Steel mill pinch roll surface laser cladding Fe-Cr alloy wear-resistant coating preparation technology

A technology of wear-resistant coating and laser cladding, which is applied in the coating process and coating of metal materials, can solve problems such as pinch roller wear, achieve the effects of improving quality, grain refinement, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

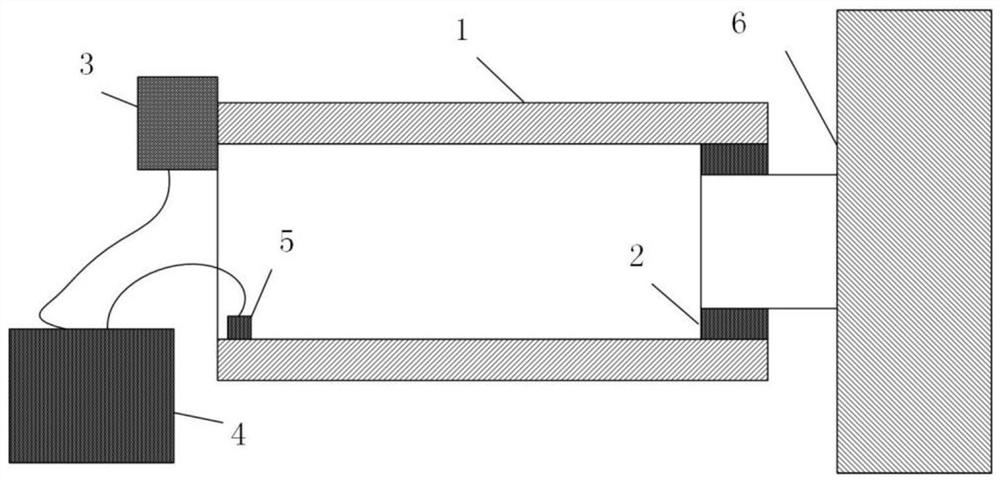

[0059] In this example, the laser cladding powder material is mixed according to the aforementioned ratio, and the mixing time is 1h by using an electromagnetic mixer. A new pinch roller without surface strengthening was selected as the test workpiece for laser cladding, and the material was 45 steel.

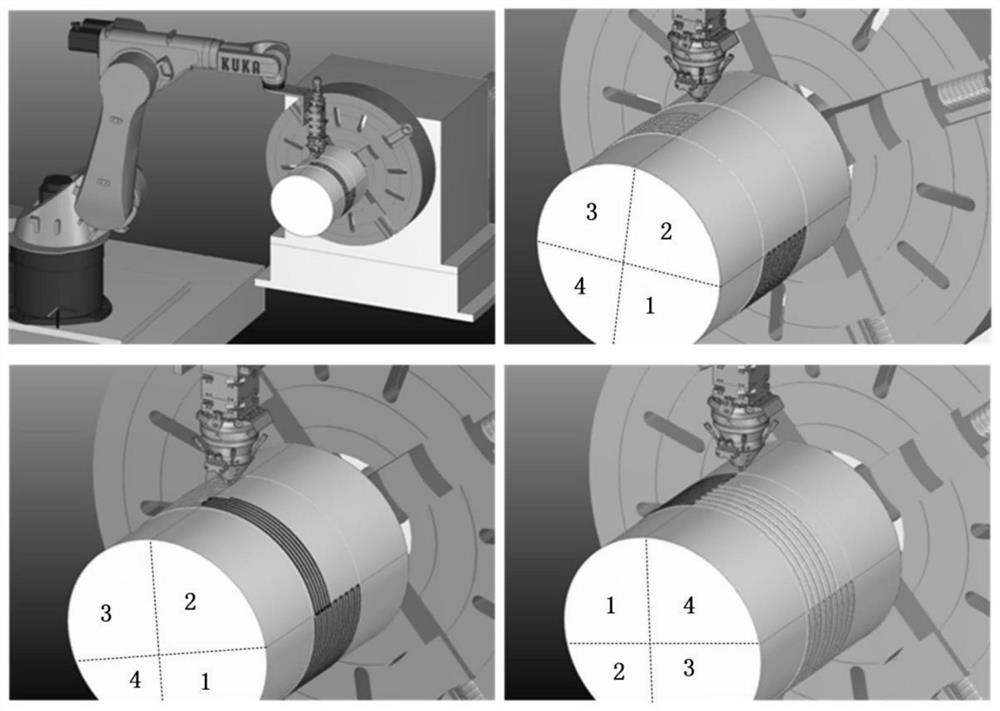

[0060] The laser cladding experiment adopts ZKYC-LCD-4000 laser remanufacturing equipment: KUKA60-3 robot, YC52 coaxial powder feeding processing head, Laserline semiconductor 4000W laser, MCWL-120DT2 water cooler and RC-PGF-D-2 double barrel powder feeder. The main process parameters of laser cladding are:

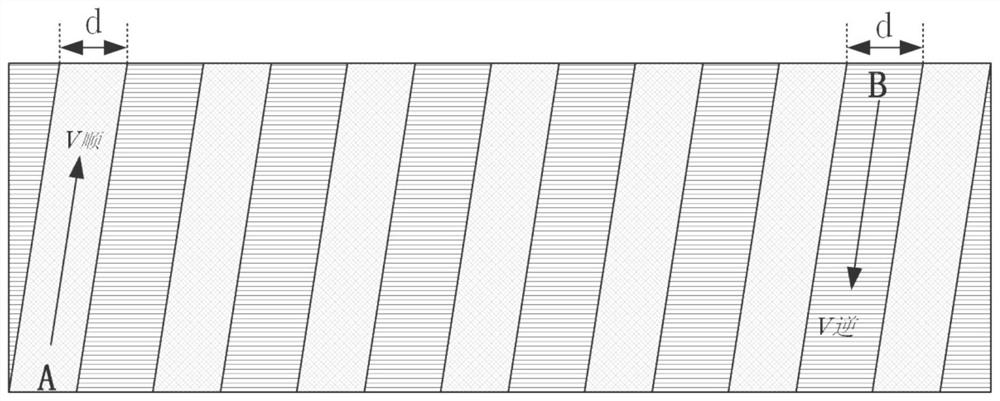

[0061] The first layer (bottom layer): laser power 2.1kW, spot size 5mm, scanning speed 1200mm / min, protective gas selection argon, flow rate 40ml / min, the bottom of the processing head is 40mm away from the surface of the workpiece; the cladding track is: the workpiece rotates continuously , the cladding head is fed in a straight line, and the cladding layer overlap rat...

Embodiment 2

[0065] The laser cladding powder material is mixed according to the aforementioned ratio, and the mixing time is 1h by using an electromagnetic mixer. The pinch roll is also selected as the base material for laser cladding.

[0066] The laser cladding experiment adopts ZKYC-LCD-4000 laser remanufacturing equipment: KUKA60-3 robot, YC52 coaxial powder feeding processing head, Laserline semiconductor 4000W laser, MCWL-120DT2 water cooler and RC-PGF-D-2 double barrel powder feeder. The main process parameters of laser cladding are:

[0067] The first layer (bottom layer): laser power 2.1kW, spot size 5mm, scanning speed 1200mm / min, argon as shielding gas, flow rate 40ml / min, the bottom of the processing head is 40mm from the surface of the workpiece; workpiece rotation, cladding processing head straight line The feeding and cladding tracks adopt two helical lines interlaced. The first helical line starts from one end of the pinch roller, and the distance between channels is 1 / 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com