Building glass homogenizing furnace

A technology of architectural glass and homogenizing furnace, which is applied in the field of architectural glass homogenizing furnace, which can solve the problems of low glass homogenization treatment effect, low air temperature uniformity, dust blockage, etc., to achieve convenient operation, improve effect, and ensure normal use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

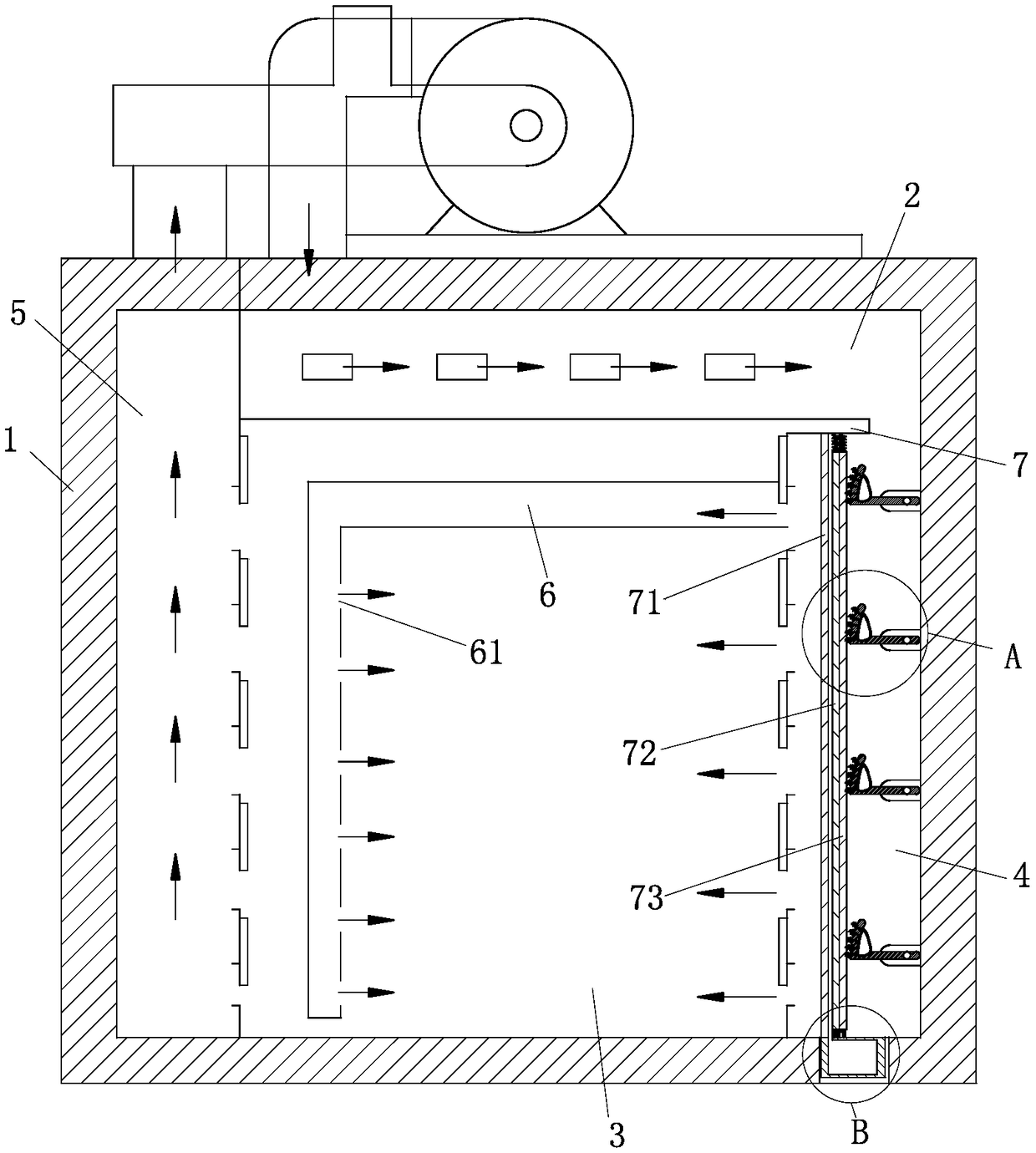

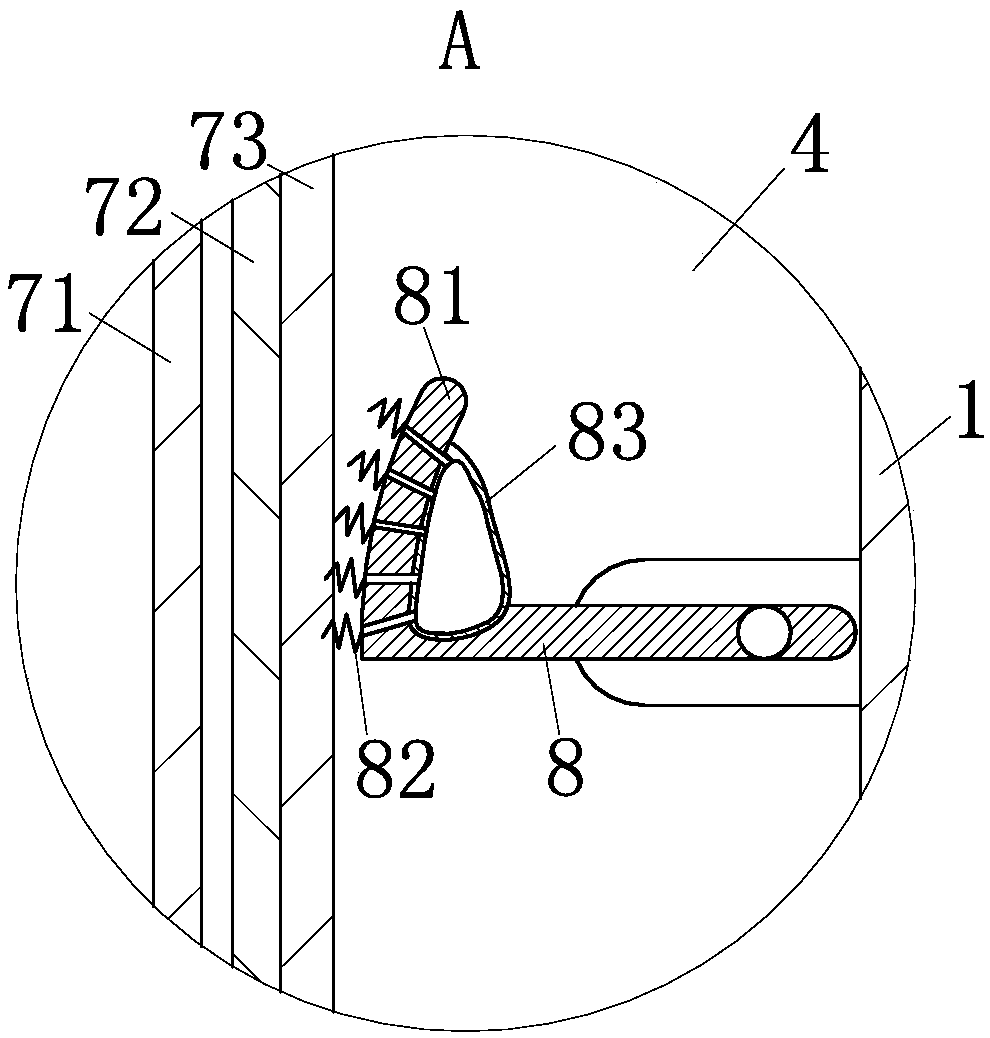

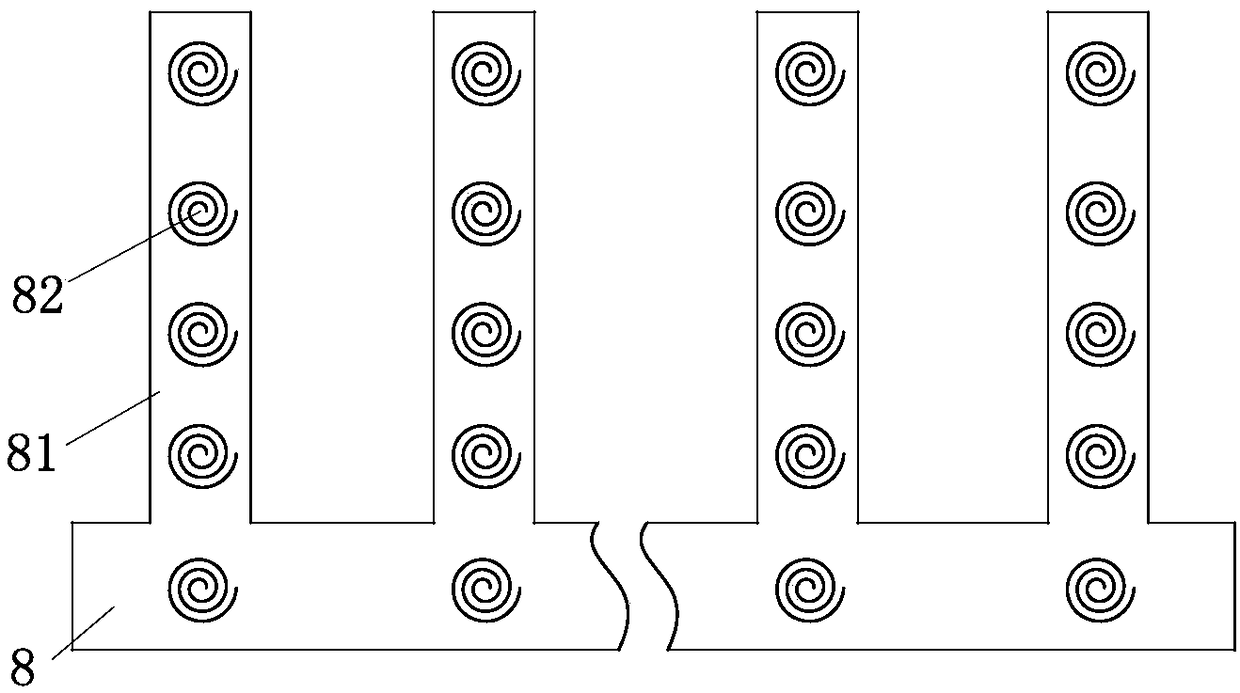

[0024] use Figure 1-Figure 5 The structure of an architectural glass homogenization furnace according to an embodiment of the present invention is described as follows.

[0025] Such as figure 1As shown, a homogeneous furnace for architectural glass according to the present invention includes a furnace body 1, a fan and a heater. The furnace body 1 is provided with an air inlet and an air outlet communicating with the fan; the inside of the furnace body 1 is divided It is a heating chamber 2, a heating chamber 3, an air inlet channel 4 and an air outlet channel 5; the heating chamber 3 is arranged at the middle position of the furnace body 1; the heater is arranged in the heating chamber 2; the air inlet The channel 4 communicates with the heating chamber 2; the side walls of the air inlet channel 4 and the air outlet channel 5 are provided with a plurality of side air holes; the heating chamber 3 is also provided with a built-in air channel 6; The air duct 6 is a tubular s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com