Patents

Literature

116results about How to "Fully exclude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

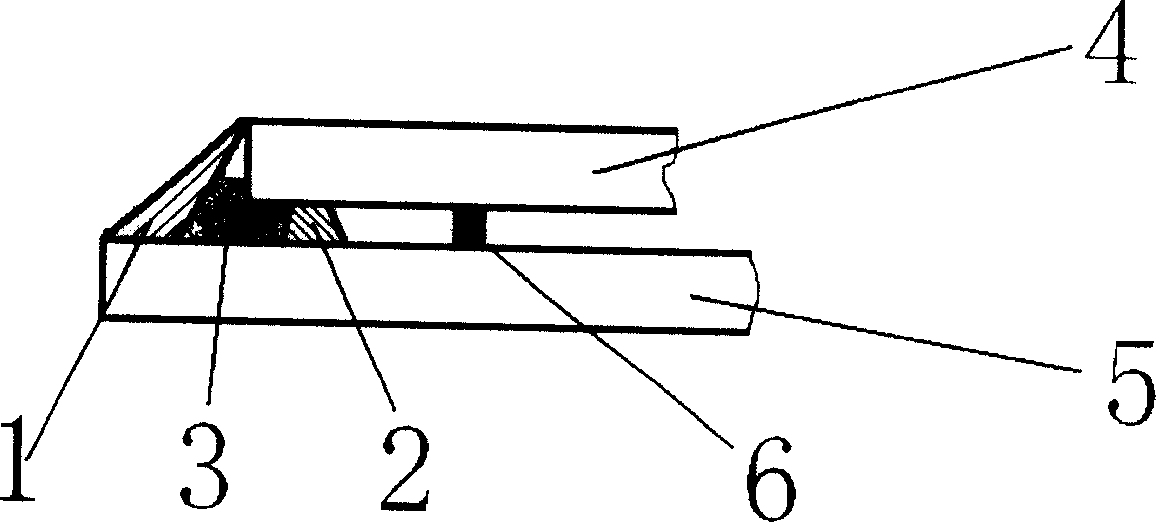

Method for sealing edge of vacuum glass

InactiveCN102311222AEasy to placeSolder edges are neat and beautifulGlass reforming apparatusSoldering

The invention provides a method for sealing edge of vacuum glass. The method is characterized in that: a glass soldering material is put on the periphery of a vacuum glass raw sheet; and an inner impermeable layer is arranged at the inner side of the glass soldering material so that the glass solder liquid is limited to flowing into the inner cavity of the vacuum glass raw sheet, wherein the inner impermeable layer is made from powdery or fibrous materials.

Owner:黄家军

Preparation method of chinlon 6 cool jade fiber

ActiveCN103757738AStrong wear resistanceStrong coolnessArtifical filament manufactureMonocomponent polyamides artificial filamentWoven fabricAluminium

The invention discloses a preparation method of a chinlon 6 cool jade fiber. The fiber is prepared by the steps of adopting an extraction technology and a nanotechnology, allowing jade and other beneficial mineral materials such as aluminum, silicon, titanium, zirconium and other elements to reach the sub-nanometer particle size, then fusing into a chinlon 6 melt, and carrying out spinning processing to obtain the fiber. The chinlon 6 cool jade fiber has the strength equivalent to a conventional chinlon 6 fiber, has strong wear resistance, has strong cool feel compared with an ordinary silk woven fabric, and is simple in spinning process and high in practicability.

Owner:FUJIAN JINJIANG TECH

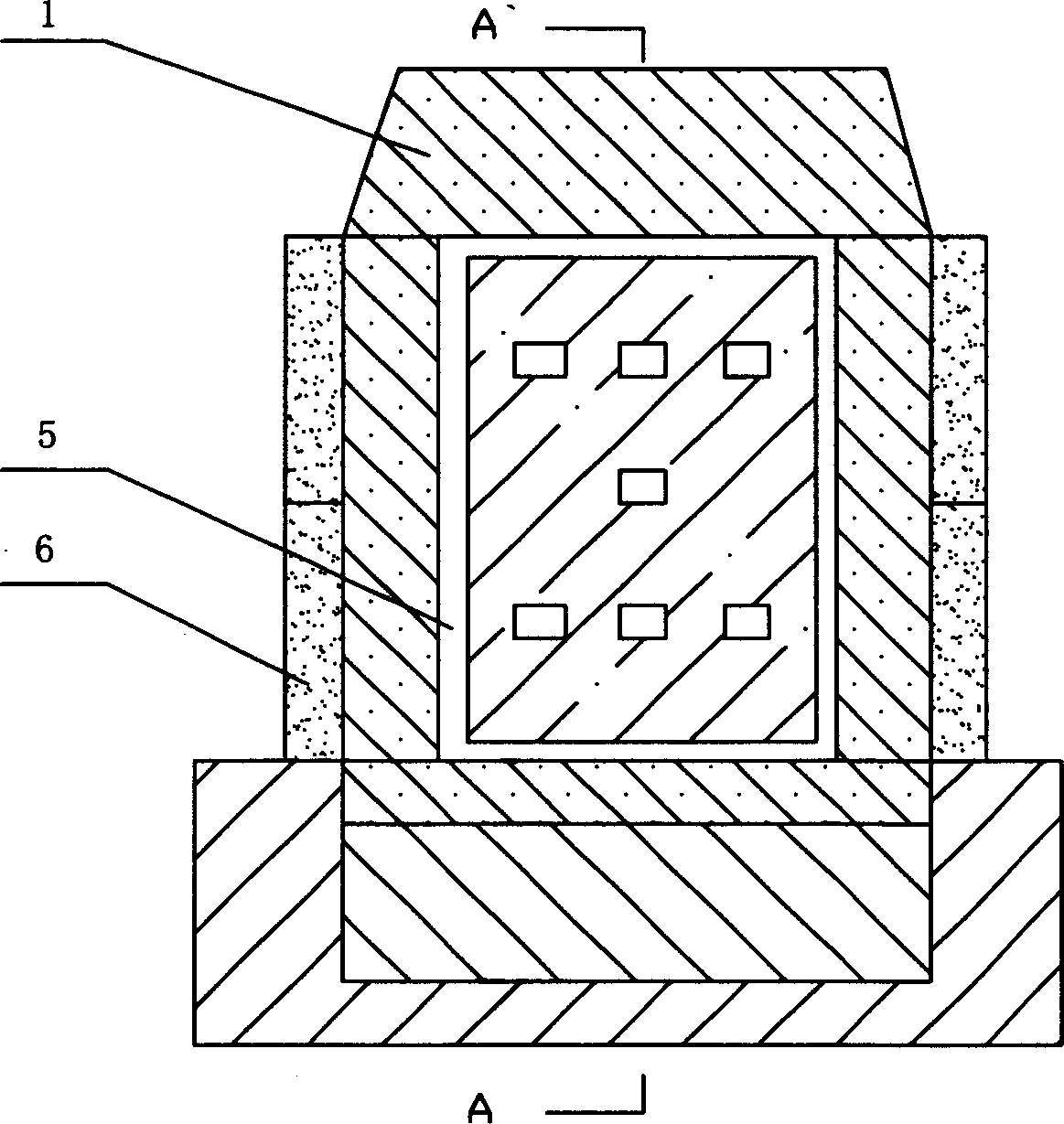

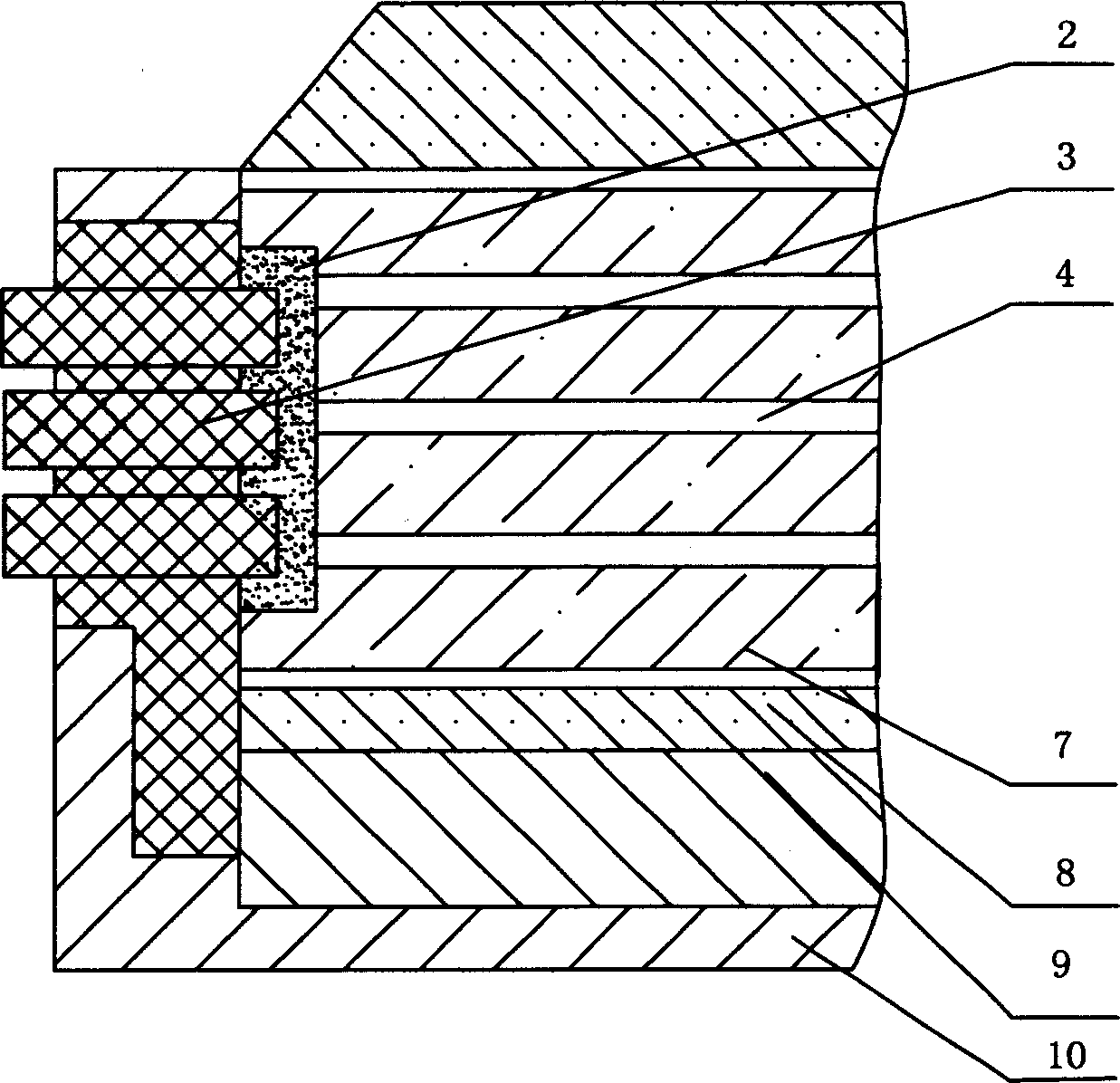

Method for enhancing performance of electric heating tube

ActiveCN101340745AImprove high temperature performanceImprove reliabilityHeating element shapesManufacturing technologyWork in process

The invention relates to a method used for improving electric heating management performance, belonging to the manufacture technique of an electric heating device. The method of the invention comprises the steps as follows: a: austenitic stainless steel pipe is taken as the external pipe of the electric heating pipe; after electric heating wire and MgO powder are filled in the external pipe by a routine method, the diameter of the external pipe is shortened by the pipe contracting disposal; b: after the pipe contracting disposal, the half finished product is disposed by high temperature once; c: after the high temperature disposal, the pipe-bending process is carried out by a bending deformation method so as to bend the external pipe as bent shape; d: routine moisture-removal disposal or stress-removal disposal or secondary high-temperature disposal is carried out on the half finished product after the pipe-bending process; e: the pipe port is closed after the moisture-disposal disposal or the secondary high-temperature disposal. The method of the invention adds the high temperature polishing disposal or high temperature oxidation disposal or high temperature oxidation disposal process in suitable procedure of the processing technology of the electric heating pipe, thus achieving the objects of improving the high temperature performance, reliability and prolonging the service life of the electric heating pipe by most economical processing steps.

Owner:ZHENJIANG DONGFANG ELECTRIC HEATER +1

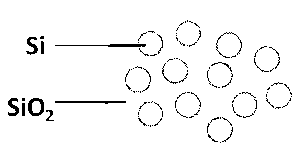

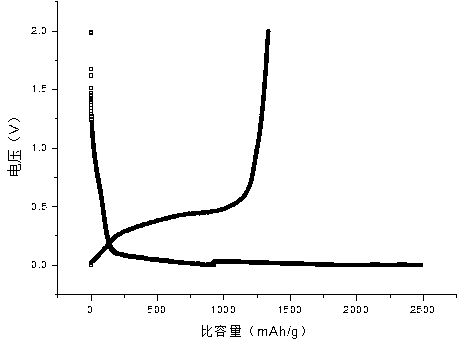

Lithium ion battery silicon-based negative material and preparation method thereof

InactiveCN103236517ASmall particle sizeAlleviate volume effectCell electrodesSilicon monoxideSilicon oxide

The invention relates to a lithium ion battery silicon-based negative material and a preparation method thereof, which belong to the technical field of lithium ion battery negative materials. The lithium ion battery silicon-based negative material is prepared from silicon monoxide; the macroscopic particle diameter of the negative material is 10-25 micrometers; according to a microstructure, the negative material is composed of nanometer silicon particles covered with silica; the internal silicon particle diameter of the negative material is 20-30 nanometers; and at 0.1C discharge rate, the first discharge capacity of the negative material reaches 2010-2640 mAh / g, and is 420-790 mAh / g after 50 cycles. The negative materials with the structure characteristic combines the dispersion and the reduction of silicon particles; and on one hand, the silicon particles can be dispersed by a pore channel structure of silica so as to provide a space for the expansion of silicon in charge and discharge processes, on the other hand, the particle diameter of silicon can be reduced, and therefore, a volume effect of silicon in the charge and discharge processes can be weakened.

Owner:中国东方电气集团有限公司

Method for precission shaping ceramic blank by semi-water-base injection-moulding gel process

The invention belongs to the field of inorganic material, relating to the improvement of a ceramic blank precision molding technique. The steps of the invention includes: mixing, blending and ball-milling, eliminating gas, adding in catalyst or reducing agent, adding in initiator, injection molding and gelating, and demolding and drying. The invention uses less water, thoroughly eliminates organic matter, reduces the blank shrinkage and avoids larger-sized ceramic blanks from cracking in the drying course. Besides, the gelated blanks have better machining property before glycol, glycerine, and other solvents are eliminated.

Owner:BEIJING AVIATION MATERIAL INST NO 1 GRP CORP CHINA AVIATION IND

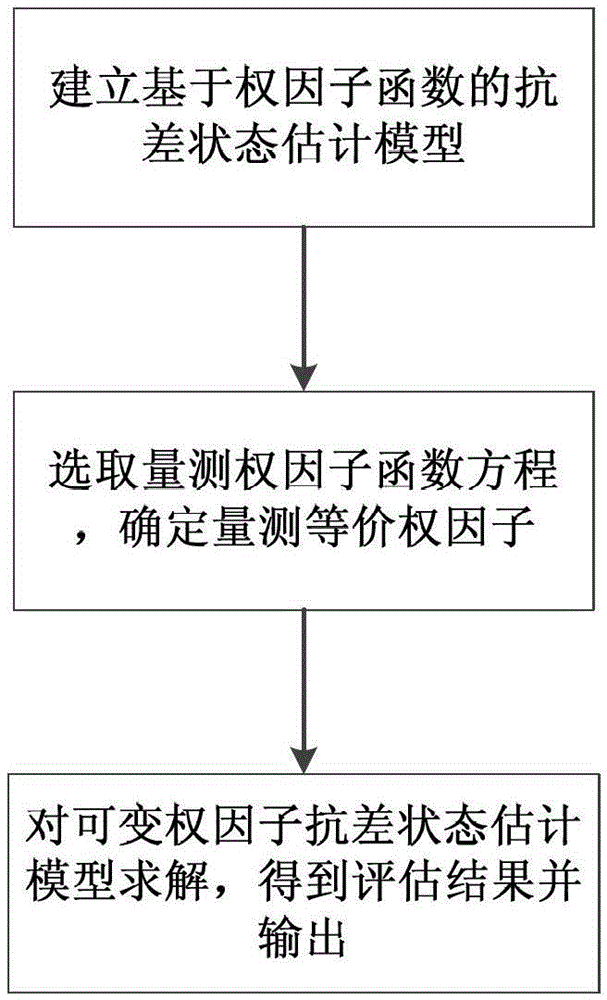

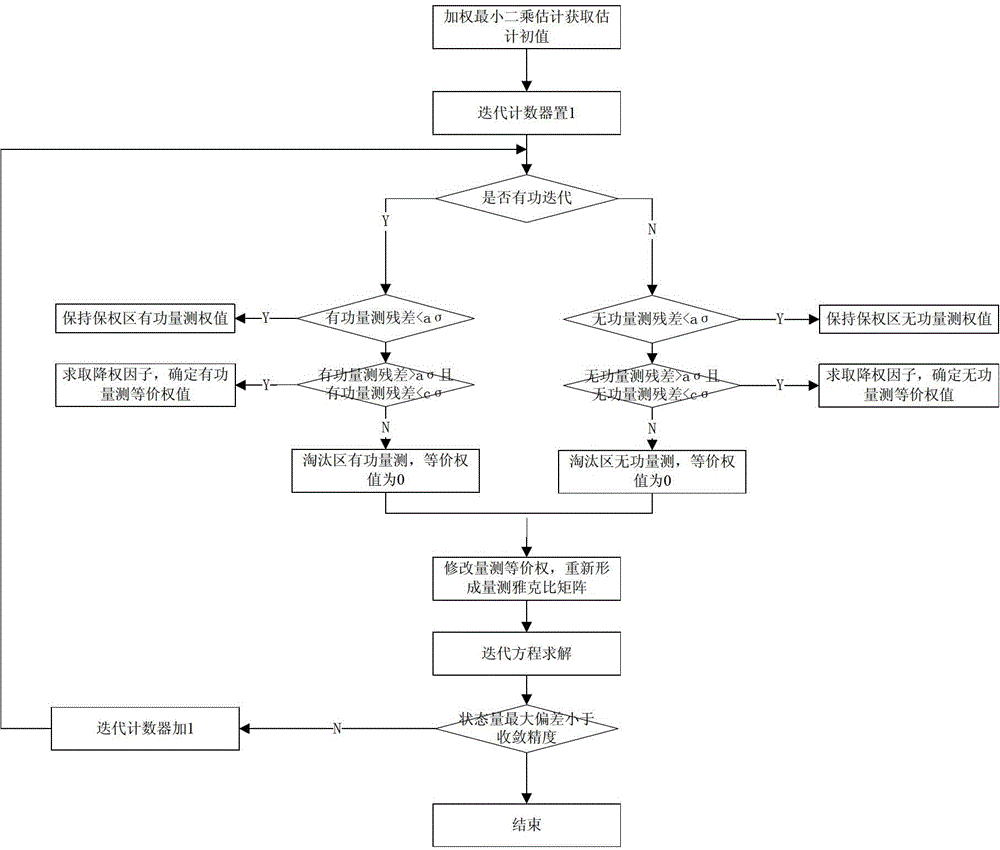

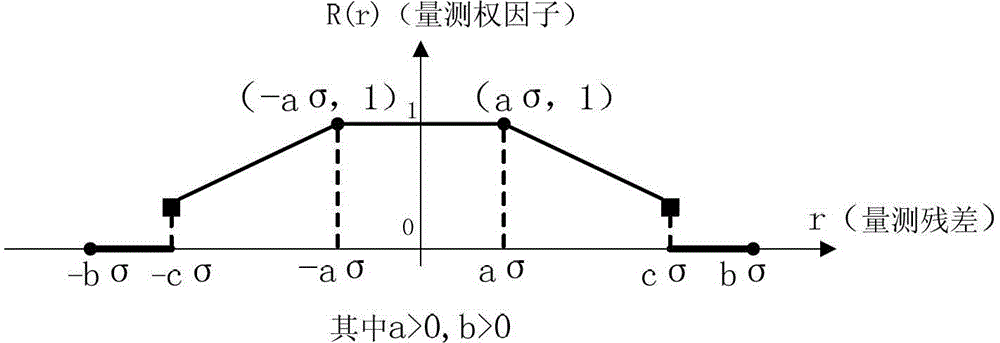

Robust state estimation method based on piecewise linearity weight factor function

InactiveCN103336904AProcessing accuracyTake advantage ofSpecial data processing applicationsEstimation methodsElectric power system

The invention provides a robust state estimation method based on a piecewise linearity weight factor function and belongs to the technical field of power system computation. The method includes the steps of step 1, establishing a robust state estimation model based on the weight factor function, step 2, selecting and measuring a weight factor function equation and determining and measuring equivalent weight factors, and step 3, solving the variable weight factor robust state estimation model, and obtaining and outputting estimation results. Aiming at section difference of traditional weight least square estimation on bad data identification, the robust state estimation method based on the piecewise linearity weight factor function is proposed, a weight least square estimation method and the robust estimation principle are combined, therefore, computation efficiency and quickness of the weight least square estimation are reserved, and also the state estimation algorithm has high robust performance.

Owner:STATE GRID CORP OF CHINA +1

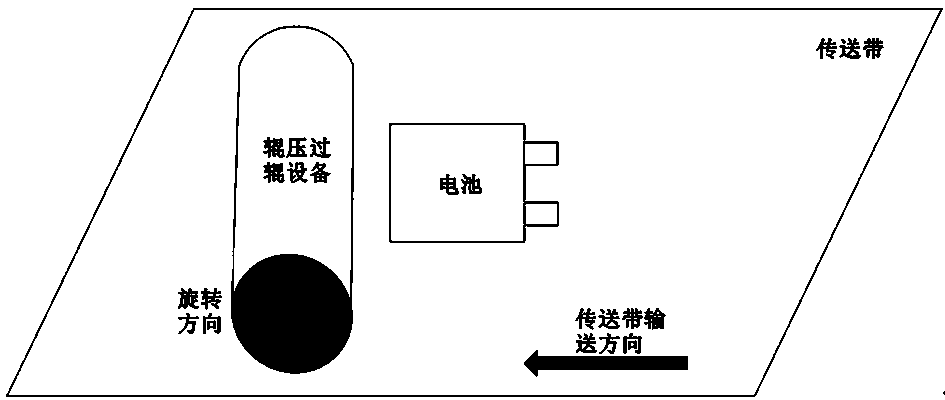

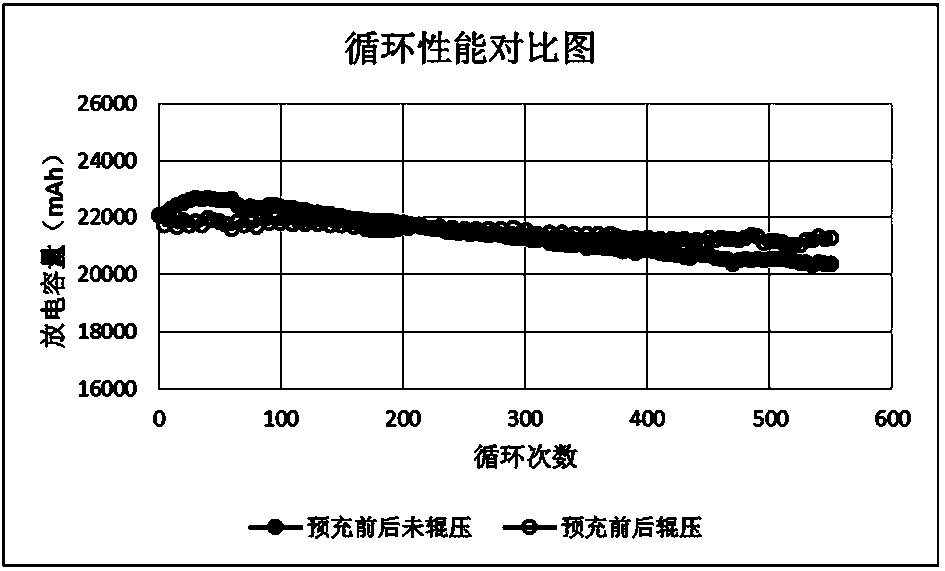

Novel control method for improving lithium ion soft-package laminated battery diaphragm fold

InactiveCN108155424AImprove performanceGuaranteed plastic effectFinal product manufactureSecondary cells charging/dischargingElectrical batteryPre-charge

The invention relates to a novel control method for improving lithium ion soft-package laminated battery diaphragm fold. The problem that the battery performance is influenced due to the fold of the soft-package laminated lithium ion battery diaphragm is solved. The control method comprises the following steps: laying down a battery after liquid injection, thereby ensuring that the electrolyte sufficiently infiltrates a pole piece; and then performing rolling on the lay-down battery, and controlling the pressure and speed of the rolling in the rolling process; pre-charging the battery after the rolling is ended; and performing secondary rolling on the completely pre-charged battery, further shaping the diaphragm, and releasing the gas to finish the secondary package. The contacting interface between a positive / negative pole piece and the diaphragm is better by comparing the lithium ion soft-package laminated battery prepared based on the control method with the battery without performing the rolling shaping, the dead lithium existing in the fold area caused by the diaphragm fold is avoided, thus the capacity of the positive / negative material is sufficiently played, and the batteryperformance is improved.

Owner:JIANGSU FRONT NEW ENERGY +1

Method for precisely shaping non-water-base injection molding gel of ceramic body

ActiveCN102085688AAchieve precision moldingAchieve sintering densificationCeramic shaping apparatusCross-linkWater based

The invention belongs to the field of inorganic nonmetallic materials, relating to a method for precisely shaping the non-water-base injection molding gel of a ceramic body. The method comprises the following steps of: mixing one or more of anhydrous alcohol organic solvents with low viscosity to serve as a solvent; adding ceramic powder, an organic monomer and a cross linking agent, wherein the organic monomer and the cross linking agent can be dissolved in a solvent system; after mixed milling, obtaining the non-water-base ceramic slurry with high ceramic powder volume weight and good flowability; adding a proper quantity of initiator; pouring the initiator into a die after the initiator is evenly mixed with the mixture; solidifying slurry gel in the presence of a catalyst or reducing agent or under the heating condition so as to precisely shape the non-water-base ceramic solvent; removing glue and sintering for the obtained blank to obtain the required ceramic. Because of adopting the non-aqueous solvent in the process, the method can be suitable for precisely shaping the gel of the easily-hydrolytic ceramic powder raw material, and the danger that the large-size ceramic blank is easy to deform and crack in the drying process can be avoided.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Method for machining small deep hole of part by using peck type variable speed drilling

ActiveCN104551091AReduce processing costsNo breakageOther manufacturing equipments/toolsAdverse effect compensationPunchingHigh pressure

The invention relates to the technical field of machining of a small deep hole of a mechanical part, in particular to a method for machining the small deep hole of the part by using peck type variable speed drilling. Small deep hole punching treatment is performed on drill bit rotation speed and a drill bit in a small deep hole machining process of the part, and further the phenomenon that the drill bit is broken does not occur when the small deep hole of the part is machined; the use of high-pressure cooling liquid is combined, so waste chips can be fully discharged during drilling of the drill bit to avoid obstruction of the drill bit and improve the drill bit punching efficiency; then the drill bit rotation speed is controlled to a certain extent, further the damage caused to the drill bit by elasticity or vibration produced at the moment of punching of the small deep hole is avoided, and further the machining cost of the small deep hole of the part is reduced.

Owner:CHINA HANGFA GUIZHOU LIYANG AVIATION POWER CO LTD

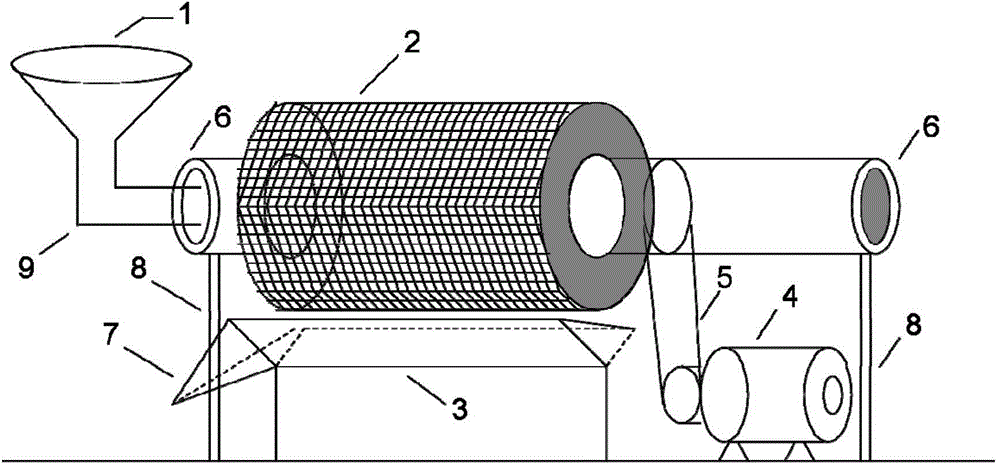

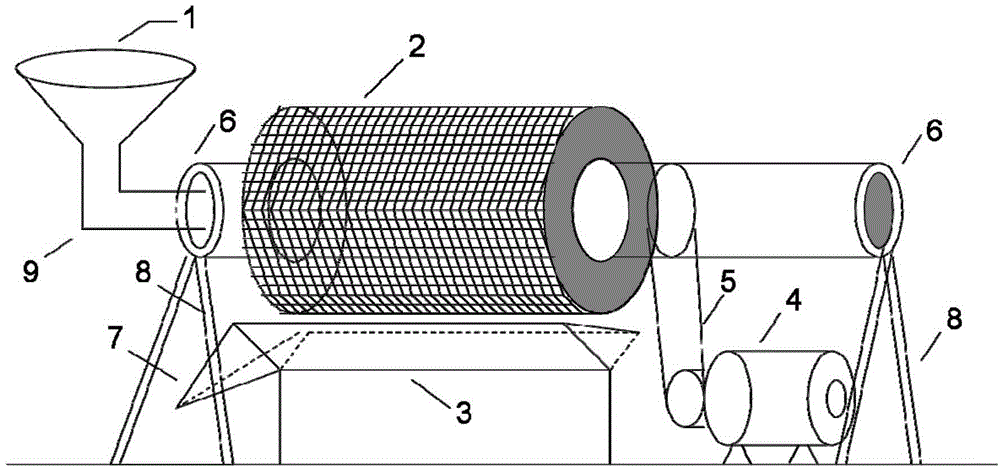

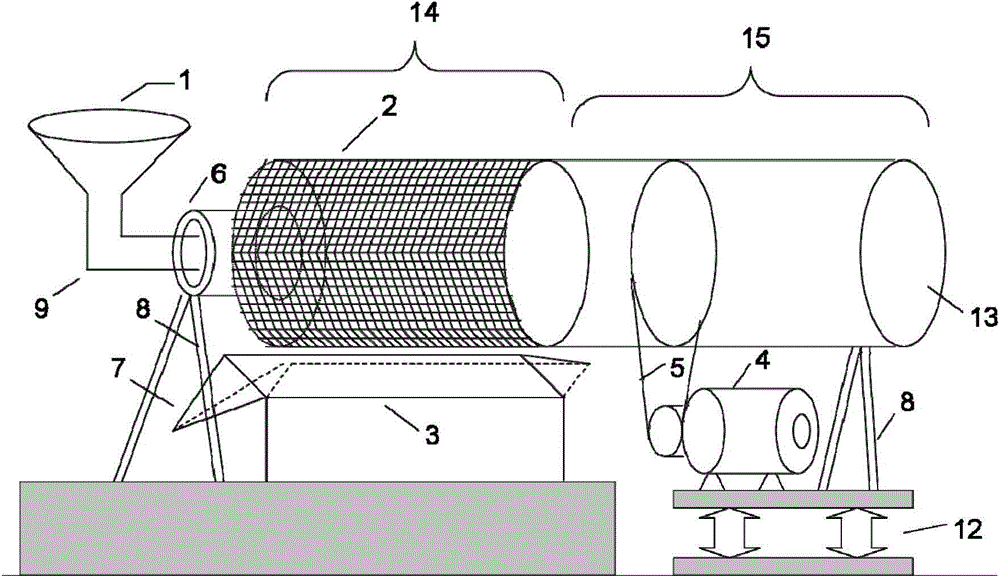

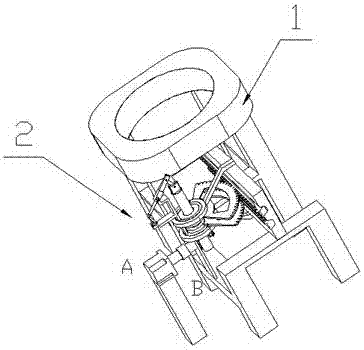

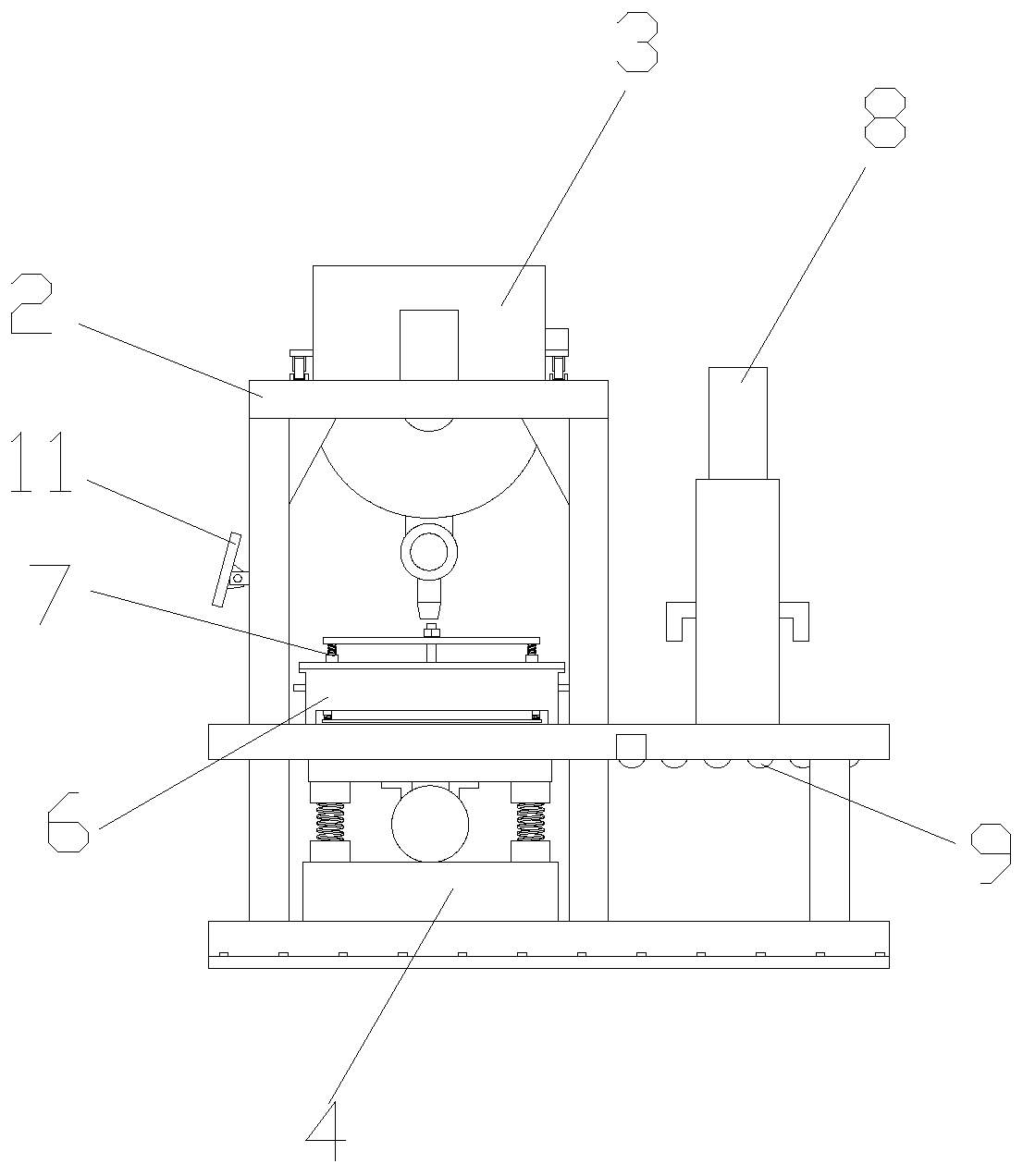

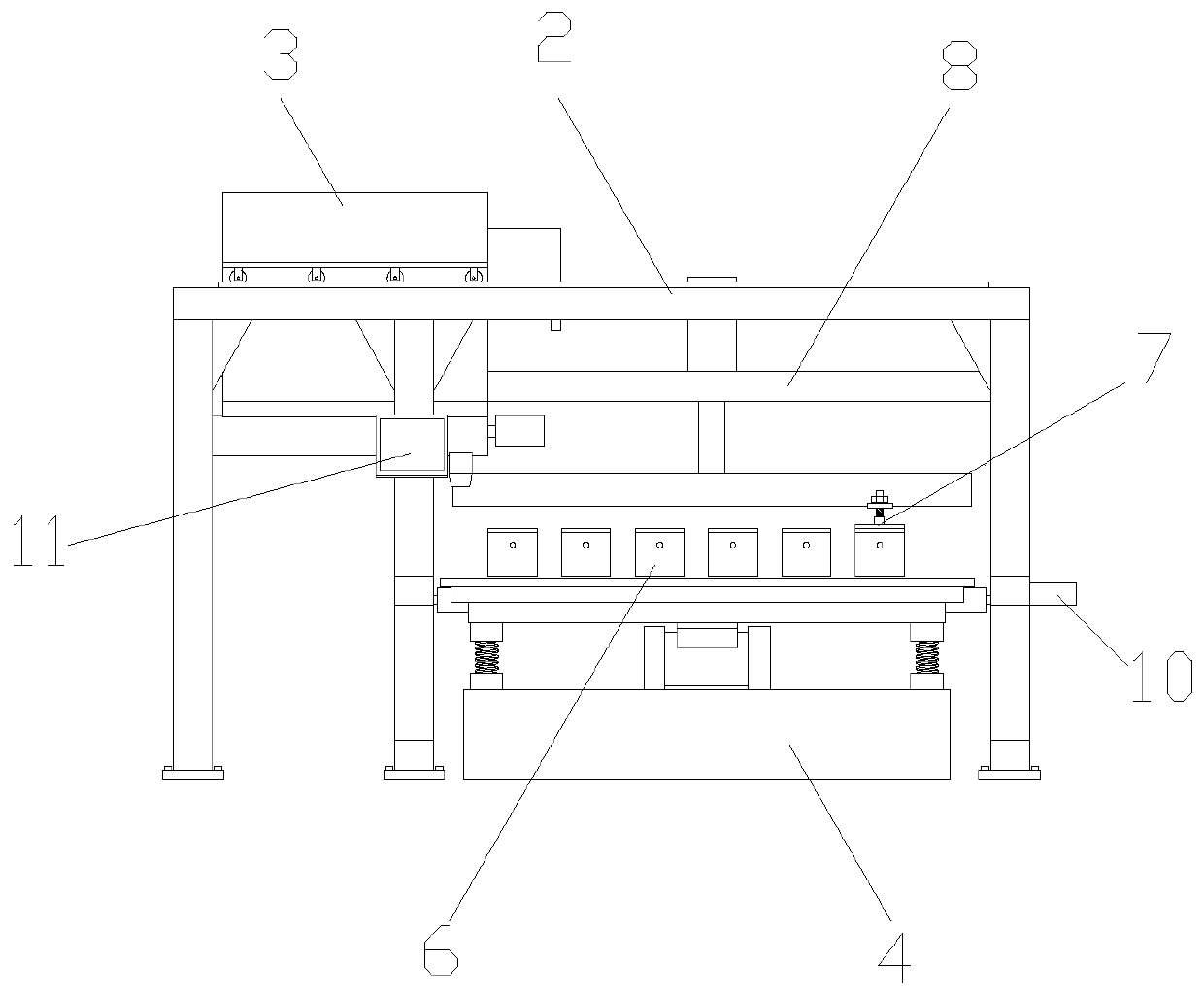

Filter device, treatment process and application thereof

ActiveCN104606940APromote exudationFully excludeMoving filtering element filtersHigh concentrationCynomorium songaricum

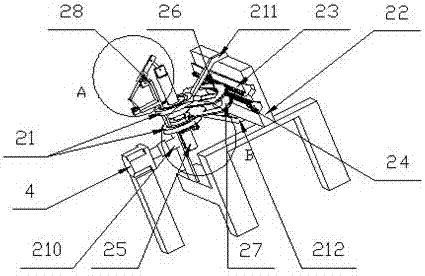

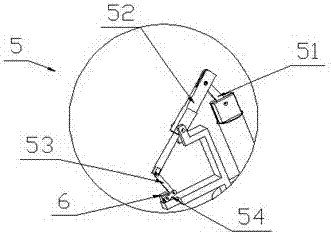

The invention provides a filter device for high-concentration herb residues and / or fruit residues. The device comprises a feeding component, a filter screen cartridge (2), a connecting shaft (6), a liquid receiving component (3), a power component (4), a transmission component (5) and a stand column (8). Under the rotation of the filter screen cartridge (2), herb residues and / or fruit residues, which are extracted by a solvent, are gathered into clusters in the screen cartridge and roll along with the rotation of the screen cartridge; herb residue clusters and / or fruit residue clusters form cracks in the rolling process and then are clustered again. The filter device has an effect of promoting the seepage of liquid in the herb residues and / or fruit residues, therefore an extracting solution or original juice are fully removed, and the solid-liquid separation effect is realized. The filter device is suitable for the berry or fruit kind of fruit residue treatment and is also suitable for filtering the extracted residues of other plants such as maca, kelp, abelmoschus esculentus, abelmoschus manihot, cistanche and cynomorium songaricum.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for increasing kiln transformation ratio of Nixing pottery large vessels

The invention provides a method for increasing kiln transformation ratio of Nixing pottery large vessels. The method comprises the following steps: 1) preparing blanks, namely producing the blanks from 50-60 parts by weight of east mud, 30-40 parts by weight of west mud and 8-15 parts by weight of iron oxide red; 2) blank forming, namely forming the blanks into various large vessels of different shapes; 3) shaping the blanks; 4) drying the blanks; and 5) firing the blanks, namely gradually increasing the temperature to the range of 500-750 DEG C at a temperature rise rate of 30-50 DEG C per hour, adding a kiln transformation material at the temperature and sealing the air holes of the kiln, and then increasing the temperature to the range of 1000-1050 DEG C at a temperature rise rate of 200-250 DEG C per hour, preserving heat at the temperature and firing for 0.5-1 hour, naturally cooling and taking out of the kiln, thereby obtaining the finished products large Nixing pottery vessels.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

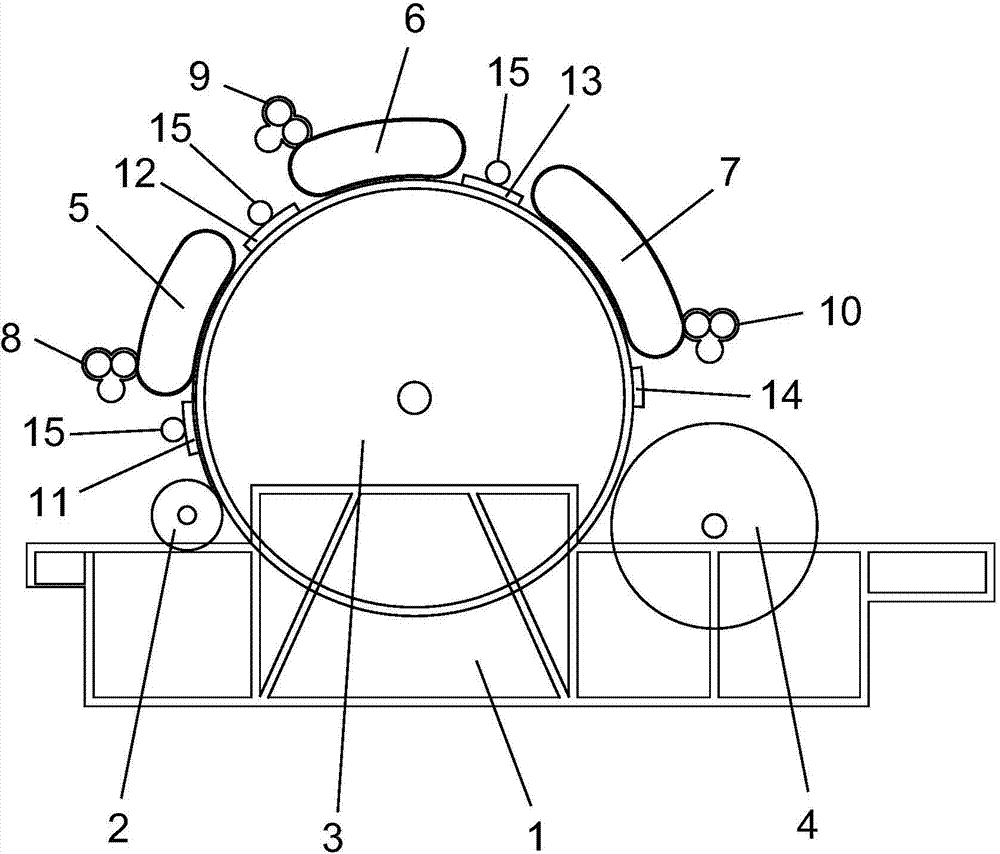

Carding machine

A carding machine comprises a rack, wherein a licker-in roller, a cylinder and a doffer are sequentially arranged on the rack from front to back; a first carding region cover plate, a second carding region cover plate and a third carding region cover plate are sequentially arranged on the top of the cylinder from front to back and correspond to the rack; partitions are respectively arranged between the first carding region cover plate and the second carding region cover plate and between the second carding region cover plate and the third carding region cover plate; the carding machine is provided with the three carding cover plates, so that three carding regions are formed; the first carding region is mainly used for clearing up and combing fibers smoothly and initially discharging impurities and short fibers; the second carding region is further used for clearing up and combing the fibers smoothly and initially discharging the impurities and the short fibers; the third carding region is mainly used for precisely combing the fibers and discharging the impurities and the short fibers further; each carding region cover plate is provided with a cover plate cleaning device; the cover plate cleaning devices can clean independently; and the cleaned carding cover plates can be used for combing operation rapidly and efficiently. The carding machine is provided with the three carding cover plates, the radian of each carding cover plate is reduced, the carding cover plates can be cleaned as soon as possible, the cleaning efficiency of the cover plates is improved further, and the carding effect is guaranteed.

Owner:QINGDAO HUANUO MACHINERY

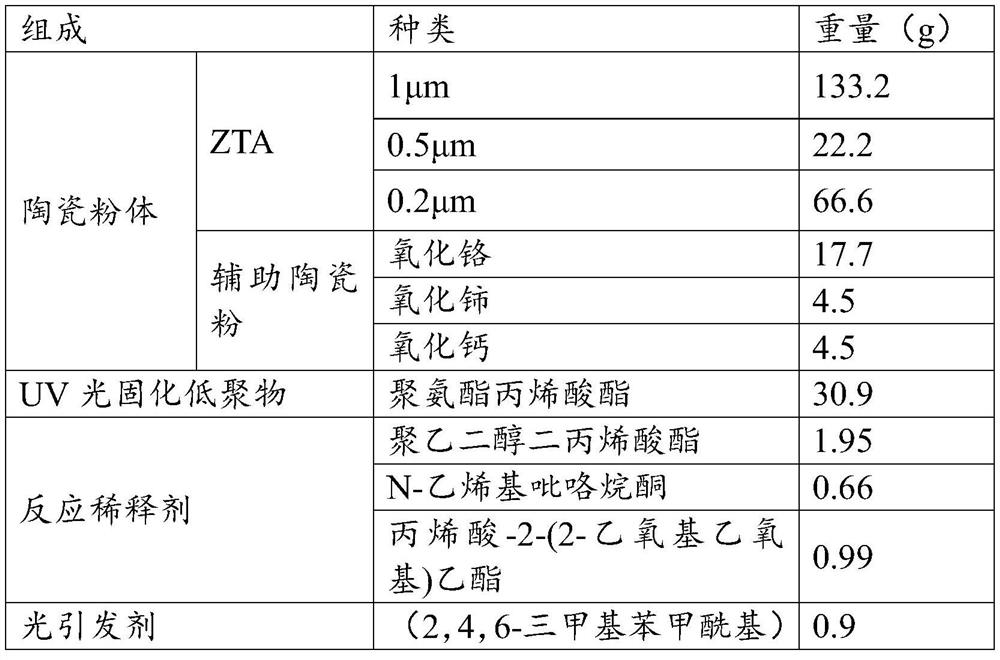

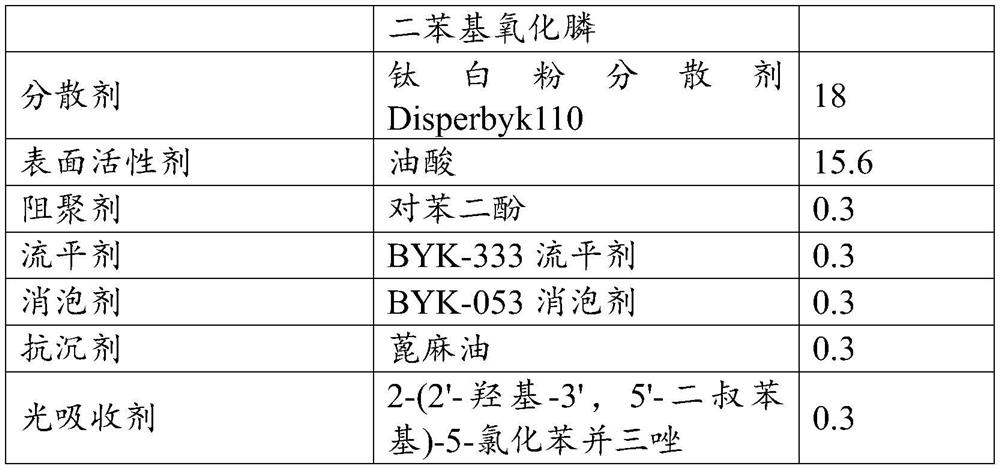

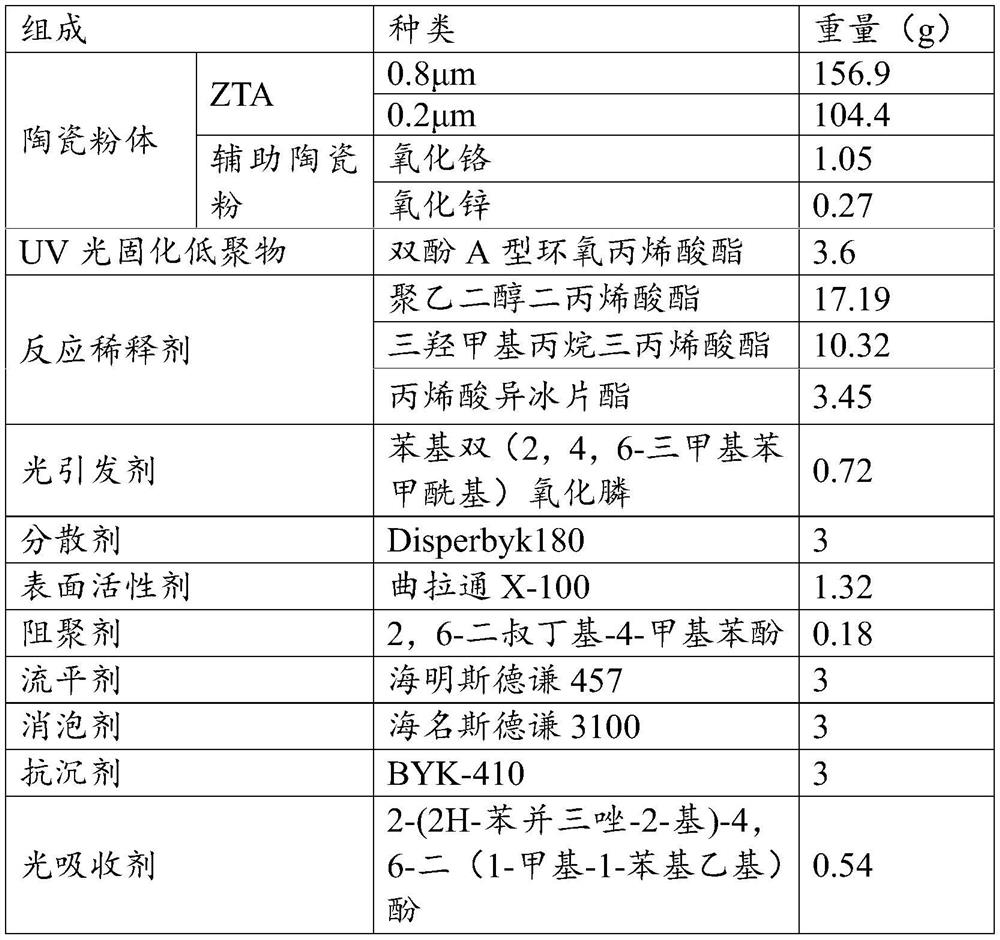

Preparation method of ceramic material

ActiveCN114380583AHigh hardnessHigh densityAdditive manufacturing apparatusCeramic shaping apparatusOxide ceramicAluminum Ion

The invention belongs to the technical field of ceramics, and provides a preparation method of a ceramic material, which comprises the following steps: degumming a zirconium oxide toughened aluminum oxide ceramic blank, pre-sintering, soaking in steeping liquor and sintering, wherein the impregnation liquid comprises a zirconium ion salt solution, an aluminum ion salt solution and urea. According to the preparation method of the ceramic material, the mixed solution of the zirconium ion salt solution, the aluminum ion salt solution and the urea is adopted as the steeping liquor to carry out post-treatment on the zirconium oxide toughened aluminum oxide ceramic green body, the compactness of the ceramic material is improved, and the defect that a ceramic product prepared through a traditional 3D printing technology is low in hardness is overcome.

Owner:重庆恩辰新材料科技有限责任公司 +1

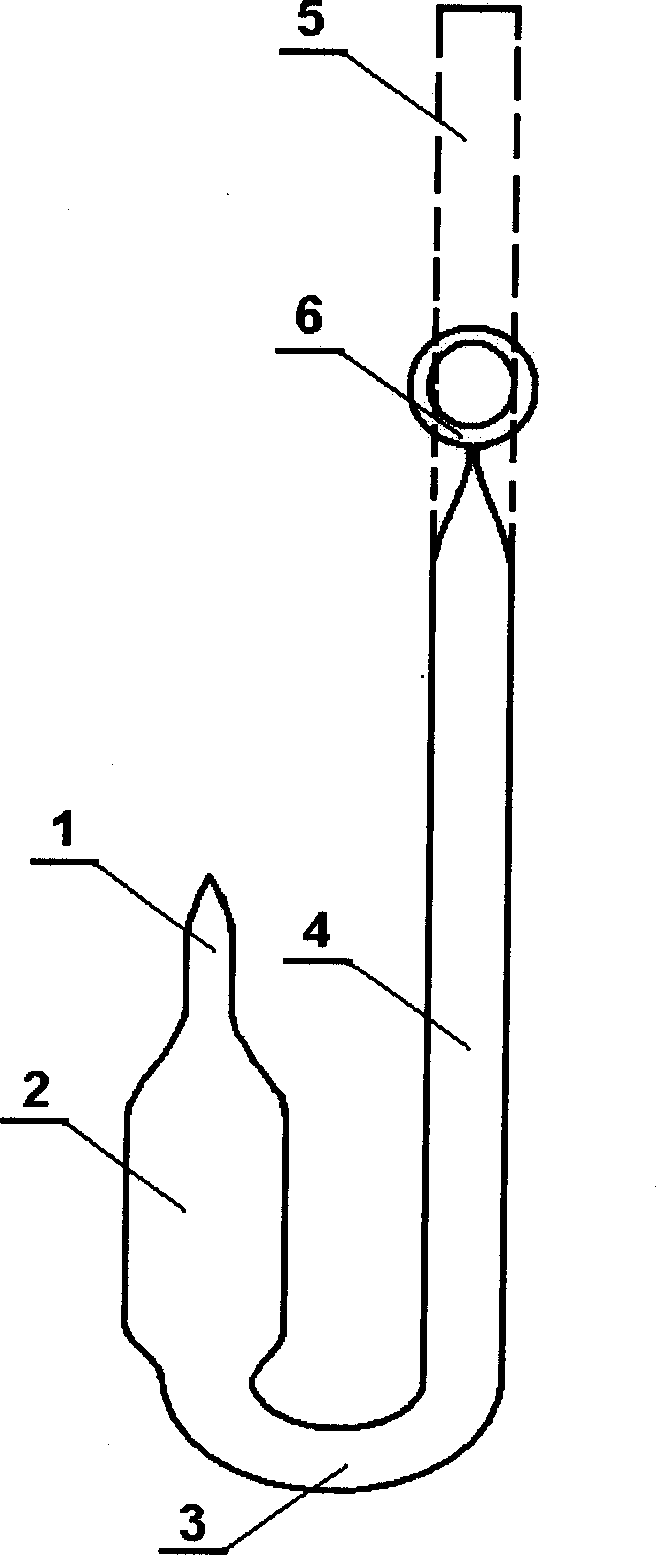

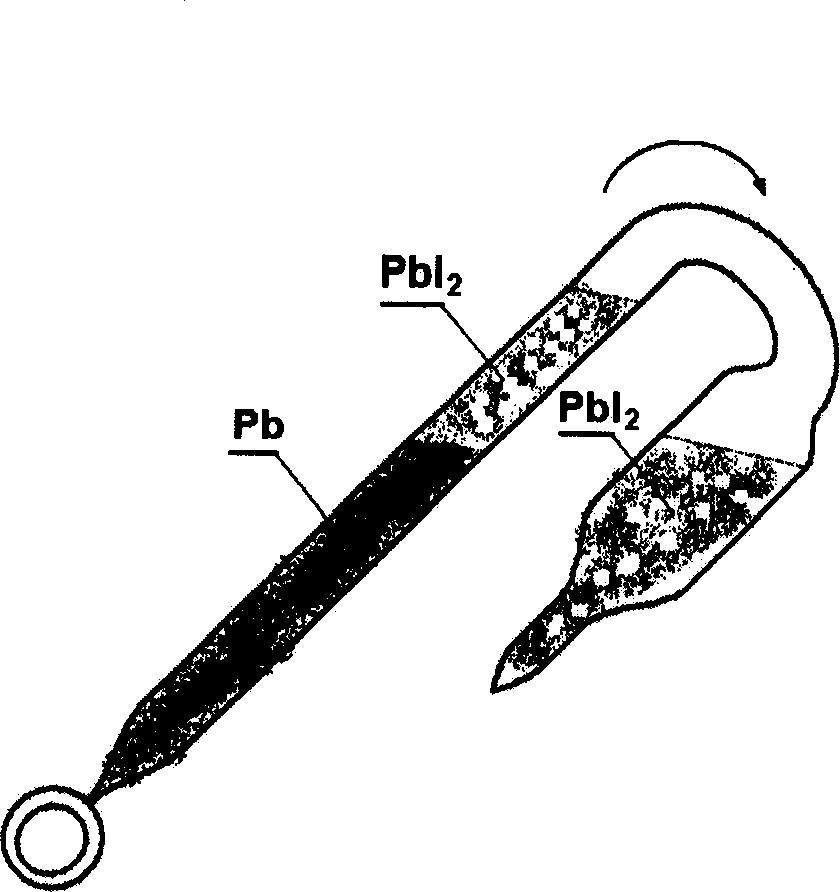

Method and appts. of using molten lead iodide to grow monocrystal

InactiveCN1834311AComplete structureUniform orange translucent statePolycrystalline material growthFrom frozen solutionsNuclear radiationDecomposition

This invention discloses method and equipment for preparing lead iodide single crystals from lead iodide melt, which comprises the steps of: cleaning an ampule, filling it with lead iodide powders, degassing and sealing the ampule, growing the single crystals and cooling. The method can effectively suppress the decomposition of lead iodide melt and the vaporization of iodine, and can remove segregated lead. The ampule is made of a quartz tube, and comprises a seed crystal bag, a growth chamber, a connecting vessel, a lead tube, a loading bag anb a hook. After filling, the ampule is placed into a two-stage temperature range vertical tubular furnace to finish the growth of the single crystals. The as-grown single crystals are orange and semi-transparent with sizes up to Phi (15-20)X30 mm. The electrical resistivity of as-grown single crystals can reach 1012-1013 ohm .cm, thus the single crystals have wide applications, especially as room temperature nuclear radiation detector.

Owner:XIHUA UNIV

Urine collecting and sampling device for laboratory medicine

InactiveCN107970046AFully excludeAccurate receptionSurgeryVaccination/ovulation diagnosticsUrine volumeMedical testing

The invention belongs to the technical field of medical examination and provides a urine collecting and sampling device for laboratory medicine. The technical scheme includes that the urine collectingand sampling device for laboratory medicine comprises a stool and a conveying mechanism on one side of the stool. The urine collecting and sampling device has advantages that the conveying mechanismcan be fixedly supported by the aid of the stool, earlier urine can be received accurately and can be effectively received in a urine cup, and urine is effectively prevented from splashing on hands, so that sanitation is realized by adoption of an operating method, and midstream urine volume can be controlled.

Owner:QINGDAO CENT HOSPITAL

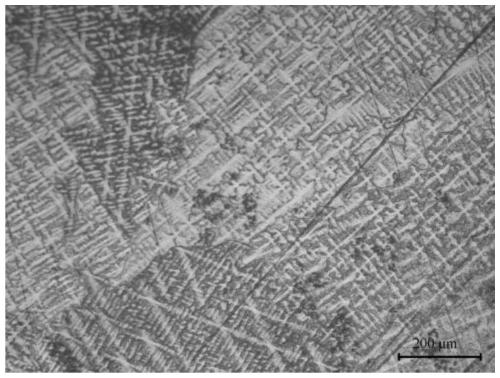

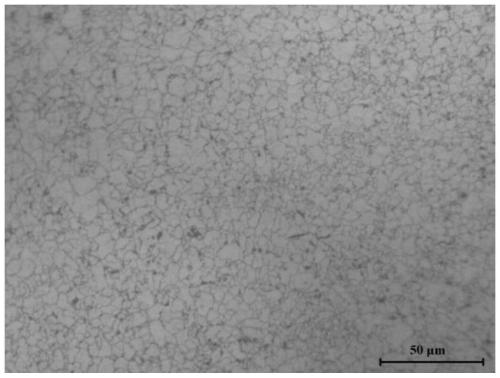

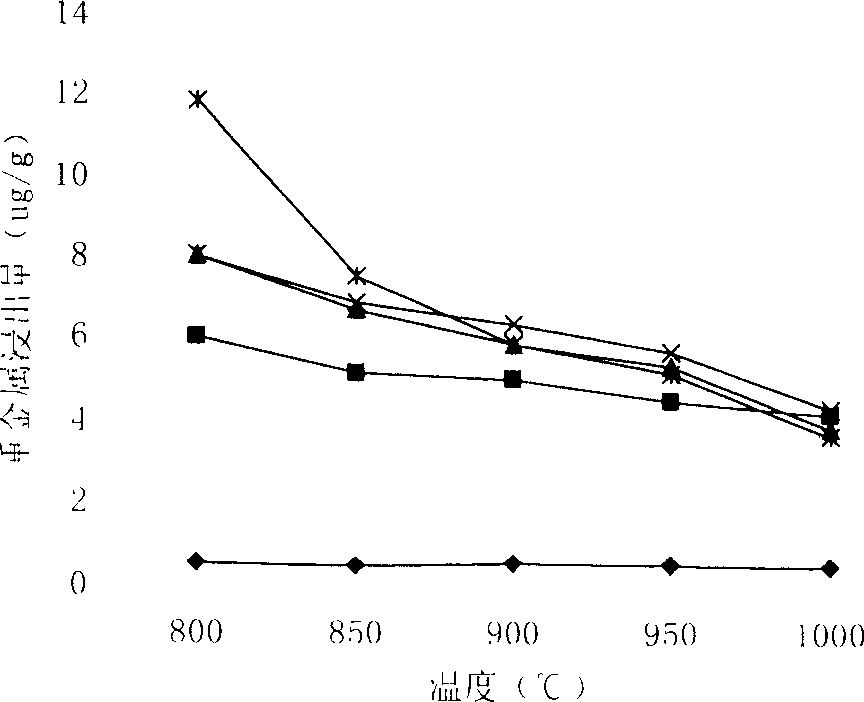

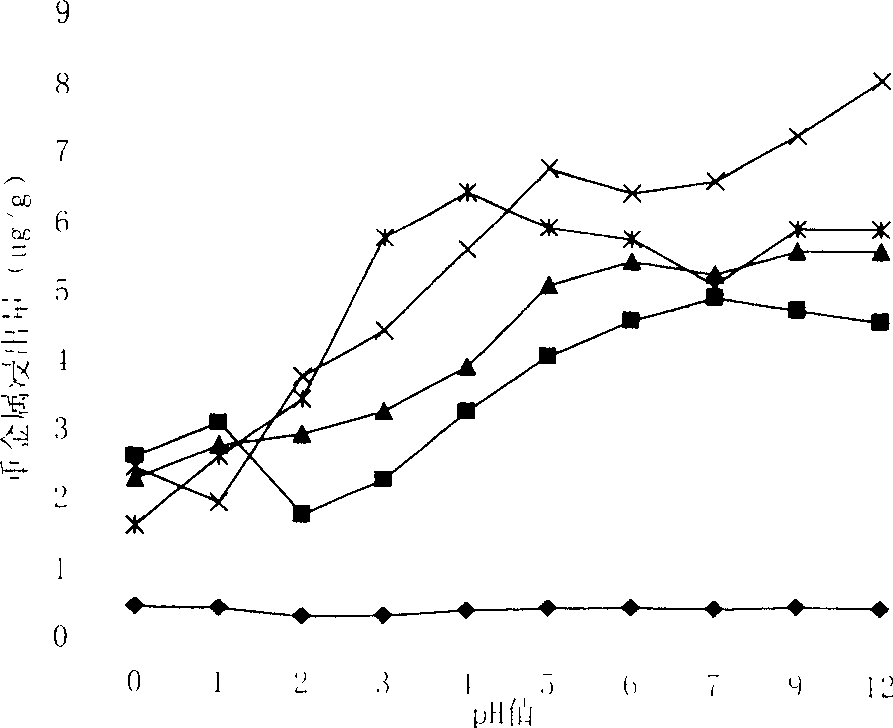

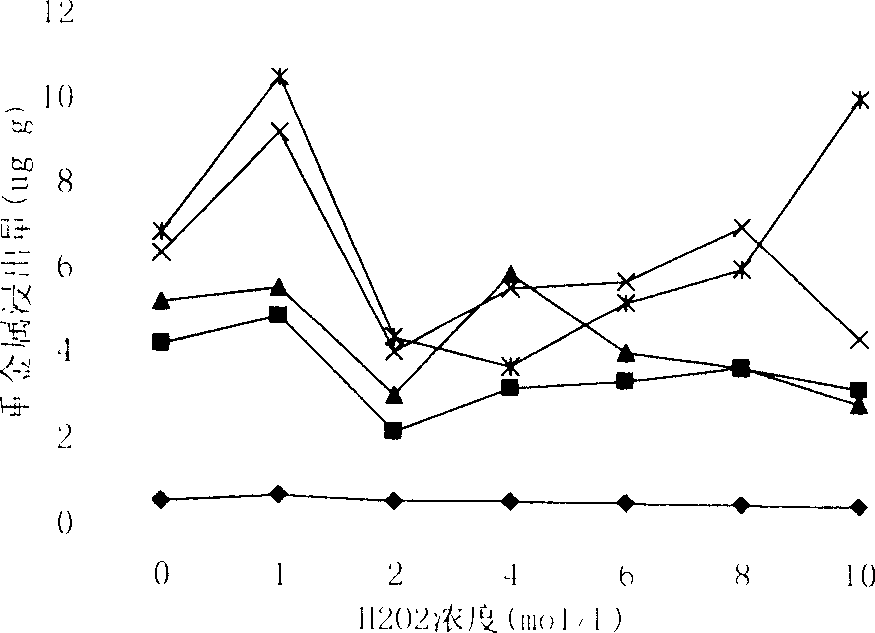

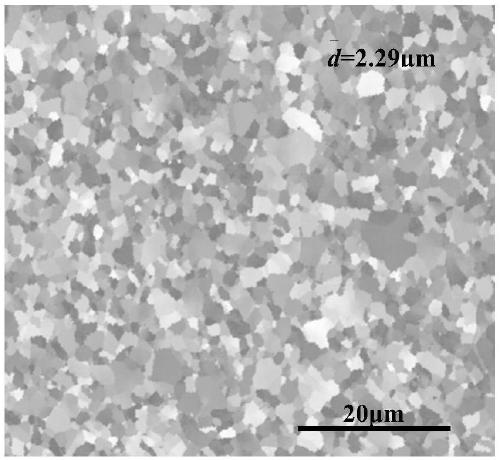

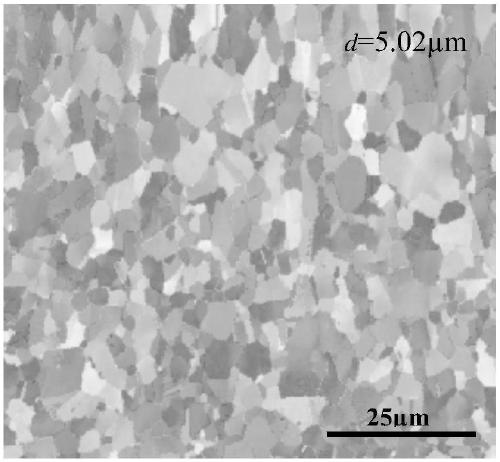

High-strength high-elasticity niobium-containing copper alloy and preparation method thereof

ActiveCN109763008AImprove plasticityIncrease elasticityTemperature control deviceMetal rolling arrangementsNiobiumHardness

The invention discloses a high-strength high-elasticity niobium-containing copper alloy and a preparation method thereof, and belongs to the technical field of copper alloy preparation. According to the high-strength high-elasticity niobium-containing copper alloy, the Vickers hardness is higher than or equal to 420 HV, the tensile strength is larger than or equal to 1300 MPa, the elongation is larger than or equal to 7.5%, the alloy grains are uniform and fine, the ultra-high strength, plasticity and elastic modulus are achieved, and the copper alloy and the preparation method can be widely used in the fields of high and new technologies such as automobiles, rail transits, electronic and electrical and aerospace; The preparation method of the high-strength high-elasticity niobium-containing copper alloy can effectively refine the grain size of the alloy, control the size and distribution of a precipitation second phase, strengthen the strength and elasticity of the alloy and improve the plasticity of the alloy.

Owner:CENT SOUTH UNIV

Petrol coke graphitization prepared carburant and petrol coke graphitization furnace filling technology

The invention relates to petroleum coke graphitization preparing carburant. It belongs to graphite manufacturing method technique field. The carburant carbon content is not less than 98.5%wt; sulfur content is not more than 0.04%wt; ash is not more than 0.4%wt; water is not more than 0.5%. The petroleum coke graphitization shove technique includes laying the bottom of furnace; setting furnace wall plate and fixing furnace core; furnace burdening and heat insulating material; covering the heat insulating material on the furnace core in box furnace body. The invention is set woodiness or graphite isolation layer between the furnace wall plate and petroleum coke, set graphite layer between furnace end carbon block and petroleum coke, and set diversion lead wire at each of the petroleum coke upper, middle, lower layers to make the graphitization more even, and thorough. The carburant performance index is better, and close to graphite smashing.

Owner:新郑市东升炭素有限公司

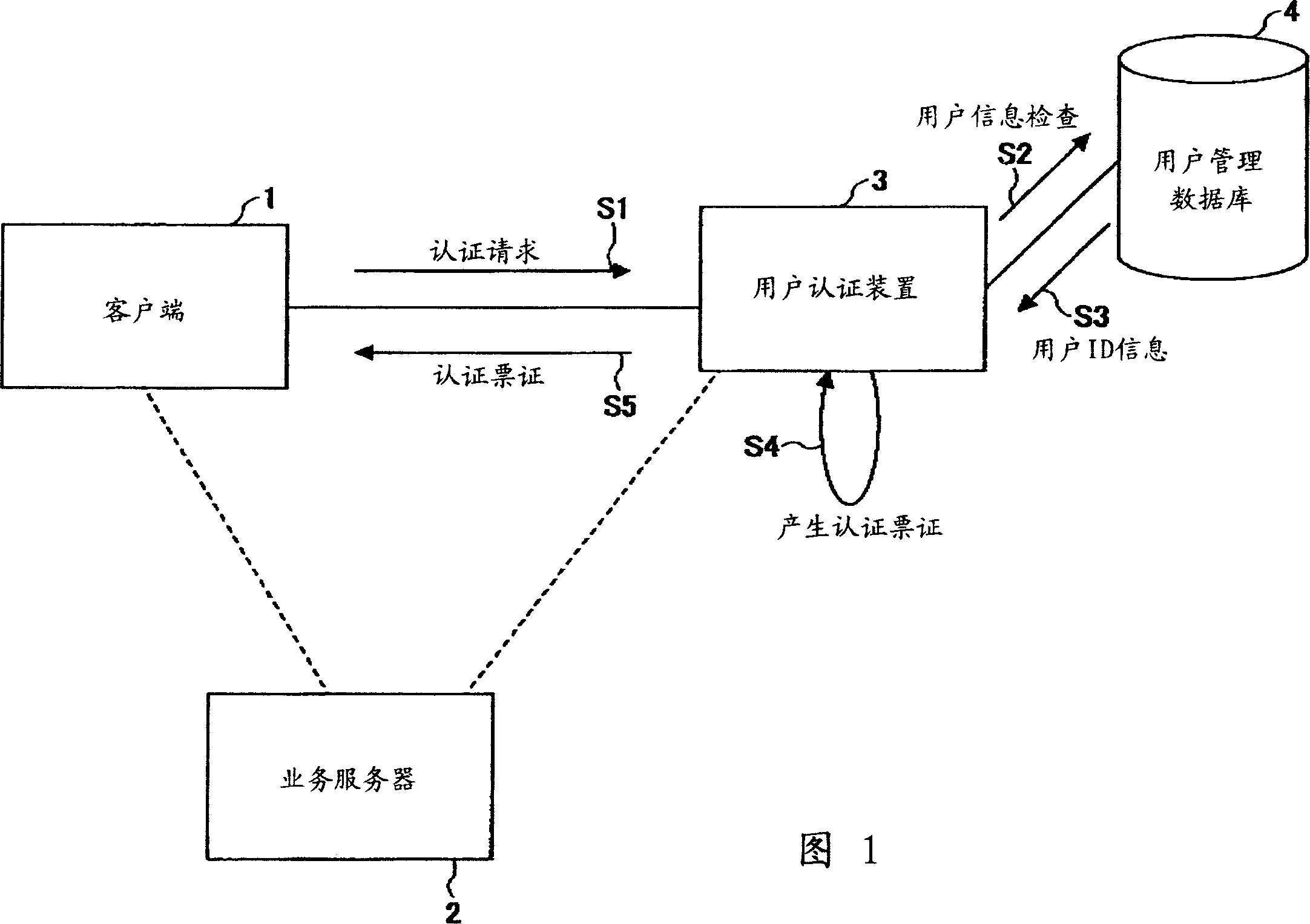

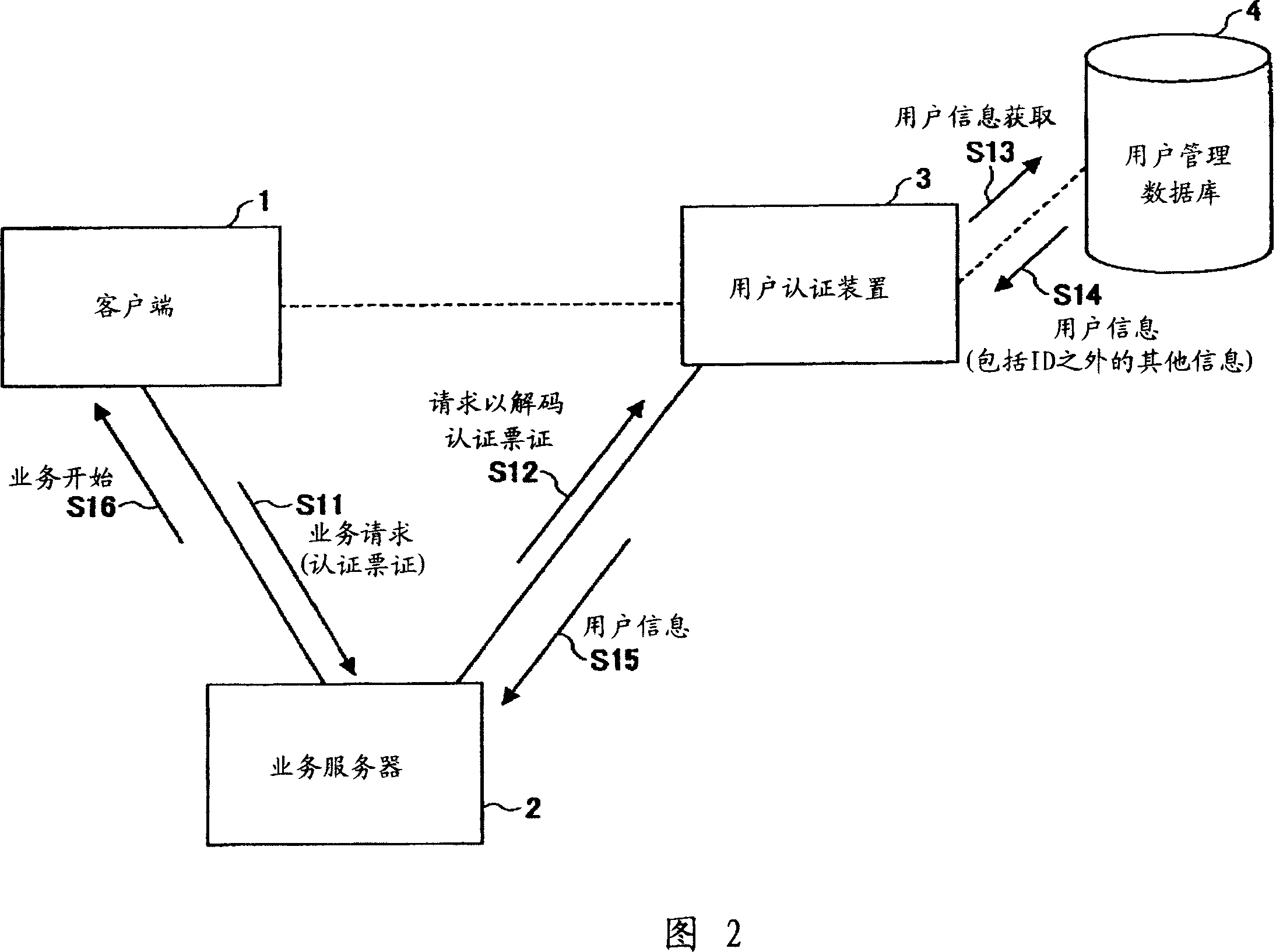

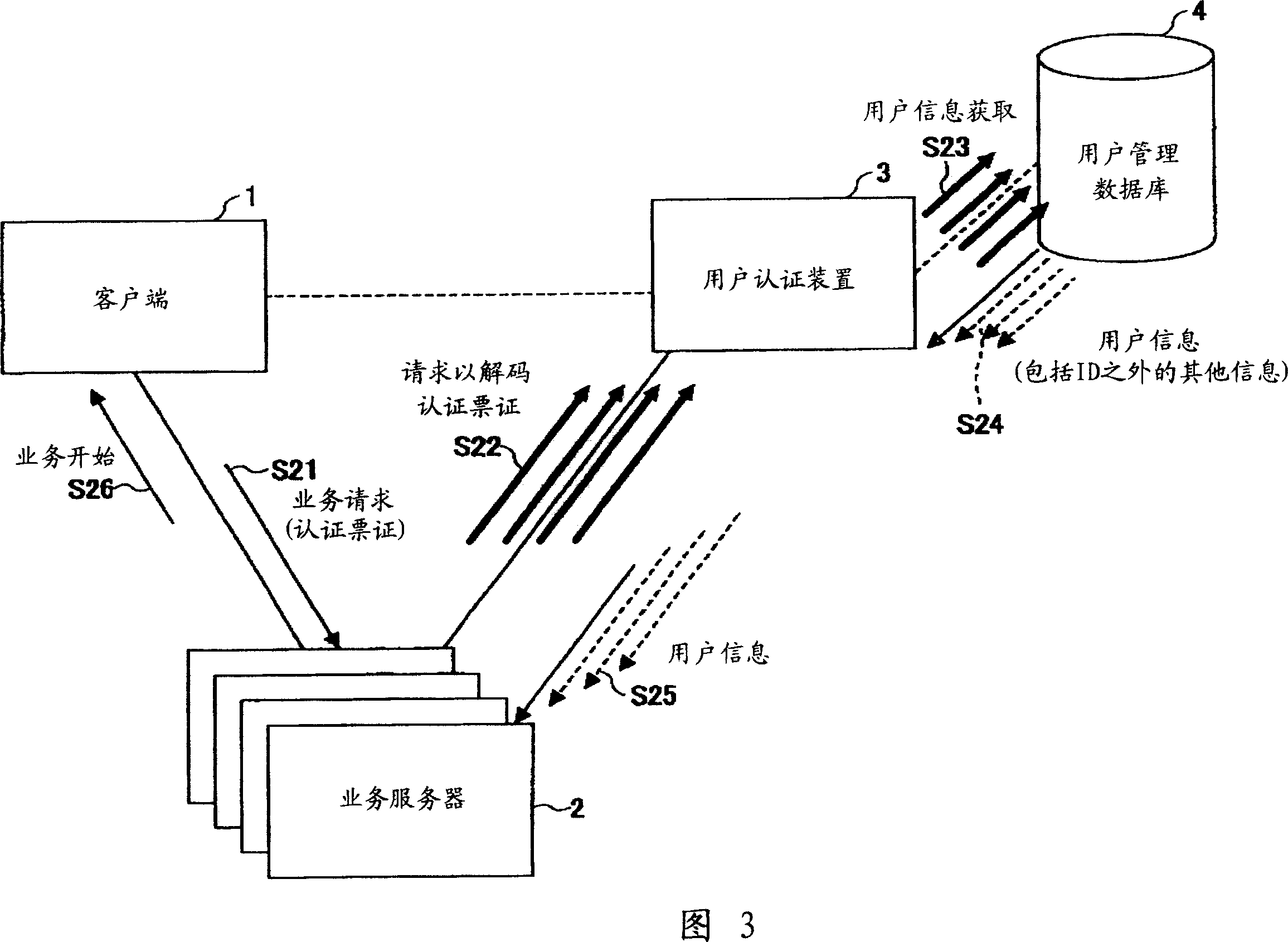

Authentication ticket processing apparatus and method with improved performance for self-contained ticket

An authentication ticket processing apparatus includes a temporary data storage unit configured to keep user information upon receiving the user information from a user management database for managing user information, the temporary data storage unit allowing access thereto to be performed at higher speed than access to the user management database. The authentication ticket processing apparatus is configured such that, when there is a need to acquire user information in response to a decoding request from a server, a check is made whether user information corresponding to the decoding request is present in the temporary data storage unit, and the corresponding user information is acquired from the temporary data storage unit if the corresponding user information is present in the temporary data storage unit.

Owner:RICOH KK

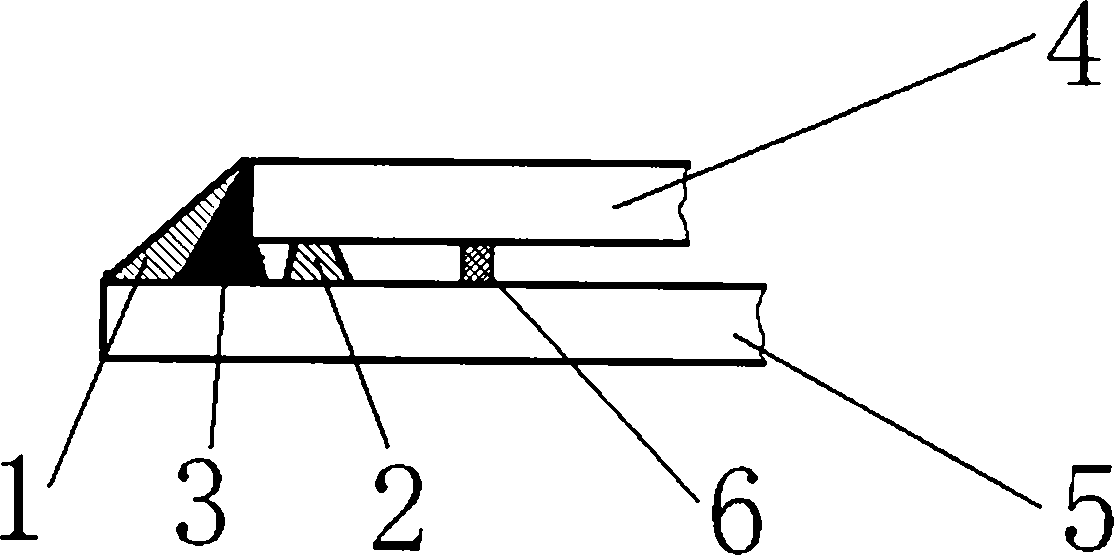

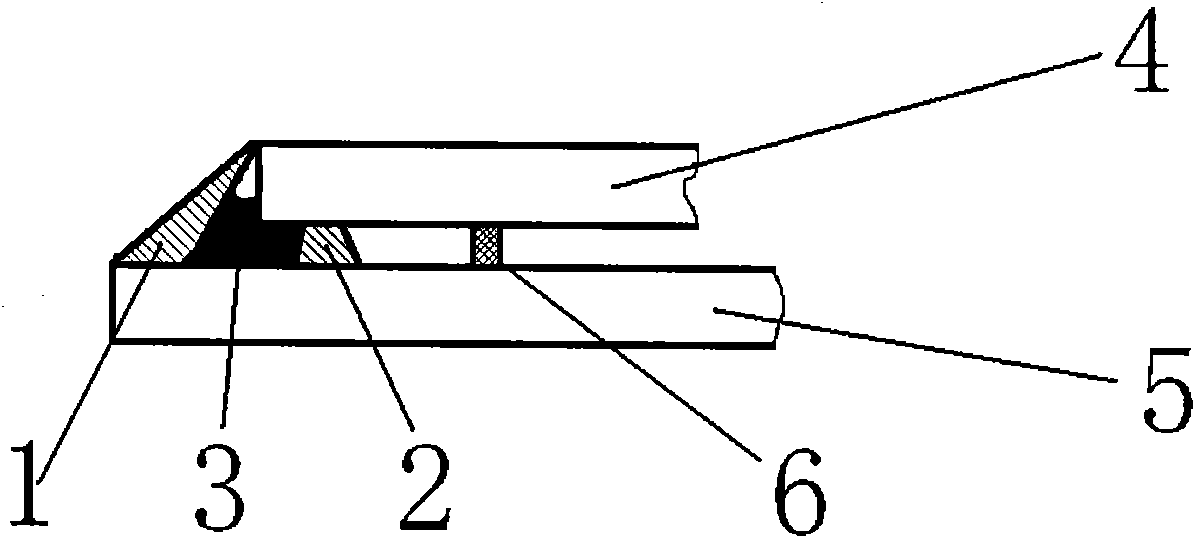

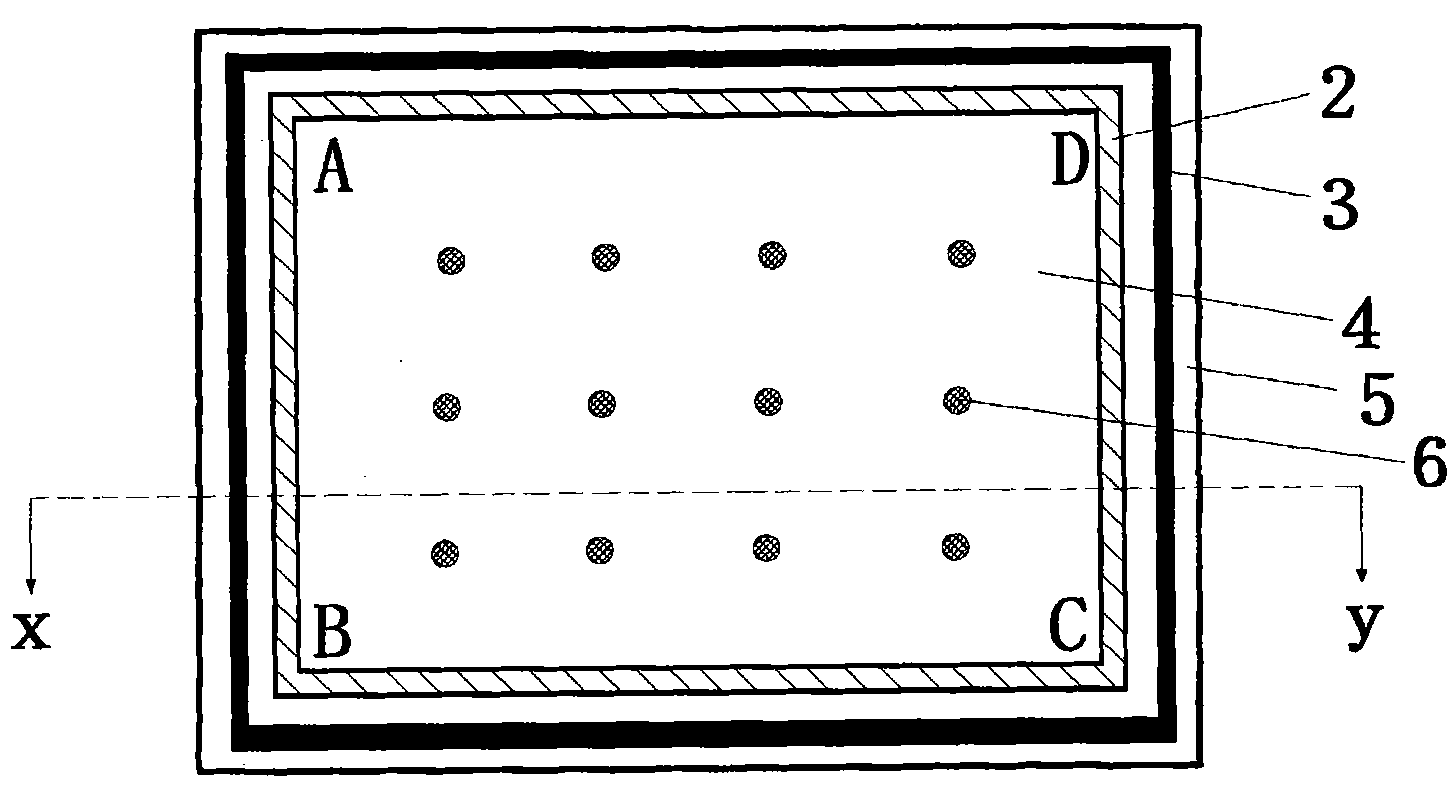

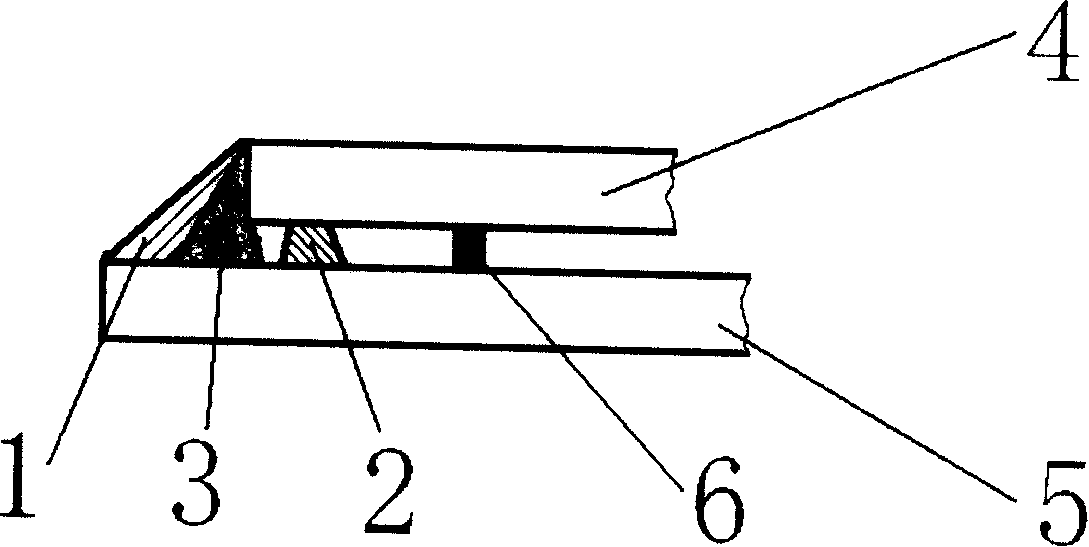

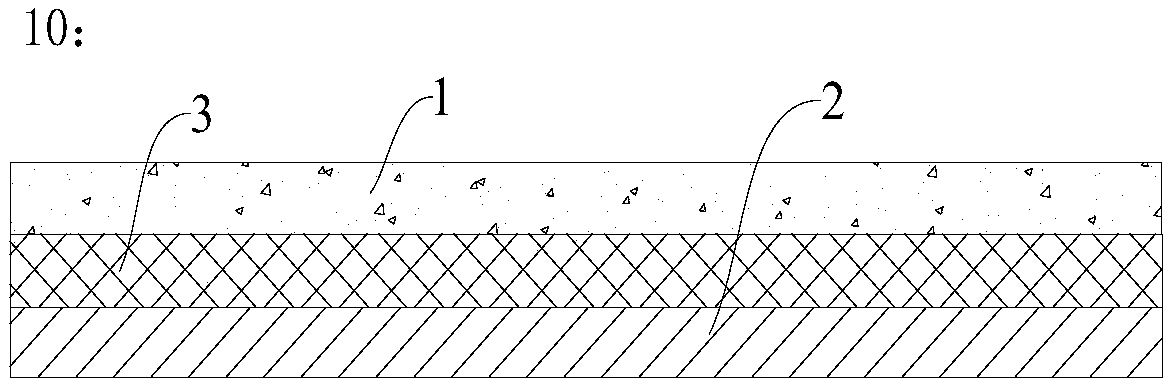

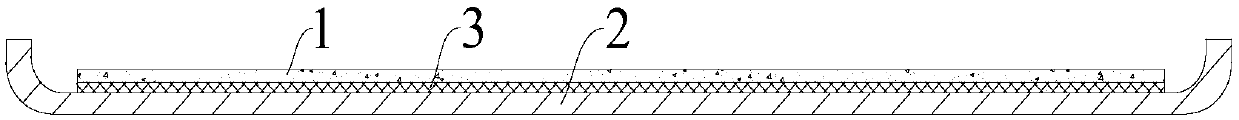

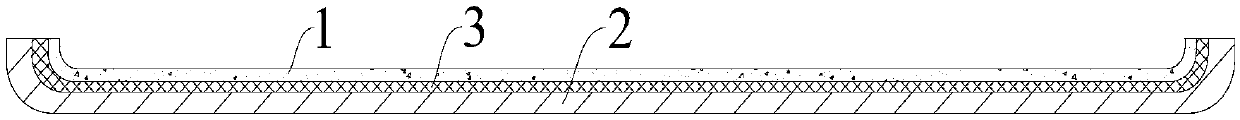

Method for sealing circumference of vacuum glass

The invention relates to a sealing method for vacuum glass periphery, which is characterized in that upper flat glass is smaller than lower flat glass, and glass welding material 3 is arranged on the periphery of the upper flat glass which is over the lower flat glass; outer side of the glass welding material is coated with an external anti-seepage layer 1, so as to prevent the glass welding liquid from flowing out of glass surface. In order to prevent the glass welding liquid from infiltrating inwards too much, an internal anti-seepage layer 2 can also be arranged on the internal side of glass welding material to confine glass liquid to infiltrate inwards. The height of the inside anti-seepage layer concretion is equal to the height of a support.

Owner:黄家军

Building material manufactured by mud as raw material and preparation method thereof

A building material for house, road, bridge, etc is prepared from sludge through drying, breaking, sieving, proportionally mixing it with clay and adhesive, shaping, sintering and cooling.

Owner:HARBIN INST OF TECH

Furnacetransmutation method for large Nixing pottery products

The invention provides a furnace transmutation method for large Nixing pottery products. The furnace transmutation method for large Nixing potteryproducts comprises the following steps: 1) preparation of blank material: using 55-65 parts by weight of east mud, 30-40 parts by weight of west mud and 5-10 parts by weight of iron ore powder to prepare the blank material; 2) shaping of blanks: making the blank material into various shapes of large vessels; 3) drying the blanks and 4) firing the blanks: loading the dried vessel blanks into a furnace and raising the temperaturegradually; specifically, raising the temperature to 500-750 DEG C at a speed of 30-50 DEG C / h, adding furnace transmutation material at 500-750 DEG C and sealing vent holes of the furnace; then, raising the temperature to 1000-1050 DEG C at a speed of 200-250 DEG C / h and firing at the constant temperature of 1000-1050 DEG C for 0.5-1h; naturally cooling and taking out of the furnace, thus obtaining finished large Nixing pottery products. The furnace transmutation method for large Nixing potteryproducts is capable of improving the furnace transmutation rate while ensuring the firing yield oflarge Nixing pottery products.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

Large-volume epoxy resin concrete pouring process

InactiveCN108285300AGuaranteed StrengthMaintain strengthBuilding material handlingEthylenediamineGas bubble

The invention discloses a large-volume epoxy resin concrete pouring process which takes epoxy resin, a curing agent ethylenediamine and a diluent xylene as cementing materials, after machine-made sandand stone are dried, the machine-made sand and the stone are uniformly stirred through mechanical stirring, and layered casting and mechanical adhesion type vibration are adopted, so that internalbubbles generated by the curing agent are fully removed. The invention provides the large-volume epoxy resin concrete pouring process, the internal gas bubbles of the concrete can be fully removed, and the large-volume pouring is realized, meanwhile the strength of the concrete can be effectively guaranteed, the advantages of high strength and weak supplement of the epoxy resin are maintained, andthe cost of later-period manual repair is reduced.

Owner:贵阳城市建设工程集团有限责任公司 +1

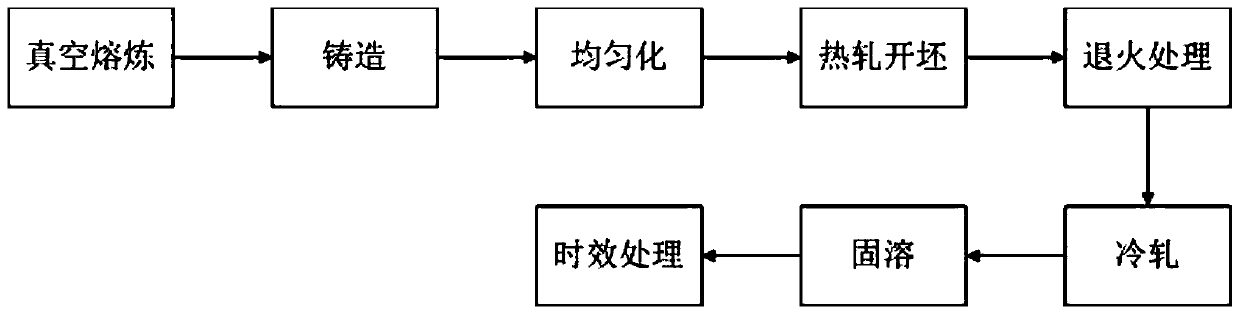

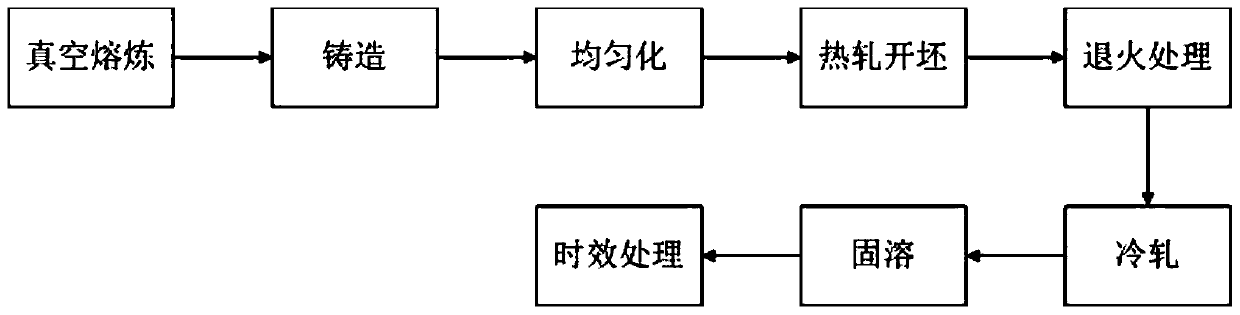

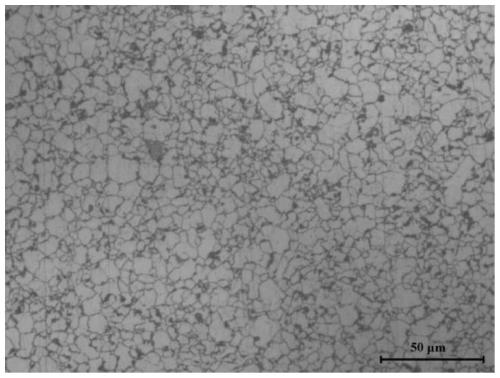

High-strength high-elasticity copper-nickel-manganese alloy and preparing method thereof

The invention discloses a high-strength high-elasticity copper-nickel-manganese alloy and a preparing method thereof, and belongs to the technical field of special material preparing. Vacuum smeltingis adopted, gas and low-smelting impurities can be sufficiently exhausted, a billet structure can be purified, an ingot microstructure is subjected to homogenization treatment and then subjected to hot rolling, deforming cracking caused by nonuniform components can be reduced, and meanwhile through hot rolling, coarse grains in the alloy can be broken; through large deforming cold rolling, grainsin the alloy can be further broken, the fiber deformed microstructure is formed, the solid-solution treatment is used for enabling the alloy structure to be subjected to perfect recrystallization, meanwhile, solute atoms are re-dissolved into a base body, a supersaturation solid solution is formed, through aging treatment, the solute atoms are separated out in a form of a second phase, temperatureand time of aging are controlled, the separated-out second phase is fine and evenly distributed in the base body, and the alloy strength can be reinforced.

Owner:CENT SOUTH UNIV

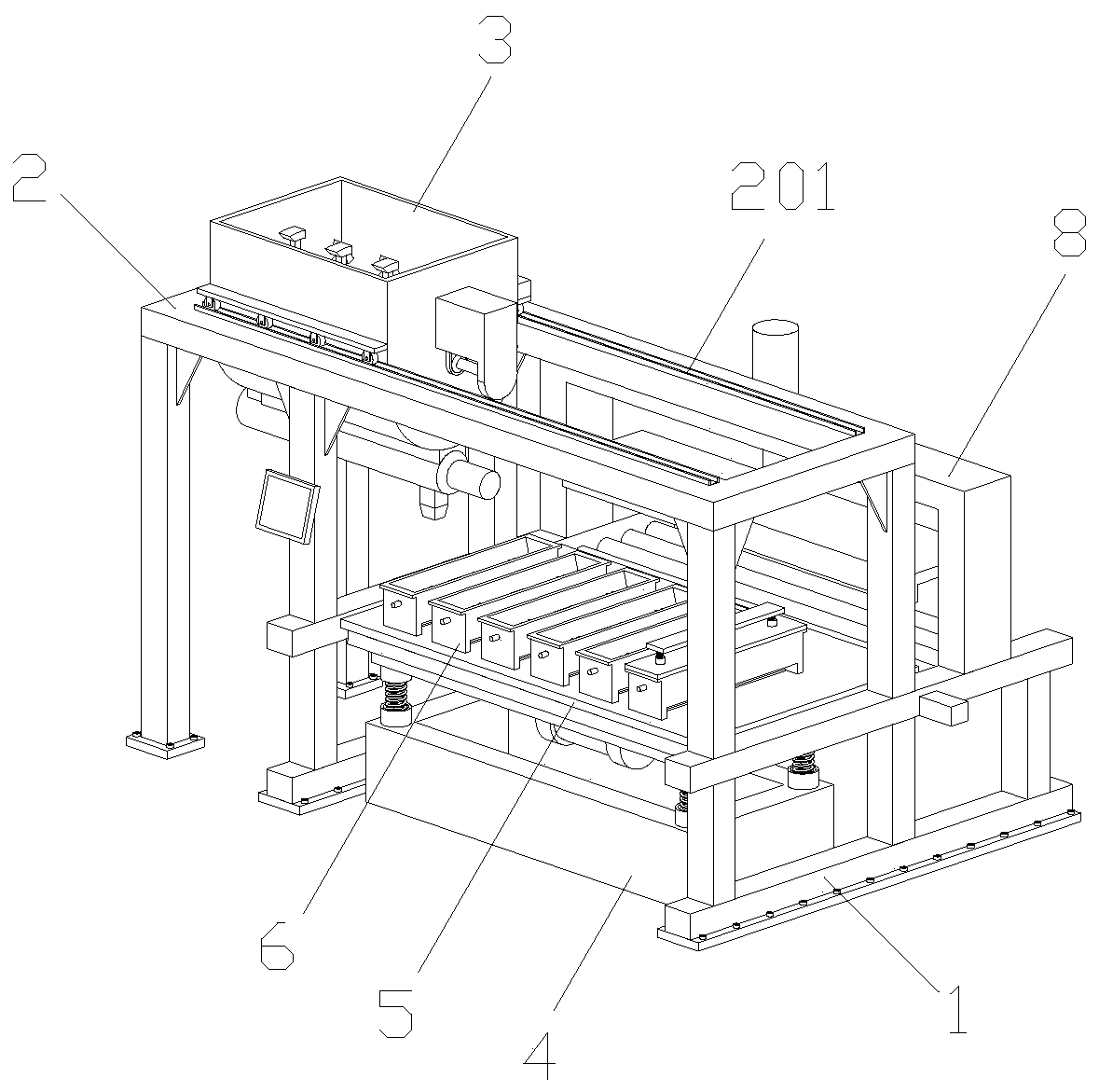

Prefabricated sleeper and production equipment and method thereof

ActiveCN111409193AEnhanced basic mechanical propertiesIncrease weightSolid waste managementCeramic shaping apparatusSilica fumeMethyl cellulose

The invention discloses a prefabricated sleeper and production equipment and method thereof. The prefabricated sleeper comprises the following raw materials, in parts by weight, 80 to 100 parts of Portland cement, 40 to 60 parts of coarse aggregate, 80 to 120 parts of fine aggregate, 50 to 70 parts of silica fume, 5 to 10 parts of anti-crack fiber, 0.2 to 1 part of methyl cellulose ether, 0.2 to 1part of starch ether and 0.5 to 2 parts of a water reducing agent. The production equipment of the prefabricated sleeper comprises a mounting frame, a stirring workbench, a stirring barrel, a vibration table, a placement plate, a prefabricated mold, a pressurizing cover, a pressurizing mechanism and a controller. According to the prefabricated sleeper, the silica fume and the anti-crack fiber inthe raw materials are combined for use, the anti-crack performance of the prefabricated sleeper is remarkably improved, concrete slurry can be rapidly and accurately injected into the prefabricated mold through the production equipment and the production method, the compactness of the prefabricated sleeper is further improved through common vibration and pressurized vibration, and the comprehensive performance of the prefabricated sleeper finished product is improved.

Owner:ANHUI ZHONGZHI RAIL TRANSPORTATION EQUIP MFG CO LTD

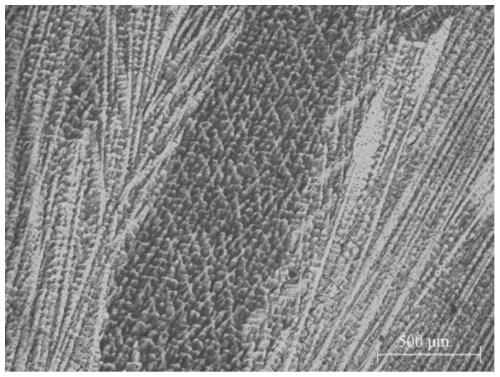

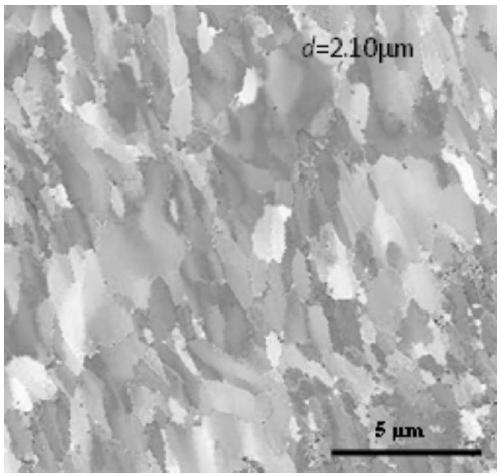

Ultrafine grained Ta material and preparation method thereof

The invention relates to an ultrafine grained Ta material and a preparation method thereof. Grain size of the ultrafine grained Ta material is smaller than or equal to 3 mu m; ultimate strength of thematerial is higher than or equal to 410 MPa, and yield strength is higher than or equal to 300 MPa. The preparation method of the material comprises the following steps: electron beam melting is performed on a Ta source, after ingot casting, an ingot is sheathed in a protective atmosphere; 3D hot-forging cogging is performed, total deformation of cogging is 65%-75%, and cogging temperature is 1150-1250 DEG C; after cogging, a sheath is removed, and low-temperature and high-temperature cross alternate rolling is performed; the ultrafine grained Ta material is obtained. The process is simple, and the prepared Ta ribbon has uniform and quite fine grains and is endowed with favorable strength, plasticity and toughness. The designed and prepared ultrafine grained Ta ribbon is applied to the high-technology fields of electronics, metallurgy, steel, chemical industry, hard alloys, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research.

Owner:CENT SOUTH UNIV +1

Adhesive sealing method in LED (light-emitting diode) encapsulating process

InactiveCN104409611AHigh degree of automationPrevent yellowingSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingAdhesiveBinding time

The invention discloses an adhesive sealing method in an LED (light-emitting diode) encapsulating process. The adhesive sealing method comprises the following steps of: firstly, arranging a distance measuring sensor connected to a controller on an adhesive sealing machine stand; then, obtaining the depth and the bowl cup mouth caliber of an LED lamp bowl cup; regulating the rotation speed and the binding time of roller wheel of the adhesive sealing machine stand according to the bowl cup depth, the bowl cup caliber and the preset adhesive filling and sealing parameters; regulating the distance between the bracket and the roller wheel of the adhesive sealing stand; and starting an adhesive sealing machine to perform adhesive sealing operation on the bowl cup on the bracket in sequence. The adhesive sealing method can be used for automatically regulating the rotation speed and the binding time of the roller wheel of the adhesive sealing stand, so that the automation degree is improved. Meanwhile, the distance between the bracket and the roller wheel and the adhesive sealing stand is automatically regulated, so that the impurities produced by grinding off the coating on the edge of the bowl cup by virtue of the roller wheel due to too short distance are avoided, and a phenomenon that the bowl cup is deformed and not adhered with the adhesive due to too long distance is avoided.

Owner:WUXI COCIS ELECTRONICS TECH

Method for converter steel tapping alloying molten steel component evening

ActiveCN103160636ASolve uneven compositionQuality improvementManufacturing convertersAlloyMolten steel

The invention relates to a method for converter steel tapping alloying molten steel component evening. The method includes that in the process of steel tapping, alloy and carburant are added into molten steel. The alloy is alloying alloy. The method for the converter steel tapping alloying molten steel evening is characterized in that the alloying alloy is added after the carburant is added. According to the method, the problems that in a traditional method, after a converter is tapped, the molten steel enters a steel ladle to lose the self dynamic condition, and molten steel components are not even are solved, so that steel quality is improved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

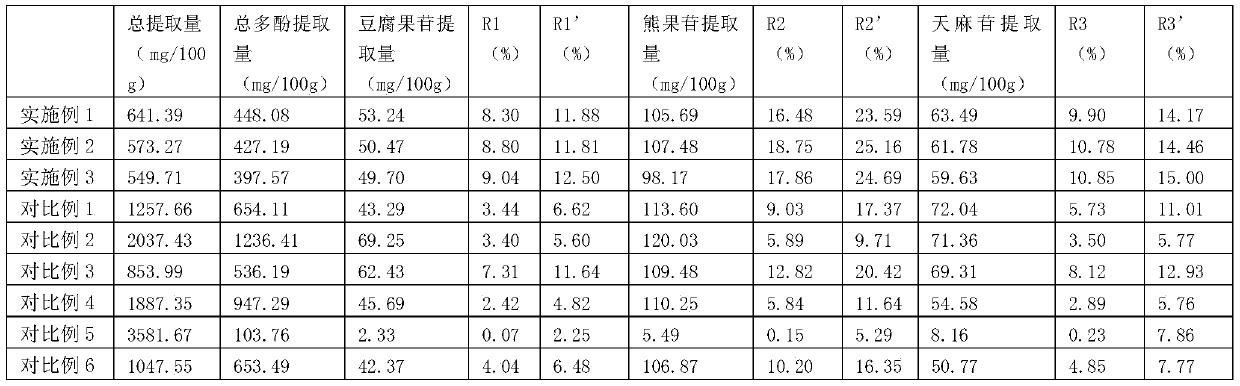

Preparation method and application of macadamia nut green skin extract

The invention belongs to the field of extraction of plant natural products, and particularly relates to a preparation method and application of a macadamia nut green skin extract. The preparation method comprises the steps of cellulase hydrolysis and protease enzymolysis, and then phenolic glycoside compounds with high utilization value such as arbutin, tofu glucoside and gastrodin in macadamia nut green skins are extracted by an ultrasonic extraction method, and finally, the green skin extract is obtained through degreasing treatment and decolorization treatment. The green skin extract obtained by the preparation method and the phenolic glycoside compounds such as the arbutin, the tofu glucoside and the gastrodin are high in content, the extraction process is simple, complex extraction, purification and separation operations are not needed, reagents, raw materials and the like used in the process are easy to obtain, and the cost is low. The preparation method can be applied to preparation of health-care foods and cosmetics containing the arbutin, the tofu glucoside, the gastrodin and the like.

Owner:JIANGCHENG ZHONGAO AGRI TECH DEV

Sealing method for direct-insert type light-emitting diode (LED) lamp

The invention discloses a sealing method for a direct-insert type light-emitting diode (LED) lamp. The sealing method comprises the following steps: firstly, setting the heights of a mold strip and a sticking point, and selecting a diffusant and a coloring agent; secondly, heating epoxy resin A, mixing the epoxy resin with epoxy resin B at a certain ratio, adding the diffusant and the coloring agent, stirring the diffusant and the coloring agent, and carrying out vacuum-pumping treatment on stirred mixed glue; thirdly, fixing the bound LED bracket on a loading rack; fourthly, adjusting the glue-pouring quantity, the glue-extruding speed, the sticking time and the sticking distance; and finally starting a pouring machine and carrying out sealing treatment on the bound LED bracket. The epoxy resin A is heated and then is mixed with the epoxy resin B at the certain ratio, so that the mixing viscosity is reduced; the diffusant and the coloring agent are added and stirred, so that the problem of yellow discoloration of the baked LED lamp is avoided by controlling the mixing ratio and the mixing time; and the quality and the yield of the LED lamp are improved, so as to improve the cost performance of an LED display screen.

Owner:苏州市英富美欣科技有限公司

Laminated glass, preparation method and applications thereof

ActiveCN110871612AImprove bubblesGood optical performanceCasings/cabinets/drawers detailsGlass/slag layered productsOrganic filmElectronic equipment

The invention provides laminated glass, a preparation method and applications thereof. The laminated glass comprises at least two glass members and at least an organic film, wherein the organic film is arranged between the two adjacent glass members, the thickness of the glass member is 0.1-0.5 mm, and the thickness of the organic film is 25-100 [mu]m. According to the invention, the laminated glass is proper in the thicknesses of the glass member and the organic film, attractive in appearance, good in optical performance, excellent in mechanical property, good in falling resistance, free of glass splashing during breaking and good in safety, can be used for shells of electronic equipment, and can be effectively applied to the field of actual production.

Owner:BYD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com