Piezoelectric composite diaphragm for lithium metal battery as well as preparation method and application of piezoelectric composite diaphragm

A lithium metal battery and piezoelectric composite technology, applied in secondary batteries, battery pack parts, circuits, etc., can solve the problem of poor affinity between polyolefin diaphragm and electrolyte, weak ability of lithium dendrite growth, unfavorable lithium ion Deposition and other issues, to achieve controllable and multiplier performance improvement, improve transmission capacity, and good application effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

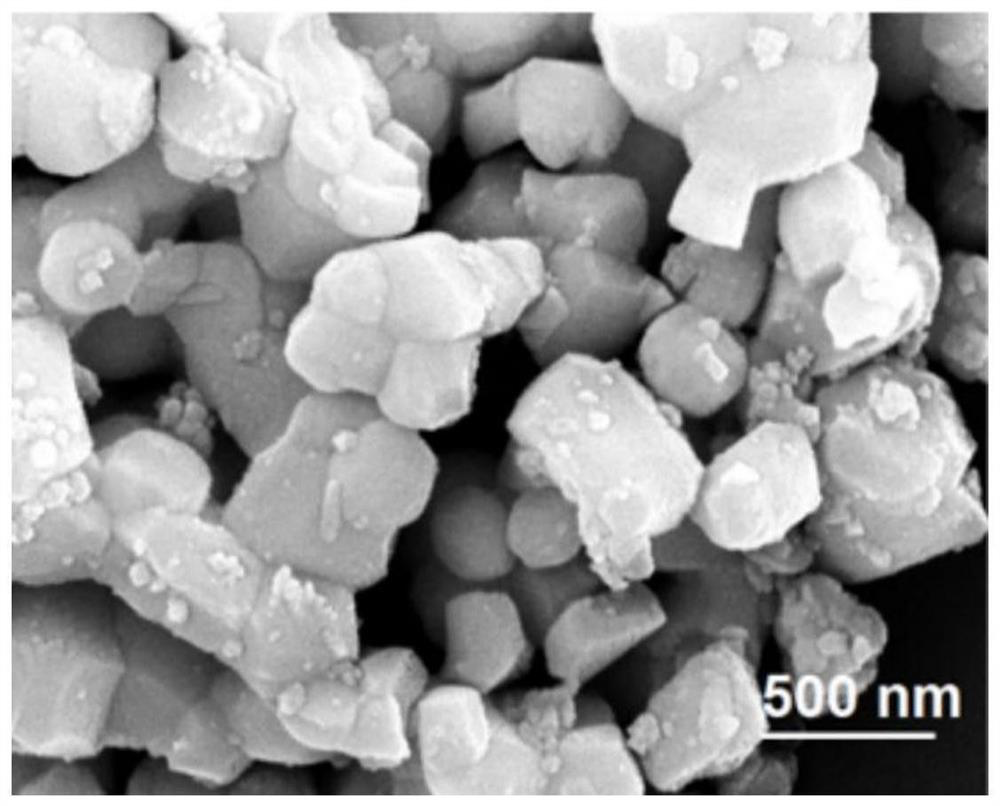

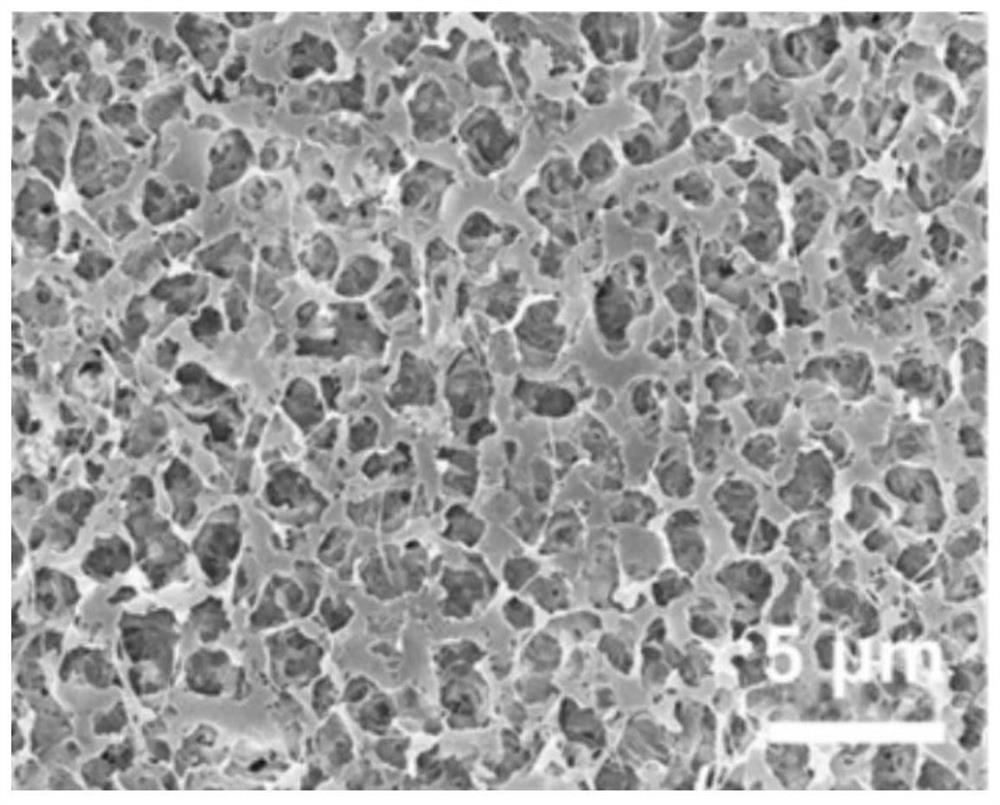

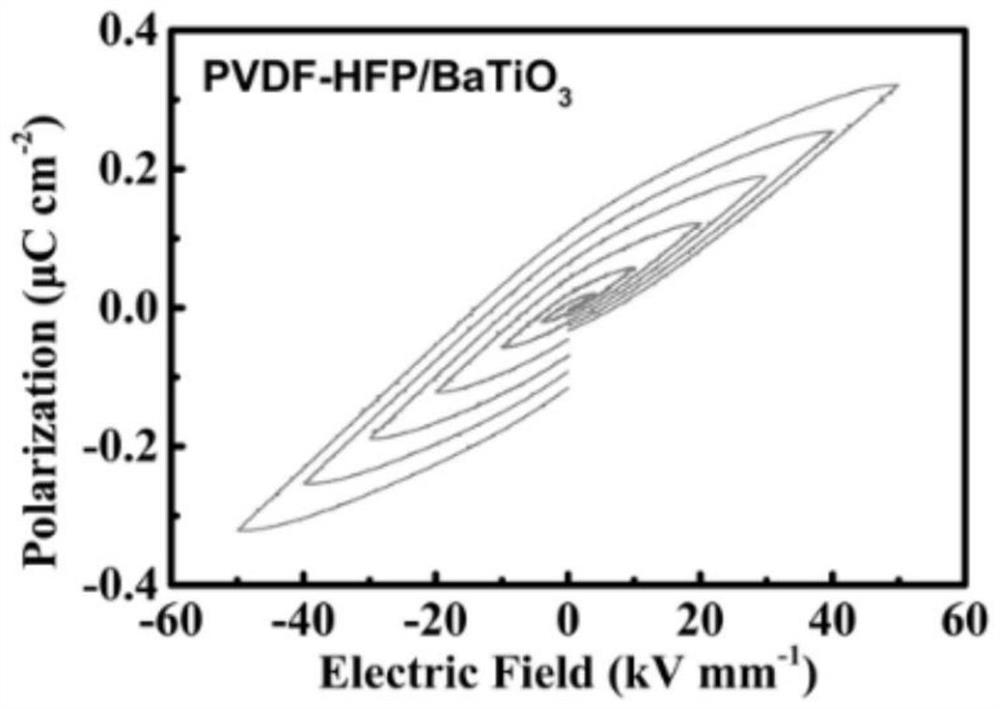

[0046] Embodiment 1. A piezoelectric composite diaphragm for a lithium metal battery in this embodiment is prepared from polyvinylidene fluoride-hexafluoropropylene powder, barium titanate particles, acetone and deionized water. Prepared by doctor blade coating and DC voltage polarization, the mass ratio of the barium titanate particles to polyvinylidene fluoride-hexafluoropropylene powder is 5:100, the particle size of the barium titanate particles is 300nm, the The molecular weight of polyvinylidene fluoride-hexafluoropropylene powder is 600,000.

[0047] The method for preparing the lithium metal battery piezoelectric composite separator of Example 1 is carried out in the following steps:

[0048] Step 1: Disperse the barium titanate particles in acetone, and ultrasonically treat them for 1 hour at room temperature to obtain a piezoelectric ceramic dispersion;

[0049] Step 2: Add polyvinylidene fluoride-hexafluoropropylene powder into the piezoelectric ceramic dispersion ...

Embodiment 2

[0053] Example 2. The difference between this example and Example 1 is that the mass ratio of the barium titanate particles to the polyvinylidene fluoride-hexafluoropropylene powder is 10:100. Other steps and parameters are the same as in Example 1.

Embodiment 3

[0054] Example 3. The difference between this example and Example 1 is that the mass ratio of the barium titanate particles to the polyvinylidene fluoride-hexafluoropropylene powder is 20:100. Other steps and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com