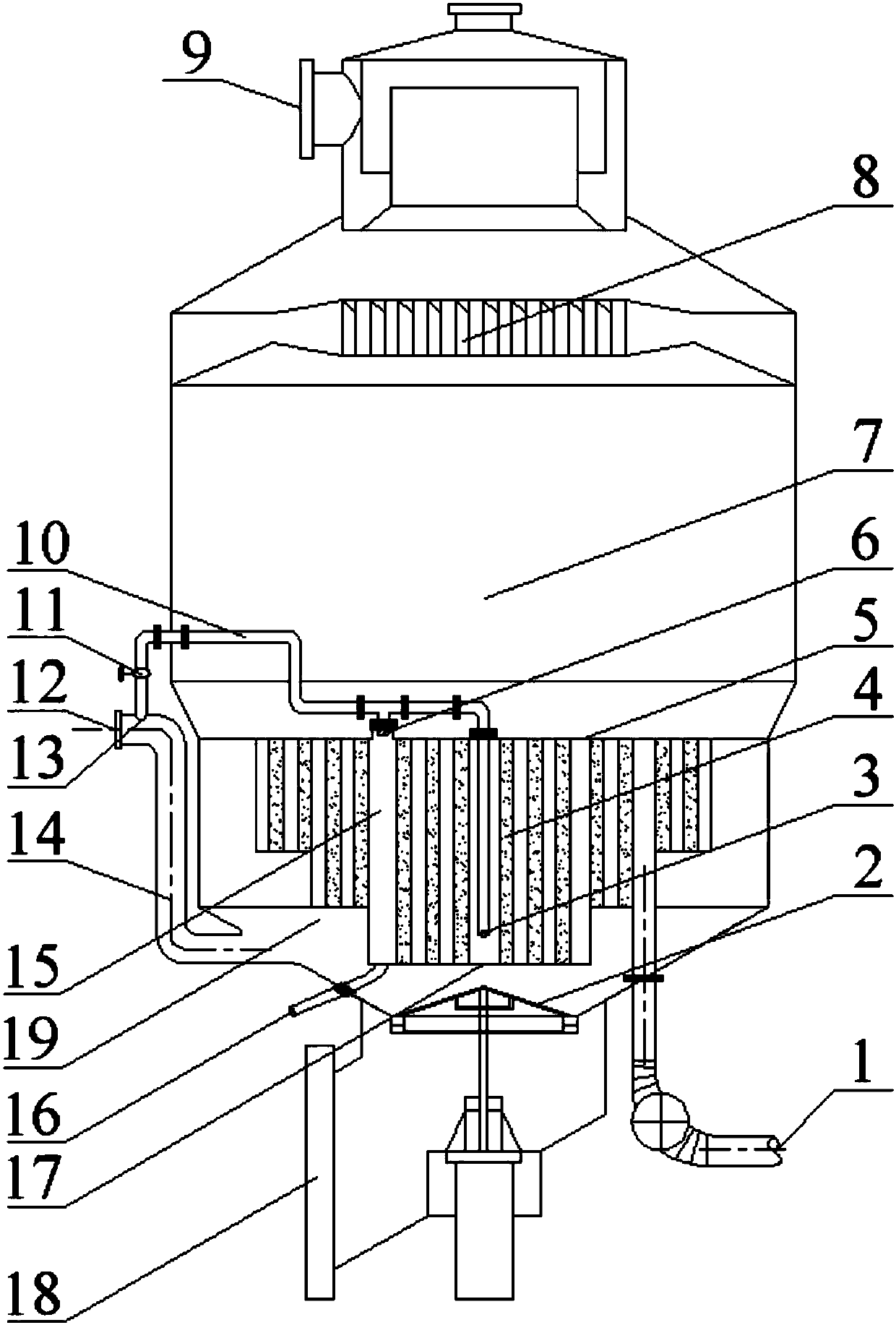

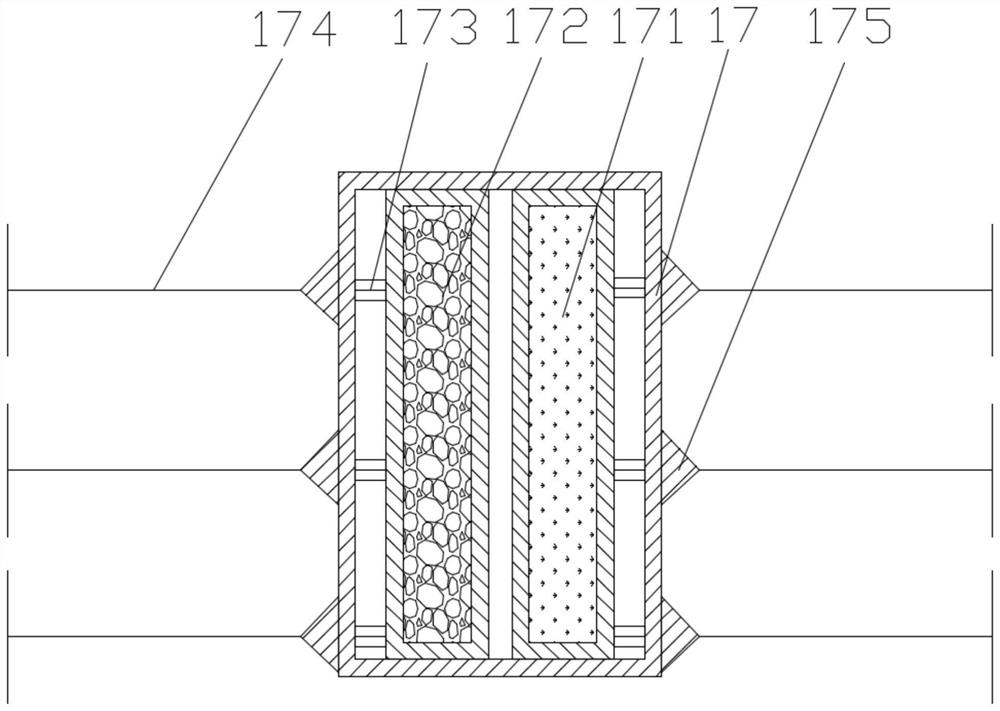

Landscape aquatic ecological purifying treating system and method for composite medium artificial wet land

ActiveCN101074134ALow costLess investmentSustainable biological treatmentBiological water/sewage treatmentConstructed wetlandMarsh

Landscape aqueous ecological purifying treatment system and method for composite medium artificial marsh are disclosed. The artificial marsh system consists of dregs filtering system, pump well, composite medium artificial marsh with artificial plant, medium purifying layer, lining, substrate, water collector and water distributor, controlling well and automatic controlling system. Downstream water passes to artificial marsh through water take-out system, lifting water pump and water distributor, landscape water feed is timing controlled by lifting water pump, water passes into landscape water upstream through water collector, controlling pipe, controlling well and water well, which is micro-ecological environment with artificial marsh plant and medium purifying layer, and artificial marsh level is controlled by controlling pipe. It's cheap, has less consumption, excellent purifying effect and no secondary environmental pollution.

Owner:ZHOUSHAN DAREN ENVIRONMENTAL PROTECTION TECH

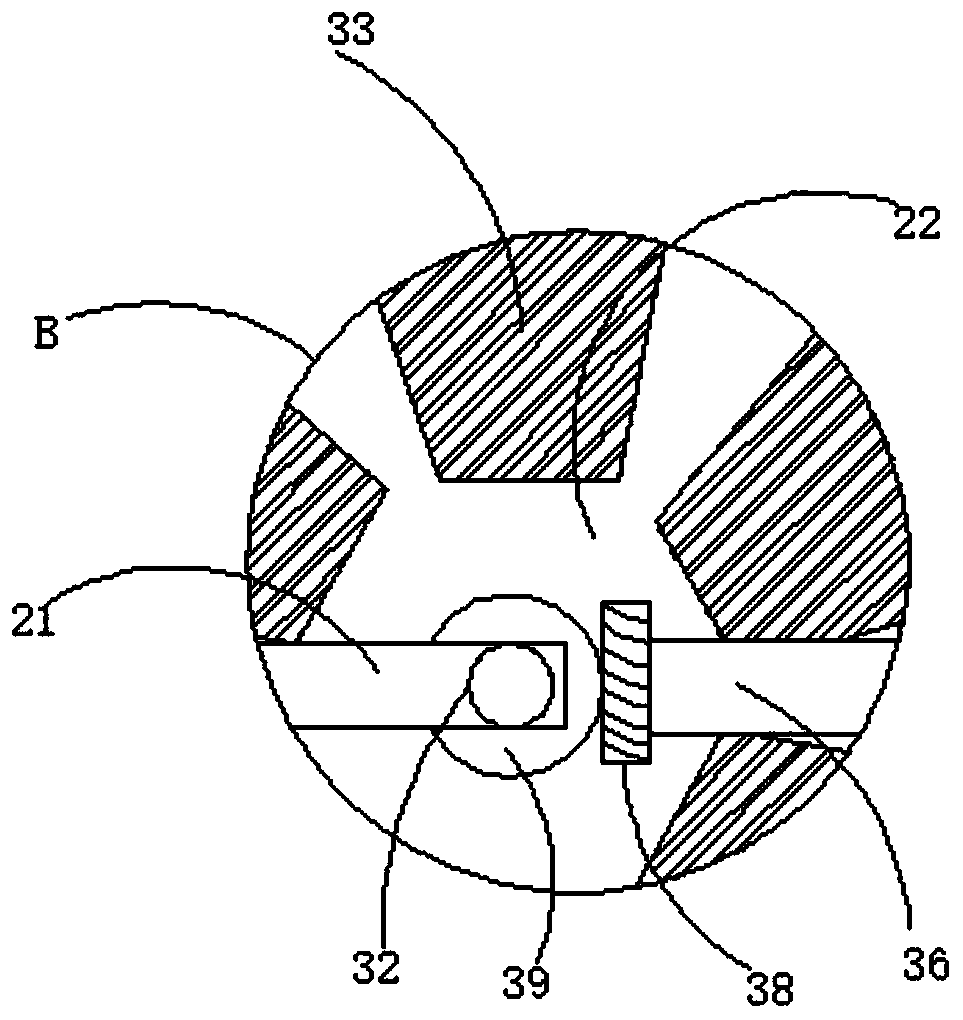

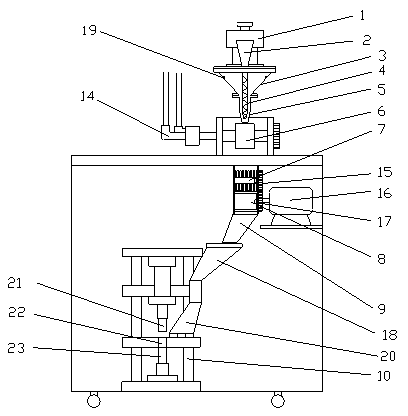

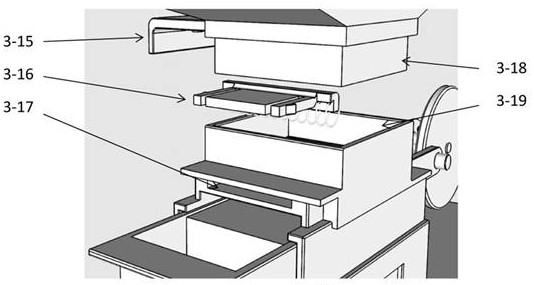

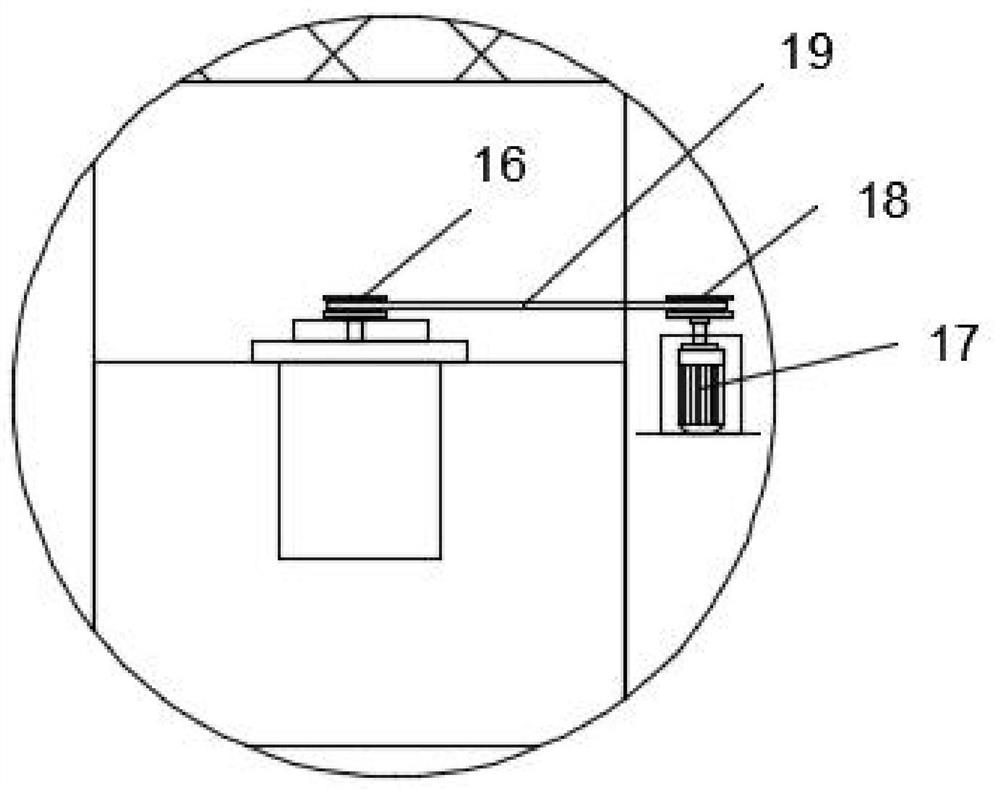

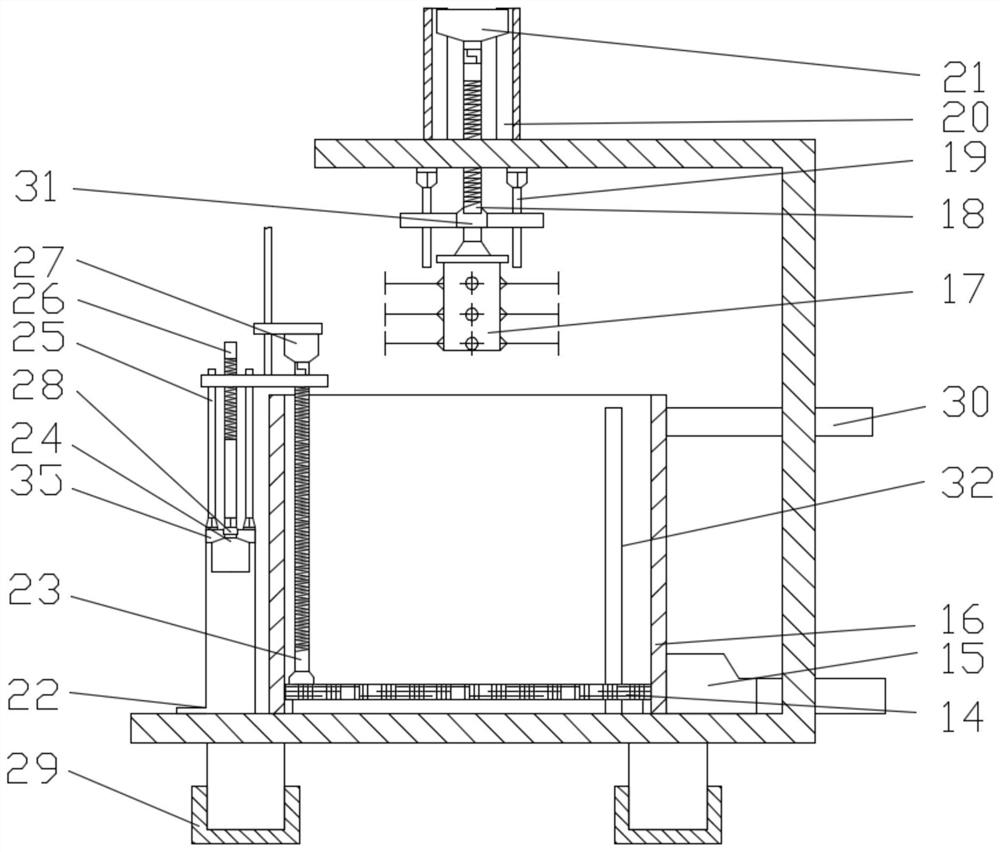

Pure powder granulation negotiable machine

ActiveCN104275822ARealize integrated productionIncrease productivityGrain treatmentsShaping pressEngineeringTableting

The invention provides a pure powder granulation negotiable machine and belongs to the field of medical instruments. The pure powder granulation negotiable machine comprises a feeding device, a roller pressing device, a granulating device and a negotiable device; the feeding device is located on the upper portion of the roller pressing device, and the granulating device is arranged between the roller pressing device and the negotiable device; the feeding device is provided with a feeding screw inside; the granulating device comprises a smashing mechanism and a granulating mechanism, and a discharging hopper is arranged below the granulating mechanism and is connected to the feeding port of the negotiable device. A radial blade and drum of the smashing mechanism are integrated as designed, a fixing bolt is arranged inside the drum, the end of the smashing mechanism is provided with the blade, the smashing dead corner is avoided, the integral production of granulating and negotiable is implemented, pure powder negotiable can be implemented, additives and water are omitted, and the producing efficiency can be improved effectively.

Owner:升生健康科技(苏州)有限公司

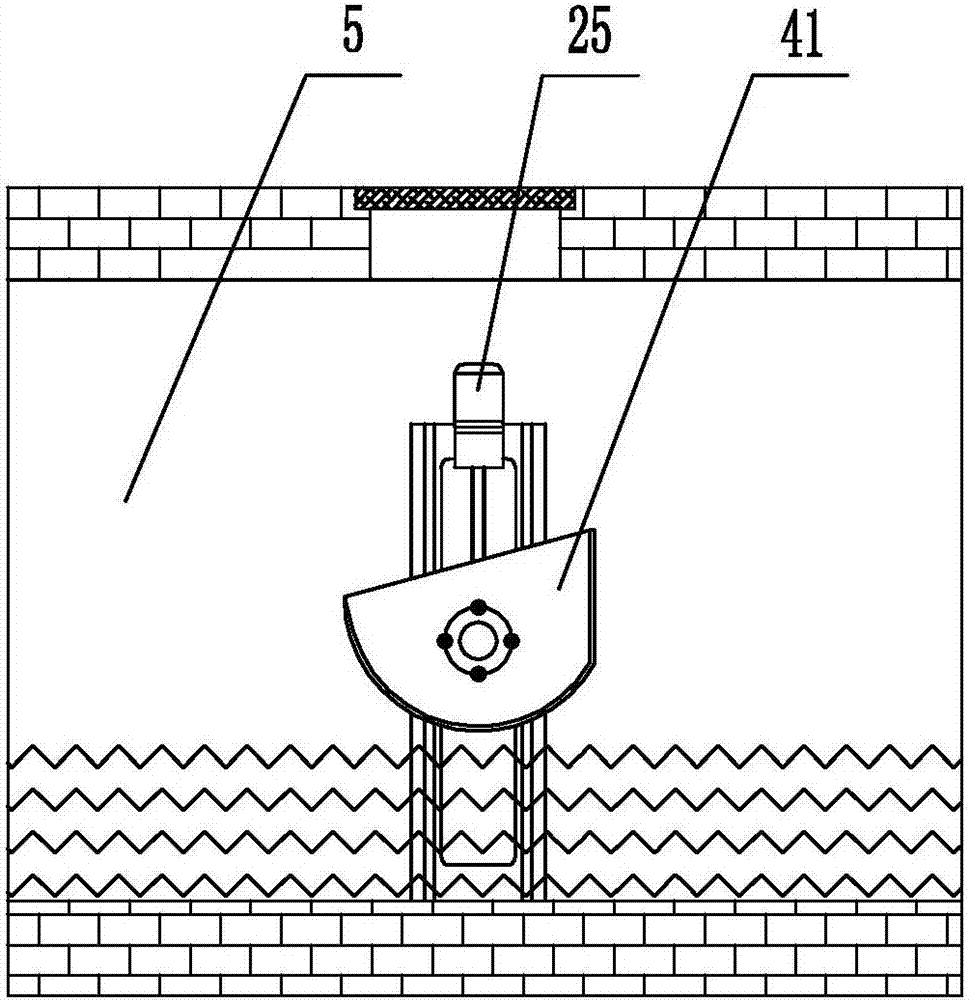

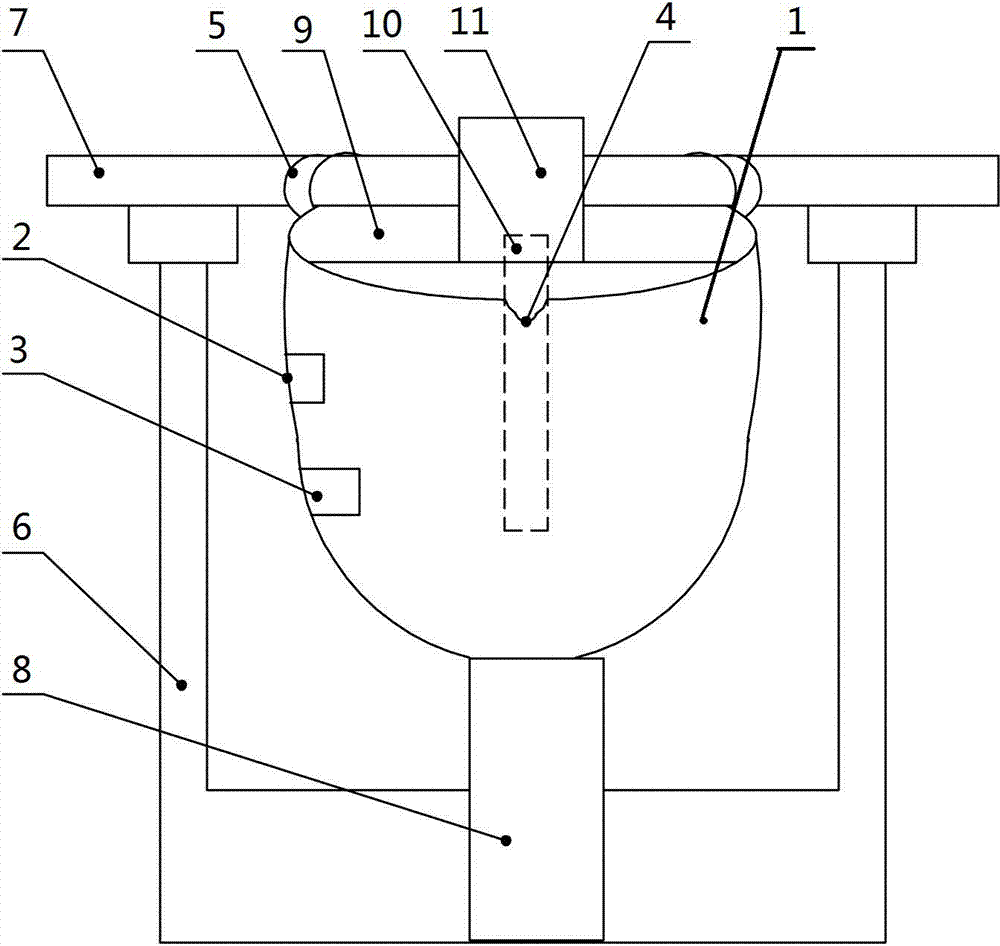

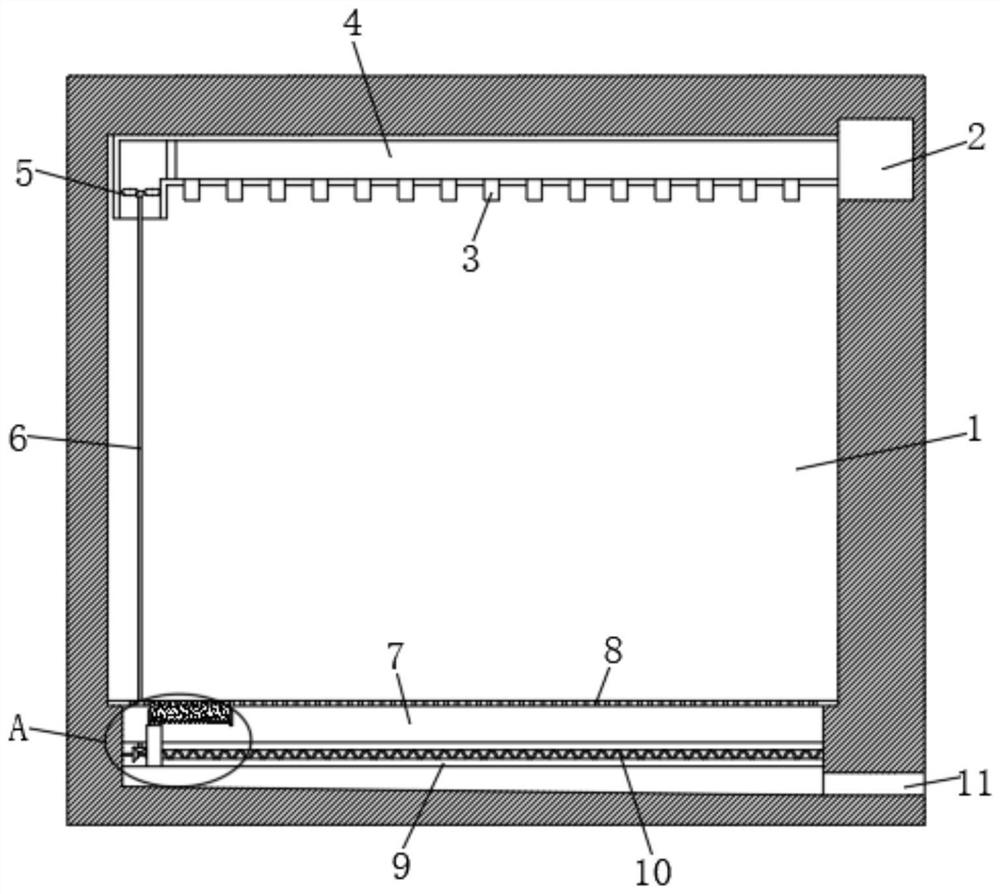

Automatic collecting device for rubbish in urban sewers

PendingCN106968325AReduce difficultyPlay a supporting roleFatty/oily/floating substances removal devicesSewerage structuresWorking environmentWaste collection

The invention relates to a collecting device for disposing rubbish accumulated in sewers in urban environmental sanitation, in particular to an automatic collecting device for rubbish in urban sewers. The automatic collecting device comprises a supporting device, a lifting device, a rotating device and a rubbish collecting device, wherein the supporting device is installed in a sewer, the lifting device is installed on the supporting device, and the rubbish collecting device is connected with the lifting device through the rotating device. The automatic collecting device has the advantages of intercepting and collecting all kinds of rubbish in a full-automatic mode and can relieve the problems that when environmental sanitation workers clean sewers, rubbish cleaning difficulty is high, rubbish searching blindness is high, rubbish collecting time is long, the area of manual rubbish intercepting and collecting is small, and the working environment is hostile, so that the automatic collecting device has practical significance and popularization prospects and is very wide in application range and easy to use and popularize.

Owner:LUSHAN COLLEGE OF GUANGXI UNIV OF SCI & TECH

Syrup heating tank

InactiveCN103757145AEasy to cause blockageSolve the blockageGlucose productionEngineeringFood processing

The invention belongs to the field of food processing equipment, and especially relates to a syrup heating tank. The syrup heating tank comprises a syrup heating tank main body; the syrup heating tank main body is provided with a feed inlet, a steam inlet, a dumping mouth, and a dumping device; the dumping mouth is arranged at an opening of the syrup heating tank main body; the dumping device is fixedly arranged on the syrup heating tank main body, and comprises a worm wheel, a worm rod, a pedestal, a turnover shaft, and a motor; the worm rod and the pedestal are fixed together; the worm rod and the worm wheel cooperates with each other; the turnover shaft and the worm wheel are fixed together, and the ends of the turnover shaft are arranged on the syrup heating tank main body; and the worm wheel is driven by the motor. The syrup heating tank main body is not provided with a discharge port, but the opening of the syrup heating tank main body is provided with the dumping mouth; and the whole syrup heating tank can be inclined by the dumping device, so that syrup in the syrup heating tank is discharged via the dumping mouth, and blocking of the discharge port is avoided.

Owner:重庆市合川区川洲桃片有限公司

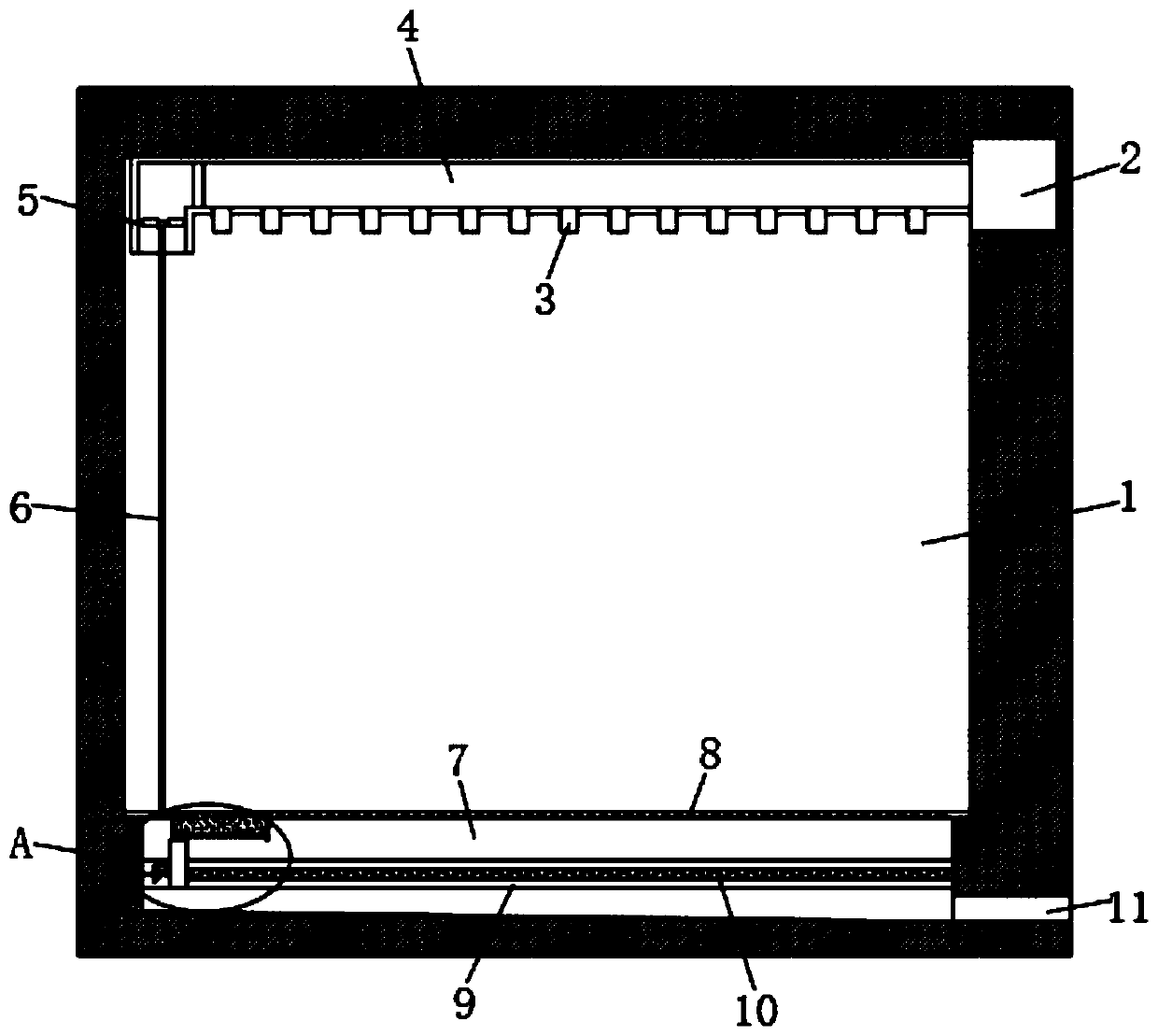

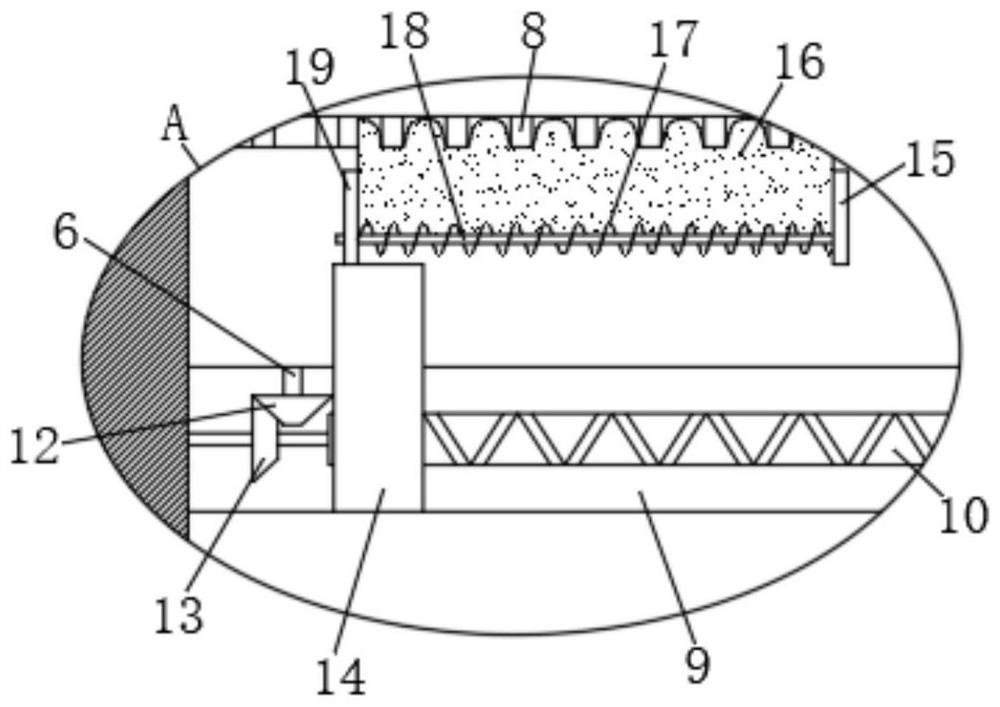

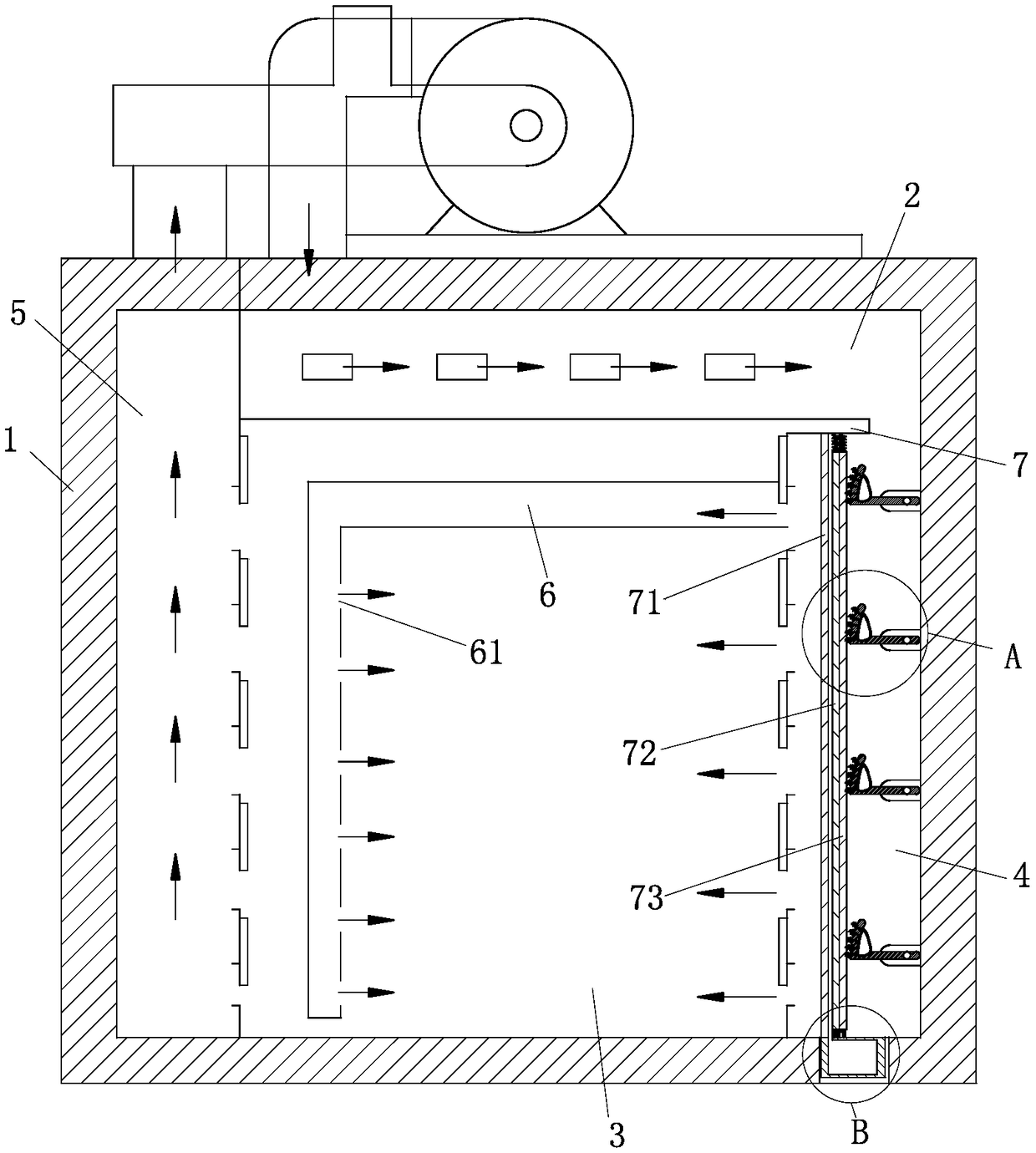

Warm gas isolation device of subway channel

ActiveCN110469938AIsolated entryAvoid churnDrying solid materials without heatFootwear cleanersEngineeringAir blower

The invention discloses a warm gas isolation device of a subway channel. The warm gas isolation device of the subway channel involves the subway channel, the top of one side of the subway channel is provided with an air blower, the air outlet end of the air blower is connected with an air outlet pipe extending along the top of the subway channel, a plurality of air outlets are formed in the lowerend of the air outlet pipe at equal intervals, an electromagnetic valve is installed at the corner of the tail end of the air outlet pipe, fan blades are arranged in the tail end of the air outlet pipe, the fan blades are connected with a connecting shaft, the ground of the subway channel is provided with a drainage groove, the bottom of the drainage groove is connected with a drainage pipe, a notch of the drainage groove is covered with an isolation net, an installation groove is horizontally formed in the inner wall of the drainage groove, the lower end of the connection shaft extends into the installation groove, and the inner wall of the installation groove is rotationally connected with a reciprocating lead screw. The warm gas heat isolation device has the advantages that the structure is reasonable, an air curtain can be formed to isolate the hot gas, the electric energy required by refrigeration of an air conditioner can be reduced, and accumulated water on the isolation net canbe timely sucked away.

Owner:杭州叶蓁科技有限公司

Lunar soil concrete and preparation method thereof

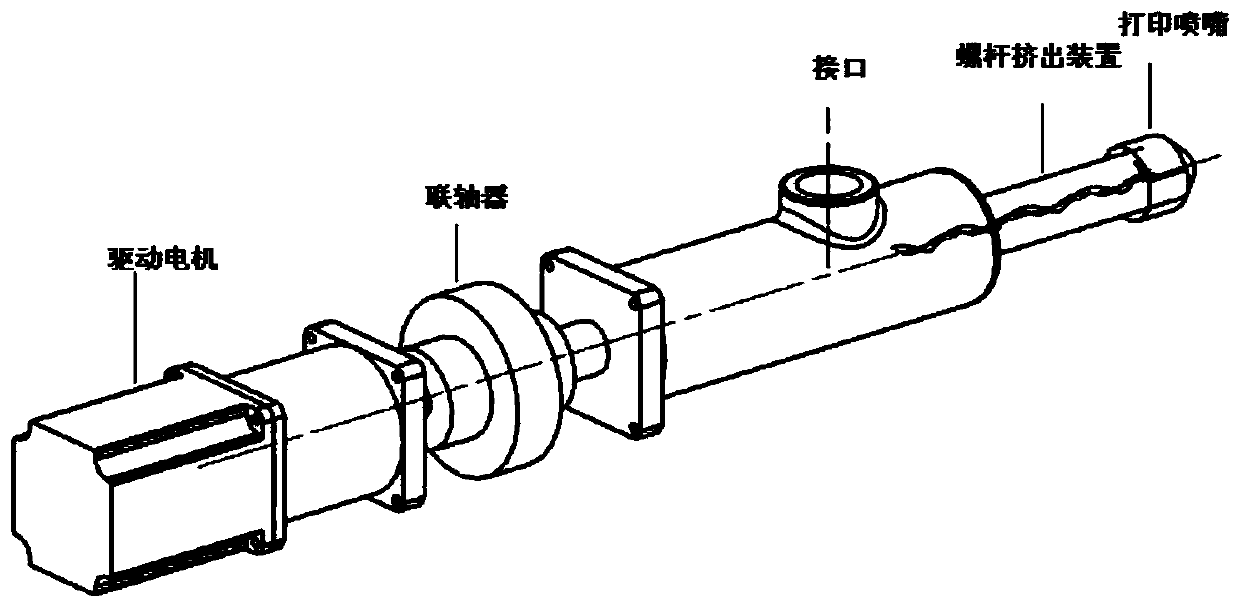

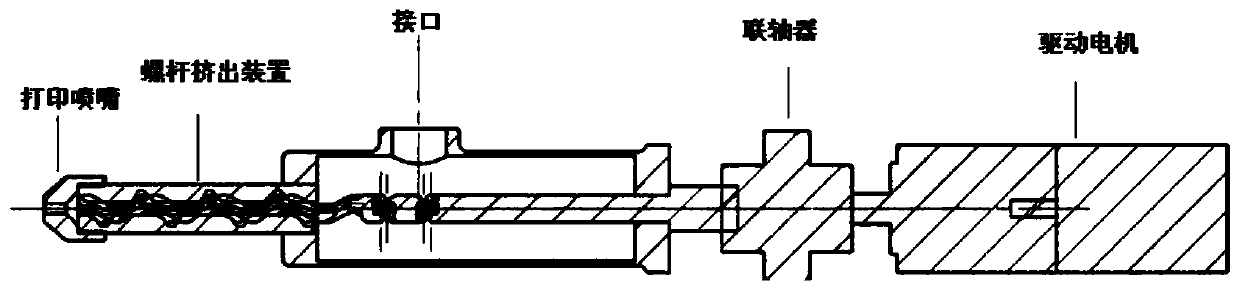

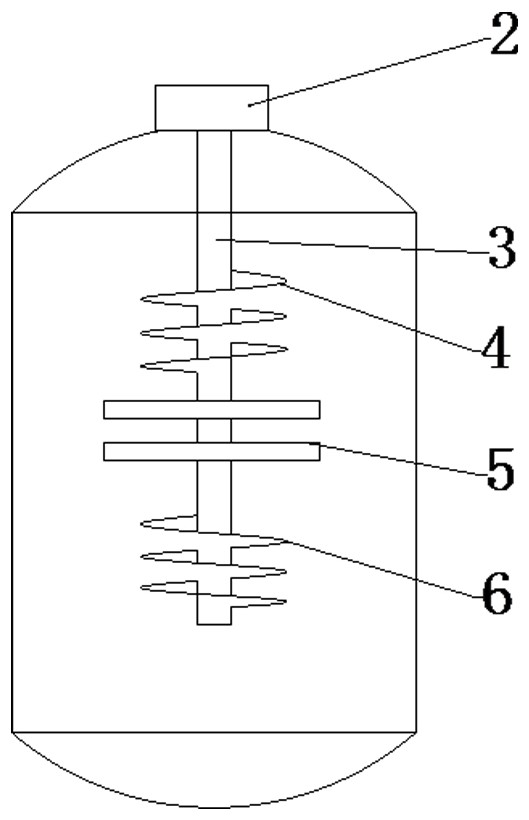

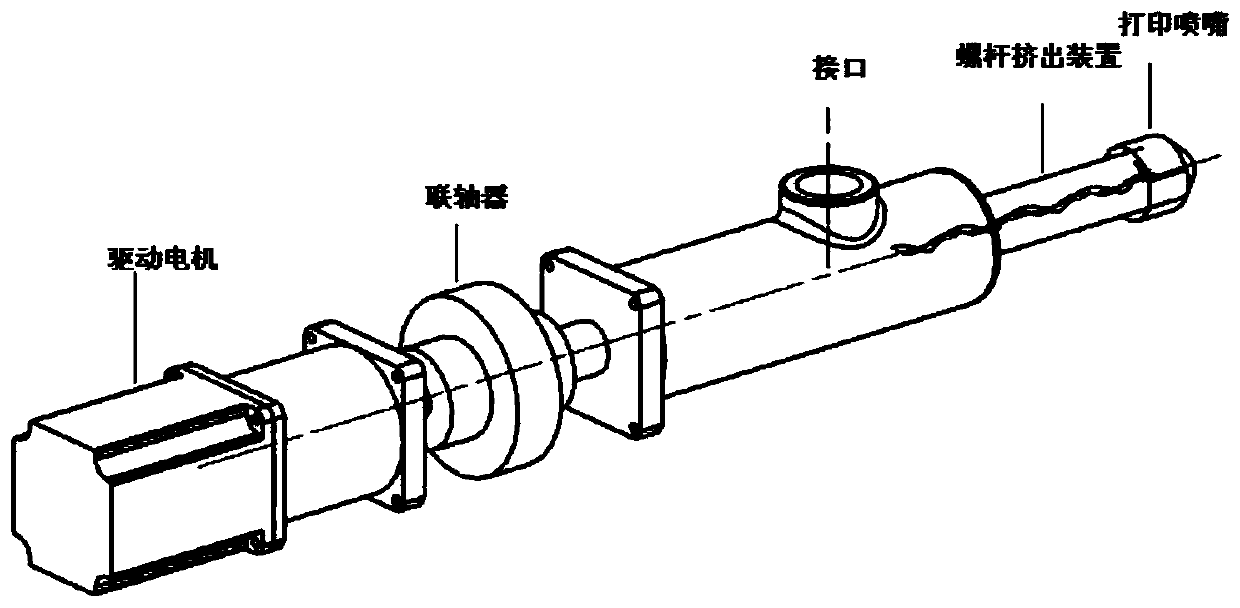

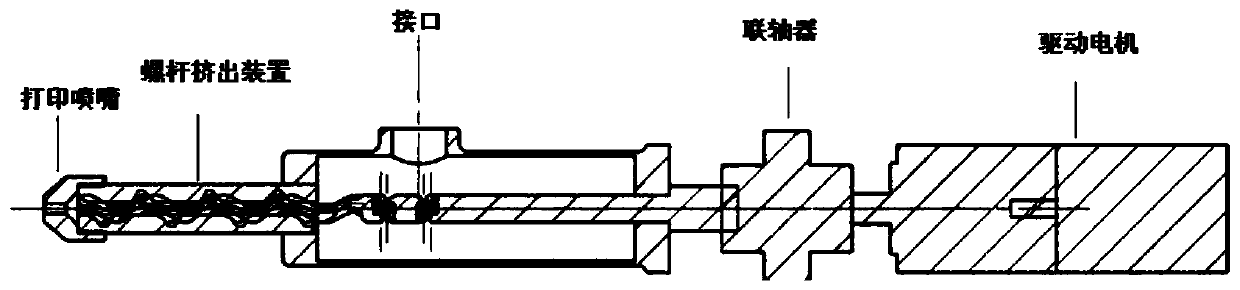

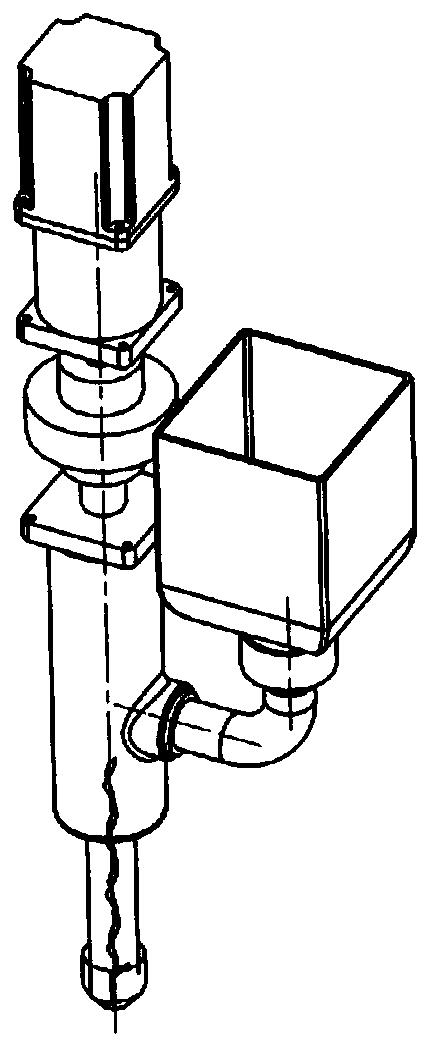

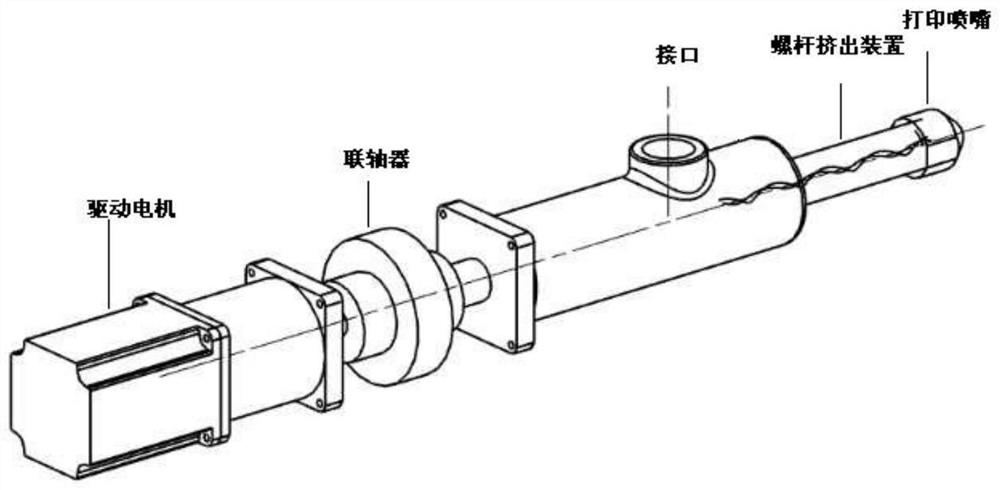

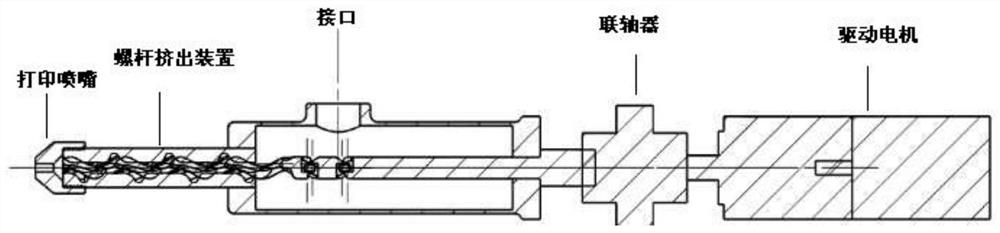

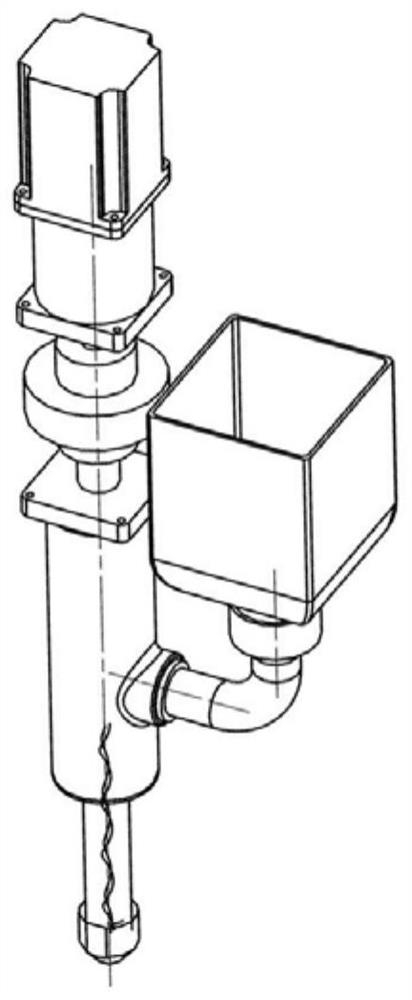

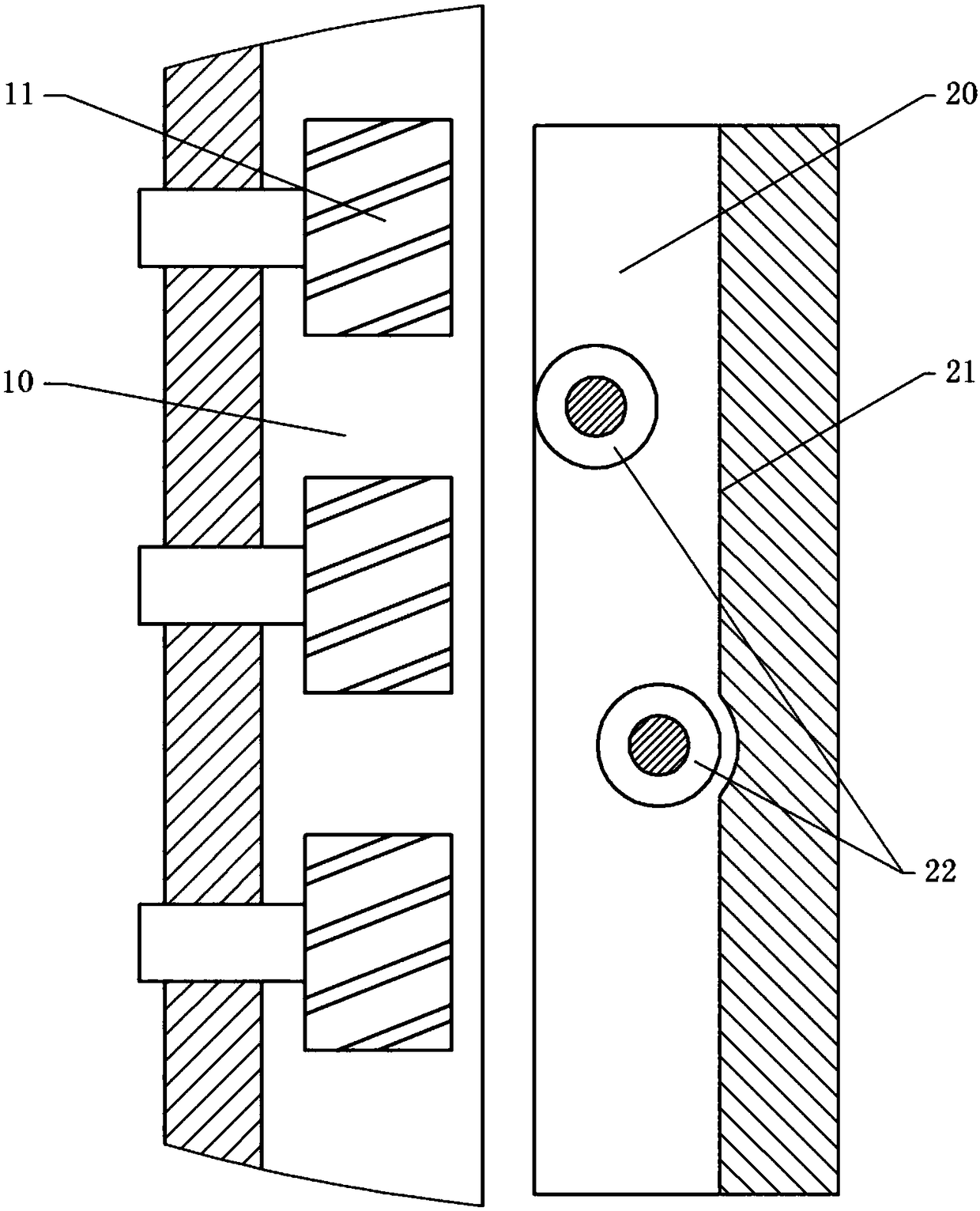

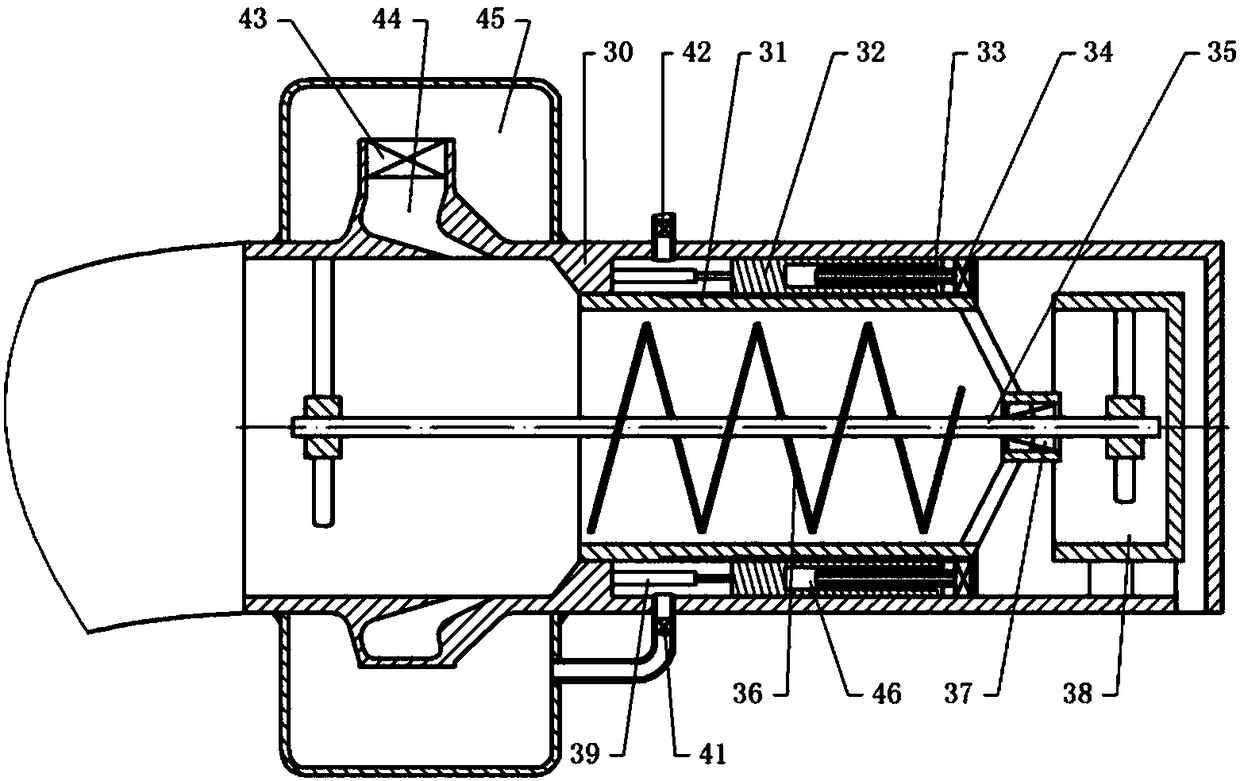

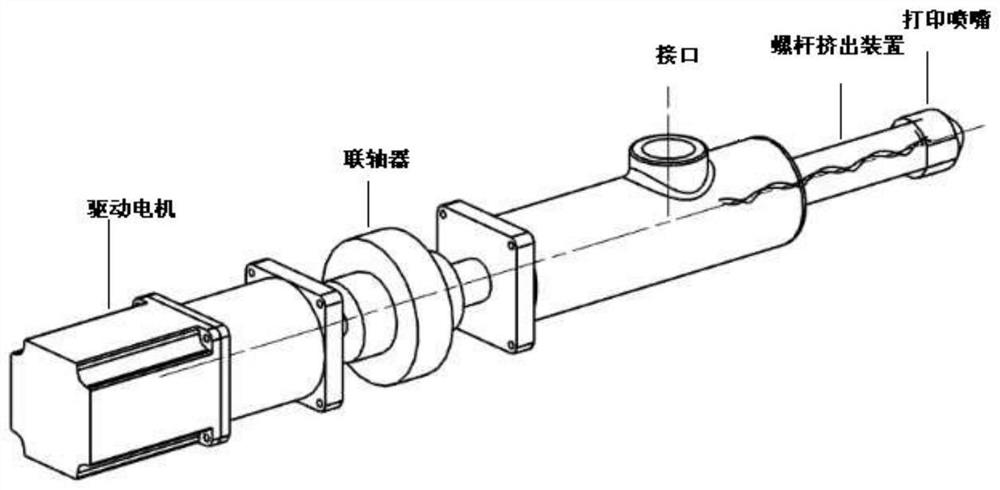

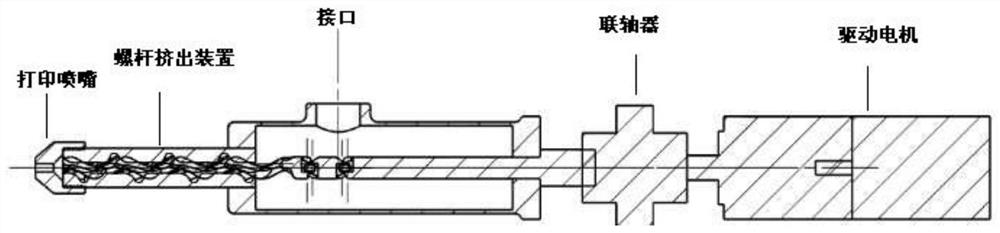

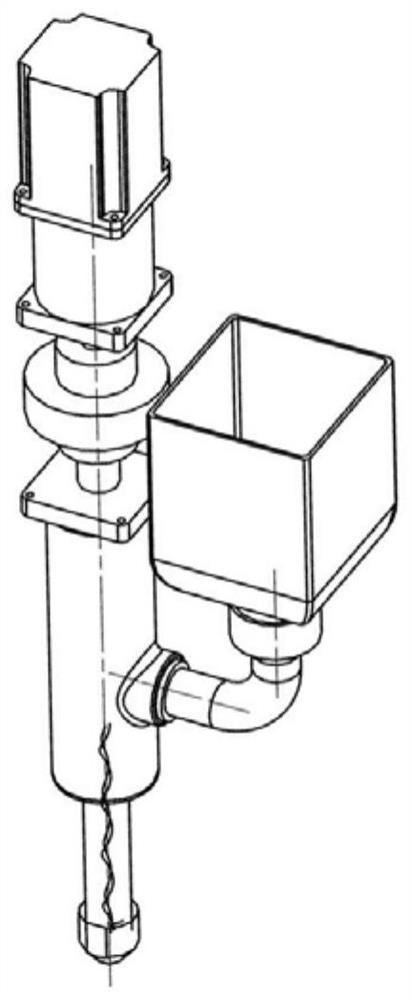

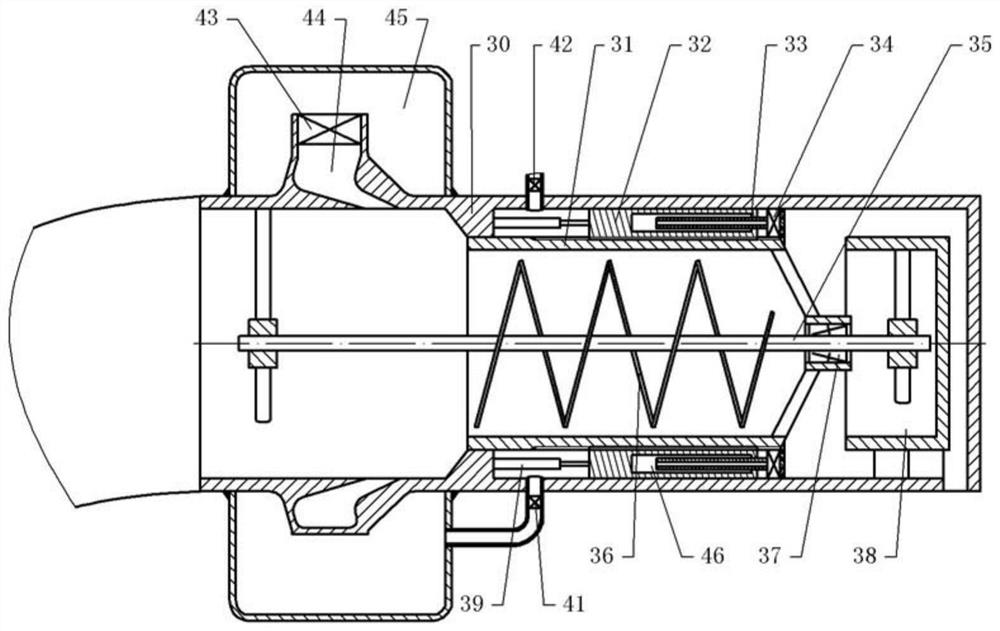

ActiveCN110256039ARealize instant refillAvoid cloggingAdditive manufacturing apparatusAviationCoupling

The invention relates to a lunar soil "concrete" and a preparation method thereof, and the lunar soil "concrete" is mainly used for aerospace, aviation, architectural paint and other technical fields. Lunar soil "concrete" hybrid 3D printing technology is an important key technology for follow-up lunar surface base construction of the moon in the future. A lunar soil simulant hybrid 3D printing device can realize continuous and controllable extrusion molding of lunar soil "concrete" by designing a lunar soil simulant hybrid 3D printing head. The hybrid 3D printing head is a key component of the lunar soil hybrid printing device, and can be employed to realize the continuous and controllable extrusion of lunar soil "concrete". The hybrid 3D printing head is a functional component integrating a drive motor, a coupling, a screw pump, an interface, a screw extrusion apparatus, a printing nozzle and other parts, and can realize the continuous and controllable extrusion molding of lunar soil "concrete" material.

Owner:BEIJING SATELLITE MFG FACTORY

Sugar boiling pot capable of recycling waste heat

ActiveCN104762418AAvoid wastingFully excludeSugar crystallisationSugar juice boiling/evaporationBoiling processProcess engineering

The invention discloses a sugar boiling pot capable of recycling waste heat. The sugar boiling pot comprises a pot bottom, a steam chamber and a steam drum, wherein the pot bottom is provided with a feed pipe and a massecuite outlet, a juice catcher and a juice steam outlet are formed in the steam chamber, a steam condensate drainage pipe, a heating steam inlet pipe and a non-condensable gas drainage pipe are arranged on the steam drum, and an outlet of the non-condensable gas drainage pipe is connected to the feed pipe; two non-condensable gas inlets, namely a non-condensable gas lower inlet and a non-condensable gas upper inlet, are formed in the non-condensable gas drainage pipe; the distance from the non-condensable gas lower inlet to a lower tube plate is 100-200mm; the non-condensable gas upper inlet is formed above an upper tube plate with a distance of 5-10mm; and a valve is arranged on the non-condensable gas drainage pipe and is used for controlling the on-off and quantity of the discharge of non-condensable gas. According to the sugar boiling pot disclosed by the invention, syrups or molasses can be heated by using the heat of the non-condensable gas, and the heat energy of the non-condensable gas can be recycled so as to ensure that the problem that the non-condensable gas is directly discharged to cause energy waste in a conventional sugar boiling process can be solved.

Owner:GUANGXI UNIV

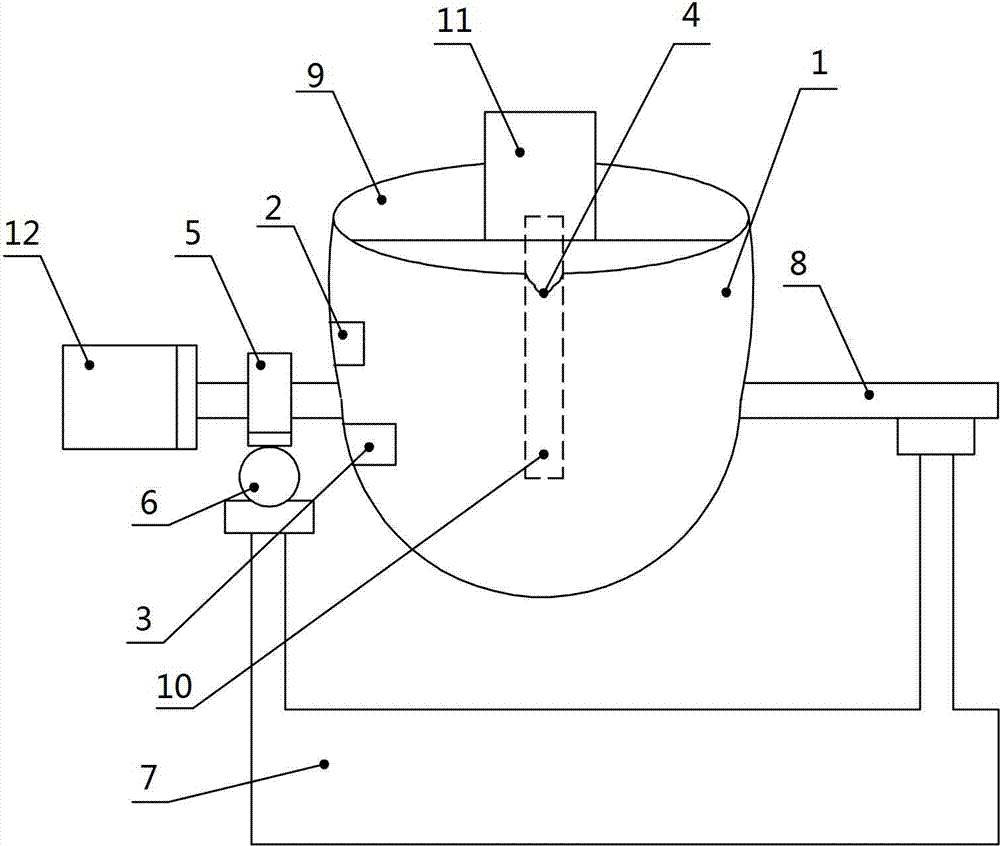

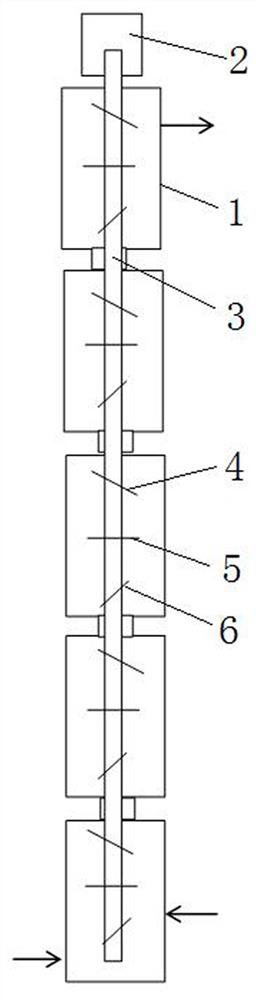

Continuous preparation system and preparation method for triisobutyl aluminum

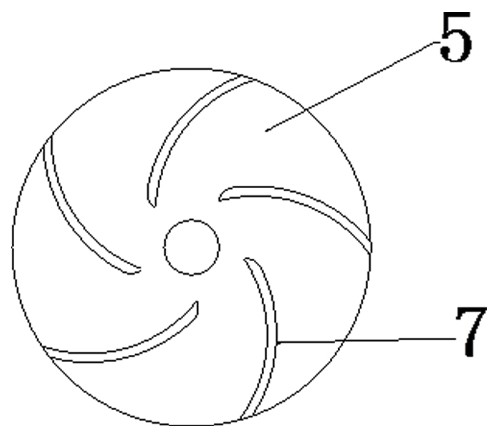

PendingCN114849629AWell mixedIncrease reaction rateProcess control/regulationLiquid degasificationRotational axisPropeller

The invention discloses a continuous preparation system and method for triisobutyl aluminum, and belongs to the technical field of triisobutyl aluminum production. The triisobutyl aluminum continuous preparation system comprises a plurality of reactors which are connected in series, and stirrers are arranged in the reactors; the stirrer comprises a rotating shaft, and a first propeller blade, a centrifugal blade and a second propeller blade which are sequentially arranged on the rotating shaft; the rotating directions of the first propeller blade and the second propeller blade are opposite; the centrifugal paddle comprises a disc body and a plurality of arc-shaped blades arranged on the side face of the disc body, and the arc-shaped blades are annularly arranged relative to the axis of the disc body.

Owner:SHANDONG ORIENT HONGYE CHEM

Lunar regolith concrete suitable for being extruded and preparation method thereof

ActiveCN110405903ARealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationDrive motor

The invention relates to lunar regolith concrete suitable for being extruded and a preparation method thereof, and the lunar regolith concrete suitable for being extruded and the preparation method thereof are mainly used in the technical fields of aerospace, aviation, building coatings and the like. A lunar regolith 'concrete' hybrid 3D printing technology is an important key technology in the future lunar follow-up lunar surface base construction. A lunar regolith simulant hybrid 3D printing device can realize continuous and controllable lunar regolith 'concrete' extrusion molding by designing a lunar regolith simulant hybrid 3D printing head. The hybrid 3D printing head is the key component of the lunar regolith hybrid printing device and is used for realizing continuous and controllable extrusion of lunar regolith 'concrete'. The device is a functional assembly integrating parts such as a driving motor, a coupler, a screw pump, a connector, a screw extrusion device and a printing nozzle into a whole, so that the continuous and controllable extrusion molding of the lunar regolith 'concrete' material is realized.

Owner:BEIJING SATELLITE MFG FACTORY

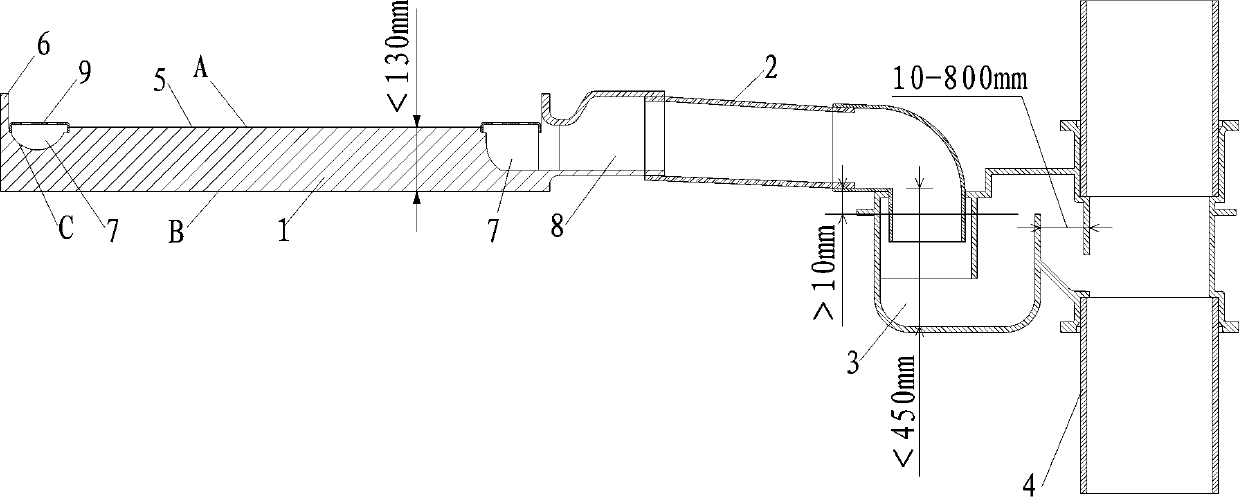

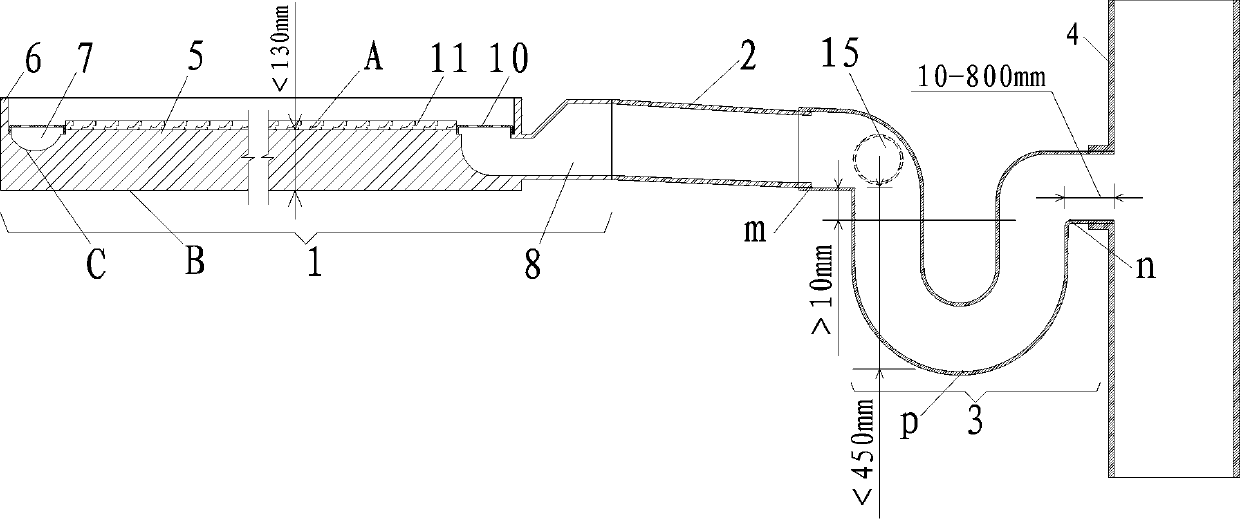

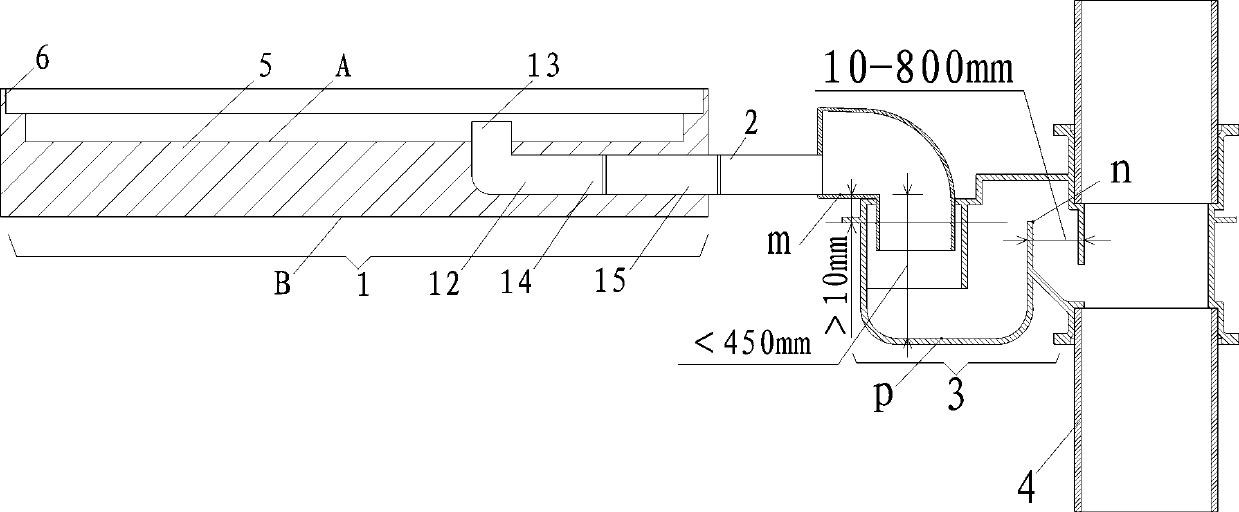

Integrated bathroom water discharging system

PendingCN110578364AIncrease profitSolve the problem of easy cloggingSewerage structuresDomestic plumbingWater dischargeEngineering

An integrated bathroom water discharging system is composed of a waterproof base plate, a water discharging transverse branch pipe, an integrated water seal and a water discharging vertical pipe. Thewaterproof base plate is composed of waterproof grounds and a waterproof stop strip, and an integrated structure is formed by the waterproof stop strip and the waterproof grounds. At least one waterproof ground close to the waterproof stop strip is provided with a ground water outlet, a water discharging outlet of the ground water outlet is connected with the water discharging transverse branch pipe, the water discharging transverse branch pipe is connected with the integrated water seal, and the integrated water seal communicates with the water discharging vertical pipe. The integrated bathroom water discharging system can solve the problems that a water discharging transverse branch pipe of a current integrated bathroom water discharging system needs to be arranged below a waterproof base plate, a water discharging branch pipe needs to vertically penetrate through the waterproof base plate, consequently, the usage clear height in a bathroom is reduced, and seepage hidden danger and difficult overhauling exist; by usage of the integrated water seal, the problem that water seals are independently arranged at various water discharging points of the bathroom water discharging system,and dryness is likely to be caused is solved, the bathroom plane and height space utilization rate can be increased, and the water discharging sanitation performance of the bathroom is improved.

Owner:林国强

Turnover type syrup heating tank

InactiveCN103749877AEasy to cause blockageSolve the blockageConfectionerySweetmeatsPiston rodFood processing

The invention belongs to the field of food processing equipment, and especially relates to a turnover type syrup heating tank. The turnover type syrup heating tank comprises a syrup heating tank main body; the syrup heating tank main body is provided with a feed inlet, a steam inlet, side ears, a dumping mouth, and a dumping device; the dumping mouth is arranged at an opening of the syrup heating tank main body; the side ears are arranged at side surfaces of the opening of the syrup heating tank main body; the dumping device comprises installing supports, a turnover shaft, and a cylinder; the installing supports are fixedly arranged on the ground; the two ends of the turnover shaft are fixedly supported by the installing supports; the side ears are inserted by the turnover shaft, and the turnover shaft is connected with the side ears via hinged connection; and a piston rod of the cylinder is fixedly connected with the bottom of the syrup heating tank main body. The syrup heating tank main body is not provided with a discharge port, but the opening of the syrup heating tank main body is provided with the dumping mouth; and the whole turnover type syrup heating tank can be inclined by the dumping device, so that syrup in the turnover type syrup heating tank is discharged via the dumping mouth, and blocking of the discharge port is avoided.

Owner:重庆市合川区川洲桃片有限公司

A kind of lunar soil concrete and preparation method thereof

ActiveCN110256039BRealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationSoil science

The invention relates to a lunar soil "concrete" and a preparation method thereof, which are mainly used in technical fields such as aerospace, aviation, and architectural coatings. The lunar soil "concrete" hybrid 3D printing technology is an important key technology for the construction of the future lunar base. The lunar soil simulant hybrid 3D printing device can realize continuous and controllable printing by designing the lunar soil simulant hybrid 3D printing head. Extrusion of lunar soil "concrete". The hybrid 3D printing head is a key component of the lunar soil hybrid printing device, which is used to realize the continuous and controllable extrusion of lunar soil "concrete". It is a functional component that integrates drive motors, couplings, screw pumps, interfaces, screw extrusion devices, printing nozzles and other components to realize the continuous and controllable extrusion of lunar soil "concrete" materials.

Owner:BEIJING SATELLITE MFG FACTORY

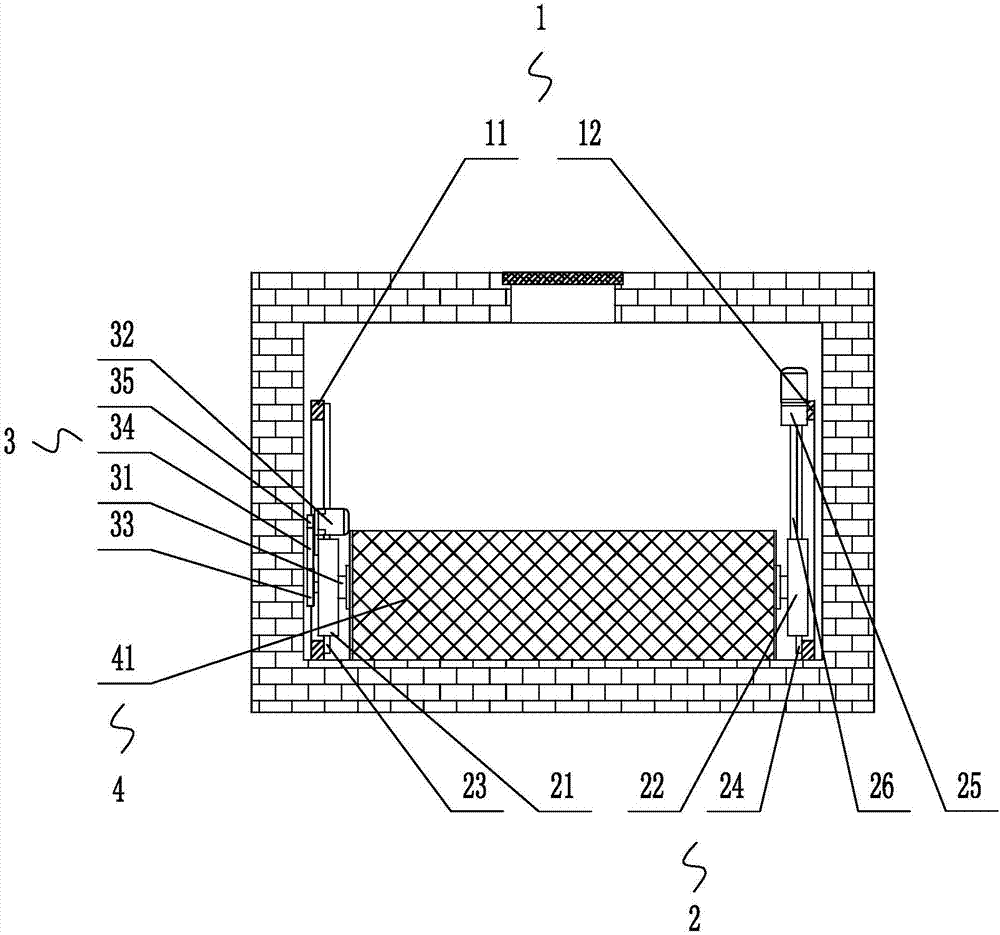

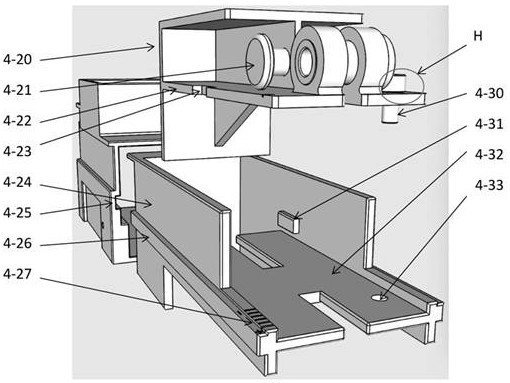

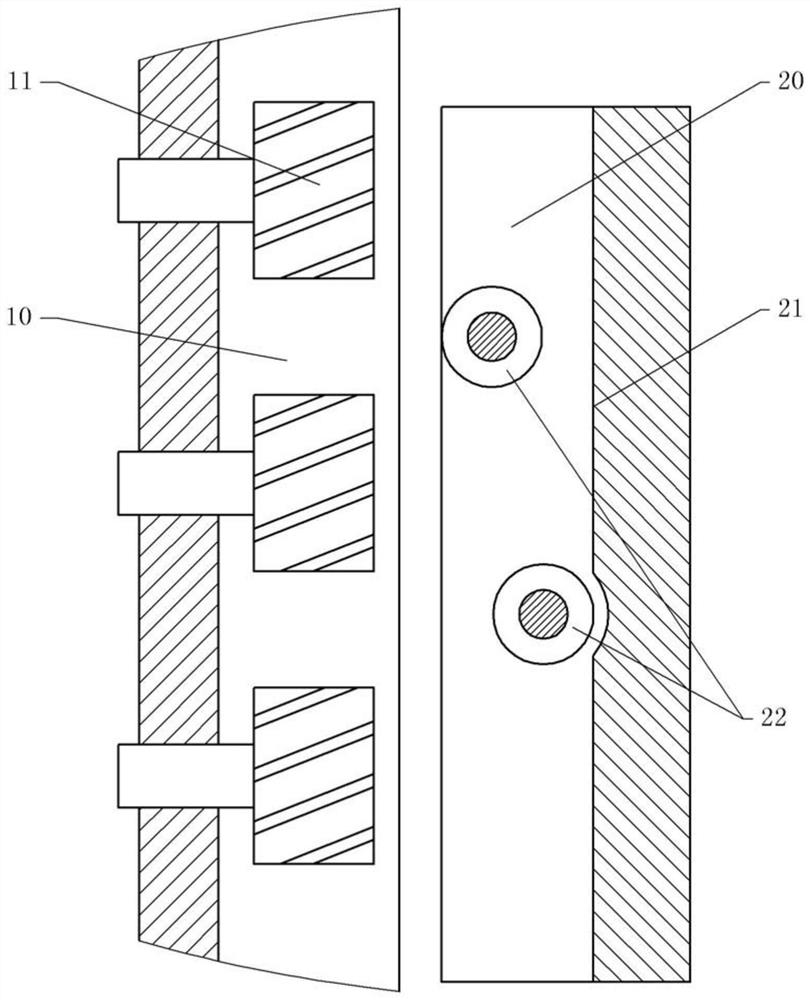

Door pocket groove-milling device

ActiveCN108481475AReduce loadReduce maintenance costsWood mortising machinesWood slotting machinesMilling cutterEngineering

The invention relates to the technical field of door and window machining and specifically discloses a door pocket groove-milling device which comprises a bed body, a feeding mechanism and a groove-milling machining mechanism, wherein the feeding mechanism and the groove-milling machining mechanism are arranged on the bed body. The feeding mechanism comprises a plurality of feeding rollers rotatably connected with the bed body. The bed body is provided with a first driving mechanism for driving the feeding rollers to rotate. The groove-milling machining mechanism comprises a tool apron fixed on the bed body and a plurality of milling cutters, wherein the milling cutters are arranged in the feeding direction of the feeding mechanism in sequence. The milling cutters are rotatably connected with the tool apron and a datum face used for limiting door plank edges is arranged on the tool apron. In the feeding direction of the feeding mechanism, a vertical distance between a rotating center of the milling cutters and the datum face increases gradually. The vertical distance of a plane passing through a rotating center of two adjacent milling cutters and being parallel to the datum face issmaller than the diameter of the milling cutters. A second driving mechanism used for driving the milling cutters to rotate is arranged on the bed body. The door pocket groove-milling device can reduce cutting quantity and loads of the milling cutters and lower damage probability of the milling cutters when milling a groove.

Owner:重庆百昶智能家居有限公司

Corn raw material distribution mechanism of automatic corn popper and production process method of corn raw material distribution mechanism

The corn raw material distribution mechanism is characterized in that a transparent material box and a material box base are embedded into a whole to form a material box assembly, the material box base is provided with a material box pull switch which can be used for closing a raw material outlet when the material box is taken out, the material box outlet is inserted into an inlet of an outer cavity base for feeding, and the outer cavity base is provided with an inner cavity. And an elastic plate is inserted into an open groove below the feeding hole of the cavity and is self-locked. The inner cavity is composed of a sliding piece and an adjusting plate. And the outer cavity seat is fixed on the bottom surface of the stainless steel mounting plate through bolts. The connecting transmission system is composed of a pin shaft, a plastic connecting rod, a crank turning wheel and a gear motor. A discharging hopper of the distribution mechanism is inserted into a reserved hole in a bottom plate of a vending machine material chamber and connected with a boiler feeding port, lugs on the two sides of an installation plate are inserted into buckles of the bottom plate of the vending machine material chamber, and the other ends of the lugs are fixed through round screws. The device is small in size, light, economical, practical and convenient to install and use.

Owner:义乌市悦粒智能科技有限公司

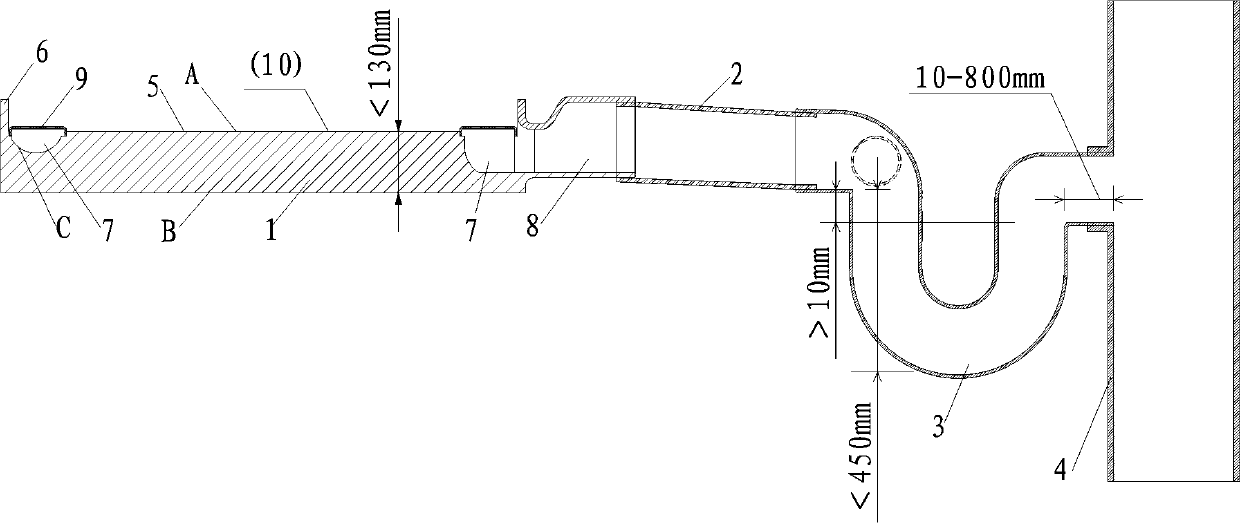

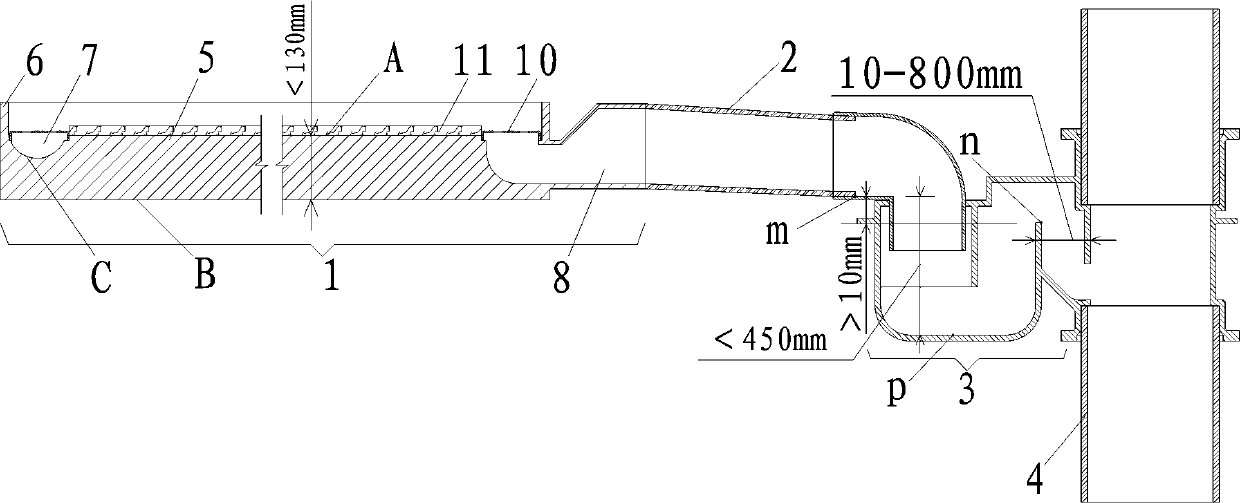

Integrated toilet water draining system

PendingCN110593363AIncrease profitSolve the problem of easy cloggingSewerage structuresDomestic plumbingEngineeringToilet

The invention discloses an integrated toilet water draining system. The integrated toilet water draining system is composed of a waterproof chassis, a water draining transverse branch pipe, an integrated water seal and a water draining vertical pipe. The waterproof chassis is composed of a waterproof ground and a waterproof blocking strip, the waterproof ground is divided into a top face and a bottom face, the waterproof blocking strip is higher than the top face and surrounds the edge of the top face or is close to the edge of the top face, and the waterproof blocking strip and the waterproofground are of an integrated structure. A ground water draining opening is formed in at least one waterproof ground close to the waterproof blocking strip, a water draining outlet of the ground waterdraining opening is connected with the water draining transverse branch pipe, the water draining transverse branch pipe is connected with the integrated water seal, and the integrated water seal is connected with the water draining vertical pipe. The problem that an existing toilet water draining system needs a toilet structure to descend or rise, a chassis is prone to generating seepage, the water seal of a floor drain is prone to drying up to generate peculiar smell can be solved, the system is applied to a building, descending is not needed or little descending is needed, the toilet sanitary water draining smoothness and sanitation conditions can be improved, and the seepage of the waterproof chassis can be completely eradicated.

Owner:KUNMING QUNZHIYING TECH

A pure powder granulating tablet press machine

ActiveCN104275822BRealize integrated productionIncrease productivityGrain treatmentsShaping pressEngineeringMedical instruments

Owner:升生健康科技(苏州)有限公司

A kind of kerosene co-refining method and its device

ActiveCN106433775BLow viscosityImprove protectionTreatment with hydrotreatment processesPtru catalystProcess engineering

The invention relates to a coal and oil coprocessing method and device. The coprocessing method comprises steps as follows: step one, oil slurry pretreatment: heavy oil, a non-hydrogenated cycling solvent and a first catalyst are mixed, oil slurry is prepared and subjected to first hydrocracking reaction, a first product is obtained and separated, and first light distillate oil and first heavy distillate oil are obtained; step two, coal and oil coprocessing, solvent oil circulation and finished product separation. The coprocessing device comprises an oil slurry pretreatment device, a coal and oil coprocessing device body, a solvent oil circulating device and an oil product quality improving device. According to the coal and oil coprocessing method and device, selectivity for the heavy oil during coal and oil coprocessing is reduced, the percentage amount of pulverized coal in a coal and oil coprocessing process is increased, and the coal and oil coprocessing method and device are more suitable for practical application.

Owner:CCTEG CHINA COAL RES INST

A kind of lunar soil concrete suitable for extrusion and its preparation method

ActiveCN110405903BRealize instant refillAvoid cloggingAdditive manufacturing apparatusCeramic shaping apparatusAviationLunar soil

Owner:BEIJING SATELLITE MFG FACTORY

Liquid cooling radiator capable of improving heat dissipation effect

PendingCN113985993AImprove cooling effectImprove cooling efficiencyDigital processing power distributionEngineeringWater tanks

Owner:常州益众电气有限公司

A kind of sugar boiling tank with waste heat recycling

ActiveCN104762418BAvoid wastingFully excludeSugar crystallisationSugar juice boiling/evaporationBoiling processProcess engineering

The invention discloses a sugar boiling pot capable of recycling waste heat. The sugar boiling pot comprises a pot bottom, a steam chamber and a steam drum, wherein the pot bottom is provided with a feed pipe and a massecuite outlet, a juice catcher and a juice steam outlet are formed in the steam chamber, a steam condensate drainage pipe, a heating steam inlet pipe and a non-condensable gas drainage pipe are arranged on the steam drum, and an outlet of the non-condensable gas drainage pipe is connected to the feed pipe; two non-condensable gas inlets, namely a non-condensable gas lower inlet and a non-condensable gas upper inlet, are formed in the non-condensable gas drainage pipe; the distance from the non-condensable gas lower inlet to a lower tube plate is 100-200mm; the non-condensable gas upper inlet is formed above an upper tube plate with a distance of 5-10mm; and a valve is arranged on the non-condensable gas drainage pipe and is used for controlling the on-off and quantity of the discharge of non-condensable gas. According to the sugar boiling pot disclosed by the invention, syrups or molasses can be heated by using the heat of the non-condensable gas, and the heat energy of the non-condensable gas can be recycled so as to ensure that the problem that the non-condensable gas is directly discharged to cause energy waste in a conventional sugar boiling process can be solved.

Owner:GUANGXI UNIV

Quick drainage mechanism for river-crossing bridge deck slope

InactiveCN112695630ASpeed up drainageImprove filtering effectBridge structural detailsGrain treatmentsWater dischargeBridge deck

The invention relates to the technical field of bridge design, and discloses a river-crossing bridge deck side slope quick drainage mechanism which comprises a bridge deck, a side slope arranged on one side of the bridge deck, a bridge foundation arranged on one side of the side slope, a coarse filter screen arranged at one end of the side slope, an underground pipeline arranged at one end of the coarse filter screen and a transfer water tank arranged on one side of the underground pipeline. A fine filter screen is arranged at the bottom of the transfer water tank; a stirring mechanism is arranged at the bottom of the fine filter screen; a longitudinal drainage ditch is formed in the bottom of the stirring mechanism; a drainage pipe is arranged at the periphery of the longitudinal drainage ditch; according to the quick drainage mechanism for the river-crossing bridge deck slope, the slope is arranged to increase the drainage amount and avoid a large amount of accumulated water on a bridge deck, the drainage efficiency is improved by arranging double-layer filtering, water flowing is accelerated by arranging the stirring mechanism, blockage is avoided, buffering and damping are effectively conducted by arranging the outer pipe, and the inner pipe is prevented from being damaged by impact and extrusion.

Owner:魏秀芹

Intelligent sewage treatment equipment and using method thereof

InactiveCN112250253AAvoid wastingEasy to replaceWater/sewage treatment by irradiationTreatment involving filtrationCouplingDrive shaft

The present invention discloses intelligent sewage treatment equipment and a using method thereof; wherein a pool wall is fixedly connected to the inner wall of the lower end of a shell, a filter is slidably connected to the inner side of the pool wall, a third bearing is fixedly connected to the upper end of the filter, and a second lead screw is fixedly connected to the upper end of the third bearing; the second lead screw is connected with a transmission shaft of a third motor through a third coupler, the second lead screw is in threaded connection with a moving plate, a motor base is fixedly connected to the upper end, located at the inner wall of the lower-end shell, of the left end of the pool wall, and a second motor is arranged at the lower end of the motor base; a transmission shaft of the second motor is connected with a third lead screw through a second coupling, the outer side of the second coupling is fixedly connected with a first bearing, the outer side of the first bearing is fixedly connected to the upper end of the motor base, and the third lead screw is in threaded connection with a moving plate; third fixing bases are fixedly connected to the left side and the right side of the first bearing and located at the upper end of the motor base.

Owner:罗上洪

A thermal insulation device for subway passages

ActiveCN110469938BIsolated entryAvoid churnDrying solid materials without heatFootwear cleanersThermal insulationSolenoid valve

Owner:杭州叶蓁科技有限公司

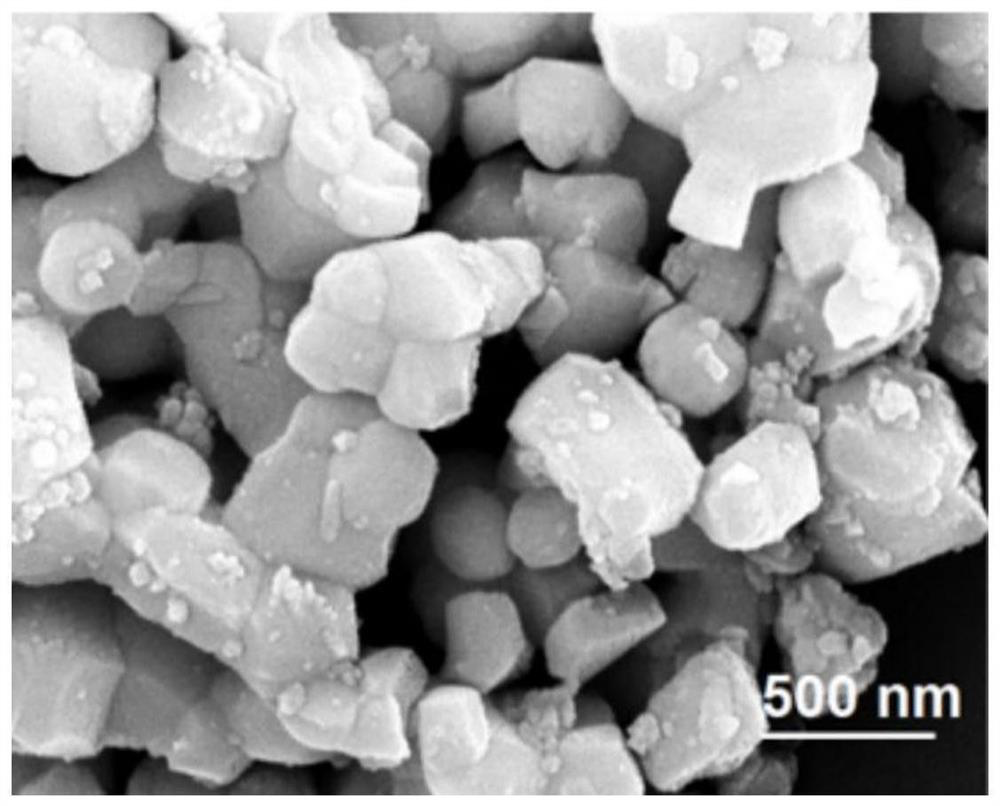

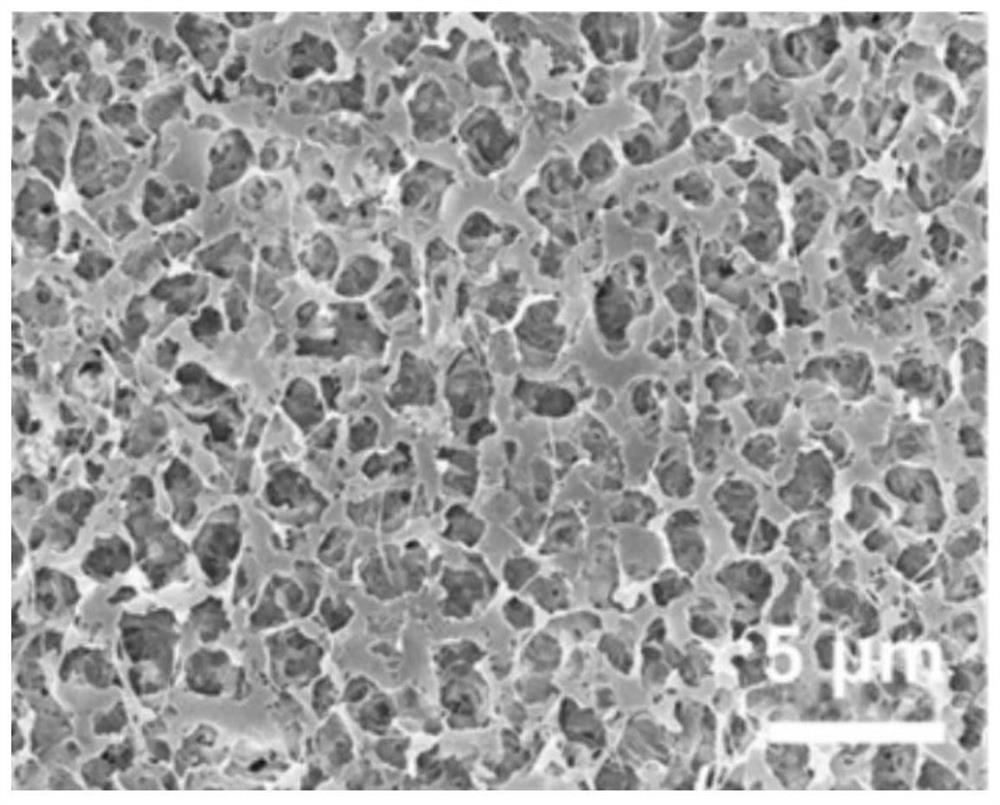

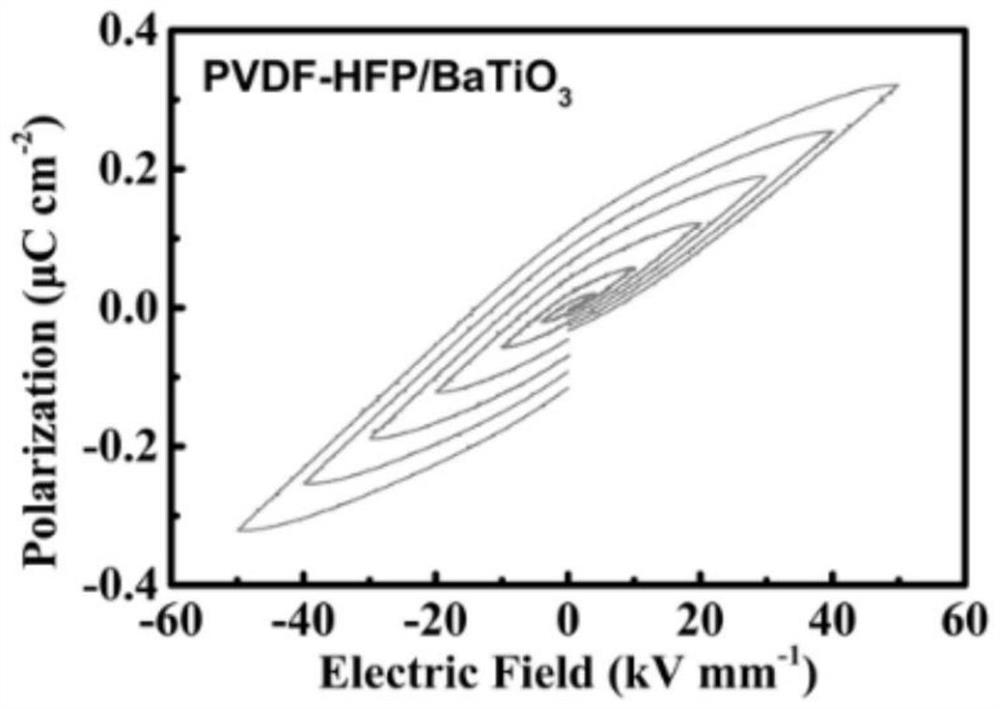

Piezoelectric composite diaphragm for lithium metal battery as well as preparation method and application of piezoelectric composite diaphragm

PendingCN114520396AImprove cycle lifeMeet application needsSecondary cellsCell component detailsPolyolefinPolyvinylidene difluoride

The invention discloses a piezoelectric composite diaphragm for a lithium metal battery as well as a preparation method and application thereof. The invention belongs to the field of lithium ion battery diaphragms. The invention aims to solve the technical problems that the existing polyolefin diaphragm is poor in affinity with electrolyte, low in lithium ion transference number and weak in lithium dendrite growth inhibition capability, and the existing modification method that ceramic particles are directly coated or used as a filler causes diaphragm pore blockage, so that lithium ion deposition is not facilitated. According to the invention, a polyvinylidene fluoride base material is used as a diaphragm base material, and piezoelectric ceramic particles are mixed with the diaphragm base material, so that the piezoelectric composite diaphragm which is consistent in morphology, controllable in porosity, excellent in piezoelectric property, good in electrolyte absorption rate and good in wettability is prepared. In the lithium ion deposition process, the piezoelectric composite diaphragm is extruded by lithium dendrites, lithium ion deposition sites can be optimized through the piezoelectric effect of the diaphragm, growth of the lithium dendrites is inhibited, the cycle life of the lithium metal battery is prolonged, and the application requirement of the diaphragm in the field of the lithium metal battery can be met.

Owner:HARBIN INST OF TECH +1

A material screening device

ActiveCN110918454BEasy to cause blockageImprove practicalitySievingDispersed particle filtrationElectric machineDust control

The invention discloses a material screening device, which comprises a first support plate, a second support plate is fixed on one side of the top end of the first support plate, and a third support plate is fixed on the end of the second support plate away from the first support plate, And the first support plate and the third support plate are arranged in parallel, the top side of the first support plate is fixed with a rotary motor, and the output shaft of the rotary motor passes through the third support plate and is fixed with a circular feed box. The invention can rotate the feeding box to complete intermittent feeding, preventing excessive feeding at one time, which is easy to cause blockage, and at the same time, can carry out agitation, dust removal and intermittent feeding through one driving source, which improves the practicability. The materials can be vibrated and screened, collected separately, which improves the convenience, and the collected materials can be dropped into the collection bags one by one for packaging, which improves the practicability. Various mechanical transmissions in the present invention pass through one driving source Realized, the equipment cost is low.

Owner:安徽省宣城市联通塑业有限责任公司

Building glass homogenizing furnace

Owner:凯里市凯荣玻璃有限公司

A kind of nano-cellulose composite material and its preparation method and application

ActiveCN109971014BBiodegradableRecyclablePulp properties modificationMicroorganism/enzyme additionPolymer scienceVegetable oil

The invention provides a nano-cellulose composite material and its preparation method and application. The present invention uses nano-cellulose as raw material, adopts TEMPO / NaClO / NaBr oxidation system to oxidize nano-cellulose, uses hexadecylamine as a monomer to carry out amidation modification on the oxidized nano-cellulose, and adds natural vegetable oil to flow The extended method is used to prepare the film, and under the condition of negative pressure, the film is impregnated with polyurethane acrylic resin, and the obtained nano-cellulose composite material not only has the biodegradability and recyclability of cellulose, but also endows the composite material with good hydrophobicity. , thermal expansion resistance, flexibility and light transmittance, it is an ideal flexible screen matrix material, and has broad application prospects in the field of flexible screen matrix materials.

Owner:GUANGXI UNIV

Door casing milling device

ActiveCN108481475BReduce loadReduce maintenance costsWood mortising machinesWood slotting machinesMilling cutterStructural engineering

The invention relates to the technical field of door and window machining and specifically discloses a door pocket groove-milling device which comprises a bed body, a feeding mechanism and a groove-milling machining mechanism, wherein the feeding mechanism and the groove-milling machining mechanism are arranged on the bed body. The feeding mechanism comprises a plurality of feeding rollers rotatably connected with the bed body. The bed body is provided with a first driving mechanism for driving the feeding rollers to rotate. The groove-milling machining mechanism comprises a tool apron fixed on the bed body and a plurality of milling cutters, wherein the milling cutters are arranged in the feeding direction of the feeding mechanism in sequence. The milling cutters are rotatably connected with the tool apron and a datum face used for limiting door plank edges is arranged on the tool apron. In the feeding direction of the feeding mechanism, a vertical distance between a rotating center of the milling cutters and the datum face increases gradually. The vertical distance of a plane passing through a rotating center of two adjacent milling cutters and being parallel to the datum face issmaller than the diameter of the milling cutters. A second driving mechanism used for driving the milling cutters to rotate is arranged on the bed body. The door pocket groove-milling device can reduce cutting quantity and loads of the milling cutters and lower damage probability of the milling cutters when milling a groove.

Owner:重庆百昶智能家居有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com