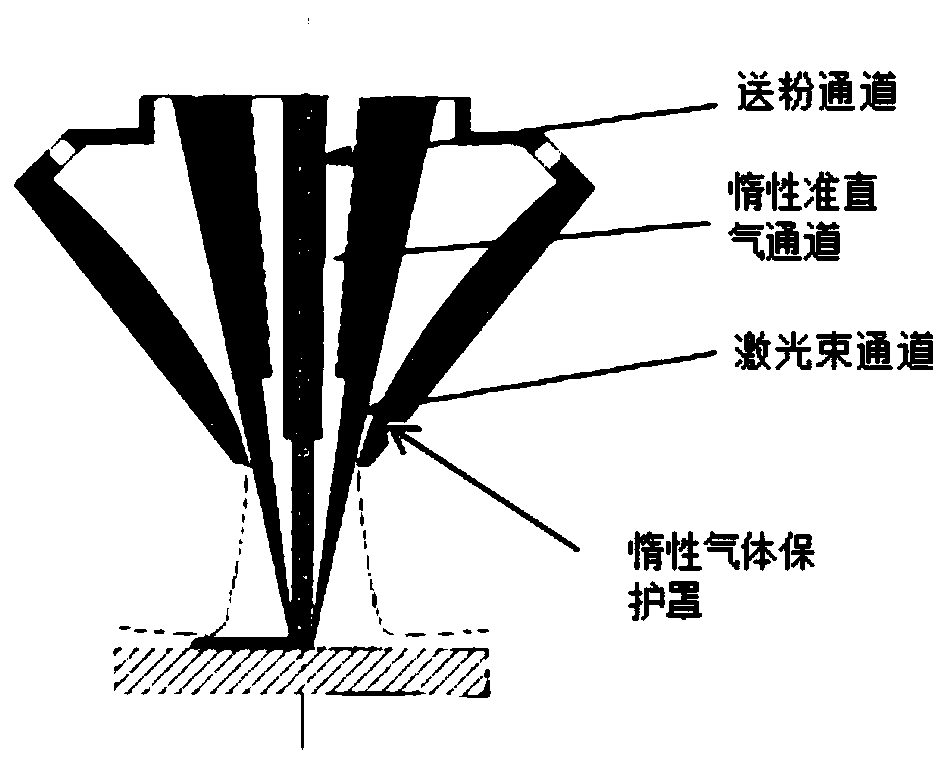

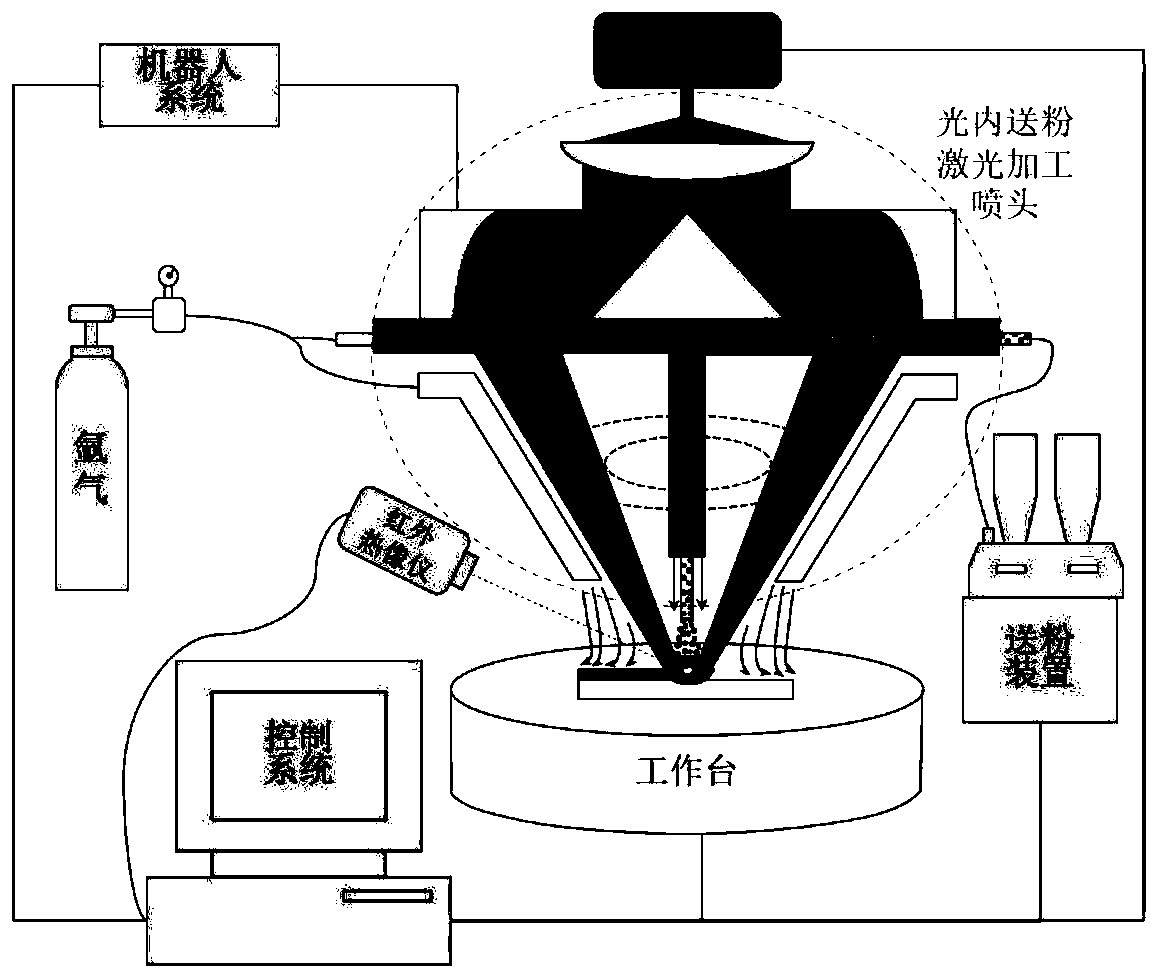

Titanium alloy additive manufacturing method based on inside-laser powder feeding laser processing nozzle

A technology of laser processing and internal powder feeding, which is applied in laser welding equipment, metal processing equipment, additive processing, etc., can solve the problems of uneven oxidation degree of formed parts, performance degradation of formed parts, uneven tissue distribution, etc., and achieve high performance Stability, uniform oxidation degree, avoiding the effect of local overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

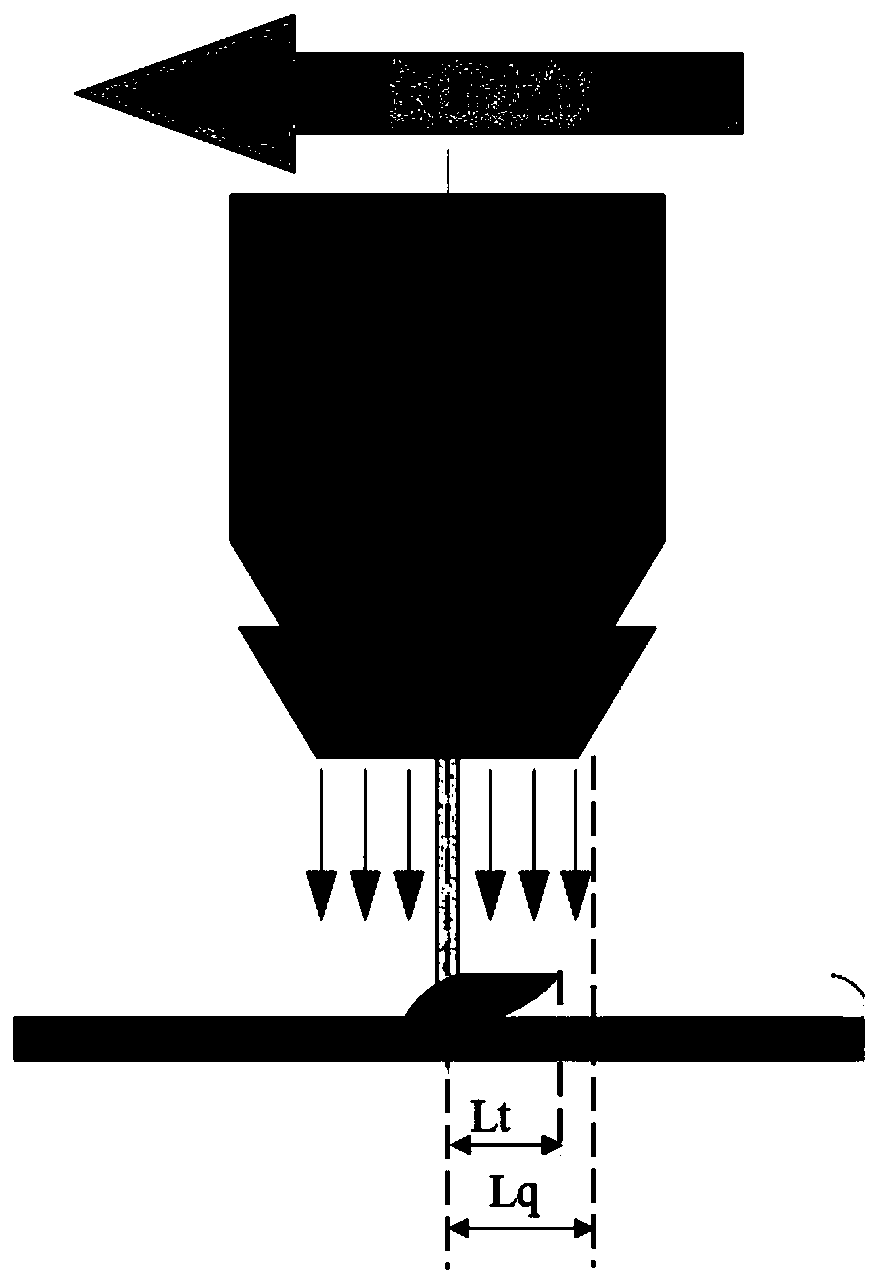

[0038]In an open environment, the laser processing nozzle with internal powder feeding is used to carry out continuous additive forming of titanium alloy with 8 horizontal channels and 90 vertical layers. The initial laser power is 1050W, and the protective gas flow rate of 30L / min is used to obtain 13.52 mm inert gas shielding length. According to the monitoring results of the infrared thermal imager, the length of the high-temperature and easy-to-oxidize region exceeds the length of the inert gas protection when the number of stacked layers is 30, 46, 67, and 85. Therefore, the laser power is reduced to 950W at the 30th layer, 920W at the 46th layer, 890W at the 67th layer, and 850W at the 85th layer, and finally a titanium alloy with a size of length × width × height = 50mm × 12mm × 40mm is obtained. pieces. Each surface of the formed part is bright silvery white.

[0039] The powder composition of the titanium alloy is shown in Table 1.

[0040] Table 1 Titanium alloy p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com