Preparation of polyaniline / argentum nano composite material

A composite material and silver nanotechnology, which is applied in the field of preparation of polyaniline/silver nanocomposite materials, can solve the problem of uneven distribution of silver particles, and achieve the effects of simple equipment, simple production process and low equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

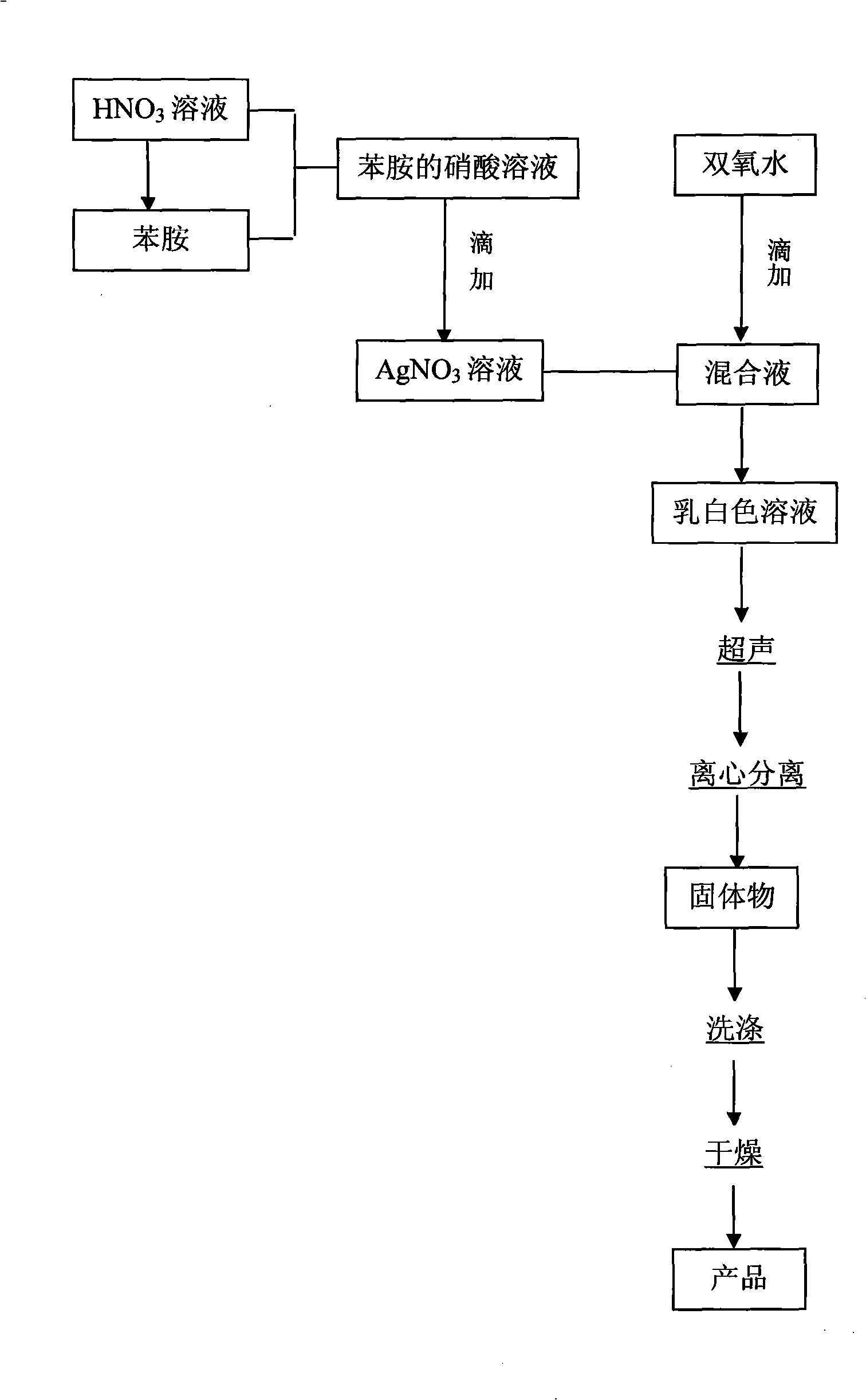

Method used

Image

Examples

Embodiment 1

[0031] Used silver nitrate (analytical pure), its main component (%) is: AgNO 3 ≥99.8%, water insoluble ≤0.005%, chloride ≤0.001%, sulfate ≤0.004%, Fe≤0.0004%, Cu≤0.001%, Pb≤0.001%, hydrochloric acid non-precipitate ≤0.02%.

[0032] Weigh 4.25g AgNO 3 Dissolve in 50mL distilled water to make 0.5mol / L AgNO 3 solution; weigh 2.33g aniline, and add 50mL 1mol / L nitric acid solution to obtain the nitric acid solution of aniline; under magnetic stirring, add the nitric acid solution of aniline dropwise to AgNO 3 In the solution, after 10 minutes of dripping, the mixture was obtained and magnetic stirring was continued. Pre-measure 26mLv / v30% H 2 o 2 , make up to 50mL with distilled water, add it dropwise to AgNO 3 In the mixed solution with aniline, after 20 minutes of dripping, a milky white solution was obtained. Then it was placed in an ultrasonic reactor, and after ultrasonication for 5 hours, a large amount of green precipitate was obtained, which was left to stand for 96...

Embodiment 2

[0034] Used silver nitrate (analytical pure), its main component (%) is: AgNO 3 ≥99.8%, water insoluble ≤0.005%, chloride ≤0.001%, sulfate ≤0.004%, Fe≤0.0004%, Cu≤0.001%, Pb≤0.001%, hydrochloric acid non-precipitate ≤0.02%.

[0035] Weigh 6.375g AgNO 3 Dissolve in 50mL distilled water to make 1.0mol / L AgNO 3 solution; weigh 2.33g aniline, and add 50mL 1mol / L nitric acid solution to obtain the nitric acid solution of aniline; under magnetic stirring, add the nitric acid solution of aniline dropwise to AgNO 3 In the solution, after 10 minutes of dripping, the mixture was obtained and magnetic stirring was continued. Pre-measure 26mLv / v30% H 2 o 2 , make up to 50mL with distilled water, add it dropwise to AgNO 3 In the mixed solution with aniline, after 20 minutes of dripping, a milky white solution was obtained. Then it was placed in an ultrasonic reactor, and after ultrasonication for 5 hours, a large amount of green precipitate was obtained, which was left to stand for 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com