Argon-filling flow stabilization device

A steady flow device and argon gas technology, which is applied in the directions of crystal growth, single crystal growth, polycrystalline material growth, etc., can solve the problems of large bias current, excessive oxygen and carbon content of the crystal rod, etc., achieve simple structure, improve crystal quality, The effect of strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

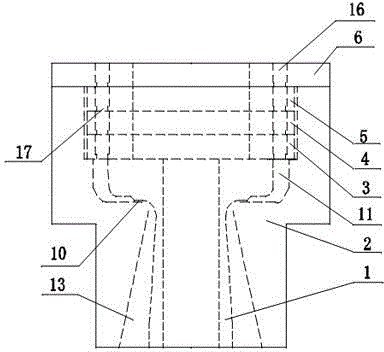

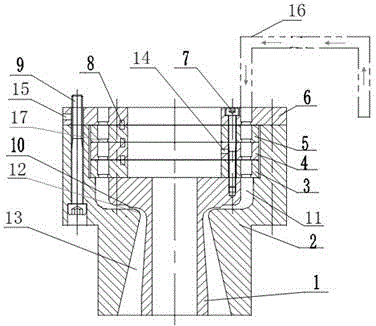

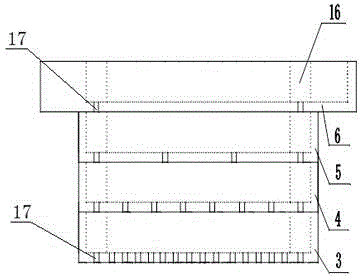

[0011] Provide the specific embodiment of the present invention below in conjunction with accompanying drawing as follows:

[0012] Such as figure 1 , figure 2 , image 3 As shown, a kind of argon gas filling and stabilizing device according to the present invention is mainly composed of a front-stage rectifier, a rear-stage stabilizing fluid, a stabilizing fluid diversion groove 11, an inner hexagonal connecting screw 7, a positioning pin 8, an inner Hexagonal connecting screw 9 forms. Among them, the pre-stage rectifier is composed of the primary distribution layer 6, the secondary distribution layer 5, the third distribution layer 4, and the final distribution layer 3. The primary distribution layer 6, the secondary distribution layer 5, the third distribution layer 4 and the final Air distribution holes 17 are respectively provided on the distribution layer 3 to form a four-stage air distribution flow multiplied step by step. The gas distribution holes 17 are evenly d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com