Chitosan-based nerve fiber membrane, preparation method, nerve guide and application

A nerve fiber and nerve conduit technology, applied in the field of nerve tissue engineering materials, can solve the problems of poor mechanical properties, easy irritation of degraded products, unfavorable local inflammation of the body, etc., and achieve good mechanical properties, favorable for cell adhesion, and suitable for biodegradation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] The preparation method of described chitosan-based nerve fiber membrane comprises the following steps:

[0071] (1) Preparation of spinning solution: spinning solution includes A solution and B solution, wherein, A solution contains degradable functional materials, carbon nanotubes modified by hydrophilic functional groups, Lycium barbarum polysaccharide, and chitosan and / or chitosan Sugar derivative; B solution contains nerve growth factor and stabilizer.

[0072] The concentration of each component in the A solution and the B solution should ensure that the total content of the composite nanofiber mass content of the orientation arrangement obtained at last is 100% and the content of each component meets the following conditions:

[0073]

[0074] In some embodiments, the concentration of each component of the above-mentioned solution A is respectively:

[0075]

[0076] The solvent used in solution A may be hexafluoroisopropanol (English abbreviation: HFIP). ...

Embodiment 1

[0090] A preparation method of chitosan-based nerve fiber membrane, which comprises the following steps:

[0091] (1). With 1.25g polylactic acid-glycolic acid copolymer (PLGA, wherein the mass ratio of lactic acid monomer and glycolic acid monomer is 75:25), 0.35g chitosan (CS, deacetylation degree is 90%) Dissolve 10 mg of Lycium barbarum polysaccharide (LBP) in 5 mL of hexafluoroisopropanol at the same time, and stir magnetically for 24 hours to fully dissolve PLGA and LBP to form a uniform solution.

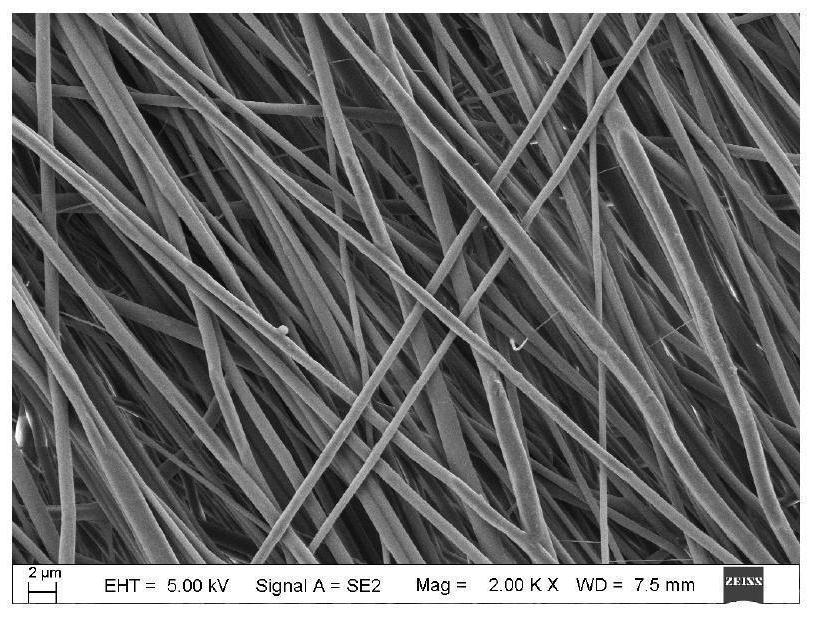

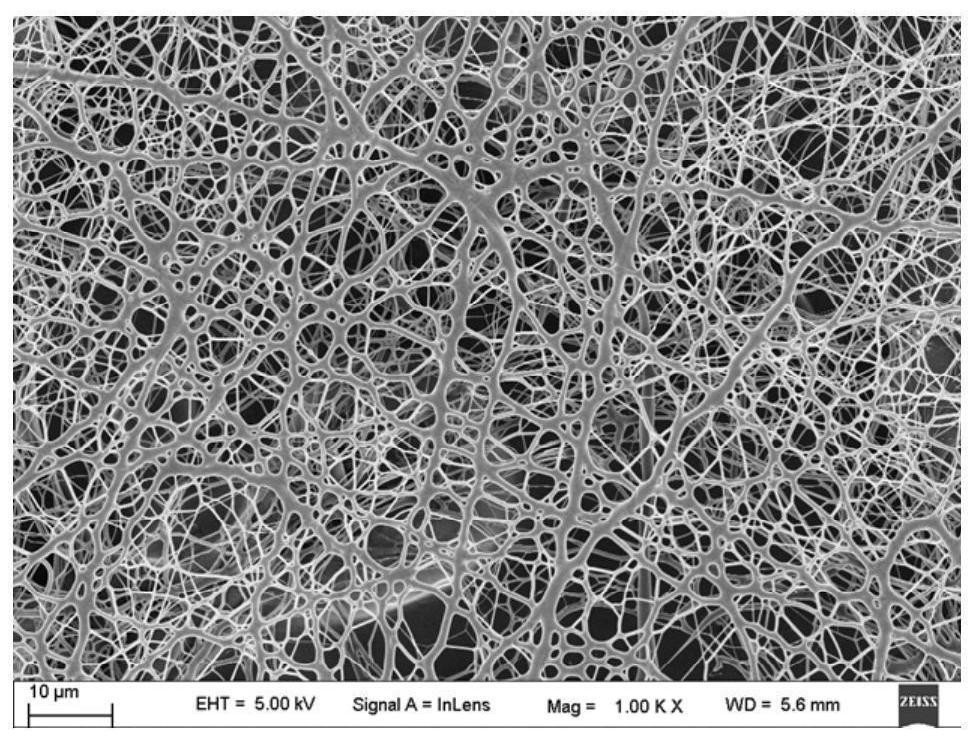

[0092] (2). Add 0.1 g carboxy-modified multi-walled carbon nanotubes (MWCNTs, average diameter 15 nm, average length 1 μm) and 100 μL Span 80 to the solution obtained in step (1), and stir magnetically for 8 hours to disperse the MWCNTs uniformly In solution, A solution was obtained.

[0093] (3). Prepare 10 μg / mL Nerve Growth Factor (NGF) aqueous solution, and add bovine serum albumin (BSA) at the same time, control the concentration of BSA to 10 mg / mL to obtain B solution....

Embodiment 2

[0097] A preparation method of chitosan-based nerve fiber membrane, comprising the following steps:

[0098] (1). 0.9g polylactic acid-glycolic acid copolymer (PLGA, wherein the mass ratio of lactic acid monomer and glycolic acid monomer is 85:15), 0.32g chitosan (CS, deacetylation degree is 90%) and 10 mg Lycium barbarum polysaccharide (LBP) were dissolved in 2.5 mL hexafluoroisopropanol at the same time, and magnetically stirred for 24 hours to fully dissolve PLGA and LBP to form a uniform solution.

[0099] (2). Add 0.01 g carboxyl-modified multi-walled carbon nanotubes (MWCNTs, average diameter 10 nm, average length 5 μm) and 50 μL Span 80 to the solution obtained in step (1), and stir magnetically for 8 hours to disperse the MWCNTs uniformly In solution, A solution was obtained.

[0100] (3). Prepare 10 μg / mL Nerve Growth Factor (NGF) aqueous solution, and add bovine serum albumin (BSA) at the same time, control the concentration of BSA to 10 mg / mL to obtain B solution. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com