Continuous preparation system and preparation method for triisobutyl aluminum

A technology of triisobutylaluminum and preparation system, which is applied to the continuous preparation system and preparation field of triisobutylaluminum, can solve the problems of low reaction rate, difficult three-phase raw materials, and high energy consumption, achieve high reaction yield, reduce Safety hazard, effect of high reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

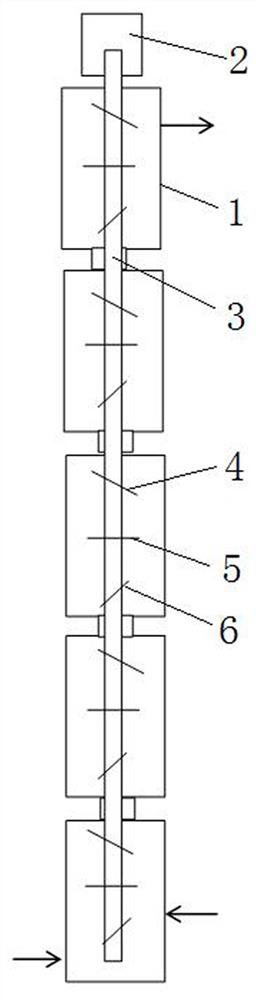

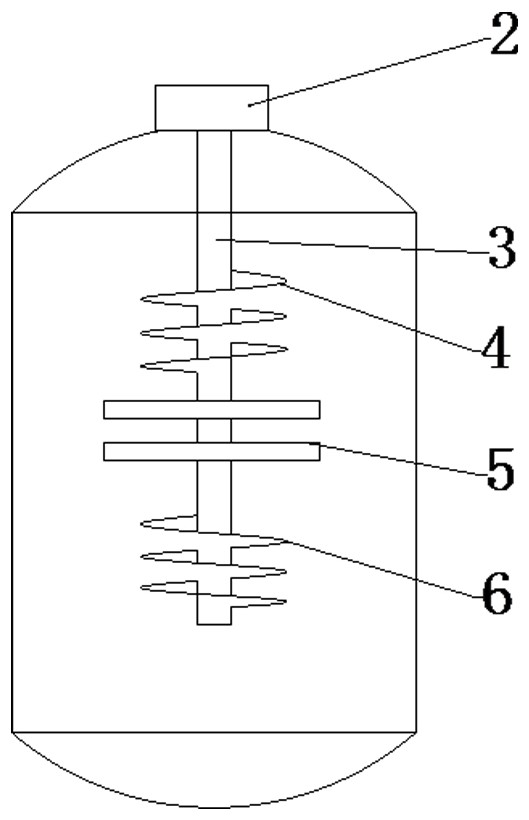

[0045] In the second aspect, the present invention provides a continuous preparation method of triisobutylaluminum, comprising the following steps:

[0046] After the active aluminum powder, solvent and isobutylene are preliminarily mixed in proportion, they are injected into the reactor at the initial position in proportion with hydrogen;

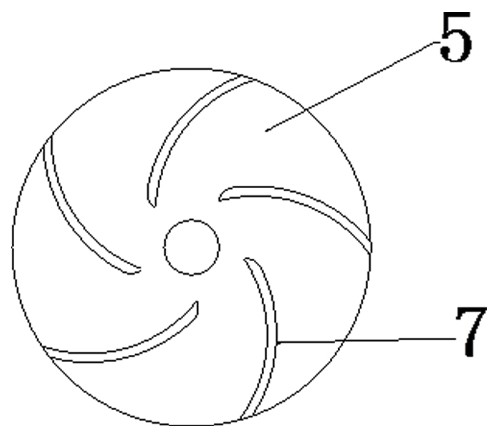

[0047] The motor starts to drive the rotating shaft to rotate, and at the same time drives the first propeller blade and the second propeller blade to rotate in opposite directions, and drives the three-phase reaction raw materials to flow in opposite directions in the reactor; The three-phase reaction raw materials are thrown to the inner wall of the reactor;

[0048] After the two materials flowing in opposite phases meet the inner wall of the reactor, they flow in the opposite direction to both sides, and collide with the material fluid thrown out by the centrifugal blades;

[0049] Through the above methods, the gas is fully dispersed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com