Petrol coke graphitization prepared carburant and petrol coke graphitization furnace filling technology

A technology of petroleum coke and carburizing agent, which is applied in the field of carburizing agent and petroleum coke graphitization furnace, which can solve the problems such as the gap in quality indicators, and achieve the effects of improving quality, reducing sulfur content and moisture content, and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Put petroleum coke with a sulfur content of ≤0.6%wt, ash content of ≤0.5%wt, and a volatile content of 6-15%wt in an electric furnace according to the following furnace loading process, heat at 2500-3000°C for 35-45 hours, and then pass through 10- 14 days of natural cooling to get the finished product.

[0014] Petroleum coke with a sulfur content of 0.5%wt, ash content of 0.5%wt, and volatile matter of 12%wt is placed in an electric furnace according to the following furnace loading process, heated at 2800°C for 43 hours, and then naturally cooled for 11 days to obtain the finished product. The inspection indicators are as follows : Carbon content 98.62%wt, sulfur content 0.03%wt, ash 0.33%wt, volatile matter 0.79%wt, moisture 0.06%. Among them, the carbon content, sulfur content, ash content, volatile matter, and water content are tested according to GB / T2001-91, YB / T1430-1997, GB / T1429-85, YB / T5189-2000, YB / T1428-1997 .

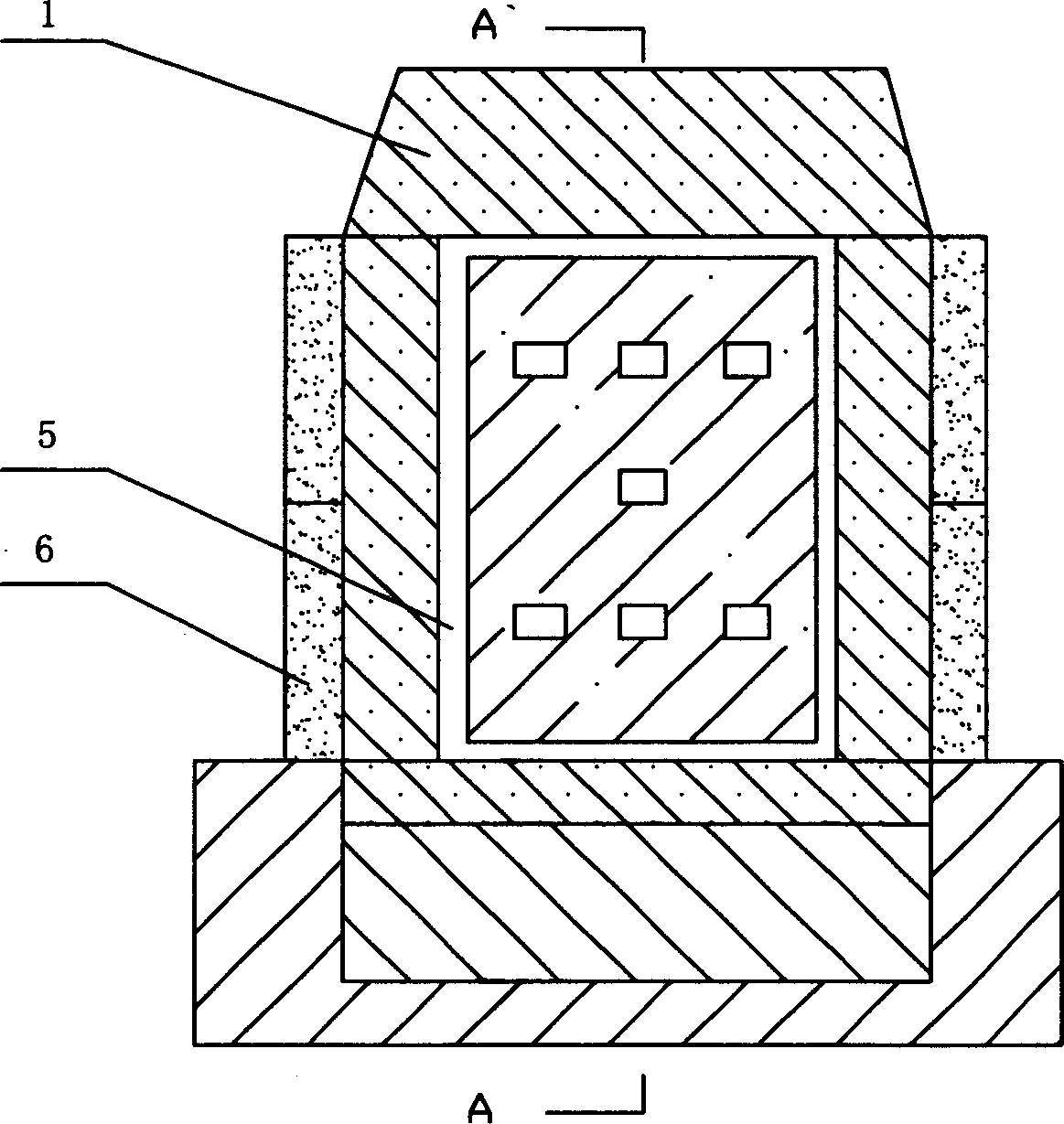

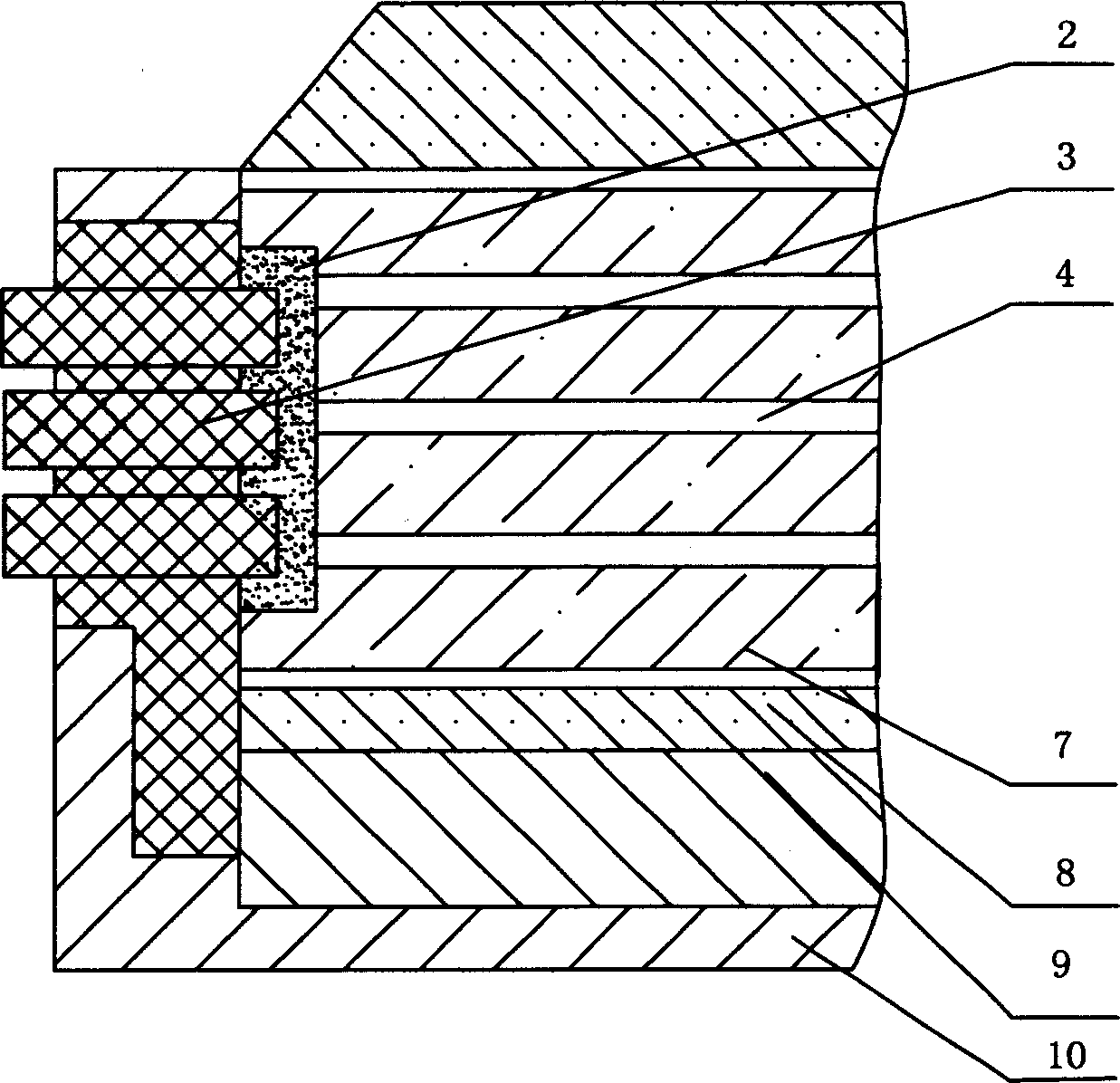

[0015] Petroleum coke graphitization furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com