A kind of alignment method of halloysite nanotubes and its coating and application

A halloysite nanotube, directional arrangement technology, applied in nanotechnology, nanotechnology, nanostructure manufacturing and other directions, can solve the problems of easy casting to the substrate, uneven thickness, inability to apply natural inorganic nanomaterials, etc. The effect of toxic substance residues, low cost, excellent alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) The substrates are two glass slides with a size of 2.5cm×7.5cm, washed with detergent powder and deionized water for 5 minutes, and dried with nitrogen gas flow for 10 minutes;

[0039] (2) Weigh 0.05g of HNTs powder (mesh 100, produced in Hunan) in 100mL of deionized water, and ultrasonically disperse for 30min to obtain HNTs aqueous suspension;

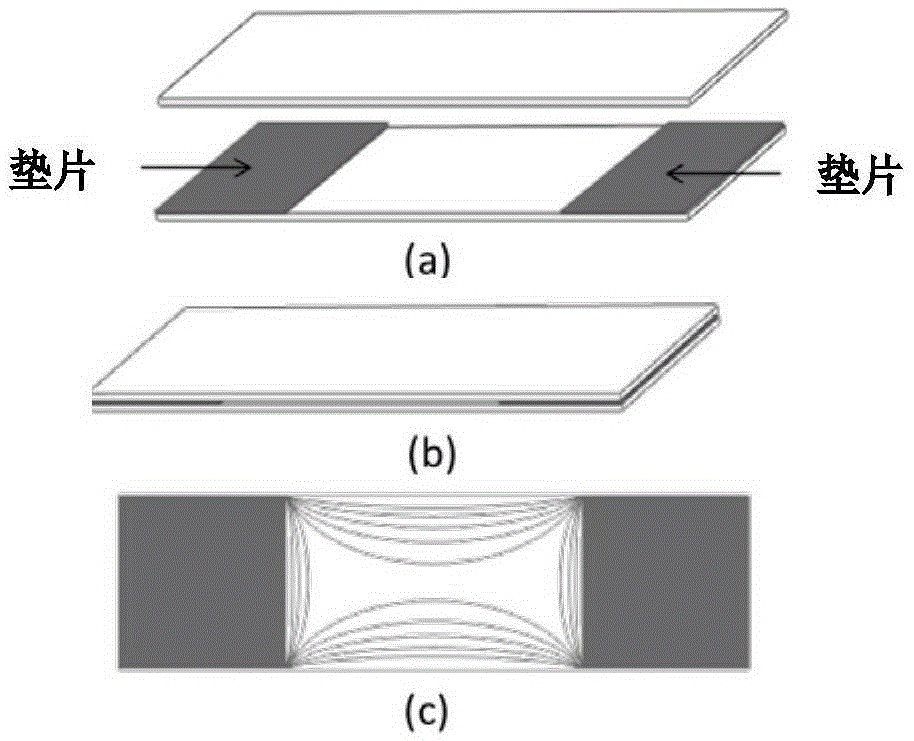

[0040] (3) build as figure 1 In the drying device shown, the gasket is a glass gasket, the length of the gasket is 25.4mm, which is the same as or slightly wider than the width of the substrate; the width is 5mm, and the thickness is 0.8mm;

[0041] (4) Use a glass syringe to draw the HNTs water suspension, and carefully inject it into the space formed by the two glass slides until it is full;

[0042] (5) Put the above-mentioned device in an environment with a humidity of 50% and a temperature of 30° C., and obtain a coating of HNTs aligned on a glass slide after evaporation and drying;

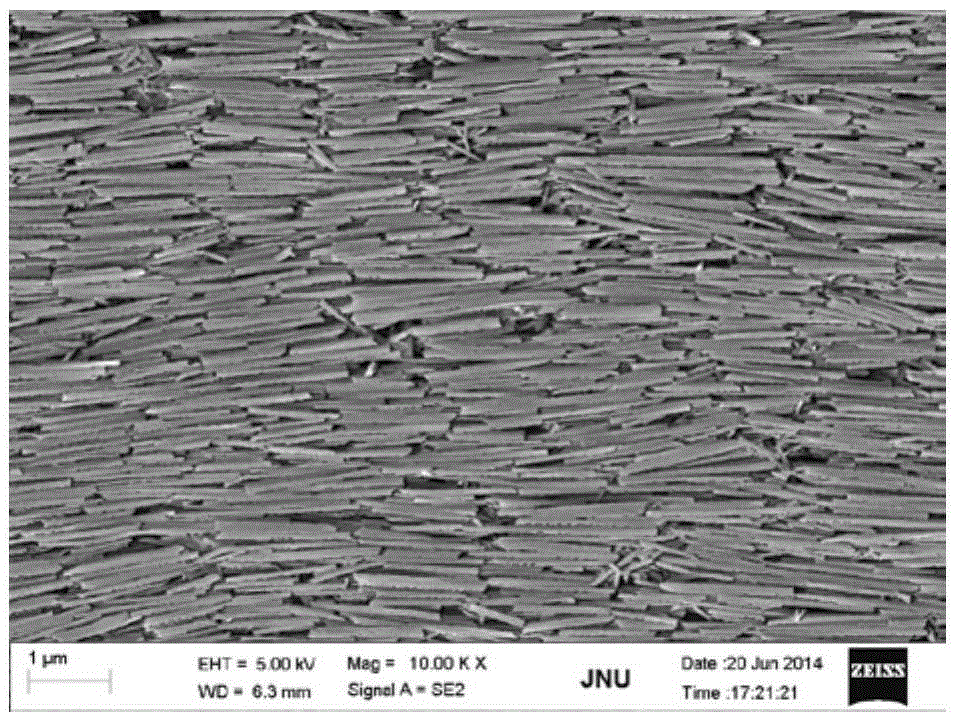

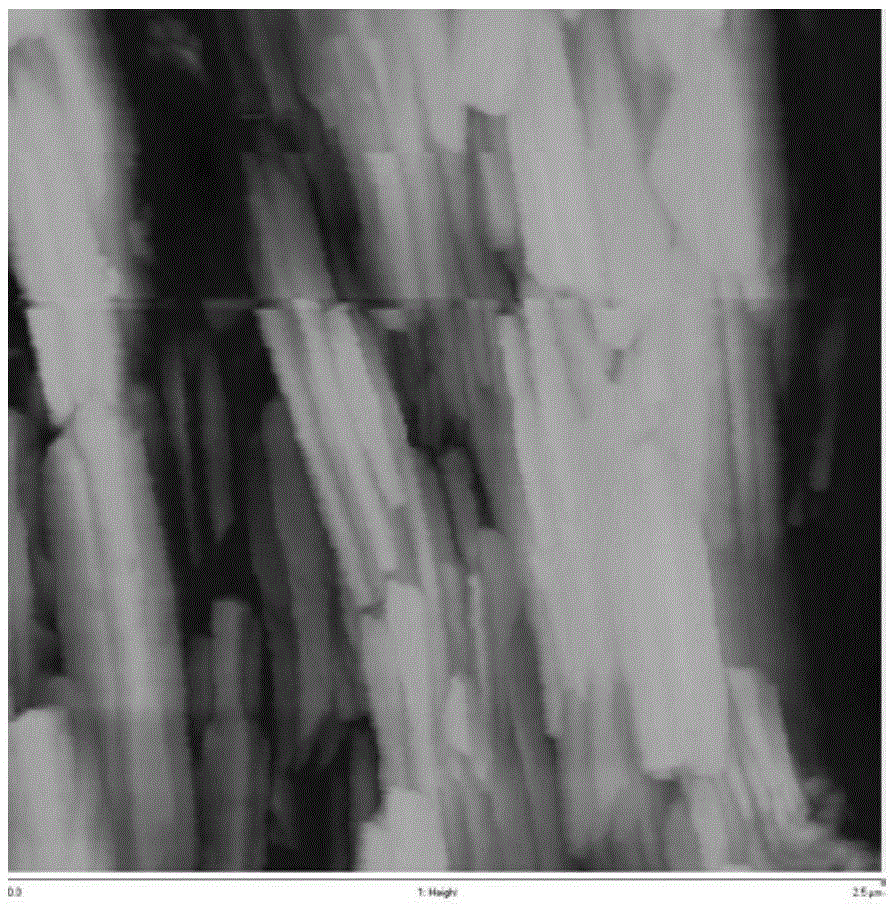

[0043] (6) The substrate sampl...

Embodiment 2

[0045] (1) The substrates are two silicon wafers with a smooth surface, the size is 2.5cm×5cm, washed with deionized water for 3 minutes, and dried with nitrogen gas flow for 10 minutes;

[0046] (2) Weigh 0.5g of HNTs powder in 100mL of deionized water, and ultrasonically disperse at 300W power for 30min to obtain HNTs suspension;

[0047] (3) build as figure 1 In the confined space drying device shown, the spacer is a glass spacer, and the length of the spacer is 25.4mm, which is the same as or slightly wider than the width of the substrate; the width is 10mm, and the thickness is 1.0mm;

[0048] (4) Draw the HNTs aqueous suspension with a glass syringe, and carefully inject it into the space formed in step (3) until it is filled;

[0049] (5) Place the above device in an environment with a humidity of 80% and a temperature of 35° C., and obtain an oriented HNTs coating on the silicon wafer substrate after evaporation and drying;

[0050] (6) The substrate samples coated w...

Embodiment 3

[0052] (1) The substrates are two stainless steel sheets with smooth surfaces, the size is 2.5cm×7.5cm, after cleaning with cotton dipped in ethyl ester, dry with nitrogen air flow for 5min;

[0053] (2) Weigh 1g of HNTs powder in 100mL of deionized water, and disperse with 150W ultrasonic wave for 60min to obtain HNTs suspension;

[0054] (3) build as figure 1 In the confined space drying device shown, the spacer is a glass spacer, and the length of the spacer is 25.4mm, which is the same as or slightly wider than the width of the substrate; the width is 15mm, and the thickness is 1.2mm;

[0055] (4) Draw the HNTs aqueous suspension with a glass syringe, and carefully inject it into the space formed in step (3) until it is filled;

[0056] (5) The above device was placed in an environment with a humidity of 40% and a temperature of 25° C., and after evaporation and drying, an aligned HNTs coating was obtained on a stainless steel substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com