Patents

Literature

34results about How to "Achieve directional alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

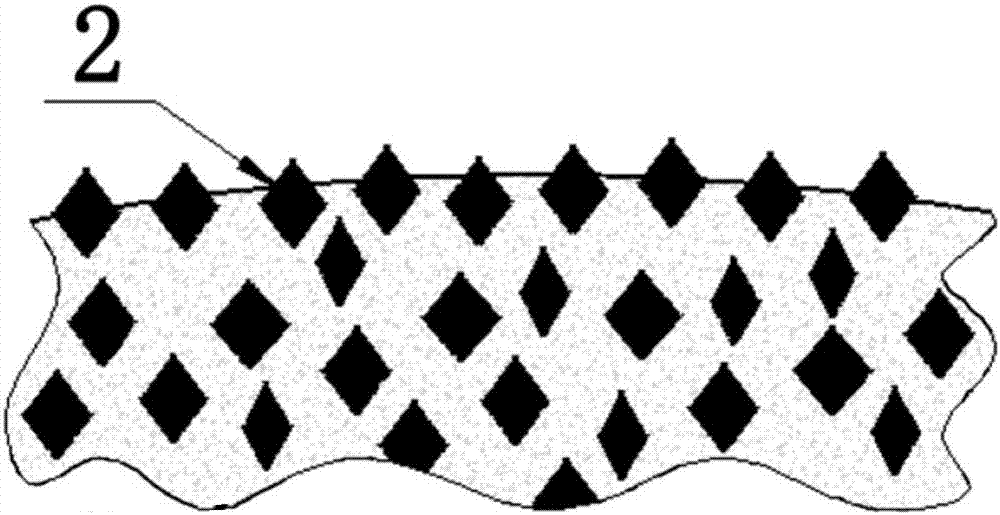

Ceramic bond grinding tool for oriented arrangement of abrasives and preparation method thereof

ActiveCN104999385AIncrease the number of effective grinding edgesImprove grinding ability of abrasive toolsAbrasion apparatusGrinding devicesSolventAbrasive

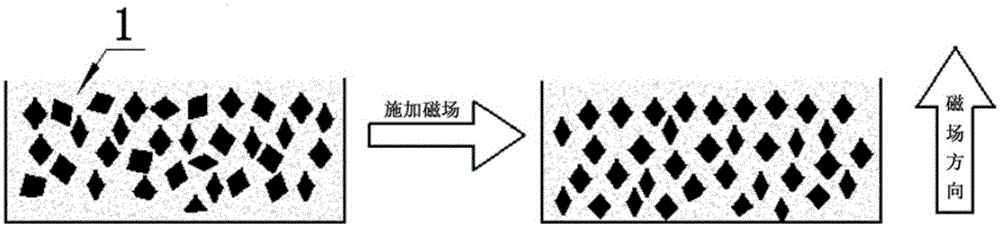

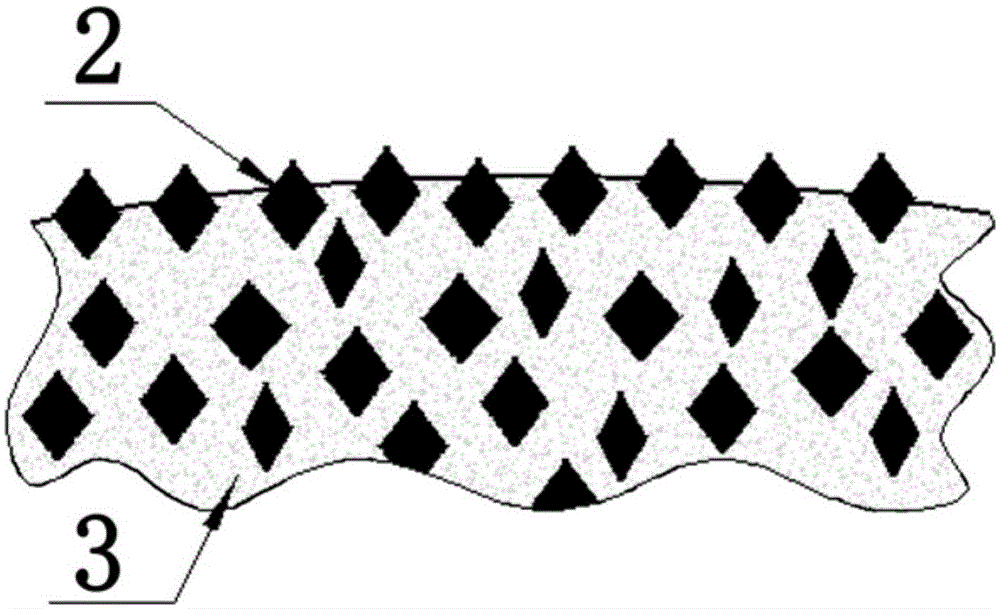

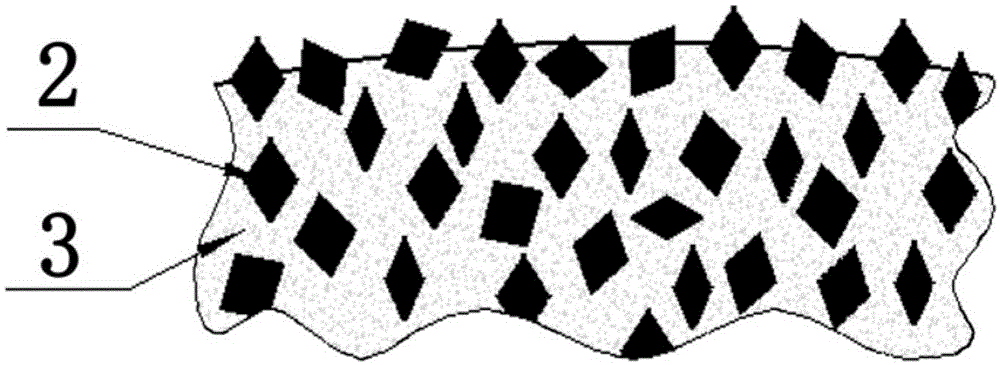

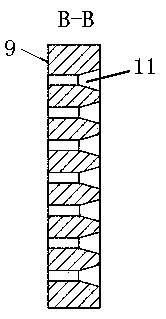

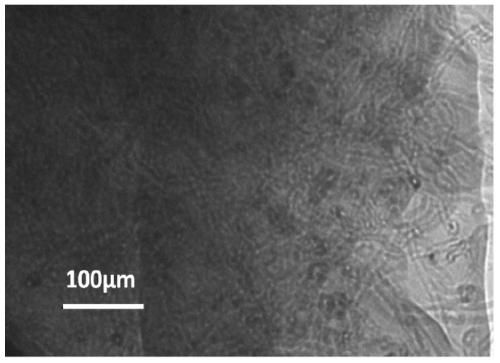

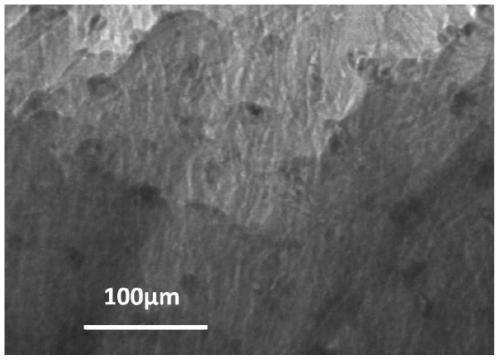

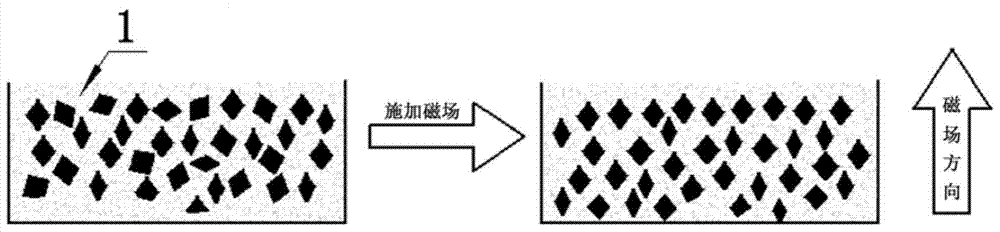

The invention discloses a ceramic bond grinding tool for oriented arrangement of abrasives and a preparation method thereof. The grinding tool is prepared by the method comprising the following steps: 1) the abrasives, a ceramic bond, a dispersing agent and a solvent are taken for mixing a slurry; 2) the obtained slurry is injected in a mold, and is put in a magnetic field with a strength of 1-50 T for magnetizing to obtain magnetized slurry; and 3) the magnetized slurry is dried and demolded to obtain a biscuit; and the biscuit is sintered and cured to obtain the ceramic bond grinding tool. In the ceramic bond grinding tool for oriented arrangement of abrasives, after the slurry is injected in the mold, the slurry is stood in the high-strength magnetic field; under the effect of electromagnetic force, the abrasives rotate to generate oriented arrangement; the ceramic bond grinding tool for oriented arrangement of abrasives is prepared through the oriented arrangement of the abrasives; an effective cutting edge in the grinding of the grinding tool is added; the grinding capacity of the grinding tool is improved; and the grinding surface quality is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

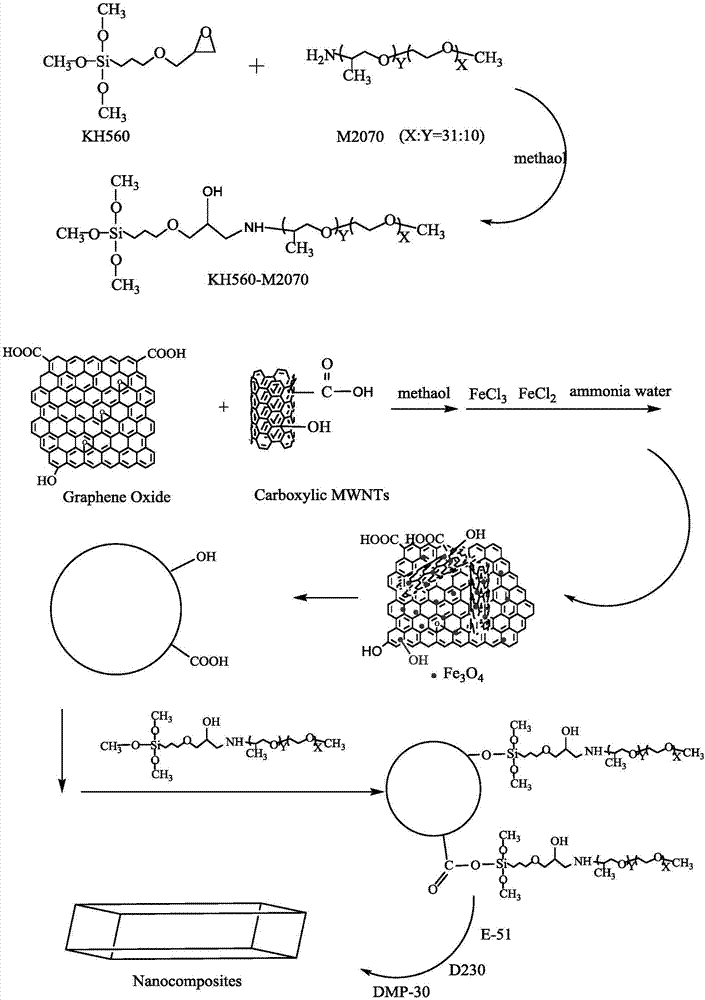

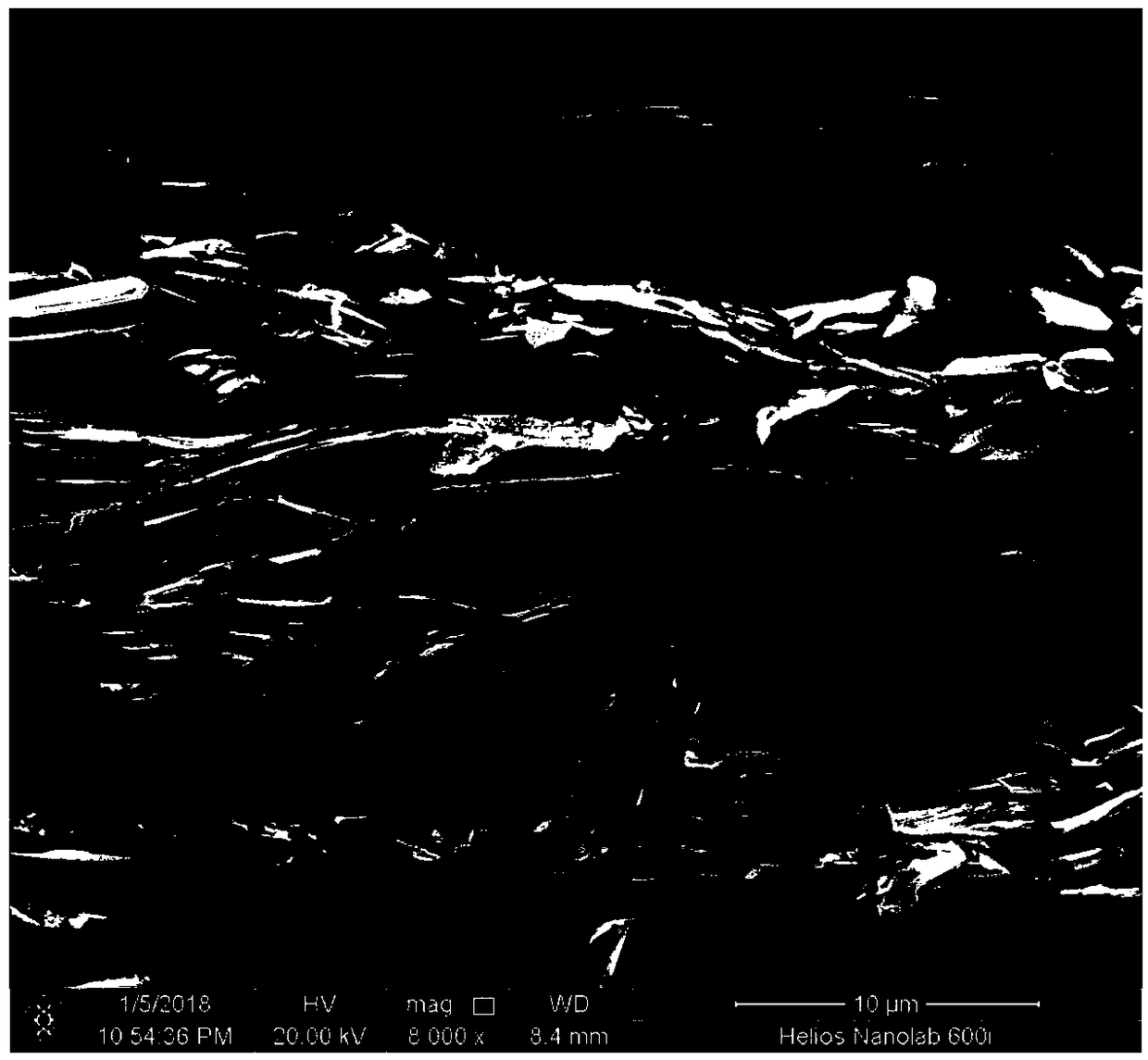

Solvent-free graphene/CNT (carbon nano tube)/Fe3O4 three-dimensional composite nano-fluid epoxy resin and preparation method thereof

The invention relates to solvent-free graphene / CNT (carbon nano tube) / Fe3O4 three-dimensional composite nano-fluid oriented reinforced epoxy resin composite material. Firstly, graphene oxide is compounded with an acidized CNT by a pi-pi bond; then, Fe3O4 is prepared by a coprecipitation method; the Fe3O4 is grafted on the surfaces of the graphene oxide and the acidized CNT, so as to obtain a magnetic graphene / CNT / Fe3O4 three-dimensional composite nano-particle. The magnetic graphene / CNT / Fe3O4 three-dimensional composite nano-particle is taken as a core, and a two-layer structure of a silane coupling agent and a polyether amine low polymer is grafted by a covalent bond, so that an obtained product is in a liquid state under the condition of the near room temperature; the obtained product isadded in an epoxy resin curing agent for curing, so as to obtain the oriented reinforced epoxy resin composite material. A preparation method is simple and easy, so that the graphene and the CNT attached on the graphene can be directionally arrayed in the epoxy resin, and the mechanical property and the thermal property to the epoxy resin can be improved certainly.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

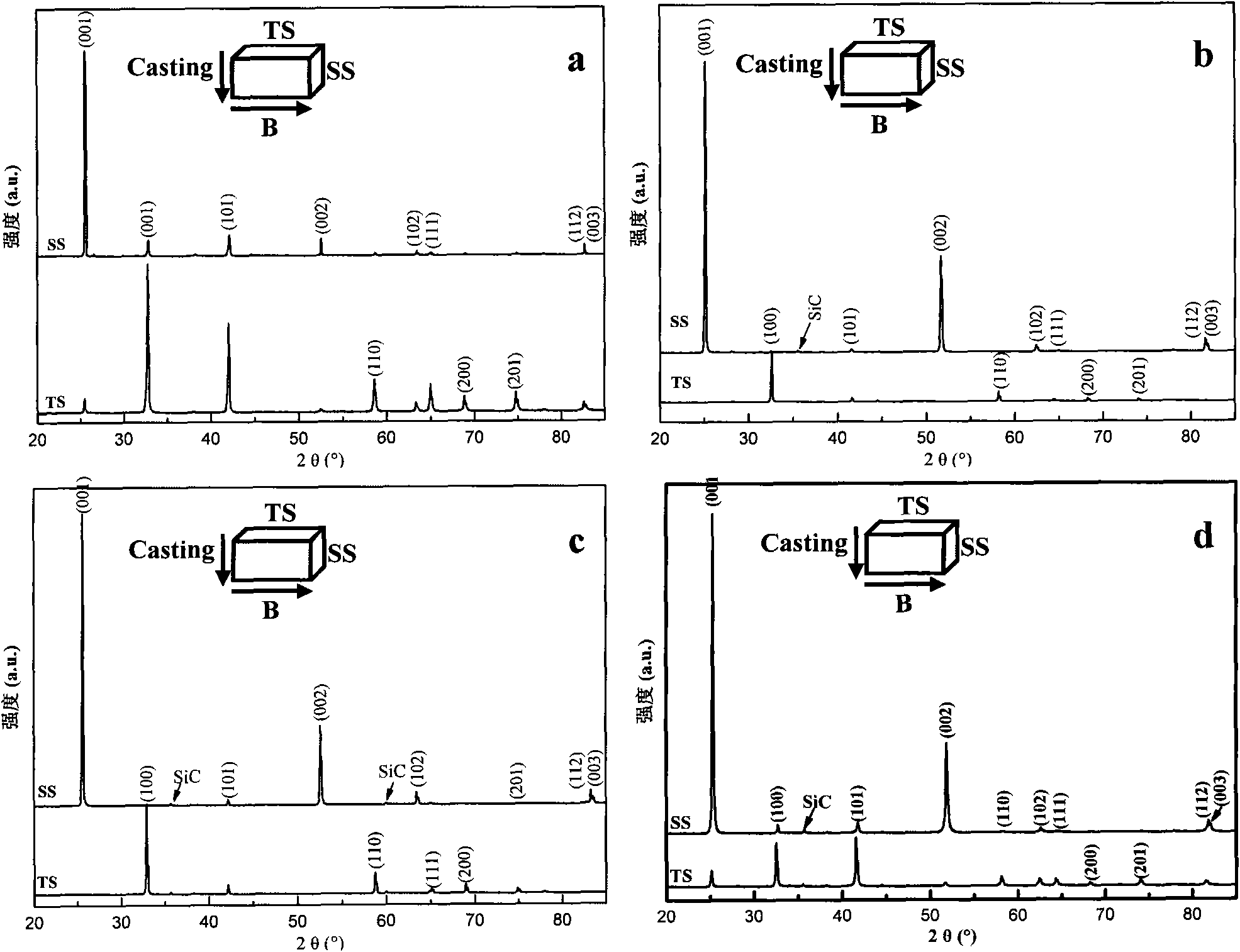

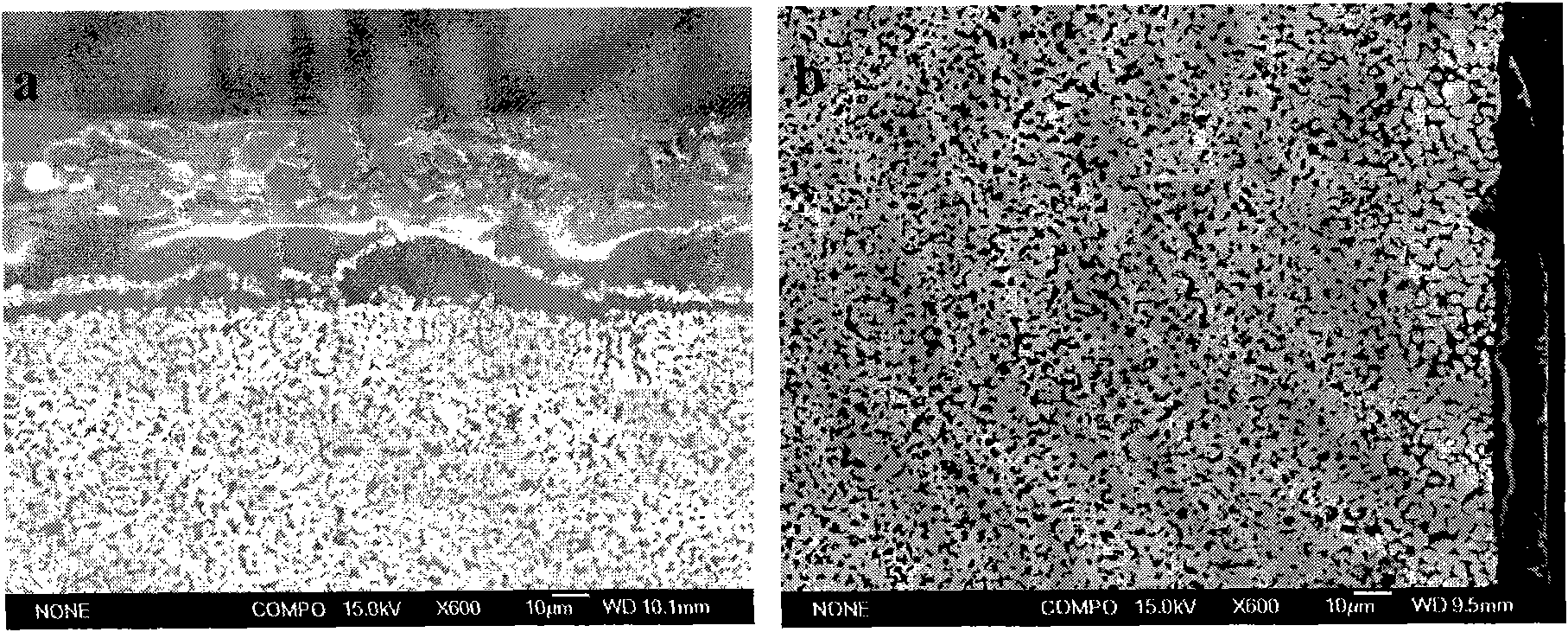

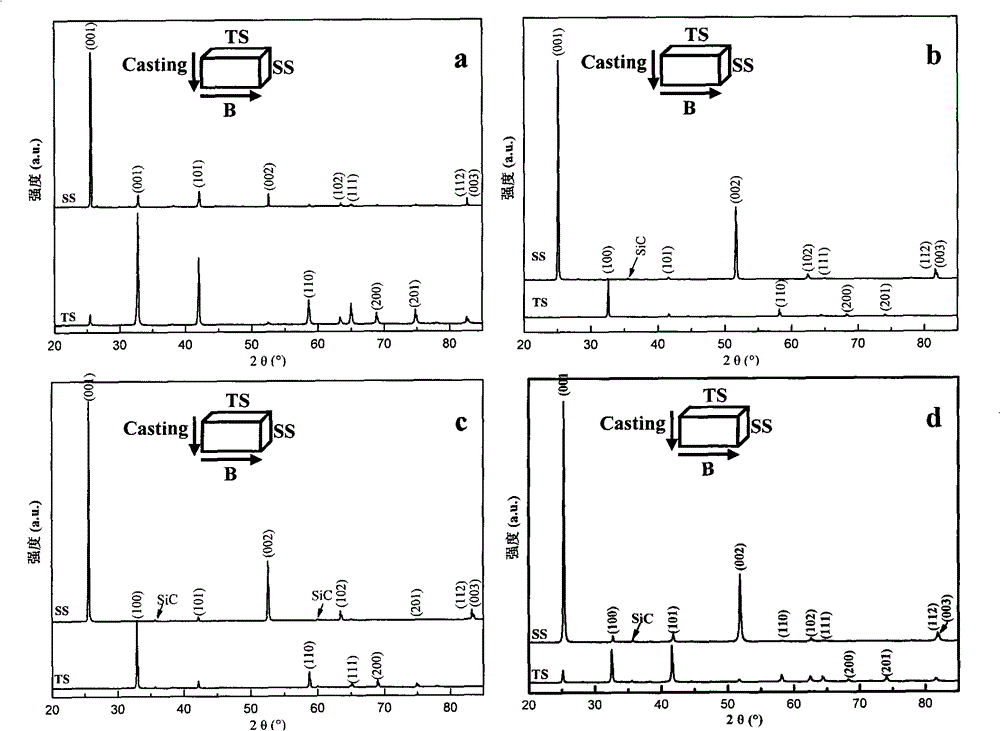

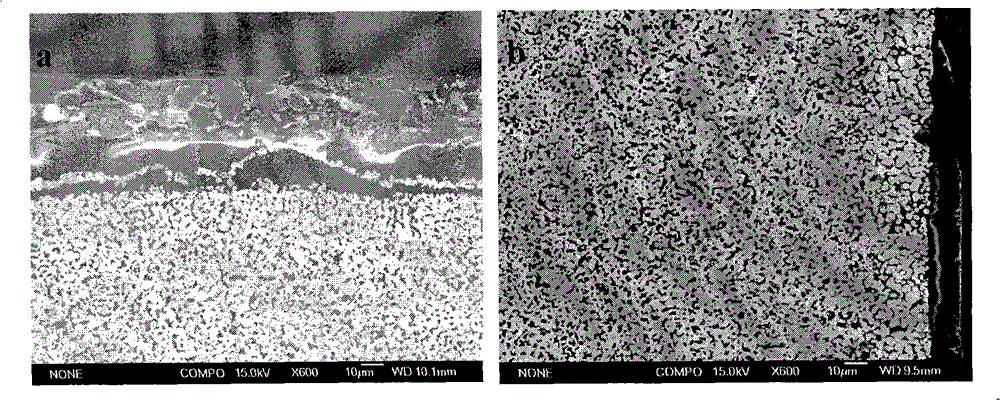

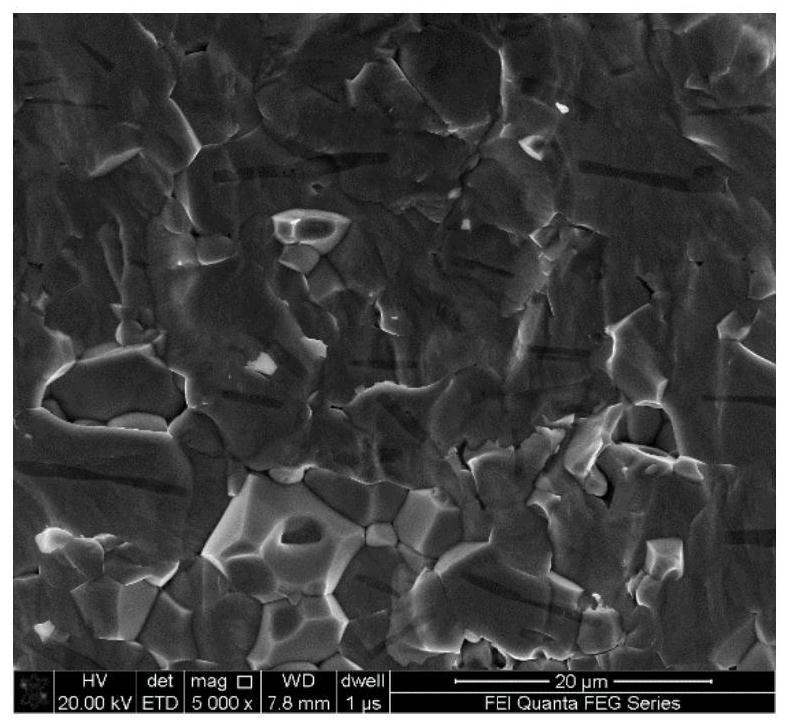

Texturing boride-based ceramics and preparing method thereof

The present invention relates to texturing boride-based ceramics and a preparing method thereof, which belongs to the field of structural ceramics material. MB2 powder is used as raw material powder in the present invention (M is Ti or Zr or Hf), and 0 to 40 wt% of beta-SIC powder is fed into the raw material powder. Polymine or acrylic copolymer is used as dispersant to be fed into water to formwater solution. The pH value of sizing agent water solution is adjusted to between 6.5 and 9, the raw material powder is mixed with the sizing agent water solution, and the mixture is defoamed. After sizing agent is casted to be solidified in the magnetic field of 10 to 30 T, the sizing agent is processed under the temperature of 500 to 700 DEG C. hot-press or discharging plasma sintering is used. Compact ceramics of which the relative density is larger than 97% is obtained by the present invention. Ceramics grains are arranged along the height orientation of (001) direction, Loterring orientation factor f(001) is larger than 0.85, and the mechanical property and the antioxygenic property appear obvious anisotropism.

Owner:中科西卡思(苏州)科技发展有限公司

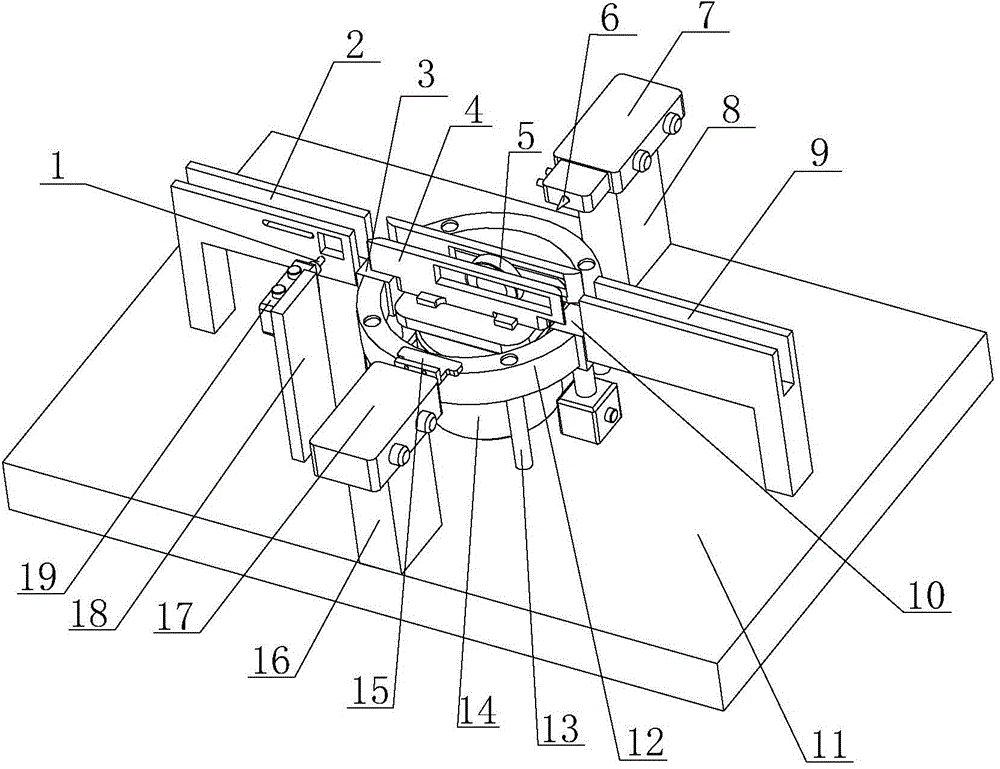

Automatic turning device for thrust ball bearing ferrule

The invention discloses an automatic turning device for a thrust ball bearing ferrule, and belongs to the technical field of bearing production equipment. The automatic turning mechanism comprises a motor, a positioning material channel and a circular check ring, wherein the top surface of the circular check ring is higher than the bottom surface of the positioning material channel; a workpiece inlet and a workpiece outlet of the circular check ring are respectively provided with an inlet stop block and an outlet stop block; the bottom surface of one end, connected with the workpiece inlet, of the positioning material channel is always higher than the end connected with the workpiece outlet; when the two stop blocks fall down, the top surfaces of the two stop blocks are not higher than the bottom surface of the positioning material channel; a positioning mechanism and a detection mechanism are respectively arranged on the two sides of the positioning material channel; through holes for realizing pressing of the positioning mechanism and detection of the detection mechanism are respectively formed in two side baffles of the positioning material channel; a quantification mechanism is arranged on the side of a material feeding channel; a control system controls a motor, a positioning pressing block driving mechanism, a probe driving mechanism and a quantification mechanism and drives cylinders of the inlet stop block and the outlet stop block to operate. The automatic turning device meets the demand that the end faces of the ferrule are needed to uniformly face to a direction during processing of the thrust ball bearing ferrule.

Owner:浙江盛达物联科技股份有限公司

Preparation process of composite material laminated plate formed by directionally arranging carbon nano-tubes

ActiveCN106084264AEasy to operateImprove mechanical propertiesSynthetic resin layered productsLaminationCarbon nanotubeHigh frequency

The invention provides a preparation process of a composite material laminated plate formed by directionally arranging carbon naon-tubes. The preparation process is characterized by comprising the following steps: (1) mixing acetone with carbon nano-tubes in a mass ratio of 100: 1, stirring for 5 min by using a high-speed cutting stirrer at the stirring rate of 20000 r / min, and drying for standby use; ..., (5) hot pressing and forming a prepreg with the upper surface and lower surface respectively laid with a copper film electrode in a composite material hot vulcanizing instrument, first heating to 40 to 60 DEG C, respectively introducing high-frequency pulse alternating-current power to the copper film electrodes at the upper end and lower end of the prepreg, wherein the electrification time is 5 to 10 minutes, removing the power after the electrification, then heating to a curing temperature of epoxy resin, thermally insulating for 2h, naturally cooling, and demolding to prepare the composite material laminated plate of carbon fiber / epoxy resin filling the carbon nano-tubes. According to the preparation process, the carbon naon-tubes are directionally arranged along the thickness direction (direction Z) of the laminated plate by utilizing a high-frequency pulse electric field, so that the preparation process is simple to operate, and the produced composite material has excellent performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

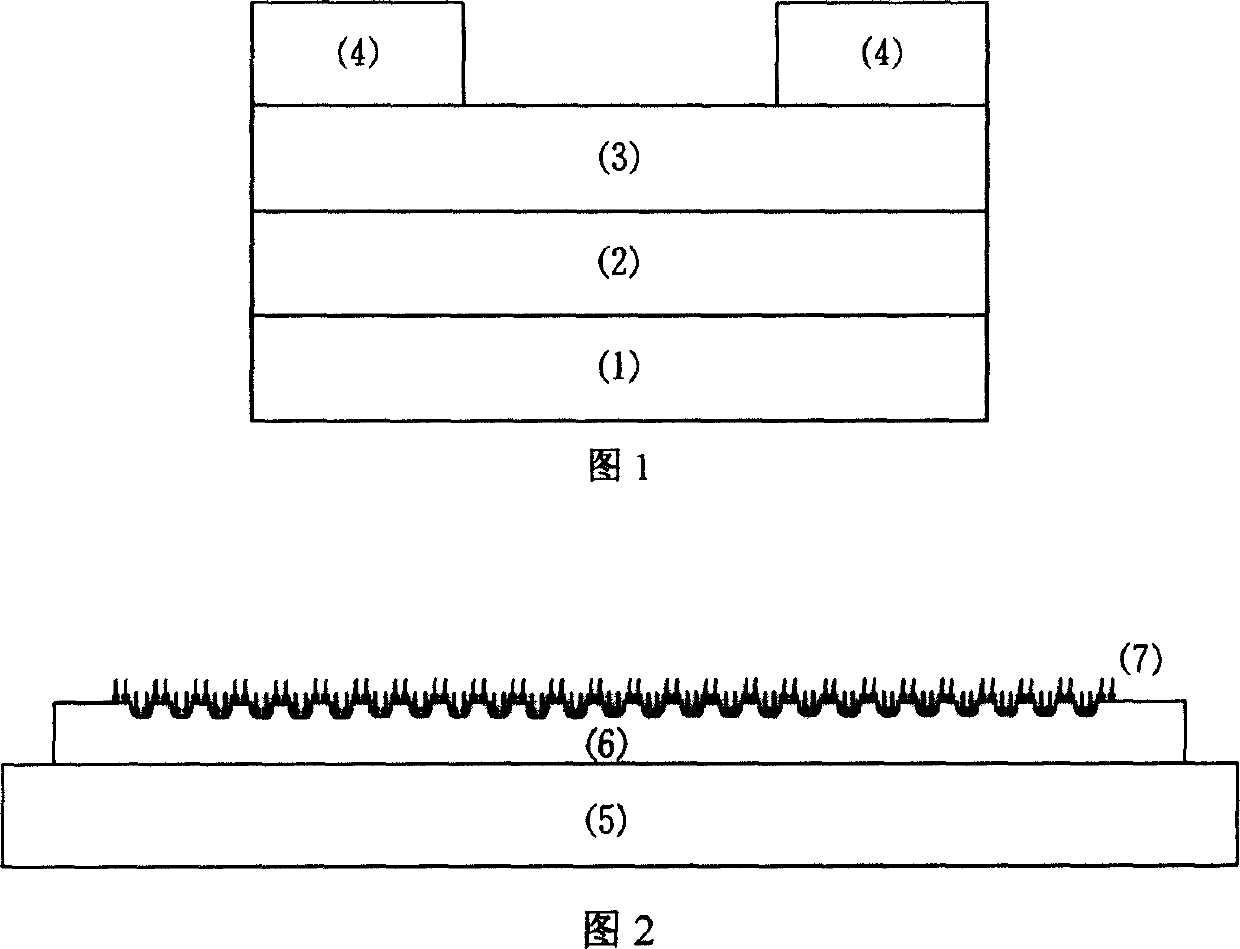

Organic field effect tube using single molecular layer as oriented transfer layer and its preparing method

InactiveCN1684286AIncreased anisotropyImprove performanceSolid-state devicesSemiconductor/solid-state device manufacturingMolecular arraySilanes

This invention provides an OFET device and its preparation method including an orientation transfer layer for transferring orientation efficiency, which can increase the carrier mobility of the OFET since the orientation transfer layer is the insulation one. Said one is a mono-film formed by processing the surface with silane coupler which can optimize the orientation result of the orientation layer and transfer it to the organic layer. This invention can improve molecular arrays of the organic molecular layer by transferring the orientation result to improve the carrier mobility of the OFET devices applying said orientation layer.

Owner:FUDAN UNIV

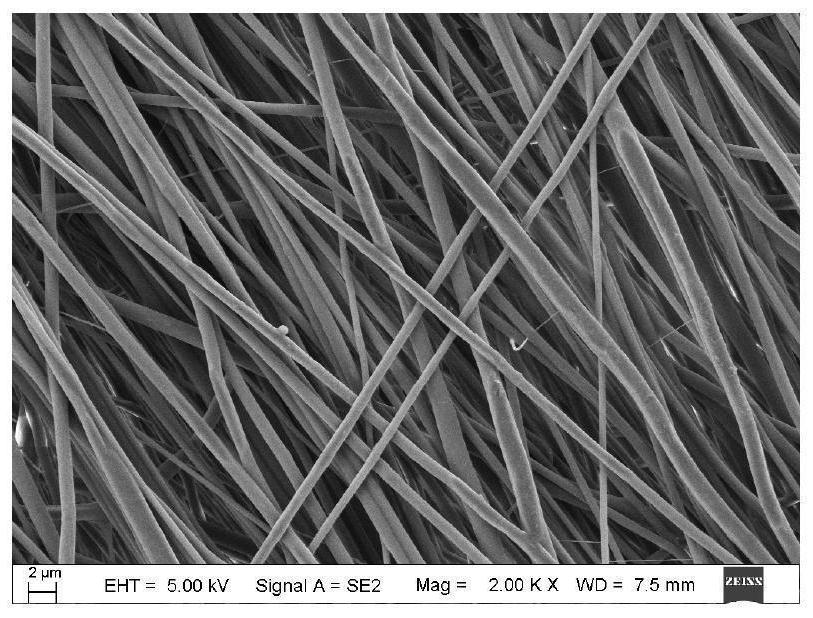

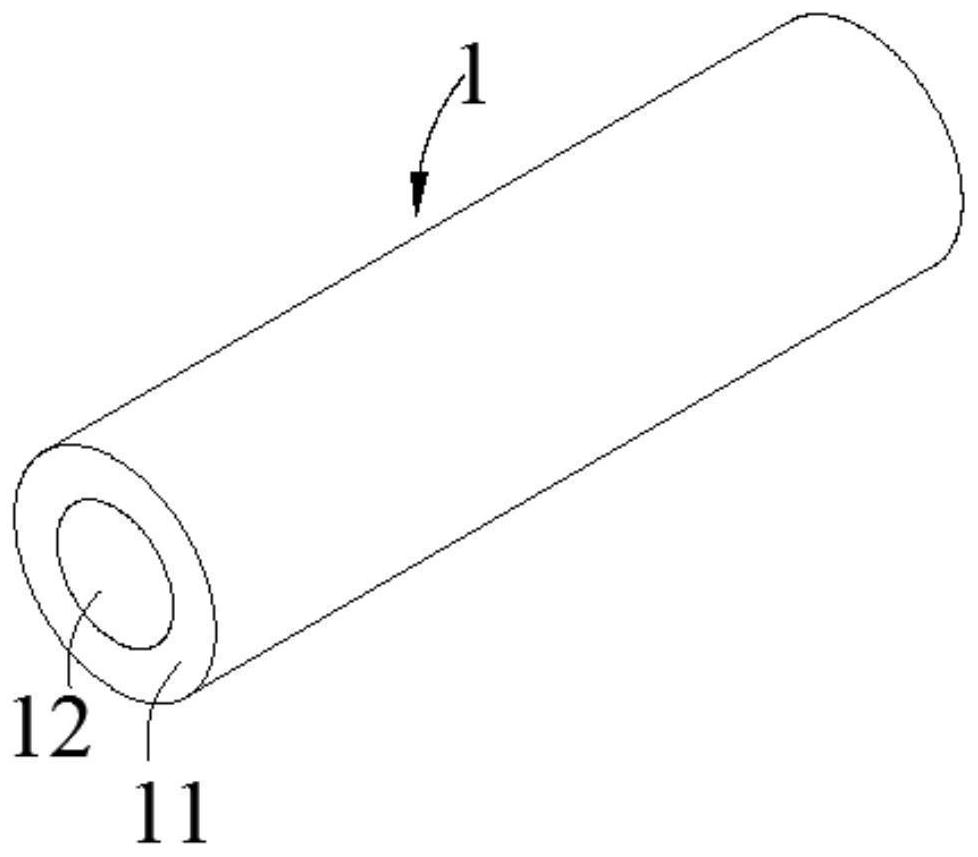

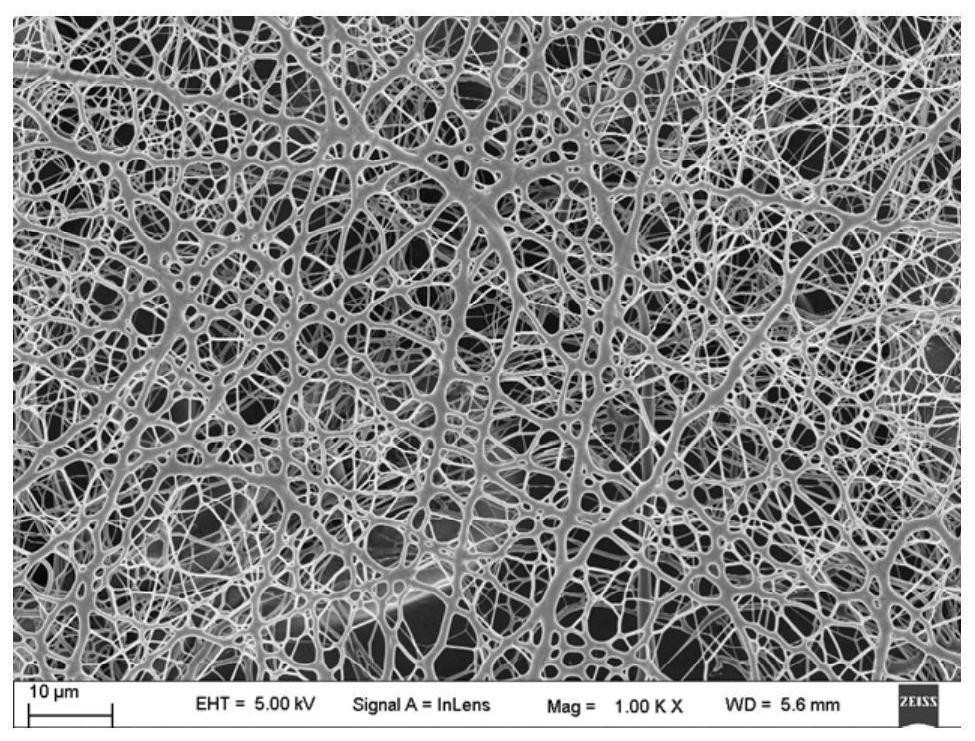

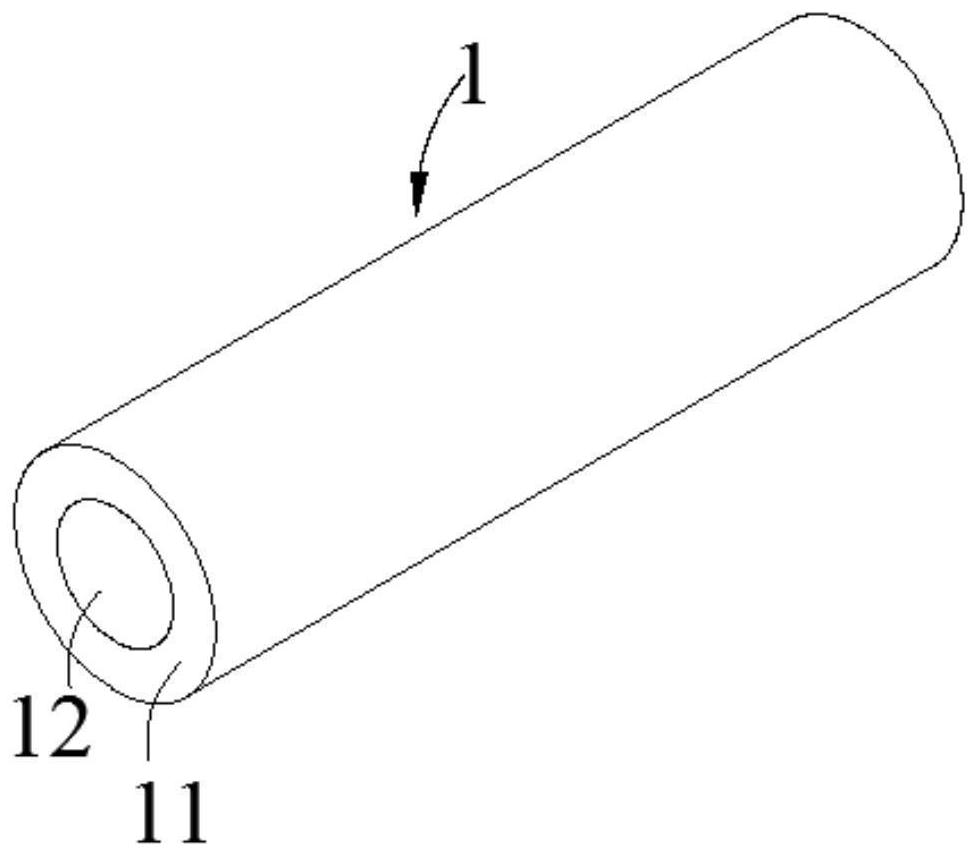

Chitosan-based nerve fiber membrane, preparation method, nerve conduit and application

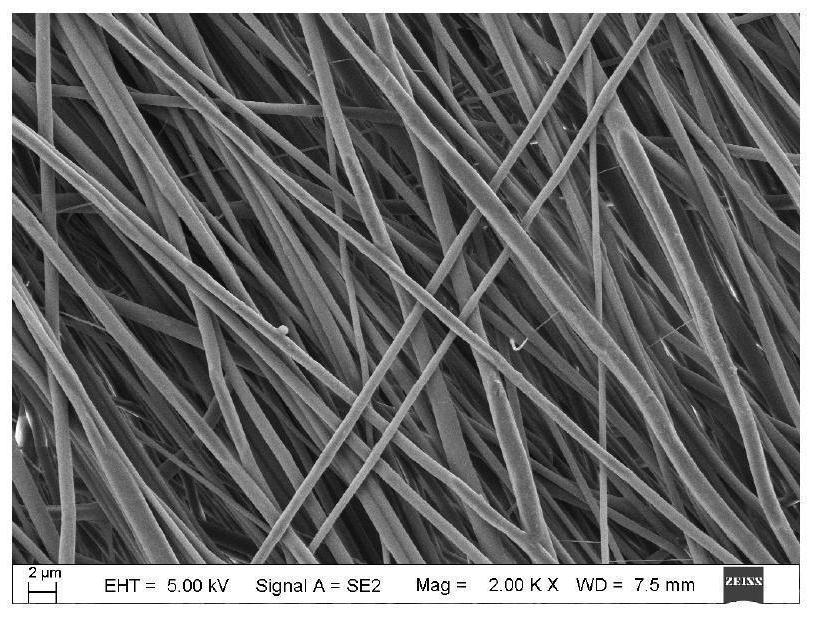

ActiveCN111632193AEasy alignmentImprove mechanical propertiesPharmaceutical delivery mechanismTissue regenerationNervous tissueNerve fiber

The invention relates to the technical field of nervous tissue engineering materials, and particularly provides a chitosan-based nerve fiber membrane, a preparation method, a nerve conduit and application. The chitosan-based nerve fiber membrane is formed by a plurality of composite nanofibers which are arranged in an directional manner; each composite nanofiber is of a core-shell structure, a shell layer of each nanofiber comprises a degradable functional material, a hydrophilic functional group modified carbon nanotube, lycium barbarum polysaccharide and chitosan and / or a chitosan derivative, and a core layer of each nanofiber comprises a nerve growth factor and a stabilizer. The chitosan-based nerve fiber membrane disclosed by the invention has the characteristics of good orientation arrangement, good mechanical property and high biological responsiveness; and during degradation, the chitosan and / or chitosan derivative hydrolysate and alkalinity of amino groups carried by the chitosan and / or the chitosan derivative hydrolysate can effectively neutralize weak acidity of degradation products, influences of acidic degradation products on the surrounding environment and tissues areavoided, and therefore the fiber membrane can be applied to nerve repair and regeneration of human bodies and animal bodies.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

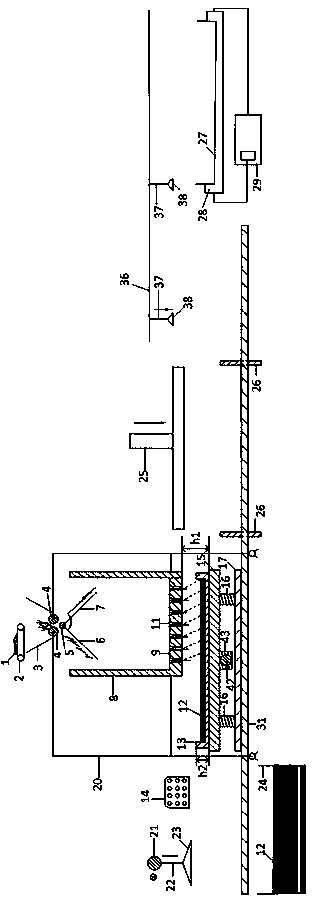

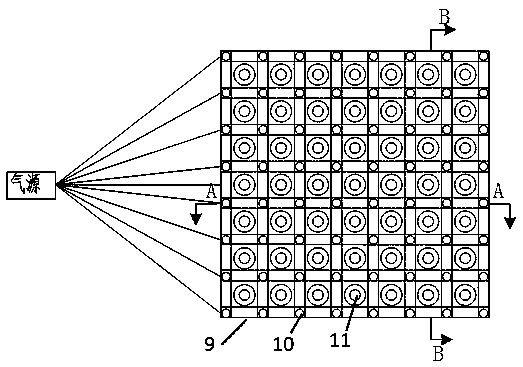

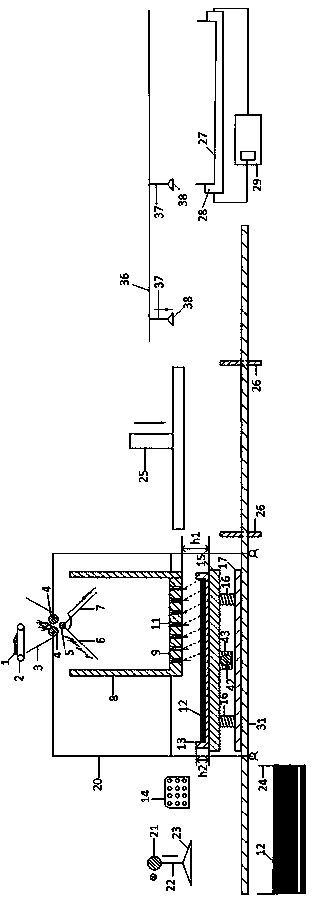

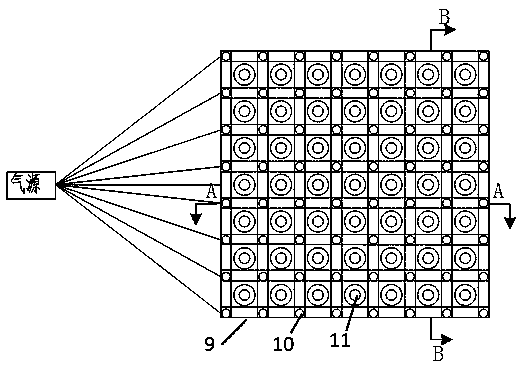

Directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method

The invention discloses a directional silk distribution short carbon fiber thermoplastic resin based prepreg preparation device and method and belongs to the field of composite material preparation. By utilizing the special structure of a vibration sieve, through the restriction effect of vibration sieve holes, carbon fiber silks which fall off through vibration from slender sieve holes to performvertical motion of a free falling body; when one ends of the fiber silks are adhered to a resin film in the falling process, the carbon fiber silks are reversely fixed by utilizing the viscosity of the resin film and one-way relative motion of the carbon fiber silks and a two-dimensional movement platform, directional arrangement and uniform distribution of carbon fibers in a movement direction are realized, and the problems of uneven distribution and difficulty in orientation of short carbon fibers in thermoplastic resin are well solved; and through control on a movement speed of the two-dimensional movement platform and control on number of times of laying, accurate control on the content of the carbon fibers in a prepreg is realized, orientation of the carbon fiber silks can be an arbitrary two-dimensional direction, crossing distribution of multiple layers of resin films and multiple layers of carbon fibers is realized, and the mechanical performance of a carbon fiber composite material is improved.

Owner:JIANGSU UNIV

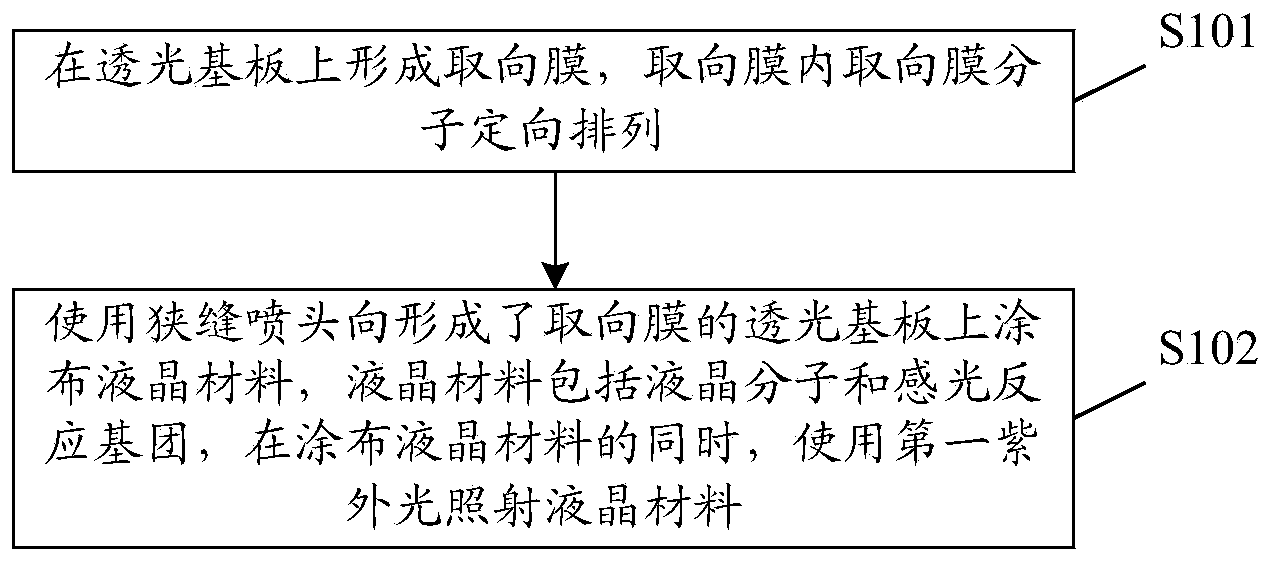

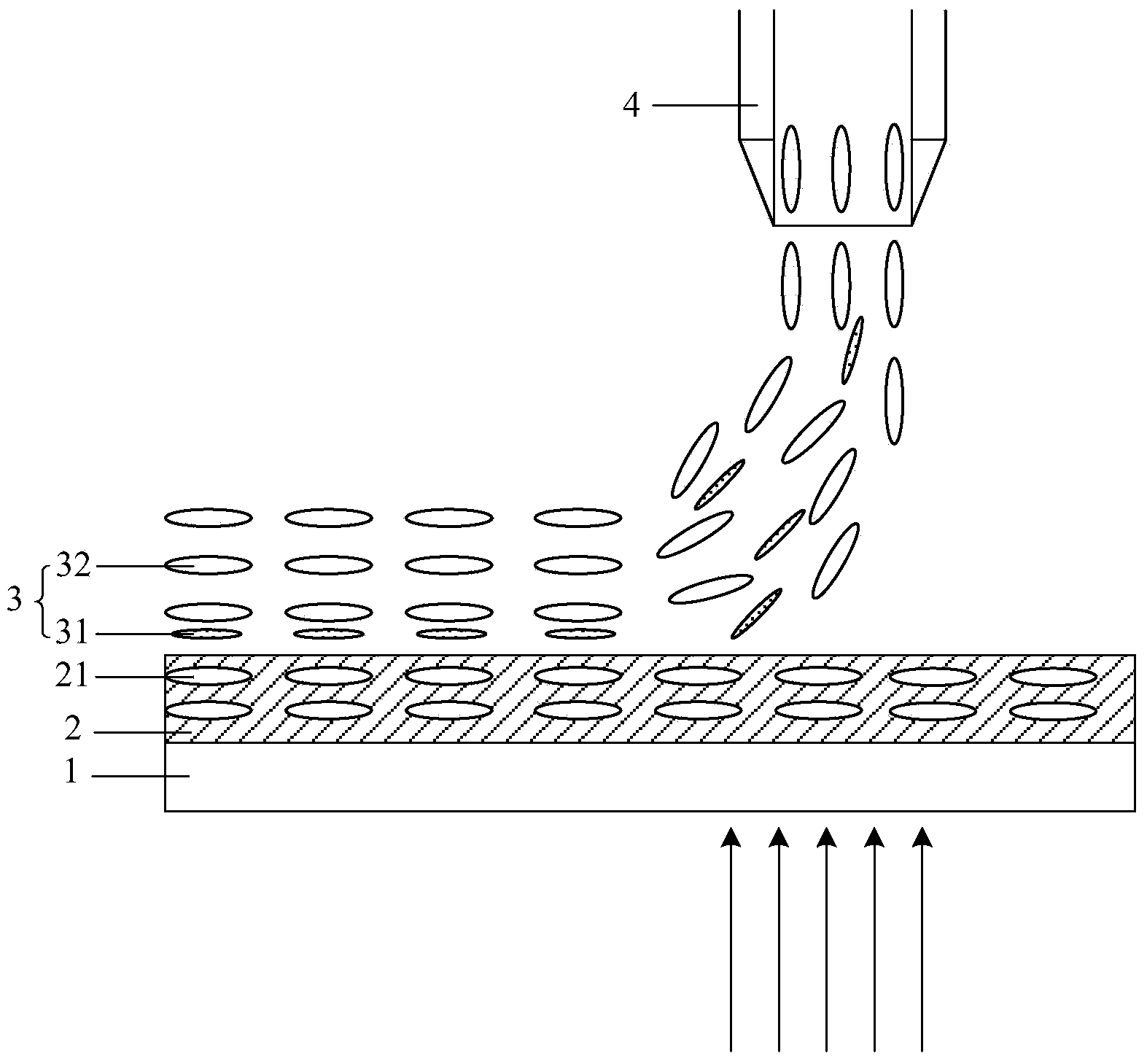

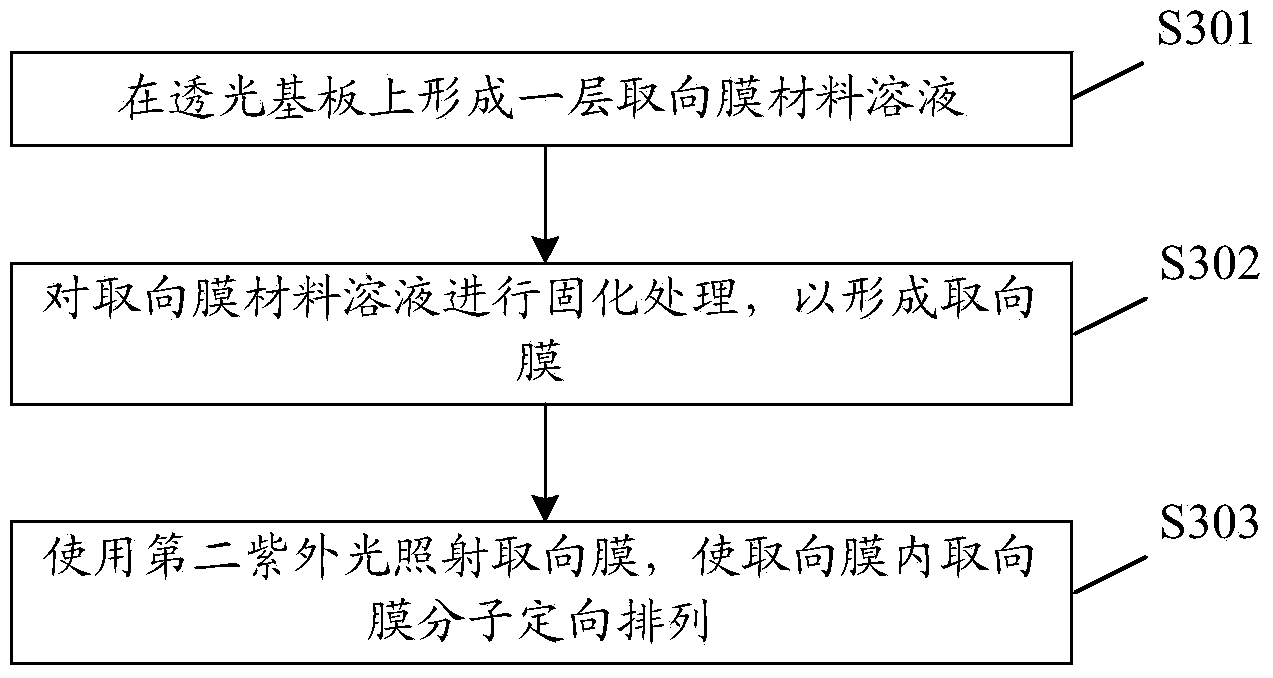

Liquid crystal coating method and display panel manufacturing method

InactiveCN104020609AImprove the display effectAchieve directional alignmentPretreated surfacesCoatingsUltraviolet lightsOptoelectronics

The embodiment of the invention discloses a liquid crystal coating method and a display panel manufacturing method and relates to the technical field of display. Orientation arrangement of liquid crystal molecules are achieved while liquid crystals are coated, so that orientation films and the instilled liquid crystal are prevented from being rubbed. The liquid crystal coating method comprises the steps that the orientation films are formed on a light-transmitting substrate, and the orientation film molecules are arranged in the orientation films in an orientation mode; a slit shower nozzle is used for coating the liquid crystal materials on the light-transmitting substrate with the formed orientation films, and the liquid crystal materials comprise the liquid crystal molecules and light-induced reaction groups; while the liquid crystal materials are coated, first ultraviolet light is used for irradiating the liquid crystal materials.

Owner:BOE TECH GRP CO LTD +1

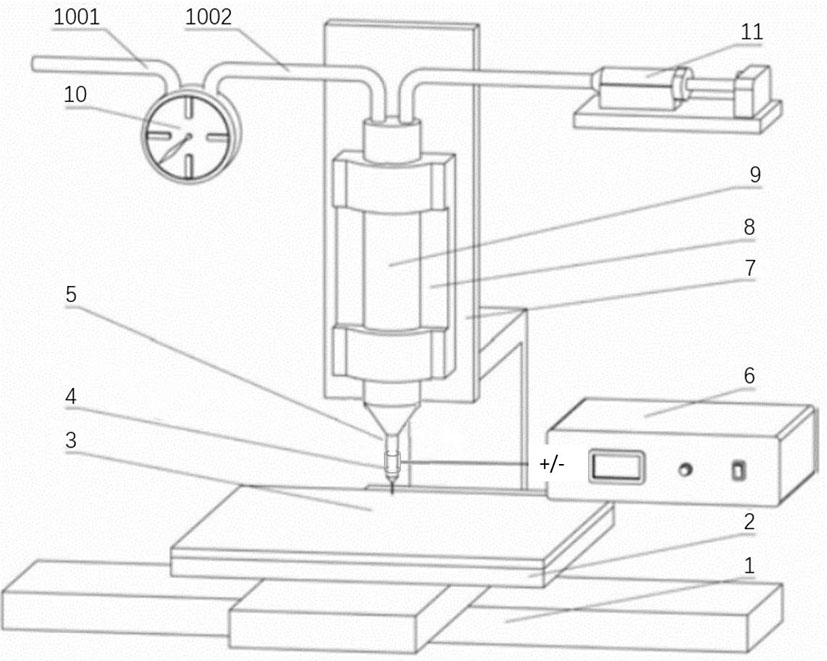

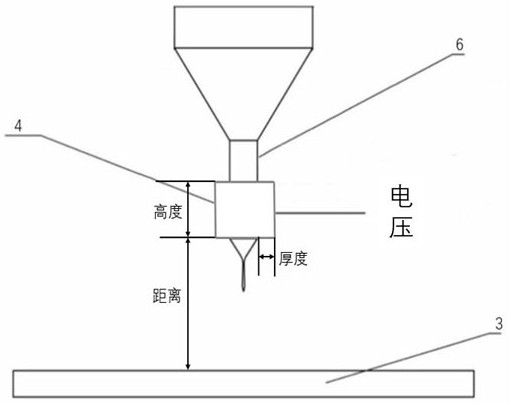

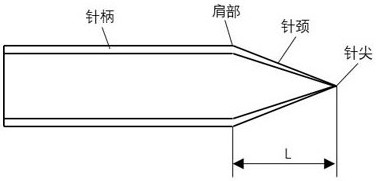

Spray deposition 3D printing device based on self-excitation electrostatic field driving, working method and application of working method of spray deposition 3D printing device based on self-excitation electrostatic field driving

ActiveCN112122614AIncreased field strengthIncrease field strengthMaterial nanotechnologyAdditive manufacturing apparatusCopper foilAlternating current

The invention discloses a spray deposition 3D printing device based on self-excitation electrostatic field driven and application of a method on printing superfine silver grids. The limitation of existing material spray deposition 3D printing in the aspects of nozzle materials, substrate materials, printing stability and the like is broken through, only one electrode is arranged a whole system, acopper foil patch is connected with an alternating-current power supply to serve as an extraction electrode and is tightly attached to the shoulder of a glass nozzle in a wound mode, parameters of thecopper foil patch are simulated and optimized through finite elements to provide the optimal electric field focusing effect, an electric field with enough strength can be obtained under the conditionthat the voltage is smaller, the power supply does not make contact with a material, material spraying is completed only by means of electric field force formed by electrostatic induction, the wholeprinting process is not interfered by residual charges, stable printing under the condition of ultrahigh resolution is achieved, when a high-viscosity nano-silver paste is used as a printing material,single-row directional arrangement of nano-silver particles is achieved, a very large height-width ratio is achieved, and the height-width ratio can still reach 0.44 when the line width of a single-layer silver line is 3 microns.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

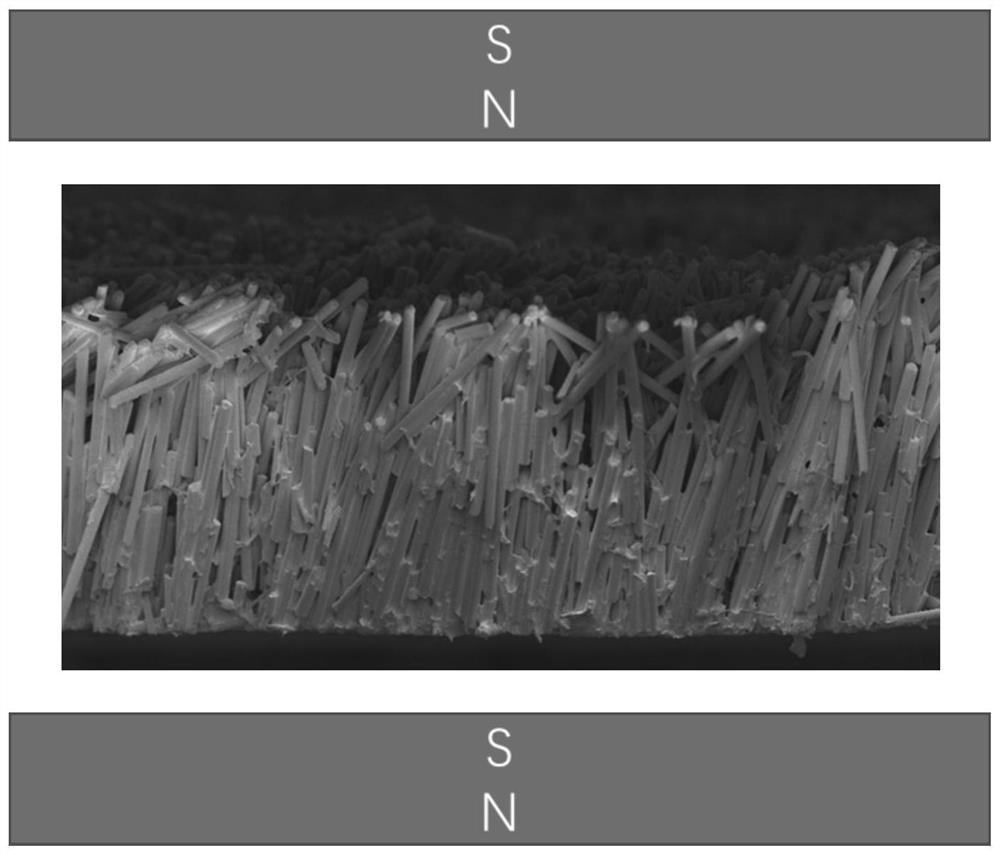

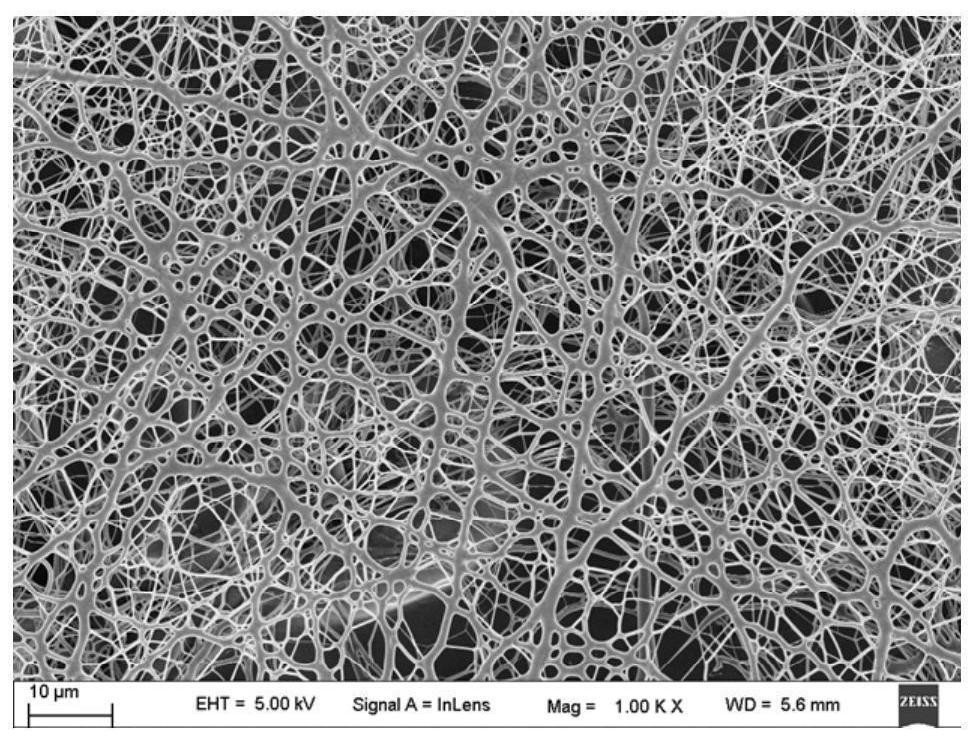

Magnetic field induced arrangement carbon fiber heat conduction material and preparation method thereof

PendingCN114456603AEasy to prepareEasy to promoteHeat-exchange elementsFirming agentPolymer chemistry

The invention discloses a magnetic field induced arrangement carbon fiber heat conduction material and a preparation method thereof, and relates to the technical field of heat management. The magnetic field induced arrangement carbon fiber heat conduction material comprises, by mass, 5-80% of carbon fibers, 10-85% of a polymer matrix, 5-15% of a curing agent, 5-15% of a film forming agent and 0.1-1% of a catalyst. The method comprises the following steps: adding 5-80% of carbon fibers into a polymer matrix, and carrying out mechanical stirring and ultrasonic dispersion to obtain a dispersion; adding a film-forming agent and a catalyst into the dispersion, and then carrying out mechanical stirring for less than or equal to 1 min to obtain a mixture; transferring the mixture into a glass or other non-magnetic container; the container and the mixture are transferred into a magnetic field, one surface of the container is perpendicular to the magnetic induction intensity direction, the mixture is changed into a solid state from a liquid state, and the mixture is moved out of the magnetic field; and transferring the solid mixture to an electrothermal constant-temperature blast drying box, and further heating and curing to obtain the directionally-arranged carbon fiber heat-conducting material.

Owner:XIAMEN UNIV

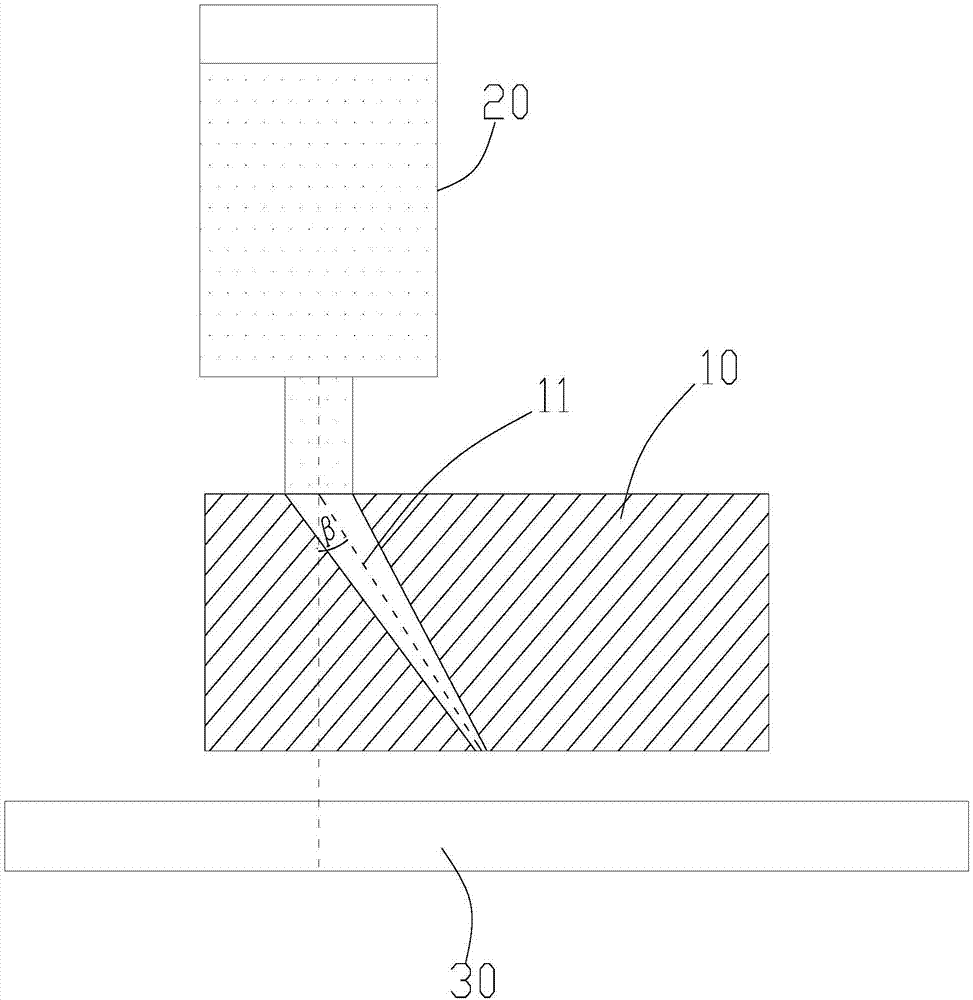

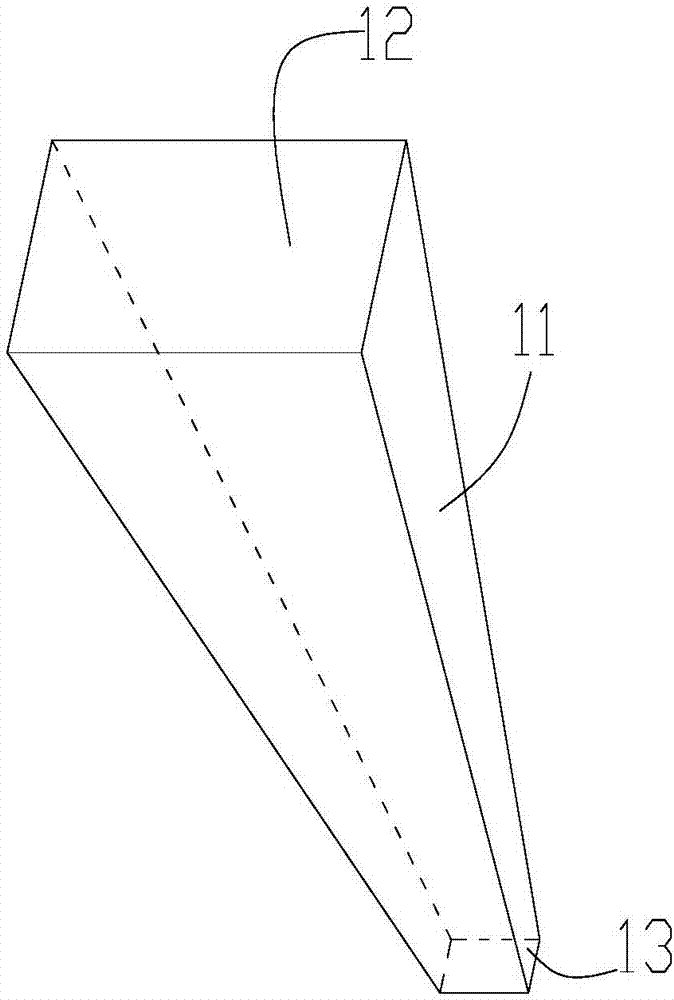

Dispensing equipment and method for preparing high thermal conducting interface material by adopting dispensing equipment

The invention discloses dispensing equipment, and further discloses a method for preparing a high thermal conducting interface material by adopting the dispensing equipment. The dispensing equipment comprises a dispensing die. The dispensing die is provided with a glue extruding channel. The glue extruding channel comprises a glue extruding channel inlet penetrating through the top surface of thedispensing die and a glue extruding channel outlet penetrating through the bottom surface of the dispensing die. The cross section area of the glue extruding channel decreases gradually from top to bottom. An included angle beta being 30-90 degrees is formed between the center axis of the glue extruding channel and a vertical line. The dispensing equipment has the characteristics that the structure is simple, the cost is low, and directional arrangement of carbon fiber can be achieved; the method can achieve directional arrangement of the carbon fiber, manufacturing of a large area of the highthermal conducting interface material can be achieved, and the high thermal conductivity interface material manufactured and obtained by adopting the method has excellent thermal conducting performance.

Owner:彗艺新材料科技(佛山)有限公司

Orientation heat transfer hexagonal boron nitride/cordierite textured ceramic and preparation method thereof

PendingCN108640690ASimple processSignificant directional heat transfer characteristicsCordieriteThermal conductivity

The invention relates to an orientation heat transfer hexagonal boron nitride / cordierite textured ceramic and a preparation method thereof, in particular to textured ceramic and a preparation method thereof. The invention aims to solve the problem of small heat conductivity difference between a direction of the h-BN textured ceramic perpendicular to a slice layer and a direction of the h-BN textured ceramic parallel to the slice layer. The orientation heat transfer hexagonal boron nitride / cordierite textured ceramic is prepared from the components in mass fraction: h-BN powder, MgO powder, nanometer Al2O3 powder and melted quartz powder. The preparation method comprises the steps of weighing the raw materials, mixing the raw materials, evaporating, drying and sieving; then loading into a graphite die, prepressing to obtain a blank body, and finally hot pressing and sintering. According to the orientation heat transfer hexagonal boron nitride / cordierite textured ceramic and the preparation method thereof provided by the invention, the hexagonal boron nitride / cordierite textured ceramic with a texture characteristic is prepared through a hot pressing and sintering technology, and theorientation degree of h-BN crystal particles is improved, so that the orientation heat transfer of the h-BN ceramic is realized, and the heat conductivity difference between the direction perpendicular to the slice layer and the direction parallel to the slice layer is 12.2 times. The orientation heat transfer hexagonal boron nitride / cordierite textured ceramic and the preparation method thereofprovided by the invention are applicable to preparing a textured ceramic heat protection material.

Owner:HARBIN INST OF TECH

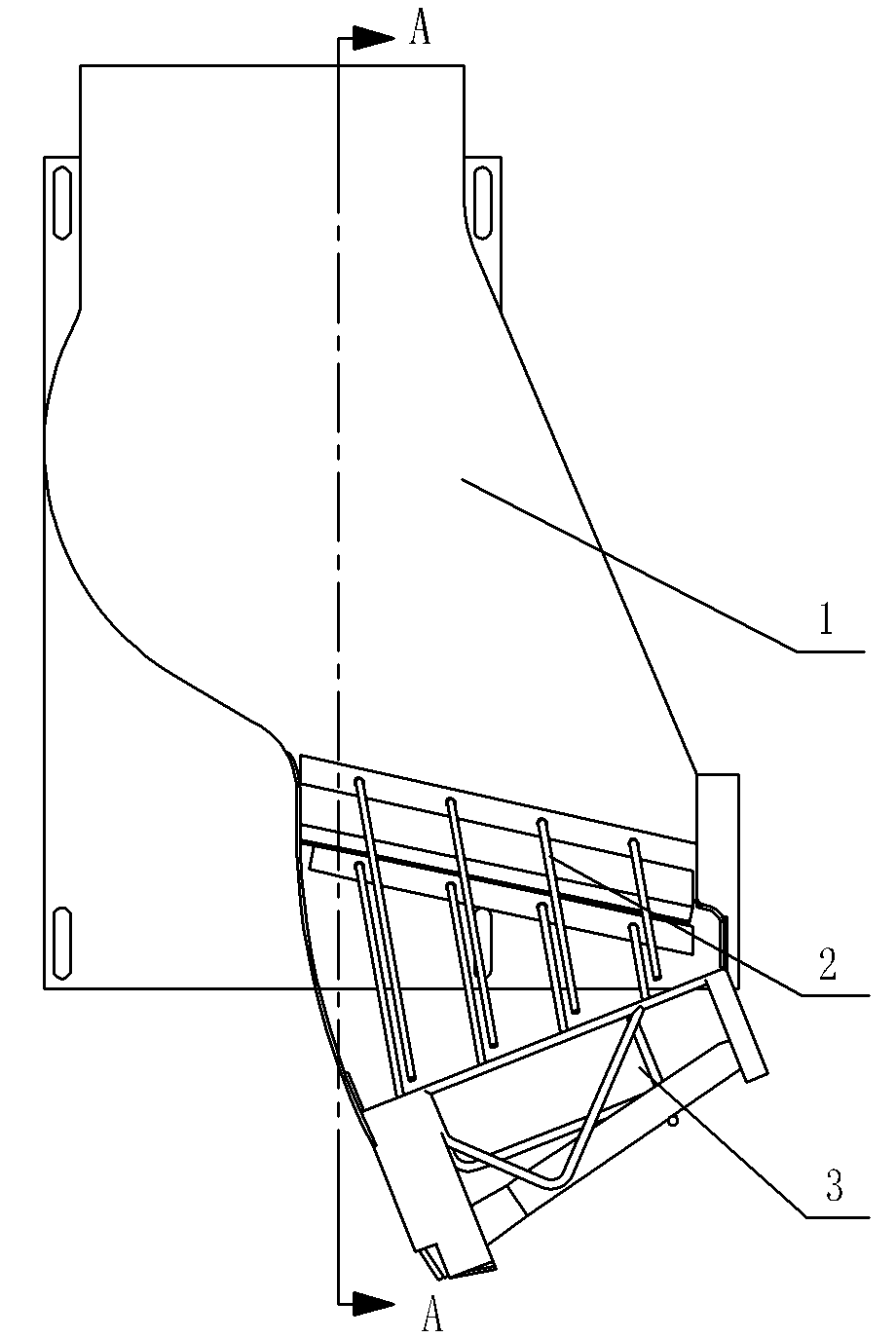

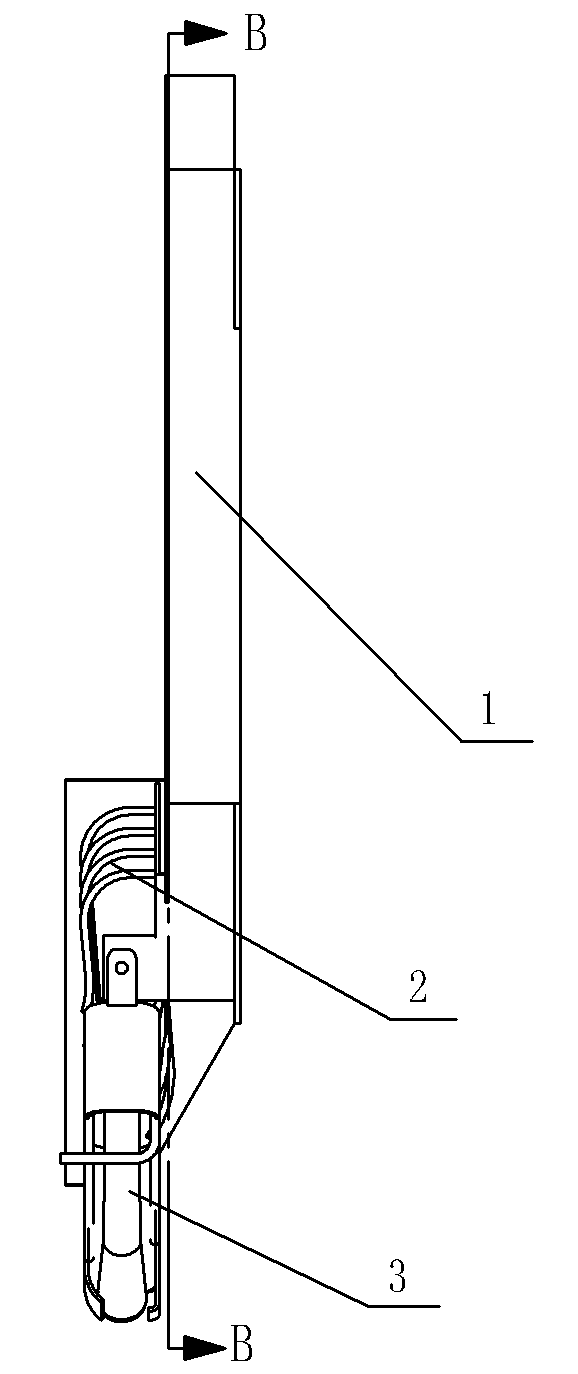

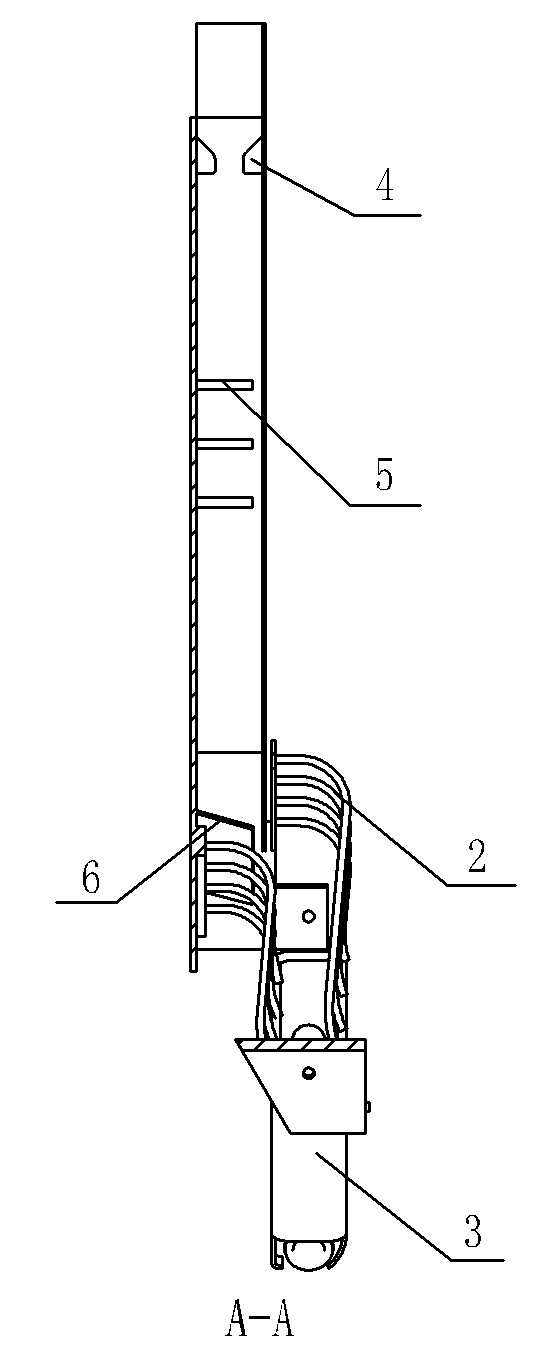

An apparatus for directionally arranging blank tubes of an automatic doffer

InactiveCN102719946ARealize automatic U-turnAchieve directional alignmentTextiles and paperEngineeringInternal cavity

Provided is an apparatus for directionally arranging blank tubes of an automatic doffer and relates to the field of spinning machinery. Artificial doffing and tube sleeving is basically applied to the prior ring spinning frame, causing high labor intensity and low efficiency. The apparatus comprises a hollow box body with openings on both the top and the bottom thereof. A pair of projections, which are mounted on both the left and the right sides of the interior of the top opening, forms a crack with the width less than the diameter of the large end of one blank tube but slightly greater than the small end of the same, and the width of the middle part of the top opening is greater than the diameter of the large end of the blank tube. A concave arc surface is formed by the out-extending left sidewall of the box body. A shunting and guiding mechanism, which is mounted in the inner chamber of the box body, is connected with the top opening at the middle part thereof and divides the inner chamber of the box into a left channel and a right channel. A horizontal baffle is mounted at the bottom opening of the box body. The apparatus, which achieves the automatic u-turn of the blank tubes, satisfies the requirement that the large ends and small ends of the blank tubes are arranged towards same direction when the ring spinning frame performs automatic sleeving so that the directional arrangement for the ring spinning frame under automatic sleeving is achieved, labor intensity of workers and labor cost are reduced, and production efficiency is enhanced.

Owner:浙江今朝智能装备有限公司

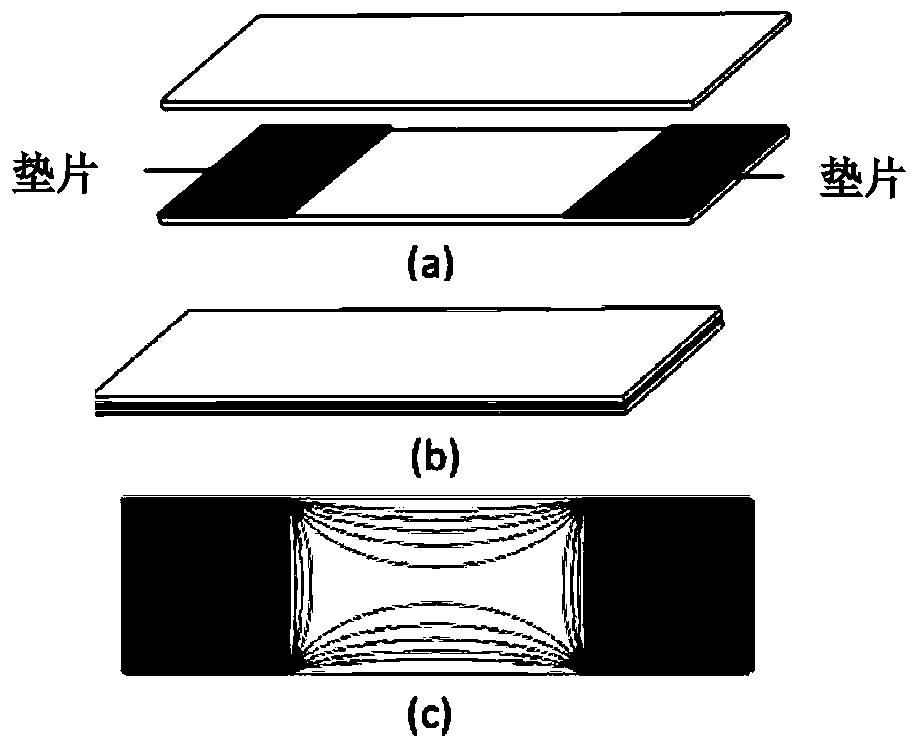

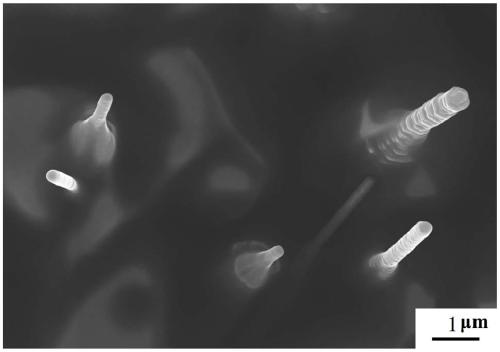

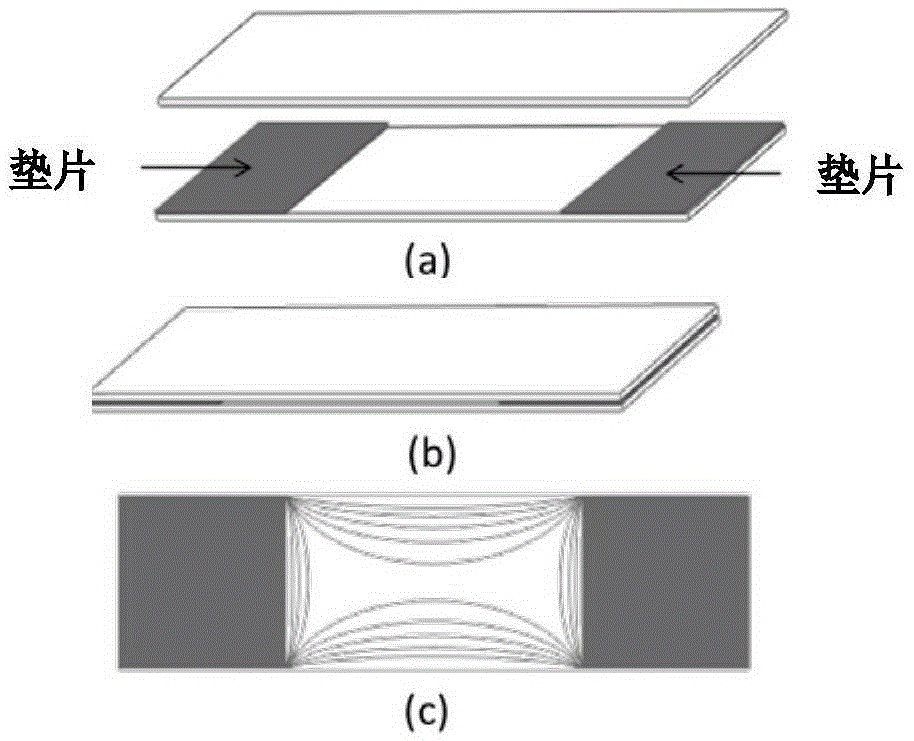

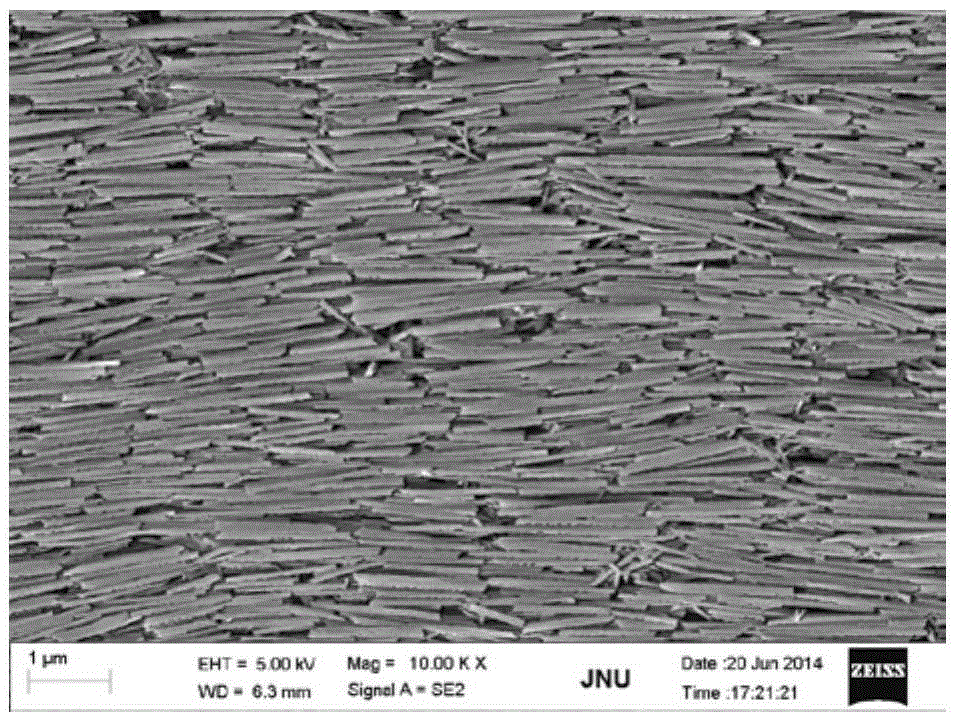

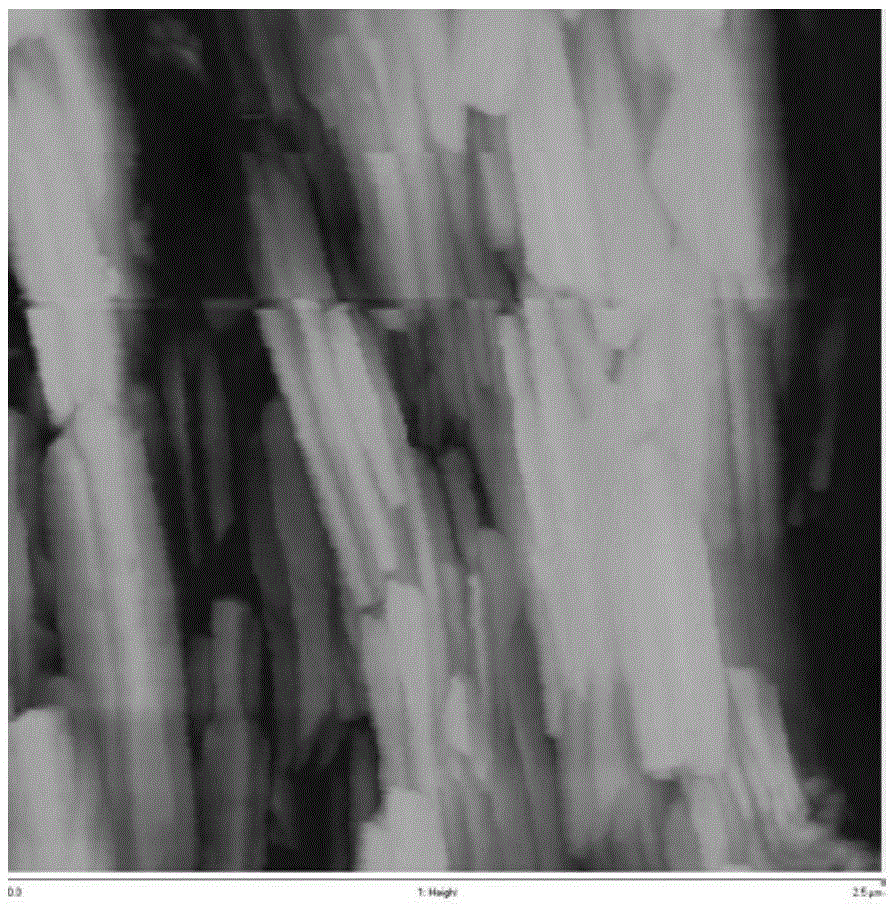

Directional arrangement method of halloysite nanotubes and coating and application of halloysite nanotubes

ActiveCN104386647ANo pollution in the processGood dispersionMaterial nanotechnologyIndividual molecule manipulationHalloysiteEvaporation

The invention belongs to the technical field of nanometer surface preparation and discloses a directional arrangement method of halloysite nanotubes and a coating and application of the halloysite nanotubes. The directional arrangement method comprises the following specific steps: (1) constructing a restricted evaporation space device, namely oppositely placing planes of two substrates, and clamping gaskets uniform in height between two sides in the middle to form a middle restricted evaporation space position; (2) injecting a halloysite nanotube aqueous suspension into the space position of the restricted evaporation space device in the step (1); (3) horizontally standing the device filled with the halloysite nanotube aqueous suspension to obtain a directionally arranged halloysite nanotube coating on the surfaces of the substrates after the suspension is subjected to restricted gradual evaporation. According to the preparation method, water is used as a dispersing medium, so that environment pollution is avoided; an airtight restricted space does not need to be constructed, so that the adverse effect that the coating thickness is difficult to control to cause that the coating is easy to flow out of the substrates is avoided, and the large-range directional arrangement of natural inorganic nanomaterials (halloysite nanotubes) on multiple substrate materials is realized.

Owner:JINAN UNIVERSITY

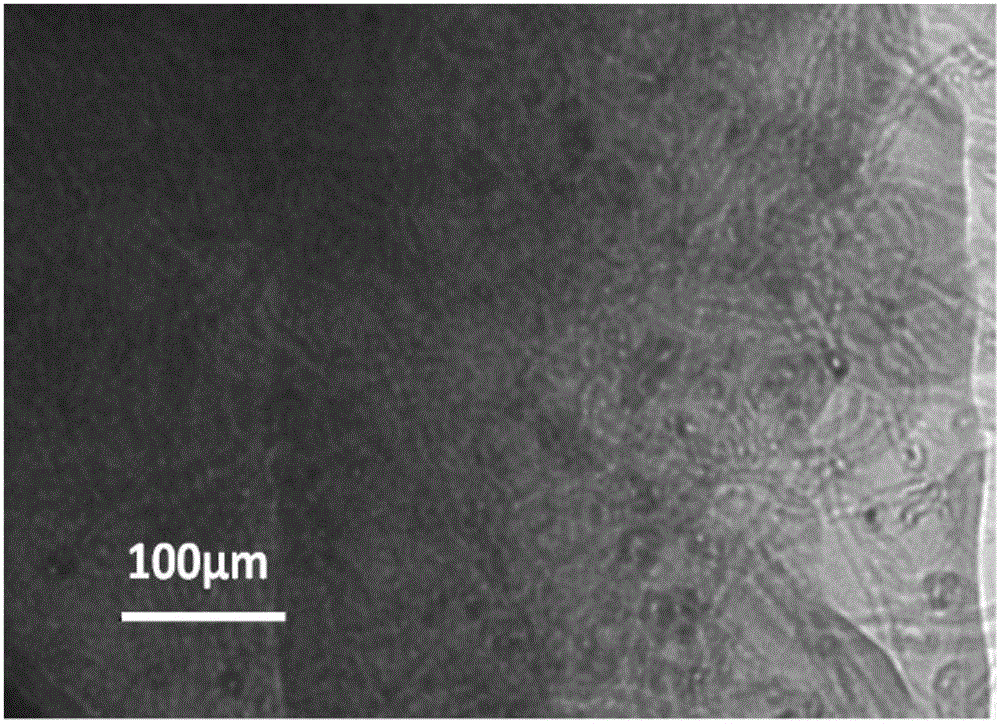

A method for preparing a composite sheet comprising low-damage and aligned SIC nanowires

The invention provides a preparation method of a composite material thin sheet containing low-damage and orientation-arrangement SiC nanowires, and relates to a preparation method of thin sheet of SiCnanowires. The method solves the problems that in the preparation process of the existing laminar composite material, the SiC nanowire fracture is serious, and due to the high specific surface area of the SiC nanowires, the SiC nanowire can be easily agglomerated and cannot be easily and uniformly dispersed in slurry. The method comprises the steps of 1, material weighing; 2, SiC nanowire pre-dispersion; 3, SiC nanowire low-damage ball milling dispersion; 4, gas removal treatment; 5, tape casting; 6, drying. The invention provides the method for preparing the thin sheet of the low-damage andorientation-arrangement SiC nanowires; the method process is simple; the SiC nanowires are arranged along the tape casting direction; the problem that the SiC nanowire can be easily agglomerated can be solved; the damage to the SiC nanowires is small. The method is suitable for preparing the SiC nanowire thin sheet.

Owner:HARBIN INST OF TECH

Aqueous UV metal printing ink and preparation method thereof

The invention relates to the technical field of printing ink and particularly relates to aqueous UV metal printing ink and a preparation method thereof. The printing ink includes: aqueous acrylic resin, active monomer, aluminum powder pigment, a photoinitiator, a dispersant, an adhesion improver, a flatting agent, a defoamer, and water. In the invention, the aluminum powder pigment, formed by compositing a metal aluminum layer on a sheet PET base material, has great compatible dispersibility of the PET and solution system and metallic glossiness of the aluminum at the same time; then by meansof photo-curing crosslinking, during the crosslinking polymerization of the aqueous acrylic resin and active monomer, the PET base material can be added to the crosslinking structure, thus achieving oriented arrangement of the aluminum powder pigment; so that the formed printing ink layer has compactness, high stability and high glossiness; furthermore, by means of the additives, the printing inkhas proper viscosity, leveling property and high adhesion force.

Owner:DONGGUAN SONGYAN ZHIDA IND DESIGN CO LTD

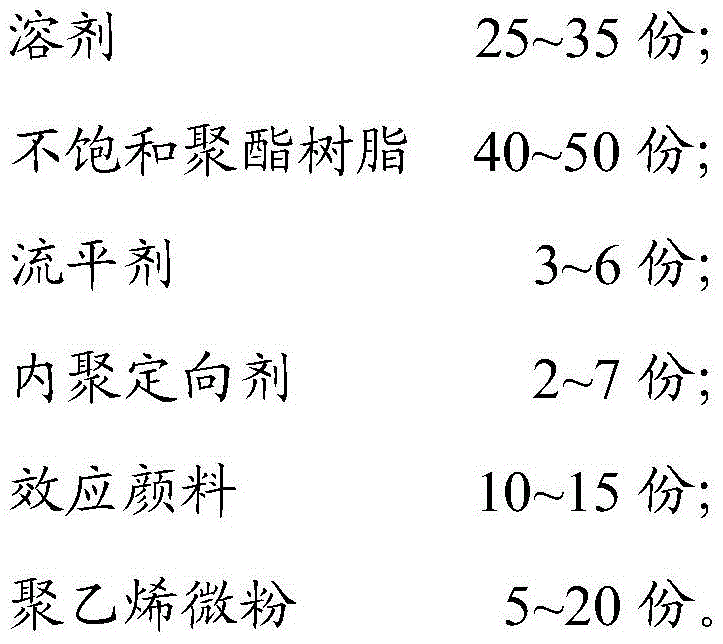

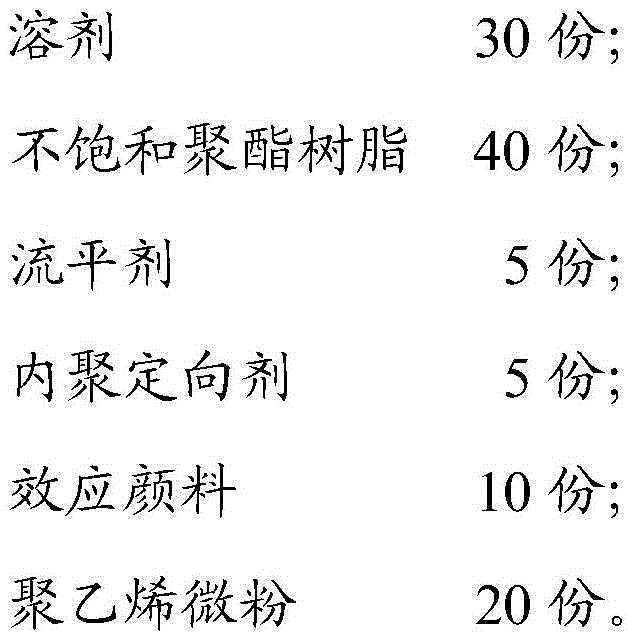

A coating for coating the surface of metal materials and its preparation method

The invention discloses a coating for coating surfaces of metal materials. In percentage by weight, the coating for coating surfaces of metal materials comprises 25-35 parts of solvent, 40-50 parts of unsaturated polyether resin, 3-6 parts of leveling agent, 2-7 parts of cohesive directional agent, 10-15 parts of effect pigment and 5-20 parts of polyethylene micro powder. The invention also discloses a preparation method of the coating for coating surfaces of metal materials. Due to addition of the cohesive directional agent, the solvent release property of the coating for coating surfaces of metal materials is strengthened; and a substrate is coated with the coating and the cohesive directional agent prompts the solvent to volatilize rapidly, so that a coating film shrink rapidly, and by means of the rapid and strong shrinking force, the directional arrangement of the effect pigment is realized, the shielding property of the coating is improved, the appearance of the coating film is uniform in color and smooth and the metal texture is improved. As the polyethylene micro powder is added, the wear resistance of the coating is improved and the coating film is scratch-resistant; and the coating surface does not need to be electroplated with gold oil, so that the cost is saved.

Owner:JIANGSU ZHONGYING PAINT

Device and method for preparing directional cloth chopped carbon fiber thermoplastic resin-based prepreg

Owner:JIANGSU UNIV

A preparation process of composite laminates with carbon nanotubes aligned

ActiveCN106084264BStable parallel electric fieldReduce viscositySynthetic resin layered productsLaminationEpoxyFiber

The invention provides a preparation process of a composite material laminated plate formed by directionally arranging carbon naon-tubes. The preparation process is characterized by comprising the following steps: (1) mixing acetone with carbon nano-tubes in a mass ratio of 100: 1, stirring for 5 min by using a high-speed cutting stirrer at the stirring rate of 20000 r / min, and drying for standby use; ..., (5) hot pressing and forming a prepreg with the upper surface and lower surface respectively laid with a copper film electrode in a composite material hot vulcanizing instrument, first heating to 40 to 60 DEG C, respectively introducing high-frequency pulse alternating-current power to the copper film electrodes at the upper end and lower end of the prepreg, wherein the electrification time is 5 to 10 minutes, removing the power after the electrification, then heating to a curing temperature of epoxy resin, thermally insulating for 2h, naturally cooling, and demolding to prepare the composite material laminated plate of carbon fiber / epoxy resin filling the carbon nano-tubes. According to the preparation process, the carbon naon-tubes are directionally arranged along the thickness direction (direction Z) of the laminated plate by utilizing a high-frequency pulse electric field, so that the preparation process is simple to operate, and the produced composite material has excellent performance.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

A kind of alignment method of halloysite nanotubes and its coating and application

ActiveCN104386647BNo pollution in the processGood dispersionMaterial nanotechnologyIndividual molecule manipulationHalloysiteDispersed media

The invention belongs to the technical field of nanometer surface preparation and discloses a directional arrangement method of halloysite nanotubes and a coating and application of the halloysite nanotubes. The directional arrangement method comprises the following specific steps: (1) constructing a restricted evaporation space device, namely oppositely placing planes of two substrates, and clamping gaskets uniform in height between two sides in the middle to form a middle restricted evaporation space position; (2) injecting a halloysite nanotube aqueous suspension into the space position of the restricted evaporation space device in the step (1); (3) horizontally standing the device filled with the halloysite nanotube aqueous suspension to obtain a directionally arranged halloysite nanotube coating on the surfaces of the substrates after the suspension is subjected to restricted gradual evaporation. According to the preparation method, water is used as a dispersing medium, so that environment pollution is avoided; an airtight restricted space does not need to be constructed, so that the adverse effect that the coating thickness is difficult to control to cause that the coating is easy to flow out of the substrates is avoided, and the large-range directional arrangement of natural inorganic nanomaterials (halloysite nanotubes) on multiple substrate materials is realized.

Owner:JINAN UNIVERSITY

Vitrified bond abrasive tool with directional arrangement of abrasives and preparation method thereof

ActiveCN104999385BImprove grinding performanceExtend your lifeAbrasion apparatusGrinding devicesSlurrySolvent

The invention discloses a ceramic bond grinding tool for oriented arrangement of abrasives and a preparation method thereof. The grinding tool is prepared by the method comprising the following steps: 1) the abrasives, a ceramic bond, a dispersing agent and a solvent are taken for mixing a slurry; 2) the obtained slurry is injected in a mold, and is put in a magnetic field with a strength of 1-50 T for magnetizing to obtain magnetized slurry; and 3) the magnetized slurry is dried and demolded to obtain a biscuit; and the biscuit is sintered and cured to obtain the ceramic bond grinding tool. In the ceramic bond grinding tool for oriented arrangement of abrasives, after the slurry is injected in the mold, the slurry is stood in the high-strength magnetic field; under the effect of electromagnetic force, the abrasives rotate to generate oriented arrangement; the ceramic bond grinding tool for oriented arrangement of abrasives is prepared through the oriented arrangement of the abrasives; an effective cutting edge in the grinding of the grinding tool is added; the grinding capacity of the grinding tool is improved; and the grinding surface quality is improved.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

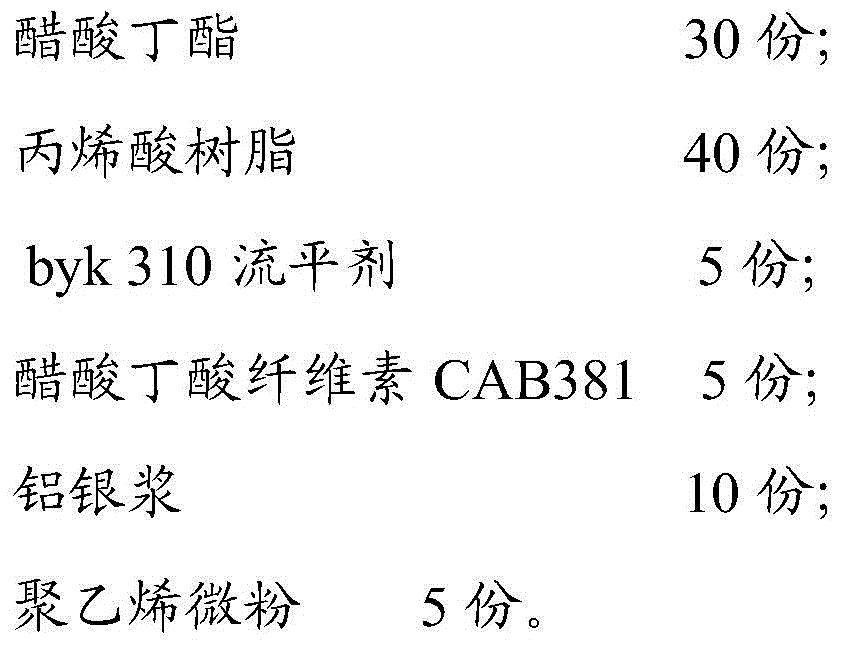

Metallic ink with imitation aluminum foil effect

The present invention provides a metallic ink with an imitation aluminum foil effect. The problem of luster lack of inks using water as a main solvent is mainly solved. The metallic ink contains 50% of an aqueous emulsion, 20% of 1200 mesh silver powder, 10% of water, 15% of alcohol, 2% of a dispersant, 1% of an antifoaming agent and 2% of butyl ether. The metallic ink has a suitable viscosity, asuitable levelability and a high adhesion.

Owner:哈尔滨大东方新材料科技股份有限公司

Chitosan-based nerve fiber membrane, preparation method, nerve guide and application

ActiveCN111632193BEasy alignmentImprove mechanical propertiesPharmaceutical delivery mechanismTissue regenerationHuman bodyCarbon nanotube

The invention relates to the technical field of nerve tissue engineering materials, and specifically provides a chitosan-based nerve fiber membrane, a preparation method, a nerve guide and an application. The chitosan-based nerve fiber membrane is formed by a number of composite nanofibers arranged in orientation; each composite nanofiber has a core-shell structure, and its shell layer contains degradable functional materials, carbon nanotubes modified with hydrophilic functional groups, wolfberry Polysaccharide, and chitosan and / or chitosan derivatives, the core layer contains nerve growth factor and stabilizer. Because the chitosan-based nerve fiber membrane of the present invention has good orientation arrangement, good mechanical properties, and high biological responsiveness, the alkalinity of chitosan and / or chitosan derivative hydrolyzate and self-carried amino groups can effectively It neutralizes the weak acidity of the degraded products and avoids the influence of the acidic degraded products on the surrounding environment and tissues, so it can be applied to the nerve repair and regeneration of human and animal bodies.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Texturing boride-based ceramics and preparing method thereof

The present invention relates to texturing boride-based ceramics and a preparing method thereof, which belongs to the field of structural ceramics material. MB2 powder is used as raw material powder in the present invention (M is Ti or Zr or Hf), and 0 to 40 wt% of beta-SIC powder is fed into the raw material powder. Polymine or acrylic copolymer is used as dispersant to be fed into water to formwater solution. The pH value of sizing agent water solution is adjusted to between 6.5 and 9, the raw material powder is mixed with the sizing agent water solution, and the mixture is defoamed. After sizing agent is casted to be solidified in the magnetic field of 10 to 30 T, the sizing agent is processed under the temperature of 500 to 700 DEG C. hot-press or discharging plasma sintering is used. Compact ceramics of which the relative density is larger than 97% is obtained by the present invention. Ceramics grains are arranged along the height orientation of (001) direction, Loterring orientation factor f(001) is larger than 0.85, and the mechanical property and the antioxygenic property appear obvious anisotropism.

Owner:中科西卡思(苏州)科技发展有限公司

Preparation method of piezoelectric ferroelectric ceramic material based on 3D printing technology

PendingCN113754433AHigh textureImprove performanceAdditive manufacturing apparatusComposite materialFerroelectric ceramics

The invention discloses a preparation method of a piezoelectric ferroelectric ceramic material based on a 3D printing technology. The preparation method comprises the following steps: step 1, preparing lead-based or lead-free piezoelectric ferroelectric ceramic pre-sintered powder; step 2, preparing 3D printing piezoelectric ferroelectric ceramic slurry from the lead-based or lead-free piezoelectric ferroelectric ceramic pre-sintered powder and adding a template accounting for x% of of the ceramic pre-sintered powder, wherein x is larger than 1 and smaller than or equal to 5; step 3, realizing directional arrangement of the template in the powder through a 3D printing photocuring process so as to prepare a 3D-printed piezoelectric ferroelectric ceramic green body; and step 4, degreasing and sintering the 3D-printed piezoelectric ferroelectric ceramic green body to obtain the piezoelectric ferroelectric ceramic material with a texture degree based on the 3D printing technology. According to the method, the mode of scraping via a scraper in a 3D printing process is applied to the directionally-arranged template, and the template with a certain size can be transversely distributed in each layer of the cured green body, so the preparation method of piezoelectric ferroelectric textured ceramic is not limited to a traditional tape casting method any more.

Owner:XI AN JIAOTONG UNIV +2

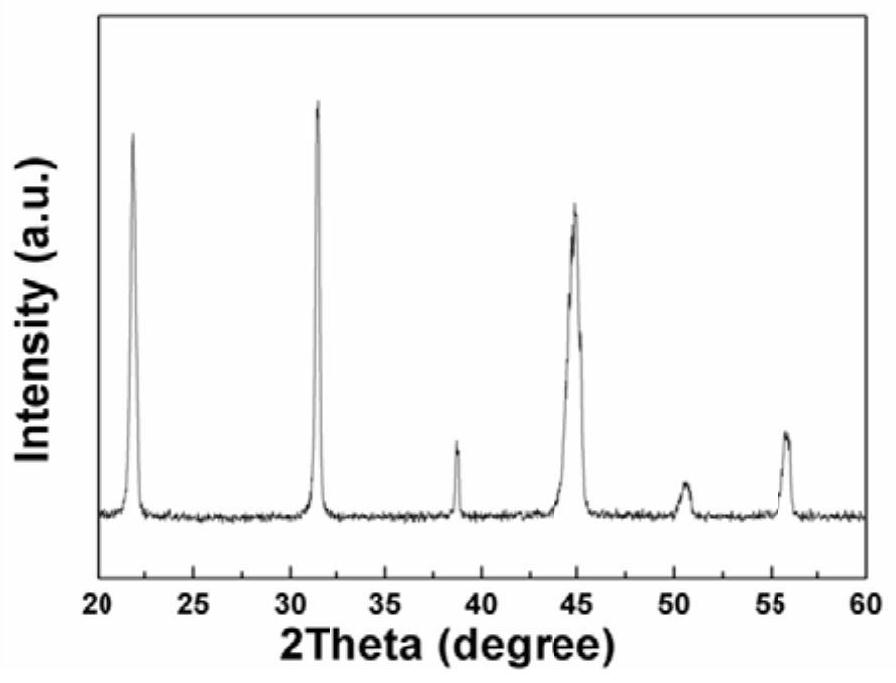

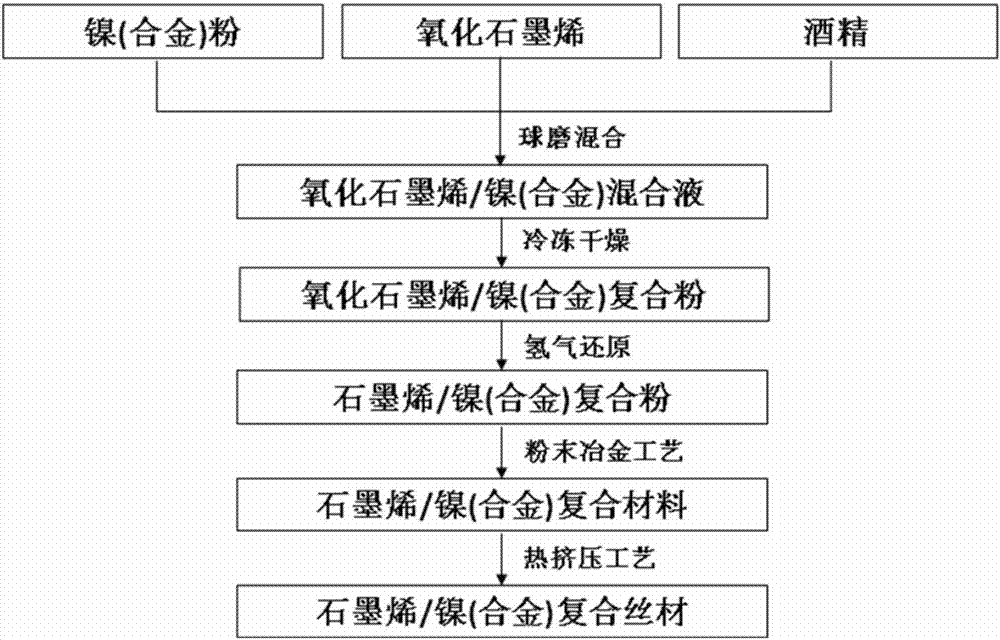

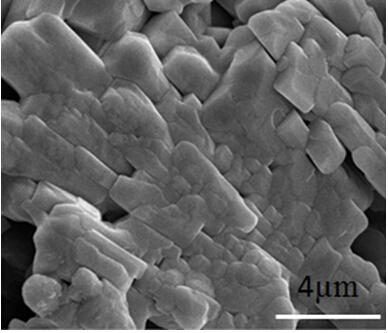

A kind of graphene/nickel-based composite material and preparation method thereof

The invention provides a graphene / nickel composite material and a preparation method thereof. According to the preparation method of the graphene / nickel composite material, nickel or nickel alloy powder and oxidized graphene are subjected to mechanical ball milling and are mixed, and ethyl alcohol is added during mechanical ball milling for wet milling so that oxidization of the nickel powder can be avoided; and oxidized graphene / copper composite powder is obtained preliminarily through the ball milling process, and then a graphene / copper composite block material and a graphene / copper composite wire are obtained through the techniques such as reduction, powder metallurgy and hot extrusion. According to the composite material, graphene is evenly distributed, the interface bonding of a matrix and a reinforcement body is good, and the graphene / nickel composite material has excellent physical performance. According to the graphene / nickel composite material and the preparation method thereof, the technique is simple, the process can be controlled easily, and large-scale production and application can be achieved easily.

Owner:SHANGHAI HIWAVE COMPOSITE MATERIALS CO LTD

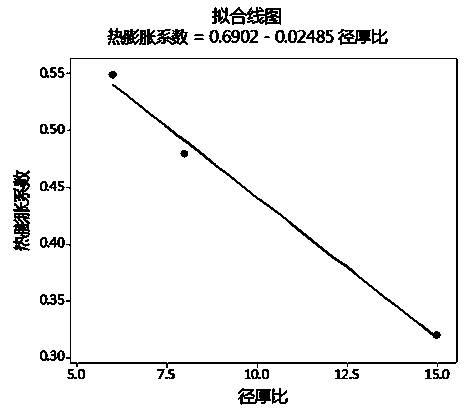

A kind of cordierite honeycomb ceramic carrier with full oxide as raw material and preparation method thereof

ActiveCN106365669BShape is easy to controlAchieve directional alignmentCeramicwarePass rateThermal expansion

The invention discloses a cordierite honeycomb ceramic carrier using complete oxides as a raw materials and a preparation method thereof. The cordierite honeycomb ceramic carrier comprises 32-38% of alumina, 12-15% of active magnesia and 47-54% of silica dioxide. The raw materials including oxides are chemical products and have wide available sources. The morphology of the raw materials is easy to control, and the materials ,can achieve a big diameter-to-thickness ratio. The inventions has the advantages of being simple in the preparation method, easy to implement, high in softening temperature, high in pass rate in the extrusion and baking processes. The cordierite mainly uses alumina as a template to grow, so it is prone to achieving the directional array of the cordierite. The acquired ceramic carrier has a low coefficient of thermal expansion.

Owner:SHANDONG AOFU ENVIRONMENTAL PROTECTION SCI & TECH

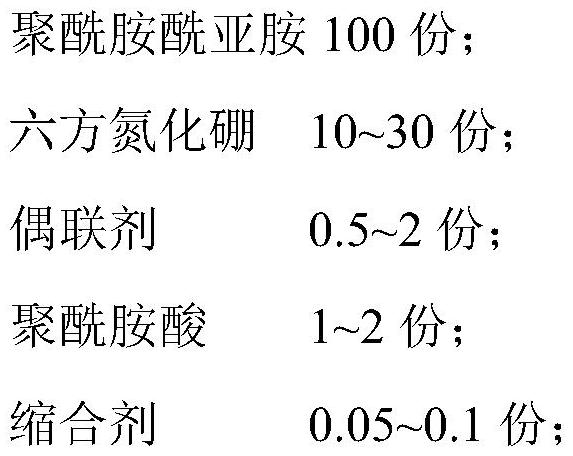

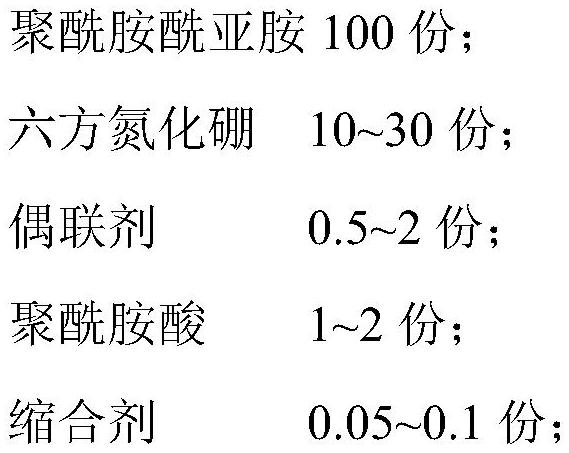

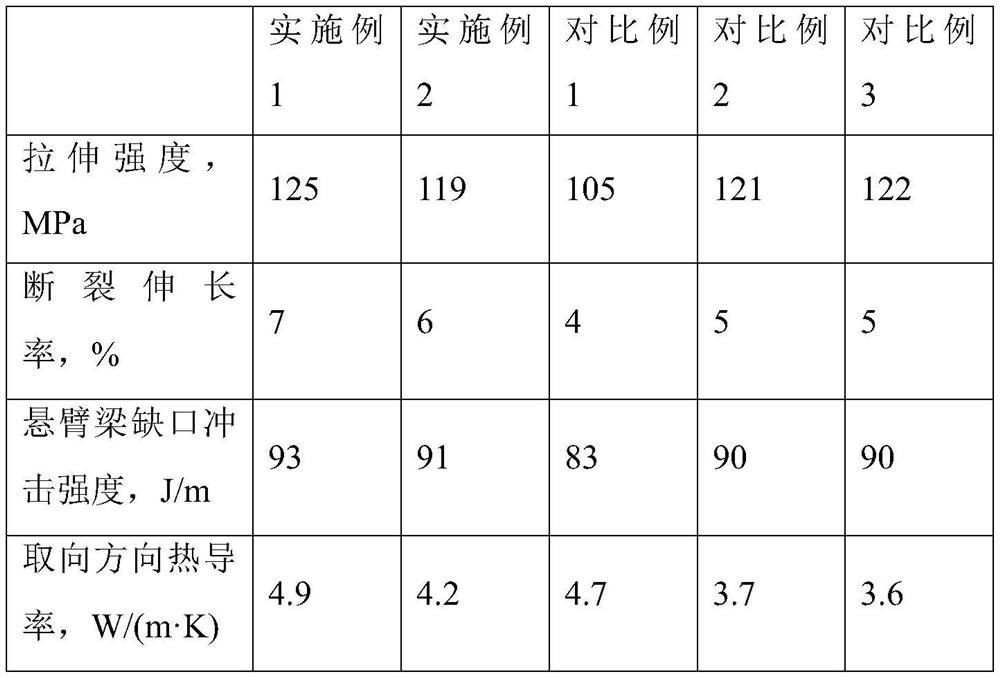

Heat-conducting anisotropic polyamide-imide composite material and preparation method thereof

The invention provides a heat-conducting anisotropic polyamide-imide composite material and a preparation method thereof, and solves the problem of contradiction between the heat-conducting property and the mechanical property of polyamide-imide in the prior art. The composite material comprises the following raw materials in parts by weight: 100 parts of polyamideimide; 10 to 30 parts of hexagonal boron nitride; 0.5 to 2 parts of a coupling agent; 1-2 parts of polyamide acid; 0.05 to 0.1 part of a condensing agent; the hexagonal boron nitride is hexagonal boron nitride micro-nano powder obtained by compounding micron-sized hexagonal boron nitride and nano-sized hexagonal boron nitride. The hexagonal boron nitride with insulativity is used as a heat-conducting filler, the addition amount of the filler is reduced through micro-nano compounding of the hexagonal boron nitride, and meanwhile, the hexagonal boron nitride is subjected to surface treatment to improve the compatibility with a matrix; the dispersity of the heat-conducting filler is improved by adopting a solution blending mode; and the melt is sheared by adopting melting processing, so that the heat-conducting anisotropic polyamide-imide composite material with highly-oriented filler is formed.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

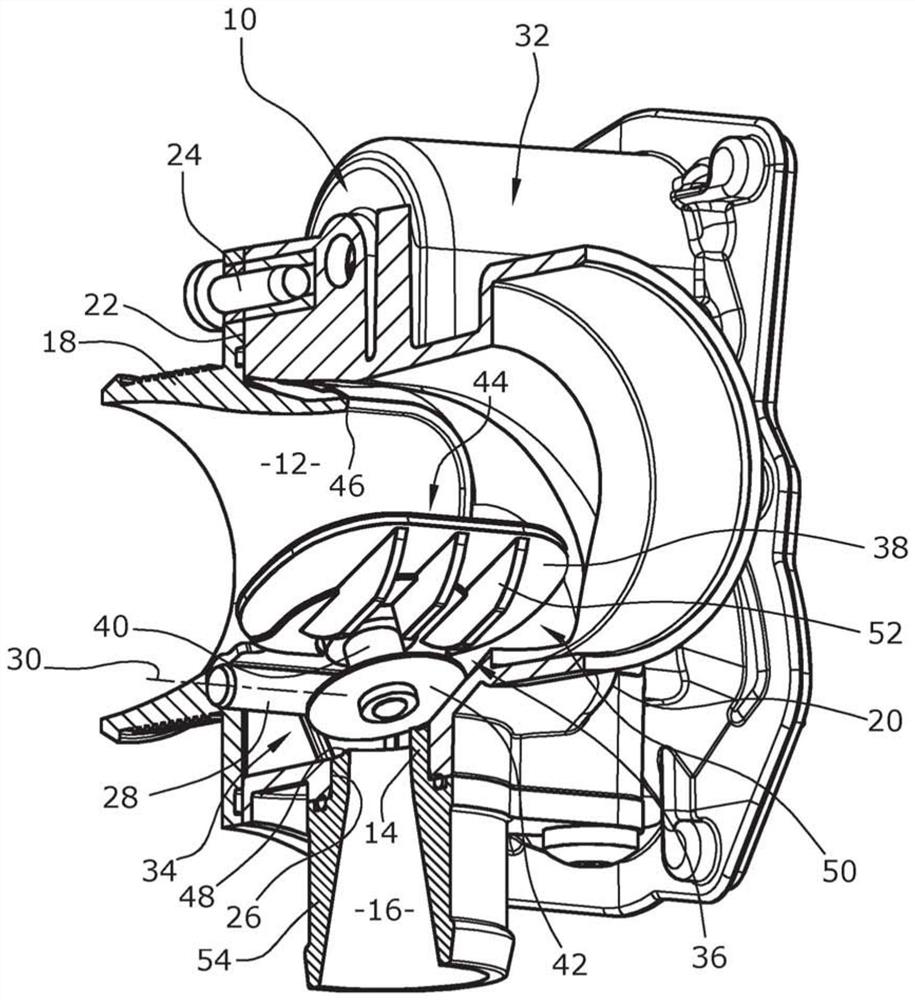

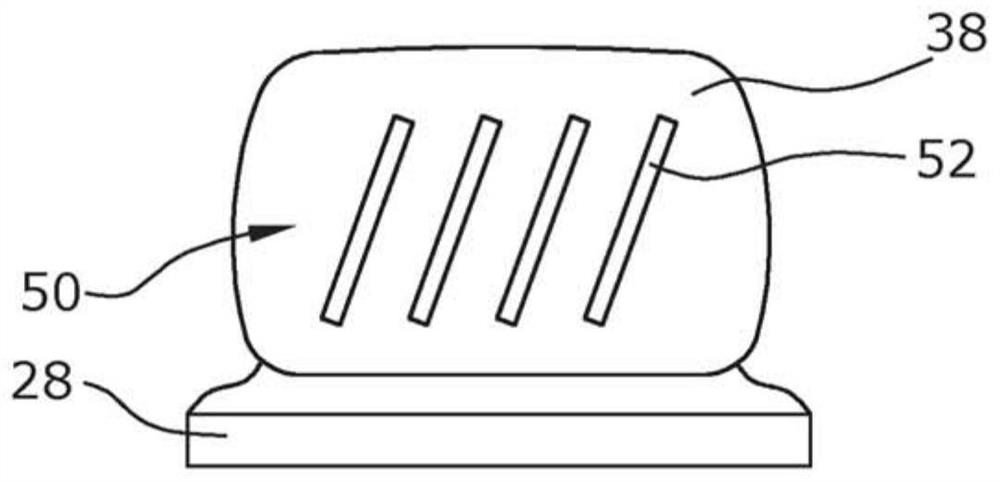

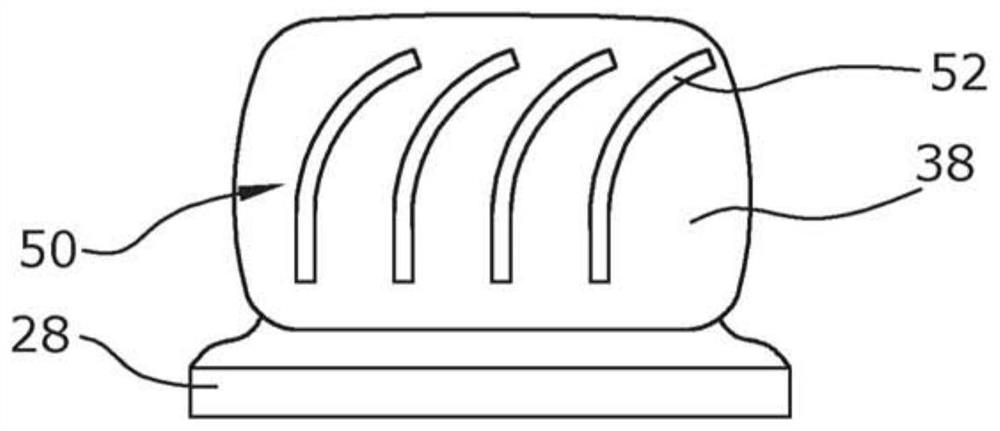

Regulators for internal combustion engines

ActiveCN108431394BImprove efficiencyPower optimizationExhaust gas recirculationEngine controllersExhaust fumesExhaust gas recirculation

Owner:PIERBURG GMBH & CO KG NEUSS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com