Door casing milling device

A groove milling device and door sleeve technology, applied in the field of door and window processing, can solve the problems of large cutting amount, large load, and easy damage of the milling cutter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

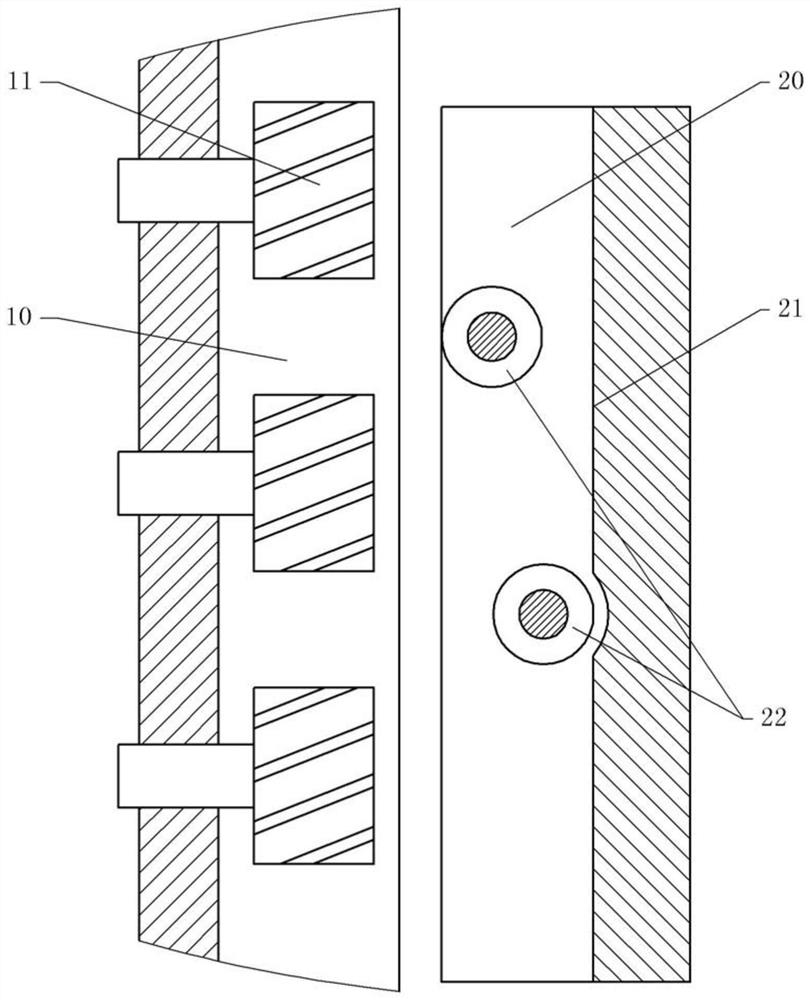

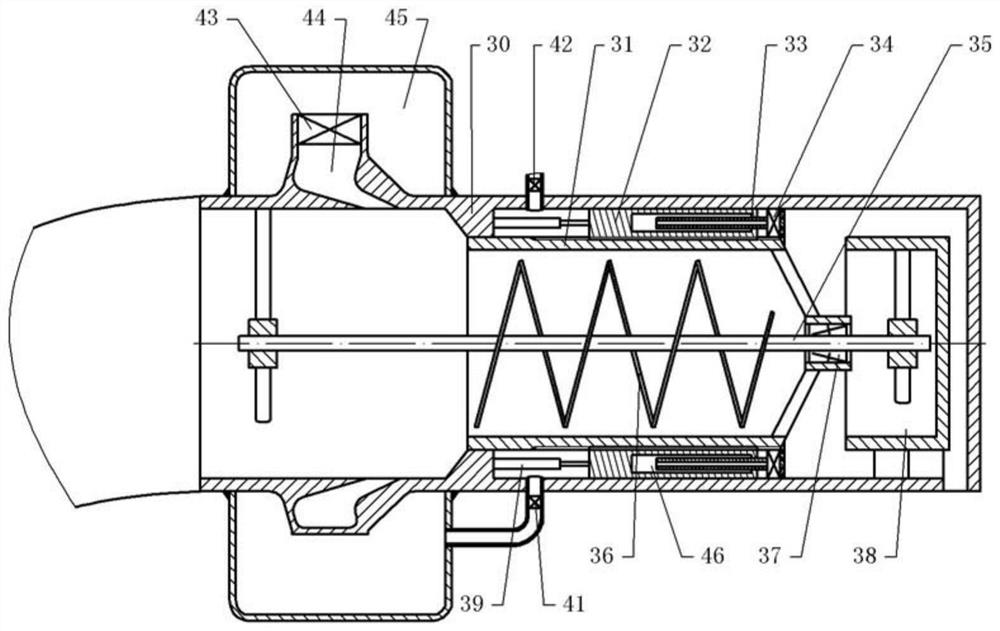

[0020] The reference signs in the accompanying drawings of the description include: bed 10, feed roller 11, tool holder 20, datum surface 21, milling cutter 22, air duct 30, feed pipe 31, piston 32, slide rod 33, press nozzle 34, Rotating shaft 35, spiral guide piece 36, one-way bearing 37, sleeve pipe 38, reciprocating cylinder 39, air outlet check valve 41, intake check valve 42, solenoid valve 43, high-pressure air inlet 44, high-pressure chamber 45, air chamber 46.

[0021] The slot milling device of the door cover in this embodiment includes a bed 10, a feeding mechanism, a slot milling mechanism and a dust removal mechanism. Such as figure 1 As shown, the feeding mechanism includes several feed rollers 11 that are rotatably connected to the bed 10, and the first drive motor that drives the feed rollers 11 to rotate is installed on the bed 10; the plate is placed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com