Solvent-free graphene/CNT (carbon nano tube)/Fe3O4 three-dimensional composite nano-fluid epoxy resin and preparation method thereof

A carbon nanotube, three-dimensional composite technology, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of difficulty in achieving monodispersion, affecting the effect of orientation and arrangement, and achieve the improvement of compatibility problems, remarkable modification effect, The effect of solving the problem of reunion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

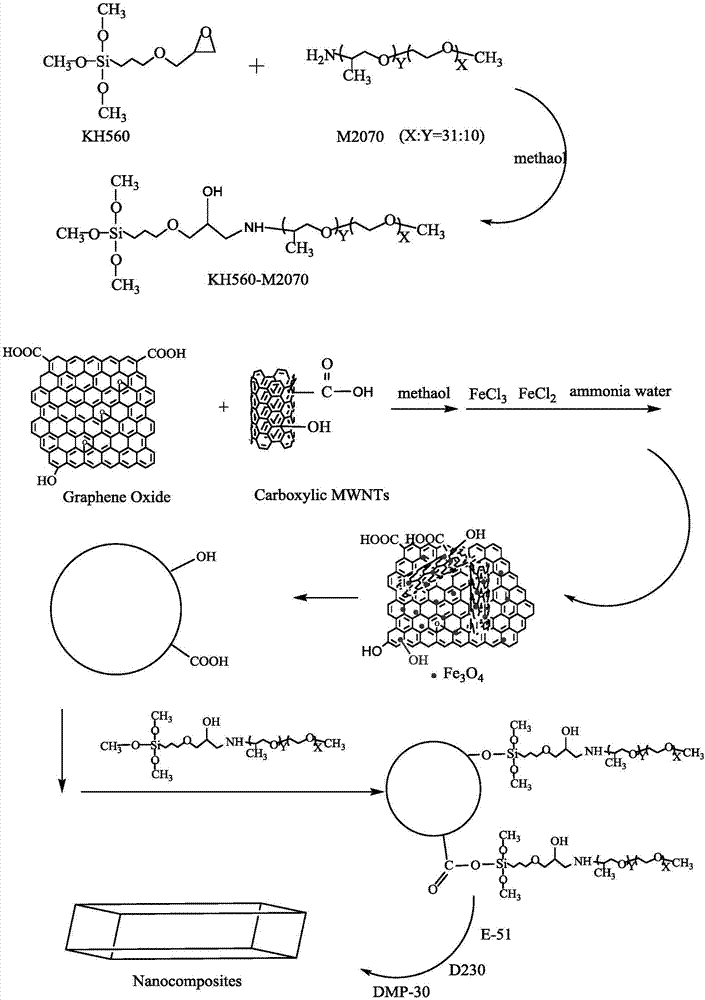

[0038] Graphene / Carbon Nanotube / Fe 3 o 4 Preparation of the composite: 0.5 g of acidified carbon nanotubes and 0.5 g of graphene oxide were dissolved in 50 mL of methanol, and stirred ultrasonically at room temperature for 1 h to obtain a black suspension. 4.48g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) dissolved in a certain amount of deionized water, added to the above black suspension, stirred ultrasonically at room temperature for 0.5h, and then 1.65g of ferrous chloride tetrahydrate (FeCl 2 4H 2 O) Dissolved in a certain amount of deionized water, added to the reaction solution, stirred ultrasonically at room temperature for 0.2 h, then added 30 g of ammonia water, stirred ultrasonically at room temperature for 1 h, and obtained a black suspension. After the reaction is completed, the above suspension is centrifuged, and the lower layer of precipitate is removed, and the precipitate is repeatedly washed with deionized water until neutral to obtain graphene / carbon n...

Embodiment 2

[0042] Graphene / Carbon Nanotube / Fe 3 o 4 Preparation of the composite: 0.5 g of acidified carbon nanotubes and 0.5 g of graphene oxide were dissolved in 50 mL of methanol, and stirred ultrasonically at room temperature for 1 h to obtain a black suspension. 2.24g ferric chloride hexahydrate (FeCl 3 ·6H 2 O) dissolved in a certain amount of deionized water, added to the above black suspension, stirred ultrasonically at room temperature for 0.5h, and then 0.83g ferrous chloride tetrahydrate (FeCl 2 4H 2 O) dissolved in a certain amount of deionized water, added to the reaction solution, stirred ultrasonically at room temperature for 0.2 h, then added 15 g of ammonia water, stirred ultrasonically at room temperature for 1 h, and obtained a black suspension. After the reaction is completed, the above suspension is centrifuged, and the lower layer of precipitate is removed, and the precipitate is repeatedly washed with deionized water until neutral to obtain graphene / carbon nano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com