Patents

Literature

103results about How to "Tissue distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

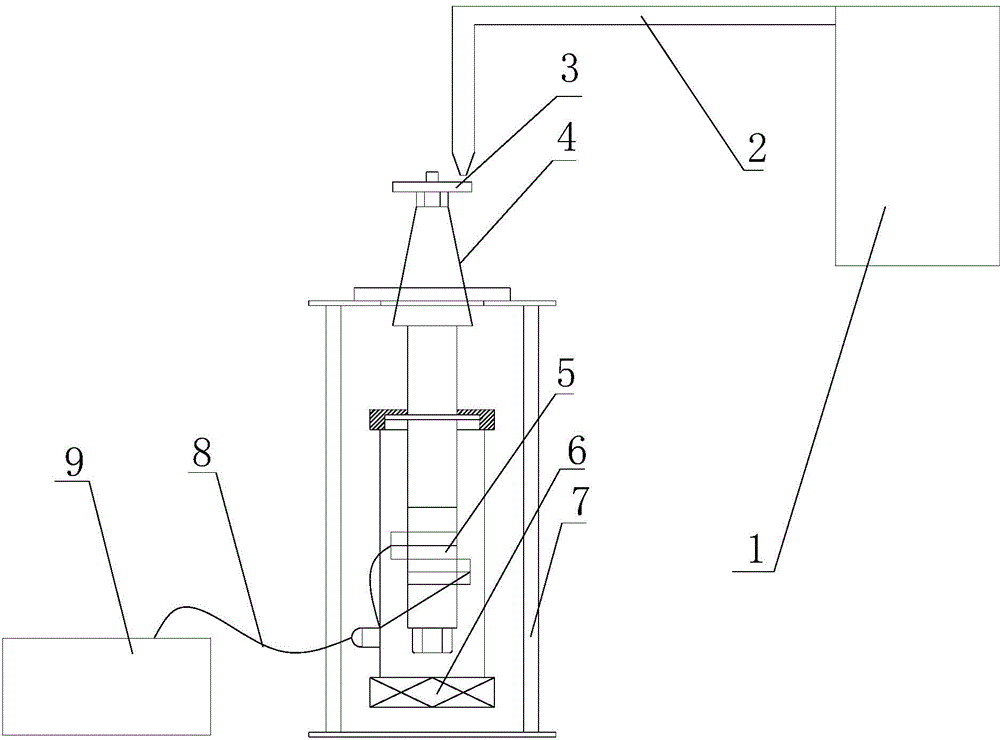

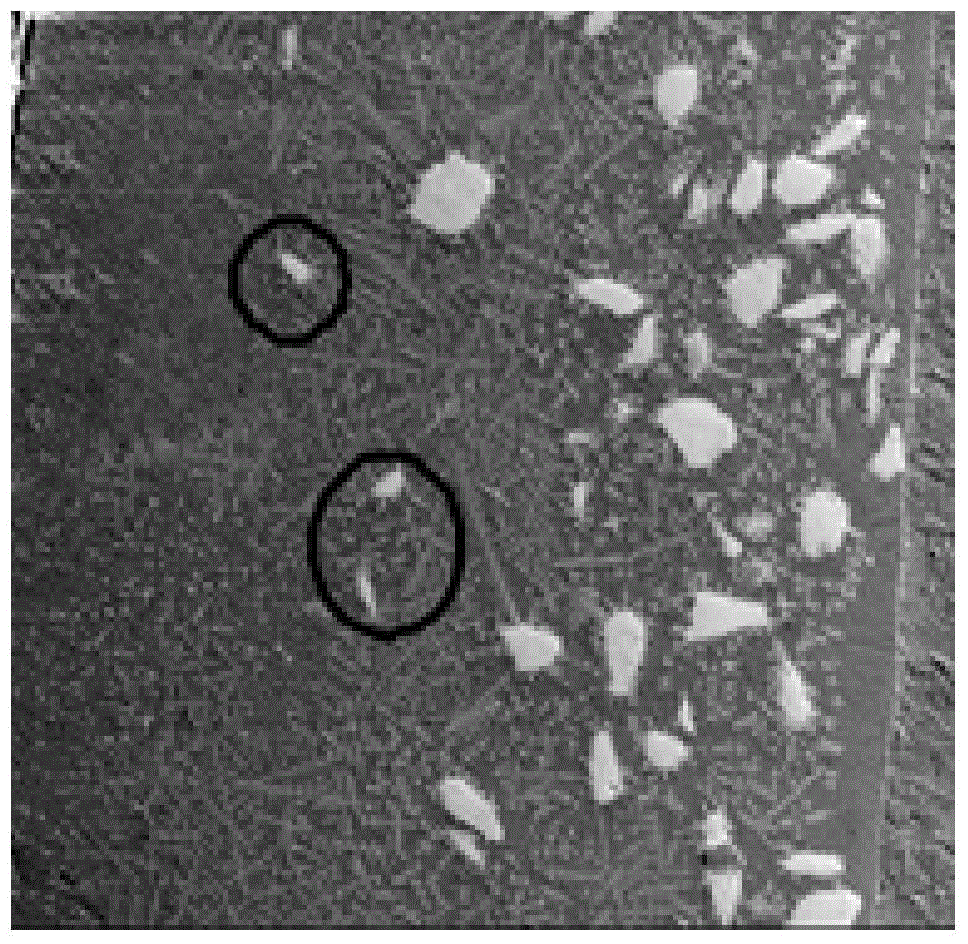

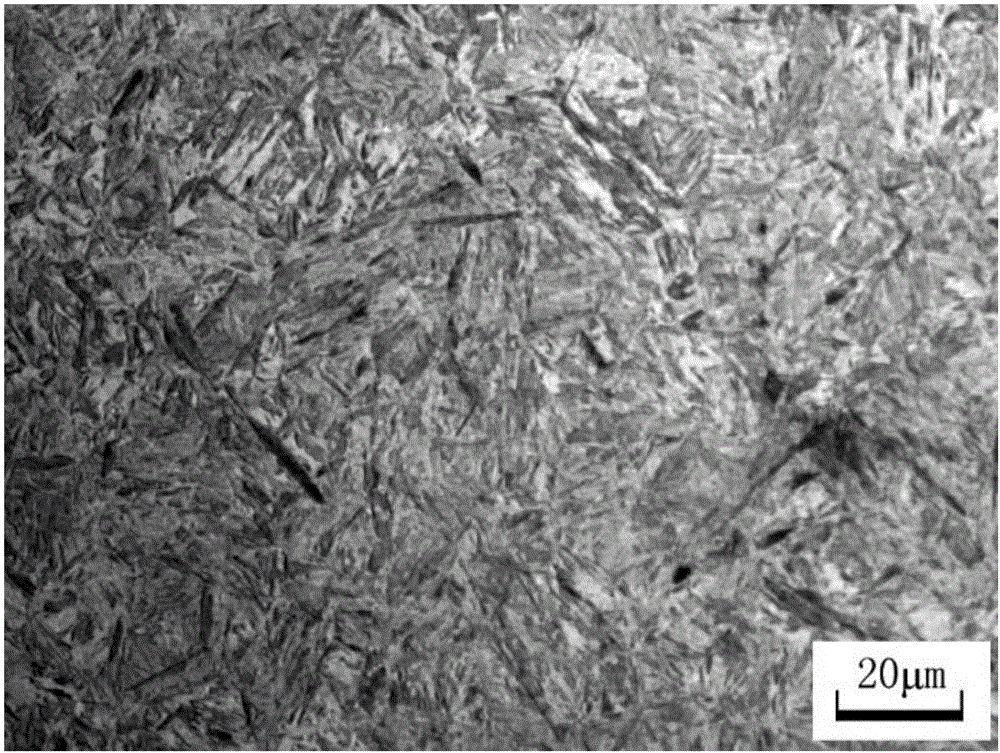

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Crack controlling means for laser deposition formed metal parts

InactiveCN1737197AImprove coagulation stateImprove liquidityMetallic material coating processesLaser beam welding apparatusClosed loop feedbackClosed loop

The invention relates to a crack-controlling method of metal parts by laser melting formation in laser material processing domain, which comprises closed-loop control of fused bath temperature, which comprises the two specific steps of exerting closed-loop feedback control on fused bath temperature by using optical imaging system and PID control device with calorific radiation transmitted from melting zone and adjusting horsepower of laser, and introduction of ultrasonic vibration, which comprises the specific steps of introducing ultrasonic vibration under the piece of work when forming by laser melting. The invention can deduce residual stress and crack, improve structure and can be used in multiple relative domains such as forming, manding and surface peening by laser melting.

Owner:SHANGHAI JIAO TONG UNIV

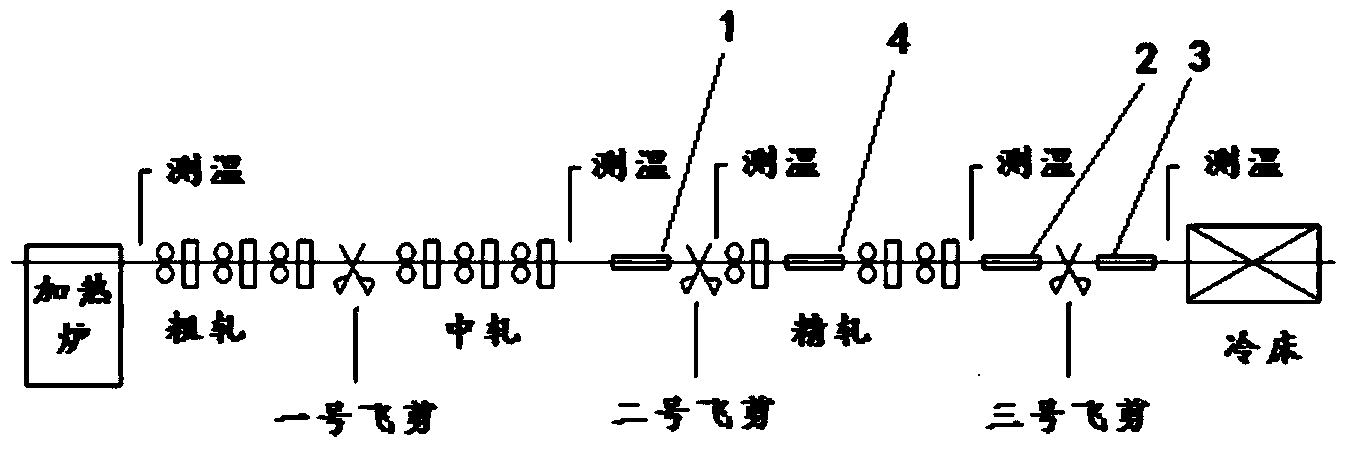

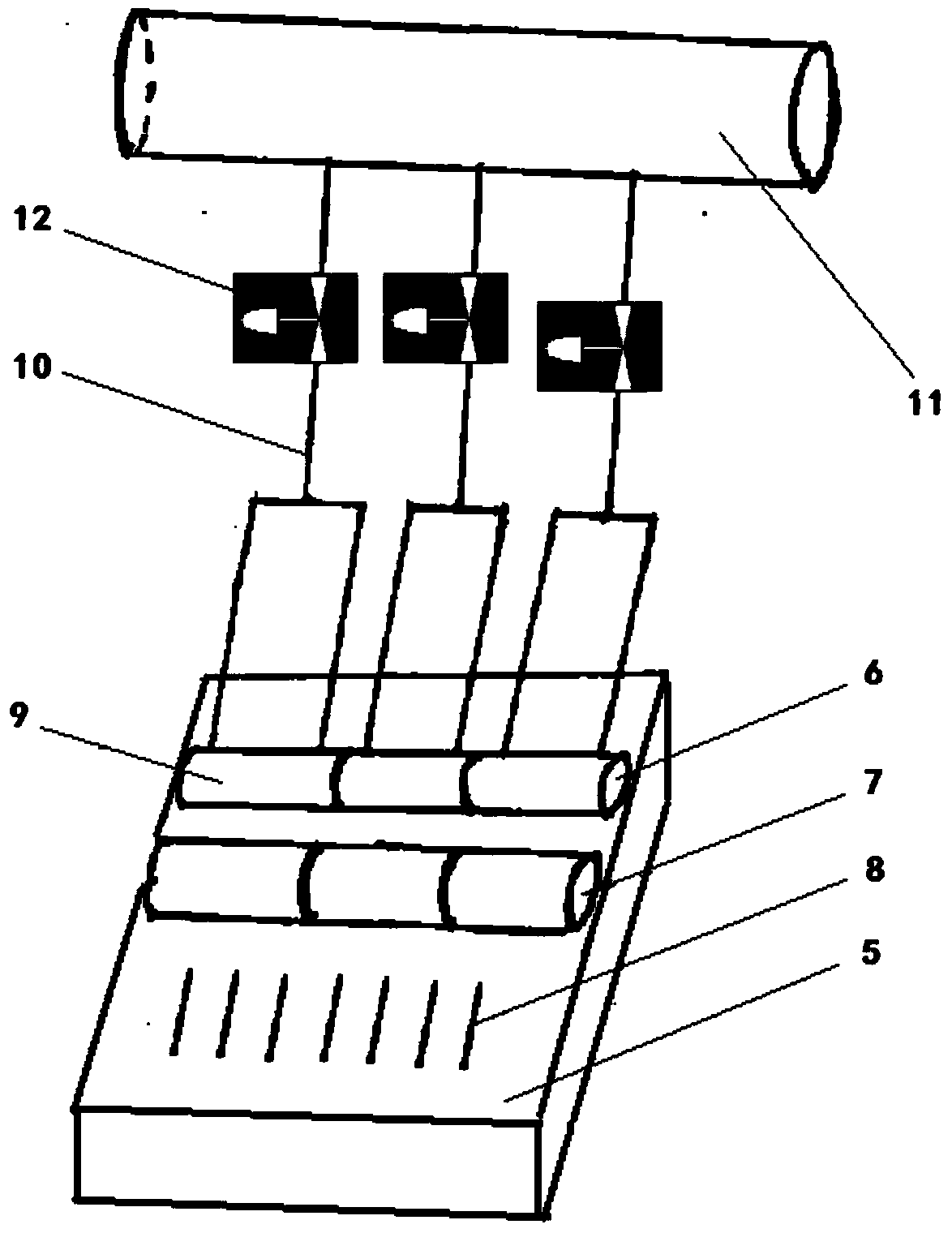

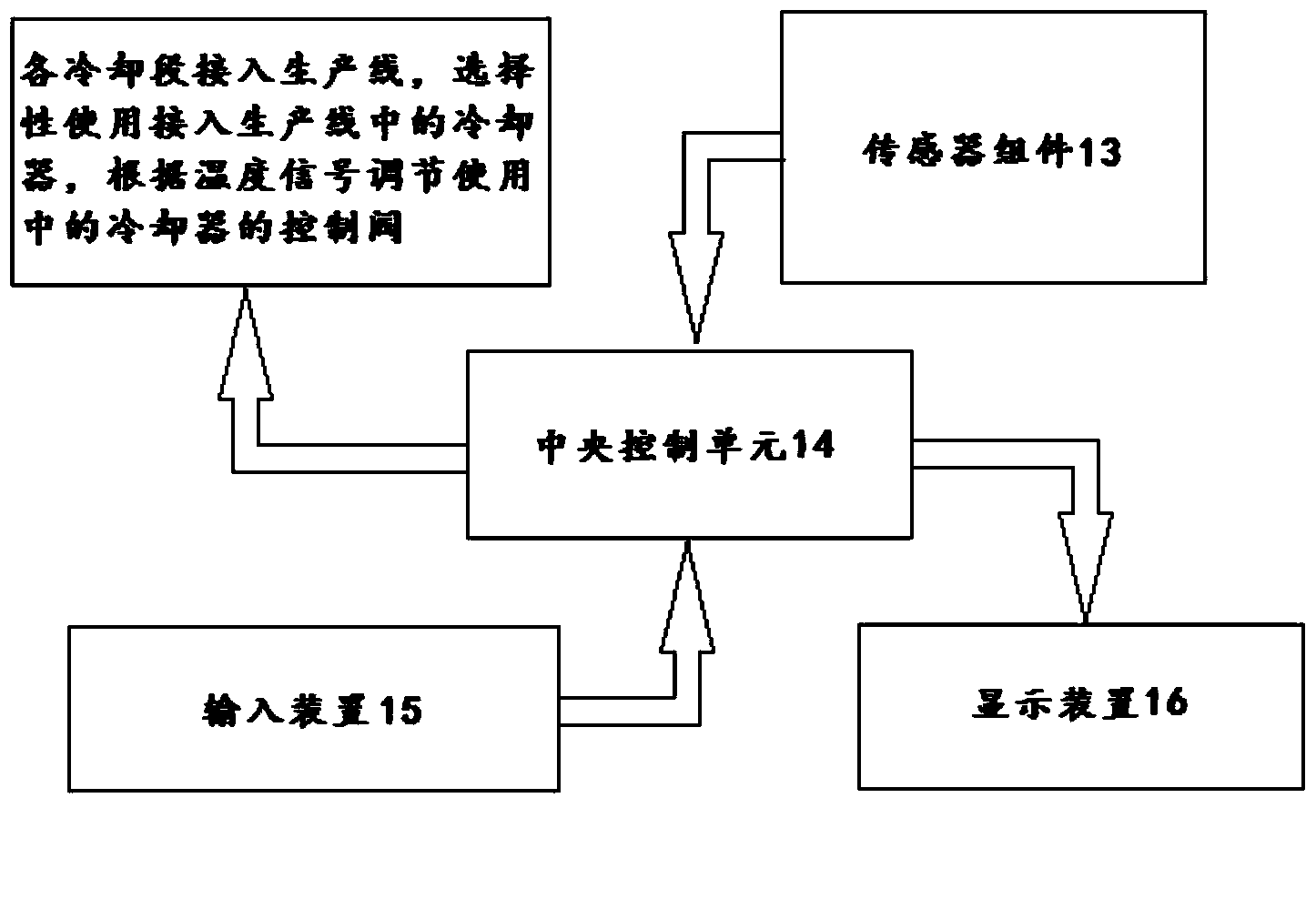

Controlled rolling and controlled cooling system for bars

ActiveCN103551403APrevent "overcooling"Large temperature difference in the axial directionTemperature control deviceWork treatment devicesProduction lineEngineering

A controlled rolling and controlled cooling system for bars comprises a first cooling section at the position of an outlet of an intermediate mill group, a machine cooling section of a finishing mill group, a second cooling section between the finishing mill group and a third flying shear, a third cooling section between the third flying shear and a cooling bed, a sensor module and a central control unit. The first cooling section, the second cooling section and the third cooling section respectively comprise one or a plurality of cooling lines arranged on a horizontal moving trolley and a bypass roll table, one cooling line or the bypass roll table can be selectively connected to a production line by horizontally moving the horizontal moving trolley, and every production line comprises one or a plurality of series connection coolers. Every cooler is connected to a water supply main pipe through one water supply branched pipe, control valves are arranged in the water supply branched pipes, and the coolers connected to the production lines are selected and used by opening and closing of the control valves. According to the controlled rolling and controlled cooling system, a plurality of cooling sections can be selected flexibly, the coolers in every cooling section can also be selectively used simultaneously, and accordingly the system not only is good in applicability, but also improves bar finished product performances.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

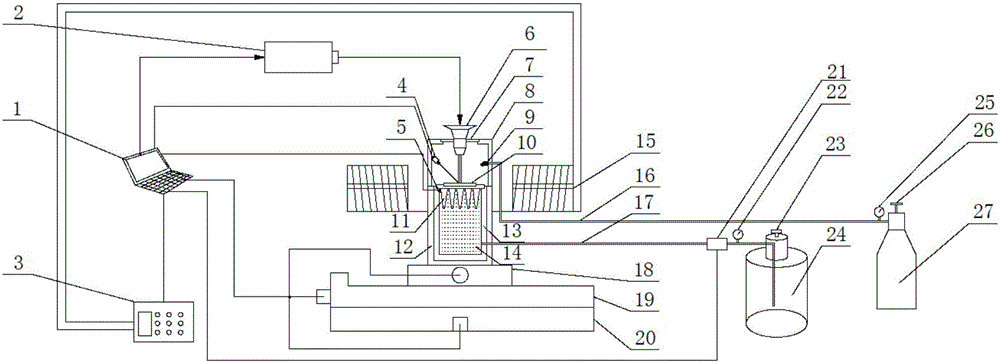

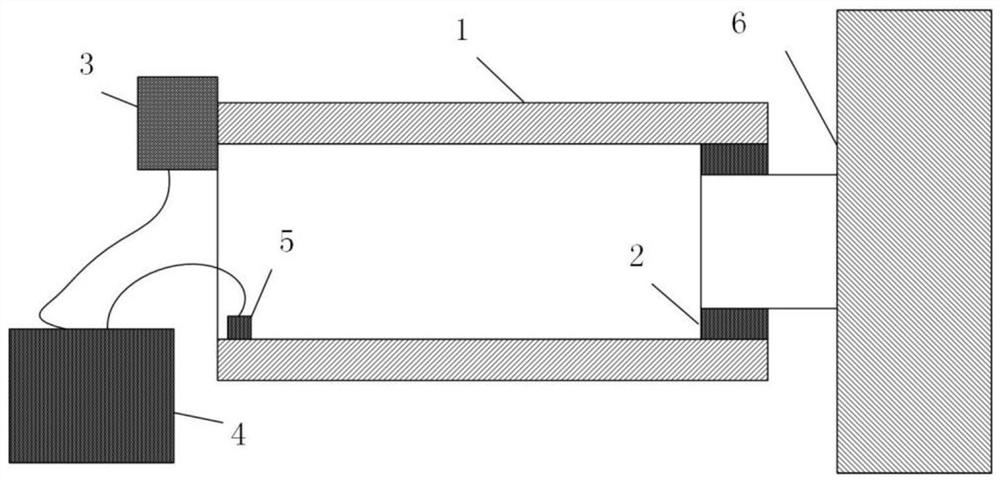

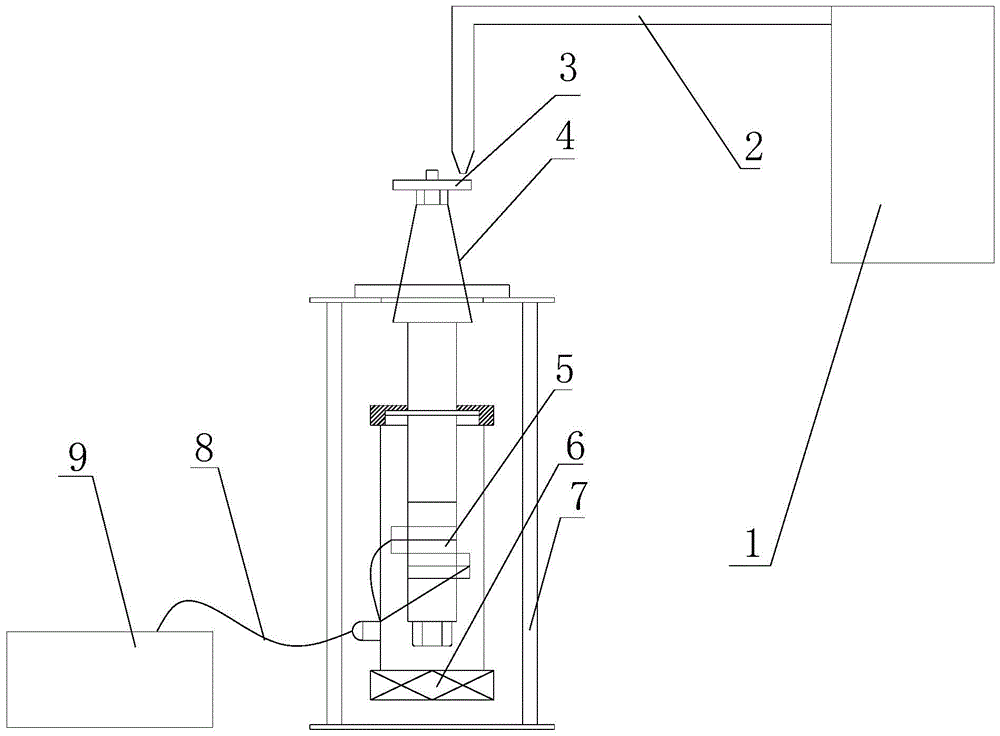

Method and device for conducting laser cladding with assistance of electromagnetic stirring in forced cooling environment

ActiveCN106757001AAvoid destructionImprove qualityMetallic material coating processesEngineeringCopper

The invention provides a method and device for conducting laser cladding with the assistance of electromagnetic stirring in a forced cooling environment. The device comprises a fiber laser, a liquid nitrogen forced cooling platform, an electromagnetic stirring platform, a temperature detection and feedback system and a computer control system. The method comprises the steps that a sample is placed on a special clamp made of red copper, the red copper clamp is forcibly cooled through liquid nitrogen, then cold is indirectly transmitted to the sample, and thus forced cooling of the sample in the laser cladding process is achieved. Meanwhile, the magnetic field intensity of the electromagnetic stirring platform is adjusted and controlled through a computer, and thus the laser cladding process with the assistance of electromagnetic stirring under forced cooling is achieved. According to the method and device for conducting laser cladding with the assistance of electromagnetic stirring in the forced cooling environment, laser cladding is conducted with the assistance of forced cooling and electromagnetic stirring to prepare a composite coating so that the good metallurgical bonding capacity of the composite coating with a matrix can be remarkably improved, a hard phase and uniform tissue distribution in the clad coating are achieved, grains are refined, and stress concentration is avoided; and defects such as cracks and pores of the laser clad coating are eliminated, and the quality of the clad coating is improved.

Owner:JIANGSU UNIV

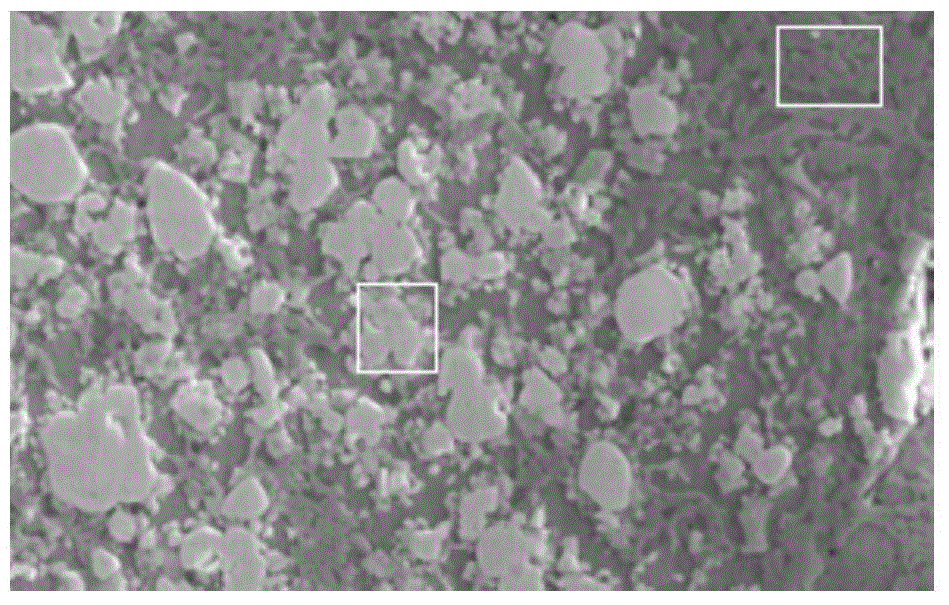

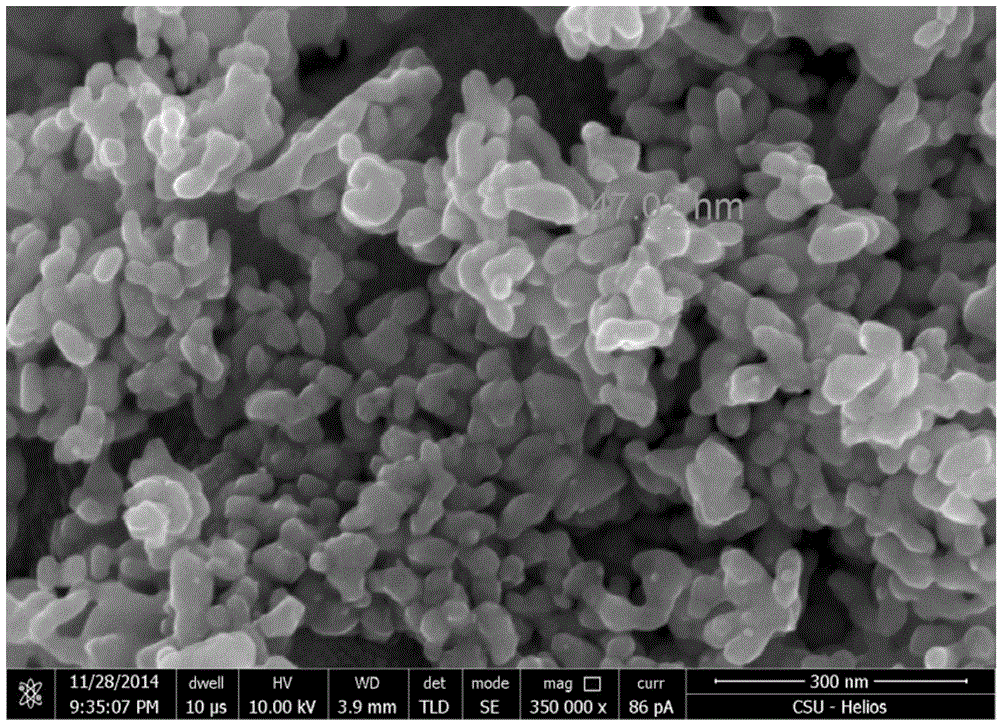

Method for preparing WC-Co cemented carbide through microwave sintering

The invention provides a method for preparing WC-Co cemented carbide through microwave sintering. The method comprises the steps of WC powder and Co powder batching and mixing, compacting and sintering, wherein in the step of sintering, compacts, SiC chips, carbon black and alumina powder are put in an alumina fiber insulating bag sleeve and then the alumina fiber insulating bag sleeve is put in a microwave high temperature furnace, the products in the furnace are heated to 500-600 DEG C at a heating speed of 5-10 DEG C / min and the heat is preserved and then the products are heated to 1400-1500 DEG C at a heating speed of 30-80 DEG C / min and the heat is preserved, thus obtaining the WC-Co cemented carbide. The method has the advantages of simple process, convenience in operation, short sintering period and low energy consumption, can replace the existing WC-Co cemented carbide processes, is used for producing the WC-Co cemented carbide by adopting the intermittent or continuous microwave sintering mode and is suitable for industrial application. The prepared WC-Co cemented carbide has excellent performances.

Owner:CENT SOUTH UNIV

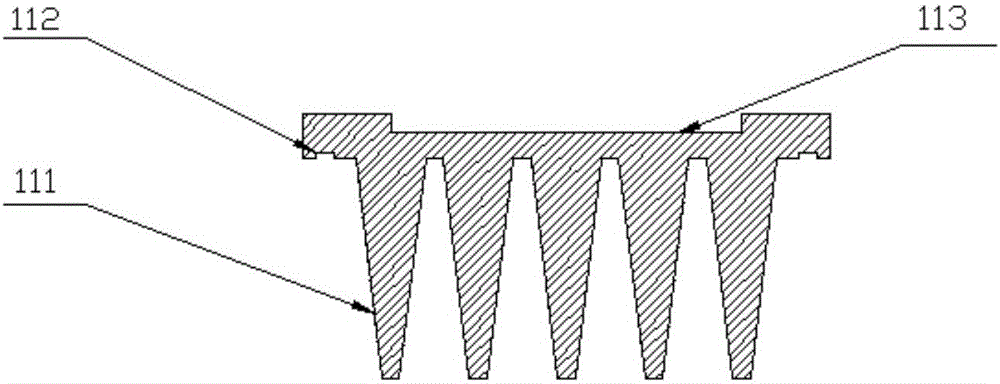

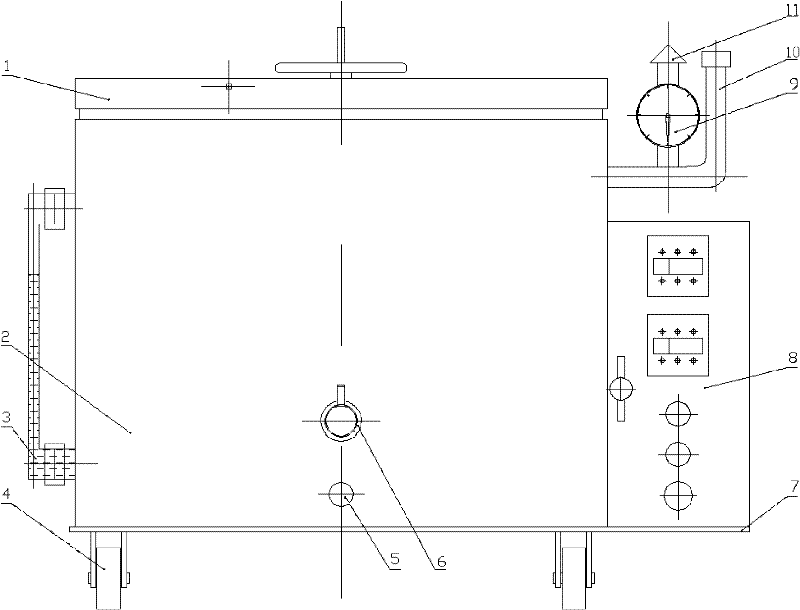

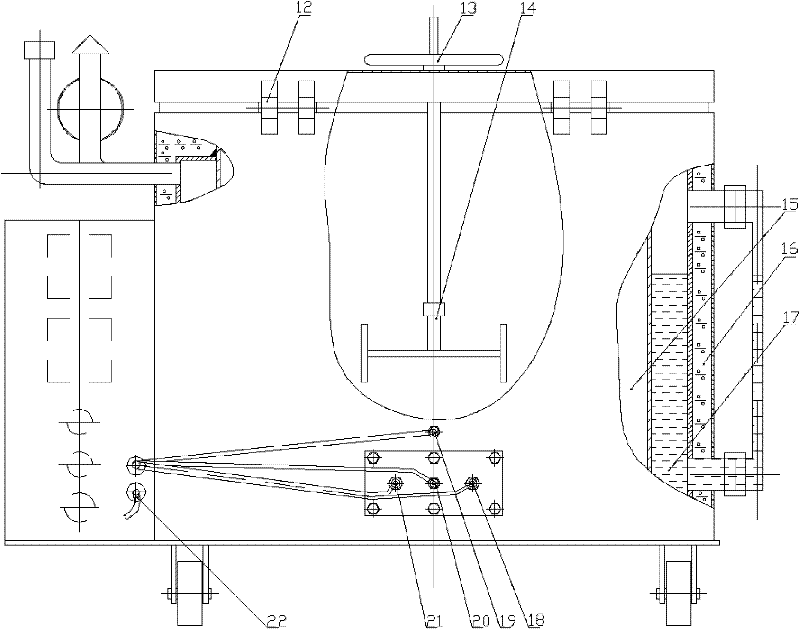

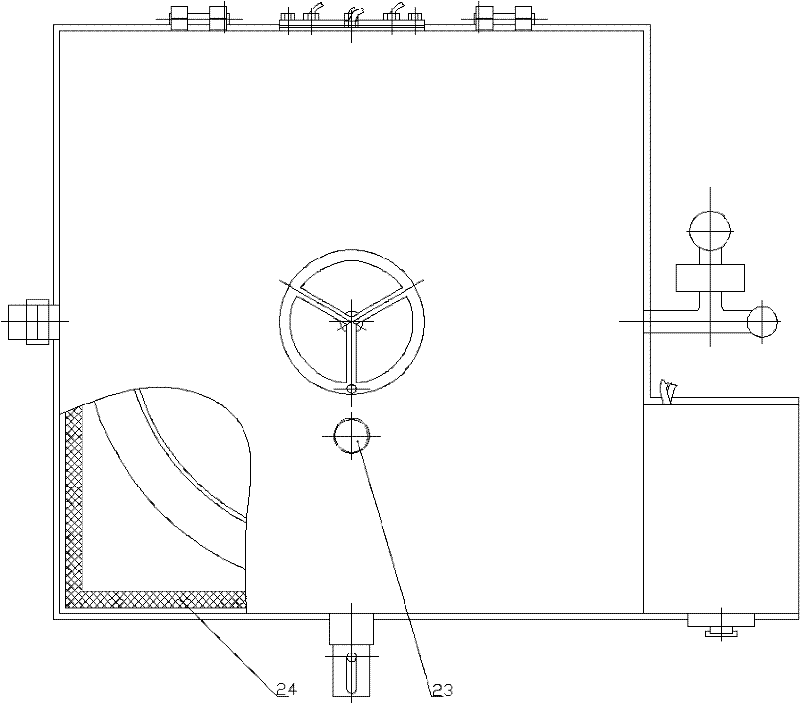

Paraffin wax melting and heat insulating device capable of automatically controlling temperature

InactiveCN102211010AFast meltingTissue distributionRotary stirring mixersMixer accessoriesElectricityParaffin wax

The invention provides a paraffin wax melting and heat insulating device capable of automatically controlling temperature, which comprises a box body, a paraffin wax container, a heating system and an agitating mechanism, wherein a box body cover is arranged on the upper end of the box body, and the agitating mechanism is arranged on the box body cover; the paraffin wax container is arranged in the box body, a heating layer and a heat insulating layer are arranged between the paraffin wax container and the box body, and heat conducting oil is filled in the heating layer; a paraffin wax outlet is arranged on the lower part of the box body; and the heating system comprises an electric heating wire, a paraffin wax thermocouple, a paraffin wax temperature controller, a heat conducting oil thermocouple and a heat conducting oil temperature controller, the paraffin wax thermocouple is arranged in the paraffin wax container, the paraffin wax thermocouple is connected with the paraffin wax temperature controller, both the electric heating wire and the heat conducting oil thermocouple are arranged in the heating layer, and both the electric heating wire and the heat conducting oil thermocouple are connected with the heat conducting oil temperature controller. The device can realize automatic control on paraffin wax temperature and meet the requirements for the melting and heat insulating properties of the paraffin wax in the processing process of filling weak rigid parts with paraffin wax.

Owner:SHANDONG UNIV

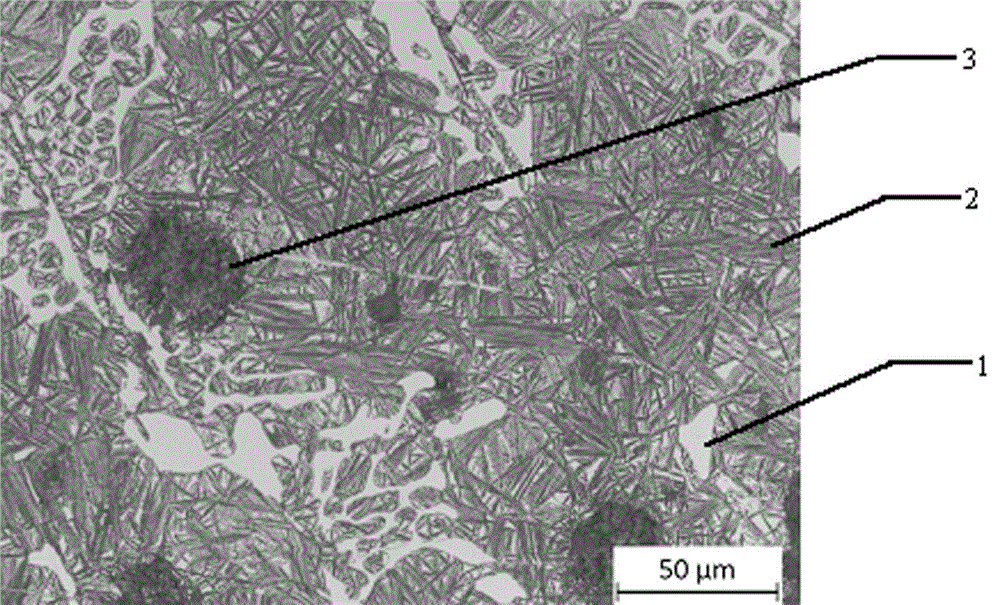

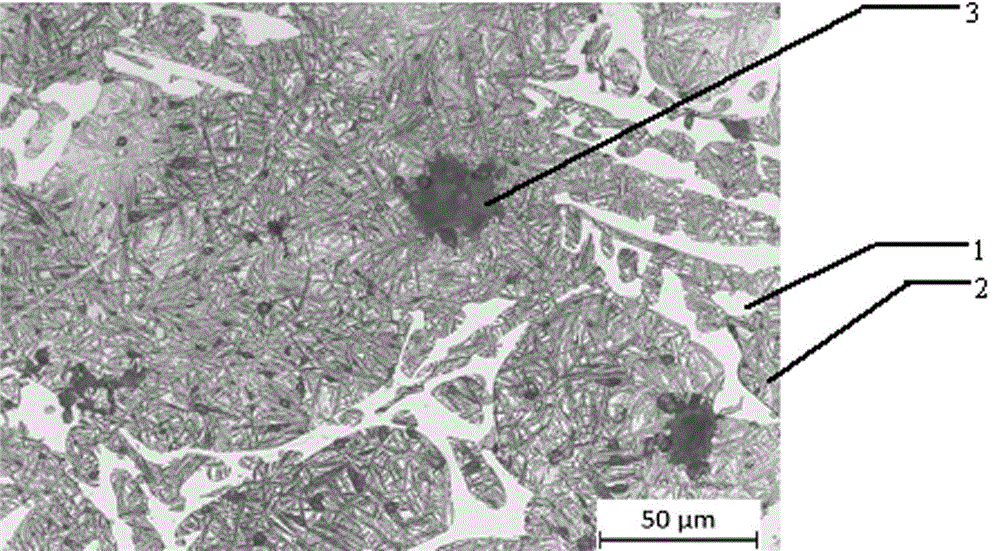

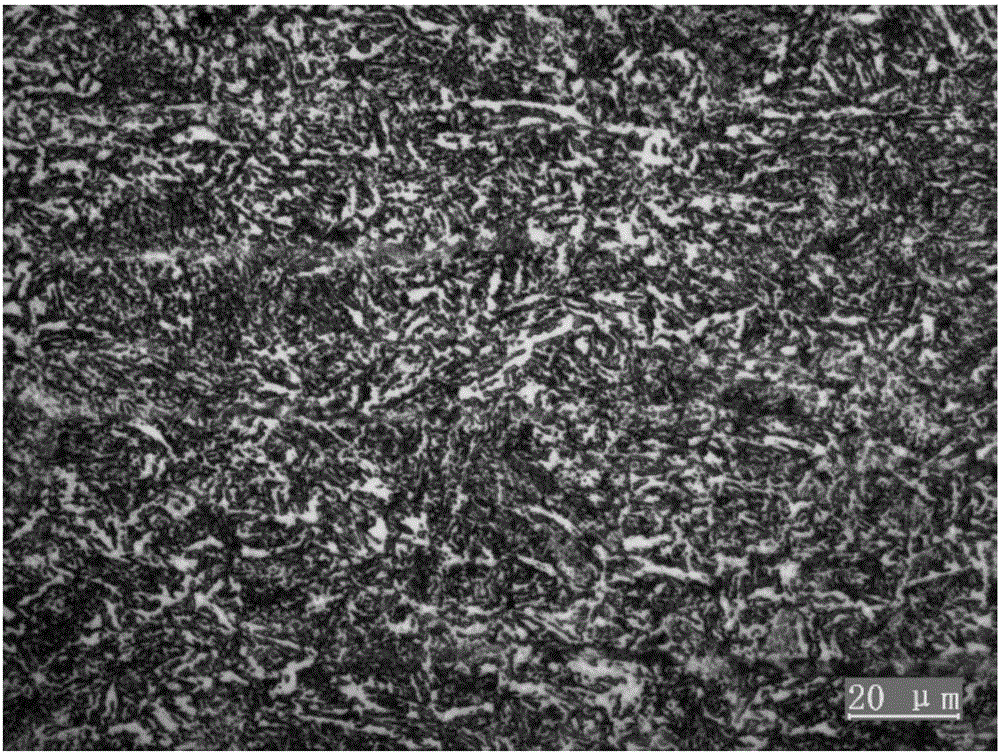

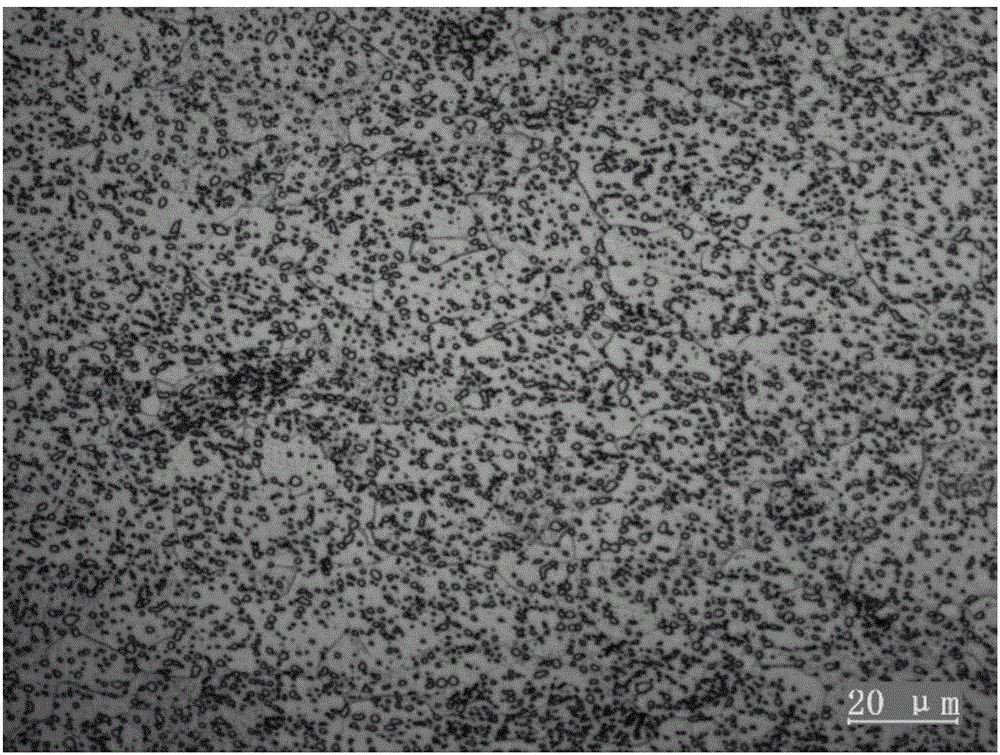

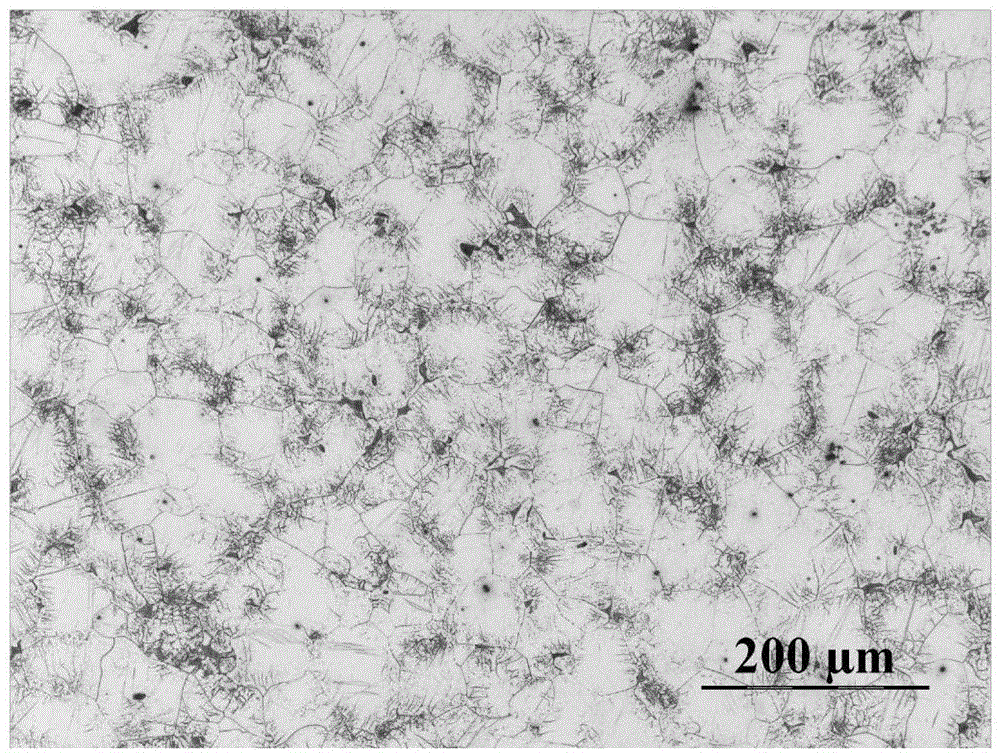

Vanadium-containing carbidic austempered ductile iron and preparation method thereof

A vanadium-containing carbidic austempered ductile iron comprises the following ingredients in percent by mass: 3.20-3.70 percent of C, 2.50-3.30 percent of Si, 0.4-0.8 percent of Mn, less than or equal to 0.040 percent of P, less than or equal to 0.007 percent of S, 0.01-0.04 percent of Ce, 0.01-0.04 percent of Mg, 0.30-1.80 percent of Cr, 0.25-0.70 percent of V and the balance of Fe. The preparation method of the vanadium-containing carbidic austempered ductile iron comprises the following steps: (1), heating and smelting pig iron, steel scrap, ferromanganese and ferrovanadium; (2), placing a rare-earth magnesium nodularizer into a groove in the bottom of a ladle, placing a nucleating agent on the rare-earth magnesium nodularizer, casting for 10-30 s at the temperature of 1,350-1,430 DEG C, and cooling to obtain ductile iron; and (3), heating the cooled ductile iron to reach a temperature of 850-920 DEG C, keeping the temperature for 2-4 h, then placing the heated ductile iron into 45% KNO3+55% NaNO3 molten salt at the temperature of 280-320 DEG C, keeping the temperature for 1-3 h, taking out the ductile iron, and cooling the ductile iron to the ordinary temperature to obtain the vanadium-containing carbidic austempered ductile iron. The vanadium-containing carbidic austempered ductile iron is high in ductility and hardness and excellent in comprehensive mechanical property.

Owner:GUANGDONG INST OF MATERIALS & PROCESSING

Cold-rolled shifting fork steel member for automobile and producing method

The invention discloses a cold-rolled shifting fork steel member for an automobile and a producing method. The cold-rolled shifting fork steel member is characterized by comprising the steel chemical ingredients, by weight percentage, of 0.20-0.35% of C, 0.10-0.35% of Si, 0.50-1.50% of Mn, 0.40-1.50% of Cr, 0.0030-0.0070% of Ca, 0.0008-0.005% of B, 0.40-1.10% of Ni, 0.015-0.030% of Als, 0.015-0.040% of Nb, 0.015-0.030% of Ti, smaller than or equal to 0.15% of P, smaller than or equal to 0.008% of S, the balanced of Fe and unavoidable impurities. By means of appropriate hot rolling, cold rolling and cover annealing, the excellent accurate stamping performance can be achieved. The shifting fork portion is quenched and tempered, so that the hardness of the work portion of the shifting fork portion is greatly improved, and the service life of the shifting fork portion is prolonged.

Owner:武汉钢铁有限公司

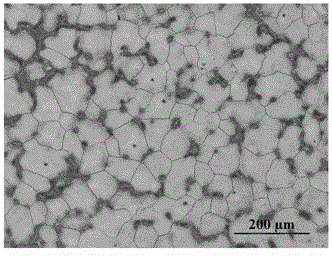

Zirconium refinement method for magnesium alloy crystalline grains

The invention provides a zirconium refinement method for magnesium alloy crystalline grains. The method includes the following steps that a, after potassium fluozirconate and a magnesium ingot are dried, under protection of a mixed fused salt system including NaCl and KCl, the potassium fluozirconate and the magnesium ingot are subjected to a reduction reaction for 35-45 min at the temperature of 900-1300 DEG C, casting is carried out for 4-5 min at the casting speed of 10-15kg / min at the temperature of 1040-1070 DEG C at the electromagnetic vibration frequency of 200-400 Hz, and a magnesia-zirconia master alloy ingot is obtained; b, pre-deformation treatment is carried out on the magnesia-zirconia master alloy ingot to obtain a magnesia-zirconia master alloy refiner; c, after a magnesium alloy raw material is smelted, the magnesia-zirconia master alloy refiner is added at the temperature of 750-780 DEG C, and after surface dross is removed, stirring, drossing and peeling are carried out. Compared with the prior art, the adopted refiner is magnesia-zirconia master alloy subjected to pre-deformation treatment, zirconium particles are fine and evenly distributed, the refining effect is good, a magnesium alloy structure is evenly distributed, the quality of a magnesium alloy product is improved, and the method is suitable for experimental and industrial application.

Owner:SHANGHAI JIAO TONG UNIV

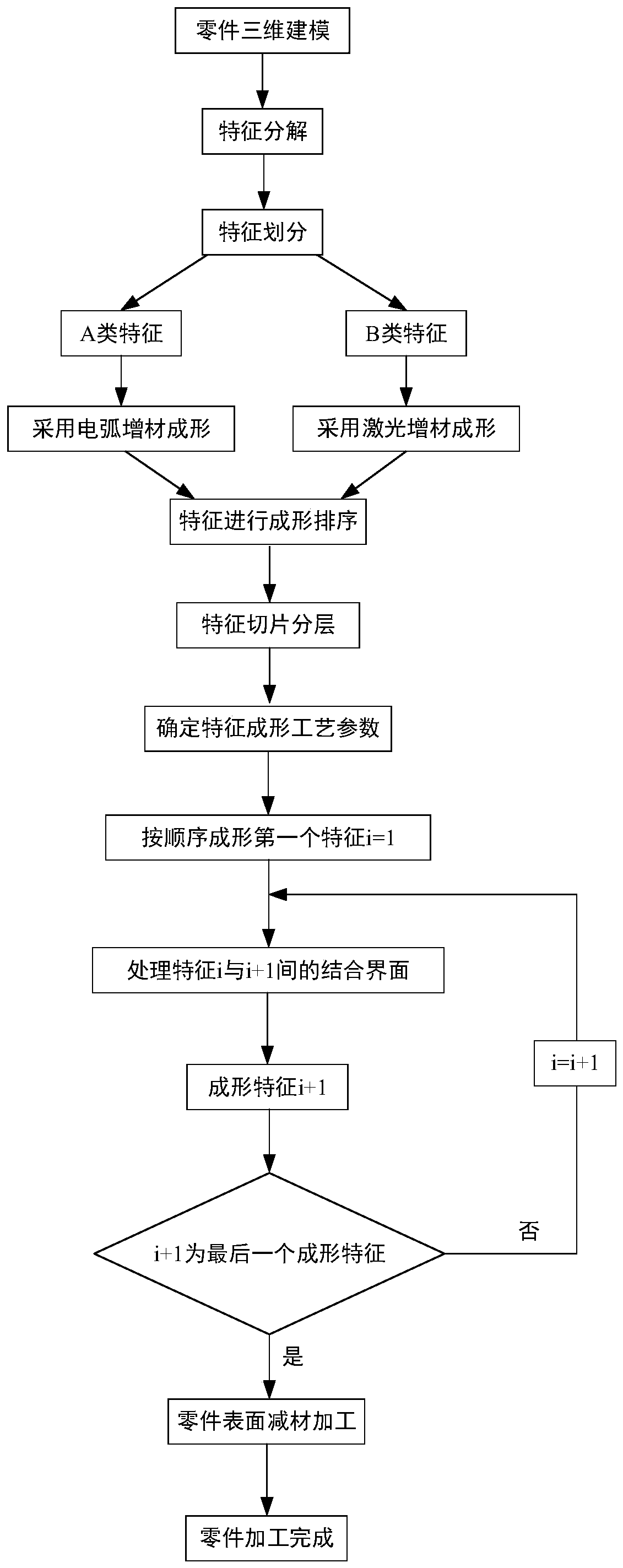

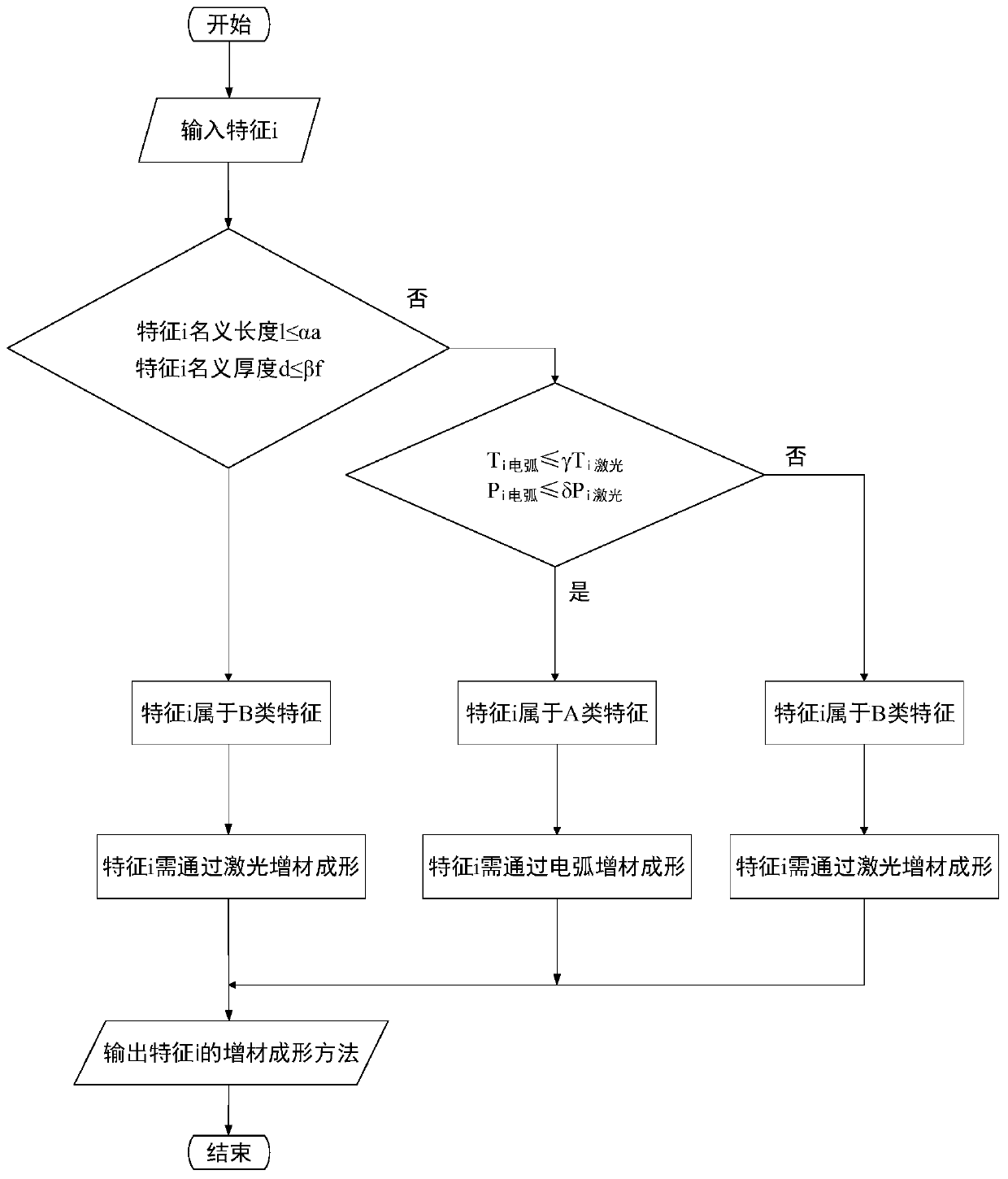

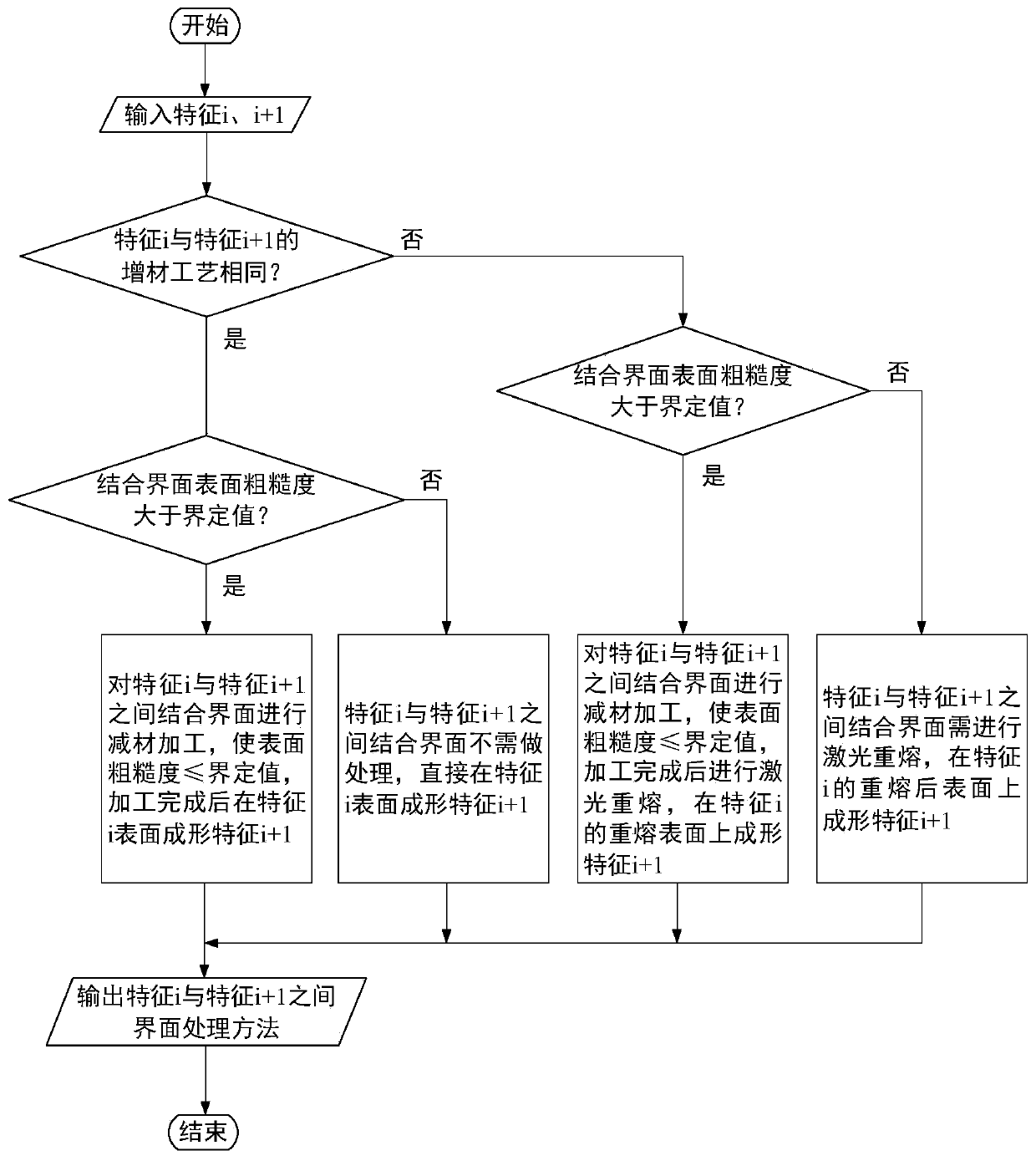

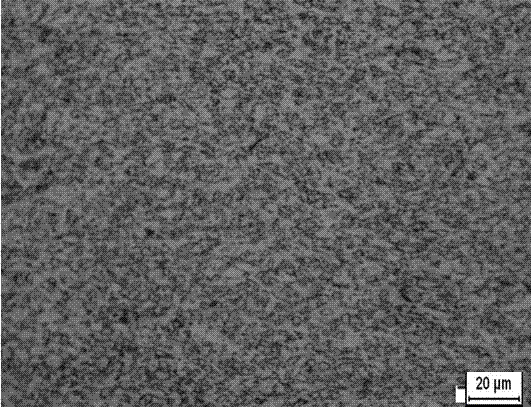

Complex metal part forming method adopting combination of electric arc additive and laser additive

ActiveCN111545915AGuaranteed forming effectImprove mechanical propertiesLaser beam welding apparatusLaser additive manufacturingMachining

The invention discloses a complex metal part forming method adopting combination of an electric arc additive and a laser additive. The complex metal part forming method comprises the steps that three-dimensional modeling is conducted on a part entity, geometric feature decomposition is conducted on a three-dimensional entity model, a part feature additive forming method is divided, forming processparameters of all features are determined, forming sorting is conducted on all the features, slicing and layering treatment is conducted on all the features, and all the features are sequentially formed according to the feature forming sorting and a treatment method of a combination interface between the adjacent features. According to the complex metal part forming method, the advantages of efficient electric arc additive manufacturing forming and fine laser additive manufacturing forming are effectively combined, compared with traditional forging, the machining period is shortened, the overall forming performance of a part is guaranteed, the quality of a fine and complex structure is guaranteed, the production efficiency is improved, and the machining cost is reduced. Meanwhile, a laserremelting method is adopted, the number of cracks and air holes in a combination interface area of a dissimilar additive process is reduced, meanwhile, structure distribution is more uniform, and themechanical property of the combination interface is improved.

Owner:XI AN JIAOTONG UNIV

Steel material for CT80 level coiled tubing and manufacturing method thereof

ActiveCN102899581AReduce solubilityIncrease the level of detailTemperature control deviceManufacturing technologyNiobium

The invention belongs to the technical field of tubing steel manufacturing, and particularly relates to a steel material for a CT80 level coiled tubing and a manufacturing method thereof. The steel material comprises the following chemical components in percentage by mass: carbon: 0.11 to 0.13%, silicon: 0.30 to 0.40%, manganese: 0.70 to 0.90%, chromium: 0.50 to 0.60%, nickel: less than or equal to 0.25%, Mo: 0.13 to 0.15%, copper: 0.30 to 0.40 %, niobium: 0.02 to 0.04%, and the balance being iron and inevitable impurities, wherein nitrogen is less than or equal to 0.004%, phosphorus is less than or equal to 0.015% and sulfur is less than or equal to 0.005% in the purities. The manufacturing method comprises the following steps: the alloy is smelted, a solid core metal calcium cored wire is used for final deoxidation in the smelting process, and then the controlled rolling and controlled cooling rolling is carried out after an ingot is formed, and the finished product is a 4.5mm strip. The steel material provided by the invention has the advantages of complete deoxidation, fine grain and uniform microstructure, and better yield strength, elongation and hardness value.

Owner:LAIWU IRON & STEEL GRP +1

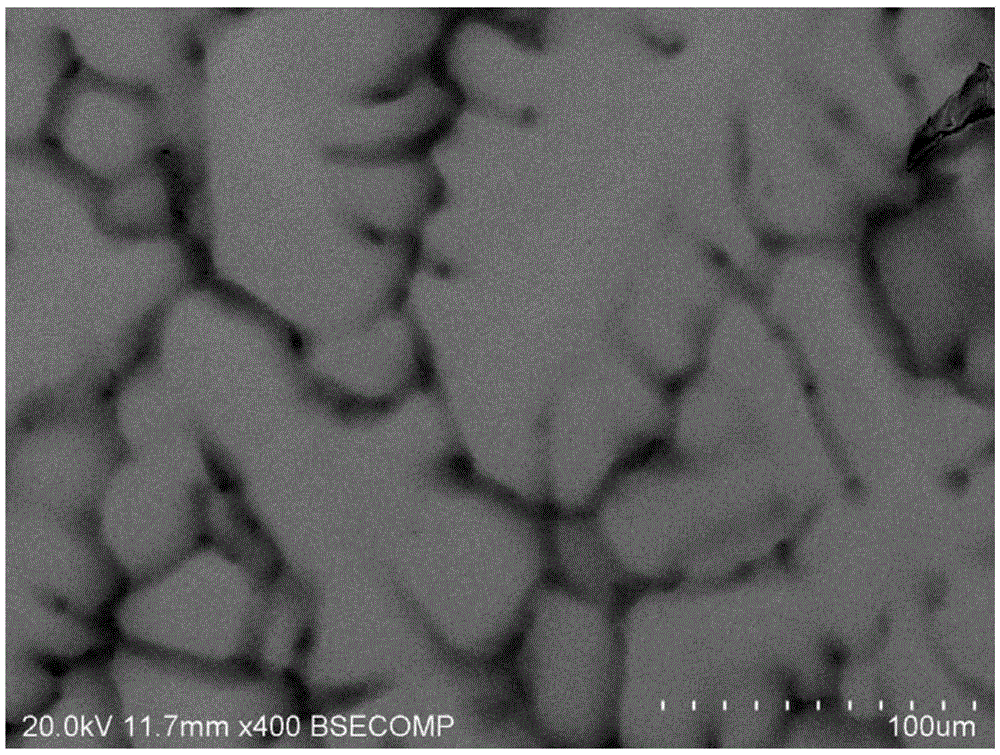

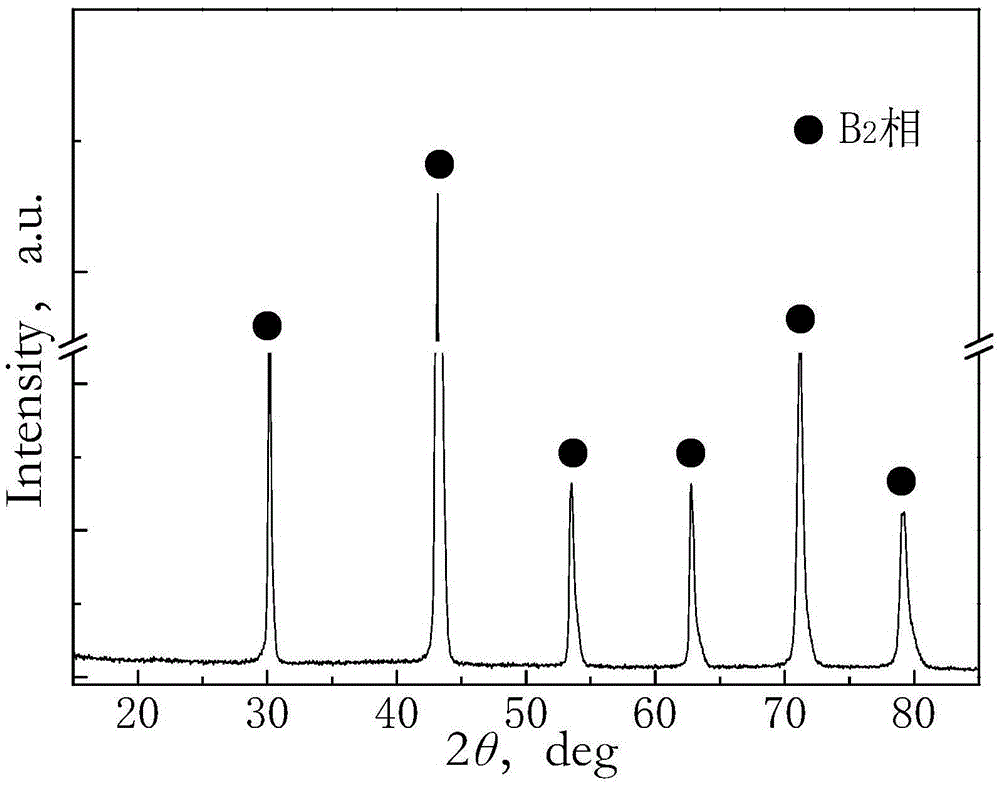

Preparation method of NiAlIr alloy

The invention provides a preparation method of a NiAlIr alloy. The preparation method is method that after being smelted, raw materials are cast through pressure to obtain the nickel aluminum iridium alloy under the condition of vacuum. Compared with the prior art, the preparation method has the advantages that the NiAlIr alloy prepared by the provided preparation method of the NiAlIr alloy is completely composed of a NiAl phase and an IrAl phase of a B2 crystal structure; structure distribution of the NiAlIr alloy is uniform; the minimum diameter of a prepared NiAlIr alloy wire is up to 0.8 mm; and a difficult problem that the NiAlIr alloy material used for an electrode slice of sparking plug can not be prepared in the prior art is solved; and therefore, application prospects of the preparation method of the NiAlIr alloy are very broad.

Owner:HUNAN UNIV OF SCI & TECH

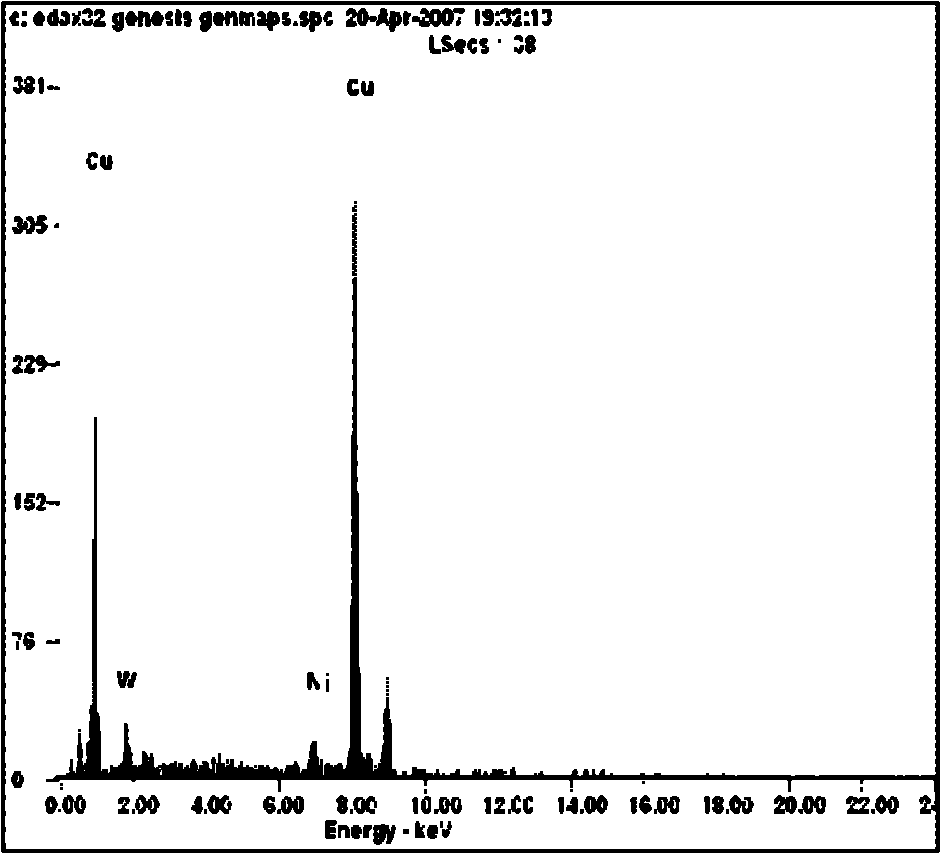

Cu-W-Ni copper matrix composite used for liner, electroforming method and electroforming solution thereof

InactiveCN101787552ATissue distributionReduce processing costsAmmunition projectilesElectroforming processesCrystalliteFine grain

The invention discloses a Cu-W-Ni copper matrix composite used for a liner, an electroforming method and an electroforming solution thereof, belonging to the electroforming field. The electroforming solution comprises the following components by proportion: 200-250g / L of NiSO4.7H2O, 60-90g / L of Na2WO4.2H2O, 6-10g / L of CuSO4.5H2O, 1-3g / L of CuCl2.2H2O, 270-320g / L of Na3C6H5O7.H2O, 0.3-0.5g / L of C12H25SO4Na, 1.0-1.5g / L of saccharin and 0.25-1mL / L of 1,4-butynediol. The electroforming condition comprises: the pH value of 10% of dilute sulphuric acid is regulated at 5.5-7.0, the temperature is 50-70 DEG C, the current density is 5-15A / dm2, the mechanical stirring is adopted, and a phosphorus-copper plate with 99.9% of Cu and 0.02-0.06% of P is used as an anode. The Cu-W-Ni copper matrix composite prepared in the invention has fine grains and homogeneous structure, and the Cu-W-Ni copper matrix composite liner is easily thickened through electroforming and has no defect on the surface and stable process.

Owner:CENT SOUTH UNIV

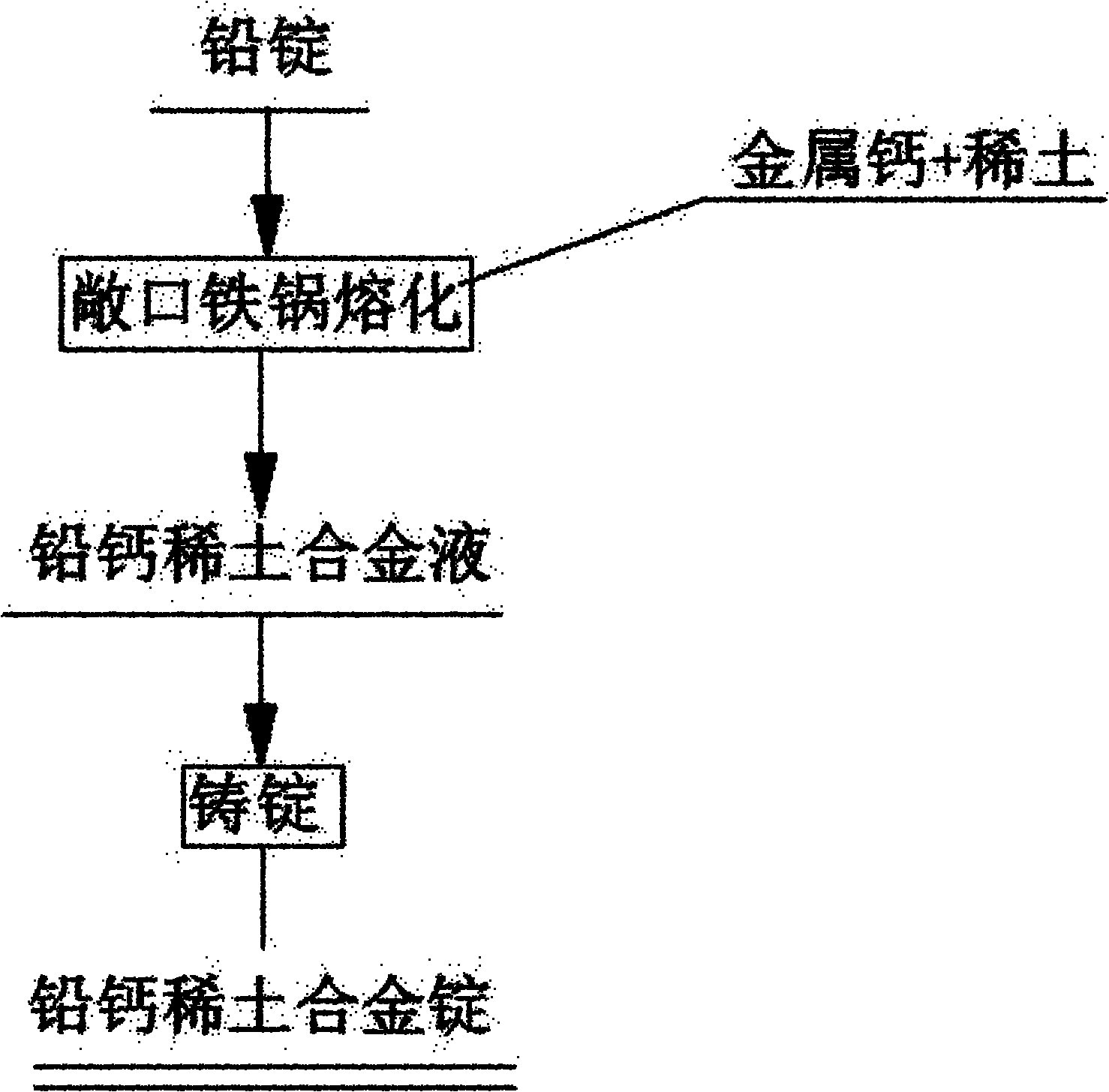

Direct production method for lead calcium rare earth alloy

The invention discloses a direct production method for a lead calcium rare earth alloy. The method is characterized by comprising the following steps of: A, putting lead ingots into an open iron pot, and heating to smelt the lead ingots into liquid lead; B, putting the needed metal calcium and rare earth into an iron bell jar; C, arranging the bell jar in the step B on an end part of a stirrer shaft, stirring the liquid lead and rapidly mixing the calcium and rare earth in the bell jar so as to prepare lead calcium rare earth alloy liquid in the liquid lead; and D, casting the lead calcium rare earth alloy liquid produced in the step C into ingots so as to prepare the lead calcium rare earth alloy ingot products, wherein the needed metal calcium and rare earth in the steps B and C are rapidly thrown into the whirlpool of the stirred liquid lead so as to prepare lead calcium rare earth alloy liquid. The method is mainly used for directly producing the lead calcium rare earth alloy.

Owner:ZHUZHOU SMELTER GRP

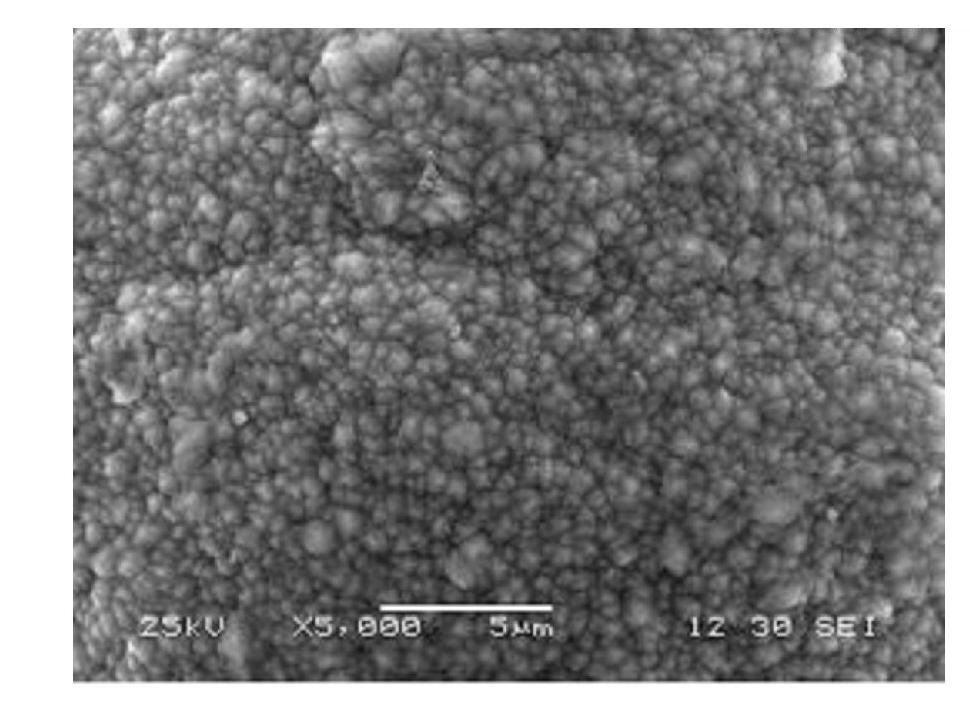

Method of preparing nano-crystalline powdered alloy powder

The invention provides a method of preparing nano-crystalline powdered alloy powder, and belongs to the field of a powder metallurgy preparation technology. The method comprises the steps: preparing an oxide precursor by adopting a solution method; carrying out reductive sintering on the precursor powder in hydrogen; and obtaining pure nickel-tungsten alloy powder with fine crystal particles. According to the method provided by the invention, all raw materials are mixed by using a liquid phase, reactants can be uniformly mixed on an atom level, and the problem that the alloy powder is difficult to mix can be solved; meanwhile, the method has the characteristics of low cost and high use ratio of raw material powder; in addition, because the nano-crystalline powdered alloy powder is plied as nano-crystalline powder, and the method is higher in rigidity, wearability, corrosion resistance, resistance to high temperature oxidation and the like.

Owner:UNIV OF SCI & TECH BEIJING

Wear-resistant surfacing flux-cored wire

InactiveCN107186380AImprove scalabilityImprove toughnessWelding/cutting media/materialsSoldering mediaWear resistantHardness

The invention discloses a wear-resistant surfacing flux-cored wire. The wear-resistant surfacing flux-cored wire consists of a flux core and a low-carbon steel-tape sheath coating the outer side of the flux core, wherein the flux core comprises the following components: Cr, C, Ti, Nb, Zr, B, W, Mo, Si, Mn, Mg, Cu, Ni, Sr, Sm, Sc, Y, Eu, and the balance of Fe and inevitable impurities. The wear-resistant surfacing flux-cored wire is reasonable in composition and high in bonding strength with base metal, a surfacing layer is favorable in toughness, hardness, creep resistance and wear resistance, and the service life of hardware is prolonged.

Owner:天长市通联焊业有限公司

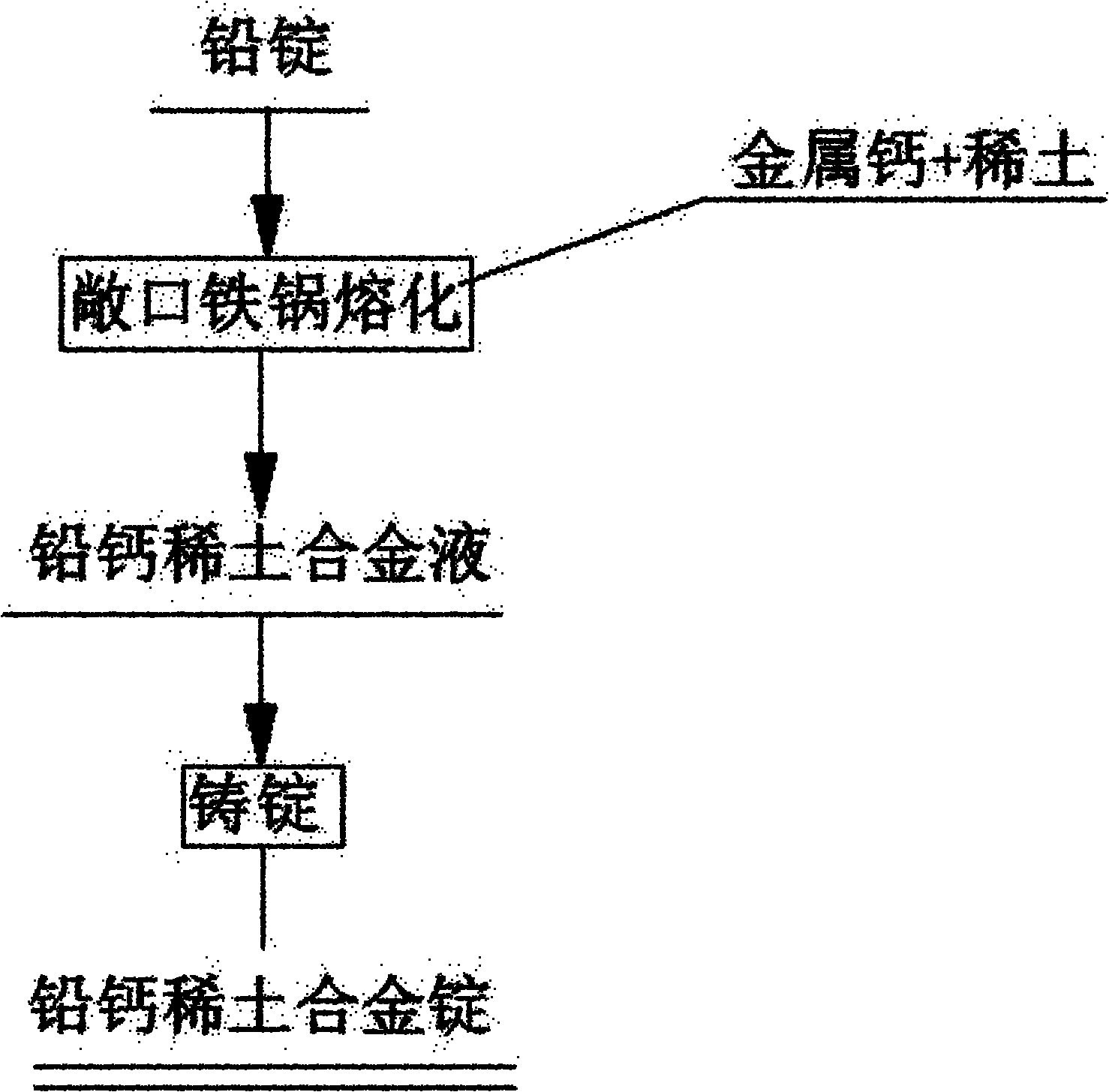

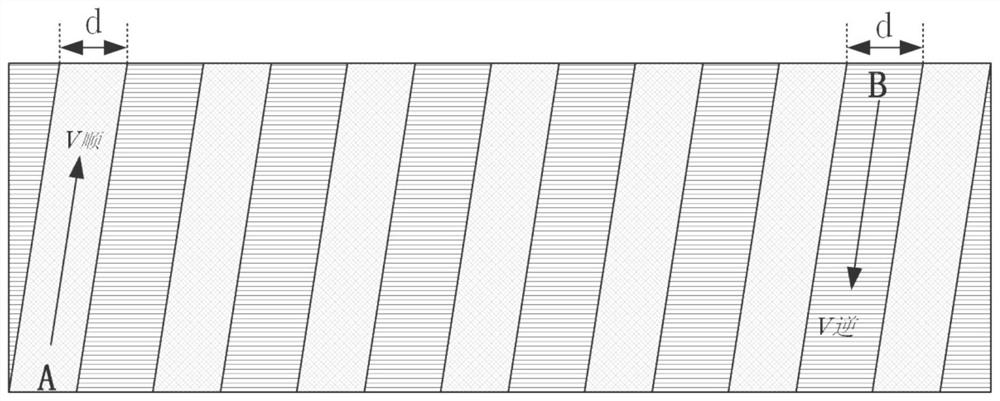

Steel mill pinch roll surface laser cladding Fe-Cr alloy wear-resistant coating preparation technology

PendingCN111719148AImprovement ingredientsConvenient ratio controlMetallic material coating processesProduction lineAlloy

The invention relates to the technical field of laser cladding additive manufacturing, and discloses a steel mill pinch roll surface laser cladding Fe-Cr alloy wear-resistant coating preparation technology. The steel mill pinch roll surface laser cladding Fe-Cr alloy wear-resistant coating preparation technology comprises the steps that spherical powder is prepared by powder materials by molar mass percentage; an electromagnetic power mixing device is used for mixing powder, and the grain size is 45-105[mu]m; the number of cladding layers of laser cladding is 2, a cladding track of a first layer cladding layer adopts the alternating mode of two spiral lines, the first spiral line is started from one end of a pinch roll, and after the operation of a first spiral line track is completed, a second spiral line is started from the other end; and a second layer of the cladding layers adopts the partition cladding mode, symmetric cladding is carried out according to four areas, and stress relief treatment is carried out by adopting vibration aging equipment in the cladding process of each area. Through the combination of the blending of the powder materials and the cladding mode, by combining with the synchronous vibration aging treatment, the wear-resisting property and average Rockwell hardness of surface coatings of the pinch roll can be improved, the coating quality is improved, and a change cycle of parts on a production line is prolonged.

Owner:NANJING ZHONGKE RAYCHAM TECH

Surface modified SiC reinforced aluminum-based composite material and preparation method thereof

The invention discloses a surface modified SiC reinforced aluminum-based composite material and a preparation method thereof. The surface modified SiC reinforced aluminum-based composite material is characterized by taking a metal aluminum as a matrix and taking a surface modified SiC porous ceramic as a reinforcement; the preparation method includes the steps that firstly SiC is deposited on a carbon foam substrate through a CVI method; a carbon foam framework is removed through an oxidation method to obtain a SiC porous ceramic blank body; the SiC porous ceramic is further obtained through aPIP method; then porous SiC whiskers are prepared on an outer layer of the SiC porous ceramic through laser sintering; and finally the SiC reinforced aluminum-based composite material is prepared through high-pressure infiltration. The surface-modified SiC reinforced aluminum-based composite material is uniform in structure distribution and good in forming property, and due to surface modification, the strength of the composite material is ensured and the wear resistance of the composite material is improved. By means of the surface modified SiC reinforced aluminum-based composite material, the problems that SiC of a traditional silicon carbide reinforced aluminum-based composite material is not uniformly dispersed in an aluminum matrix, the wear resistance is poor are solved, and the surface modified SiC reinforced aluminum-based composite material can be widely applied to bearing structural parts in the aerospace field.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

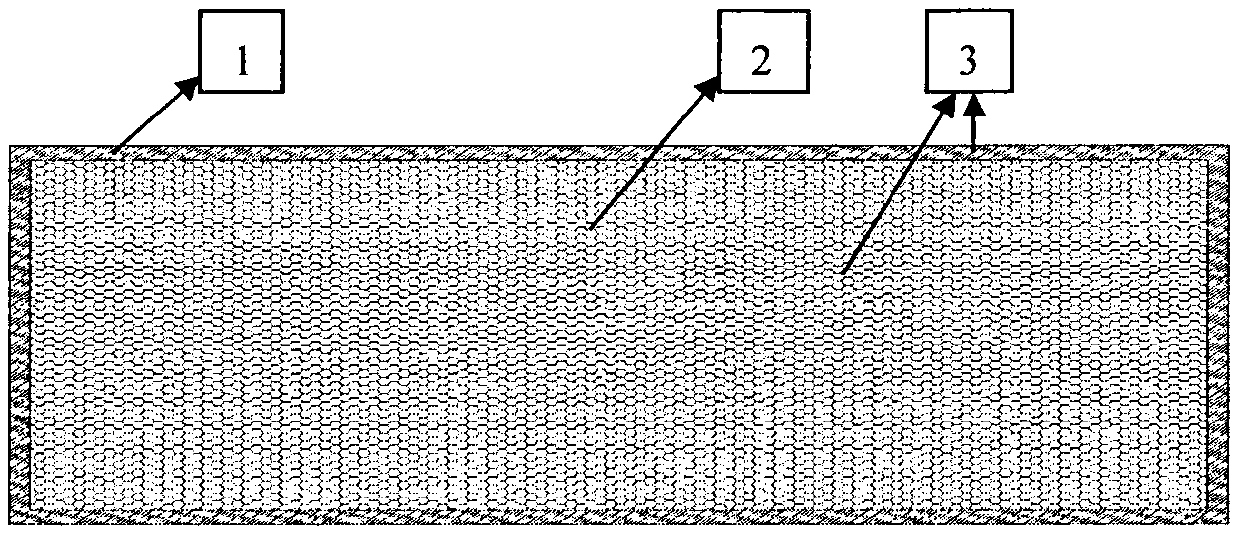

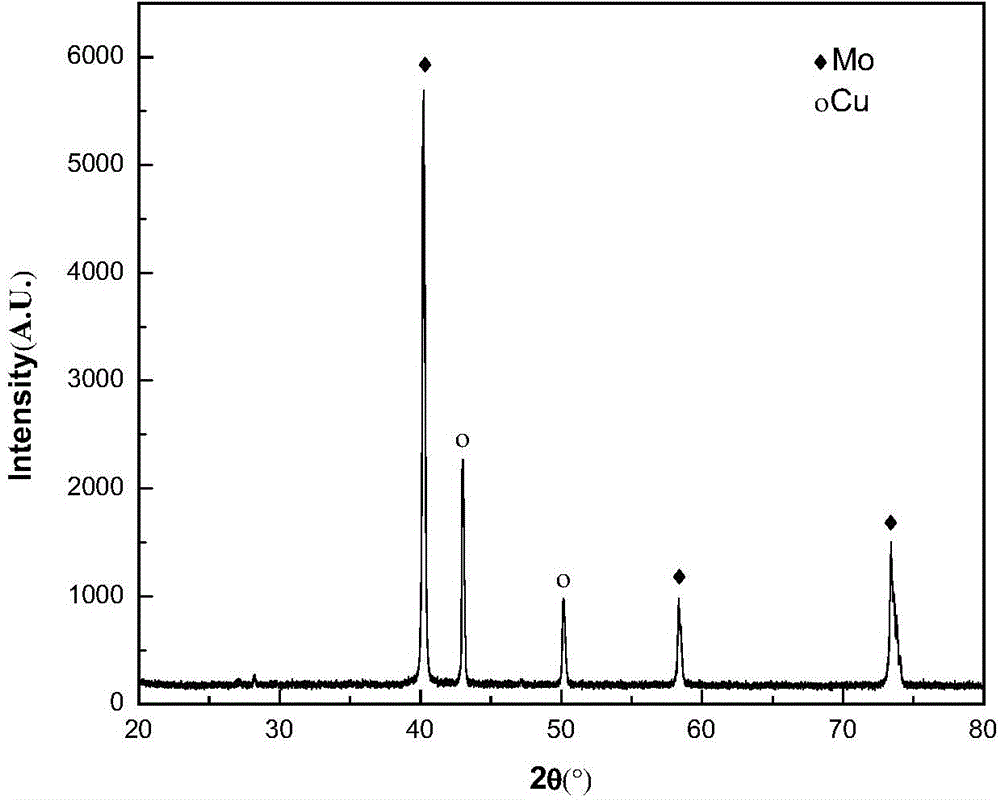

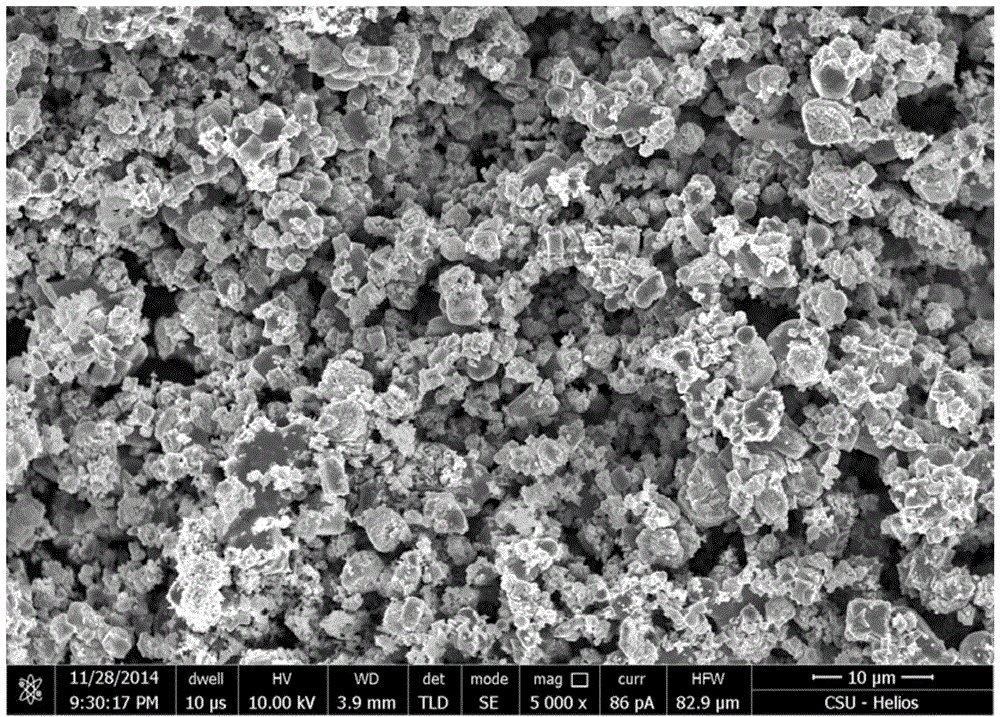

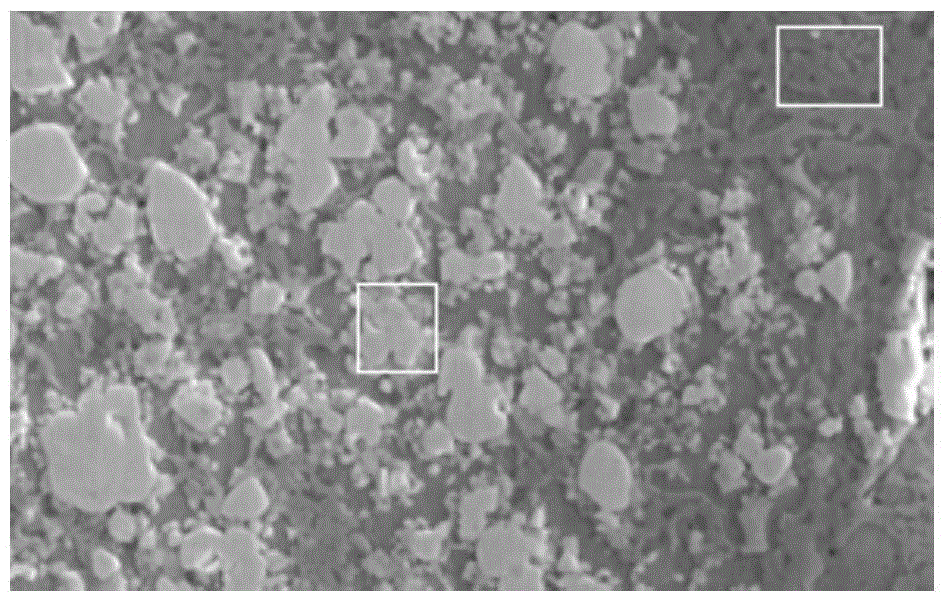

Preparation method for high-dispersion superfine nanometer Mo-Cu compound powder

The invention discloses a preparation method for high-dispersion superfine nanometer Mo-Cu compound powder. Firstly, an ammonia-water solution of copper salt is added to a deionized water solution of molybdenum salt, a mixed solution is formed, the pH of the mixed solution is adjusted to be 5-7, then the water solution is heated, filtered, washed, dried and calcined, and precursor molybdenum and copper oxide power is obtained; secondly, the precursor powder is restored in hydrogen, and the high-dispersion superfine nanometer Mo-Cu compound powder is obtained. The nanometer powder prepared through the method has the advantages of being large in specific surface area, fine and uniform in particle diameter, high in purity and the like. Through the simple and effective method that the molybdenum and copper precursor powder is prepared through chemical coprecipitation, magnetic stirring and thermostatic waterbath heating, and then is calcined and restored, the method is simple and rapid, the process is easy to operate and control, the yield of the powder is large, efficiency is high, and the preparation method is suitable for industrial volume production.

Owner:HUNAN UNIV OF SCI & TECH

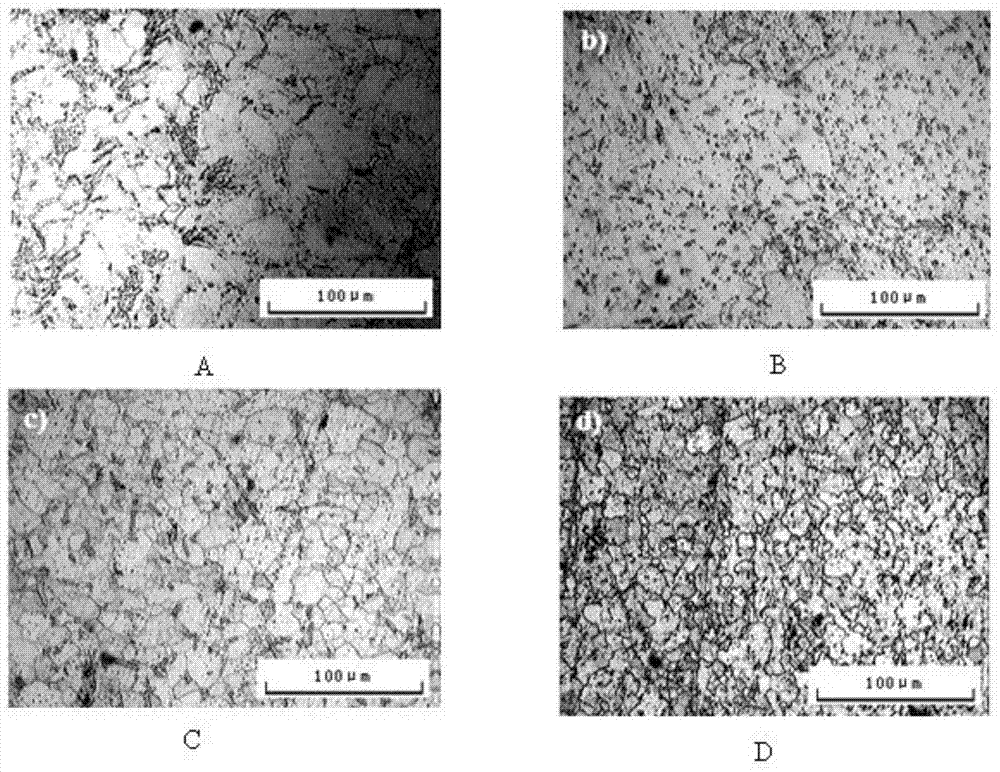

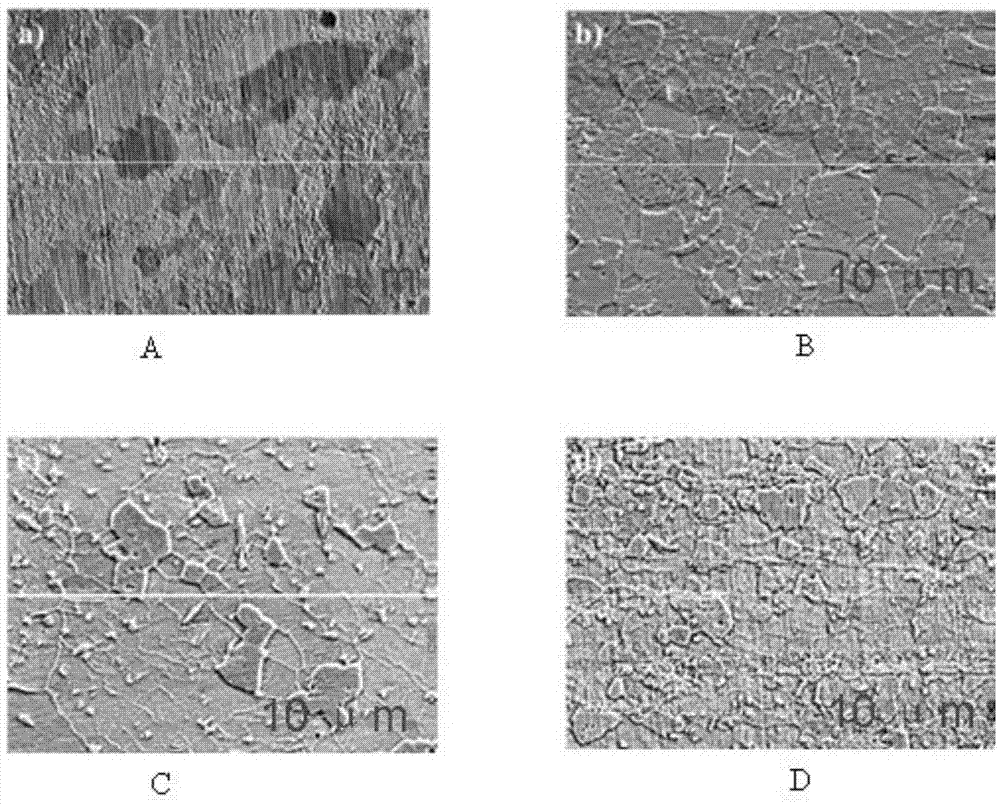

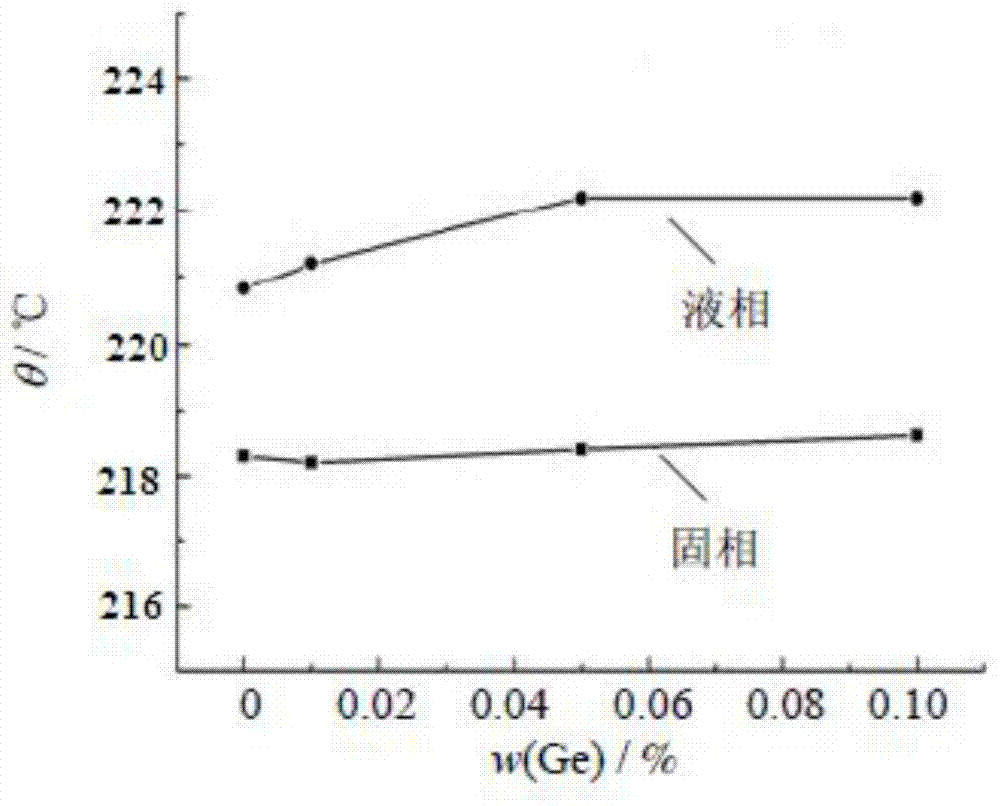

Lead-free brazing filler metal

InactiveCN104741820ATissue distributionImprove antioxidant capacityWelding/cutting media/materialsSoldering mediaFiller metalMoisture

The invention belongs to the technical field of brazing filler metal and relates to lead-free brazing filler metal. The lead-free brazing filler metal is composed of, by mass, 0.5% to 4.0% of Cu, 0.04% to 0.2% of Ni, 0.005% to 1.0% of Ge, 0.05% to 2.0% of Bi and the balance Sn. Compared with the prior art, 0.005% to 1.0% of Ge and 0.05% to 2.0% of Bi are added to the brazing filler metal, structure distribution of the brazing filler metal can be even, and the melting point and the melting range of brazing filler metal alloy are reduced; due to the fact that germanium is high in oxyphile skin effect and can be concentrated on the surface of the melting brazing filler metal, the brazing filler metal is prevented from being further oxidized. Thus, oxidization resistance of the brazing filler metal can be remarkably improved by adding tiny germanium and the brazing filler metal is prevented from becoming yellow. In addition, the moisture and the tensile strength of the brazing filler metal can be remarkably improved by adding tiny germanium.

Owner:东莞腾马电子有限公司

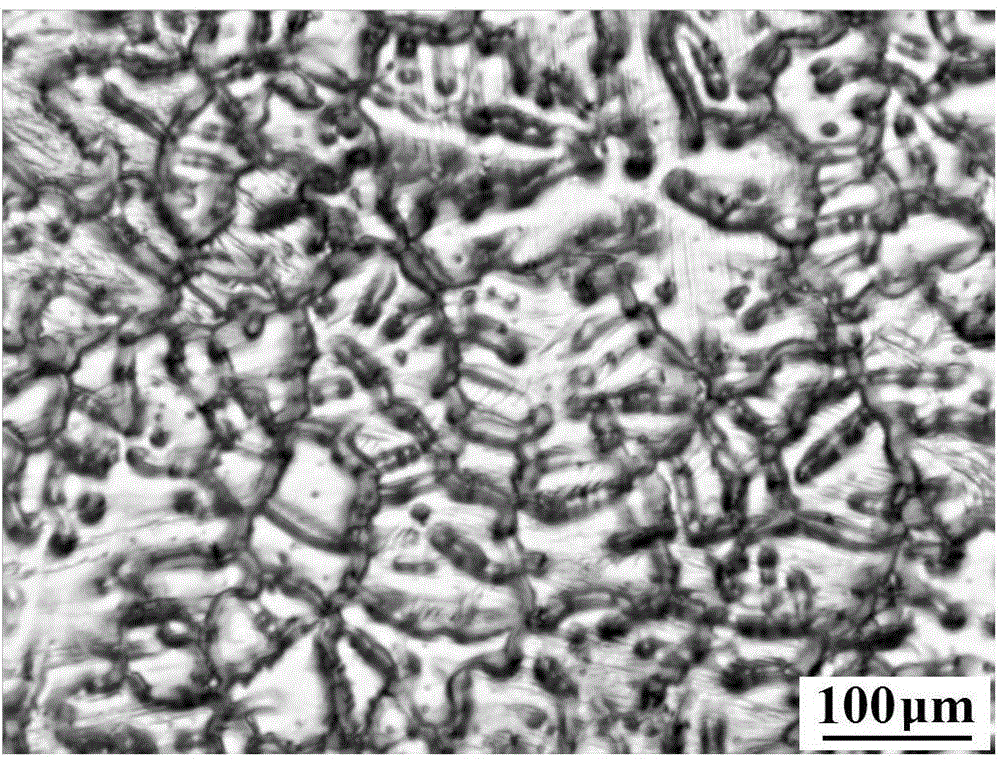

Modification treatment method of aluminium alloy

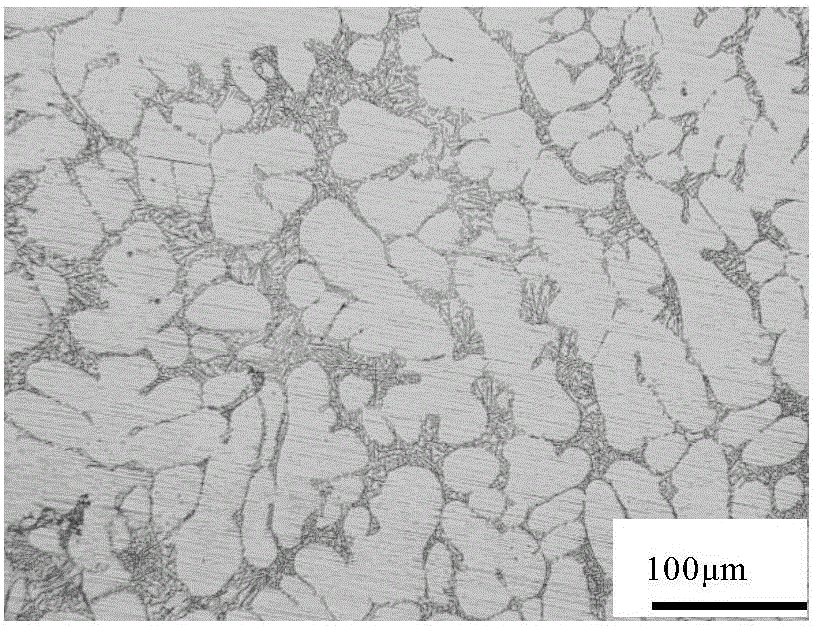

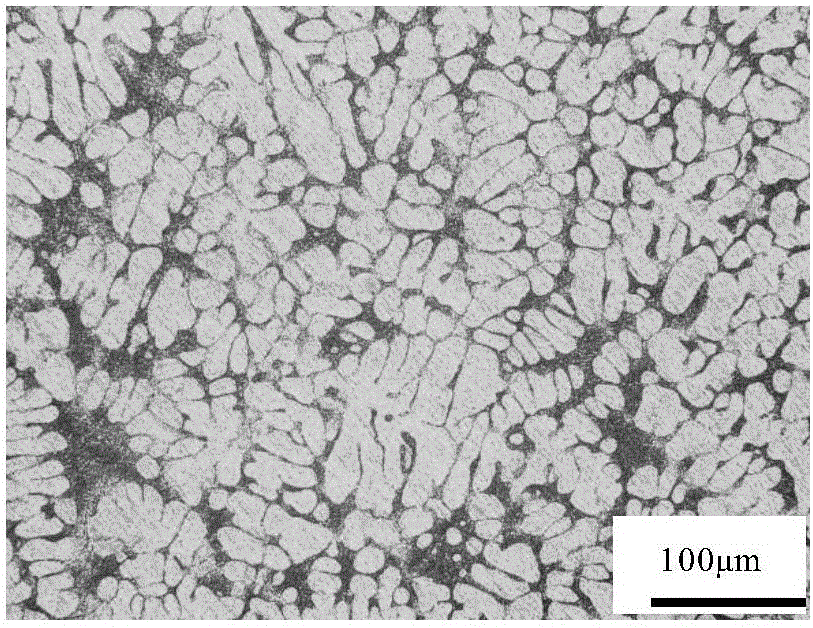

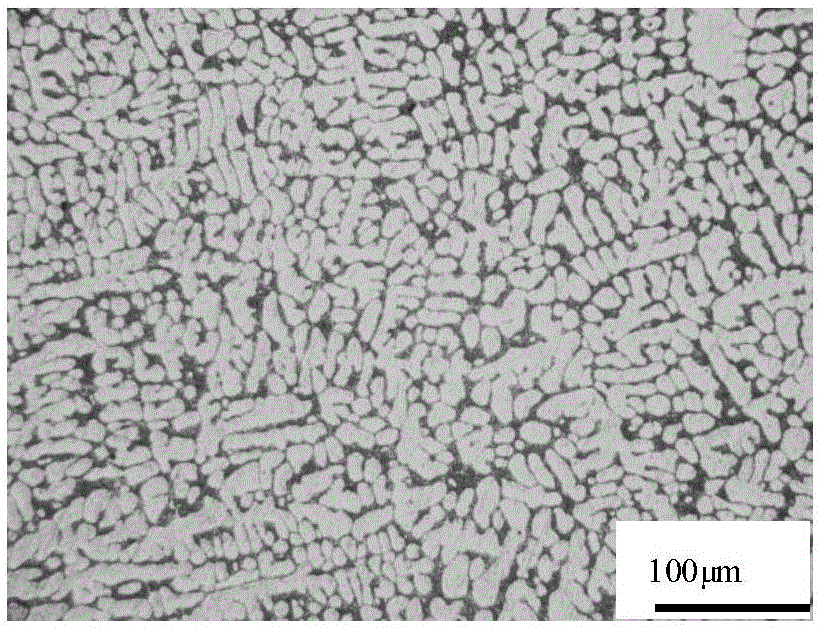

The invention belongs to the technical field of aluminium alloys, and relates to a modification treatment method of an aluminium alloy. The modification treatment method is characterized in that Al-10Zr and Al-12Er intermediate alloys are adopted as an alterant, an A356 aluminium alloy is adopted as a modification object; 0.20% of Zr and 0.40% of Er are added, and the microstructure and performance of the A356 aluminium alloy are remarkably improved through the technological processes like batching, smelting and modification treatment; and tensile strength of the A356 aluminium alloy subjected to modification treatment of the Al-10Zr intermediate alloy and the Al-12Er intermediate alloy is 225 MPa, elongation is 6.4%, and tensile strength and elongation are respectively improved by 52.8% and 36.2% compared with tensile strength and elongation of the A356 aluminium alloy which is not subjected to modification treatment.

Owner:JIANGSU UNIV OF TECH

Method for preparing tungsten carbide ceramic material

The invention discloses a method for preparing a tungsten carbide ceramic material, wherein the method comprises the steps: putting a tungsten carbide powder into a graphite mold, firstly, applying the pressure of 17-20 MPa and carrying out cold compression, then removing the pressure, starting to heat up when the vacuum degree is less than 10 Pa, heating up to 1900-2000 DEG C, controlling the pressure to be 25-30 MPa and keeping for 25-30 minutes, and cooling to 800-1000 DEG C. The method can obtain a binder-free tungsten carbide hard alloy having the advantages of high density, fine crystal grains and uniform distribution of microstructure.

Owner:张家港市华舰五金工具有限公司

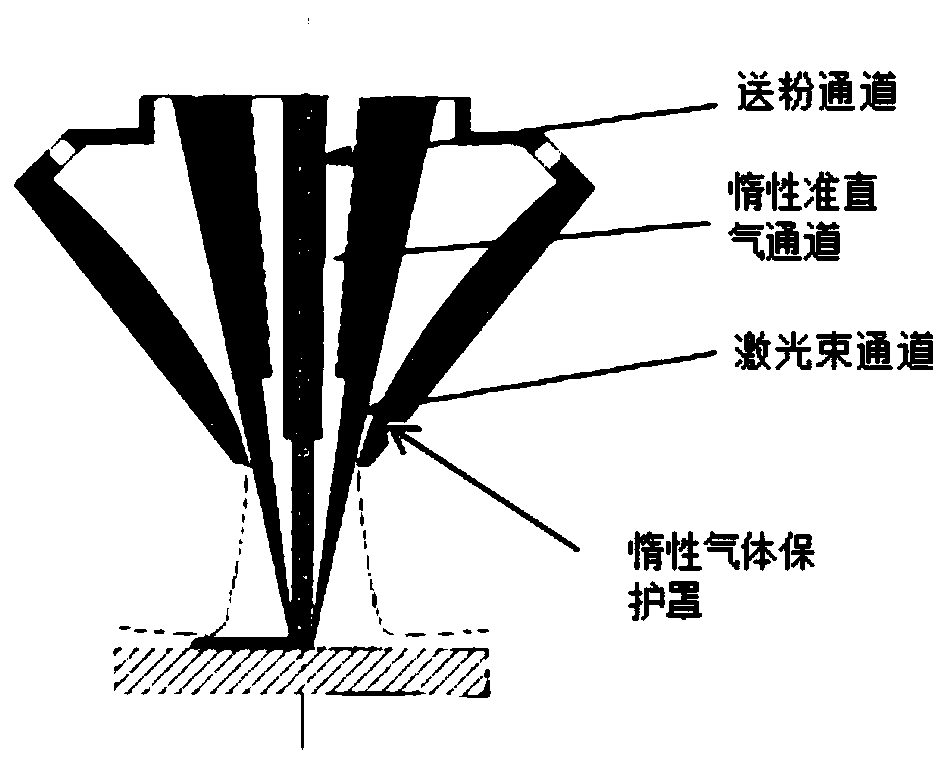

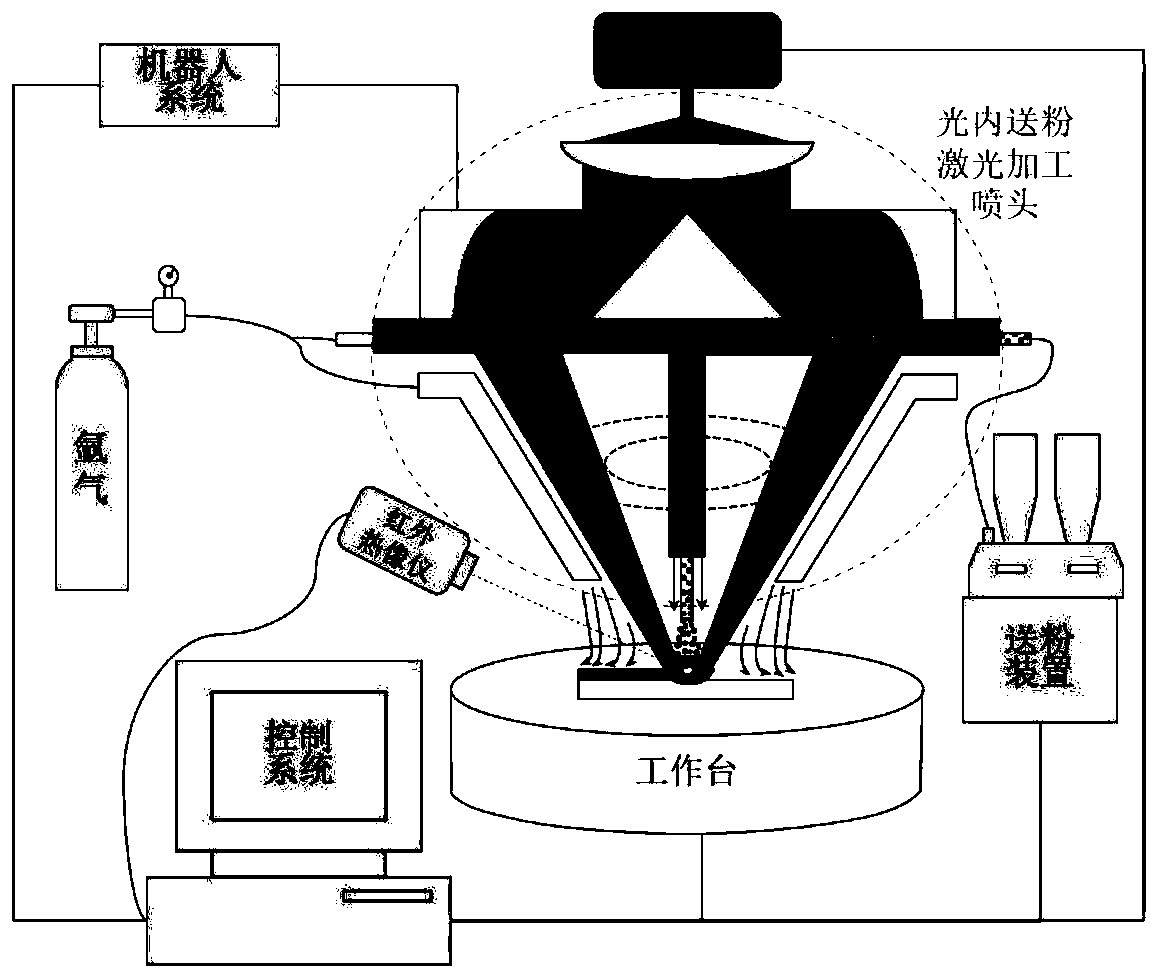

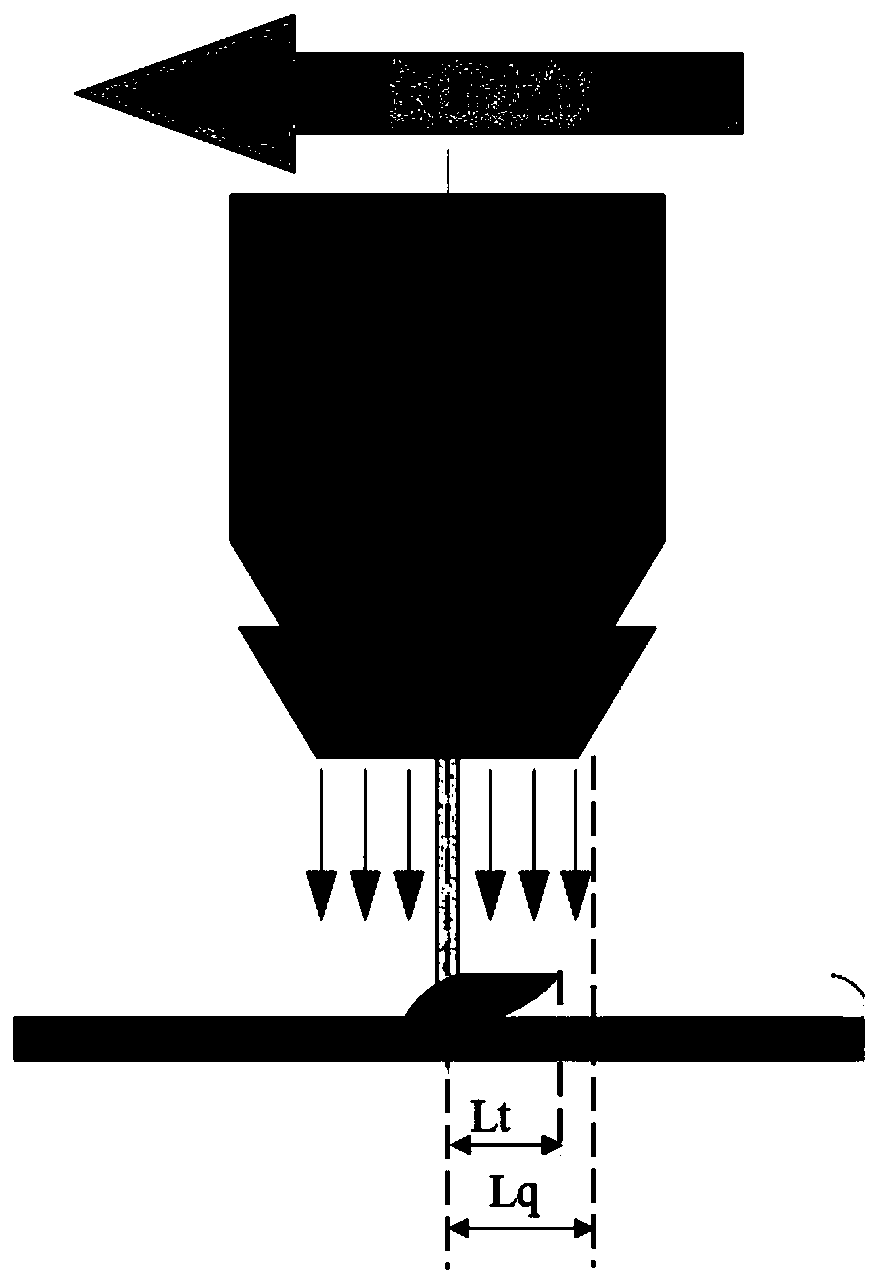

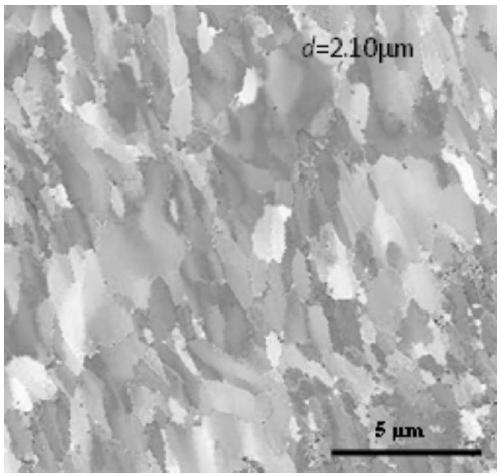

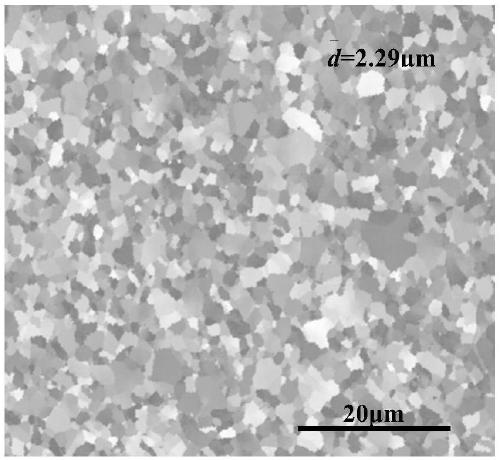

Titanium alloy additive manufacturing method based on inside-laser powder feeding laser processing nozzle

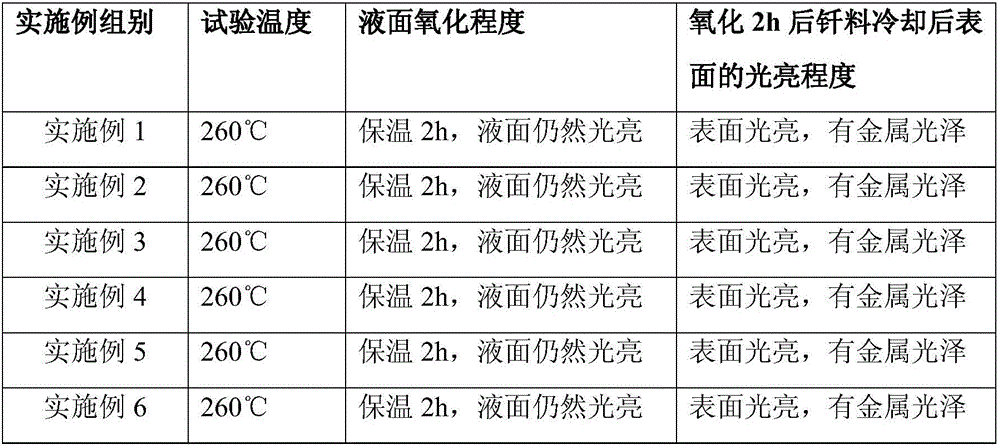

ActiveCN111545914AUniform oxidationTissue distributionAdditive manufacturing apparatusWelding/soldering/cutting articlesLaser processingLoop control

The invention provides a titanium alloy additive manufacturing method based on an inside-laser powder feeding laser processing nozzle, and belongs to the technical field of titanium alloy manufacturing. The method is characterized in that it is guaranteed that L < t > is smaller than or equal to L < q > in the additive manufacturing process, wherein the L < q > is the distance from a powder centerto the outermost side of protective gas, and the L < t > is the maximum distance from the powder center to the position, where the temperature is 400 DEG C, of a formed part in the additive manufacturing process. According to the method, it is guaranteed that the L < t > is smaller than or equal to the L < q >in the additive manufacturing process through a closed-loop control means, which means that it is guaranteed that the protective gas can fully cover the high-temperature area of the formed part in the additive manufacturing process, the situation that the local temperature is too high and uncontrollable due to heat accumulation in the additive manufacturing process is avoided, and it is guaranteed that a final titanium alloy is uniform in components and stable in performance; and according to the data of the embodiment, the surface of the titanium alloy formed part obtained through the embodiment is bright silvery white, and when the stacked height reaches 40 mm, no obvious oxidation discoloration exists; and meanwhile, the content of oxygen elements in all parts of the interior of the formed part is lower than 1,000 ppm.

Owner:苏州天至尊科技有限公司

Ultrafine grained Ta material and preparation method thereof

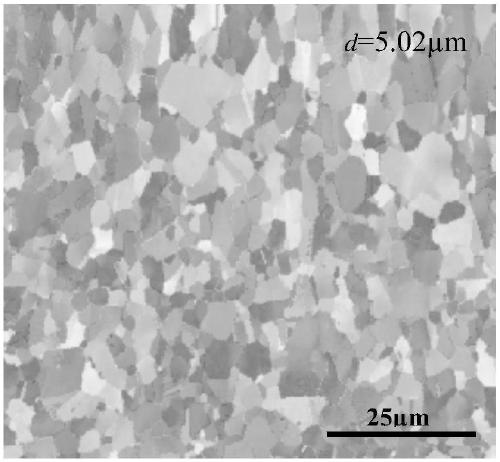

The invention relates to an ultrafine grained Ta material and a preparation method thereof. Grain size of the ultrafine grained Ta material is smaller than or equal to 3 mu m; ultimate strength of thematerial is higher than or equal to 410 MPa, and yield strength is higher than or equal to 300 MPa. The preparation method of the material comprises the following steps: electron beam melting is performed on a Ta source, after ingot casting, an ingot is sheathed in a protective atmosphere; 3D hot-forging cogging is performed, total deformation of cogging is 65%-75%, and cogging temperature is 1150-1250 DEG C; after cogging, a sheath is removed, and low-temperature and high-temperature cross alternate rolling is performed; the ultrafine grained Ta material is obtained. The process is simple, and the prepared Ta ribbon has uniform and quite fine grains and is endowed with favorable strength, plasticity and toughness. The designed and prepared ultrafine grained Ta ribbon is applied to the high-technology fields of electronics, metallurgy, steel, chemical industry, hard alloys, atomic energy, superconducting technology, automotive electronics, aerospace, medical health and scientific research.

Owner:CENT SOUTH UNIV +1

Preparation method of anti-corrosion impeller for chemical pump

InactiveCN106634070AHigh hardnessExtended service lifeAnti-corrosive paintsMetallic material coating processesImpellerManufacturing technology

The invention belongs to the technical field of manufacturing of pump accessories, and particularly relates to a preparation method of an anti-corrosion impeller for a chemical pump. The preparation method comprises processes of preparation of a ceramic macromolecular material layer, impeller surface treatment, coating adhesion and the like. Compared with the prior art, the preparation method has the following advantages: tissues in ceramic macromolecular liquid is uniformly distributed, so that the segregation phenomena are reduced, the surface can be smooth, and the impeller surface can meet the design requirements; the working efficiency of the impeller is improved; the impeller surface is high in corrosion resistance, high in hardness, and relatively high in wear resistance and corrosion resistance, so that the service life of the impeller can be prolonged.

Owner:ANHUI TENGLONG PUMP VALVE MFG CO LTD

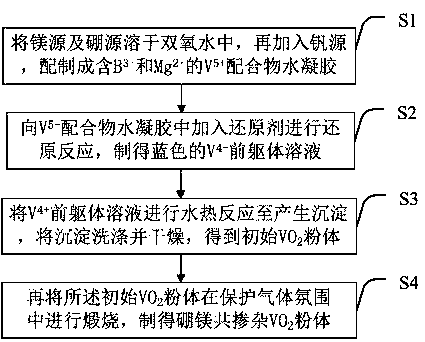

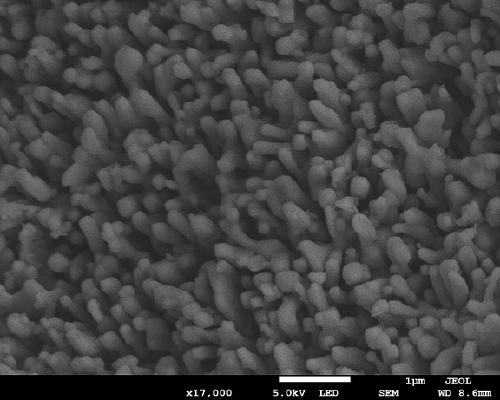

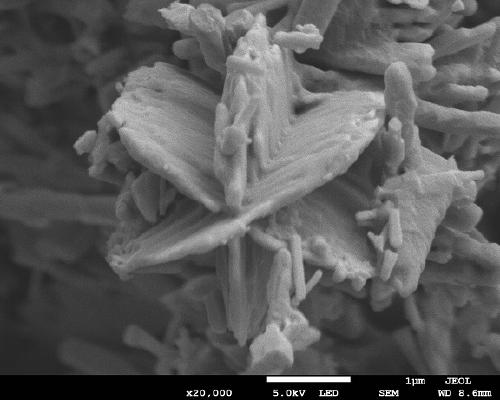

Boron magnesium co-doped VO2 powder, preparation method and application thereof

ActiveCN109502643ASmall particle sizeLower phase transition temperatureNanotechnologyVanadium oxidesShielding gasCoordination complex

The invention discloses a boron magnesium co-doped VO2 powder, a preparation method and an application thereof. The preparation method comprises the following steps: dissolving a magnesium source anda boron source into hydrogen peroxide, and then adding a vanadium source, thereby preparing a V5+ complex hydrogel containing B3+ and Mg2+; adding a reducing agent into the V5+ complex hydrogel for performing reduction reaction, thereby acquiring a blue V4+ precursor solution; performing hydrothermal reaction on the V4+ precursor solution till generating sediment, cleaning and drying sediment, thereby acquiring an initial VO2 powder; calcining the initial VO2 powder under a protective gas atmosphere, thereby acquiring the boron magnesium co-doped VO2 powder. The invention can solve the problemof the prior art that a VO2 material with both low phase-transition temperature and high visible light transmittance cannot be acquired.

Owner:SHENZHEN UNIV

High-strength wear-resisting flux-cored wire

InactiveCN107309572AReduce pollutionImprove scalabilityWelding/cutting media/materialsSoldering mediaHigh intensityWear resistance

The invention discloses a high-strength wear-resisting flux-cored wire. The high-strength wear-resisting flux-cored wire is composed of a flux core and a sheath coating the outer side of the flux core. The flux core comprises following components of Si, B, Cu, C, Mn, Ni, Al, Ti, Mo, V, Sn, Sr, Hf, Nd, Ce, Y, Eu and the balance Fe and inevitable impurities. According to the high-strength wear-resisting flux-cored wire, the components of the flux core are reasonable; after welding, deposited metal has excellent toughness, strength and wear resistance; and the service life of a metal component is remarkably prolonged.

Owner:天长市通联焊业有限公司

Unleaded brazing filler metal

InactiveCN106425154ATissue distributionImprove wettabilityWelding/cutting media/materialsSoldering mediaAlloyTissue distribution

The invention relates to an unleaded brazing filler metal, and belongs to the technical field of brazing filler metal. The brazing filler metal is prepared from, by mass, 0.3%-1.0% of Cu, 0.01%-0.11% 0f Ni, 0.005%-0.10% of Ge, 0.05%-2.0% of Bi, 0.05%-2.0% of Zn, 0.005%-0.5% of Ce, 0.005%-0.3% of Er and the balance Sn. Compared with the prior art, tissue distribution of alloy of the unleaded brazing filler metal is uniform; in addition, the unleaded brazing filler metal has functions of anti-oxidation and stain inhibiting, and has good wettability, good mechanical property and low melting point at the same time.

Owner:DONGGUAN GUANGXIN INTPROP SERVICES CO LTD +1

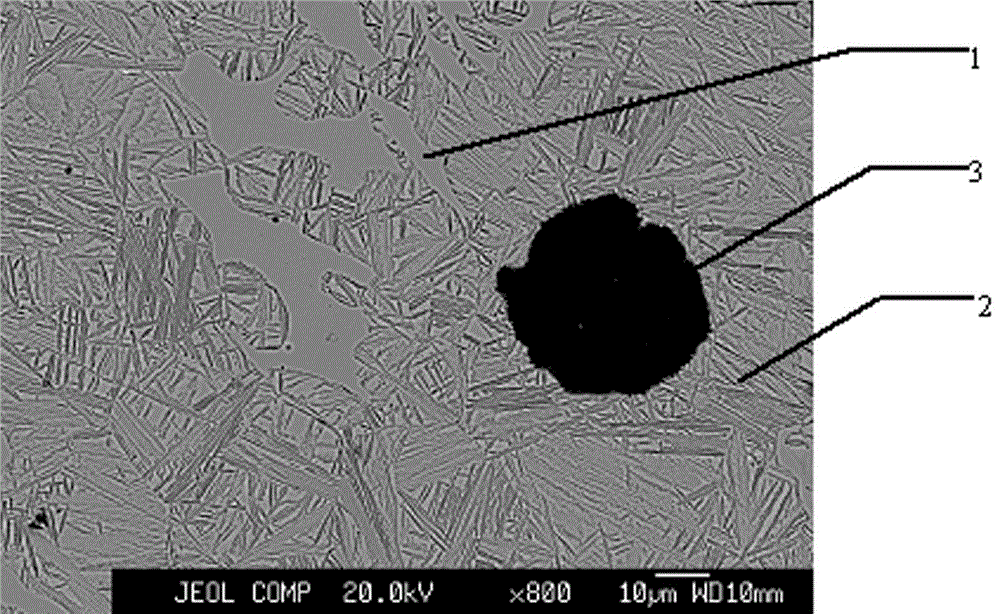

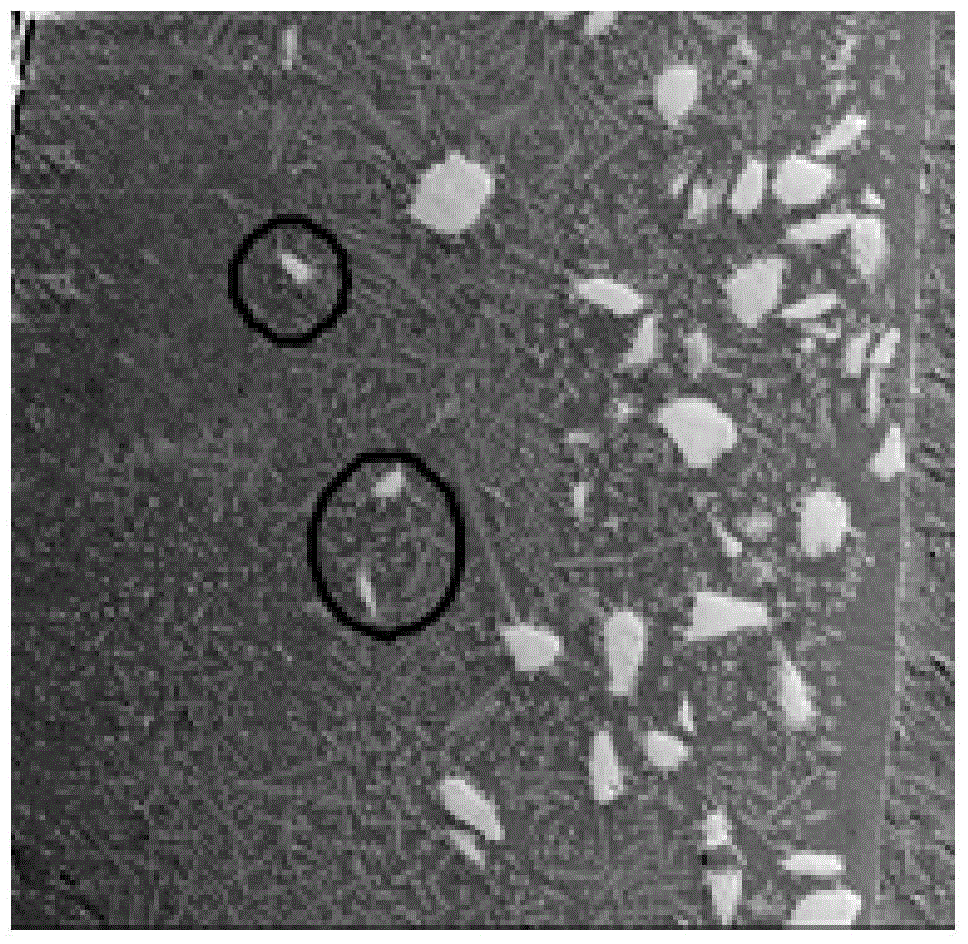

A method for preparing ultra-high hardness cladding layer by synchronous ultrasonic vibration assisted laser technology

InactiveCN104451673BGuaranteed hardnessGuaranteed wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing ultra-high hardness cladding layer by synchronous ultrasonic vibration assisted laser technology. The specific scheme is to introduce ultrasonic vibration synchronously in the process of cladding Ni-based cermet coating, and this method can improve the flow of liquid metal In the process of solidification, the growing dendrite network can be broken and dispersed to various parts of the melt to form evenly distributed small crystal nuclei to prevent segregation of cermets, thereby It ensures that the cladding layer does not crack while obtaining ultra-high hardness; the equipment is simple, it is convenient for calibration and installation, the energy consumption is small, and the working environment is good. The obtained coating cermet has uniform particle distribution, high hardness and good wear resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing high silicon steel strip by powder tape casting and high-temperature diffusion sintering

InactiveCN107900356AQuality improvementImprove uniformityTransportation and packagingMetal-working apparatusSolventFerrosilicon

The invention discloses a method for preparing high silicon steel strip by powder tape casting and high-temperature diffusion sintering. According to the method, water-atomized iron powder and high-purity ferrosilicon powder with the Si content being 50-70% are adopted as raw materials to form Fe-4.5-6.7% Si mixed powder; a solvent, a dispersing agent, an adhesive and a plasticizer are added intothe mixed powder so as to prepare stable slurry which is uniformly dispersed, and a biscuit is prepared on a tape casting machine; the biscuit is subjected to vacuum or reducing atmosphere protectionsintering at 1060-1160 DEG C, so that Fe powder particles are not completely sintered, Si and Fe are partially alloyed, and a multi-hole and incompletely-alloyed high silicon steel blank is formed; and repeated cold rolling and incomplete sintering are carried out on the high silicon steel blank, finally vacuum or reducing atmosphere protection sintering is carried out on the high silicon steel blank at 1250-1320 DEG C, so that homogenization alloying of the high silicon steel is realized, and the high silicon steel strip with the Si content being 4.5-6.7%, the thickness being 0.1-0.5 mm and the density greater than or equal to 7.38 g / cm<3> is obtained.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com