Preparation method of oxidized nanocellulose

A technology of nanocellulose and cellulose, applied in the field of preparation of oxidized nanocellulose, can solve the problems of uneven oxidation of nanocellulose, insufficient environmental protection of nanocellulose, and easy to corrode equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing oxidized nanocellulose in one embodiment of the present invention comprises the following steps:

[0029] breaking the cellulose raw material into pieces to obtain cellulose pieces;

[0030] Add the cellulose fragments to the aqueous solution containing citric acid, then add the polyol and sulfuric acid solution, stir evenly, raise the temperature to 95°C-100°C, and let it stand for 3h-5h to obtain the cellulose suspension;

[0031] Suction filtration of the cellulose suspension under vacuum conditions to recover citric acid to obtain cellulose pulp;

[0032] The cellulose pulp is washed with deionized water, and the pH of the cellulose pulp is adjusted to neutrality with lye;

[0033] Add water to the cellulose pulp, adjust the mass percentage of the solid content of the cellulose pulp to 1%-5%, add NaBr and TEMPO under the condition of stirring, after stirring evenly, add the NaClO solution dropwise, real-time monitoring of the precise pH , th...

Embodiment 1

[0056] A method for preparing oxidized nanocellulose, comprising the steps of:

[0057] The wood pulp board is crushed into wood pulp board fragments with a diameter and a length of less than 10mm with a pulverizer;

[0058] Wood pulp board fragments are added in the aqueous solution that mass percent content is 80% citric acid, and the quality of wood pulp board fragments accounts for 8% of the aqueous solution quality of citric acid, then adds 10% of the aqueous solution quality of citric acid Ethylene glycol, and finally add sulfuric acid solution accounting for 5% of the mass of the aqueous solution of citric acid, and the solid content of the added sulfuric acid solution is 30% by mass, stir evenly and heat up to 95°C for standing reaction for 3h to obtain a cellulose suspension ;

[0059] Suction filtration of the cellulose suspension under vacuum conditions, evaporation and recrystallization of the filtrate at room temperature or recovery of citric acid by distillation u...

Embodiment 2

[0064] A method for preparing oxidized nanocellulose, comprising the steps of:

[0065] The straw pulp board is crushed into straw pulp board fragments with a diameter and a length of less than 10 mm with a crusher;

[0066] The straw pulp board fragments are added to the aqueous solution of 65% citric acid by mass percentage content, and the quality of the straw pulp board fragments accounts for 10% of the aqueous solution quality of citric acid, and then add 1% of the aqueous solution quality of citric acid Ethylene glycol, finally add sulfuric acid solution accounting for 1% of the mass of the aqueous solution of citric acid, and the solid content of the added sulfuric acid solution is 30% by mass, stir evenly, heat up to 100°C and let stand for reaction for 5h to obtain a cellulose suspension ;

[0067] Suction filtration of the cellulose suspension under vacuum conditions, evaporation and recrystallization of the filtrate at room temperature or recovery of citric acid by...

PUM

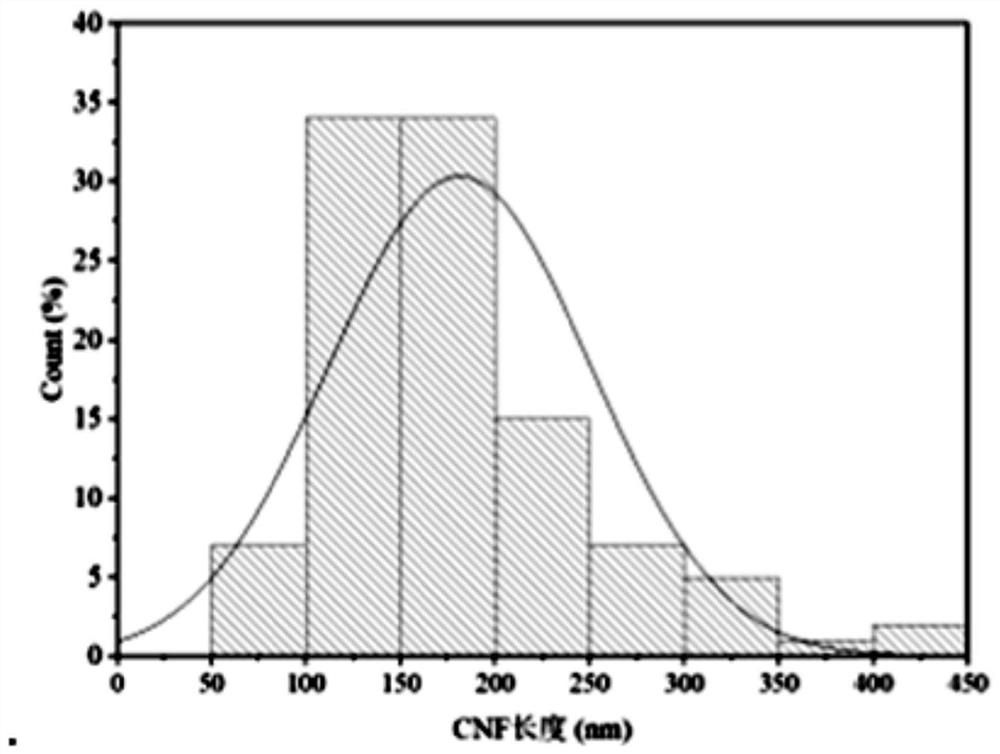

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com