Biomass-based porous carbon material, preparation method thereof, and application thereof in supercapacitor

A technology of porous carbon materials and biomass, which is applied in the fields of hybrid capacitor electrodes, carbon compounds, chemical instruments and methods, etc., can solve problems such as the development limitation of carbon materials, and achieve the effects of low price, reduced production cost and good rate capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

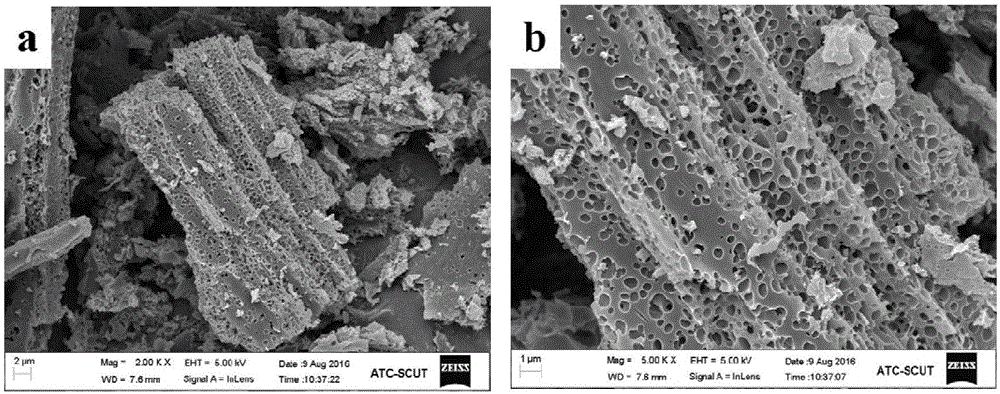

[0036] A method for preparing a biomass-based porous carbon material, comprising the steps of:

[0037] (1) drying the rice stalks in an oven at 60°C for 12 hours and pulverizing them;

[0038] (2) Pre-carbonize the crushed rice stalks for later use. The pre-carbonization process is to raise the temperature from room temperature to 300° C. at a rate of 5° C. / min, and keep it warm for 90 minutes; add a certain amount of KOH to the container, and add a small amount of water to KOH was dissolved, and the pre-carbonized rice straw was added to the container (the mass ratio of KOH and rice straw was 1:1), stirred evenly, and dried in an oven at 60°C for 12 hours;

[0039] (3) Carrying out the carbonization activation of the above-mentioned dried rice straw and KOH mixture in an argon atmosphere, raising the temperature from room temperature to a target temperature of 750° C. at a rate of 3° C. / min, and keeping it warm for 2 hours to obtain carbides;

[0040] (4) The carbide was wa...

Embodiment 2

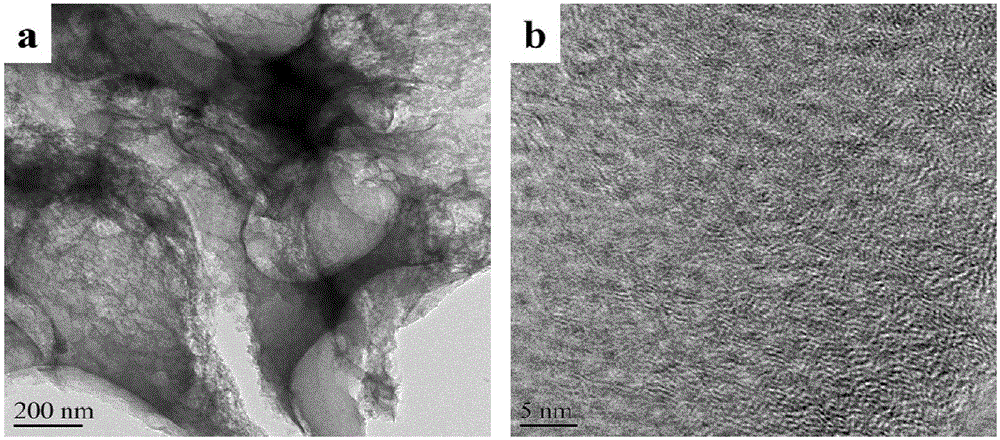

[0042] A method for preparing a biomass-based porous carbon material, comprising the steps of:

[0043] (1) drying the rice stalks in an oven at 60°C for 12 hours and pulverizing them;

[0044] (2) Add a certain quality of KHCO into the beaker 3 , adding a small amount of water will KHCO 3 Dissolve, add rice stalks to the beaker (KHCO 3 The mass ratio with the rice stalk is 5:1) and stirred evenly, and dried in an oven at 60°C for 12 hours;

[0045] (3) the above-mentioned dried rice straw and KHCO 3The mixture was carbonized and activated in a nitrogen atmosphere, and the temperature was raised from room temperature to a target temperature of 1000 °C at a rate of 3 °C / min, and kept for 2 hours;

[0046] (4) The carbide was washed 4 times with 20% sodium hydroxide by mass fraction, then washed 2 times with 1M hydrochloric acid, and finally washed to neutrality, and dried in an oven at 60°C for 12 hours to obtain a rice stalk-based porous carbon material that was Substance...

Embodiment 3

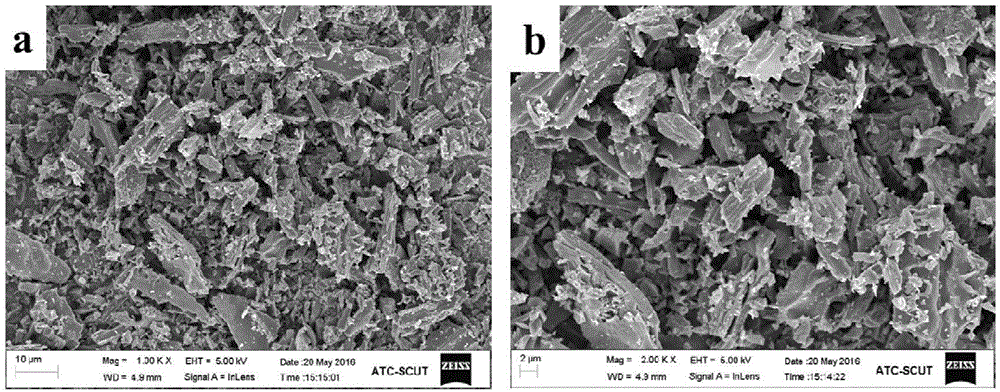

[0048] A method for preparing a biomass-based porous carbon material, comprising the steps of:

[0049] (1) drying the rice stalks in an oven at 60°C for 12 hours and pulverizing them;

[0050] (2) Add a certain quality of KHCO to the container 3 , adding a small amount of water will KHCO 3 Dissolve, add rice stalks to the beaker (KHCO 3 The mass ratio with the rice straw is 1:1), stir evenly, and dry in a 60°C oven for 12 hours;

[0051] (3) the above-mentioned dried rice straw and KHCO 3 The mixture was carbonized and activated in an argon atmosphere, and the temperature was raised from room temperature to a target temperature of 800°C at a rate of 3°C / min, and kept for 2 hours;

[0052] (4) The carbide was washed 4 times with 20% sodium hydroxide by mass fraction, then washed 2 times with 1M hydrochloric acid, and finally washed to neutrality, and dried in an oven at 60°C for 12 hours to obtain a rice stalk-based porous carbon material that was Substance-based porous c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com