Patents

Literature

200results about How to "Address uneven distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Biomass-based porous carbon material, preparation method thereof, and application thereof in supercapacitor

InactiveCN106587055AWide variety of sourcesLow priceCarbon compoundsHybrid capacitor electrodesPorous carbonBiological activation

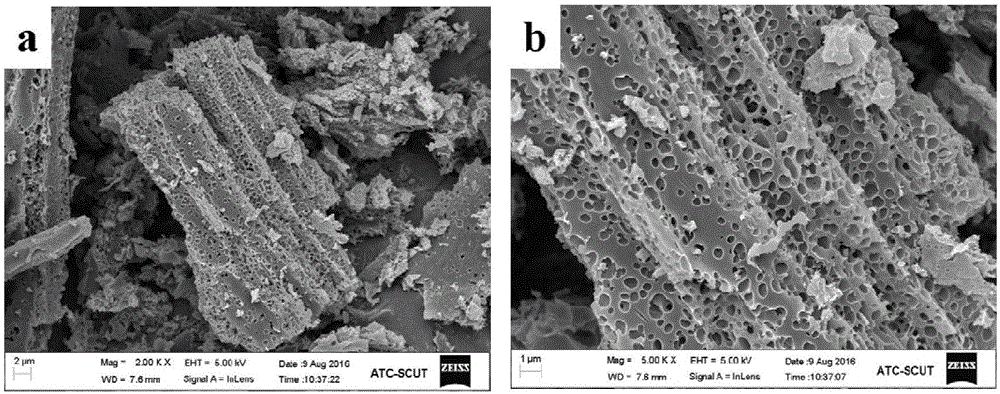

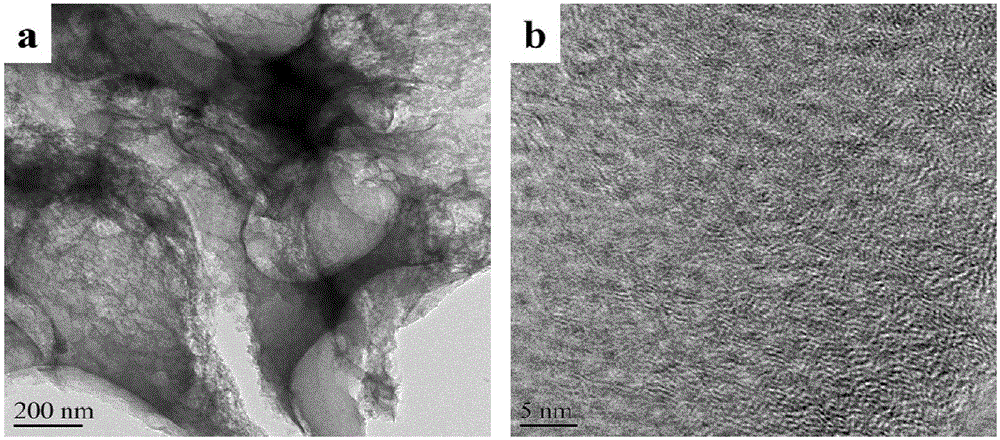

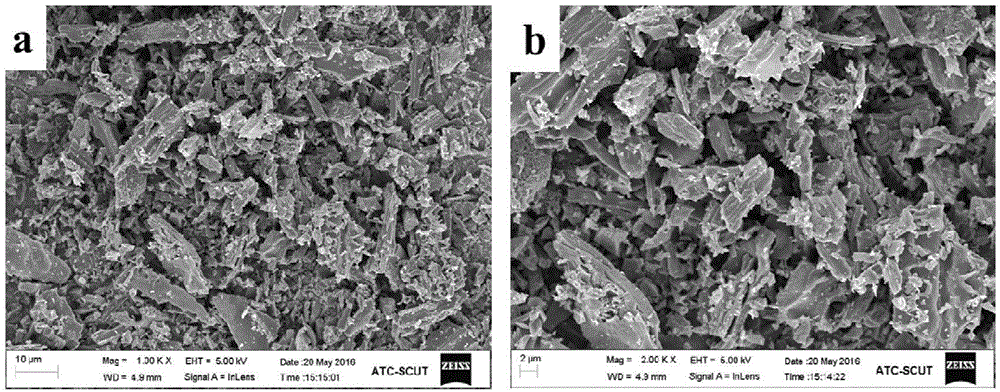

The invention belongs to the field of material science and energy storage and discloses a biomass-based porous carbon material, a preparation method thereof, and an application thereof in a supercapacitor. The method includes the steps of: 1) drying and crushing rice straws; 2) non-carbonizing or pre-carbonizing the crushed rice straws, uniformly mixing the rice straws with an activator water solution and drying the mixture, or non-carbonizing or pre-carbonizing the crushed rice straws and directly mixing the rice straws with a solid activator uniformly to produce a mixed product; and 3) placing the mixed product in a tube furnace to perform carbonizing activation in an inert gas atmosphere at high temperature; 4) washing the carbonized product in an acid solution and an alkali solution, and washing the carbonized product with deionized water to neutral, and drying the washed product to prepare the biomass-based porous carbon material. The porous carbon material has excellent supercapacitor performance and is simple in preparation method.

Owner:SOUTH CHINA UNIV OF TECH

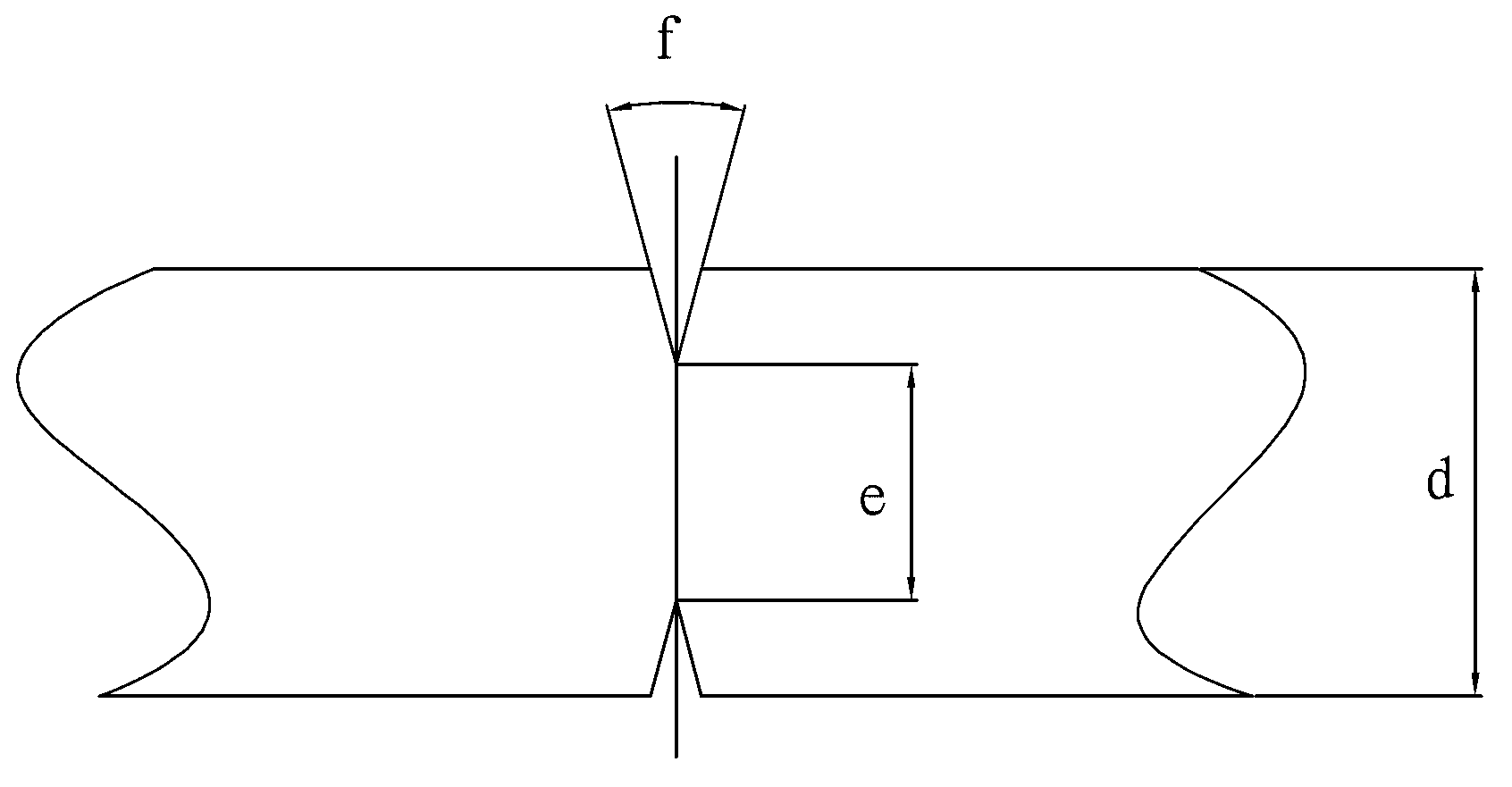

Laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel

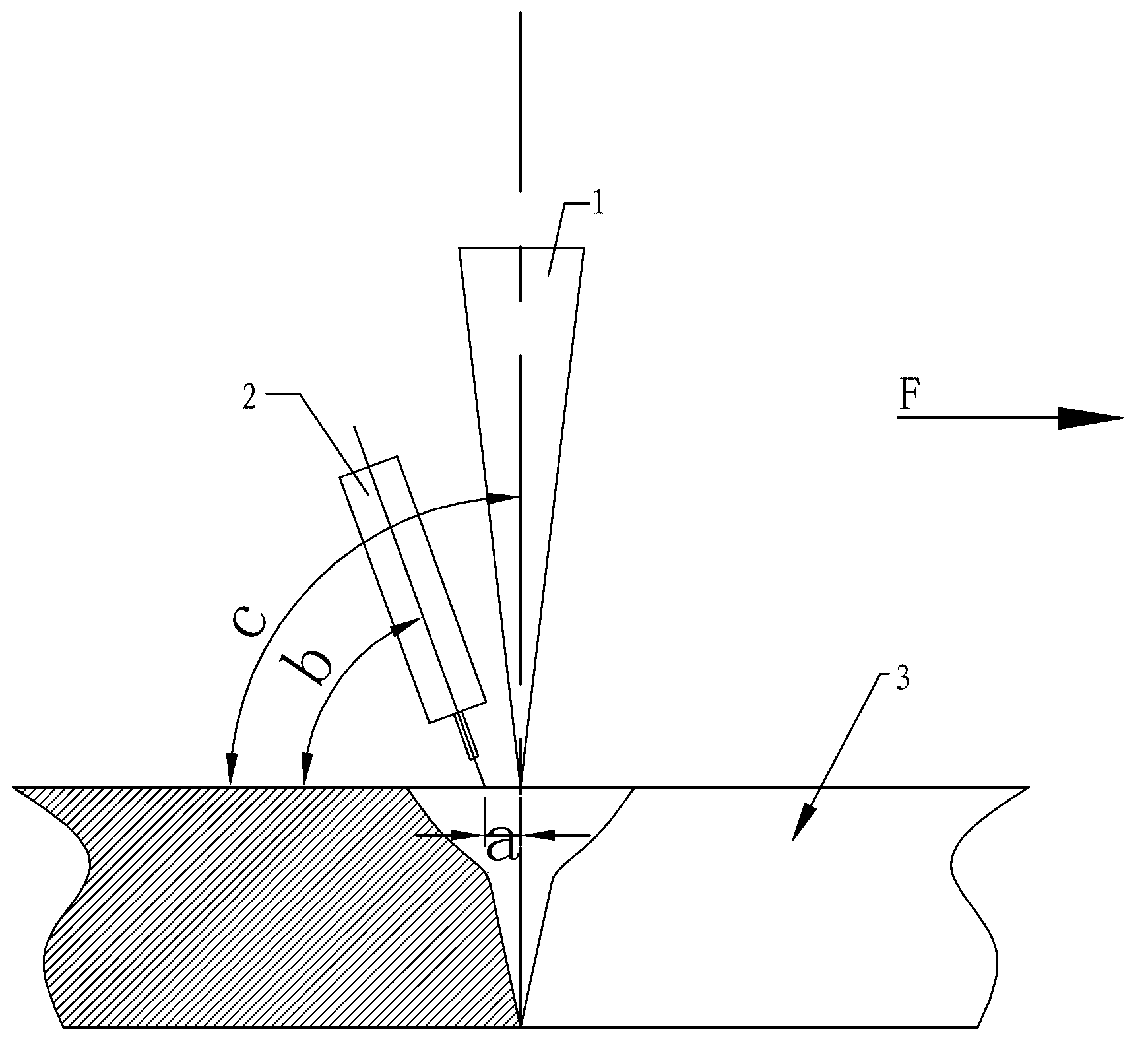

The invention discloses a laser and MIG (metal-inert gas) arc composited welding method for high-nitrogen steel. The laser and MIG arc composited welding method is characterized by comprising the following steps of: design of a welding joint; design of a welding mode; setting of a composite way and heat source spaces; selection of protective gas for the composite welding; setting of welding technology parameters according to the composite way; and synchronous implementation of the composite welding. Compared with the prior art, the laser and MIG arc composited welding method has the advantages of being capable of implementing the welding of the high-nitrogen steel with middle thickness and achieving weld joints which have clean and smooth surfaces and are good in forming and free from sunken parts; and meanwhile, the welding method has the characteristics of low loss and uniform distribution of nitrogen elements at connectors, high welding penetration, high welding speed, small deformation of workpieces, low assembly requirements and the like.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

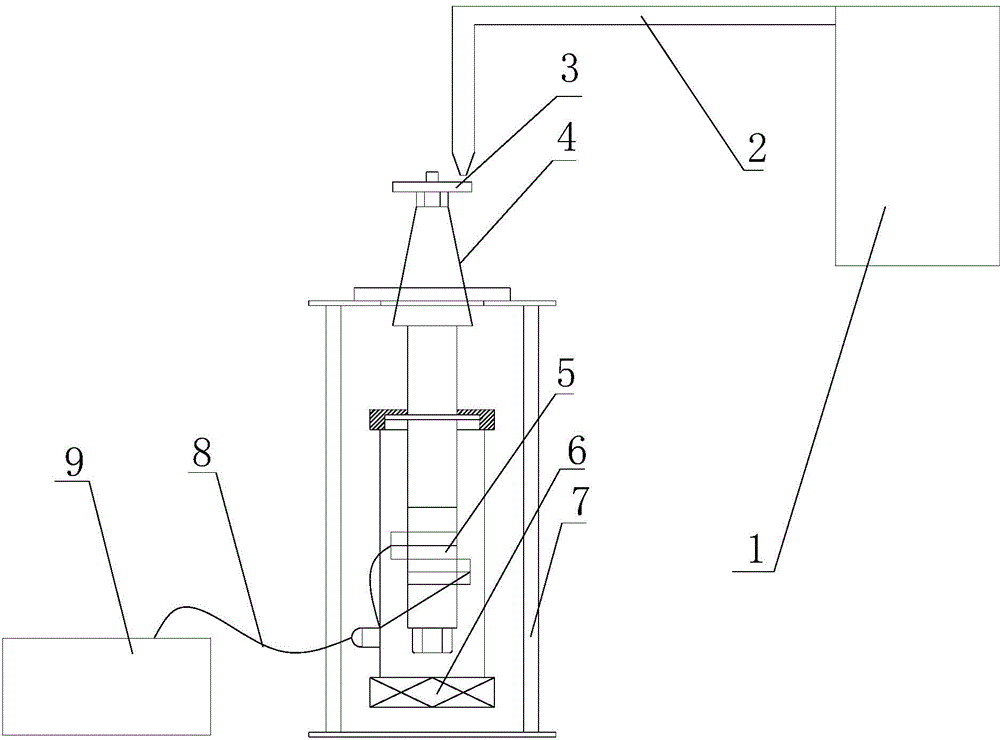

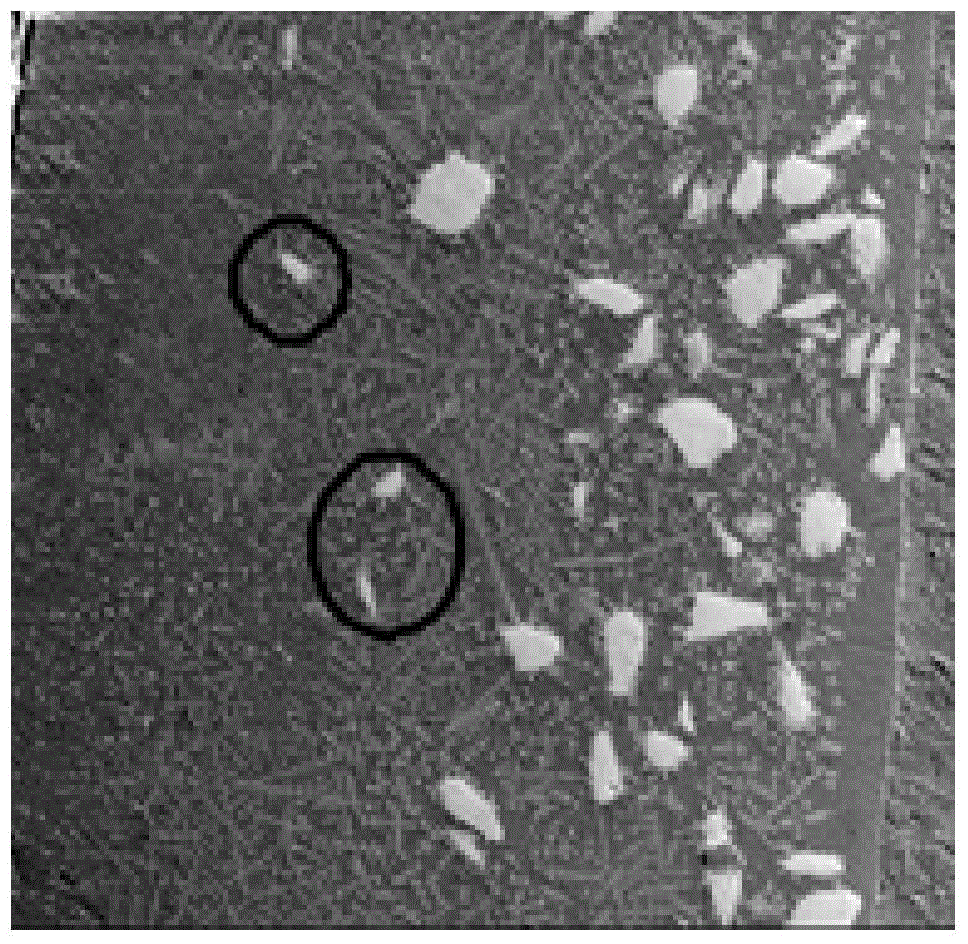

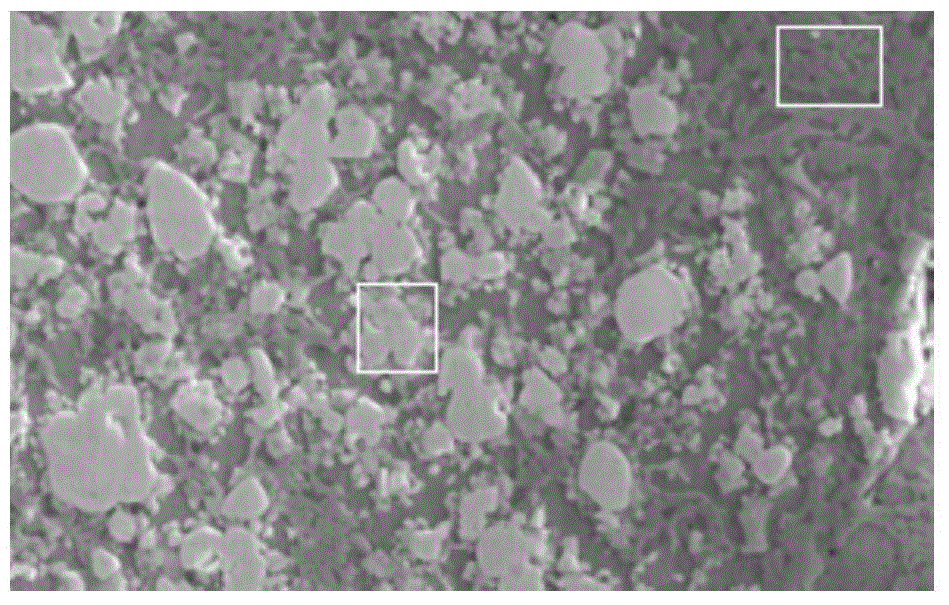

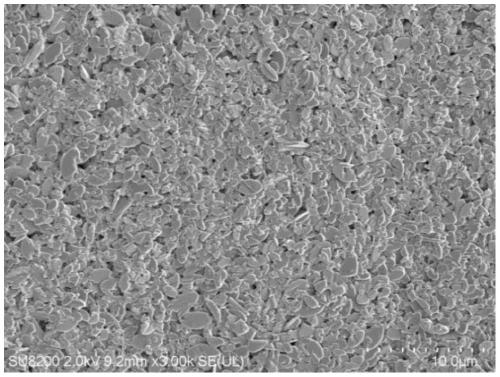

Method for preparing ultra-high hardness cladding layer through synchronous ultrasonic vibration assisting laser technology

InactiveCN104451673AIncreased microhardnessImprove wear resistanceMetallic material coating processesCeramic coatingLiquid metal

The invention provides a method for preparing an ultra-high hardness cladding layer through the synchronous ultrasonic vibration assisting laser technology. According to the specific scheme, the method includes the steps that ultrasonic vibration is synchronously introduced in the Ni-based metal ceramic coating cladding process, mobility of liquid metal can be improved in the mode, tissue distribution is more uniform, in the solidification process, a growing dendrite net can be broken and made to be dispersed to all portions of melt, small crystal nucleuses which are uniformly distributed are formed, segregation of metal ceramic is avoided, and therefore it is guaranteed that the cladding layer is not prone to cracking when ultra-high hardness is acquired; equipment is simple, calibration and installation are facilitated, energy consumption is low, the working environment is good, and acquired coating metal ceramic particles are uniform in distribution, high in hardness and good in abrasion resistance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Indoor fingerprint map constructing method based on crowdsourcing fingerprint

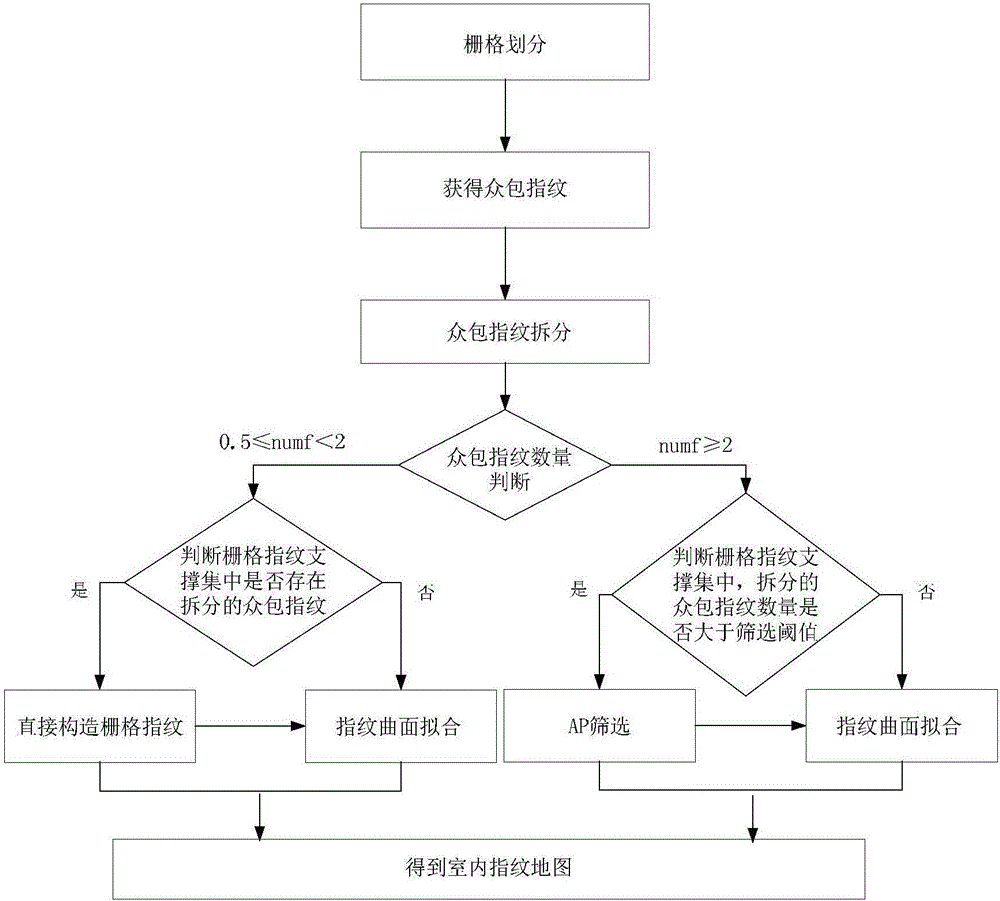

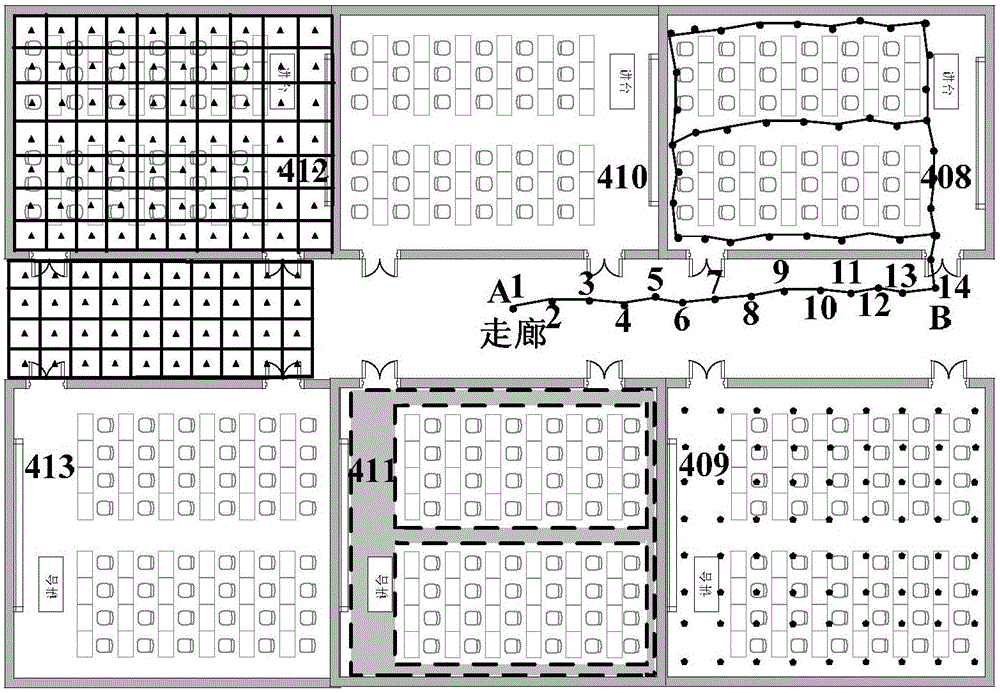

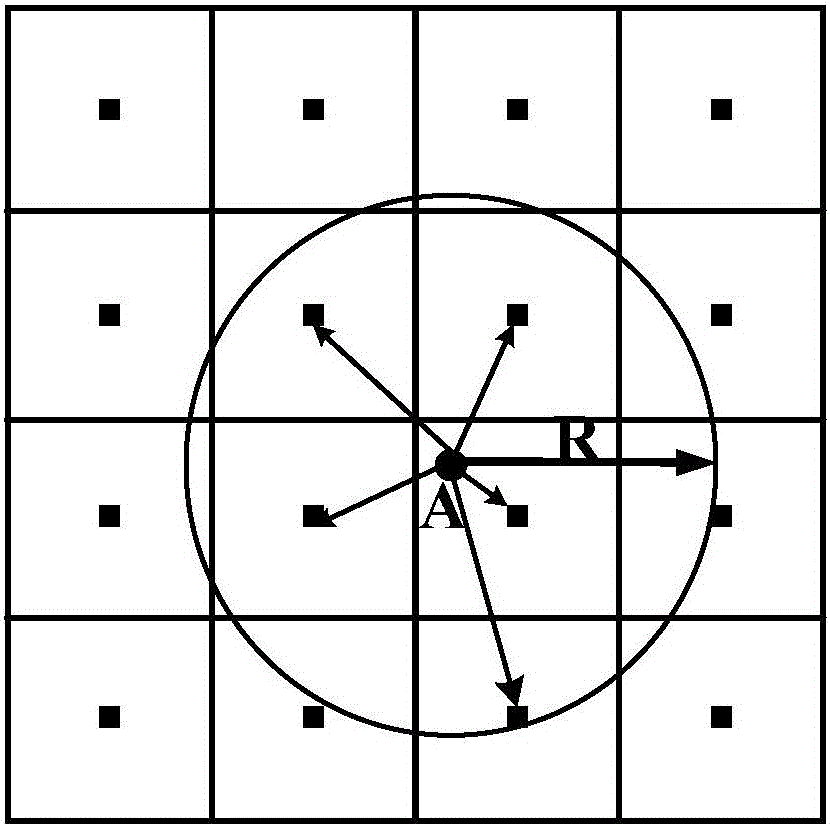

ActiveCN106792465AReduce collection workloadIncrease the number of fingerprintsWireless commuication servicesLocation information based serviceWorkloadData mining

The invention discloses an indoor fingerprint map constructing method based on crowdsourcing fingerprint, and belongs to the indoor positioning technology based on the fingerprint. The method is capable of solving the existent problems of constructing the indoor fingerprint map based on the crowdsourcing fingerprint that the positioning accuracy is not high and the calculated amount is larger because the crowdsourcing fingerprint position marking is not accurate, the dimensions are different and the distribution is not uniform, and is used for the technical field of the communication and wireless network. The method comprises a step of grid division, a step of crowdsourcing fingerprint acquisition, a step of crowdsourcing fingerprint resolution, a step of crowdsourcing fingerprint number judgment, a step of AP screening, a step of directly constructing grid fingerprint and a step of fingerprint surface fitting. The method is capable of reducing the workload of the fingerprint acquisition, improving the positioning accuracy, and reducing the workload of the fingerprint comparison.

Owner:HUAZHONG UNIV OF SCI & TECH

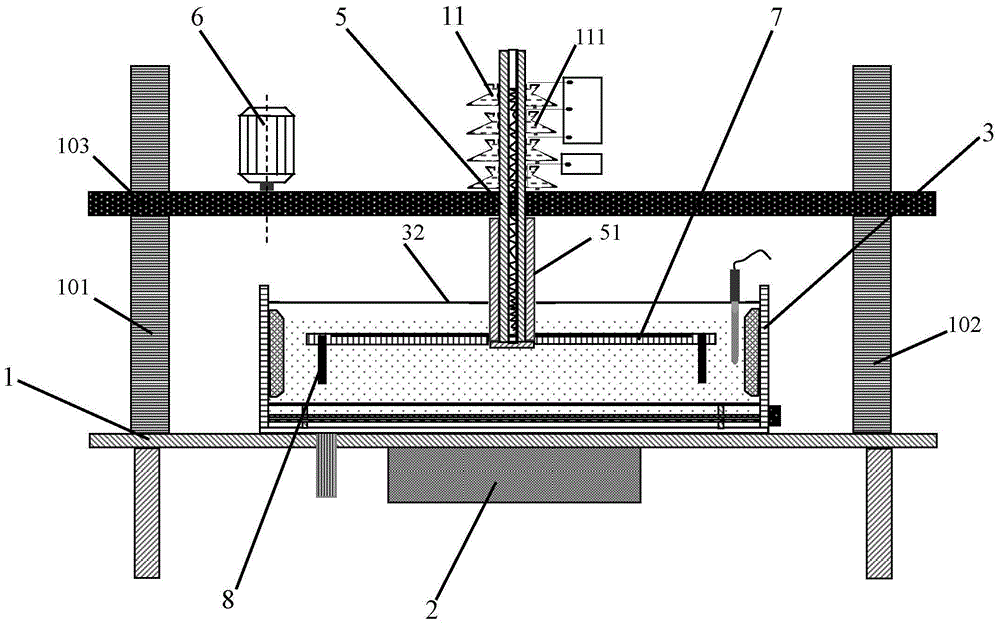

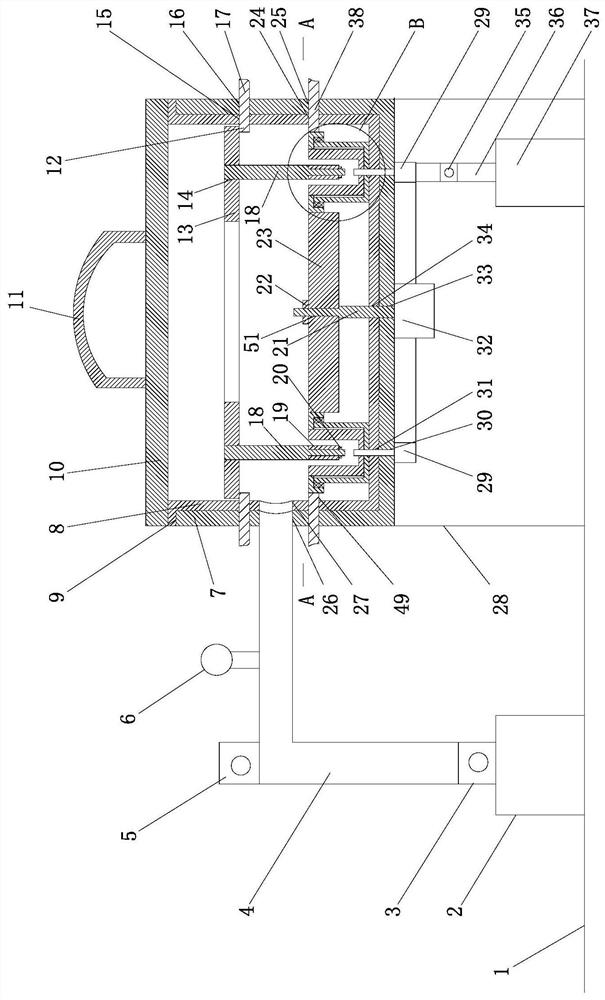

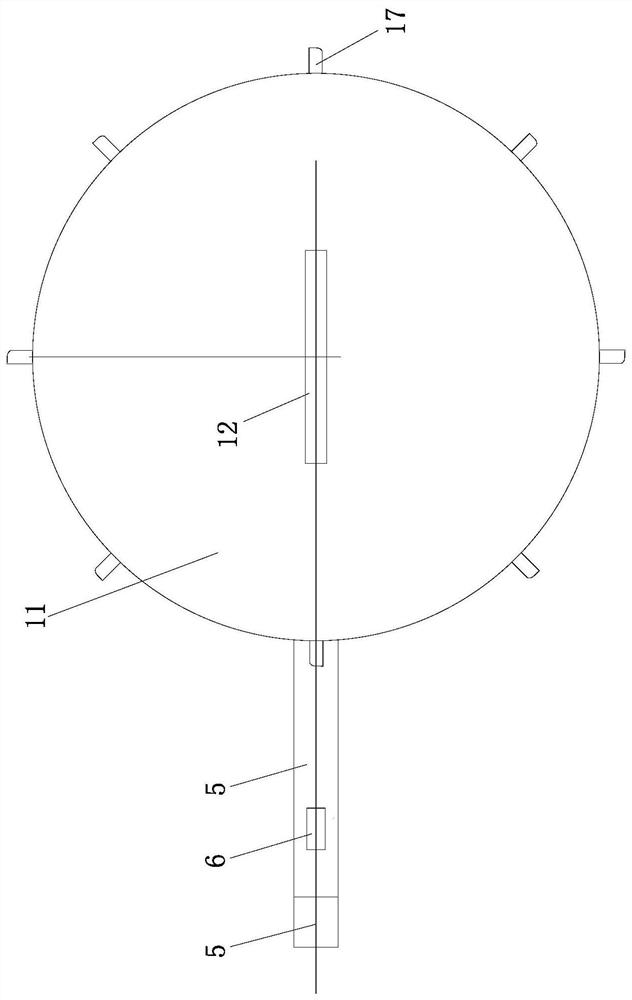

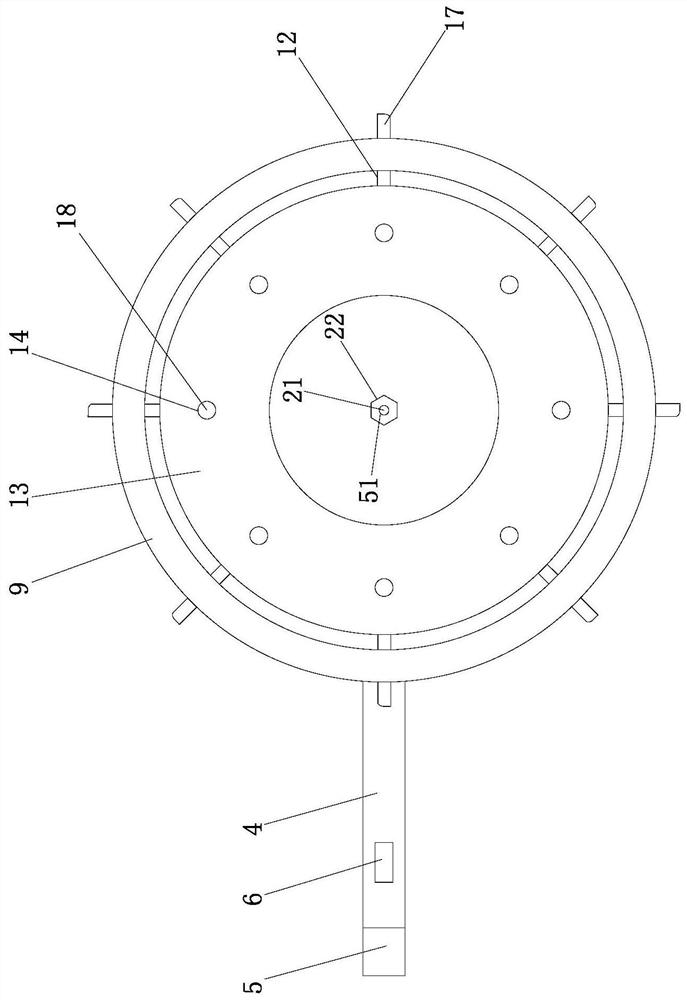

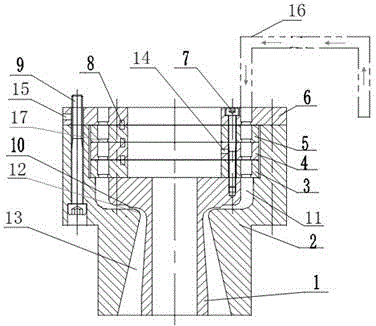

Double-column rotary corrosive-wear testing machine

ActiveCN105806772ASolve the precise test problem of relative speedAchieve deliveryWeather/light/corrosion resistanceInvestigating abrasion/wear resistanceTemperature controlPlatinum

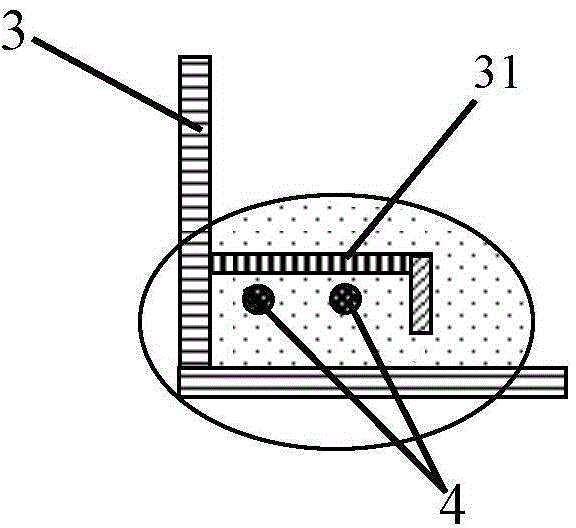

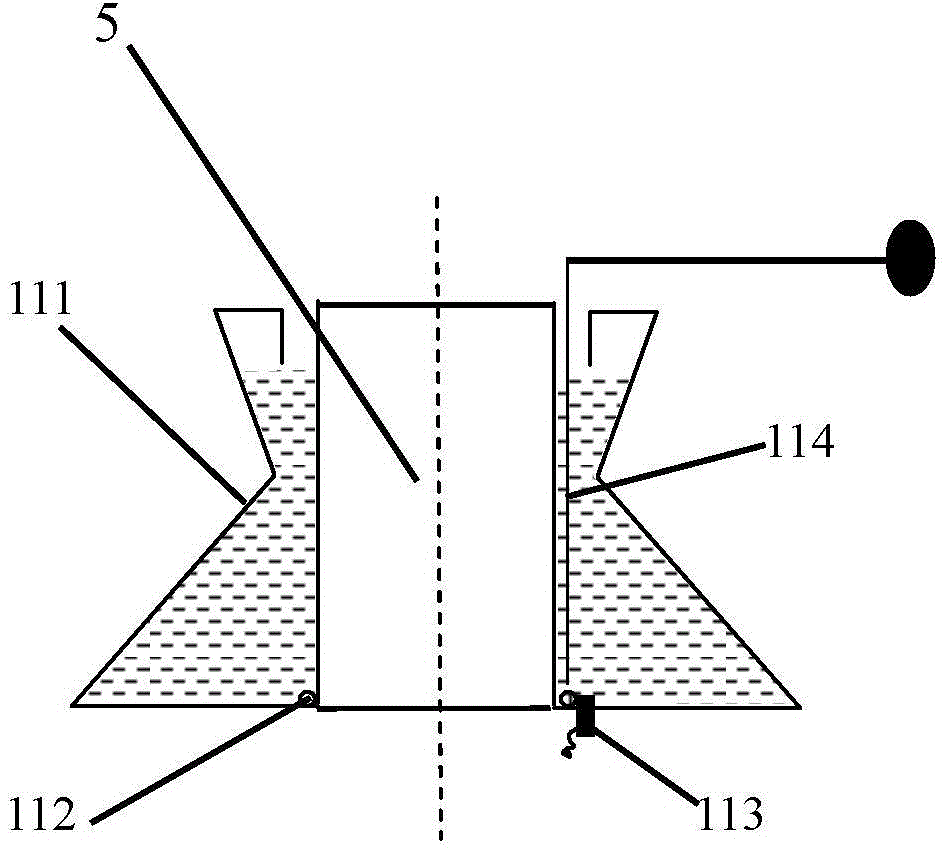

The invention provides a double-column rotary corrosive-wear testing machine, comprising a testing stand, which is provided with two columns, wherein a crossbeam is arranged on the columns and a through hole is formed in the center of the crossbeam; a crossbeam elevating and driving mechanism, which is arranged on the test stand and connected with the crossbeam; a testing drum, which is arranged on the center of the test stand, wherein an annular temperature control / cooling pipeline is arranged in the lower part of the testing drum; a transmission shaft, which passes through and is arranged in the through hole in the crossbeam; a sample clamping disc, which is fixed at the lower end of the transmission shaft, wherein the upper end surface of the sample clamping disc is provided with an annular groove, and the outer sides of the annular groove are provided with installation through holes; working electrodes, i.e., to-be-tested samples, which are inserted into the installation through holes; an auxiliary electrode, i.e., an annular platinum wire, which is arranged in the annular groove of the sample clamping disc; reference electrodes, which are uniformly distributed on the sample clamping disc at positions corresponding to the working electrodes; and a dynamic connection pool, which comprises annular dovetail cups, wherein the annular dovetail cups sleeve the upper part of the transmission shaft, leading-out circular rings are arranged at the bottom of the inner sides of the annular dovetail cups, the outer sides of the leading-out circular rings are provided with wiring copper columns penetrating the bottoms of the cups, the interior of each annular dovetail cup is provided with an electric needle, the lower ends of the electric needles are certain distance away from the leading-out circular rings, and the working electrodes, the auxiliary electrode and the reference electrodes are connected with the dynamic connection pool through leads.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation of polyaniline / argentum nano composite material

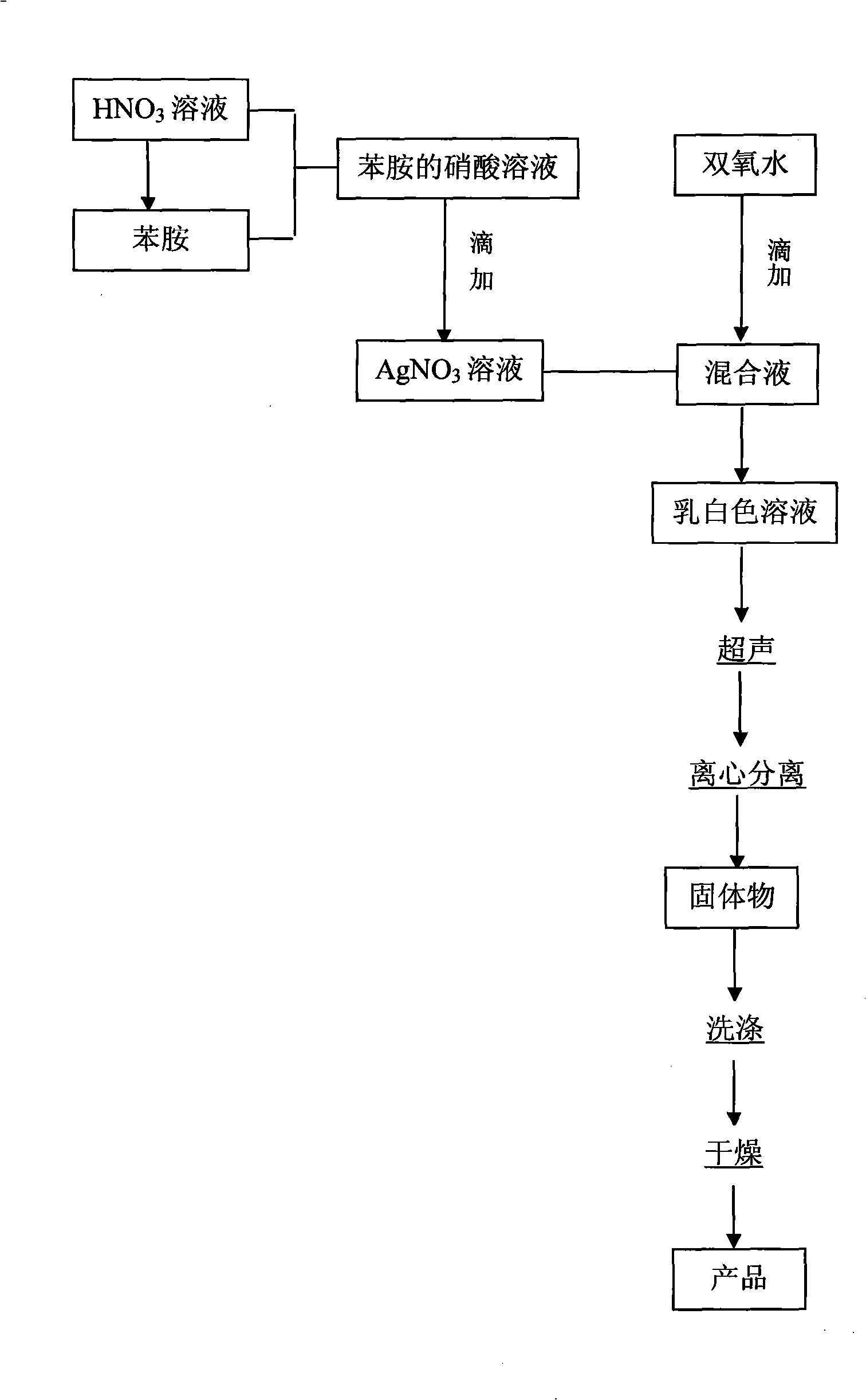

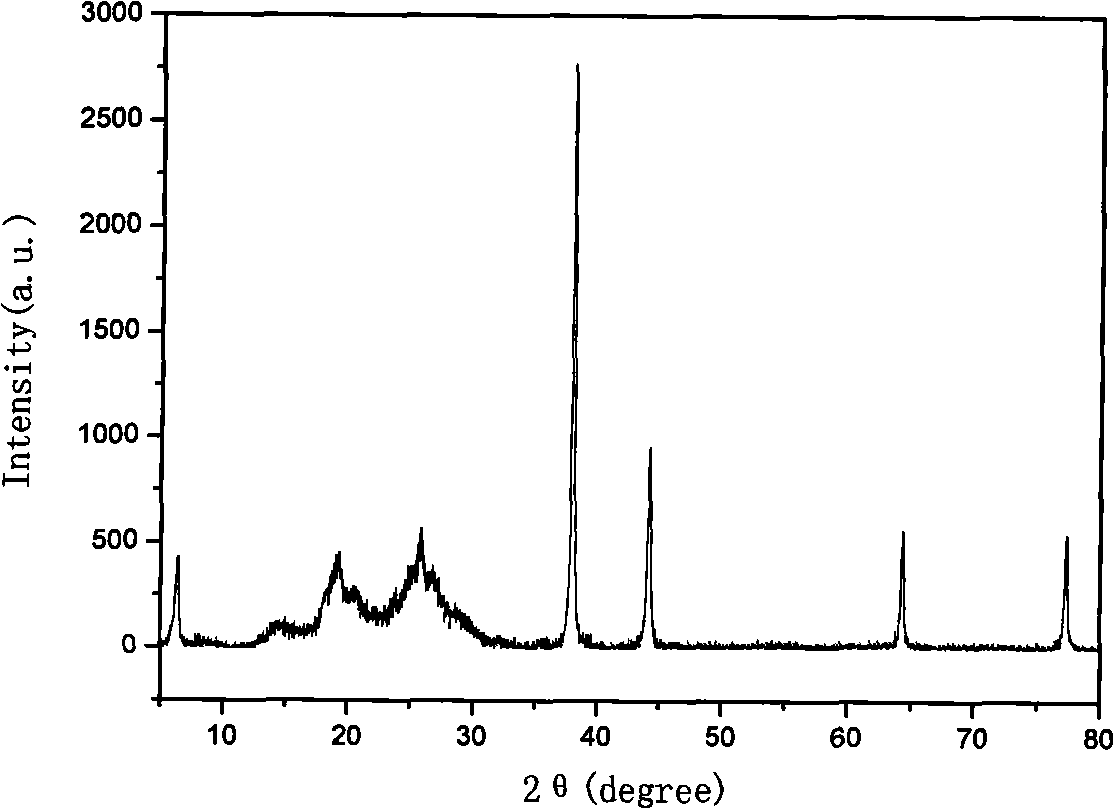

The invention relates to a preparation method of a polyaniline / Ag nanometer composite material, in particular to the method of adopting hydrogen peroxide as the oxidant to induce aniline to polymerize and as the reducing agent to reduce silver nitrate, and utilizing the sonochemical method to prepare polyaniline / Ag nanometer composite material. Nitric acid is added into aniline to make the nitric acid solution of aniline; while magnetic stirring, the nitric acid solution of aniline is dripped into the silver nitrate solution; while further magnetic stirring, the prepared hydrogen peroxide solution is dripped into the mixture; and then the mixture is put in an ultrasonic reactor after dripping is finished for ultrasonication, standing, and then conducting centrifugal separation, solid washing and drying to get green powder. The invention designs to use the double situ-compound method of adopting hydrogen peroxide as the oxidant to induce aniline to polymerize and as the reducing agent to reduce silver nitrate; as the reaction is very slow under magnetic stirring, therefore, the energy produced by ultrasonication is used for speeding up the reaction. The method has simple production process, convenient operation and less equipment investment, and better solves the agglomeration problem of silver nanometer particles; the silver nanometer particles in the obtained composite material can evenly distribute in the polyaniline matrix.

Owner:CENT SOUTH UNIV

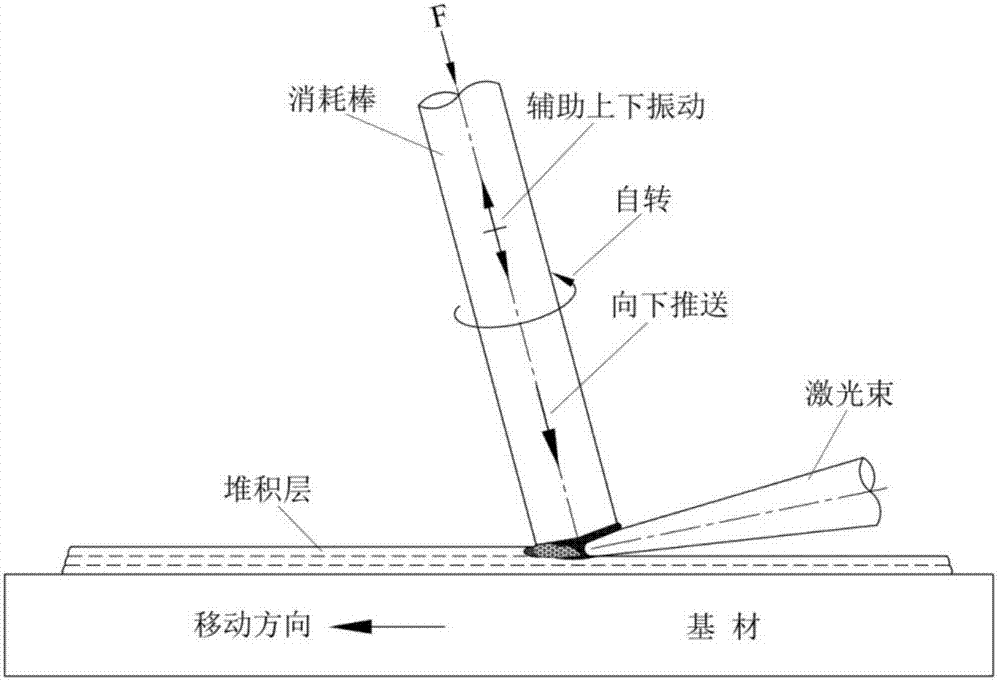

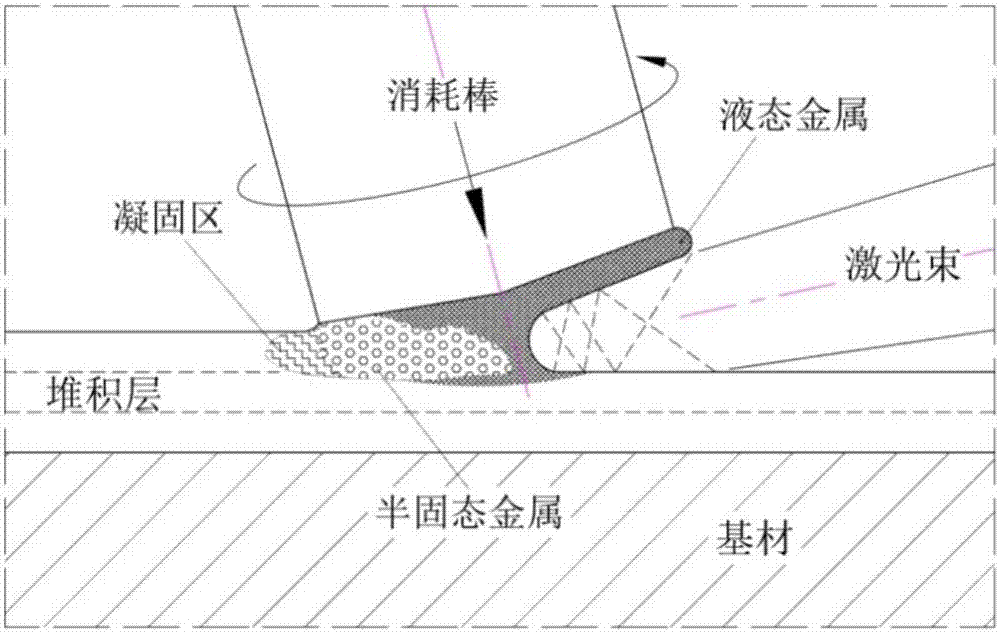

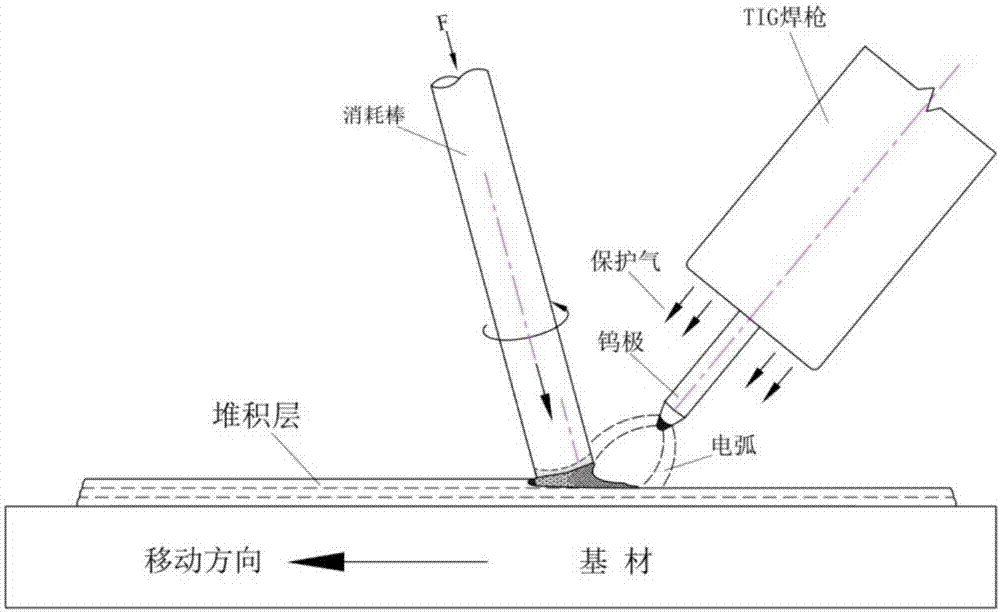

Micro-domain semi-solid state additive manufacturing method

ActiveCN107414325AReduce distortionReduced tendency to crackAdditive manufacturing apparatusArc welding apparatusMaterials preparationHigh energy

The invention provides a micro-domain semi-solid state additive manufacturing method. The problems about structure homogeneity, performance reliability, stress and deformation, air holes and cracks and the like of a molding piece are mainly solved. A stick-shaped material serves as a consumable item, and heating manners such as high energy beams, electric arcs and resistance heat are adopted for acting on the front end of the consumable item to enable the front end to be in a solid-liquid two-phase coexistence semi-solid state; and meanwhile, rotating twisting force and axial thrust are applied to the consumable item to conduct powerful effects such as shearing, stirring and extruding on semi-solid state metal, and in other words, mold-free semi-solid state flowing deformation molding is carried out. The consumable item is transited to bottom layer metal continuously in the manner to form metallurgical bonding, the stacking process is repeated according to a planned route obtained after discretization slicing treatment, and then a solid piece or a stacking layer in a special shape can be formed. The micro-domain semi-solid state additive manufacturing method is simple in operation process, the part performance is excellent, many defects in traditional additive manufacturing are overcome, and the prospects in the aspects of large structure shaping, damaged part repairing and composite material preparation are wide.

Owner:BEIJING UNIV OF TECH

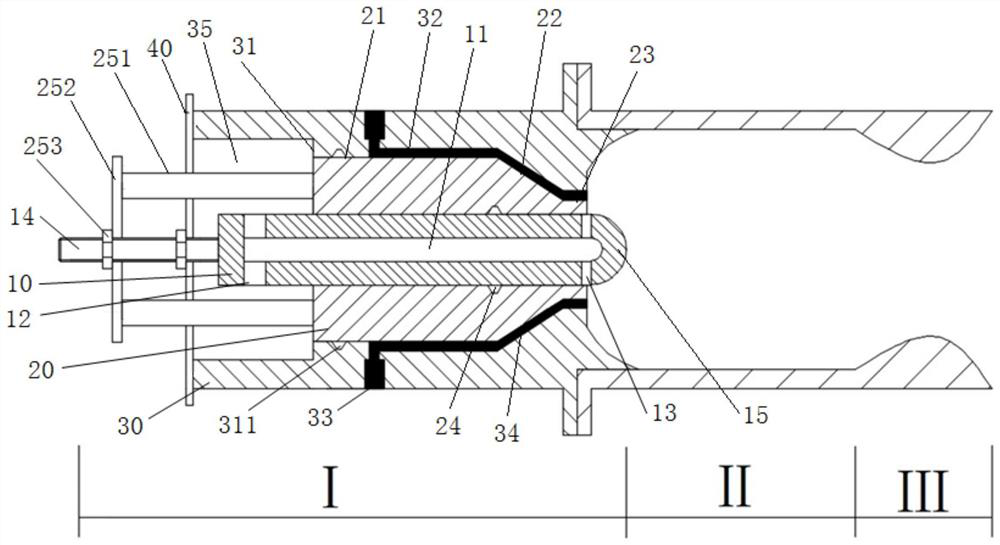

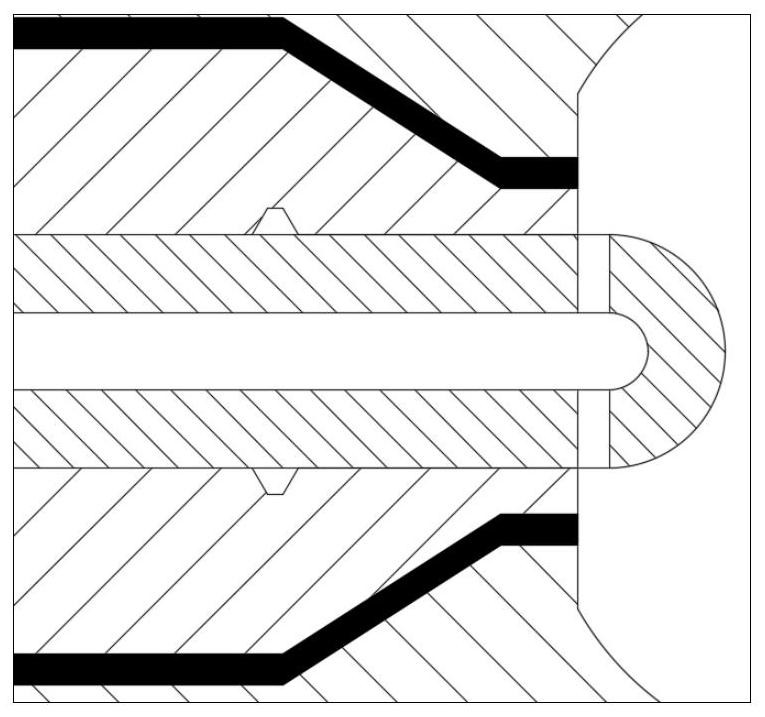

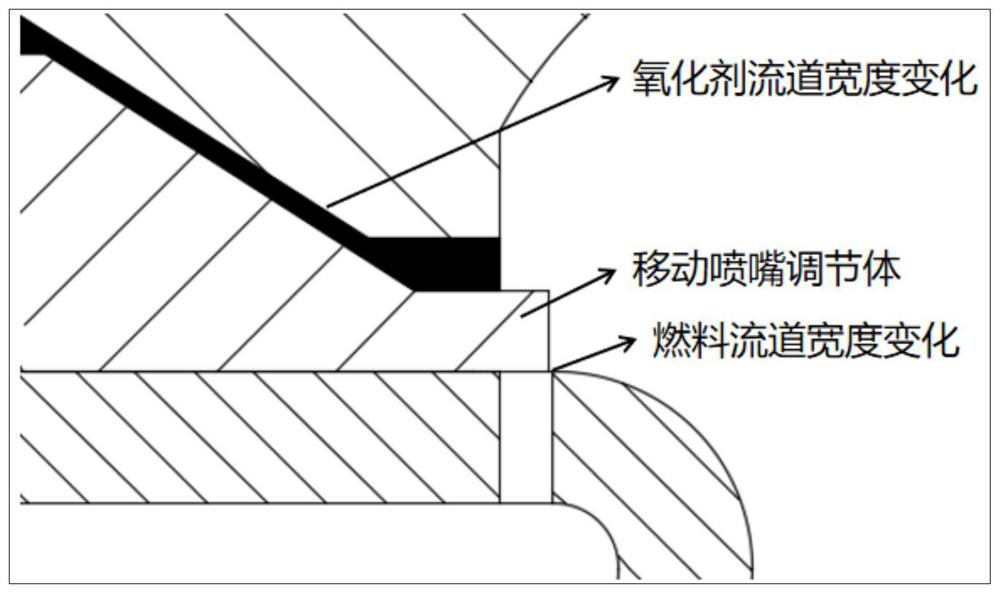

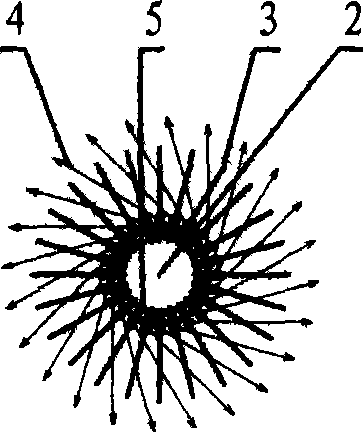

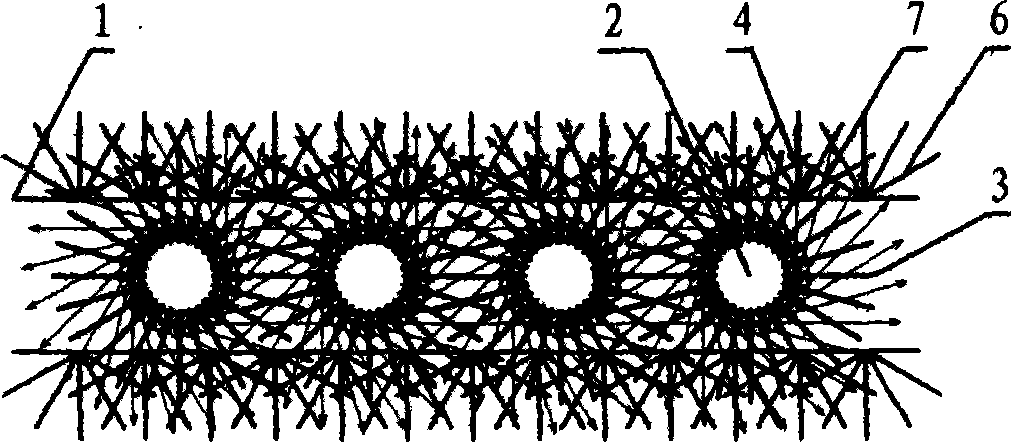

Two-component variable-thrust rotary detonation rocket engine based on pintle injector

ActiveCN113294264AStable mixing ratioReduce wasteRocket engine plantsCombustion chamberEquivalence ratio

The invention discloses a two-component variable-thrust rotary detonation rocket engine based on a pintle injector. The two-component variable-thrust rotary detonation rocket engine based on the pintle injector comprises the pintle injector, a rotary detonation combustion chamber and an exhaust nozzle which are sequentially and coaxially arranged in the axial direction; the pintle injector comprises a center rod inner nozzle, a nozzle adjusting body and an injector shell which are sequentially and coaxially arranged from inside to outside in a sleeving mode; a fuel injection runner is arranged in the center of the center rod inner nozzle, a plurality of fuel injection openings are formed in the head of the center rod inner nozzle in the circumferential direction, and a broken-line-shaped oxidizing agent runner is formed between the outer wall face of the inner side of the nozzle adjusting body and the inner wall face of the injector shell; and the nozzle adjusting body can slide in the axial direction, and therefore the injection area of the fuel injection openings and the sectional area of the oxidizing agent runner are adjusted. According to the two-component variable-thrust rotary detonation rocket engine based on the pintle injector, under the condition that the equivalence ratio is not changed, the flow of a two-component propellant can be changed, thrust can be generated and changed, a fuel flowing area can be stabilized and the combustion rate of fuel can be increased by effectively utilizing a backflow area at the head of a pintle, fuel waste is reduced, and the propellant is saved.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

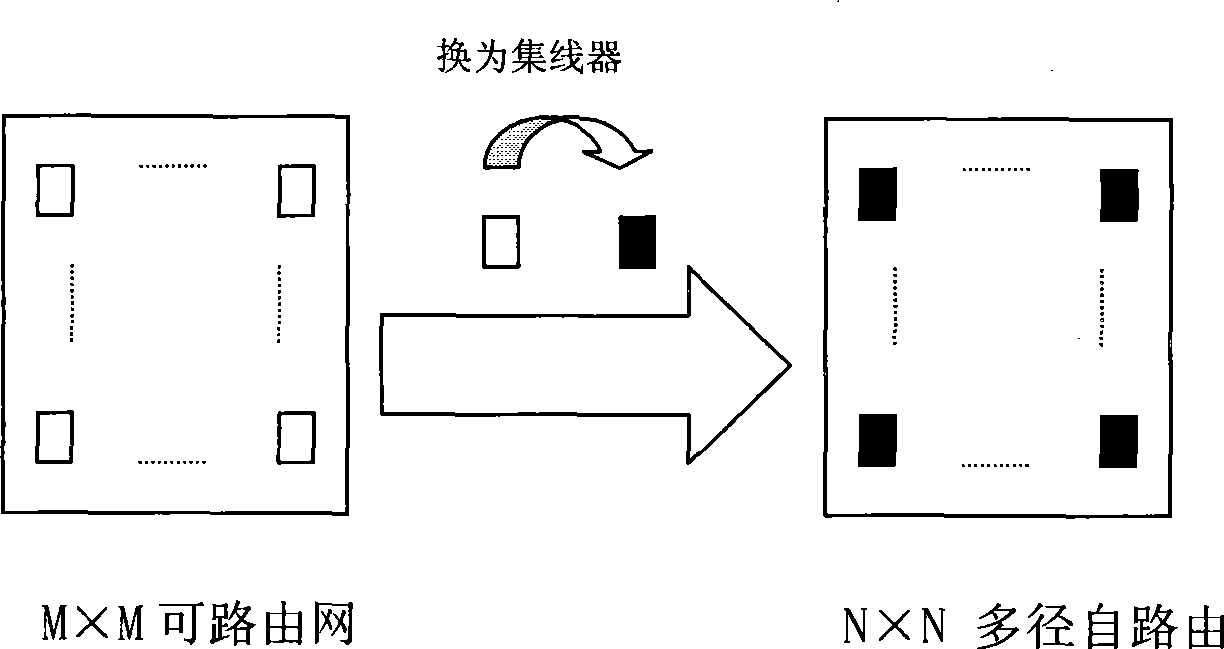

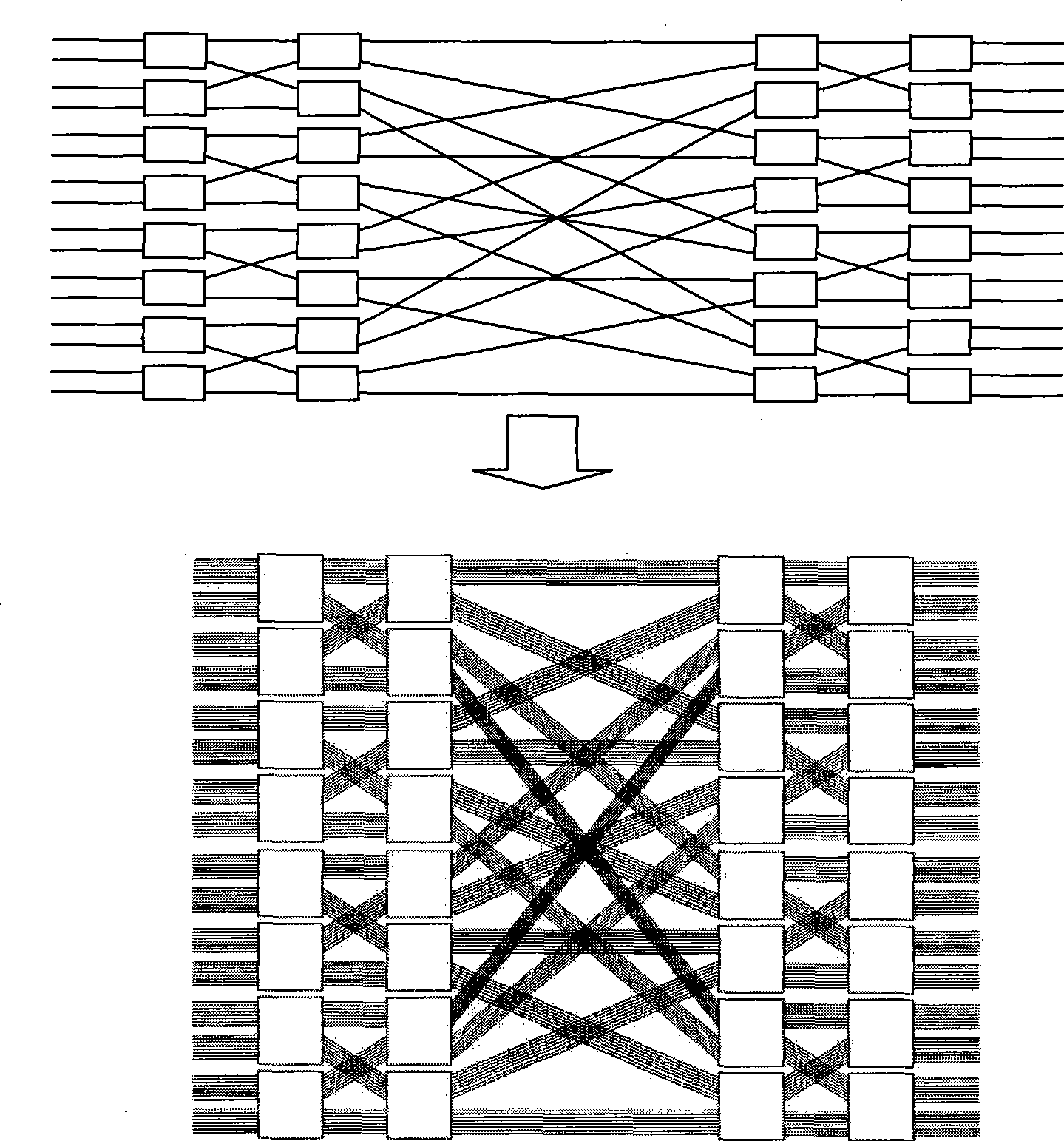

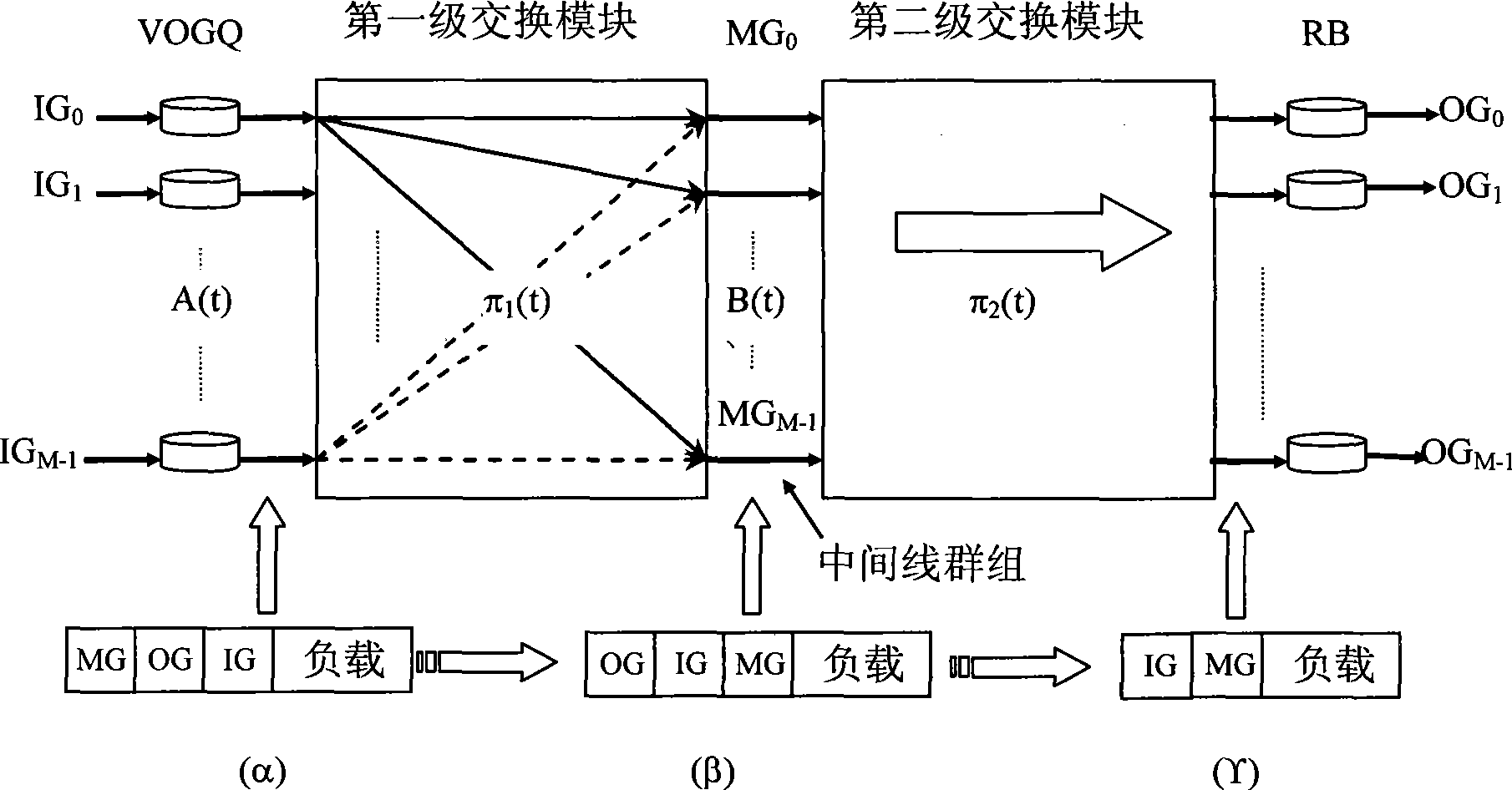

Load balance circuit type packet switching construction and constructing method

InactiveCN101388847AImprove throughputAddress uneven distributionData switching networksComputer architectureSelf routing

The invention provides a load balancing circuit type packet switching structure and construction method thereof. The method comprises: dividing the load balancing packet switching structure based on self-routing line concentrator into a first stage switching module and a second stage switching module; arranging a virtual output group queue on in front of the input end of the first stage switching module, arranging a reordering buffer memory after the output end of the second stage switching module; before sending the grouped data to the first stage switching, combining the it into data blocks in preset length, dividing it into data patches with same length, and adding self-routing labels; and after reaching the reordering buffer memory, recombining the data patches into data blocks. The method in the invention solves the problem of the uneven distribution of the data flow access-able by the circuit type switching structure, and improves the throughput of the circuit type switching structure.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL +2

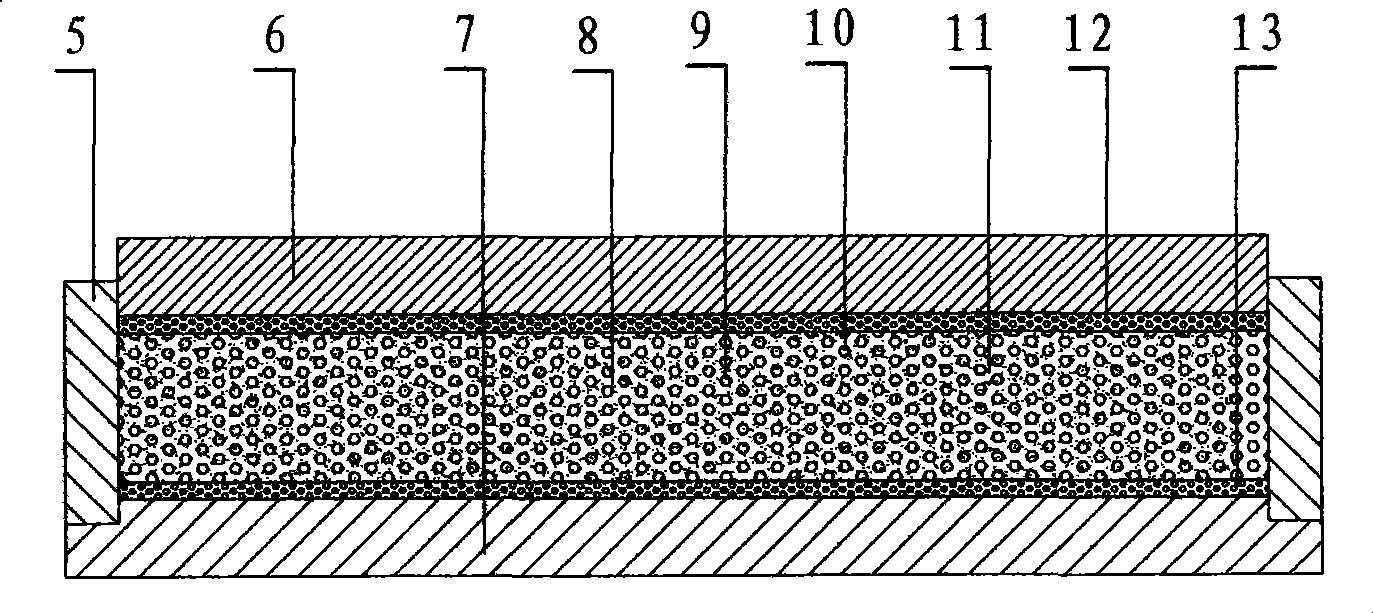

Preparation method and application method of electrocatalysis electrode

ActiveCN105776431ALarge specific surface areaExtended service lifeWater/sewage treatment with mechanical oscillationsWater/sewage treatment by electrochemical methodsHeat depositionTitanium

The invention provides a preparation method and an application method of an electrocatalysis electrode. The preparation method includes: taking titanium as a substrate, depositing Bi-SnO2-Sb2O3-CNT on the titanium substrate by means of heat deposition, and then depositing a PbO2 active surface layer on a Bi-SnO2-Sb2O3-CNT interlayer by the aid of electrodeposition to prepare a Ti / Bi-SnO2-Sb2O3-CNT / PbO2 electrocatalysis electrode. The electrocatalysis electrode is used for ultrasound electrocatalysis algae killing and microcystin degradation. The electrocatalysis electrode is taken as an anode, a stainless steel or copper sheet is taken as a cathode, microcystis aeruginosa solution added with electrolyte is subjected to electrolysis, and ultrasonic treatment is applied in the electrolytic process. The preparation method and the application method of the electrocatalysis electrode have the advantages that the electrode has more catalytic activity sites, and catalytic activity of the electrode is improved; electrical conductivity of the electrode can be improved, and energy consumption can be lowered; electrocatalytic activity is high, and service life is long; ultrasonic oxidation and electrocatalytic oxidation are combined, synergistic effect is generated, and efficiency of algae killing and microcystin degradation is highly increased.

Owner:HARBIN ENG UNIV

Mixed powder alloy with high melting point particles or fibers and low melting point particles as well as method for preparing same

The invention relates to a mixed powder alloy with high melting point particles or fibers and low melting point particles, which comprises the high melting point particles or fibers made up of one material or various materials, the low melting point particles made up of one material or various materials, an auxiliary agent and a cast die, wherein the high melting point particles or the fibers and the low melting point particles are mixed together evenly and then are pressurized, heated and melted into a liquid state low melting point material which is filled into gaps of adjacent high melting point particles or the fibers so as to form an alloy structure which is formed by enwrapping the high melting point particles or the fibers by a three-dimensional netlike framework of the low melting point material, or a new alloy material which is formed on an interface by the three-dimensional netlike framework of the low melting point material and an enwrapped high melting point material.

Owner:王广武

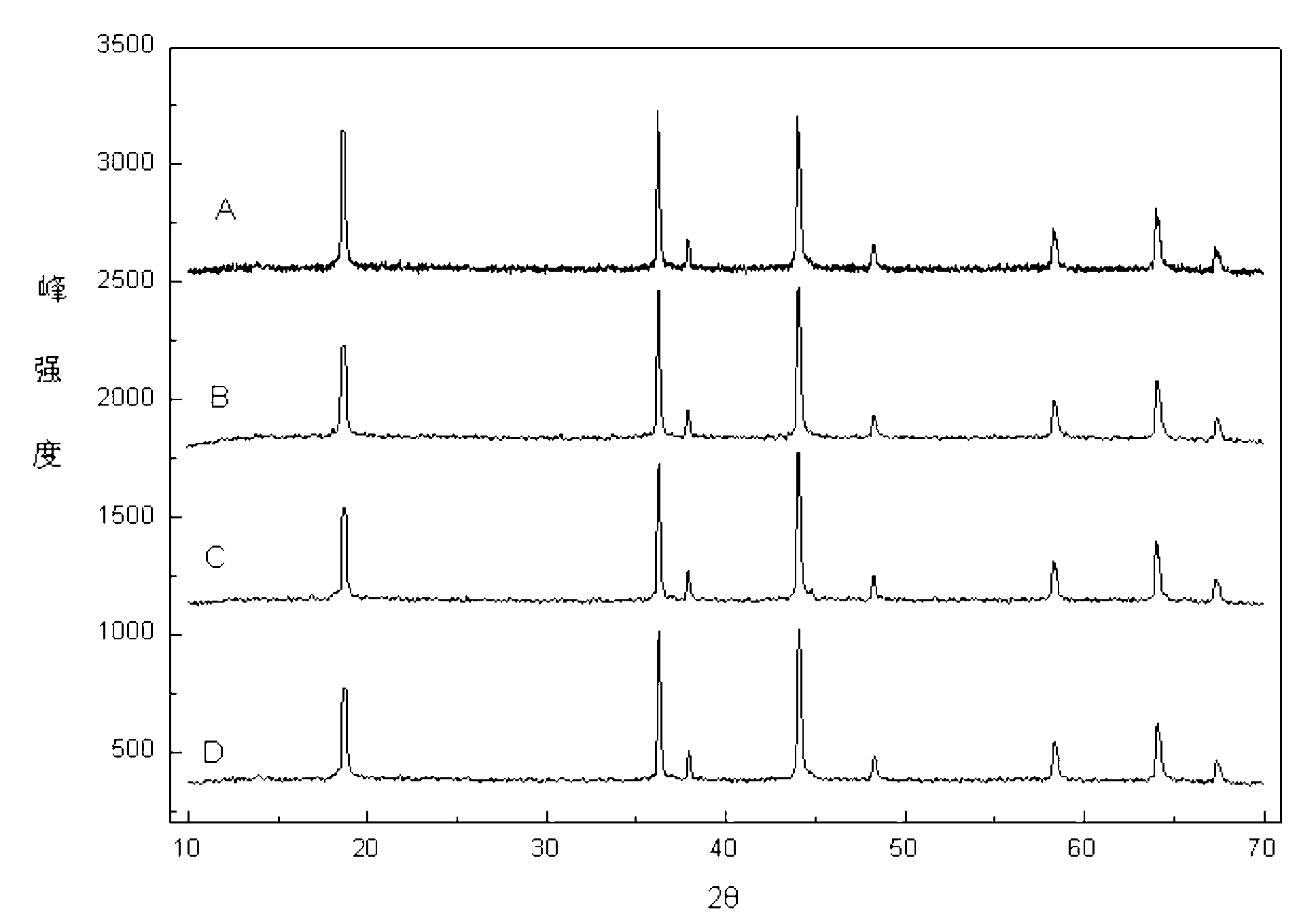

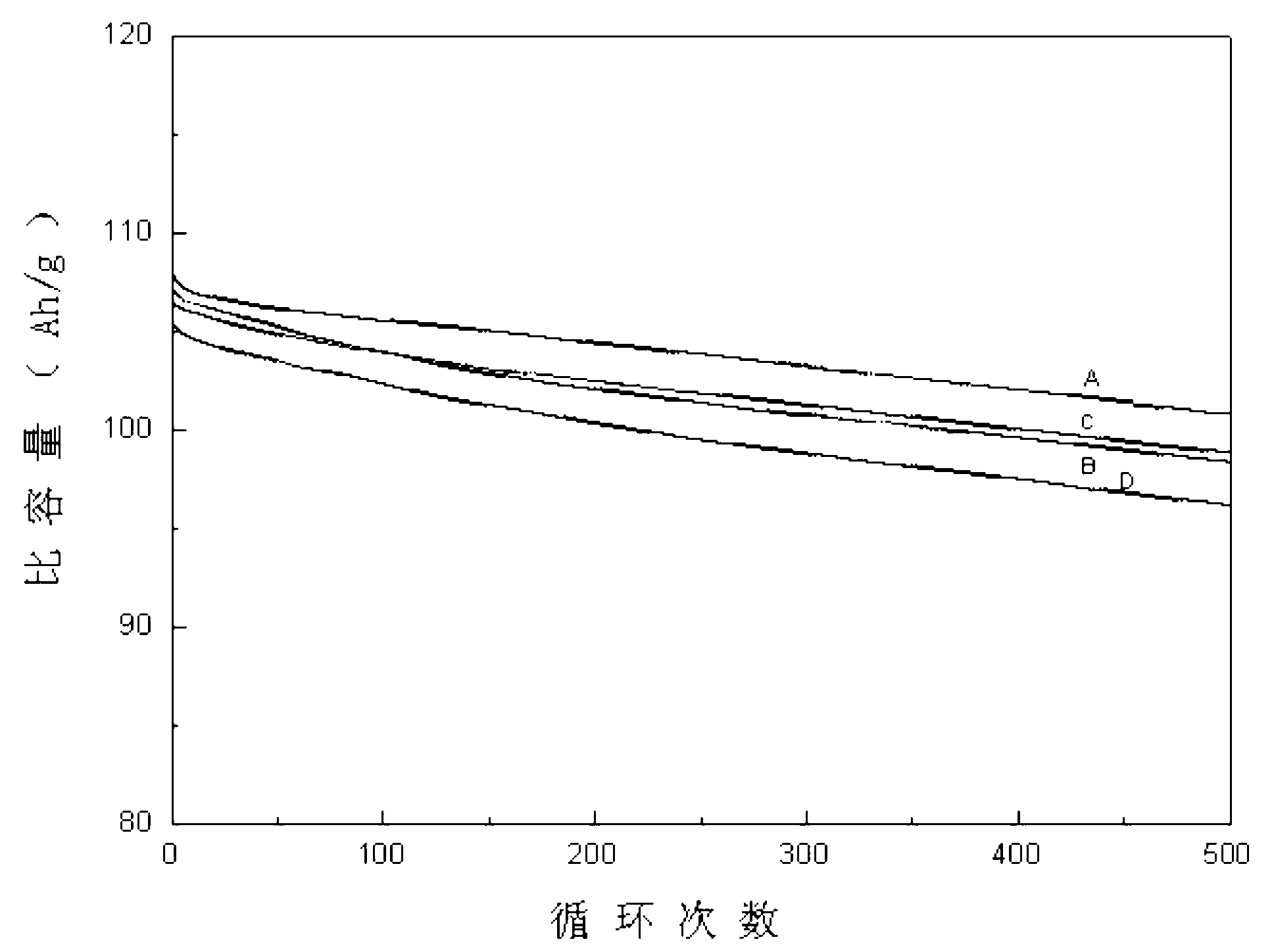

Method for preparing lithium manganate anode materials of lithium ion battery

ActiveCN103078106AAddress uneven distributionImprove cycle lifeCell electrodesPhysical chemistryManganate

The invention discloses a method for preparing lithium manganate anode materials of a lithium ion battery. The method comprises the following steps of: mixing and stirring lithium source compound and manganese source compound, placing the mixture into a rotary kiln and raising the temperature to 400-650 DEGC for pretreating, and keeping temperature for 1-8h and then cooling to normal temperature; and placing the product into a calcining furnace and raising the temperature to 750-1000 DEG C, calcining for 10-30h, then cooling the temperature to 550-650 DEG C at a speed of 1 DEG C / min-3 DEGC / min, cooling to the room temperature, and then crushing and screening the reaction product so as to obtain the lithium manganate anode materials of the lithium ion battery. The method is simple in technology and low in cost; and the battery assembled by the lithium manganate anode materials is excellent in cycling performance, high in specific capacity and wide in application prospect.

Owner:HUNAN XINDA NEW MATERIALS CO LTD

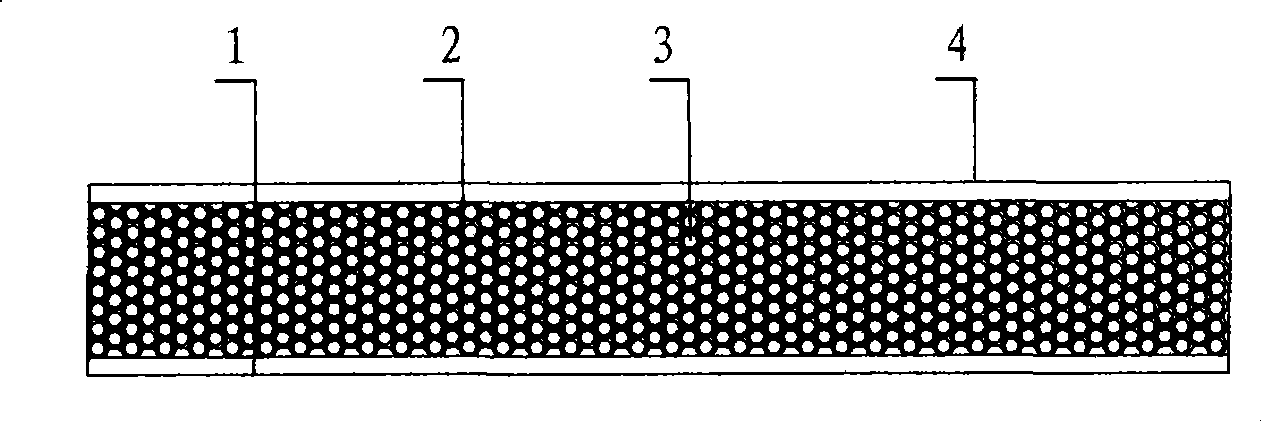

Diffusion scattering transmission safe glass and preparation method thereof

InactiveCN101519508AHigh transparencyImprove impact resistanceSynthetic resin layered productsMaterials scienceSafety glass

A diffusion scattering transmission safe glass comprises transparent organic resin, transparent SiO2 granules or transparent inorganic glass granules and additives. The ball-shaped transparent SiO2 granules or ball-shaped transparent inorganic glass granules or ball-shaped transparent organic resin granules are equally distributed inside the transparent organic resin glass.

Owner:王广武

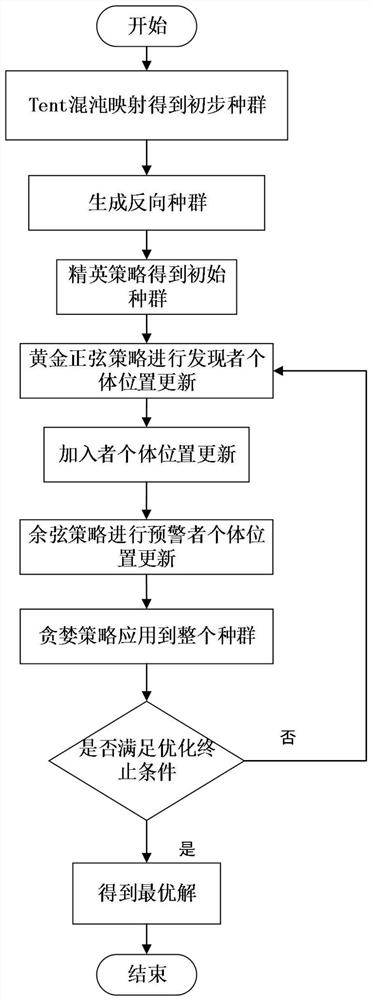

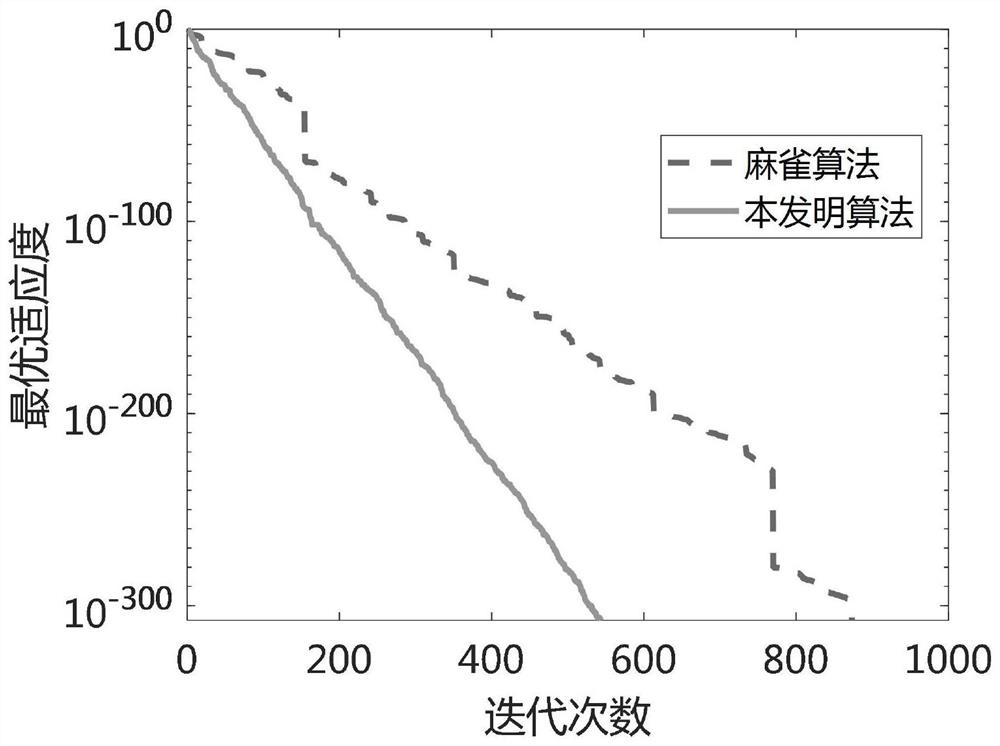

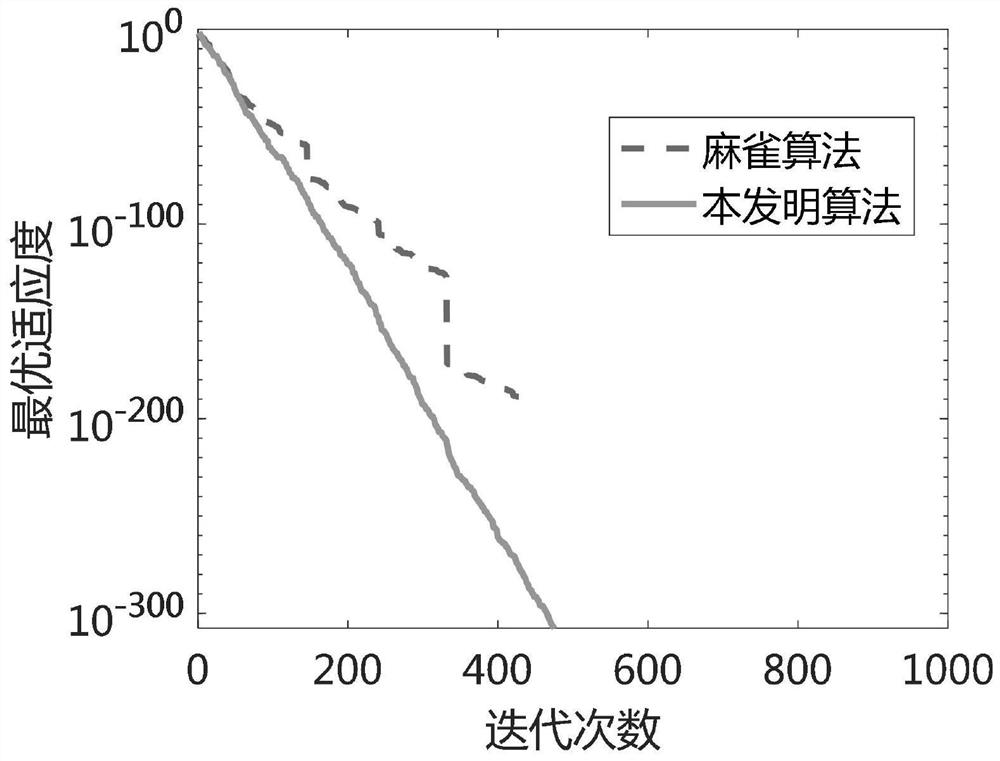

Improved sparrow intelligent optimization method based on chaotic mapping and golden sine strategy

ActiveCN112926139AAddress uneven distributionNarrow down the search spaceGeometric CADSustainable transportationLocal optimumFlight vehicle

The invention discloses an improved sparrow intelligent optimization method based on chaotic mapping and golden sine, and aims to solve the problem that the calculation amount is wasted due to the fact that an obtained solution cannot be converged to a globally optimal solution when a reentry trajectory optimization problem of a hypersonic aircraft is solved through the improved intelligent sparrow optimization method. According to the method, a Tent chaos sequence and a reverse elite population strategy are combined to generate an initialized population which is relatively uniform in a solution space; the positions of individuals are updated in a golden sine mode, and the searching step length is controlled through coefficients, so that the individuals are stably close to the optimal positions; the number of mutation individuals is reduced in the later period through a cosine strategy, and the calculation efficiency of later iteration updating is guaranteed; and by utilizing a greedy strategy, when the individuals are updated, the historical optimal positions of the individuals are kept, and the optimization process is accelerated. According to the improved sparrow optimization algorithm, the optimization efficiency is higher, a globally optimal solution can be well obtained, and the problem that local optimum is likely to happen is effectively solved.

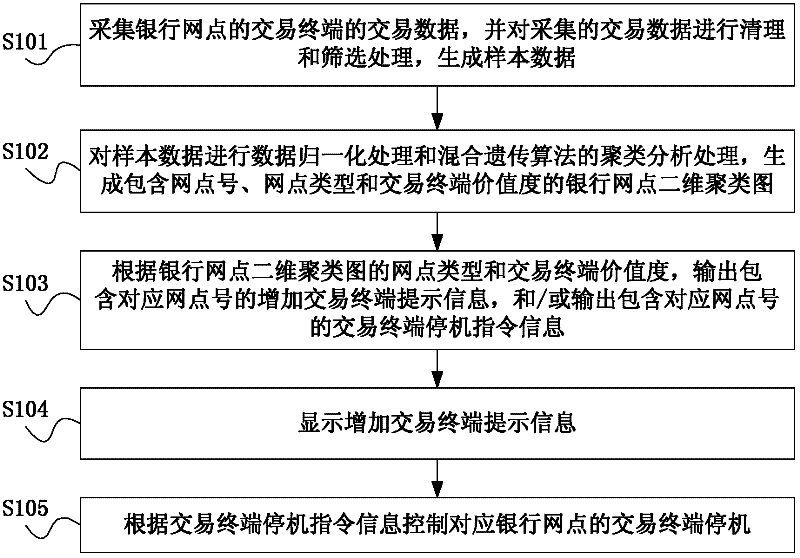

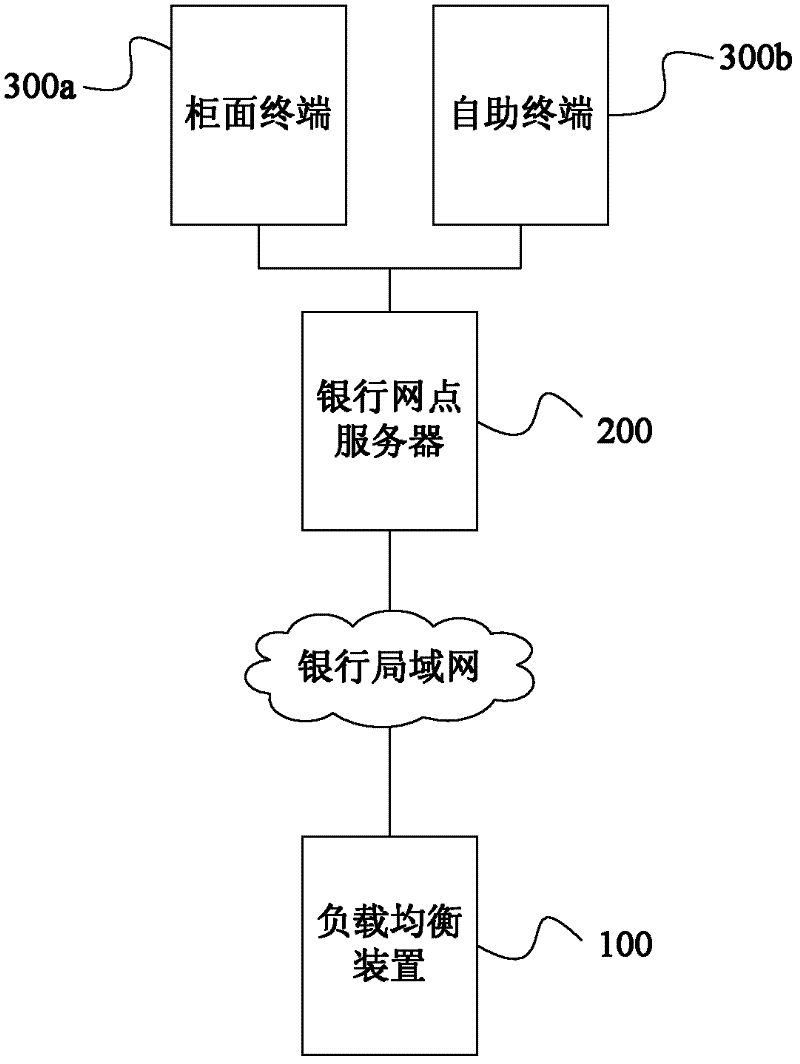

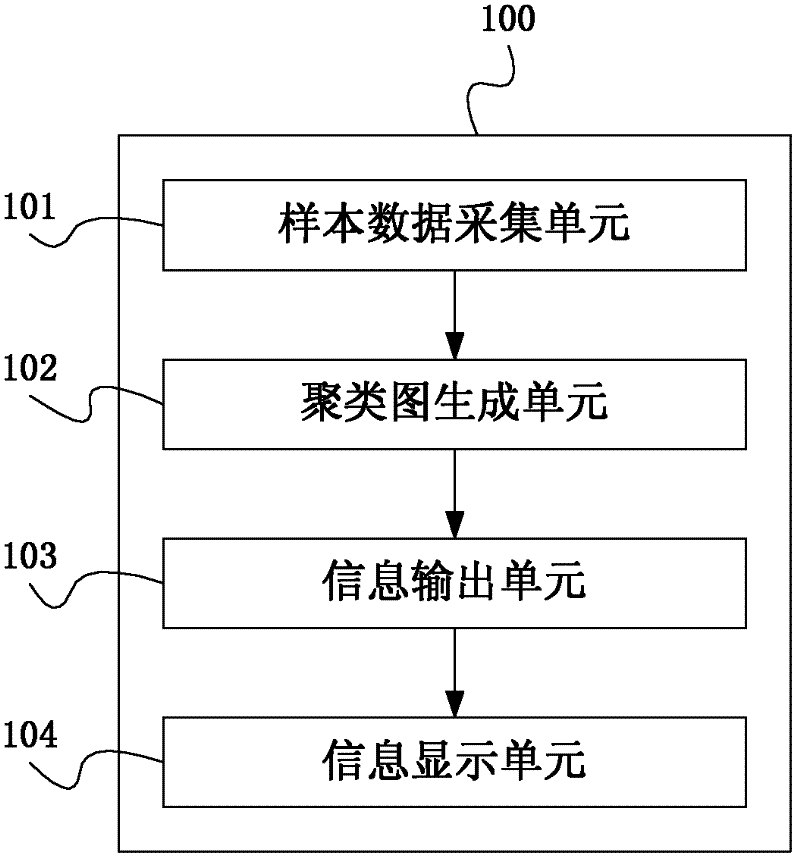

Load balancing method and system of bank terminal device

ActiveCN102521925AAddress uneven distributionSolve the waste of resourcesComplete banking machinesData switching networksGenerating unitData collecting

The invention discloses a load balancing method of a bank terminal device and a load balancing system of the bank terminal device. The system comprises a bank outlet server, a transaction terminal and a load balancing device, wherein the load balancing device comprises a sample data collecting unit for collecting transaction data of the transaction terminal through the bank outlet server and generating sample data, a cluster pattern generating unit for generating a bank outlet two-dimensional cluster pattern including website number, website type and transaction terminal value degree, an information output unit for outputting increased transaction terminal hint information including corresponding website number, and / or outputting transaction terminal shutdown instruction information including corresponding website number, and an information display unit for displaying increased transaction terminal hint information, wherein the bank outlet server receives the transaction terminal shutdown instruction information and controls transaction terminal to be shut down; the method and the system solve the problems of uneven distribution of bank outlet terminal devices and resource waste and improve the load handling capability of the bank system.

Owner:INDUSTRIAL AND COMMERCIAL BANK OF CHINA

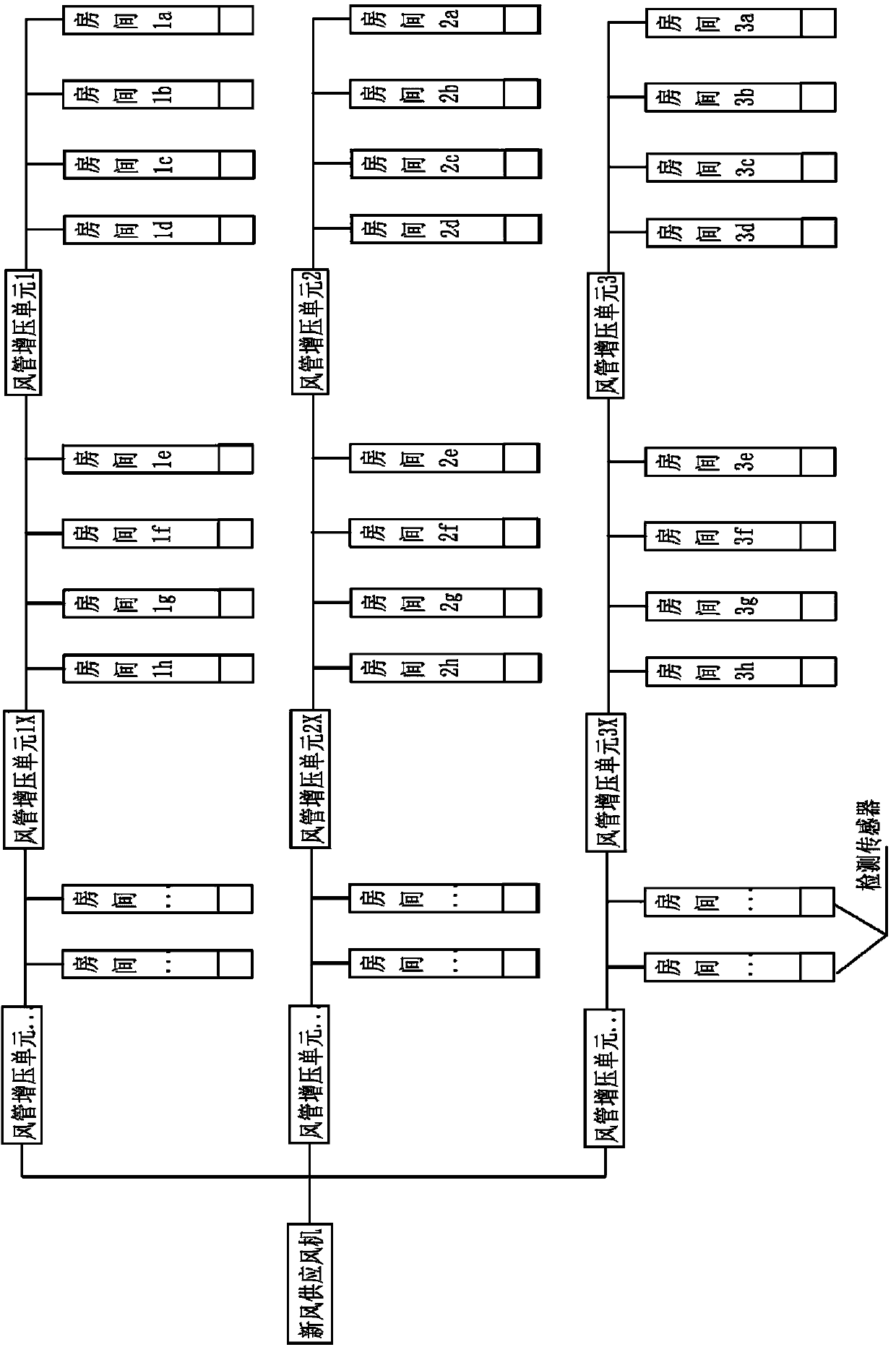

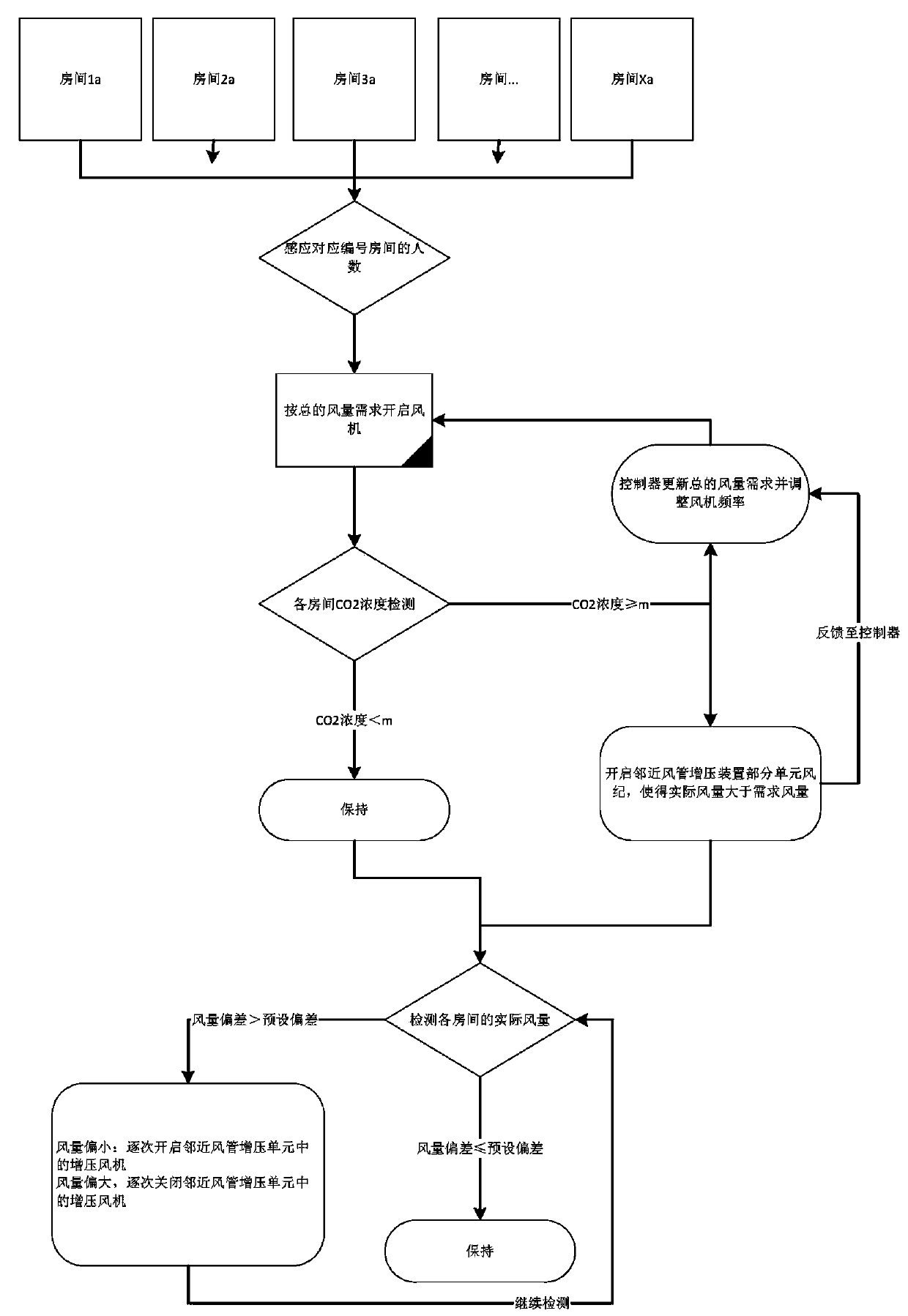

Central ventilation system capable of being adjusted as required, and air volume control method thereof

ActiveCN110440418ASystem operation distribution economyAddress uneven distributionMechanical apparatusEfficient regulation technologiesAir volumeEngineering

The invention discloses a central ventilation system capable of being adjusted as required, and an air volume control method thereof. The air volume control method of the central ventilation system comprises the steps of arranging multiple air pipe pressurization units in an air pipe of the central ventilation system at intervals; detecting the air volume demand of each room, calculating the totalair volume demand according to the air volume demand of each room, and controlling the frequency of a fan of the central ventilation system according to the total air volume demand; and detecting theactual air volume of each room, and controlling the relevant air pipe pressurization unit of the room to sequentially open or close according to the relationship between the actual air volume of eachroom and the air volume demand of each room. According to the central ventilation system capable of being adjusted as required provided by the invention, the air volume of each area can be adjusted as required so as to be distributed as required.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

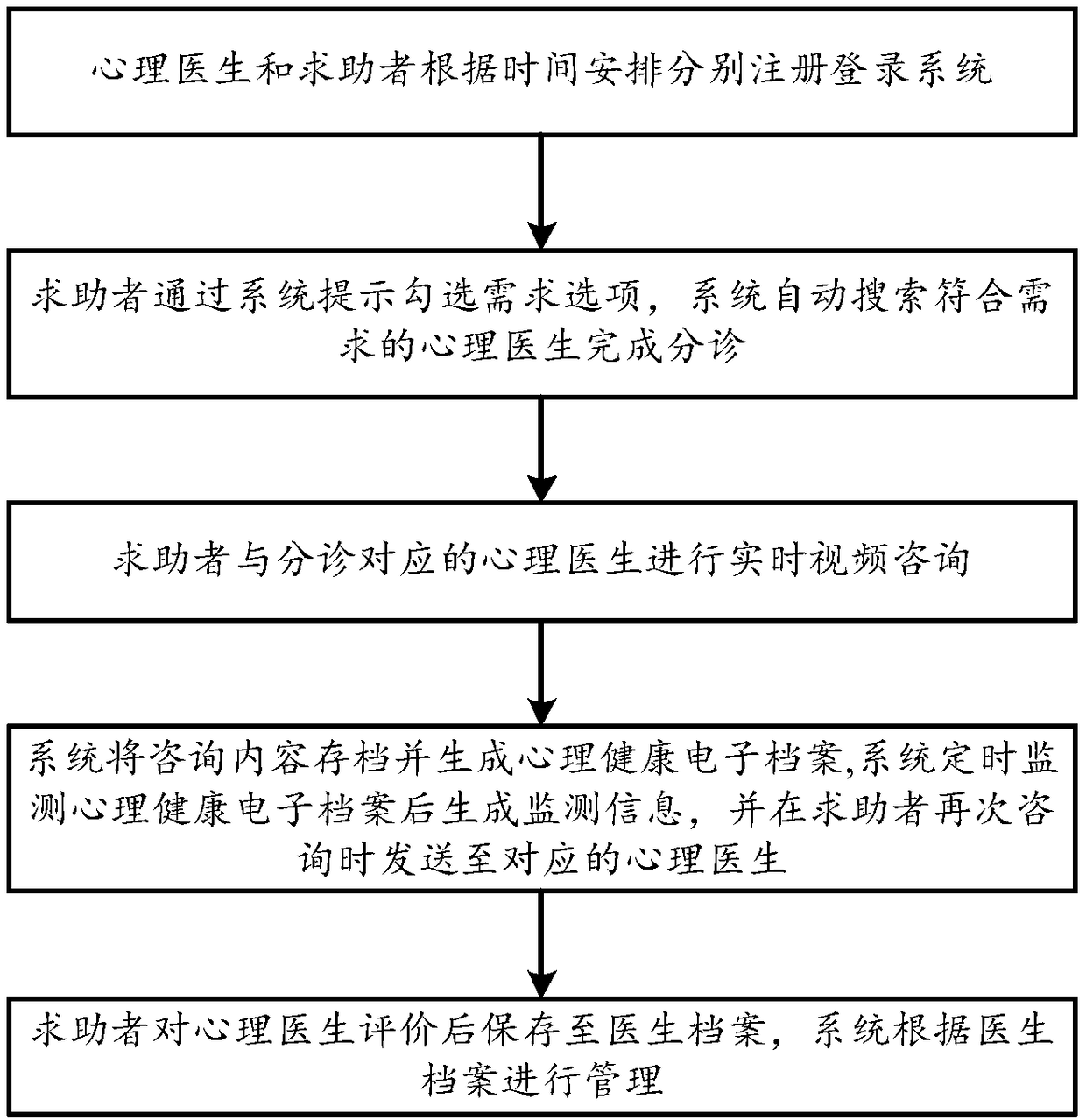

Online triage management method and system for mental illness

InactiveCN109102863ASupervise the quality of consultationSolve resource problemsMedical communicationClimate change adaptationTriageDisease

The invention discloses an online triage management method and system for mental illness and belongs to the mental illness triage management field. The method comprises steps that S1, a psychiatrist and a helper register separately to log into the system; S2, the helper checks a demand option through the system prompt, and the psychiatrist who meets the needs to complete the triage is automatically searched by the system; S3, the helper and the psychiatrist corresponding to the triage perform real-time video consultation; S4, after the consultation content is archived by the system, a mental health electronic file is further generated, the information is sent to the psychologist when the helper consults again according to the file; and S5, the psychiatrist is evaluated by the helper. The method is advantaged in that problems that psychologist resources are scarce and unevenly distributed, the offline mental illness medical treatment time is conflicted, the function of a consultation platform is single, and the psychological disease consultation effect is not good due to too-high cost in the prior art are solved, reasonable allocation of the psychologist resources is achieved, easyand quick consultation is promoted, and the consultation effect is improved.

Owner:四川三知帮健康产业有限公司

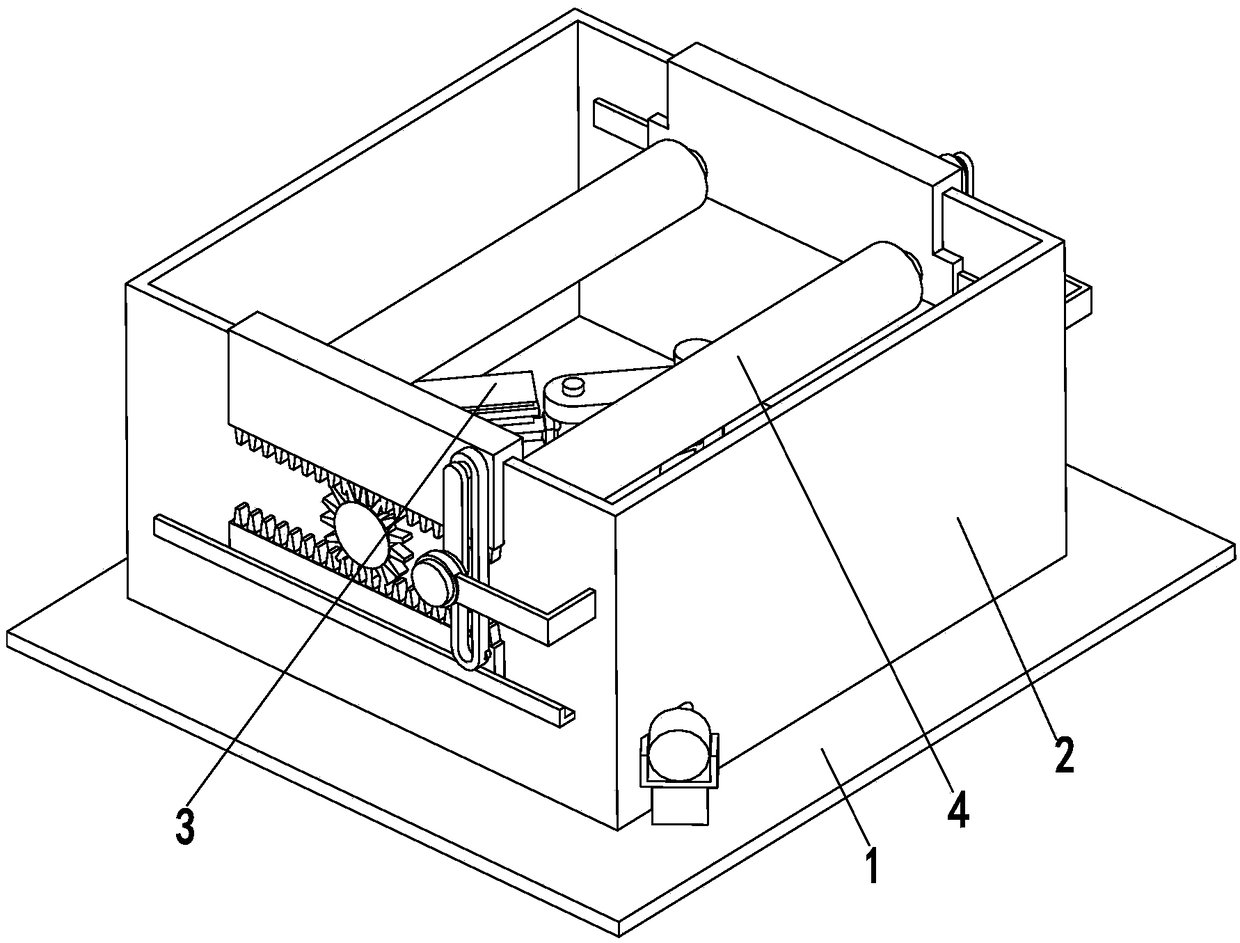

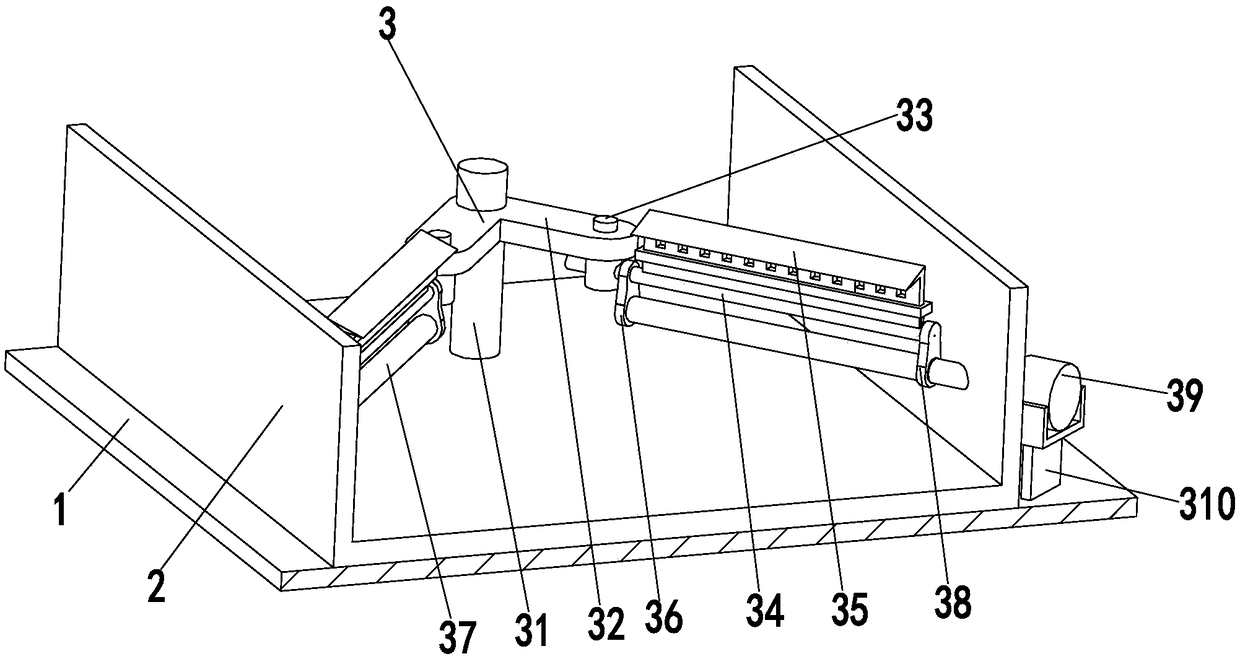

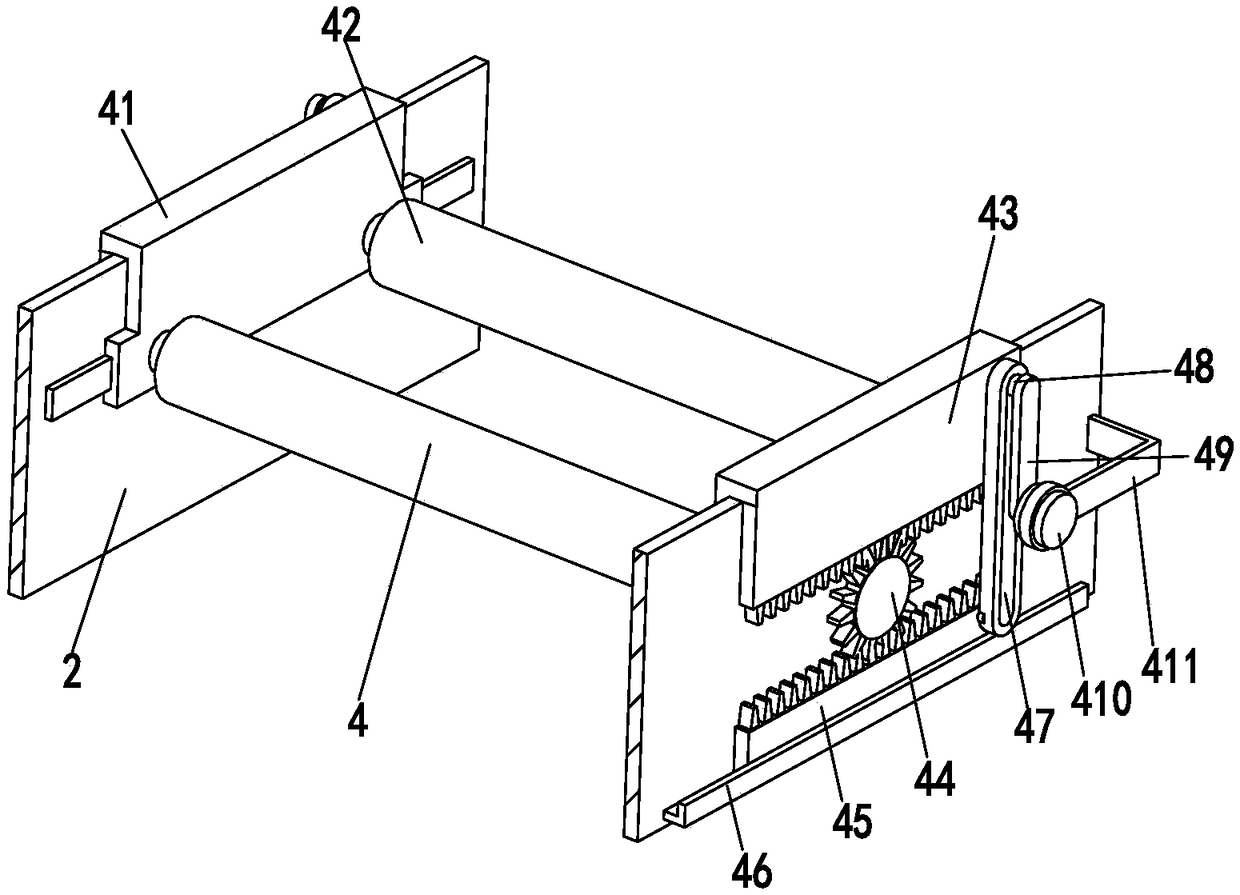

Dye vat for jig dyeing of textiles and automatic dye stirring technology

ActiveCN108754949AGuaranteed to proceed normallyExpand the scope of workLiquid/gas/vapor open-width material treatmentTextile treatment machine arrangementsEngineeringFixed Slide

The invention relates to a dye vat for jig dyeing of textiles and an automatic dye stirring technology. The dye vat comprises a bottom plate, a tank, a stirring mechanism and an oscillating mechanism,the tank is mounted on the bottom plate, the stirring mechanism is mounted at the bottom of the tank, and the oscillating mechanism is mounted on sidewalls of the tank. The stirring mechanism comprises a fixed column, a sliding rack, connection columns, stirring racks, first connection plates, rotating shafts, second connection plates, a stirring motor and a fixed support. The oscillating mechanism comprises oscillating racks, auxiliary rollers, oscillating racks, gears, auxiliary racks, fixed slide grooves, working racks, protruding columns, rotating racks, rotating motors and mounting racks. The dye vat solves the problems of uneven dye distribution, uneven dyeing and the like of an existing jig dyeing process, can automatically stir dye in the dye vat and has the advantages of even dyedistribution, dyeing evenness and the like.

Owner:浙江旺盛控股集团股份有限公司

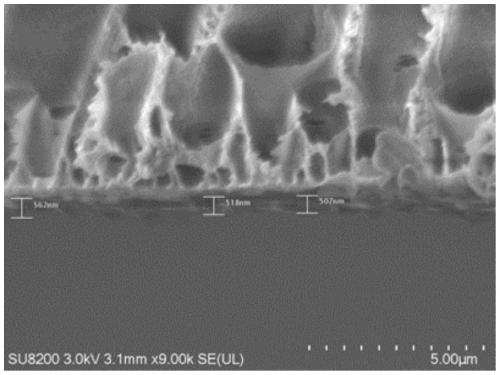

Thin film composite film taking metal organic framework as functional layer, preparation method thereof and preparation method of metal organic framework

ActiveCN111346525AAddress uneven distributionGood repeatabilitySemi-permeable membranesComposite filmPolyamide

The invention provides a preparation method of a thin film composite film taking a metal organic framework as a functional layer, which comprises the following steps: 1) mixing a metal organic framework mixed solution containing a polyamine with an alcohol to obtain a dispersion solution; (2) spraying the dispersion liquid obtained in the step (1) on a base film by utilizing a spraying technology,so that a uniform metal organic framework layer is formed on the surface of the base film; and 3) spraying a polybasic acyl chloride solution on the surface of the metal organic framework layer prepared in the step 2) by using a spraying technology, and generating a polyamide layer by using an interfacial polymerization reaction to fix the metal organic framework, thereby obtaining the thin filmcomposite film. According to the invention, the spraying technology is applied to the construction of the metal organic framework film composite film; the problems that large-scale preparation of themetal organic framework film composite film is difficult and repeatability is poor are solved, the metal organic framework film composite film with a thin functional layer and excellent dye interception performance can be prepared, and the prepared MOF film composite film has a very high industrial application prospect.

Owner:UNIV OF SCI & TECH OF CHINA

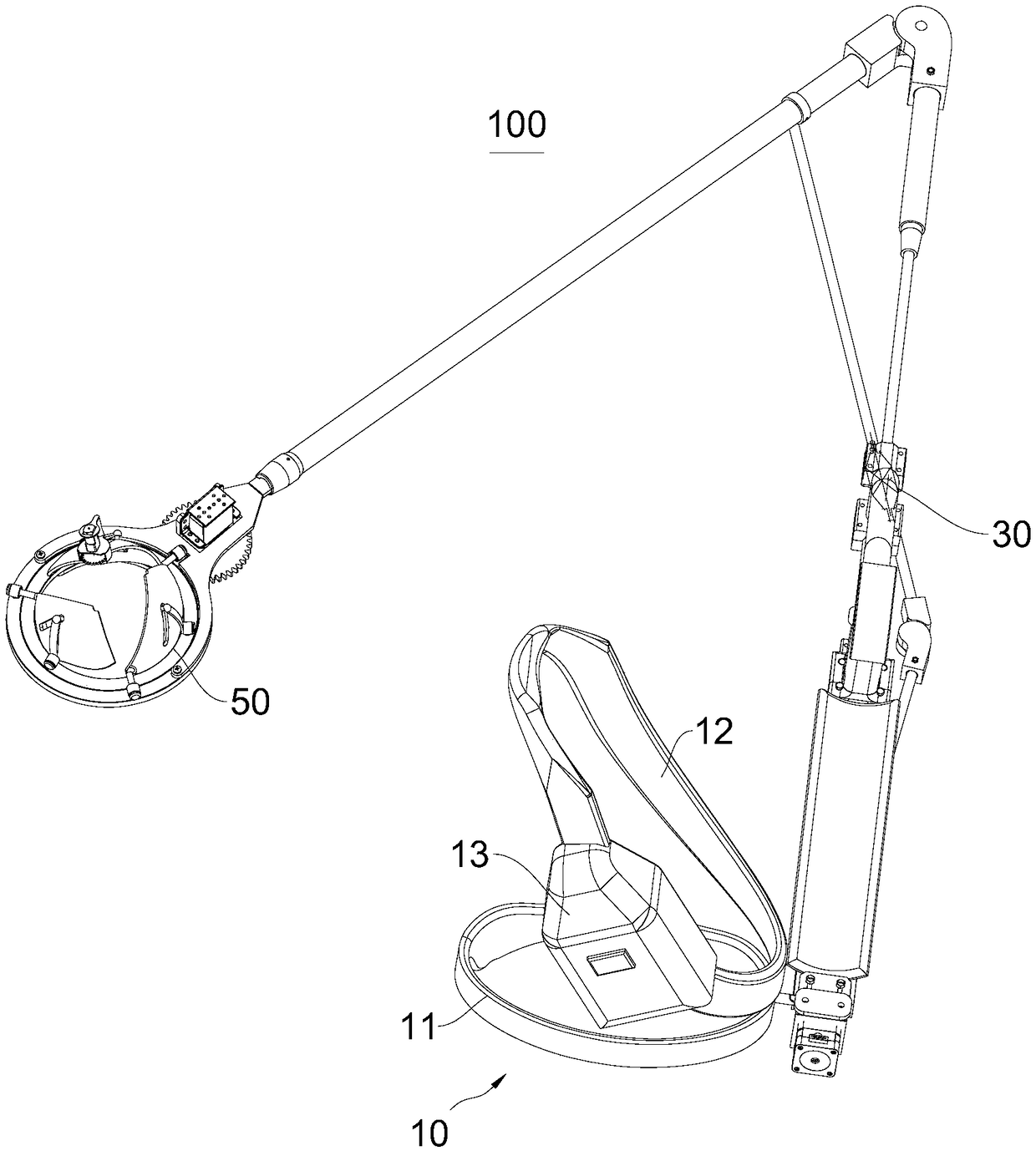

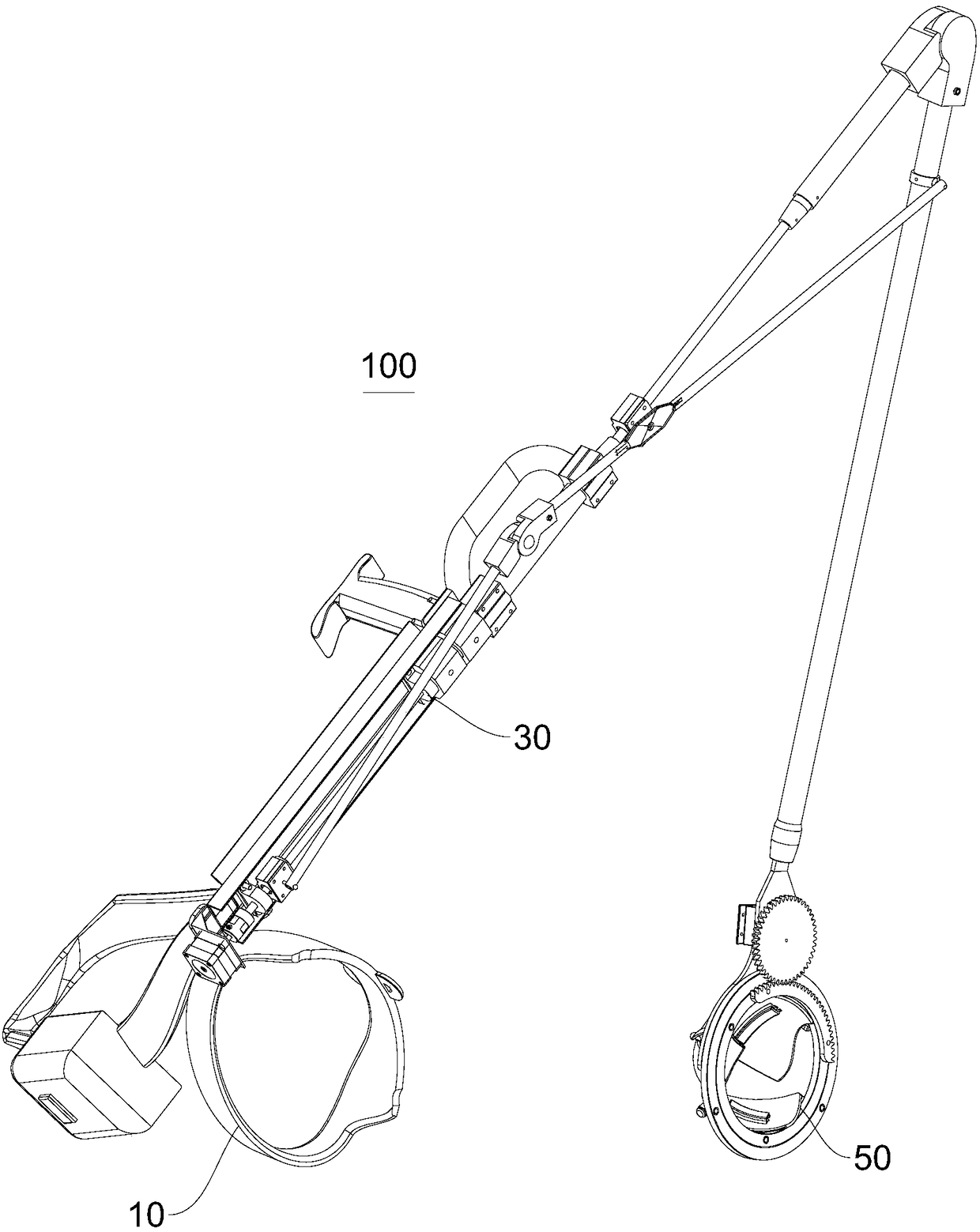

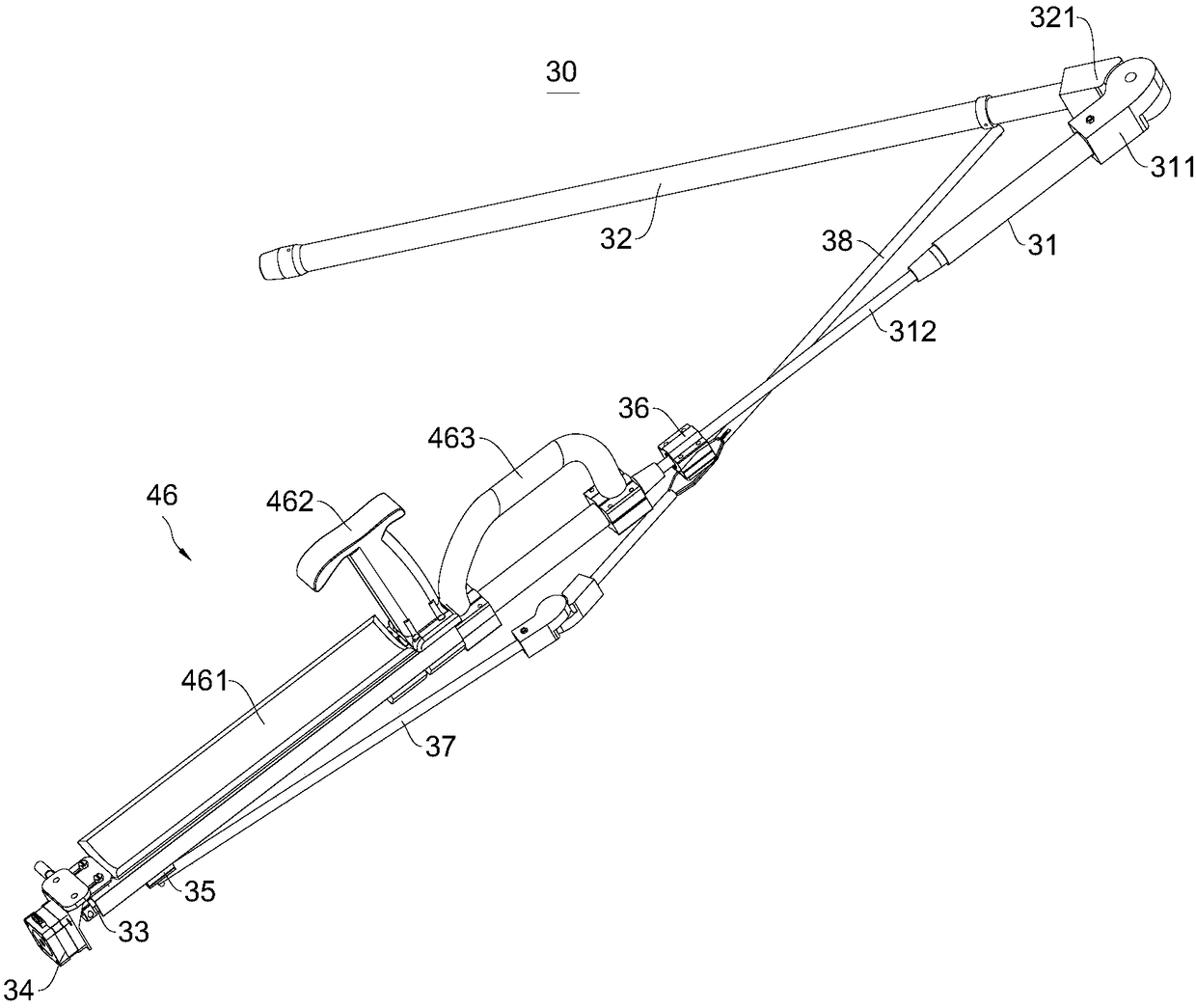

Fruit picker and picking equipment

ActiveCN108566831AAdjustable sizeEasy to operateRenewable energy machinesPicking devicesHuman bodyElectric machinery

The invention provides a fruit picker and picking equipment, and belongs to the technical field of fruit picking. The fruit picker comprises a wearing device, a positioning device and a picking device, wherein the wearing device is adaptive to a waist and shoulders of a human body; the positioning device comprises a first supporting rod, a second supporting rod, a lead screw, a first drive motor,a first slide block, a second slide block, a first drive rod and a second drive rod; and the picking device comprises a frame body, a rotary part, a second drive motor, a third slide block, a connecting rod, a cutting motor and at least two petal parts. The fruit picker is adjustable in dimension, is greatly convenient for a use, is simple in operation, improves picking efficiency, is reasonable in structural design and is high in practicability. The picking equipment comprises the fruit picker which has all functions of the fruit picker.

Owner:WUHAN POLYTECHNIC UNIVERSITY

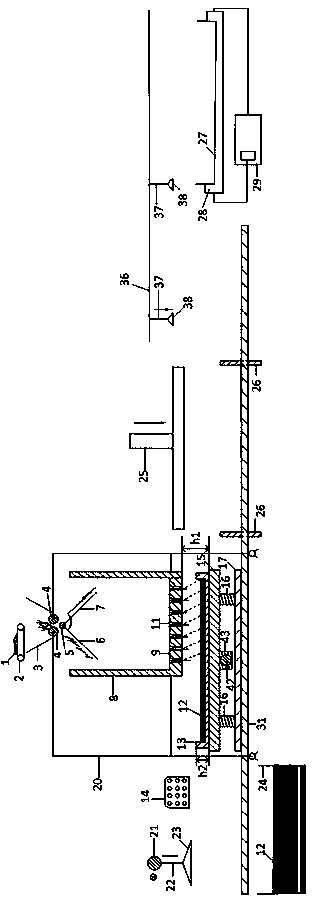

Directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method

The invention discloses a directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method and belongs to the field of composite material preparation. By utilizing the special structure of a vibration sieve, through the restriction effect of vibration sieve holes, carbon fiber silks which fall off through vibration from slender sieve holes to performvertical motion of a free falling body; when one ends of the fiber silks are adhered to a resin film in the falling process, the carbon fiber silks are reversely fixed by utilizing the viscosity of the resin film and one-way relative motion of the carbon fiber silks and a two-dimensional movement platform, directional arrangement and uniform distribution of carbon fibers in a movement direction are realized, and the problems of uneven distribution and difficulty in orientation of short carbon fibers in thermoplastic resin are well solved; and through control on a movement speed of the two-dimensional movement platform and control on number of times of laying, accurate control on the content of the carbon fibers in a prepreg is realized, orientation of the carbon fiber silks can be an arbitrary two-dimensional direction, crossing distribution of multiple layers of resin films and multiple layers of carbon fibers is realized, and the mechanical performance of a carbon fiber composite material is improved.

Owner:JIANGSU UNIV

Anti-nematode soybean breeding method

ActiveCN103503767AImprove accuracyGuaranteed survival ratePlant genotype modificationNematodeAnimal science

The invention discloses an anti-nematode soybean breeding method. The anti-nematode soybean breeding method comprises the steps of hybridizing, screening hybridized combinations, performing low-generation sick soil potting identification, screening anti-nematode individual plants, comprehensively identifying advanced-generation field disease nurseries, screening good strains, comprehensively identifying and the like. The anti-nematode soybean breeding method can effectively overcome the technical problems that anti-cyst nematode soybean breeding identification is difficult, the identification is disjointed with selection, the selection is hard, and the breeding efficiency is low. The anti-nematode soybean breeding method realizes organic combination between root disease-resistant character identification and breeding, and improves anti-cyst nematode soybean breeding efficiency.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

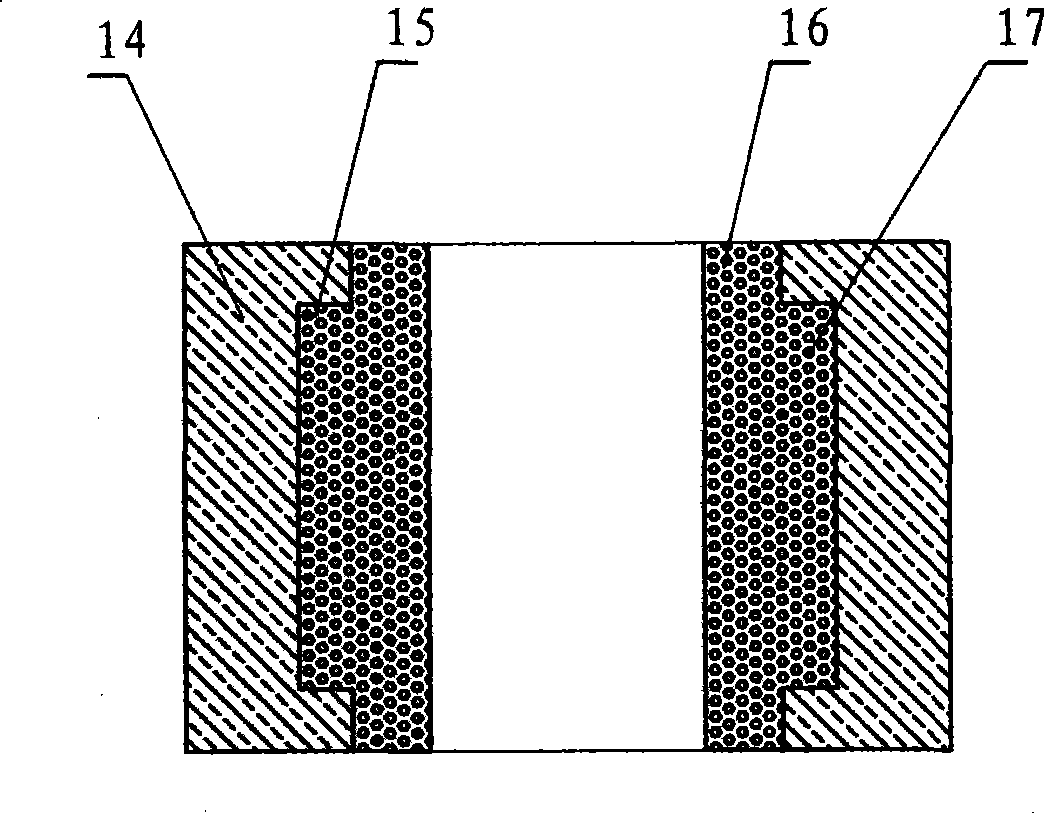

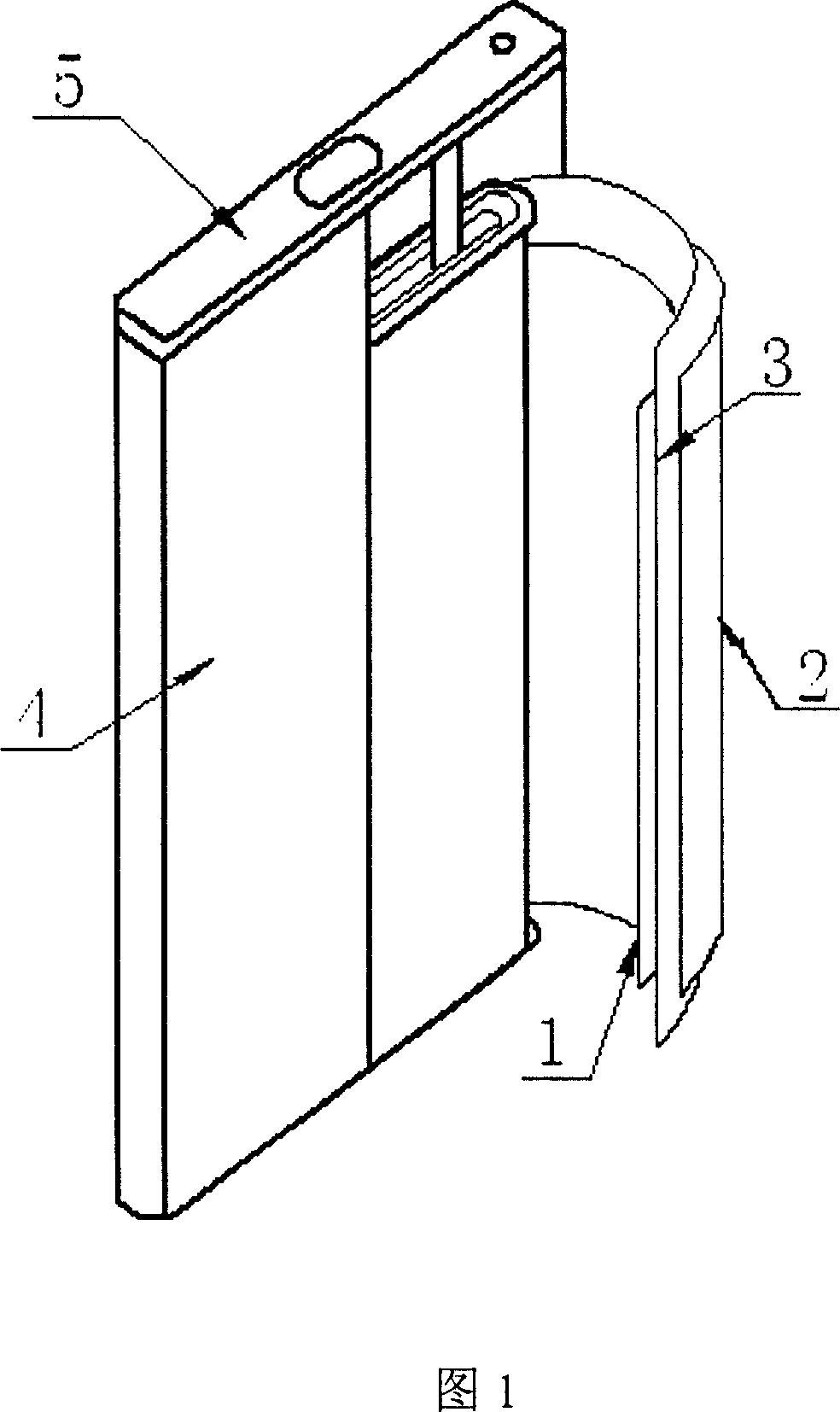

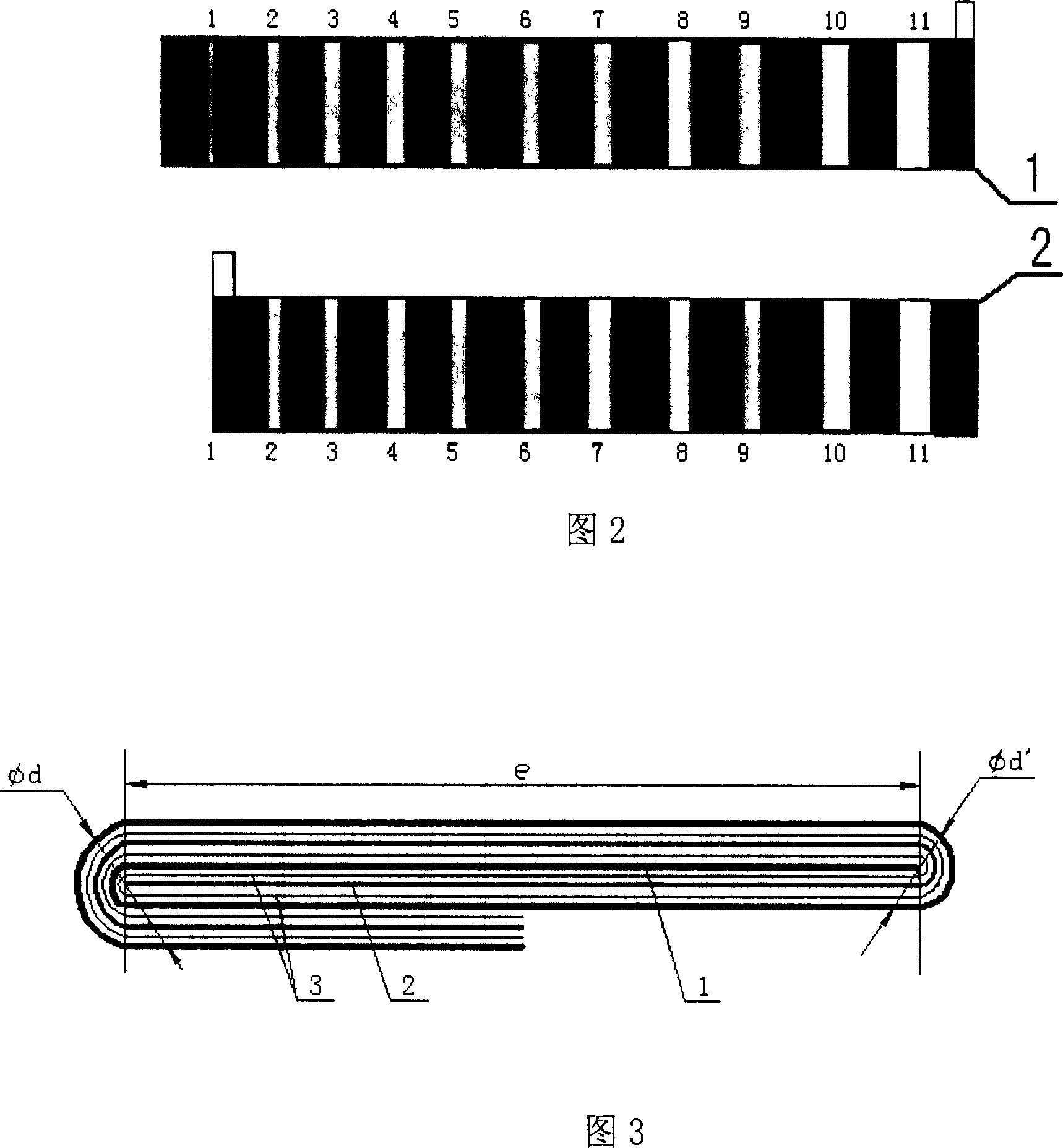

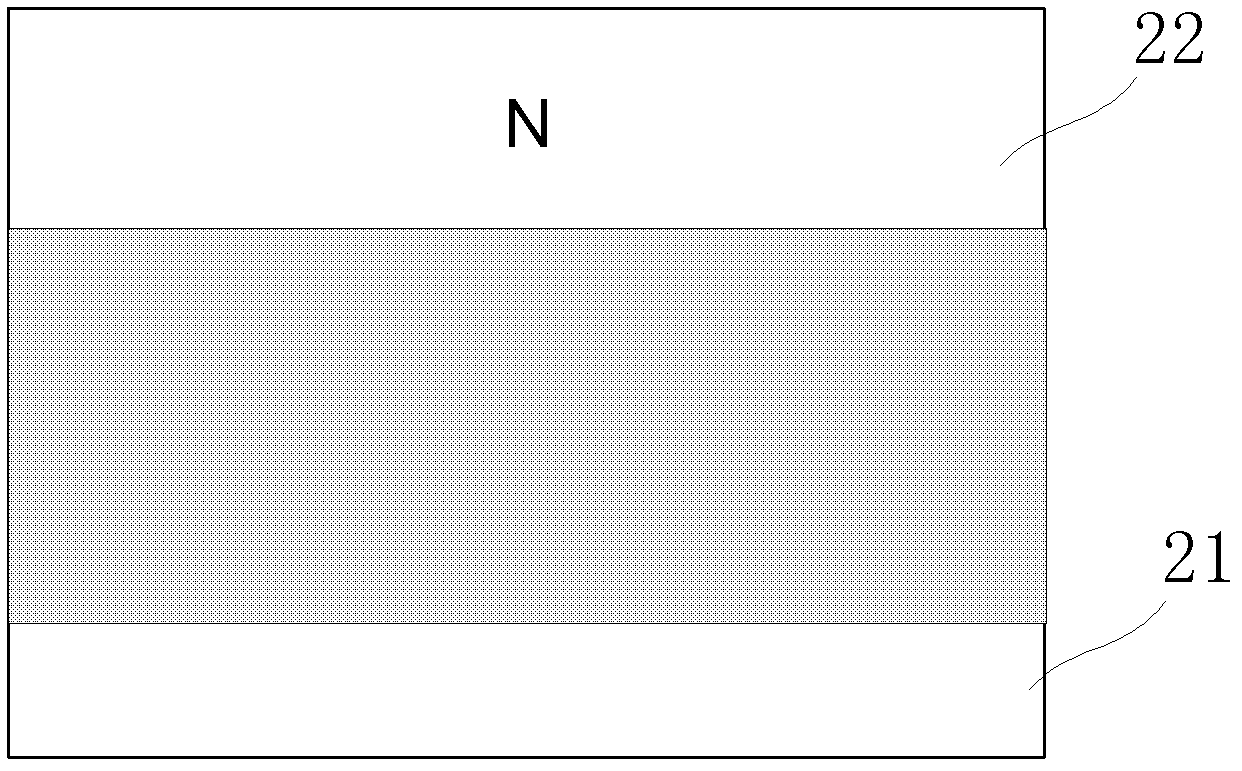

A quadrate lithium ion cell electrode core and its battery

ActiveCN1953244AAddress uneven distributionImprove cycle performanceActive material electrodesSecondary cellsSEMI-CIRCLEElectrolyte

The invention relates to a pole corn of square lithium battery, and relative battery. Wherein, said pole corn is square, which comprises anode, cathode, and baffle film between them; the anode, cathode, and baffle film are folded into square pole corn, whose two ends are semi circles, while at least one of inner ring, outer ring of anode, inner ring, outer ring of cathode is not coated with active material; therefore, said lithium battery comprises sealing cover plate, frame, pole corn and non-water electrolyte sealed in frame and cover plate. The inventive battery has better circulate property and high safety.

Owner:BYD CO LTD

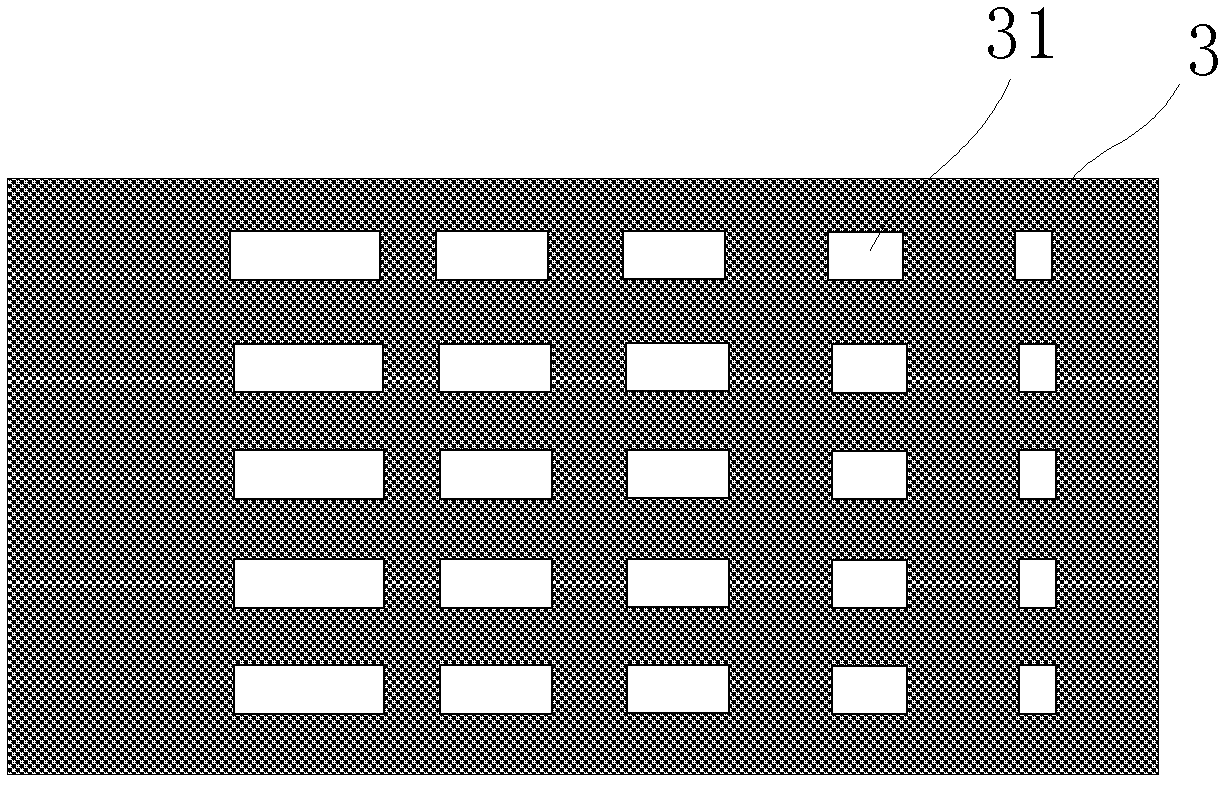

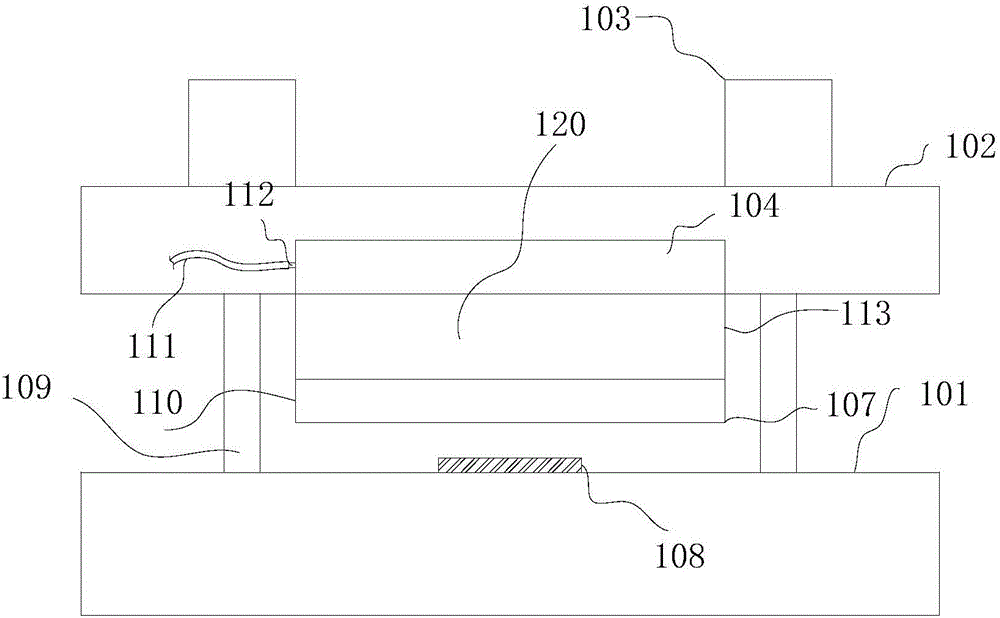

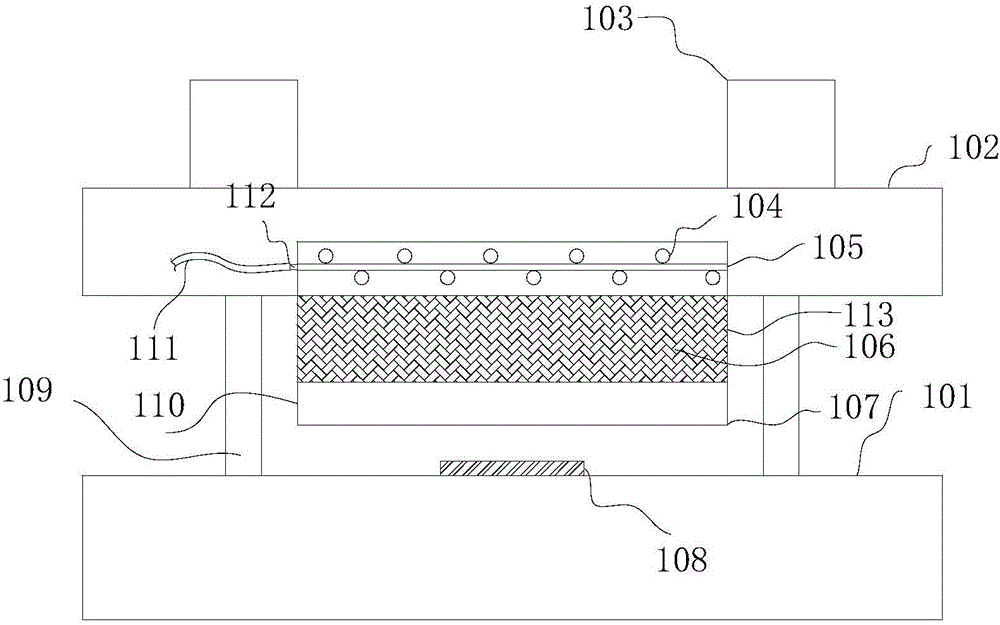

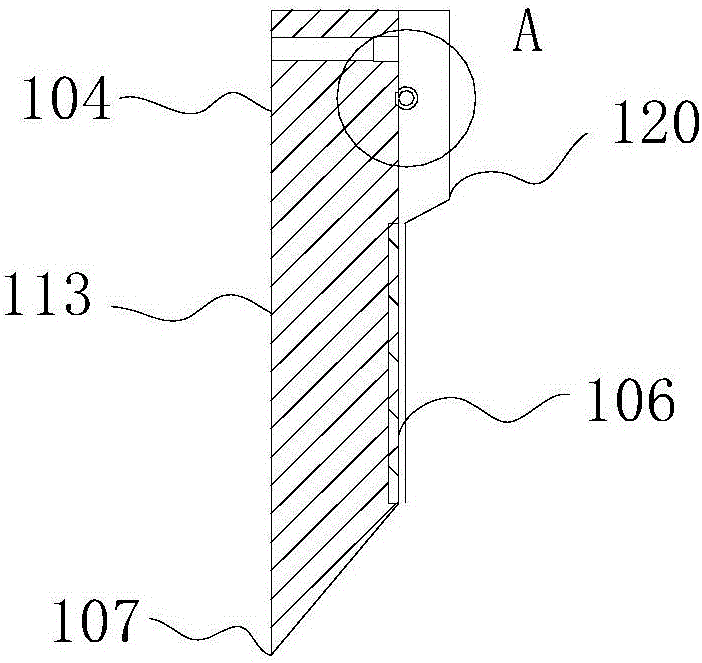

Controllable surface nitriding device and using method thereof

ActiveCN111850457ASolve the adsorption problemAddress uneven distributionSolid state diffusion coatingIron nitrideMetallic materials

The invention discloses a controllable surface nitriding device and a using method thereof, and belongs to the technical field of metal material surface treatment. The device is structurally composedof a vacuum device, a surface nitriding control mechanism and a nitrogen supply structure. The device is novel in structure. By means of the device, iron nitride can be gradually adsorbed on the surfaces of a plurality of annular metal parts in the figure in a circulating mode according to the rotating direction to generate a nitriding effect, excellent surface hardening treatment can be simply applied to materials such as stainless steel, titanium and cobalt which are difficult to treat, the iron nitride can be gradually adsorbed on the surfaces of the plurality of annular metal parts in thecirculating mode according to the rotating direction to generate the nitriding effect, the problems that the adsorption amount of the iron nitride cannot be controlled and the distribution is not uniform in the nitriding process in the past are solved, and the mechanical property of the surface of a workpiece can be further improved.

Owner:YANGZHOU UNIV

Polyarylether ether nitrile modified phenolic resin adhesive and preparation method thereof

ActiveCN107083217AImprove adhesionImprove toughnessAldehyde/ketone condensation polymer adhesivesN-vinyl-pyrrolidone polymer adhesivesUniform systemAcrylonitrile

The invention discloses polyarylether ether nitrile modified phenolic resin adhesive and a preparation method thereof. The polyarylether ether nitrile modified phenolic resin adhesive is technically characterized by being composed of the following substances in parts by weight: 50-60 parts of polyarylether ether nitrile modified phenolic resin, 6-10 parts of polyvinylpyrrolidone, 25-35 parts of butadiene-acrylonitrile rubber, 0.1-1 part of an anti-aging agent and 10-15 parts of methyl acetate. The polyarylether ether nitrile modified phenolic resin adhesive has the advantages that phenolic resin is modified by utilizing polyarylether ether nitrile, so that toughness and bonding performance of the phenolic resin are obviously improved; meanwhile, polyvinylpyrrolidone has good molecular affinity, so that polyarylether ether nitrile, butadiene-acrylonitrile rubber and phenolic resin form a uniform system, and toughness of a material is improved; besides, the polyvinylpyrrolidone has excellent bonding performance, so that coadhesiveness of the phenolic resin adhesive is also further improved.

Owner:SHANDONG YUSHIJU CHEM CO LTD

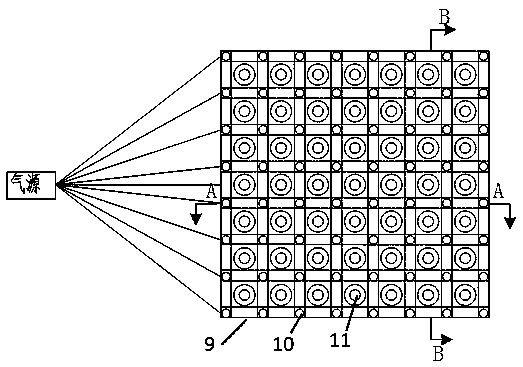

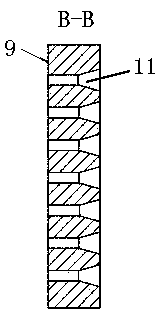

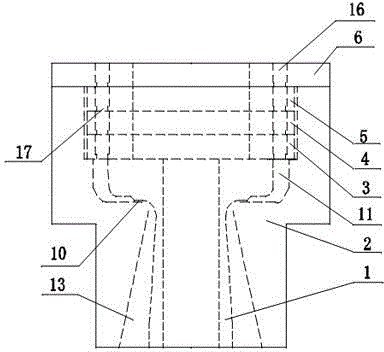

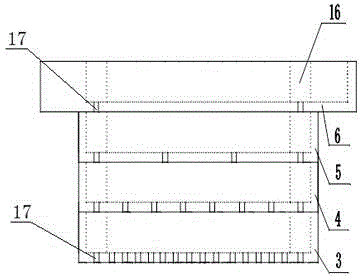

Argon-filling flow stabilization device

ActiveCN104562184ASimple structureEasy to install and operatePolycrystalline material growthBy pulling from meltArgon flowEngineering

The invention discloses an argon-filling flow stabilization device applied to filling argon in a single crystal furnace in the Czochralski method silicon single crystal production process. According to the argon filled flow stabilization device disclosed by the invention, due to the combined action of a forward stage stabilization body and a backward stage stabilization body of four-level air distribution hole flow in step-by-step multiplication of a primary shunt layer (6), a secondary shunt layer (5), a third-level shunt layer (4) and a tail-level shunt layer (3) as well as a stabilization body guide groove (11), the flow of the argon filled into the single crystal furnace is stably and orderly distributed, the bias flow is small, the argon distribution in the furnace chamber is uniform, the problems that a crystal bar swings and the oxygen and carbon content of the crystal bar exceeds the standard due to argon filling are effectively solved, and the crystal formation rate is obviously improved. The argon-filling flow stabilization device disclosed by the invention is simple in design structure, reliable to assemble and position and convenient to mount and maintain.

Owner:MCL ELECTRONICS MATERIALS

Facial mask and preparation method thereof

ActiveCN108014052AAddress uneven distributionImprove stabilityCosmetic preparationsToilet preparationsMagnesium saltHydroxyethyl cellulose

The invention relates to a facial mask and a preparation method thereof. The facial mask is prepared from a gel solution and a gelatinizing agent, wherein the gel solution is prepared from hydroxyethyl cellulose, sodium alginate, gellan gum, a moisturizer, ethylenediamine tetraacetic acid disodium salt, a preservative and deionized water; the gelatinizing agent is prepared from the following raw materials in parts by weight: water-soluble calcium salt, water-soluble magnesium salt, a preservative and deionized water. The facial mask prepared through the method provided by the invention is prepared through wrapping plant debris with gel, and uniformly coating a non-woven fabric facial mask fabric with the plant debris in advance, so that the problem that the plant debris is nonuniformly distributed on the facial mask fabric is solved; meanwhile, because of the wrapping of the gel, a facial mask solution is prevented from directly making contact with the plant debris, natural pigments inthe plant debris are effectively prevented from dissolving into the facial mask solution, and the stability of the color of the plant debris is greatly improved.

Owner:广东艾慕生物科技有限公司

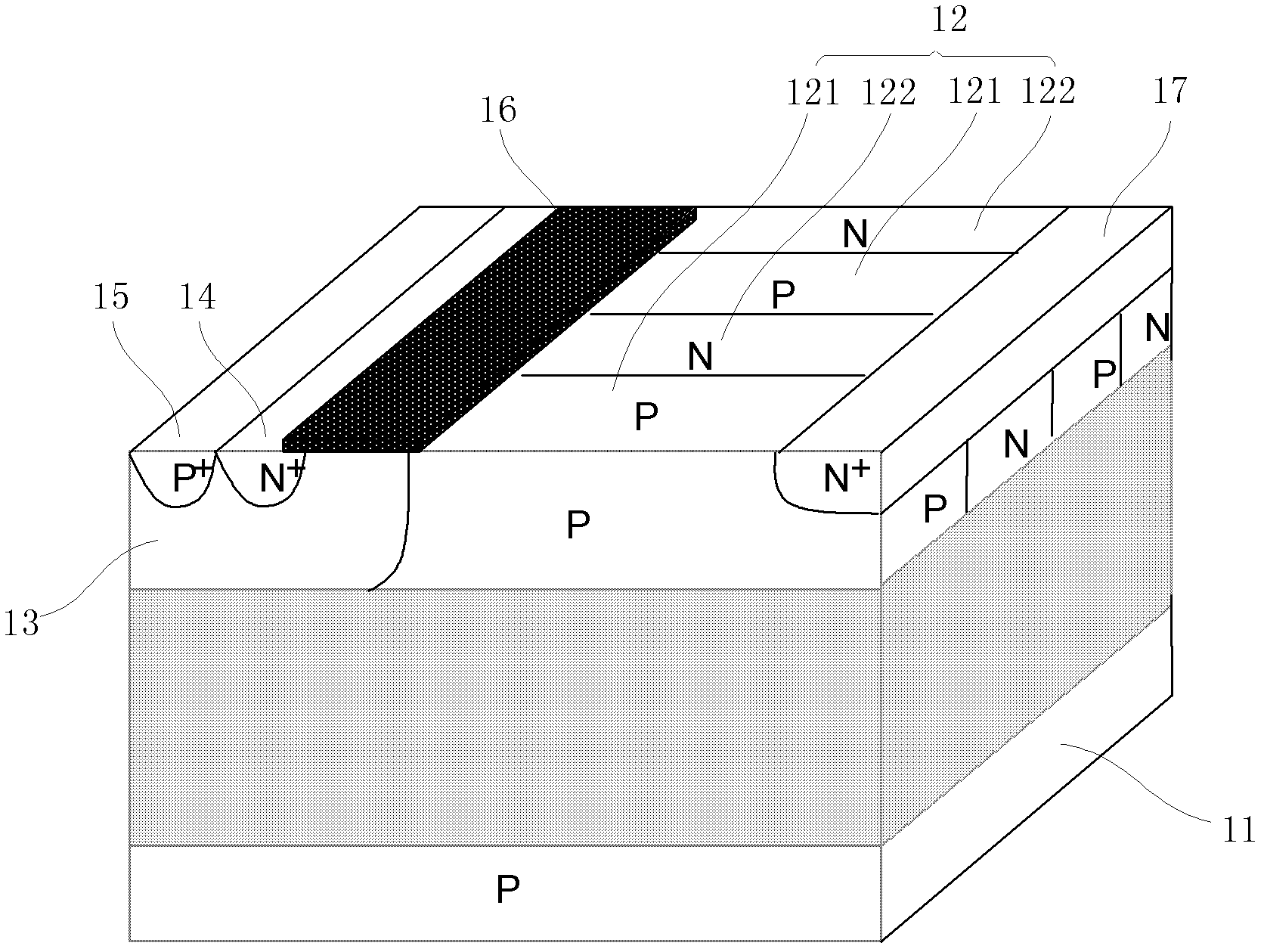

Super junction device with multiple embedded P islands and N channels and preparation method thereof

ActiveCN102593007ASolve the uneven distribution of electric fieldAddress uneven distributionSemiconductor/solid-state device manufacturingSemiconductor devicesBody regionN channel

The invention provides a super junction device with multiple embedded P islands and N channels and a preparation method thereof. The super junction device comprises a semiconductor substrate, an N-type drift region formed on the semiconductor substrate, P-type body regions on one side of the N-type drift region, and N-type leakage regions on the other side of the N-type drift region, wherein a plurality of parallel island-shaped P areas are formed in the N-type drift region at intervals, and each island-shaped P area is gradually diminished in a linear manner from N-type source regions to the N-type leakage regions; the function of the substrate-assisted depletion effect is sequentially enhanced from source ends to leakage ends under a high voltage, so that the island-shaped P areas are correspondingly decreased from the source ends to the leakage ends, and accordingly, the complementation and offset to the substrate-assisted depletion effect are realized, and the purpose of charge balance is achieved.

Owner:上海功成半导体科技有限公司

Novel rubber seal ring for explosion-proof motor and production technology for rubber seal ring for

InactiveCN104592603AExcellent ozone resistanceImprove low temperature resistanceSulfidationEngineering

The invention discloses a novel rubber seal ring for an explosion-proof motor, and belongs to the technical field of sealing rings. The rubber seal ring is characterized by comprising the following raw materials in parts by weight: 45-55 parts of neoprene, 10-20 parts of EPDM rubber, 4-6 parts of sulfidation system, 5-10 parts of a coldproof soften flux, 12-18 parts of a reinforcing agent, 5-10 parts of a coldproof assistant, and 2-5 parts of an ozone proof assistant. The rubber seal ring has the advantages that the rubber seal ring is high in ozone resistance, good in low temperature resistant performance, and reliable in sealing; the abrasion resistant capability is reinforced greatly; the product quality is more stable; the service life is prolonged by 200% to rubber seal rings for explosion-proof motors in the prior art.

Owner:南阳天一密封股份有限公司

Grid cutting equipment

ActiveCN105817693AEvenly distributedExtended retention timeNibbling shearing machinesMaintainance and safety accessoriesEngineeringKnife holder

The invention discloses grid cutting equipment which comprises a rack provided with a grid conveyor belt and a tool rest arranged on the rack and capable of moving relative to the rack, wherein a cutter used for cutting a grid is arranged on the tool rest, the cutter is of an integrated structure and is sequentially divided into a tail part fixed with the tool rest, a cutter body exposed from the cutter rest and a blade part acting with the grid from the tool rest to the rack; a cooling pipeline used for providing a heat exchange medium to the blade part is fixed on the tail part, and the cooling pipeline is externally wrapped with a porous material used for uniformly distributing the heat exchange medium; distribution lines used for dispersing the heat exchange medium are arranged on the cutter body; and the cutter is provided with a dust cap wrapping the tail part and the cutter body. According to the invention, the design that the porous material wraps a cooling pipeline is adopted, so that uniform distribution of the heat exchange medium on the surface of the cutter body is improved; the design of distribution lines is adopted; and the design of a heat exchange trough is adopted.

Owner:CHISEN POWER JIANGSU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com