Texturing boride-based ceramics and preparing method thereof

A boride and texturing technology, applied in the field of structural ceramic materials, can solve problems such as difficulty in texturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

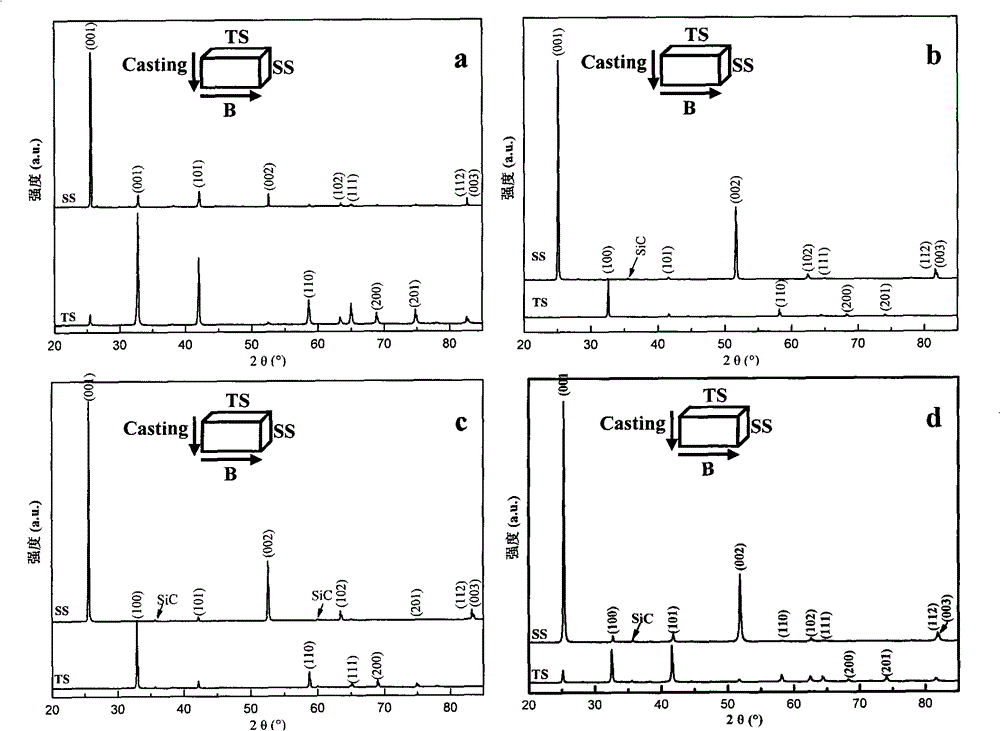

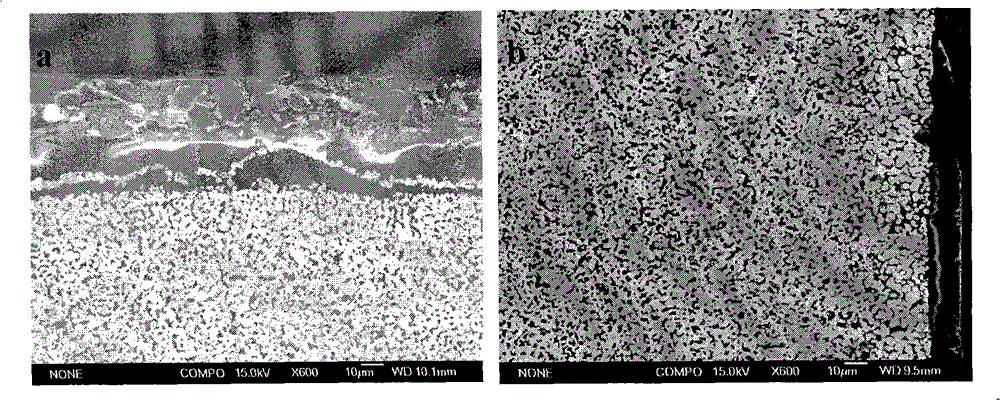

[0019] Preparation of single-phase HfB 2 Textured ceramics. First, weigh 0.3g PEI (dispersant) in a beaker, then add 2.4ml deionized water into it, ultrasonically treat for 10min, and adjust the pH to 6.5; weigh HfB 2 Powder (purity: 93%, d 50 =10μm) 21.6g, slowly added to the above solution, defoaming under vacuum after ball milling for 24h; then in a strong magnetic field of 12T, use the above slurry for grouting; after curing, take the green body out of the magnetic field and dry it. Then debinding under vacuum at 700°C for 2h; SPS sintering the green body at 1800°C / 50MPa. Material density reaches 97%, HfB 2 The Lotgering orientation factor f(00l) of the grain along the direction is 0.86, perpendicular to the plane, the hardness is 25GPa, and the toughness is 5.9MPa m 1 / 2 ; Parallel to the plane , the hardness is 19GPa, and the toughness is 4.1MPa·m 1 / 2 . figure 1 (a) shows the XRD diffraction patterns of ceramics in two directions perpendicular (SS) and parallel (T...

Embodiment 2

[0021] Preparation of HfB 2 - 5vol% SiC textured ceramics. Measure 3.0ml of deionized water with a measuring cylinder, add PEI (dispersant) 0.3g to it, weigh HfB 2 Powder (purity: 90%, d 50 =8μm) 20.52g, β-SiC (purity: 98%, d 50 =10μm) 0.32g, according to the method of Example 1, SPS sintering at 1900°C / 30MPa. Material density reaches 97%, HfB 2The Lotgering orientation factor f(00l) of the grain along the direction is 0.91, perpendicular to the plane, the hardness is 25GPa, and the toughness is 6.1MPa m 1 / 2 ; Parallel to the plane , the hardness is 18GPa, and the toughness is 4.1MPa·m 1 / 2 .

Embodiment 3

[0023] Preparation of HfB 2 - 10vol% SiC textured ceramic. Measure 4.5ml of deionized water with a measuring cylinder, add PEI (dispersant) 0.1g to it, weigh HfB 2 Powder (purity: 92%, d 50 =2μm) 19.44g, β-SiC (purity: 91%, d 50 =5μm) 0.63g, according to the method of Example 1, hot-pressing sintering (HP) at 1900°C / 30MPa. Material density reaches 97%, HfB 2 The Lotgering orientation factor f(00l) of the grain along the direction is 0.93, perpendicular to the plane, the hardness is 24GPa, and the toughness is 6.2MPa m 1 / 2 ; Parallel to the plane , the hardness is 19GPa, and the toughness is 4.2MPa·m 1 / 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com